Automatic airtightness testing device

An air-tightness testing and automatic technology, which is applied in the direction of using liquid/vacuum degree for liquid-tightness measurement and measuring the acceleration and deceleration rate of fluid, etc., can solve the problems of complex structure, high cost and lack of versatility of the detection device. Achieve the effect of reducing production costs, increasing production line capacity, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

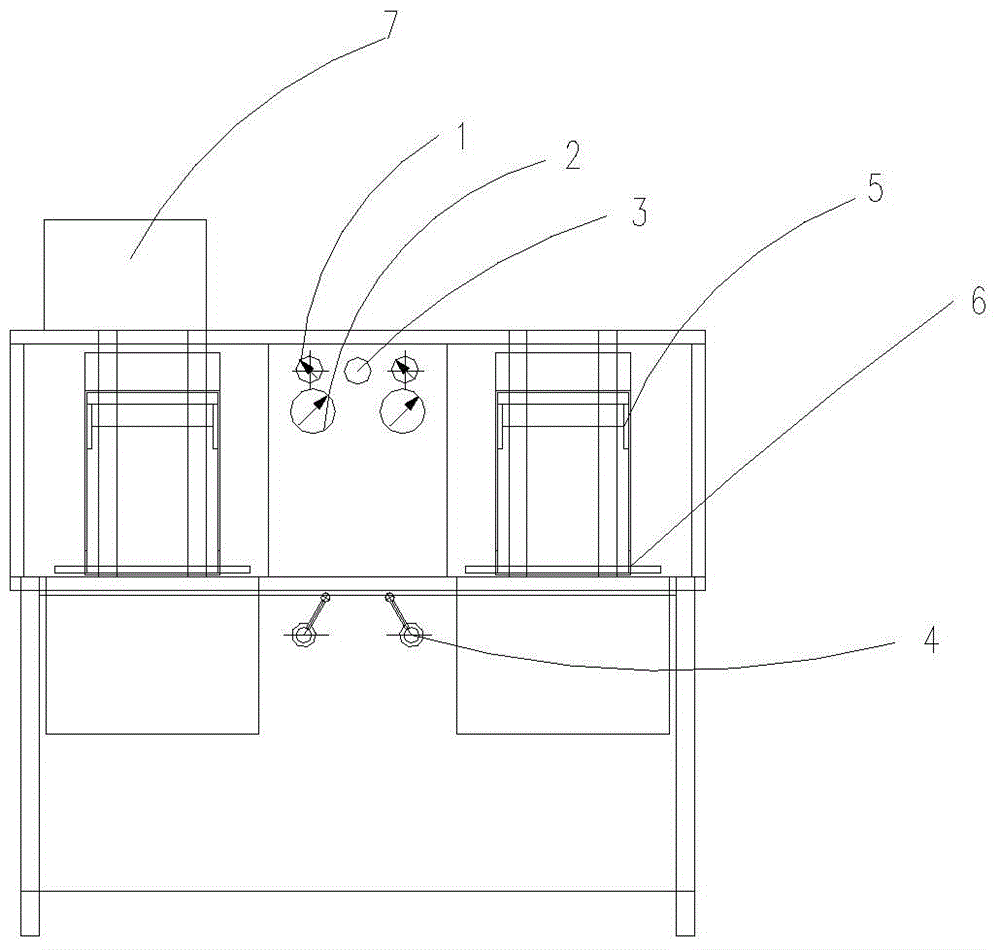

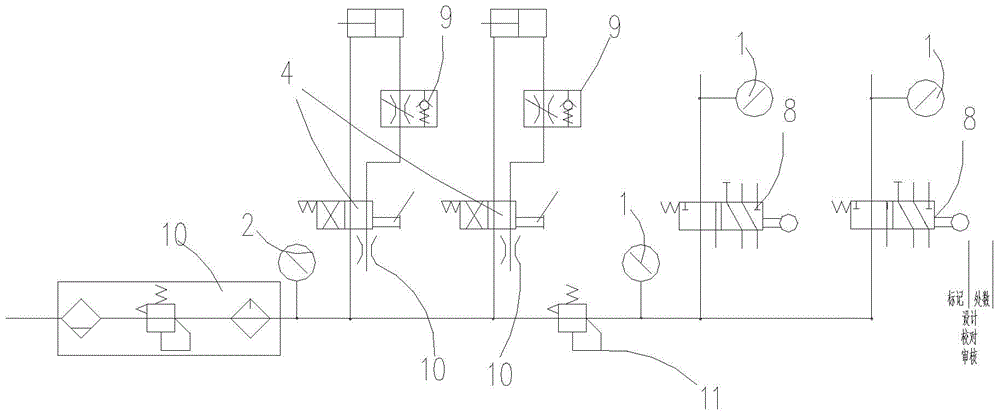

[0012] Such as figure 1 , 2 As shown, an automatic airtight testing device includes a casing, and a bracket is provided inside the casing, and an operating platform is provided on the bracket, and a guide rail 5 is respectively provided on the left and right sides of the operating platform, so that The bottom of the guide rail is provided with an automatic lifting workbench 6, and the automatic lifting workbench is arranged on the support, and a pressure regulating valve 3 is arranged inside the operating table, and the left and right sides of the pressure regulating valve are respectively A first pressure gauge 1 and a second pressure gauge 2 are provided, and a first manual rotary valve and a second manual rotary valve 4 are respectively provided at the bottom of the bracket. A master control box 7 is also arranged on the said shell.

[0013] The casing of the present invention is composed of a rear sealing plate, a side sealing plate, a cover panel, a bottom sealing plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com