Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Improve ion permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dendrite-Intercepting layer for alkali metal secondary battery

ActiveUS20160301075A1High energy densityLow material costElectrode manufacturing processesNegative electrodesElectrochemical decompositionLithium

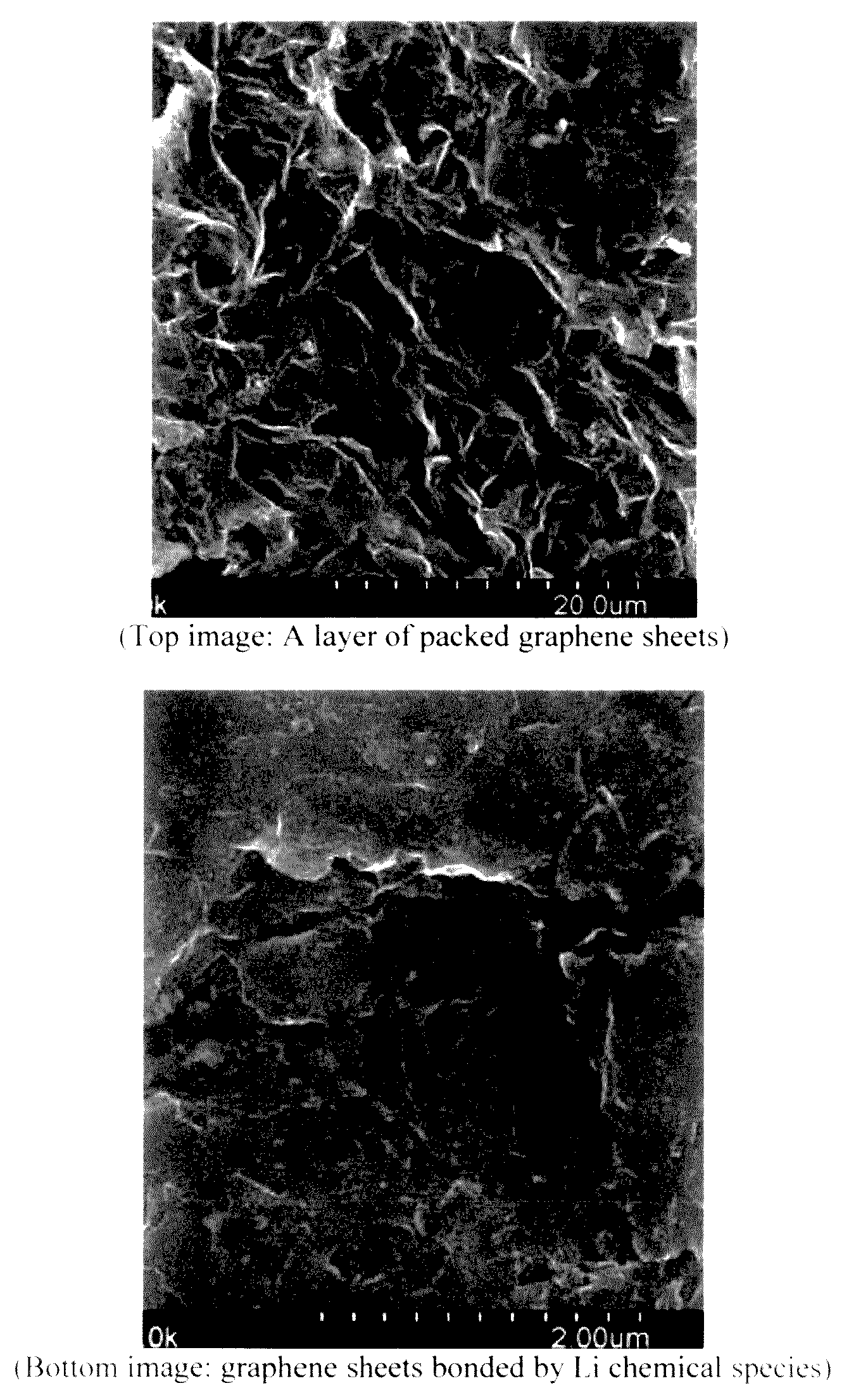

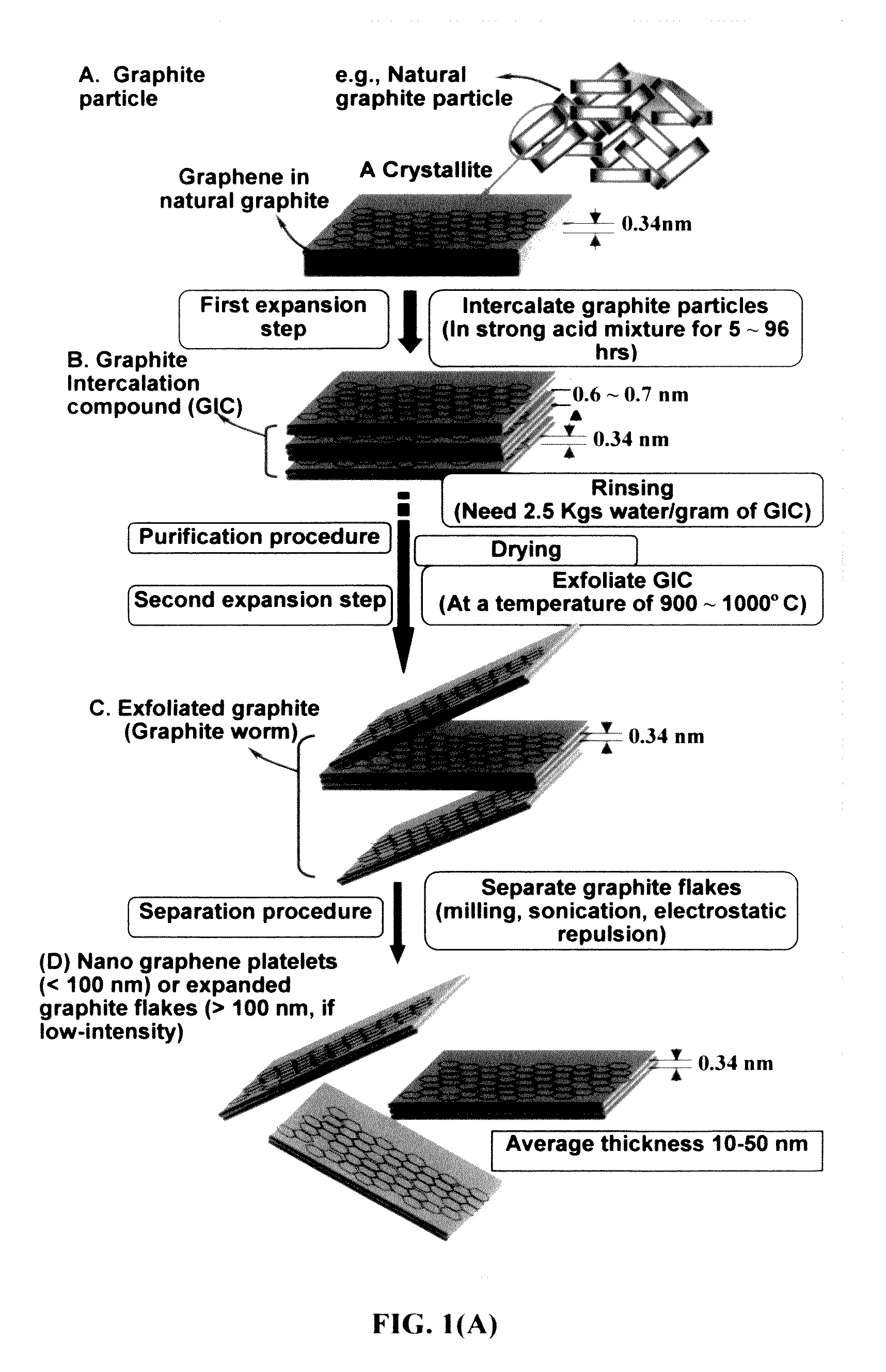

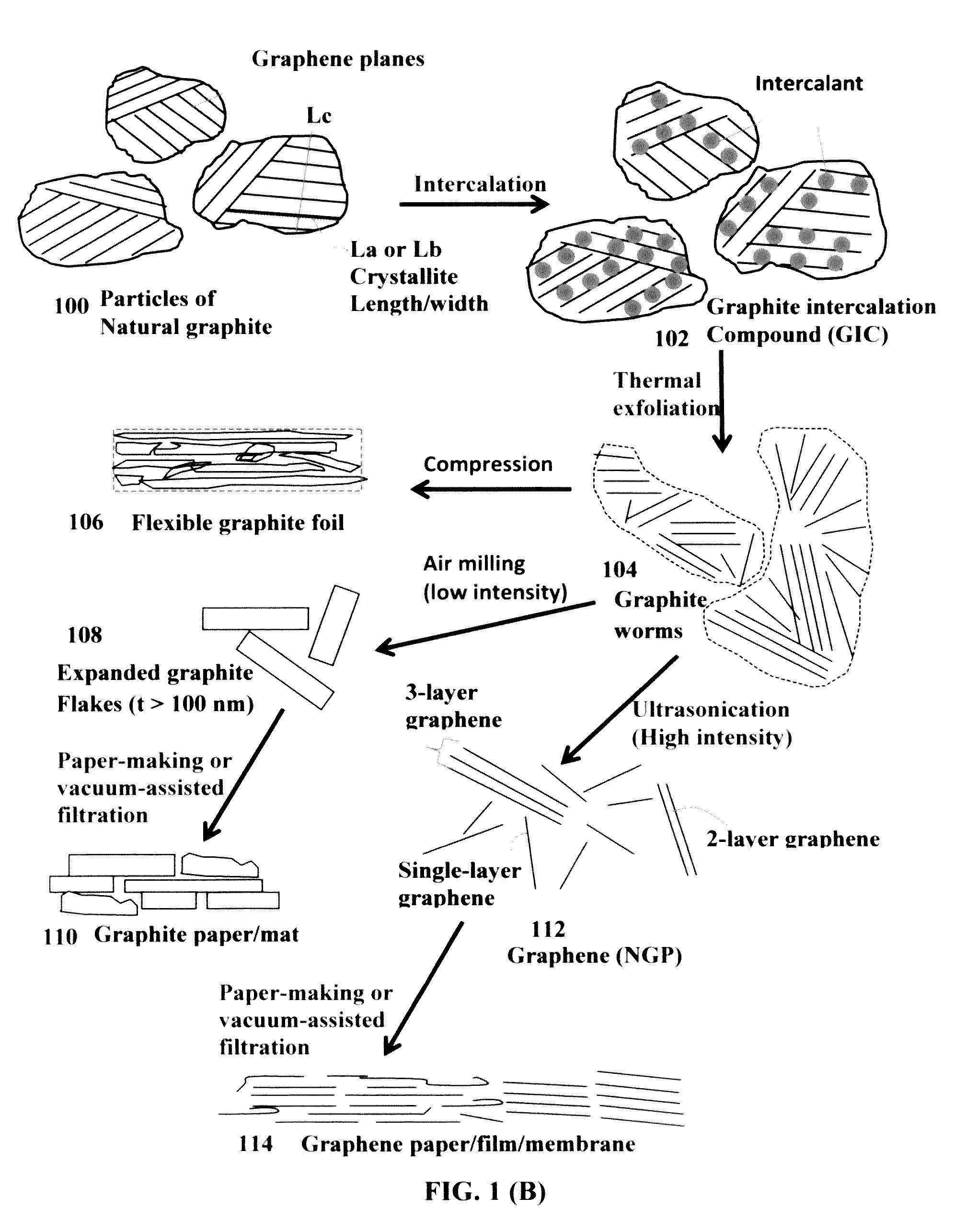

A dendrite penetration-resistant layer for a rechargeable alkali metal battery, comprising multiple graphene sheets or platelets or exfoliated graphite flakes that are chemically bonded by a lithium- or sodium-containing species to form an integral layer that prevents dendrite penetration through the integral layer, wherein the lithium-containing species is selected from Li2CO3, Li2O, Li2C2O4, LiOH, LiX, ROCO2Li, HCOLi, ROLi, (ROCO2Li)2, (CH2OCO2Li)2, Li2S, LixSOy, Na2CO3, Na2O, Na2C2O4, NaOH, NaiX, ROCO2Na, HCONa, RONa, (ROCO2Na)2, (CH2OCO2Na)2, Na2S, NaxSOy, or a combination thereof, wherein X=F, Cl, I, or Br, R=a hydrocarbon group, x=0-1, y=1-4. Also provided is a process for producing a dendrite penetration-resistant layer based on the principle of electrochemical decomposition of an electrolyte in the presence of multiple graphene sheets.

Owner:GLOBAL GRAPHENE GRP INC

Porous film and separator for battery using the same

InactiveUS20060055075A1High piercing strengthSuperior ion permeabilityMembranesButtonsPolyolefinChemistry

Provided is a porous film obtained by melt-kneading a high-molecular-weight polyolefin having a weight-average molecular weight of not less than 5×105, a thermoplastic resin having a weight-average molecular weight of not more than 2×104 and fine particles, molding the kneaded matter into a sheet, and then stretching the sheet. The porous film can be easily and simply prepared, and has a high piercing strength, and hence can be advantageously used as a separator for a battery, particularly for a lithium secondary battery.

