Silicon wafer carrier dispatching platform for double-track feeding

A scheduling platform and silicon wafer flower basket technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as reduced production efficiency and different output quantities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

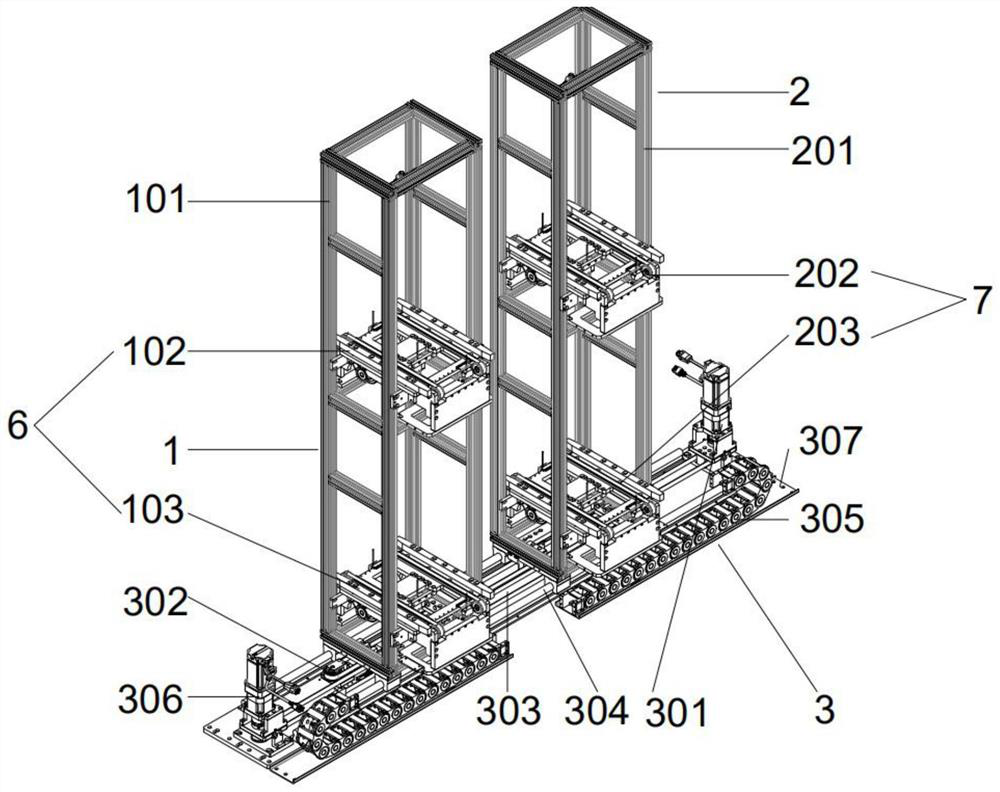

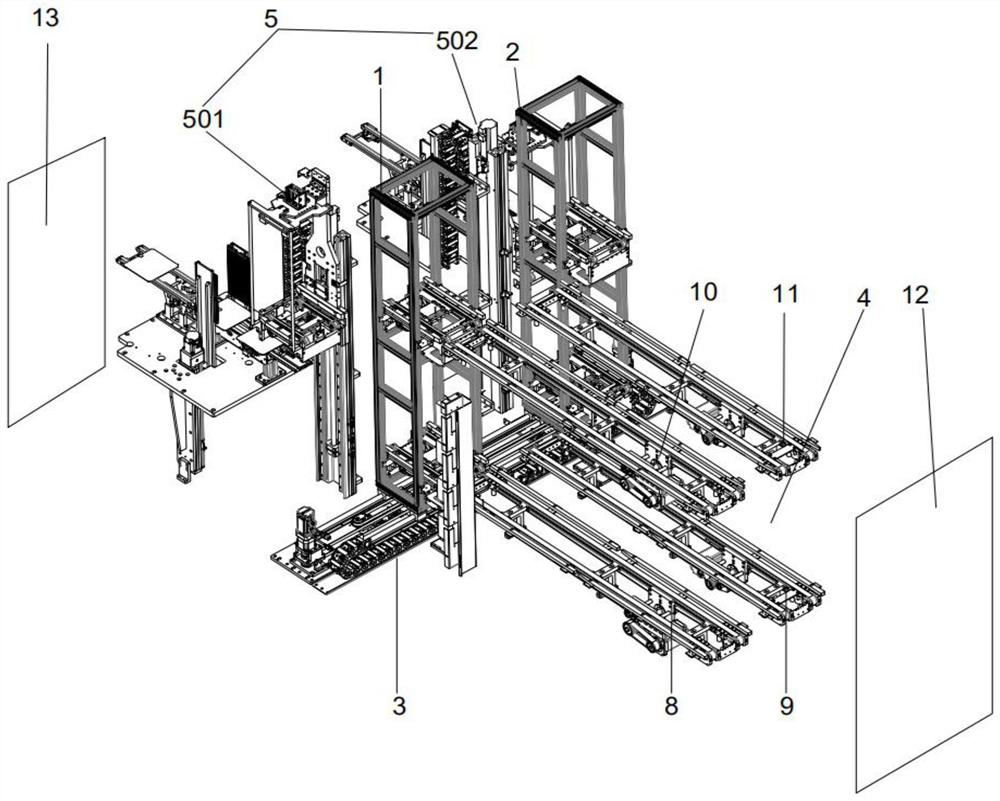

[0059] The embodiment of the present invention provides a silicon wafer flower basket scheduling platform for dual-track feeding, such as Figure 1-Figure 2 As shown, it includes a delivery module 1, a delivery module 2 and a translation module 3. The delivery module 1 and the delivery module 2 are horizontally slidably arranged on the translation module 3. The delivery module 1 and the delivery module 2 2, one side is used for docking with the flower basket transmission line 4, the delivery module 1 and the delivery module 2 2 are connected to the flower basket transmission line 4, and the opposite side is connected to the flower basket lifting system 5, and the flower basket transmission line 4 is connected to There is an AGV loading level 12 (AGV is equipped with an automatic guiding device such as electromagnetic or optical, can travel along a prescribed guiding path, and has safety protection and various transfer functions). The flower basket lifting system 5 is connected ...

Embodiment 2

[0065] On the basis of above-mentioned embodiment 1, as Figure 1-Figure 2 As shown, the first delivery module 1 and the second delivery module 2 play a role of guiding connection between the flower basket transmission line 4 and the flower basket lifting system 5;

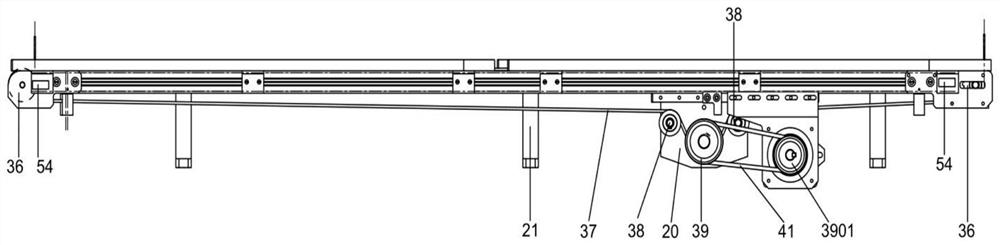