Owner:SUMITOMO CHEM CO LTD

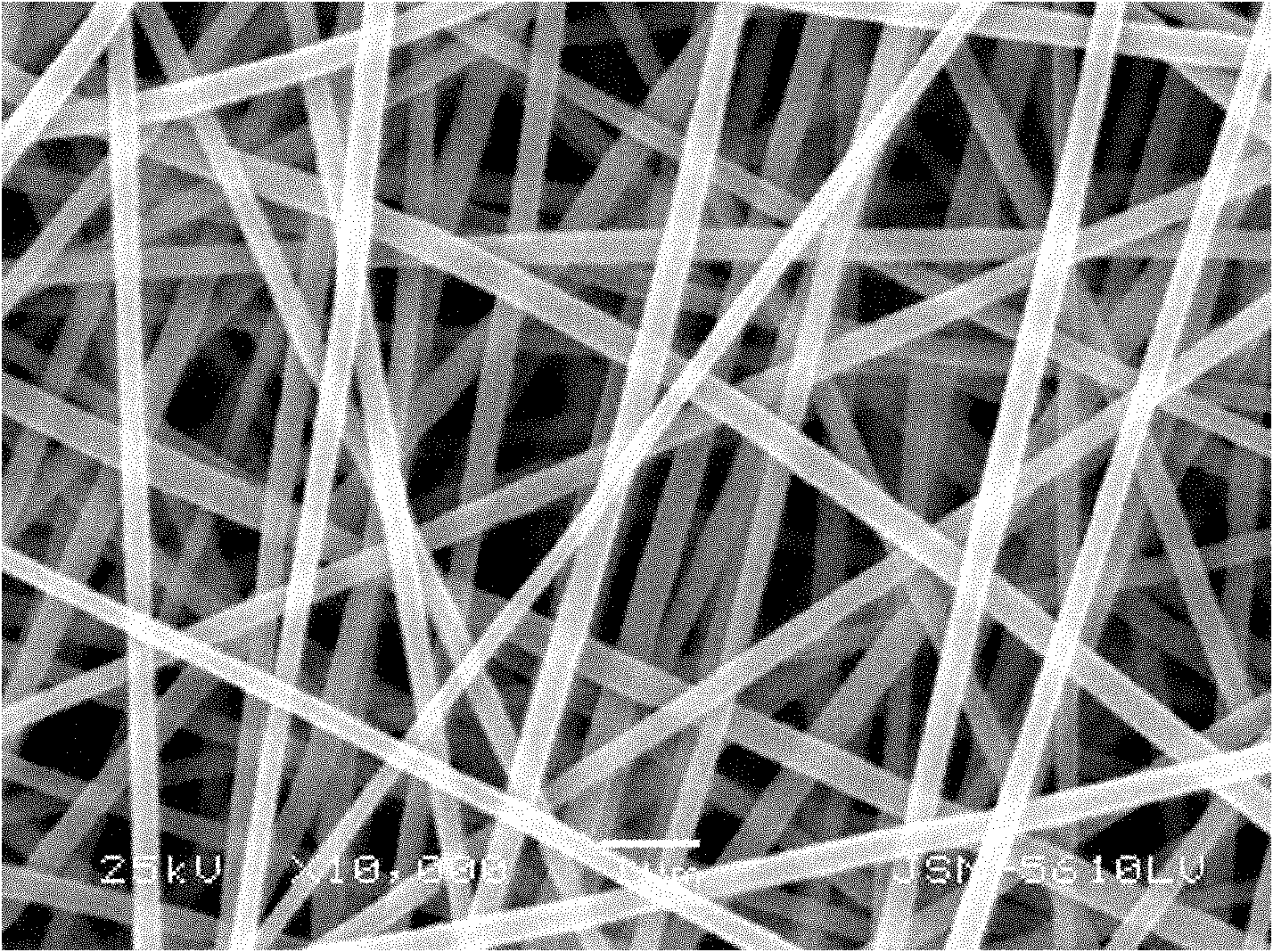

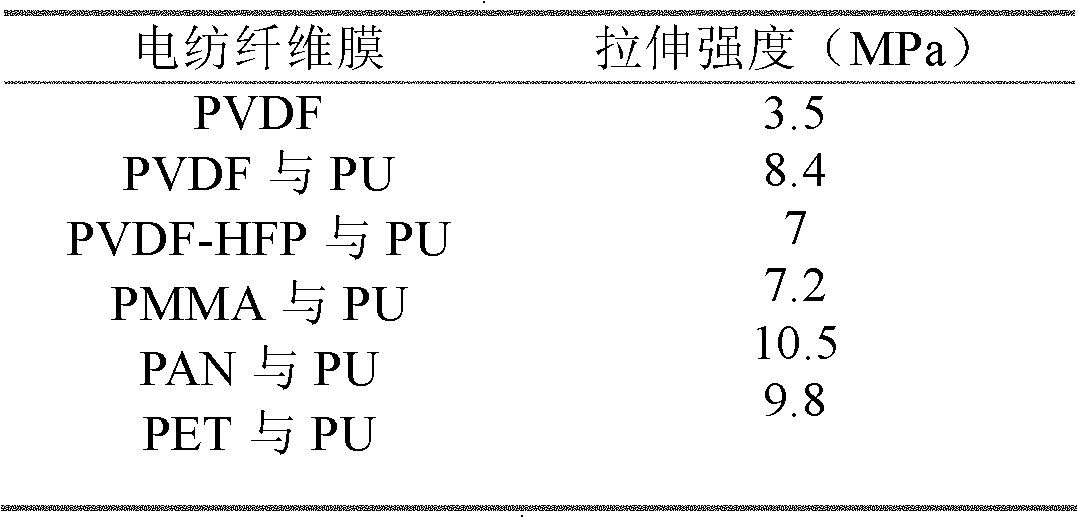

Reinforced nanofiber porous membrane and preparation method thereof

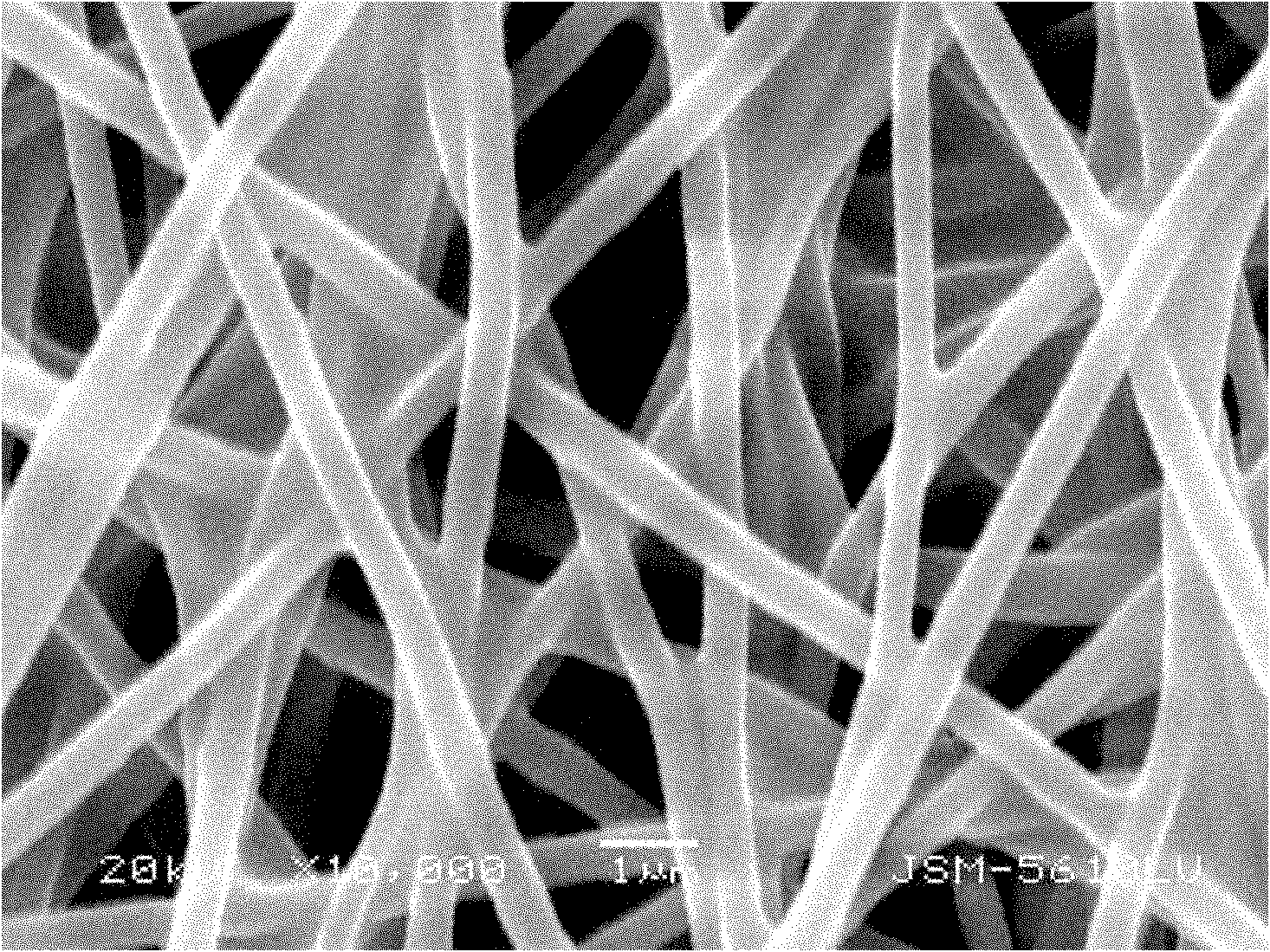

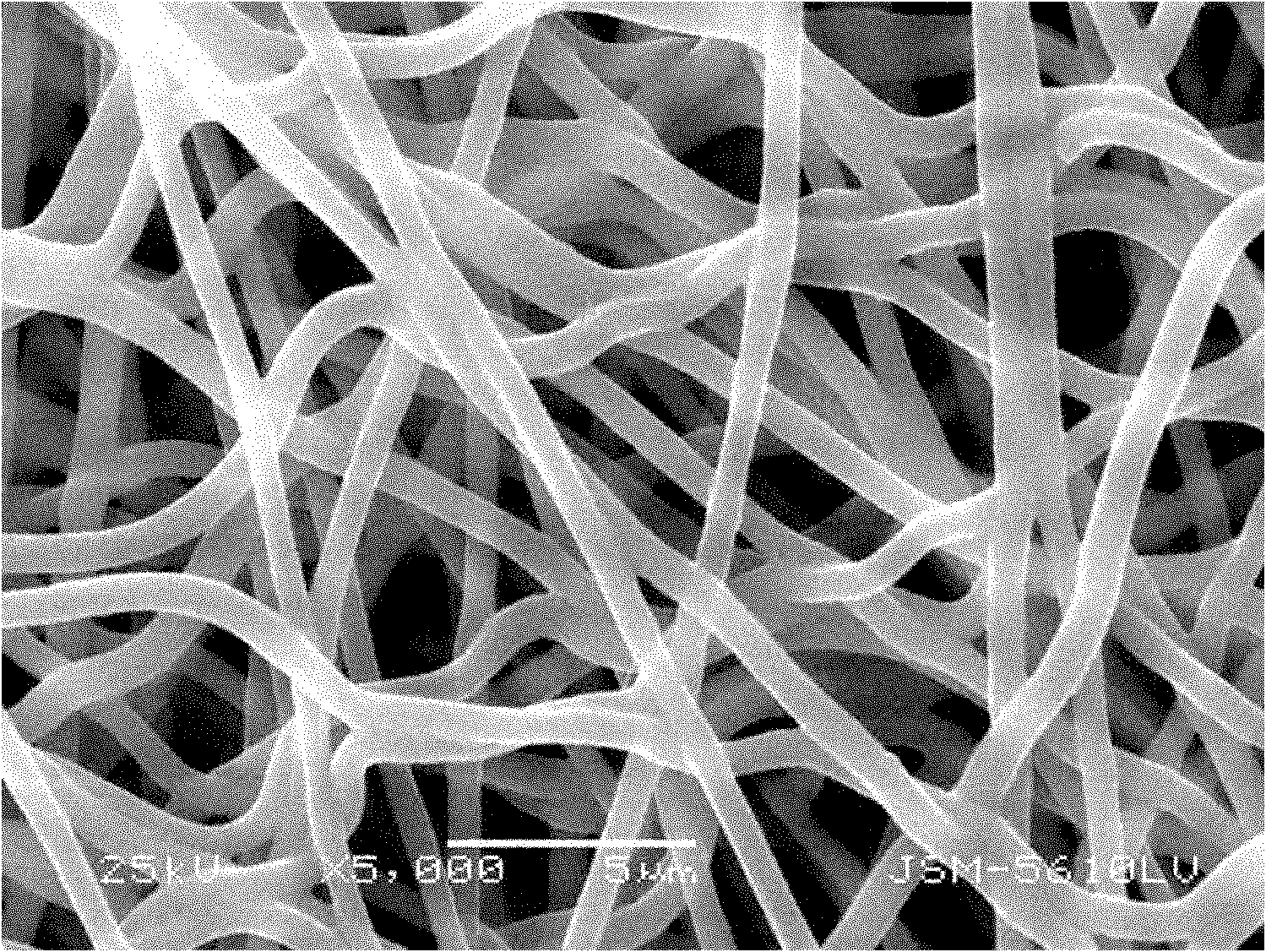

InactiveCN102140762AHigh porosityImprove wettabilityFibre typesCell component detailsFiberPolymer science

The invention relates to a reinforced nanofiber porous membrane and a preparation method thereof. The porous membrane is a two-component lithium ion battery diaphragm formed by compounding polymer resin with polyurethane, and has a semi-interpenetrating network structure, the porosity of 60 to 80 percent, and mechanical property which is 3 to 4 times higher than that of a polymer resin single-component porous membrane. The preparation method comprises the following steps of: preparing a polymer resin non-woven membrane by high-voltage electrostatic spinning, impregnating the non-woven membrane in solution of wet curing reaction polyurethane prepolymer with a high-reactivity isocyanate group, reacting -NCO in the polyurethane prepolymer with a -OH bond of water in air at room temperature to obtain the polyurethane through crosslinking and autopolymerization, so that nanofibers in the non-woven membrane are bonded to form a polymer resin and polyurethane two-component composite membrane, and the mechanical strength of the fiber membrane is greatly improved. The method is easy to operate, and the prepared non-woven membrane keeps the advantages of high porosity of a membrane prepared by an electrostatic spinning technology, and heat stability of the polymer resin, and has high ion permeability and affinity of electrolyte.

Owner:WUHAN UNIV OF TECH

Porous film

ActiveUS20100092754A1Improve heat resistanceImprove featuresHybrid capacitor separatorsFinal product manufactureChemistryHeat resistant

Provided is a porous film comprising a heat-resistant resin and two or more fillers, wherein a value of D2 / D1 is 0.15 or less where among values each obtained by measuring the average particle diameter of particles that constitute one of the two or more fillers, the largest value is let be D1 and the second largest value is let be D2.

Owner:SUMITOMO CHEM CO LTD

Enhanced bi-component nanofiber porous membrane and preparation method thereof

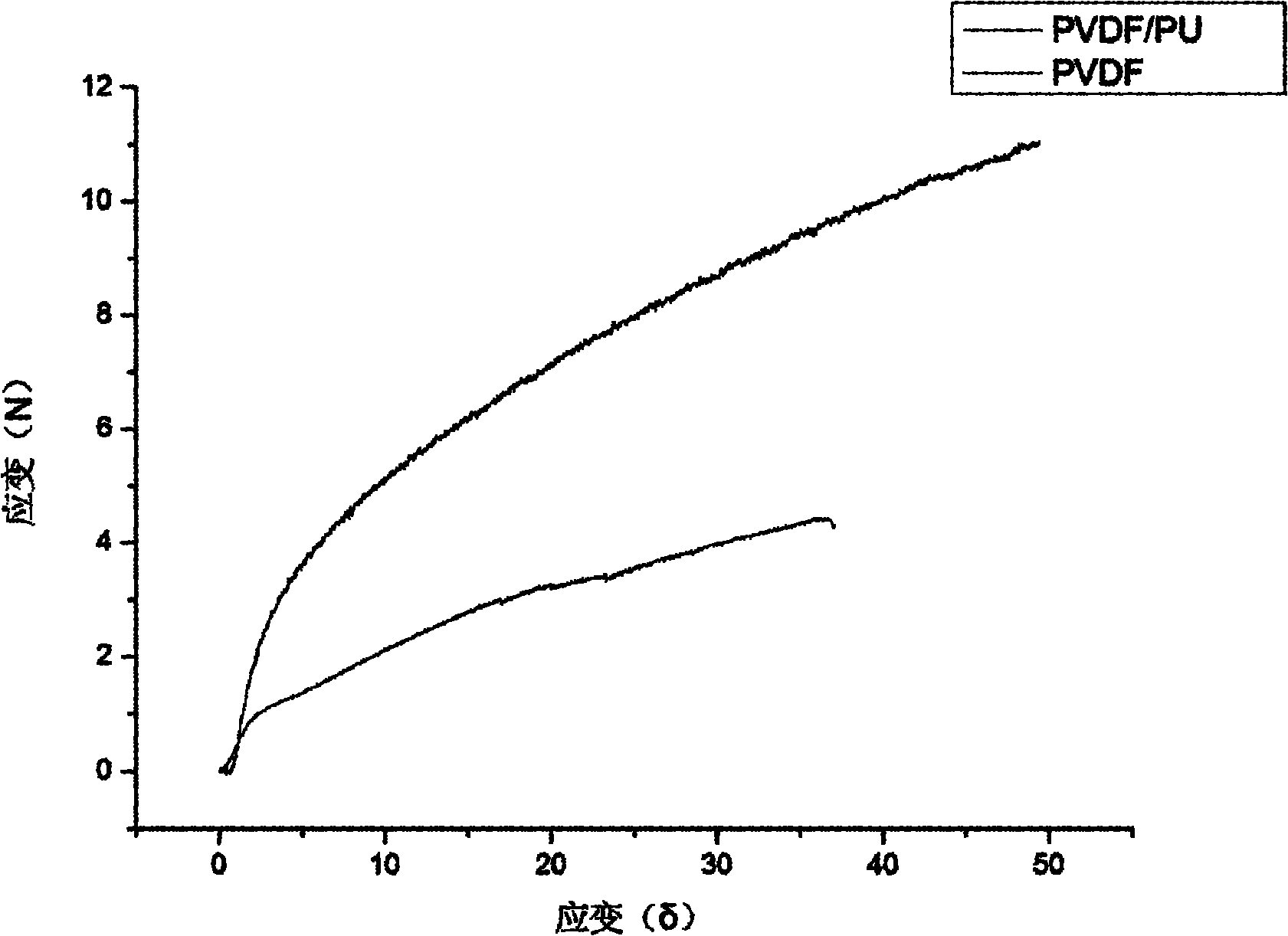

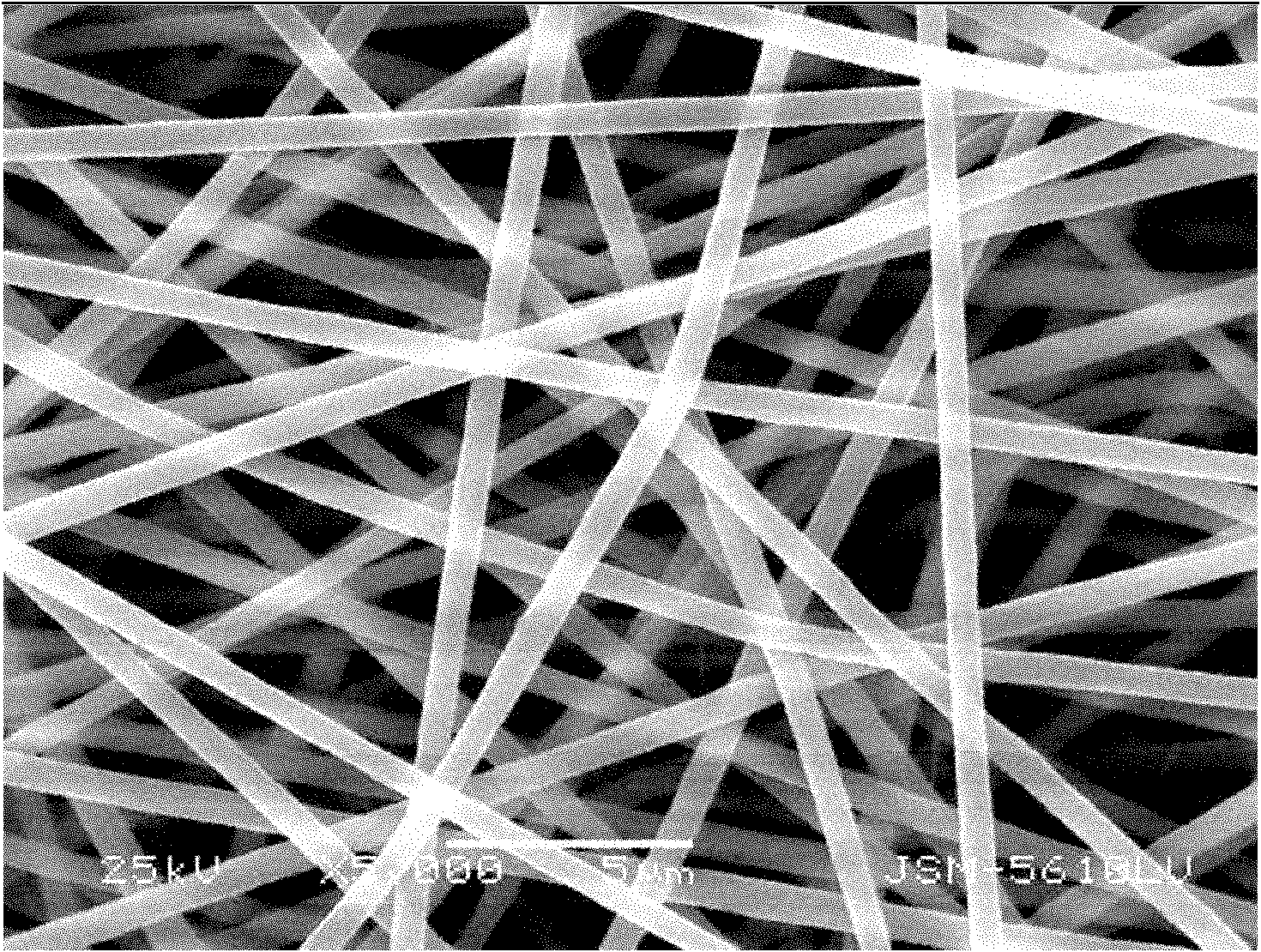

InactiveCN102140734AHigh porosityImprove wettabilityFilament/thread formingCell component detailsPolymer scienceVoid ratio

The invention relates to an enhanced bi-component nanofiber porous membrane and a preparation method thereof. The porous membrane is a lithium ion battery membrane with two components of polymer resin and polyurethane. The membrane is in a semi-interpenetrating network structure which has a void ratio of 60-80%, and the mechanical property is 2-3 times higher than a single-component porous membrane of polymer resin. The preparation method comprises the steps of: dissolving a polymer resin and polyurethane prepolymer bi-component composition in a solvent, and preparing a nonwoven membrane through an electrospinning technology; and putting the nonwoven membrane at room temperature to make -NCO in the polyurethane prepolymer react with the -OH bond of water in the air to produce polyurethanethrough crosslinking and autopolymerization. In the invention, the nanofiber in the nonwoven membrane binds to form the polymer resin and polyurethane bi-component compound membrane, and the mechanical strength of the fibrous membrane is improved greatly. The method is easy, and the prepared nonwoven membrane maintains the advantages of high void ratio, and good thermal stability of polymer resinof the membrane prepared by using the electrospinning technology, and the membrane has good ion permeability and electrolyte affinity.