[0066] The delivery module one 1 includes a mounting frame one 101 and a transmission device one 6, the transmission device one 6 is fixedly connected to the installation frame one 101, and the transmission device one 6 includes a feed flow line 102 and a discharge flow line 1 103, the feed flow line one 102 is fixedly arranged at the inner upper part of the installation frame one 101, and the discharge flow line one 103 is fixedly arranged at the inner lower part of the installation frame one 101;

[0067]The conveying module 2 2 includes a mounting frame 201 and a transmission device 2 7, the transmission device 2 6 is fixedly connected to the mounting frame 201, and the transmission device 2 7 includes a feed f...

Embodiment 3

[0071] On the basis of Example 1, such as Figure 1-Figure 2 As shown, the translation module 3 pushes the delivery module 1 and the delivery module 2 to move in the horizontal direction, the translation module 3 includes a mounting plate 307, and the left and right ends of the mounting plate 307 are symmetrically provided with a drive motor 1 301 and drive motor two 306, the front and rear ends of the mounting plate 307 are symmetrically provided with guide rails 304, the guide rails 304 are slidingly connected with the delivery module one 1 and the delivery module two 2, the delivery module one 1 and the delivery module two 2 respectively connected to the moving ends of two drag chains 305, the fixed ends of the two drag chains 305 are symmetrically arranged on the left and right sides of the mounting plate 307, and the driving motor one 301 drives the conveying module one through a synchronous belt 303 1 translates along the guide rail 304 , the driving motor 2 306 drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com