Owner:WUHAN UNIV OF TECH

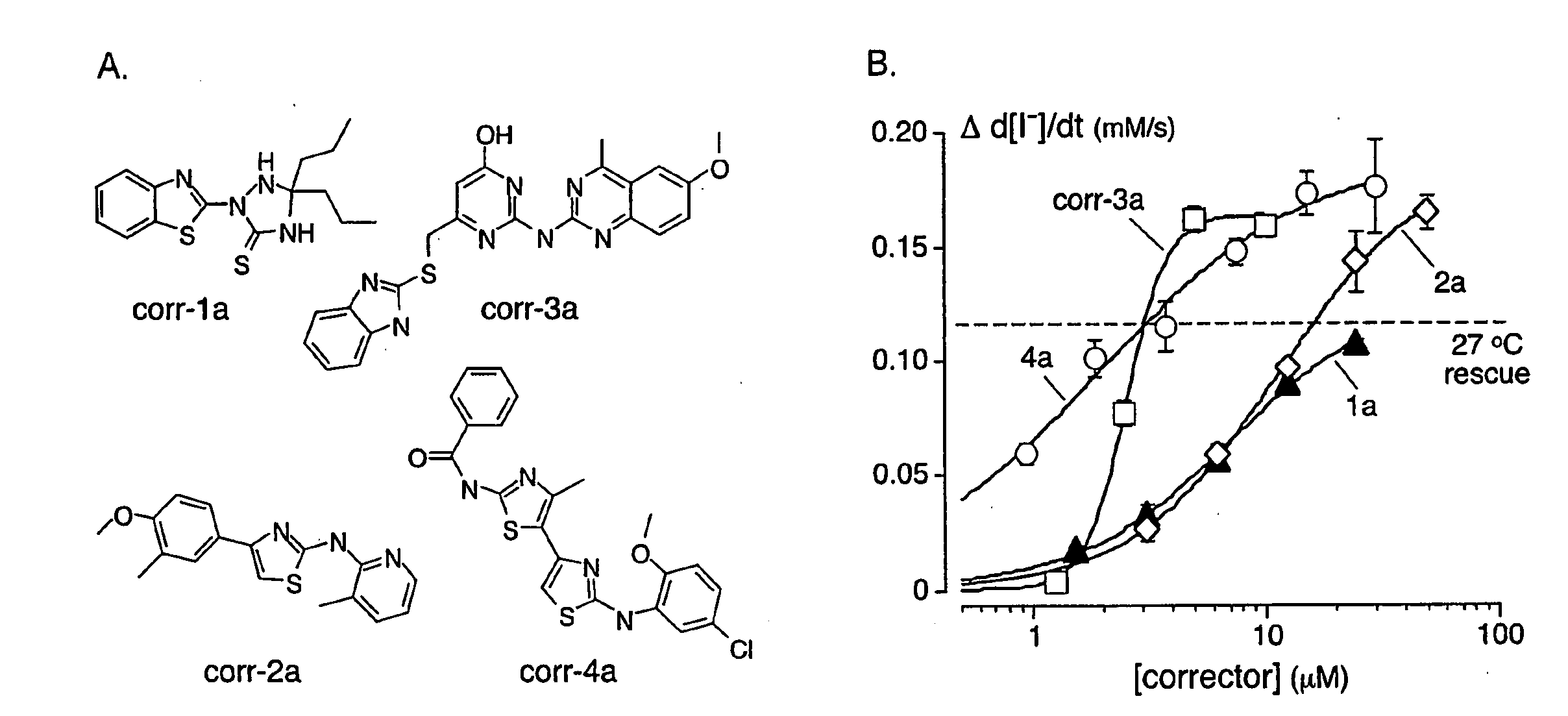

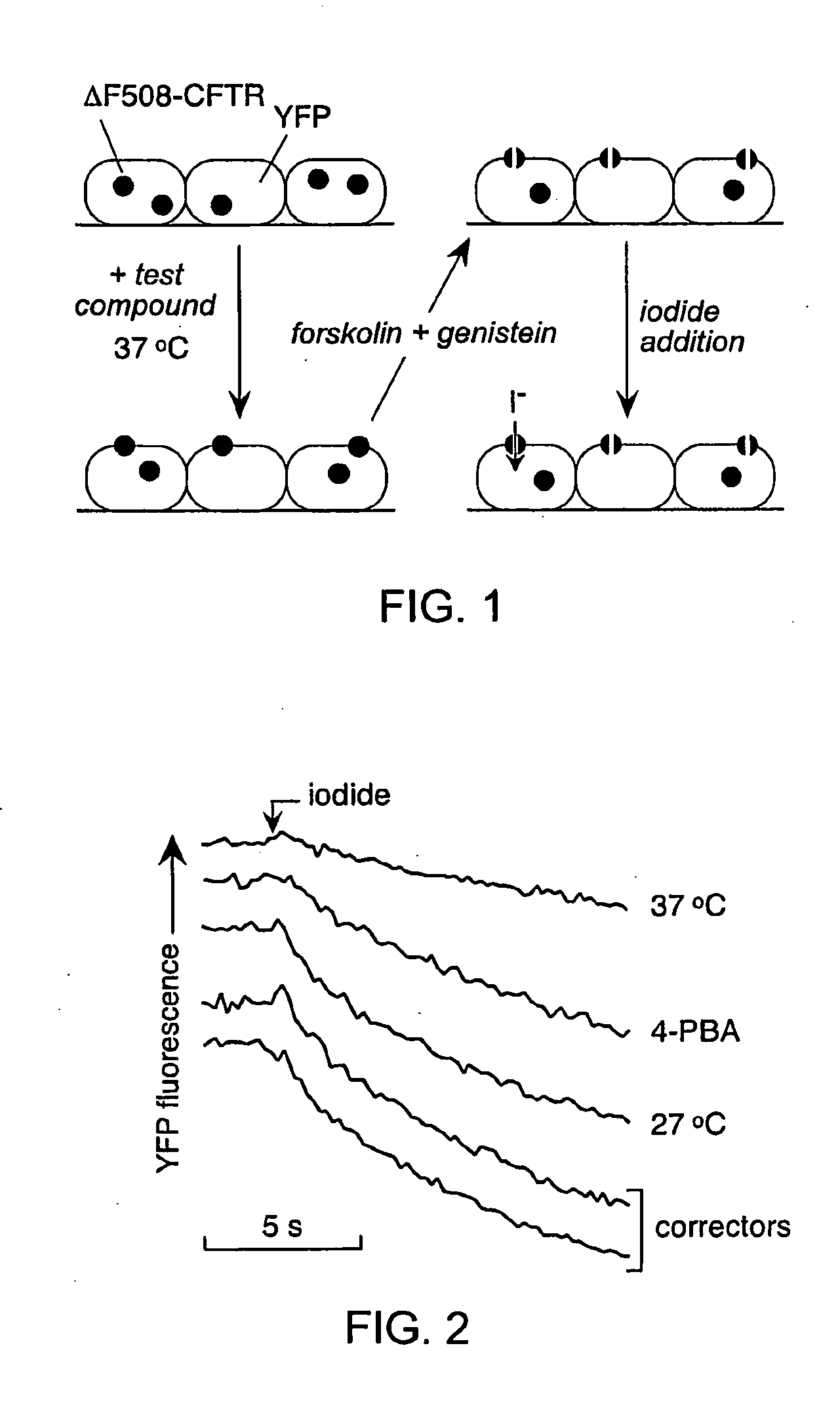

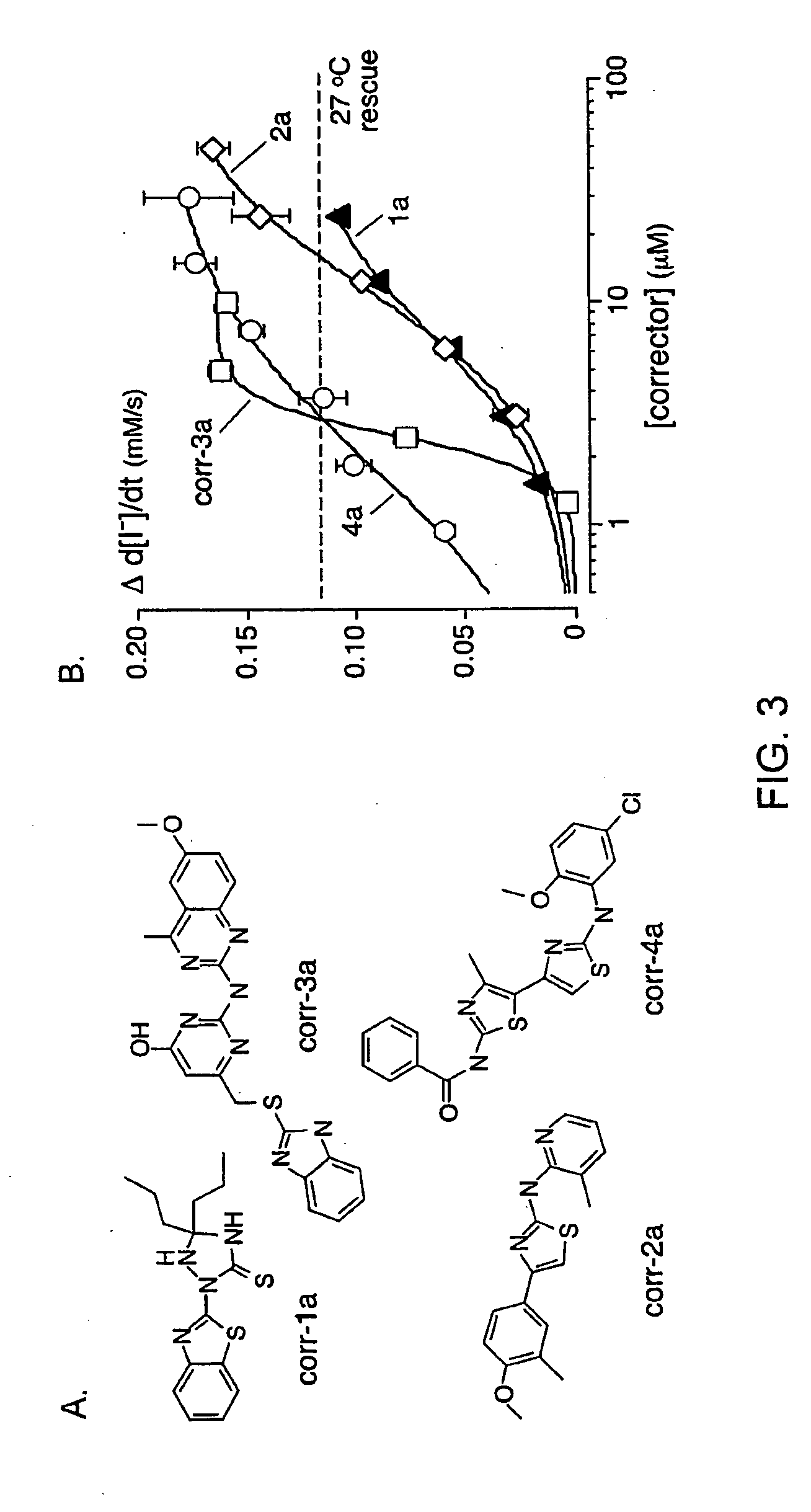

Compounds Having Activity in Correcting Mutant-Cftr Processing and Uses Thereof

ActiveUS20080318984A1Good cell permeabilityImprove ion permeabilityBiocideOrganic chemistryMutantCystic fibrosis lungs

The invention provides compositions, pharmaceutical preparations and methods for correcting cellular processing (e.g., folding, trafficking, or post-translational modification) of a mutant-cystic fibrosis transmembrane conductance regulator protein (e.g., ΔF508 CFTR) that are useful for the treatment of cystic fibrosis (CF). The compositions and pharmaceutical preparations of the invention may comprise one or more aminobenzothiazole-containing compounds, aminoarylthiazole-containing compounds, quinazolinylaminopyrimidinone-containing compounds, bisaminomethylbithiazole-containing compounds, or phenylaminoquino-line-containing compounds of the invention, or an analog or derivative thereof.

Owner:RGT UNIV OF CALIFORNIA

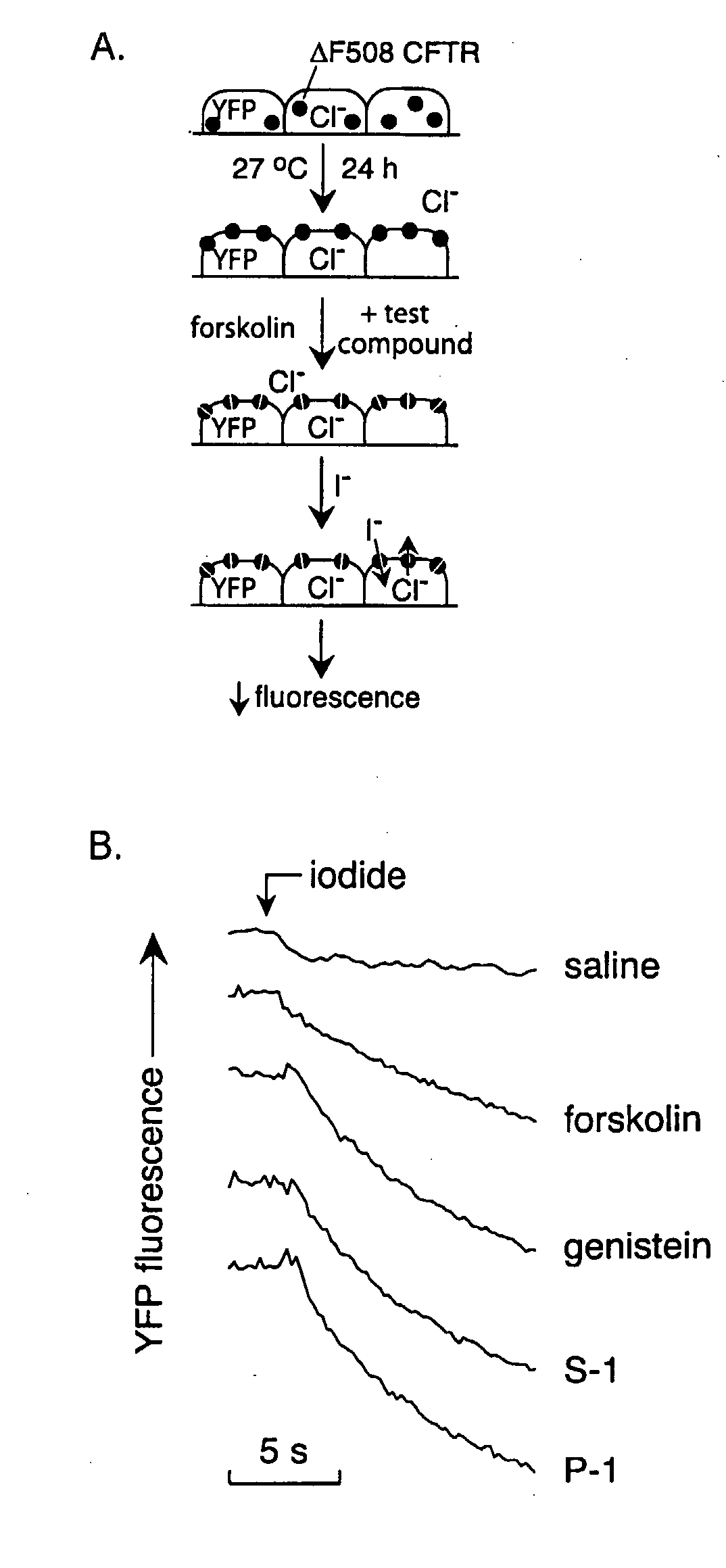

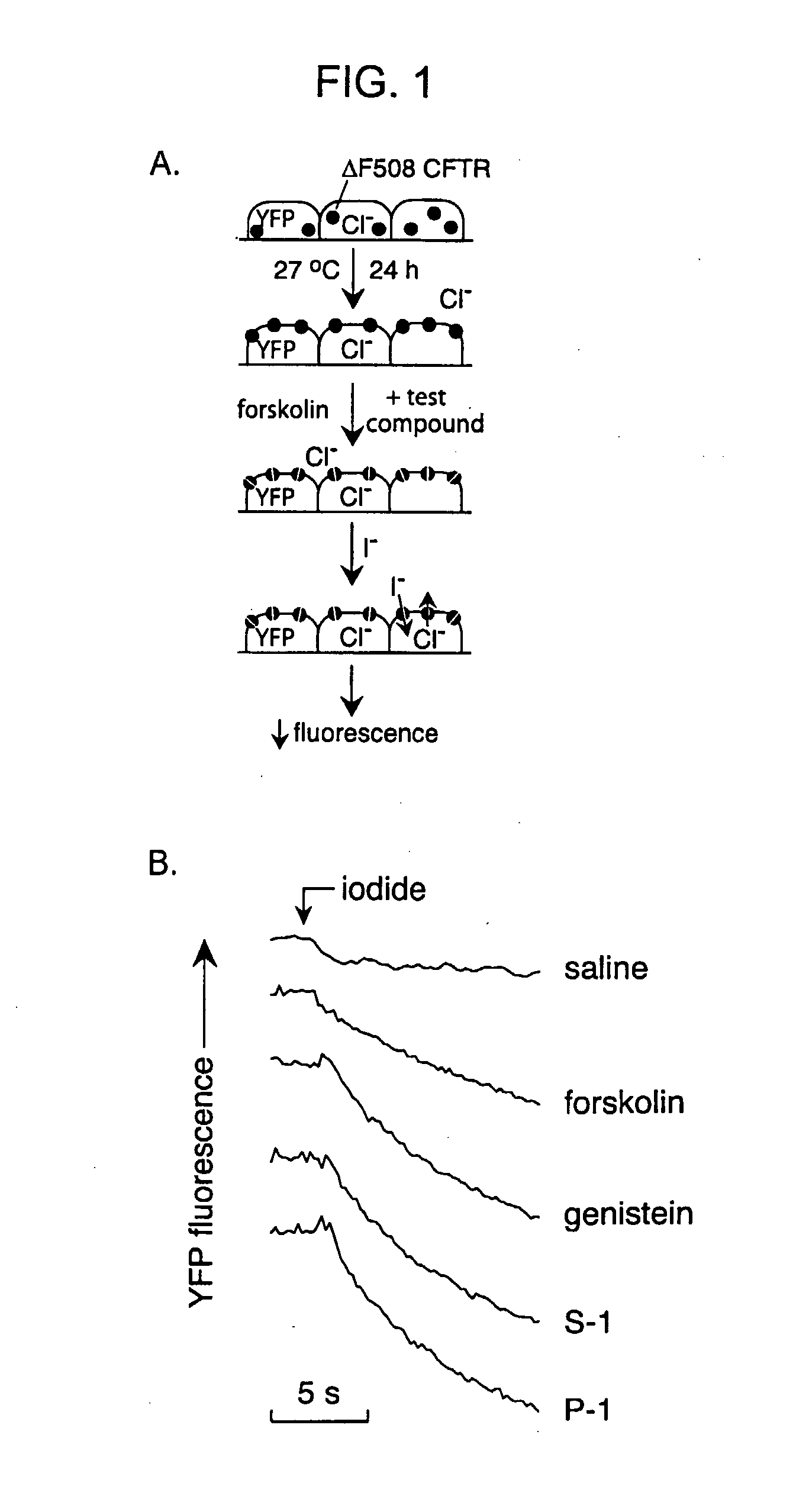

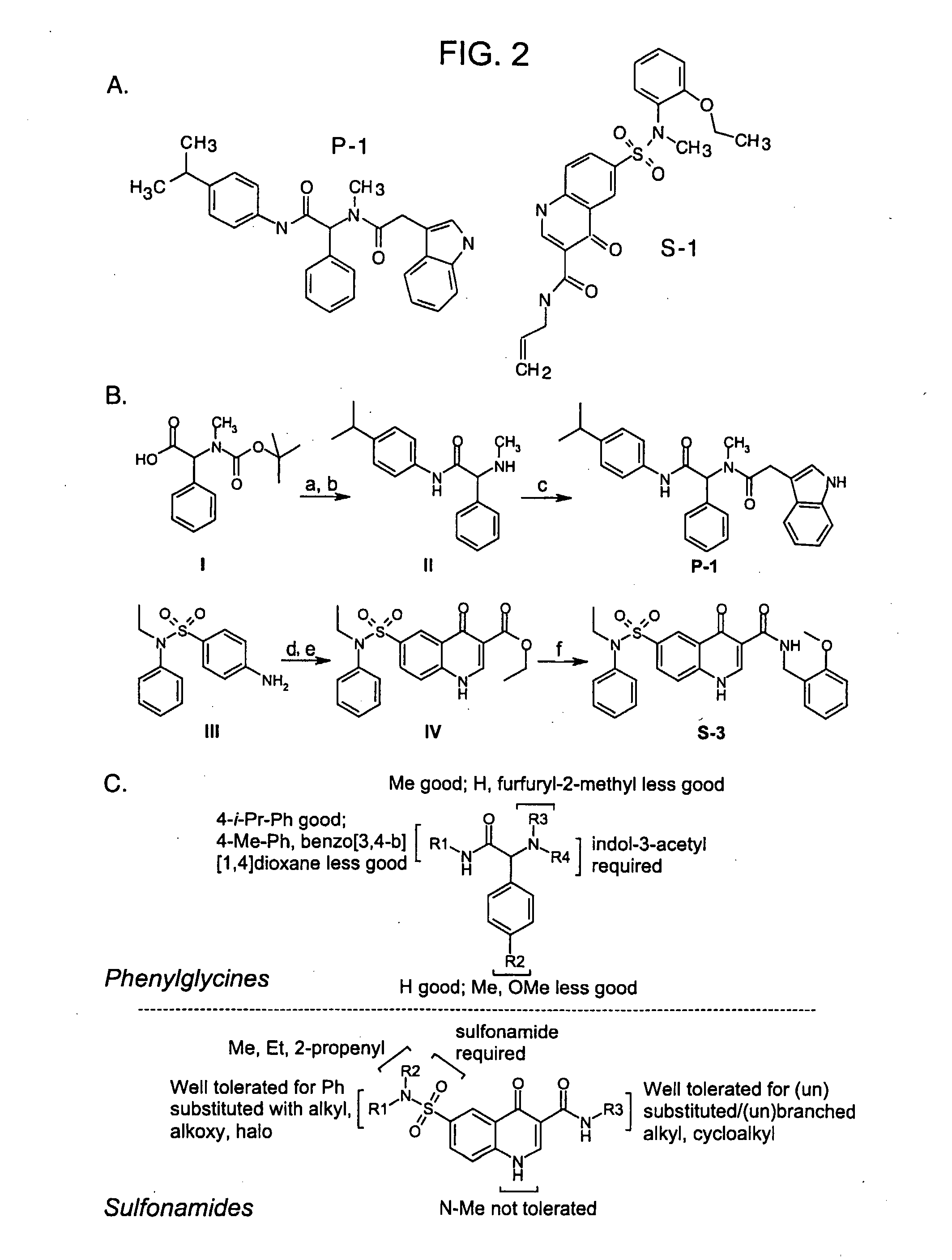

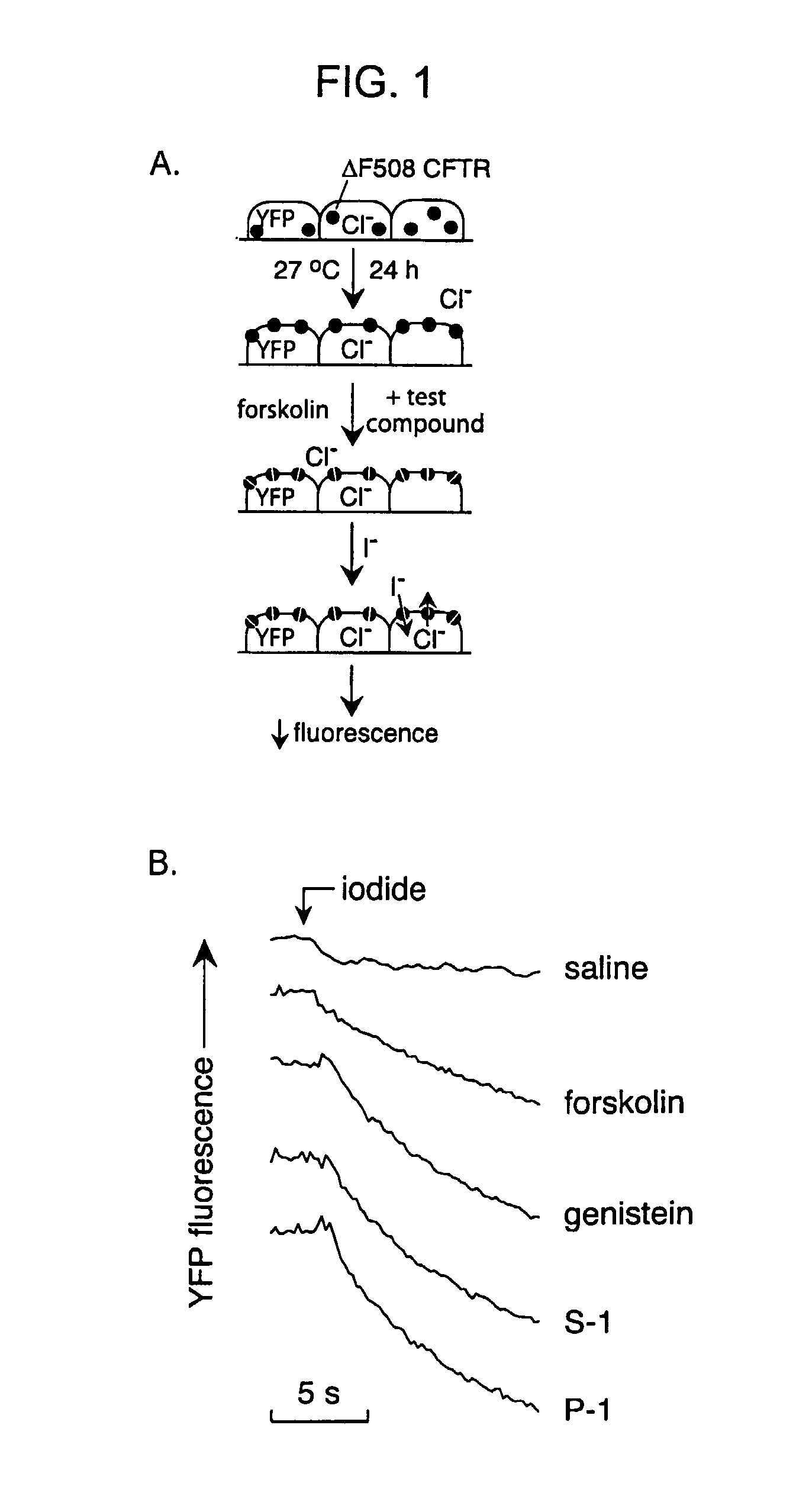

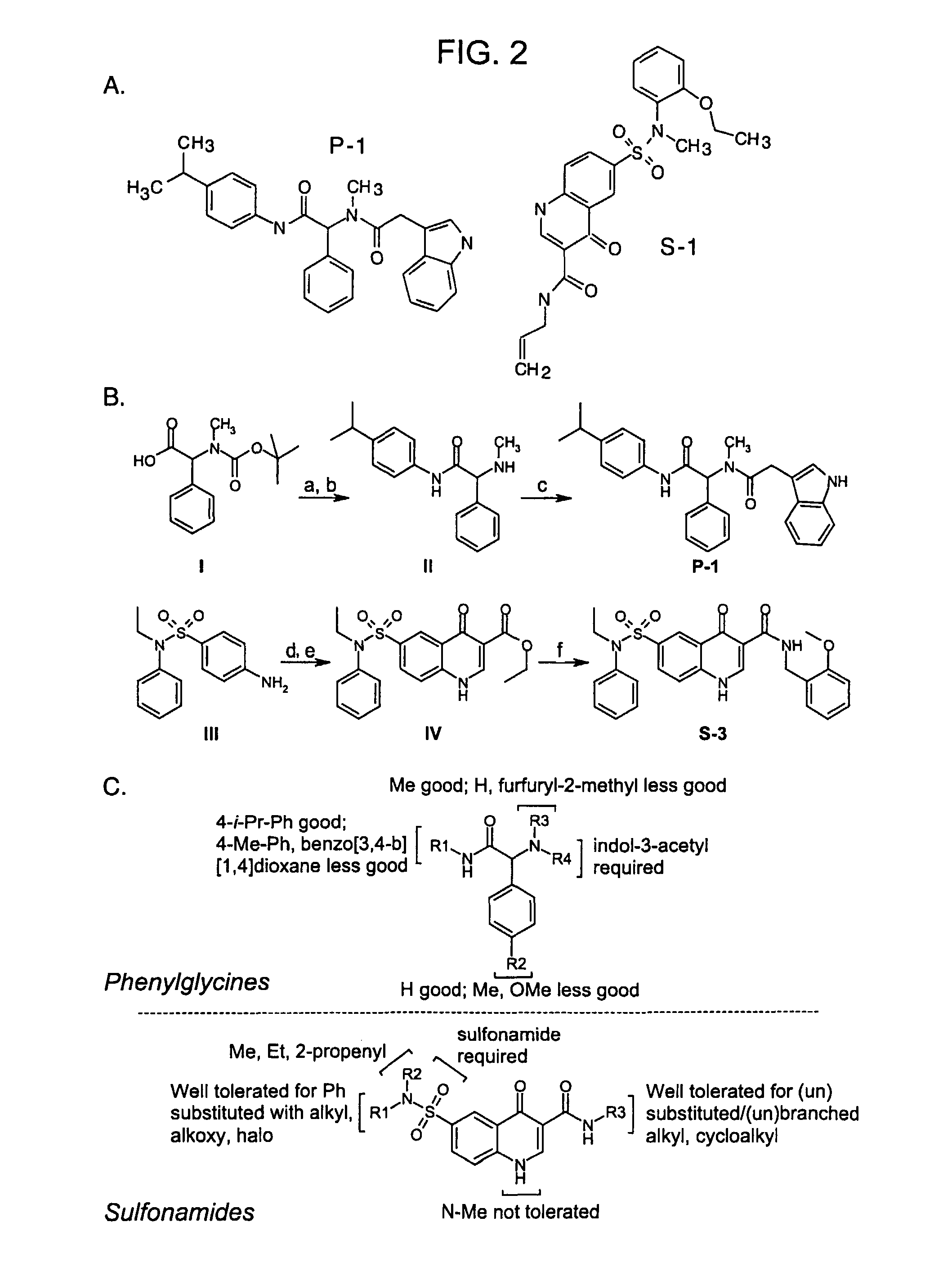

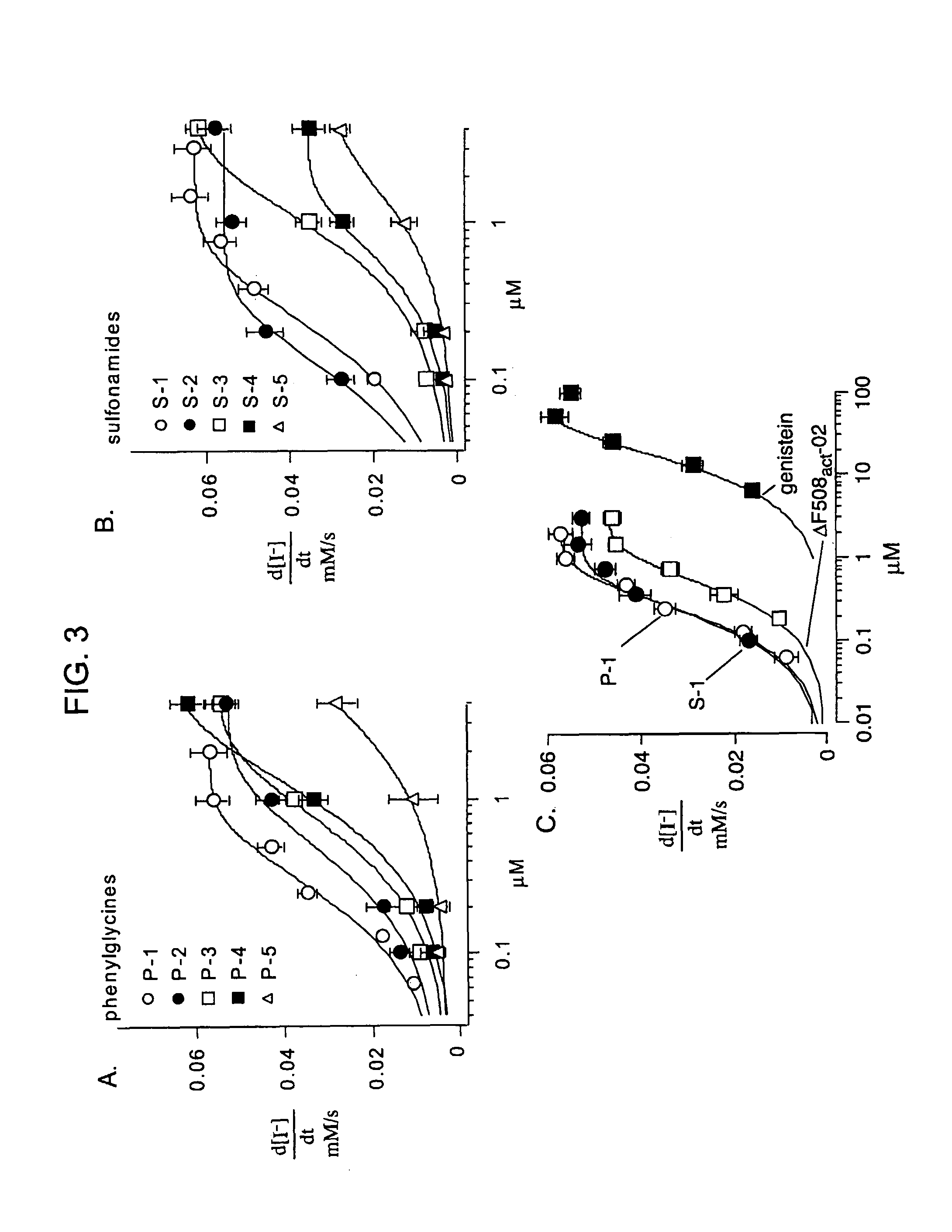

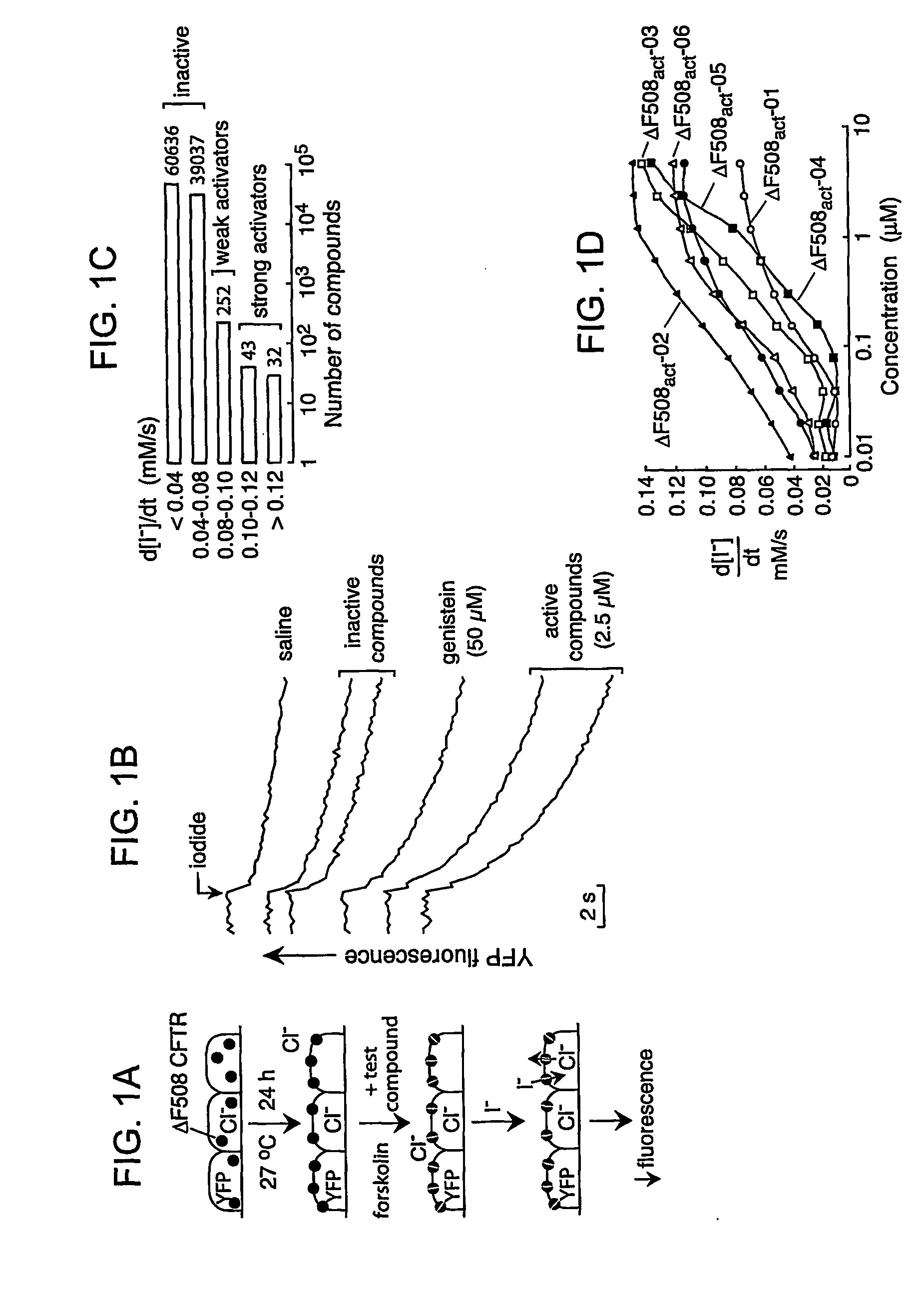

Compounds Having Activity in Increasing Ion Transport by Mutant-Cftr and Uses Thereof

ActiveUS20080319008A1High activityGood cell permeabilityBiocideOrganic chemistryCystic fibrosis lungsCystic fibrosis

The invention provides compositions, pharmaceutical preparations and methods for increasing activity (e.g., ion transport) of the mutant cystic fibrosis transmembrane conductance regulator protein (mutant-CFTR), e.g., ΔF508 CFTR, G551D-CFTR, G1349D-CFTR, or D1152H-CFTR, that are useful for the treatment of cystic fibrosis (CF). The compositions and pharmaceutical preparations of the invention may comprise one or more phenylglycine-containing compounds or sulfonamide-containing compounds of the invention, or an analog or derivative thereof.

Owner:RGT UNIV OF CALIFORNIA

Porous film, and production method and applications thereof

InactiveUS20060234031A1Improve ion permeabilityExcels in ion permeabilitySynthetic resin layered productsSecondary cellsPolyolefinAlpha-olefin

Disclosed is a porous film formed of a polyolefin resin comprising an ethylene-α-olefin copolymer (A) which comprises structural units originating from ethylene and structural units originating from one or more sorts of monomers selected from α-olefins having 4-8 carbon atoms and which satisfies the requirements (I) the intrinsic viscosity [η] is 9.0 to 15.0 dl / g; (II) the melting point Tm is not lower than 115° C. but lower than 130° C.; (III) the content of cold-xylene-soluble components included in the ethylene-α-olefin copolymer (A) is 3% by weight or less; and (IV) Tm≦0.54×[η]+114. A battery separator including the porous film and a method for the preparation of the porous film are also disclosed.

Owner:SUMITOMO CHEM CO LTD

Lithium secondary battery with improved cell characteristics

ActiveUS20100297510A1Large capacityImprove stabilityOrganic electrolyte cellsSecondary cellsLithiumSolvent

Disclosed herein is a lithium secondary cell including 20 to 100 wt. % of lithium transition metal oxide represented by a formula of Li1+zNibMncMe1−(b+c)O2, relative to a total amount of a cathode active material, as well as an electrolyte consisting of a lithium salt and a non-aqueous solvent, wherein a first additive to form a protective film (that is, a solid electrolyte interface film: SEI film) over a surface of an anode active material and a second additive to form another SEI film over the surface of the anode active material while inactivating impurities contained in the cathode active material are included in the electrolyte.

Owner:LG ENERGY SOLUTION LTD

Nonaqueous electrolyte secondary battery

ActiveUS20140170464A1Improve reliabilityLower resistanceFinal product manufactureCell component detailsPorosityHeat resistance

Owner:TOYOTA JIDOSHA KK

Separator for a non-aqueous secondary battery and non-aqueous secondary battery

ActiveUS20140255754A1Excellent ion permeabilityUniform porous structureJackets/cases materialsLi-accumulatorsPolyvinylidene fluorideStructural unit

The present invention provides a separator for a non-aqueous secondary battery including a porous substrate, and an adhesive porous layer that is formed at one or both sides of the porous substrate, contains (1) polyvinylidene fluoride resin A and (2) polyvinylidene fluoride resin B described below, and has a porosity of from 30% to 60% and an average pore size of from 20 nm to 100 nm:(1) polyvinylidene fluoride resin A is selected from the group consisting of vinylidene fluoride homopolymers and DVF copolymers containing structural units derived from vinylidene fluoride (VDF) and structural units derived from hexafluoropropylene (HFP), a total content of structural unit derived from HFP in each of the VDF copolymers being 1.5 mol % or less of a total content of structural unit in each of the VDF copolymers; and(2) polyvinylidene fluoride resin B selected from the group consisting of VDF copolymers containing a structural unit derived from VDF and a structural unit derived from hexafluoropropylene, a total content of structural unit derived from HFP in each of the VDF copolymers being greater than 1.5 mol % of a total content of structural unit in each of the VDF copolymers

Owner:TEIJIN LTD

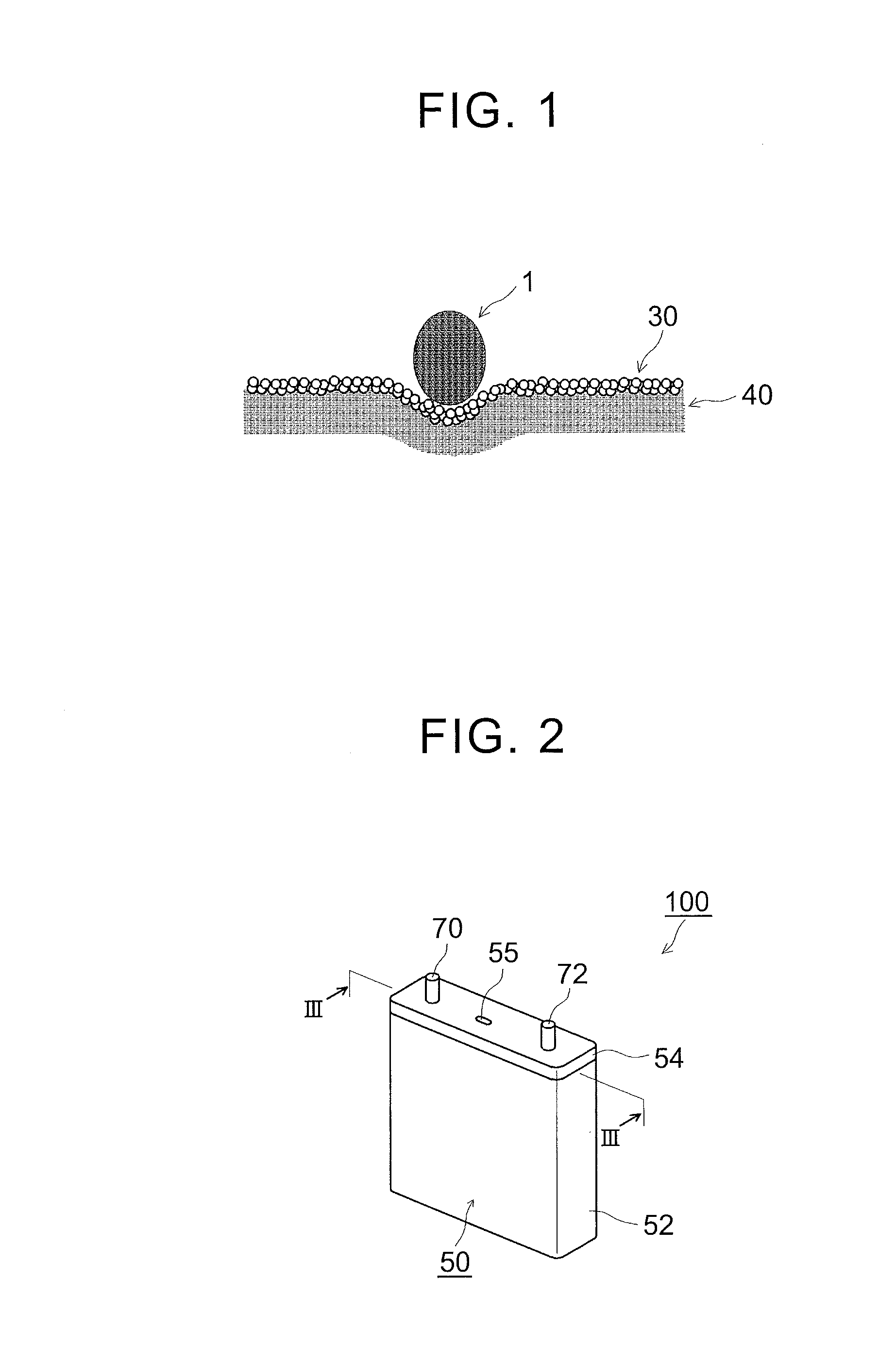

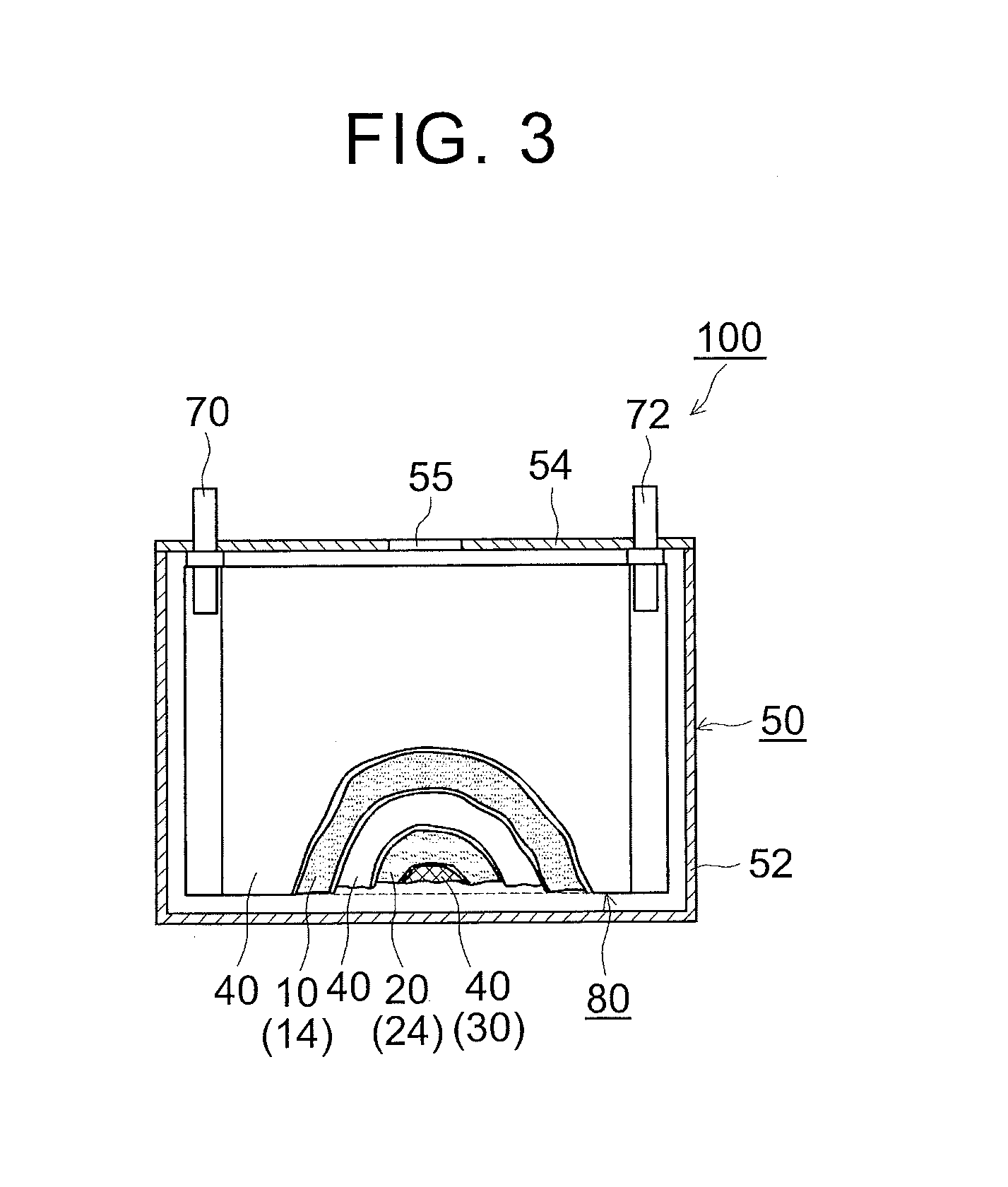

Nonaqueous electrolyte secondary battery

ActiveUS20140272534A1Excellent high rate characteristicsIncreased durabilityFinal product manufactureNon-aqueous electrolyte accumulator electrodesDiameter ratioLarge particle

The nonaqueous electrolyte secondary battery of the present invention has a positive electrode, a negative electrode, a separator interposed between the positive electrode and the negative electrode, and a nonaqueous electrolyte solution. The battery further has a porous heat-resistant layer provided between the separator and at least one of the positive electrode and the negative electrode, wherein the porous heat-resistant layer includes an inorganic filler and a binder. The inorganic filler included in the porous heat-resistant layer has a particle size distribution with two peaks, which are a first peak (P1) at a relatively small particle diameter and a second peak (P2) at a relatively large particle diameter. When the particle diameter of the first peak (P1) is D1 be and the particle diameter of the second peak (P2) is D2 being, the peak particle diameter ratio D1 / D2 satisfies the condition 0.2≦D1 / D2≦0.7.

Owner:TOYOTA JIDOSHA KK

Porous film

ActiveUS8323837B2Improve featuresImprove heat resistanceHybrid capacitor separatorsFinal product manufactureChemistryHeat resistant

Provided is a porous film comprising a heat-resistant resin and two or more fillers, wherein a value of D2 / D1 is 0.15 or less where among values each obtained by measuring the average particle diameter of particles that constitute one of the two or more fillers, the largest value is let be D1 and the second largest value is let be D2.

Owner:SUMITOMO CHEM CO LTD

Microporous polymer separators for lithium ion batteries and method for producing the same

ActiveUS20100178545A1Increase surface areaHigh porositySolid electrolytesIon-exchanger regenerationHydrophilic monomerPolymer science

Provided are separators used in power accumulators such as lithium ion secondary batteries and a preparation method thereof. The said separators are obtained through following steps: providing a polymer colloidal emulsion through a polymerization reaction of polyvinyl alcohol, hydrophobic monomer and hydrophilic monomer in water solution initiated by an initiator; coating a plastic substrate with the said polymer colloidal emulsion using tape-casting method; drying the plastic substrate coated with the polymer colloidal emulsion, and then obtaining the said separators by delaminating them from the substrate. The said separators have good liquid absorbability, high liquid absorption rate and retention, low resistivity, good mechanical strength and good thermal stability (little thermal shrinkage and little size distortion) as well as electrochemical stability. The prepared lithium ion batteries have good cycle stability and long service life.

Owner:SICHUAN INDIGO TECH CO LTD

Compounds having activity in increasing ion transport by mutant-CFTR and uses thereof

ActiveUS7939558B2Good cell permeabilityImprove ion permeabilityBiocideOrganic chemistryCystic fibrosisChemistry

The invention provides compositions, pharmaceutical preparations and methods for increasing activity (e.g., ion transport) of the mutant cystic fibrosis transmembrane conductance regulator protein (mutant-CFTR), e.g., ΔF508 CFTR, G551D-CFTR, G1349D-CFTR, or D1152H-CFTR, that are useful for the treatment of cystic fibrosis (CF). The compositions and pharmaceutical preparations of the invention may comprise one or more phenylglycine-containing compounds or sulfonamide-containing compounds of the invention, or an analog or derivative thereof.

Owner:RGT UNIV OF CALIFORNIA

Anti-fouling paint composition for ship and its preparing process

InactiveCN1386799AGrowth inhibitionEfficient killingAntifouling/underwater paintsPaints with biocidesSolventChemistry

An anti-fouling paint composition for ship is prepared from high-molecular polymer (28-36 pts.wt.), composite toxic material (25-36.6 pts.wt.), colour filler (22-32 pts.wt.), toughening agent (3.5-5 pts.wt.), sagging inhibitor (2-3 pts.wt.) and mixed solvent (30-38 pts.wt.) through mixing, stirring and dissolving. Its advantage is long service life.

Owner:周贻皓

Battery separator, and battery separator manufacturing method

ActiveUS20140349169A1Excellent adhesionExcellent heat resistanceSynthetic resin layered productsLi-accumulatorsPorous membranePolypropylene

A battery separator includes a porous membrane A with a thickness of less than 10 μm including a polypropylene resin, and a porous membrane B laminated thereon including a heat resistant resin and inorganic particles or cross-linked polymer particles, wherein the porous membrane A satisfies a specific range of thickness, average pore size, and porosity, and the entire battery separator satisfies a specific range of thickness, peeling strength at the interface between the porous membrane A and the porous membrane B, and difference in air resistance between the entire battery separator and the porous membrane A.

Owner:TORAY IND INC

Power storage device separator

InactiveUS20110206972A1Excellent durabilityLong useNon-fibrous pulp additionNatural cellulose pulp/paperPower storageIon permeability

Provided is a power storage device separator that is realized in the form of a heat-resistant, solvent-resistant, and dimensionally stable thin film. Also provided is a power storage device separator that can be realized in the form of a thin film which has excellent ion permeability and low resistance, which makes short-circuiting between electrodes and self-discharging difficult to occur, and in addition, which has excellent durability even after long periods of use under high temperature environments in the presence of organic solvents and ionic solutions.

Owner:TOMOEGAWA CO LTD

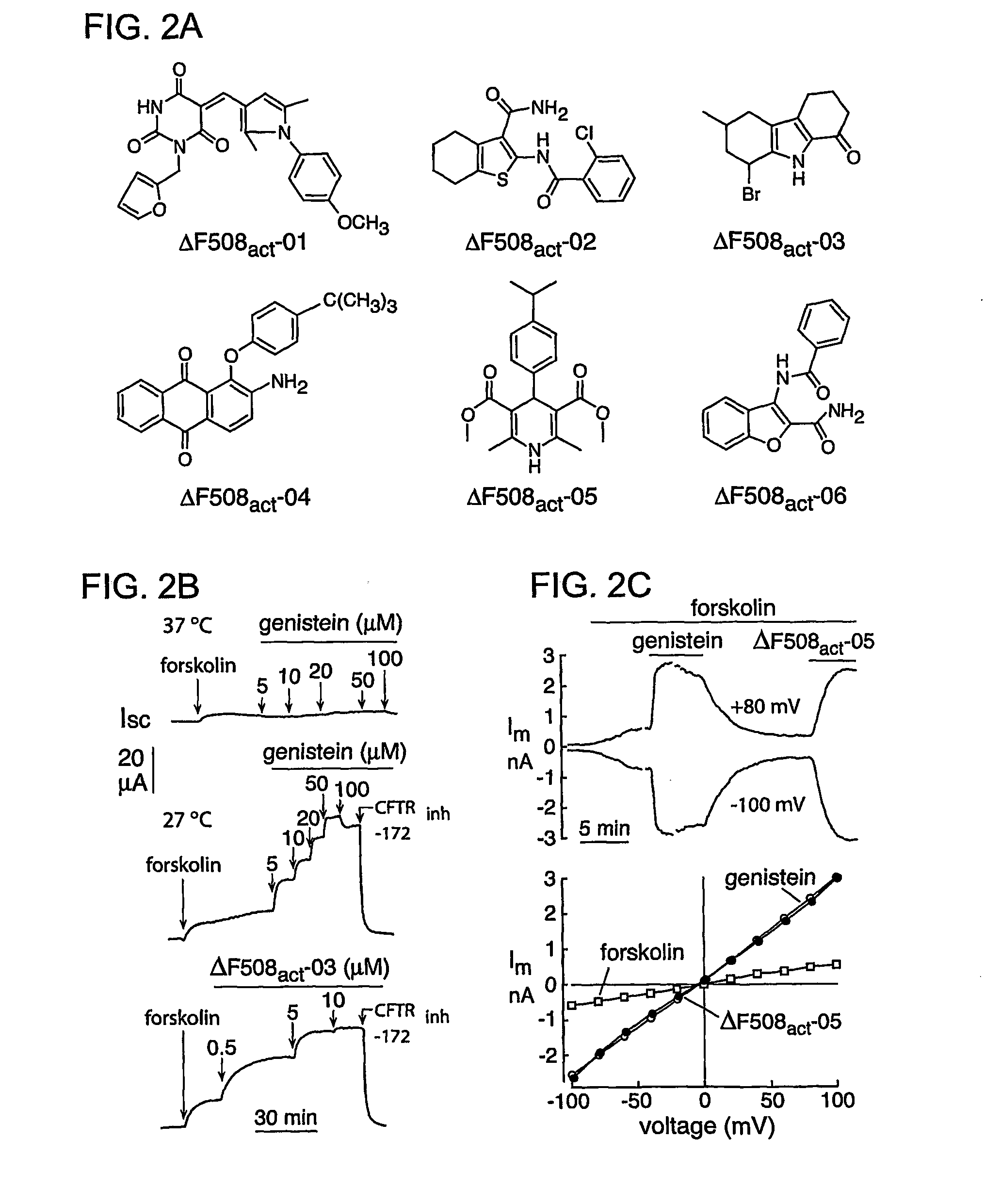

Compounds Having Activity in Increasing Ion Transport by Mutant-Cftr and Uses Thereof

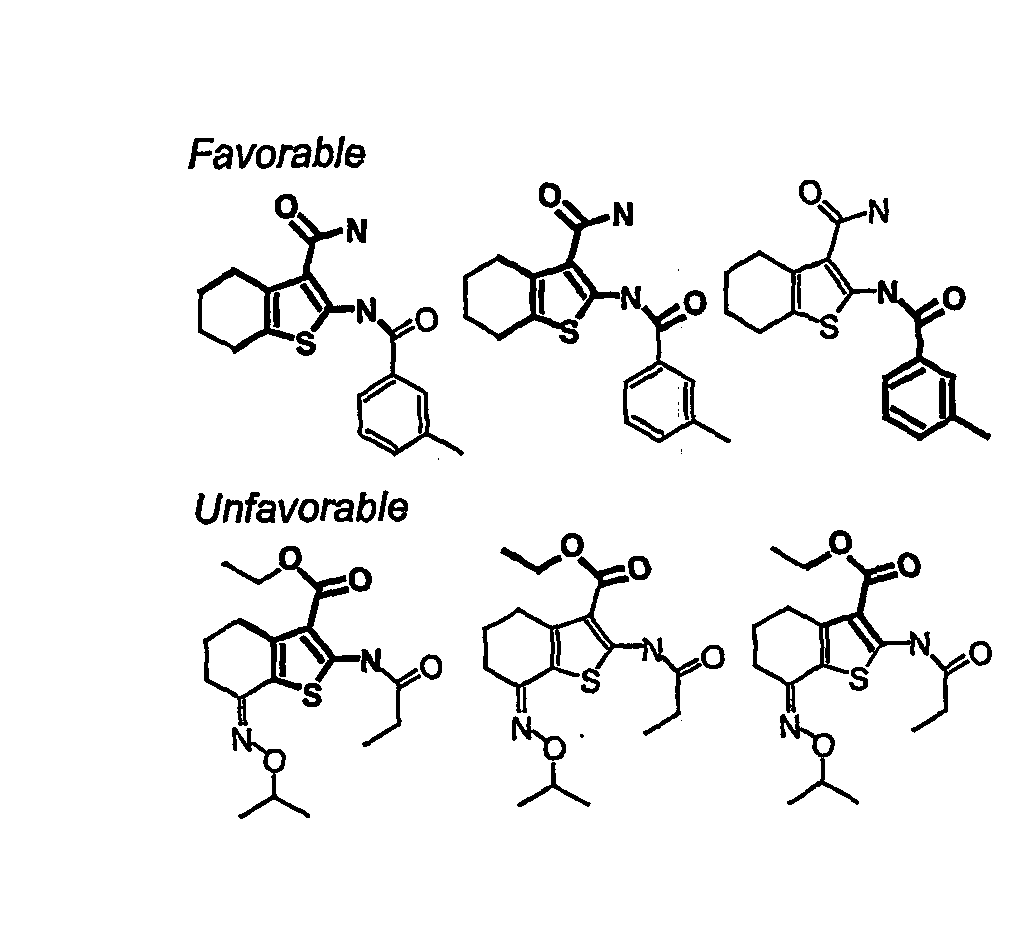

ActiveUS20070265316A1High activityEasy to transportBiocideOrganic chemistryDihydropyridineSubject matter

The invention provides compositions, pharmaceutical preparations and methods for activation of the ΔF508 cystic fibrosis transmembrane conductance regulator protein (ΔF508 CFTR) that are useful for the treatment and study of cystic fibrosis (CF). The compositions and pharmaceutical preparations of the invention may comprise one or more tetrahydrobenzothiophene, benzofuran, pyramidinetrione, dihydropyridine, tetraahydrocarbazol or anthraquinone compounds (referred to as “activator compounds”). The invention provides methods increasing ion transport in a ΔF508 CFTR in a cell by contacting the cell with an effective amount of an activator compound. In other embodiments, the invention also provides a method of treating a patient suffering from a ΔF508 CFTR-mediated disease or condition, for example CF, by administering to the patient an efficacious amount of an activator compound. Kits for use in the subject methods are also provided.

Owner:RGT UNIV OF CALIFORNIA

Battery separator, and battery separator manufacturing method

ActiveUS20150228949A1Excellent adhesionExcellent heat resistanceCell seperators/membranes/diaphragms/spacersFinal product manufacturePorous membraneElectrical battery

A battery separator includes a porous membrane A including a polyethylene resin, and a porous membrane B laminated thereon including a heat resistant resin and inorganic particles or cross-linked polymer particles, wherein the porous membrane A satisfies expressions (a) to (c), and the entire battery separator satisfies expressions (d) to (f).

Owner:TORAY IND INC

Lithium secondary battery with improved cell characteristics

ActiveUS8026008B2Large capacityImprove stabilityOrganic electrolyte cellsSecondary cellsLithiumSolvent

Disclosed herein is a lithium secondary cell including 20 to 100 wt. % of lithium transition metal oxide represented by a formula of Li1+zNibMncMe1−(b+c)O2, relative to a total amount of a cathode active material, as well as an electrolyte consisting of a lithium salt and a non-aqueous solvent, wherein a first additive to form a protective film (that is, a solid electrolyte interface film: SEI film) over a surface of an anode active material and a second additive to form another SEI film over the surface of the anode active material while inactivating impurities contained in the cathode active material are included in the electrolyte.

Owner:LG ENERGY SOLUTION LTD

Non-aqueous secondary battery separator and non-aqueous secondary battery

ActiveUS20140308567A1Excellent adhesion to electrodesImprove ion permeabilityFilm/foil adhesivesJackets/cases materialsPorous substrateHexafluoropropylene

The present invention provides a separator for a non-aqueous secondary battery including a porous substrate and an adhesive porous layer that is formed at at least one side of the porous substrate and contains the following polyvinylidene fluoride-based resin A and the following polyvinylidene fluoride-based resin B. (1) Polyvinylidene fluoride resin A selected from the group consisting of vinylidene fluoride homopolymers having a weight average molecular weight of from 600,000 to 2,500,000, and vinylidene fluoride copolymers having a weight average molecular weight of from 600,000 to 2,500,000 and containing a structural unit derived from vinylidene fluoride and a structural unit derived from hexafluoropropylene, the total content of structural units derived from hexafluoropropylene in each of the vinylidene fluoride copolymers being 1.5 mol % or less of the total content of structural units in each of the vinylidene fluoride copolymer. (2) Polyvinylidene fluoride resin B containing a structural unit derived from vinylidene fluoride and a structural unit derived from hexafluoropropylene, the total content of structural units derived from hexafluoropropylene in the polyvinylidene fluoride resin B being greater than 1.5 mol % of the total content of structural units in the polyvinylidene fluoride resin B.

Owner:TEIJIN LTD

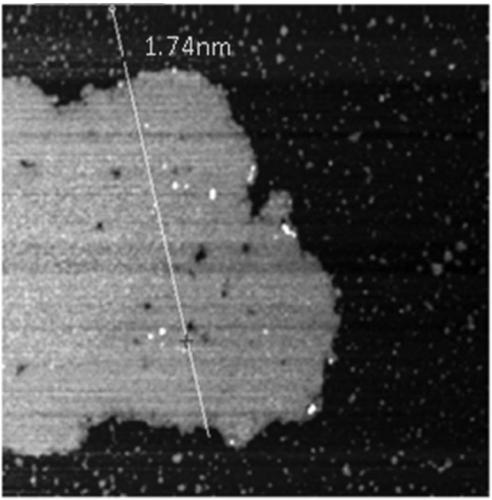

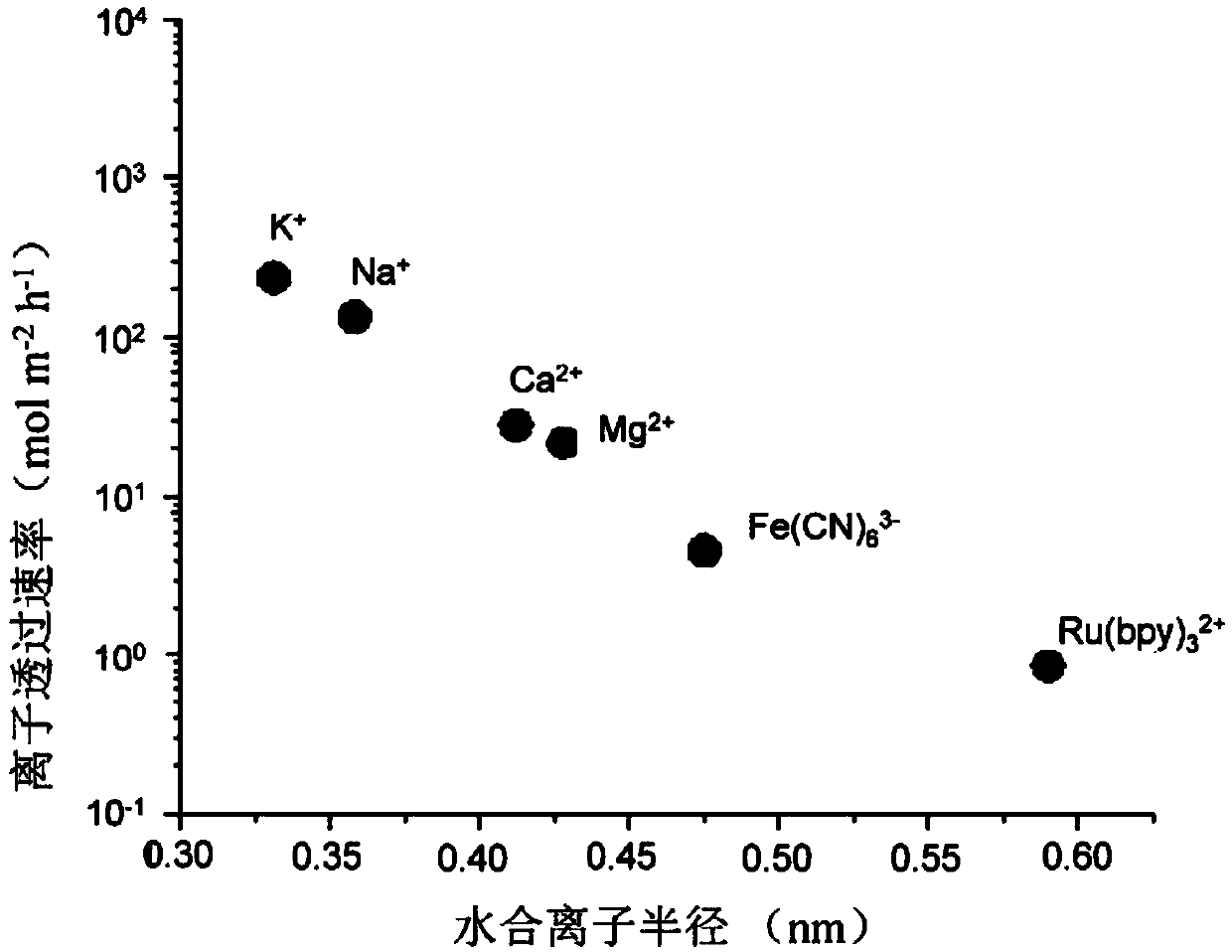

COF film, preparation method, transfer method and application thereof, and chip containing same

ActiveCN111087615AHigh hole densitySignificant separabilitySemi-permeable membranesAnalysis by thermal excitationGraphiteSingle layer graphene

The invention provides a COF film, a preparation method, a transfer method and application thereof, and a chip containing the same. According to the preparation method, the COF film is prepared through polymerization reaction between hexaamino triptycene and pyrene tetraketone; the pi-pi accumulation effect between two-dimensional COF film layers is weakened; the porous COF film with single-layerthickness and extremely high pore density is obtained; and holes do not need to be formed in a plasma bombardment mode like a traditional single-layer graphene film. The COF film has remarkable separation and detection capacity for ions with different hydrated ion radiuses and also has higher ion permeability, and due to the characteristics, the COF film can be used for preparing an ion detectionchip so as to realize ultrafast ion separation and detection.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

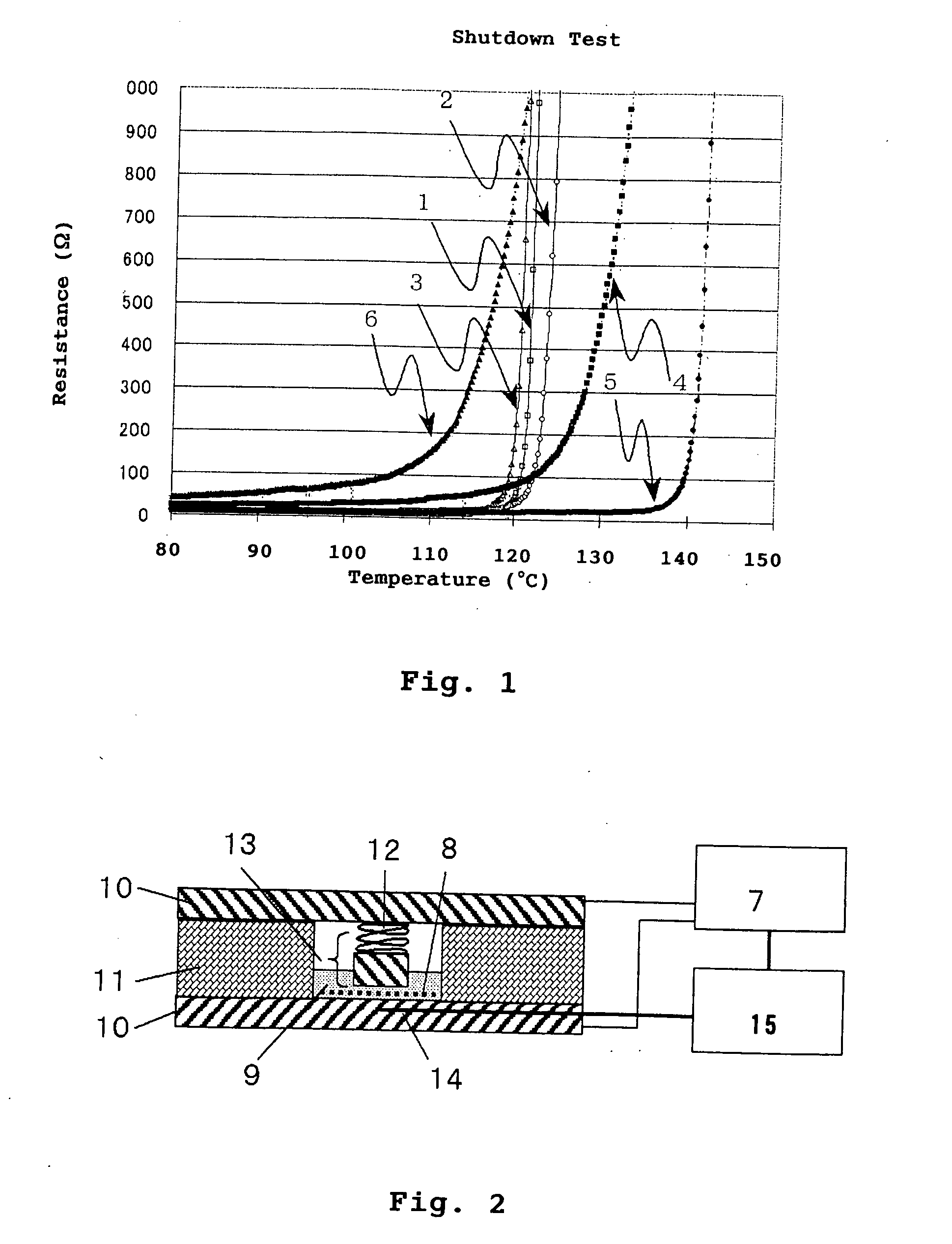

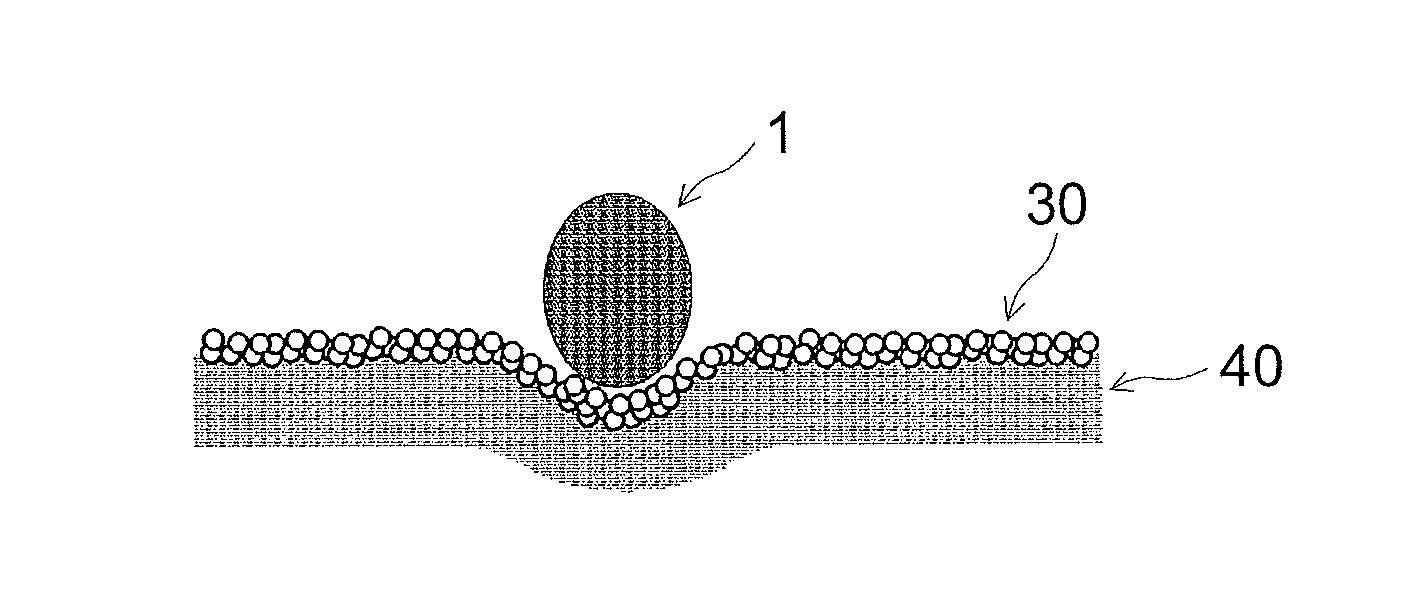

Reactive polymer-carrying porous film and processing for producing the same

InactiveUS20090202898A1Improve ion permeabilitySmall heat shrinkage ratioSolid electrolytesCell seperators/membranes/diaphragms/spacersHigh rateInternal resistance

It is intended to provide a reactive polymer-supported porous film that is capable of achieving sufficient adhesion between the electrode and the separator; reduced in internal resistance; and excellent in high rate characteristics, the porous film being useful as a battery separator which, after production of the battery, is not melted or broken under a high temperature and functions as a separator having a small heat shrinkage ratio as well as to provide a process for producing batteries using the reactive polymer-supported porous film.According to this invention, there is provided a reactive polymer-supported porous film for a battery separator, characterized in that the reactive polymer-supported porous film has: a substrate porous film of a porous film, the porous film has a temperature, at which a thickness of the porous film is reduced to ½ of a thickness when a prove is placed on the porous film in the case that the thickness of the porous film is measured by placing the probe having a diameter of 1 mm on the porous film under a load of 70 g and heating the porous film from a room temperature at a temperature-increase rate of 2° C. / minute, of 200° C. or more; and a reactive polymer supported on the substrate porous film, the reactive polymer is obtainable by reacting: a crosslinkable polymer obtainable by copolymerizing: a crosslinkable monomer having in a molecule at least one reactive group selected from a 3-oxetanyl group and an epoxy group; and a crosslinkable monomer having a reactive group capable of reacting with an isocyanate group; and a polyfunctional isocyanate to be partially crosslinked.

Owner:NITTO DENKO CORP

Separator for a non-aqueous secondary battery and non-aqueous secondary battery

ActiveUS20140242444A1Increased porous structureImprove ion permeabilityLi-accumulatorsCell component detailsPorous substrateHexafluoropropylene

A separator for a non-aqueous secondary battery including a porous substrate, and an adhesive porous layer that is formed on one side or both sides of the porous substrate and contains the following polyvinylidene fluoride resin A and the following polyvinylidene fluoride resin B:Polyvinylidene fluoride resin A: a polyvinylidene fluoride resin containing structural units derived from vinylidene fluoride and structural units derived from hexafluoropropylene, a total content ratio of structural units derived from hexafluoropropylene in each of the vinylidene fluoride copolymers being from 0.5 mol % to 1.5 mol % of a total content of structural units in each of the vinylidene fluoride copolymers; andPolyvinylidene fluoride resin B: a polyvinylidene fluoride resin containing structural units derived from vinylidene fluoride and structural units derived from hexafluoropropylene, a total content ratio of structural units derived from hexafluoropropylene in each of the vinylidene fluoride copolymers being greater than 1.5 mol % of a total content of structural units in each of the vinylidene fluoride copolymers.

Owner:TEIJIN LTD

Heat-resistant synthetic resin microporous film, separator for non-aqueous liquid electrolyte secondary battery, non-aqueous liquid electrolyte secondary battery, and method for producing heat-resistant synthetic resin microporous film

InactiveUS20170012265A1Improve stabilityUniformly formedFinal product manufactureSynthetic resin layered productsHeat resistanceSynthetic resin

Provided are a heat-resistant synthetic resin microporous film having enhanced heat resistance while having reduced deterioration of mechanical strength, and a method for producing the same. Disclosed is a heat-resistant synthetic resin microporous film which includes a synthetic resin microporous film containing a synthetic resin; and a coating layer formed on at least a portion of the surface of the synthetic resin microporous film and containing a polymer of a polymerizable compound having a bifunctional or higher-functional radical polymerizable functional group, the heat-resistant synthetic resin microporous film having a surface aperture ratio of 30% to 55%, gas permeability of 50 sec / 100 mL to 600 sec / 100 mL, a maximum thermal shrinkage obtainable when the film is heated from 25° C. to 180° C. at a rate of temperature increase of 5° C. / min, of 20% or less, and a piercing strength of 0.7 N or more.

Owner:SEKISUI CHEM CO LTD

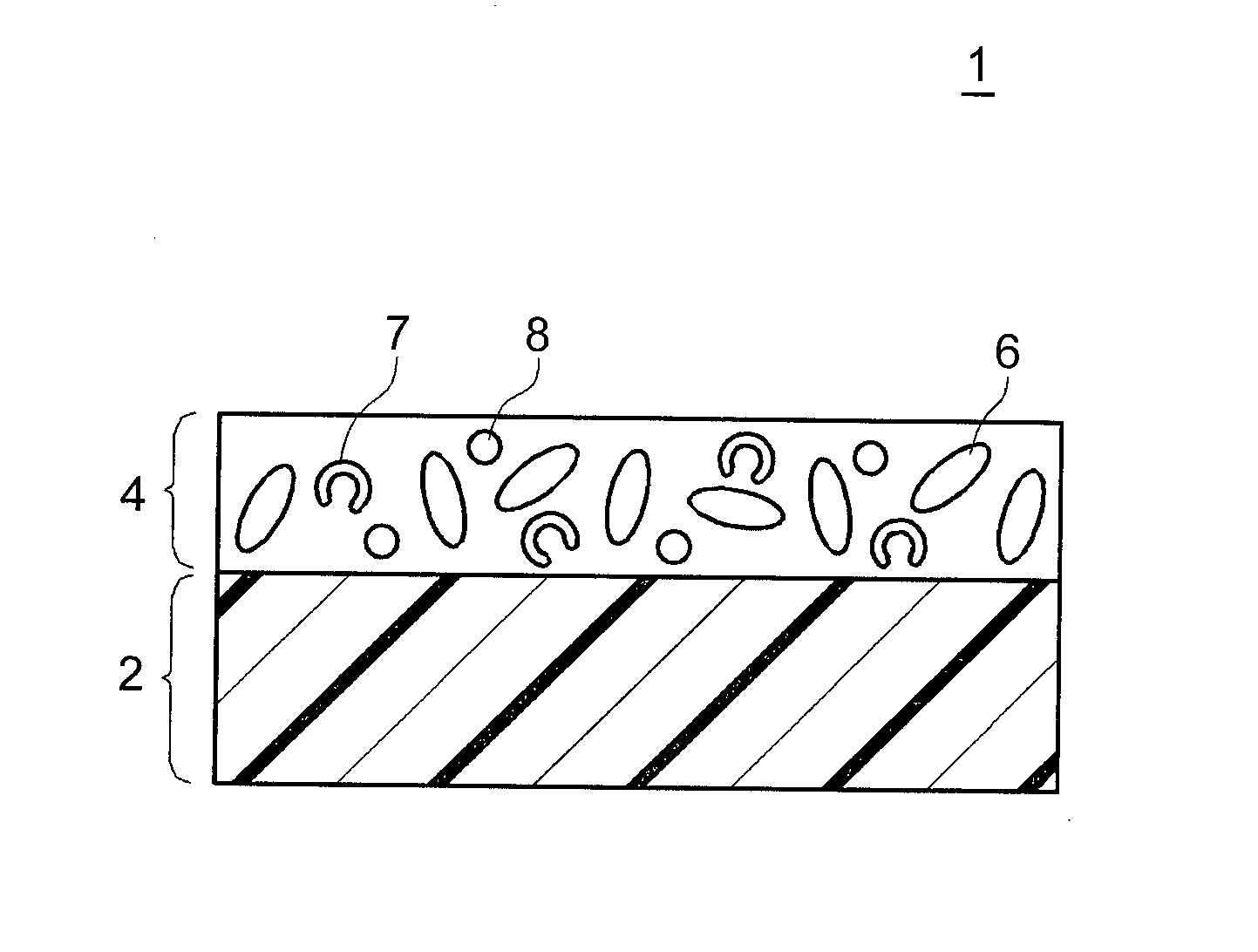

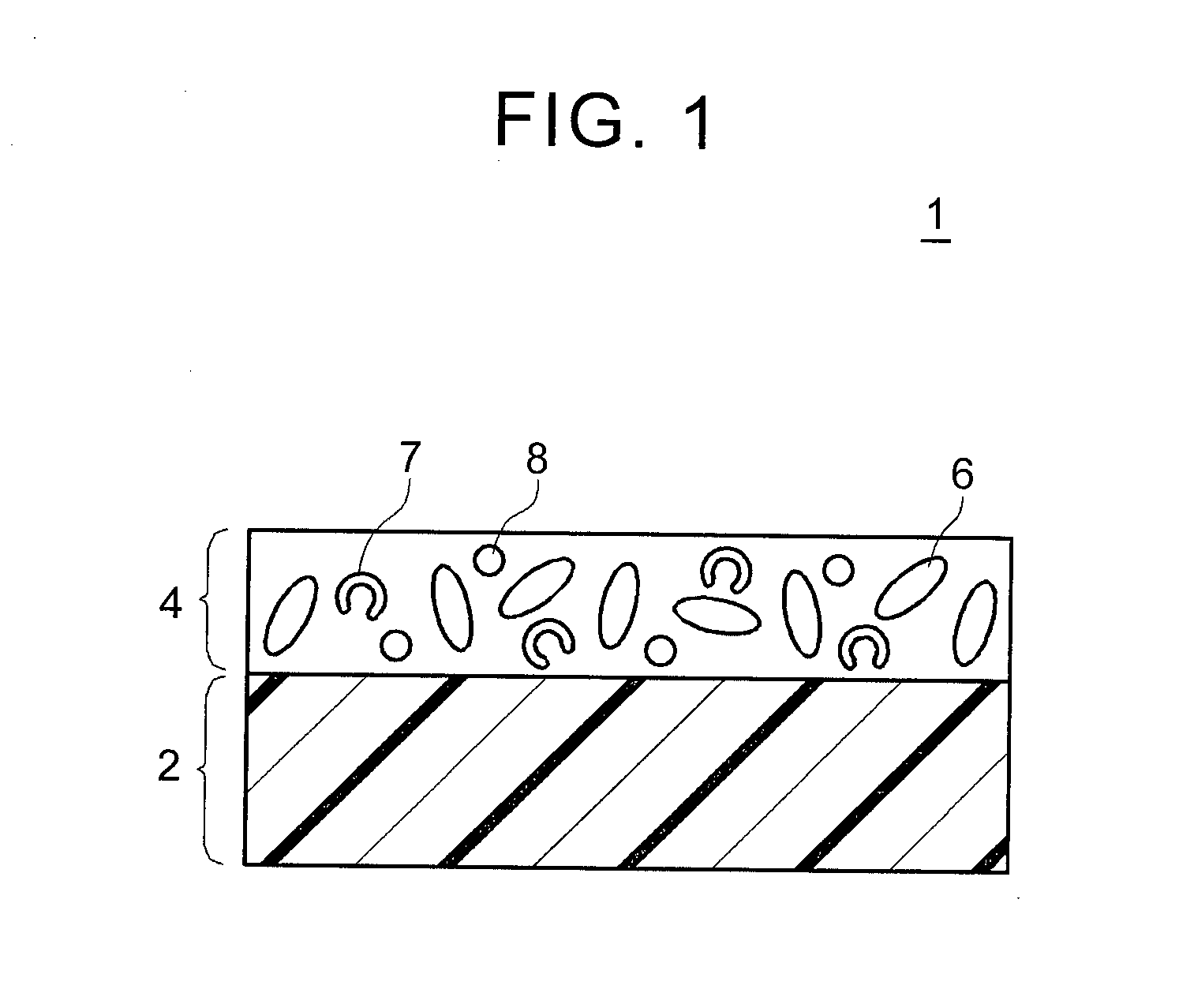

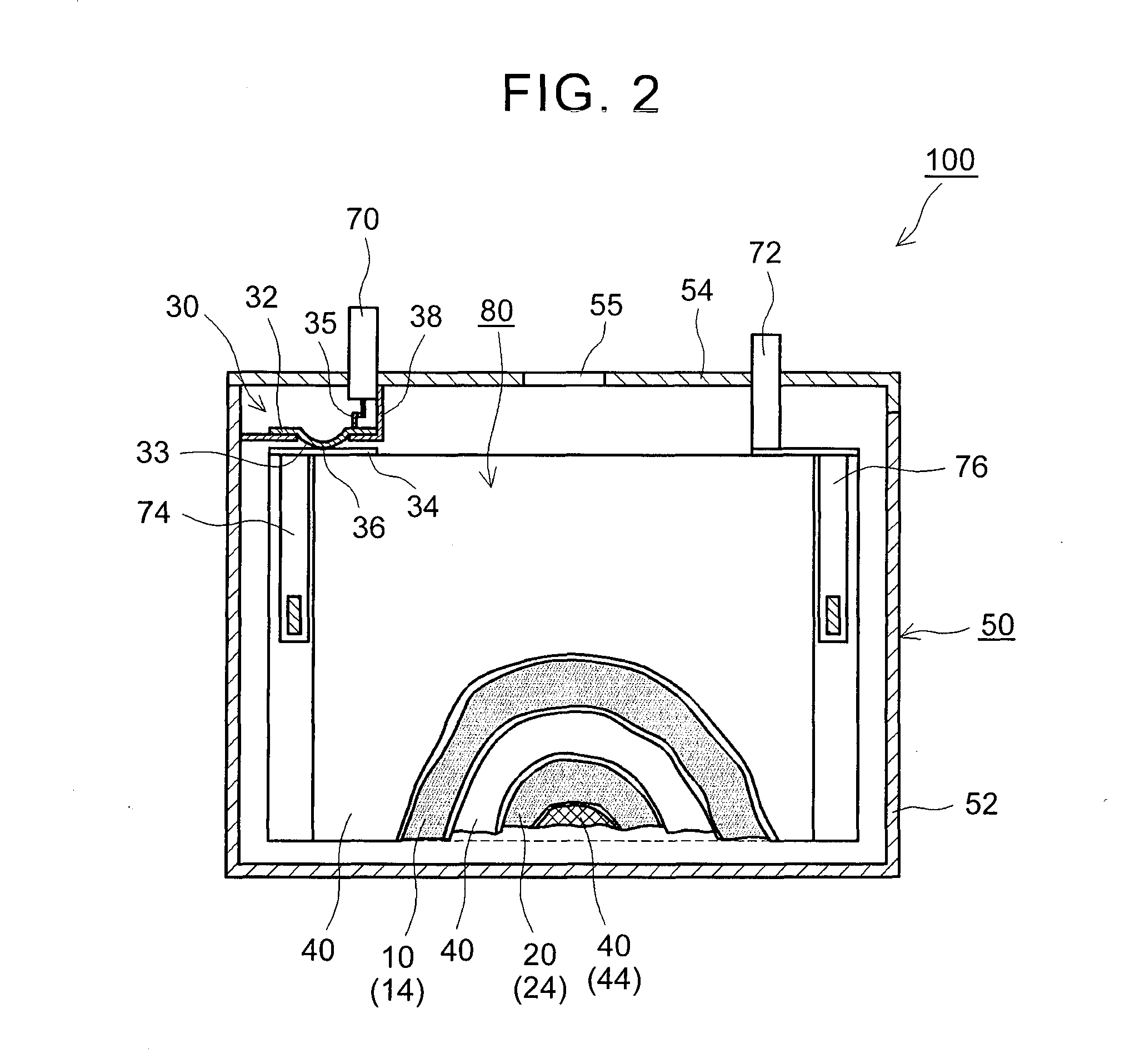

Separator for nonaqueous electrolyte secondary battery, and battery including same

ActiveUS20160380250A1Suppress generationDecreasing resistance of batteryCell seperators/membranes/diaphragms/spacersLi-accumulatorsHeat resistanceElectrolyte

A separator 1 for a nonaqueous electrolyte secondary battery, includes a resin-made substrate (2) and a porous heat resistance layer (4) disposed on the substrate. The porous heat resistance layer includes an inorganic filler (6) and hollow bodies (7). The hollow body includes a shell portion and a hollow portion. The shell portion is formed of an acryl resin. The hollow portion is formed inside the shell portion. An opening portion extending through the shell portion to spatially interconnect the hollow portion and the outside of the shell portion is formed in the shell portion.

Owner:TOYOTA JIDOSHA KK

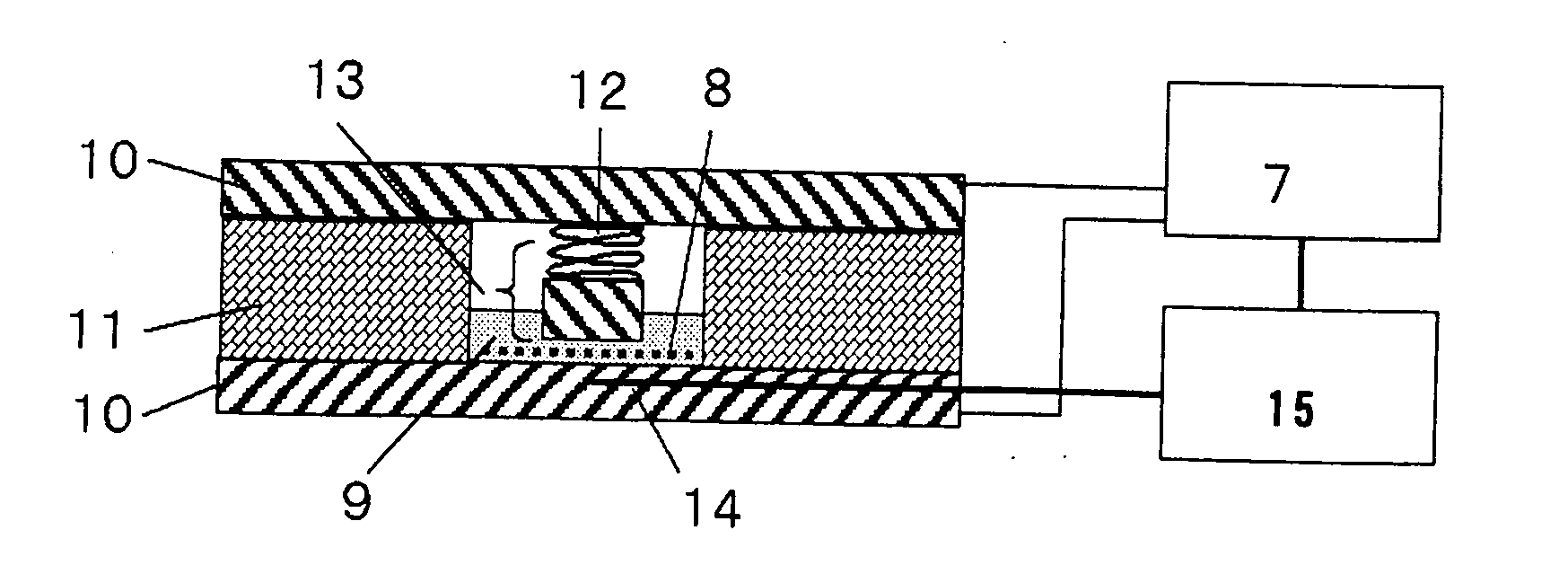

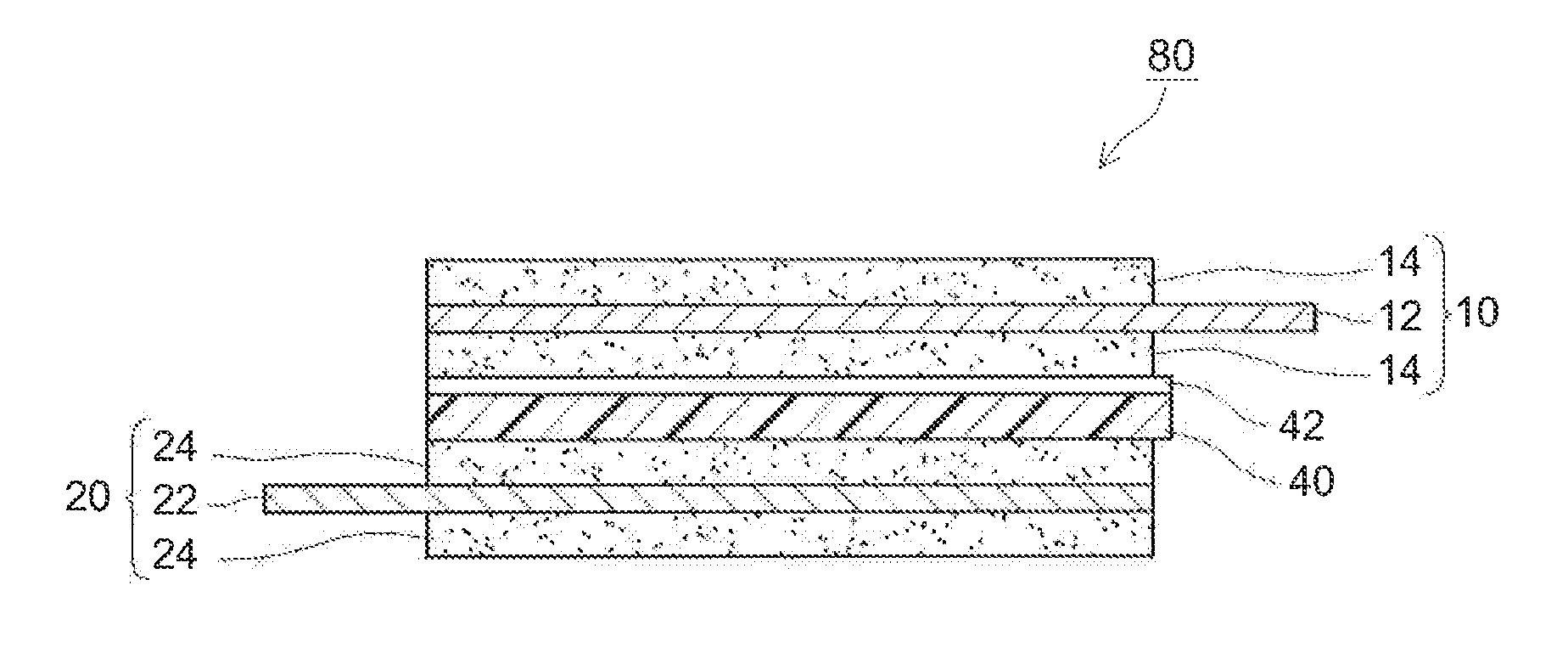

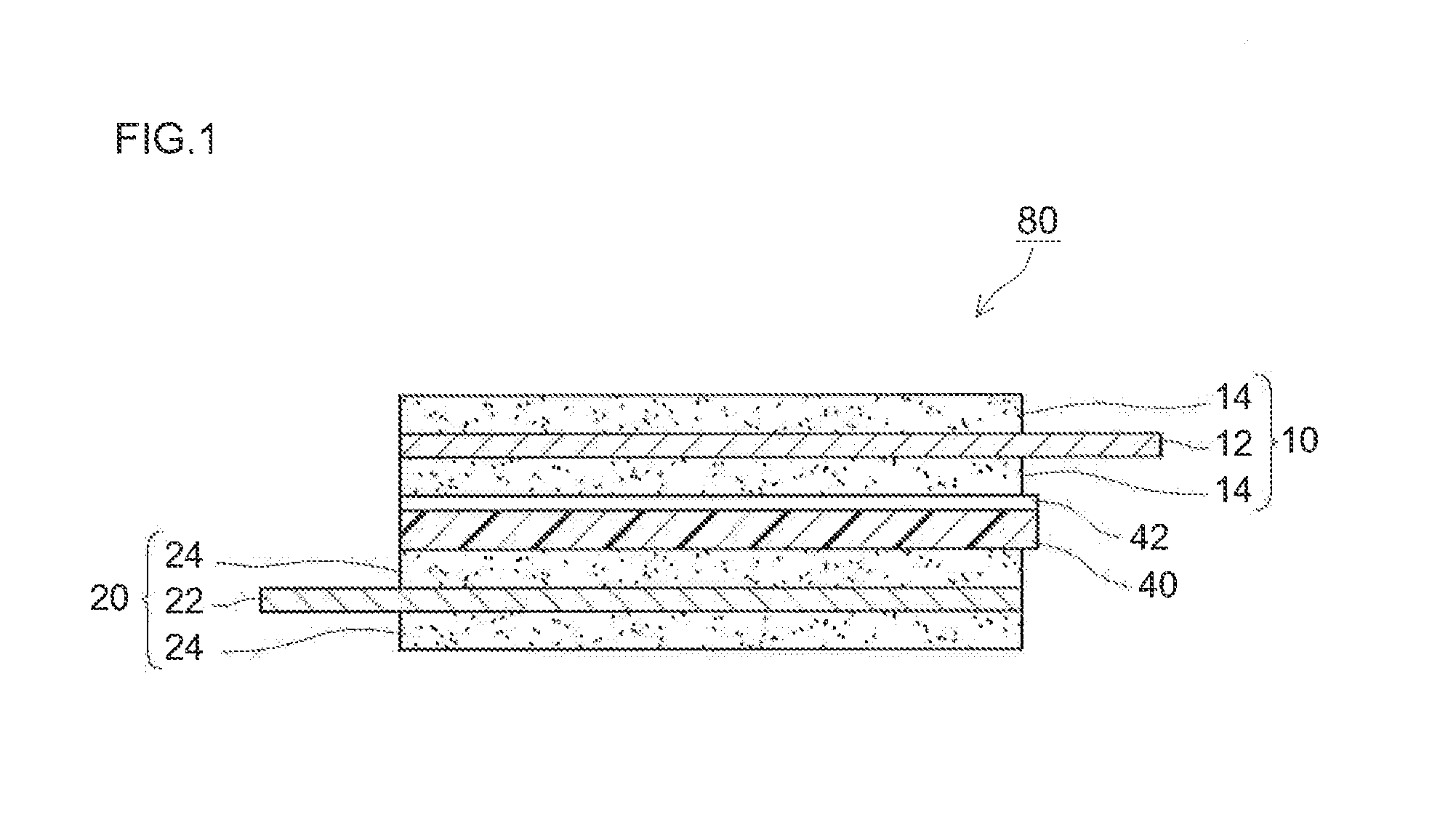

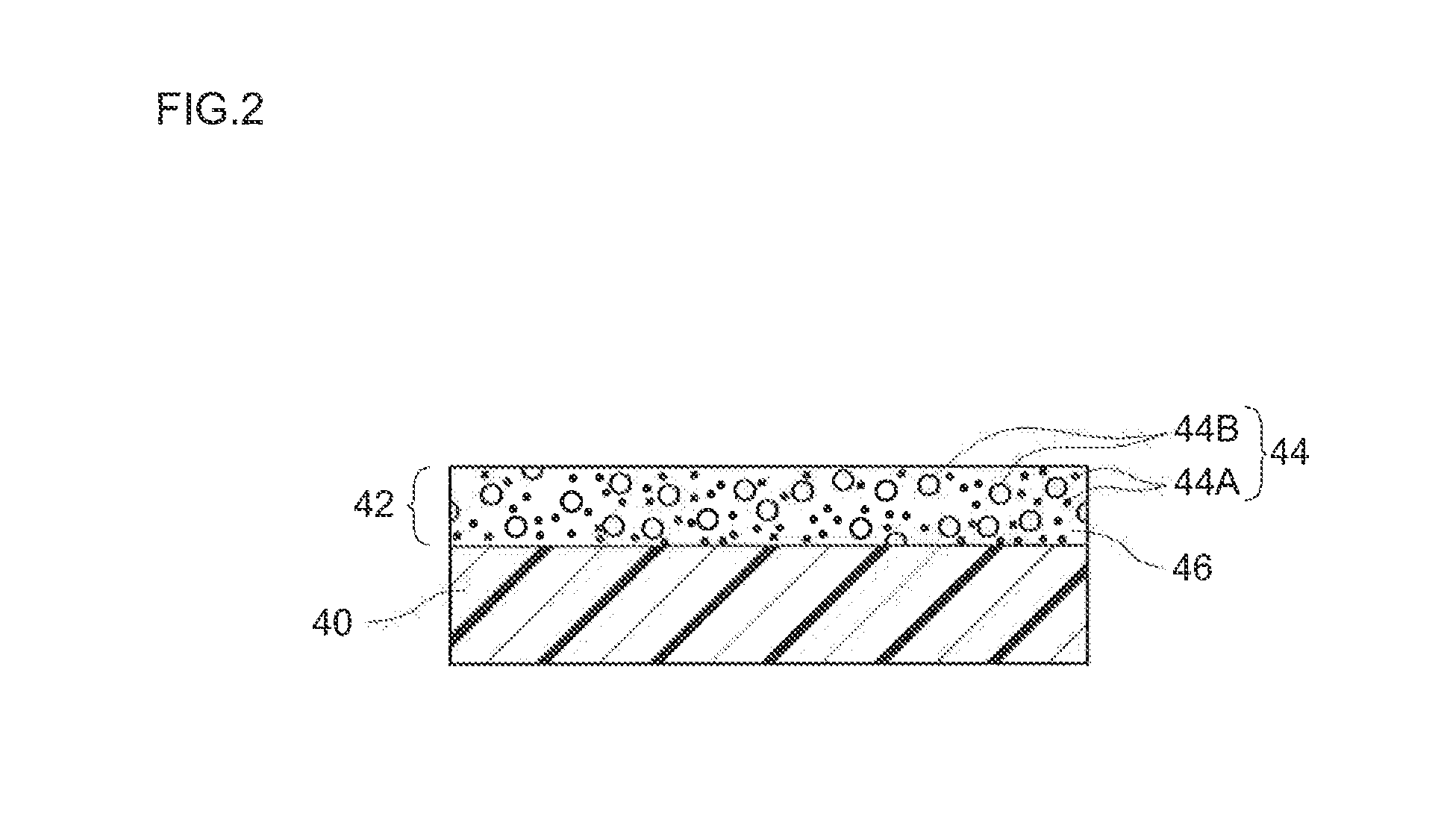

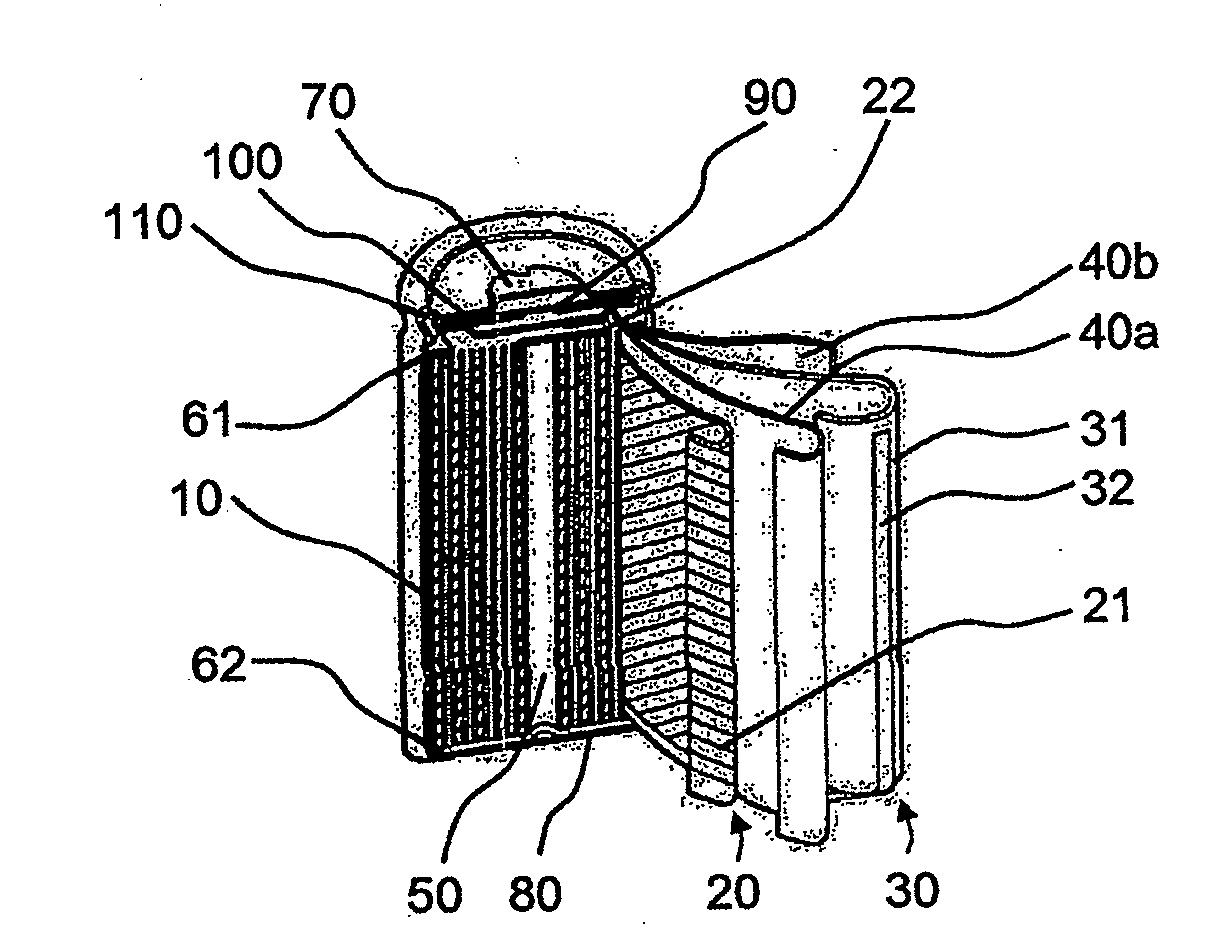

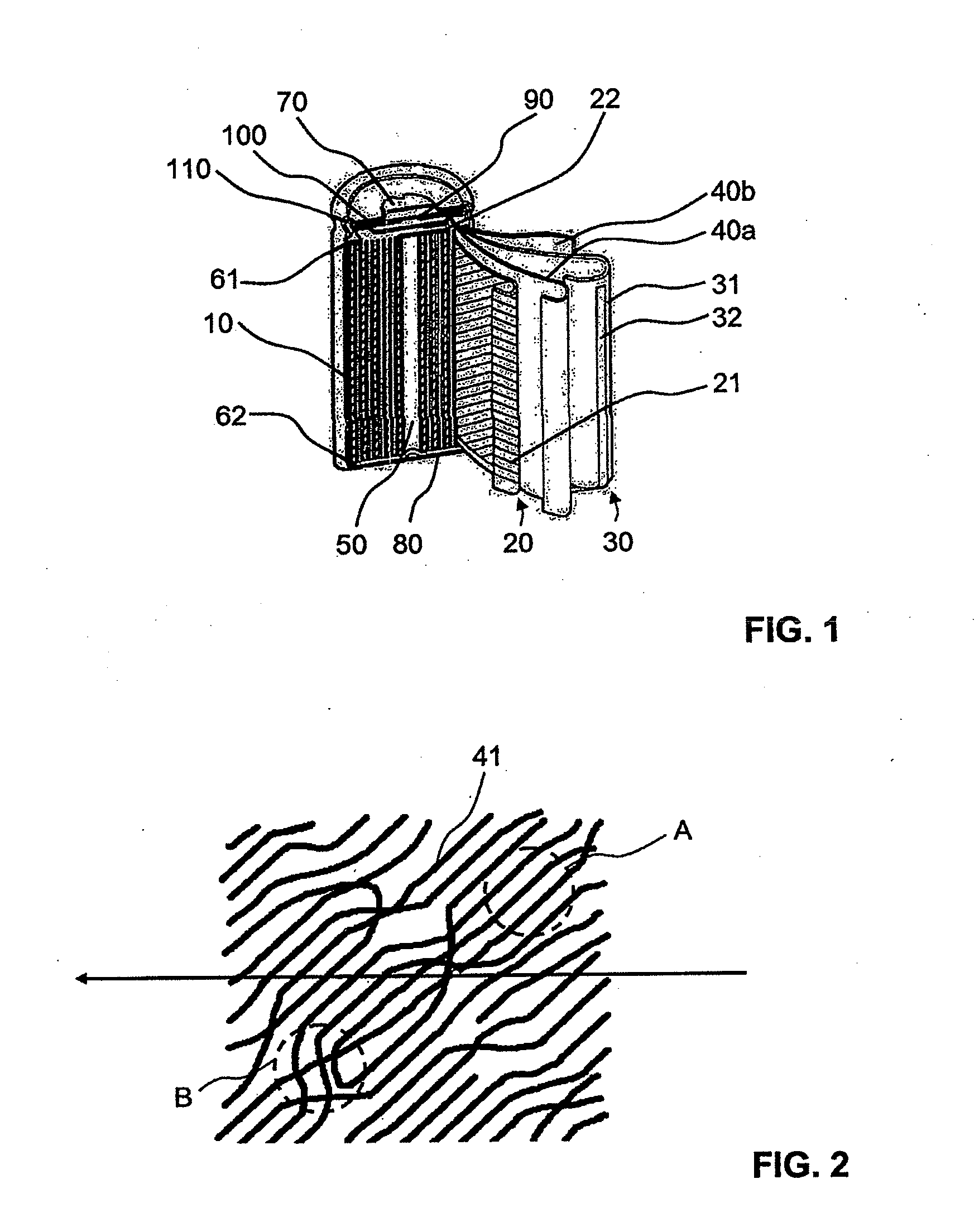

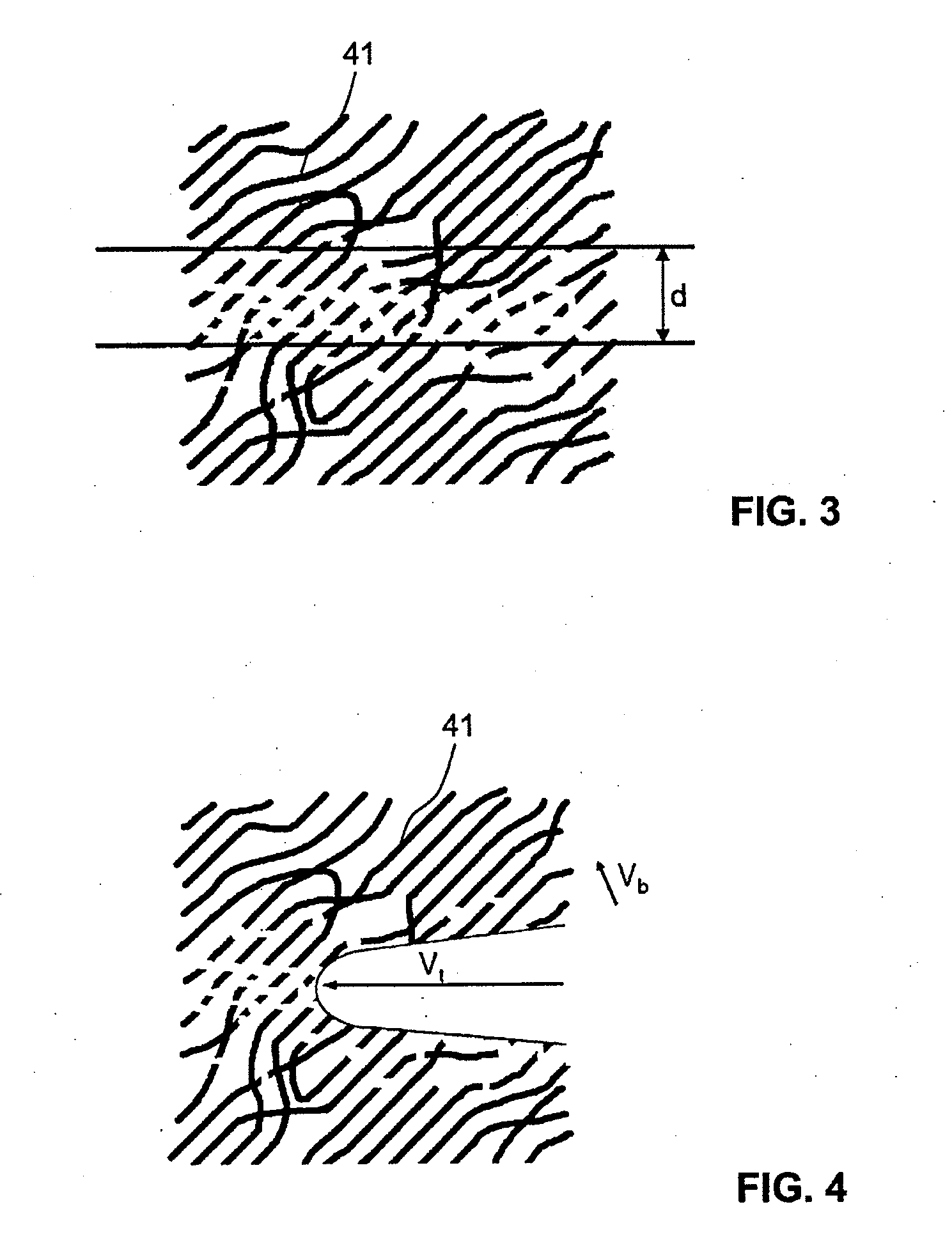

Electrochemical energy store comprising a separator

InactiveUS20120189917A1Reduce porosityImprove ion permeabilityCell seperators/membranes/diaphragms/spacersFinal product manufacturePhysicsIon

An electrochemical energy store comprising a separator (40, 40a, 40b) is described, wherein said electrochemical energy store has a positively charged electrode (20), a negatively charged electrode (30), an electrolyte, and a porous separator (40, 40a, 40b) which separates the positively charged electrode (20) and the negatively charged electrode (30) from each other. The separator (40, 4a, 40b) includes at least one microporous foil which is produced using ion irradiation, among other things. The separator (40, 40a, 40b) farther includes ion ducts (43) extending at different angles from one another.

Owner:OXYPHEN

Separator for battery

ActiveUS20170229698A1Improve ion permeabilityAdhesivenessSecondary cellsCell component detailsLithiumPolyolefin

A separator for batteries that achieves both adhesiveness to electrodes and low thermal shrinkage, which have been conventionally difficult to be compatible with each other, and has excellent ion permeability in order to further improve the safety of the separator, on the assumption that lithium ion secondary batteries are widely used for electric automobiles and the like, which require the batteries to withstand severe operating conditions. The separator for batteries is configured such that a modified porous layer containing a fluororesin and inorganic particles is laminated on at least one side of a porous membrane formed of a polyolefin resin. The content of the particles is equal to or more than 40% by volume and less than 70% volume with respect to the total of the fluororesin and the particles. The fluororesin has a crystallinity of equal to or more than 36% and less than 70%.

Owner:TORAY IND INC

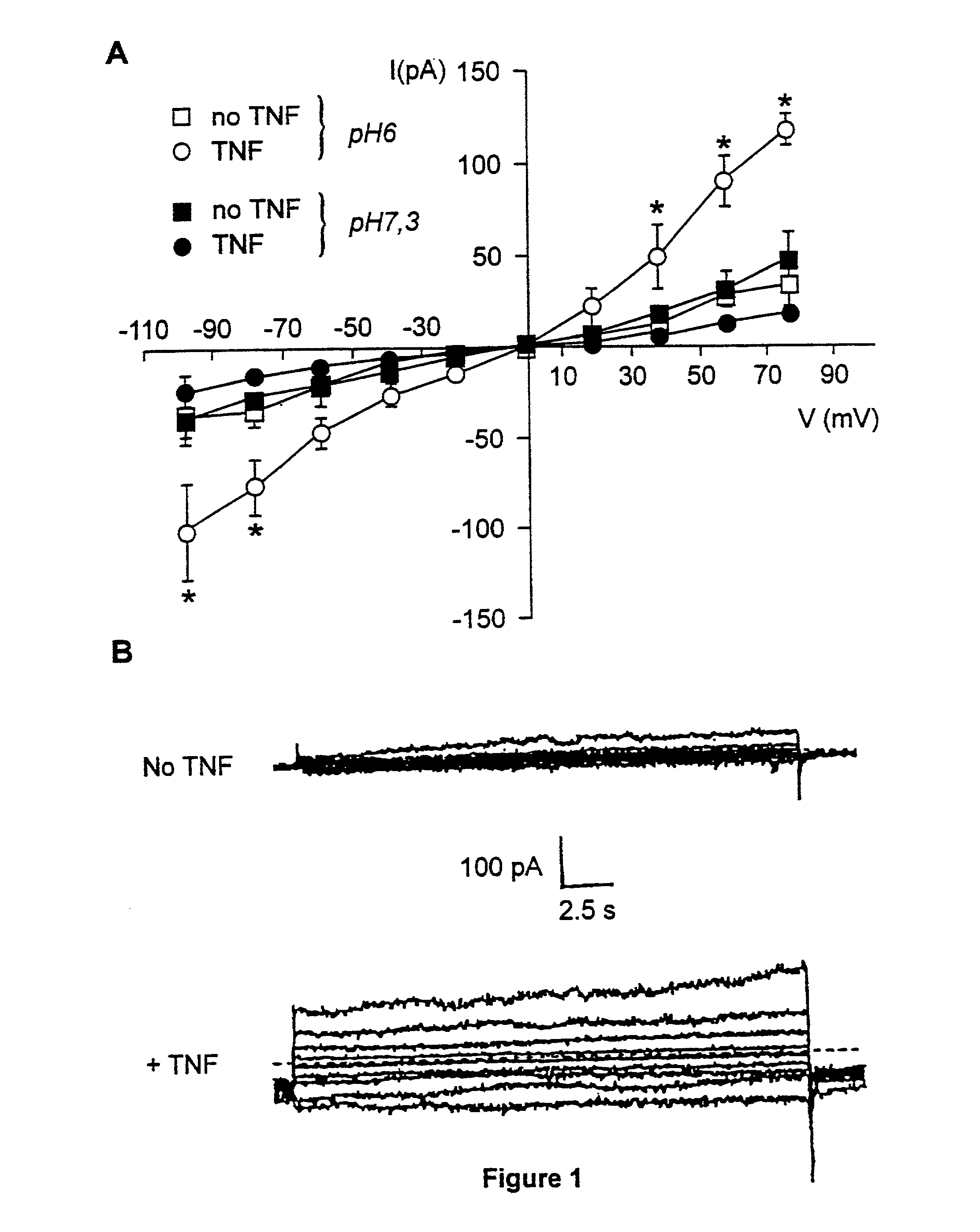

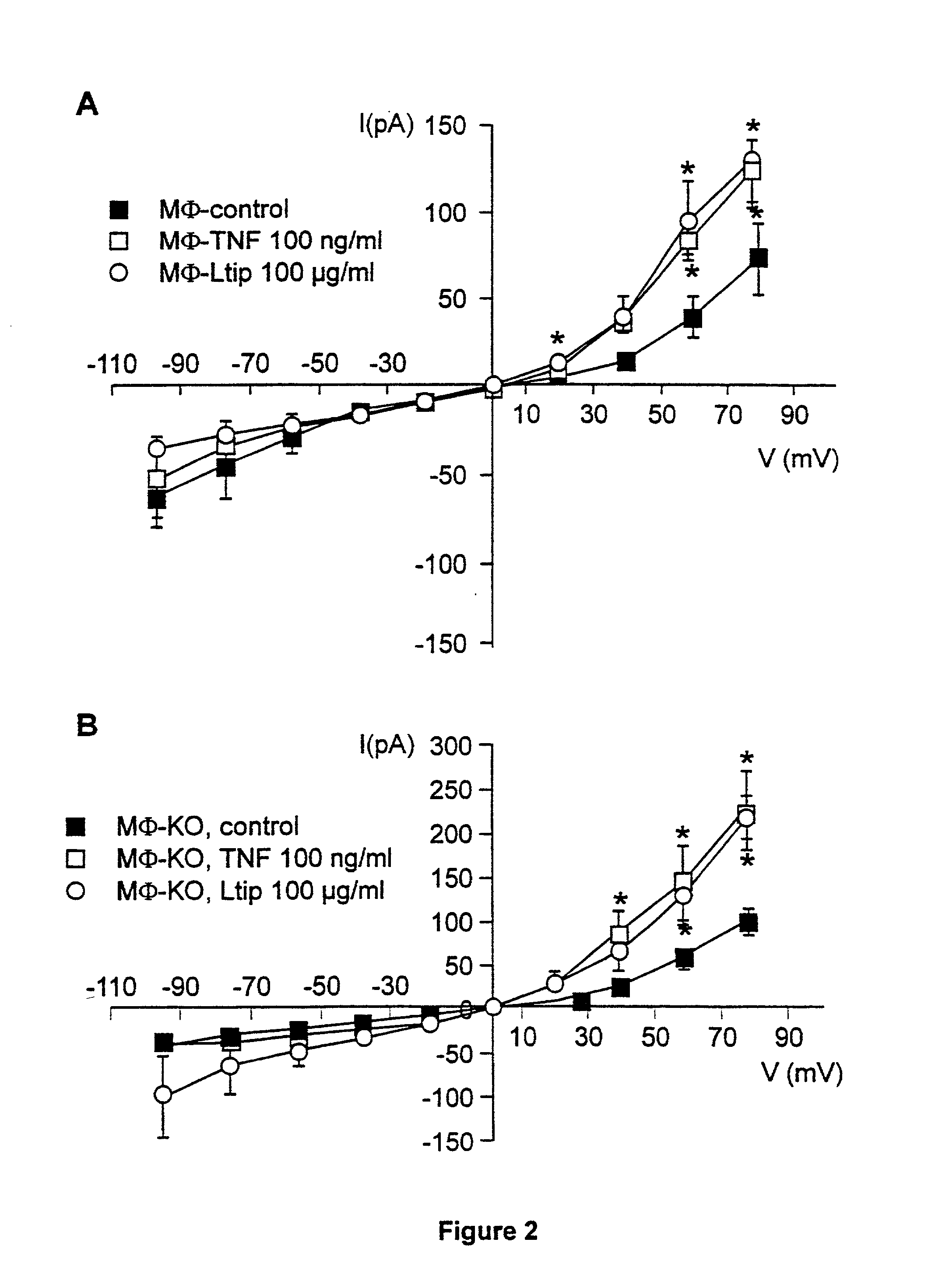

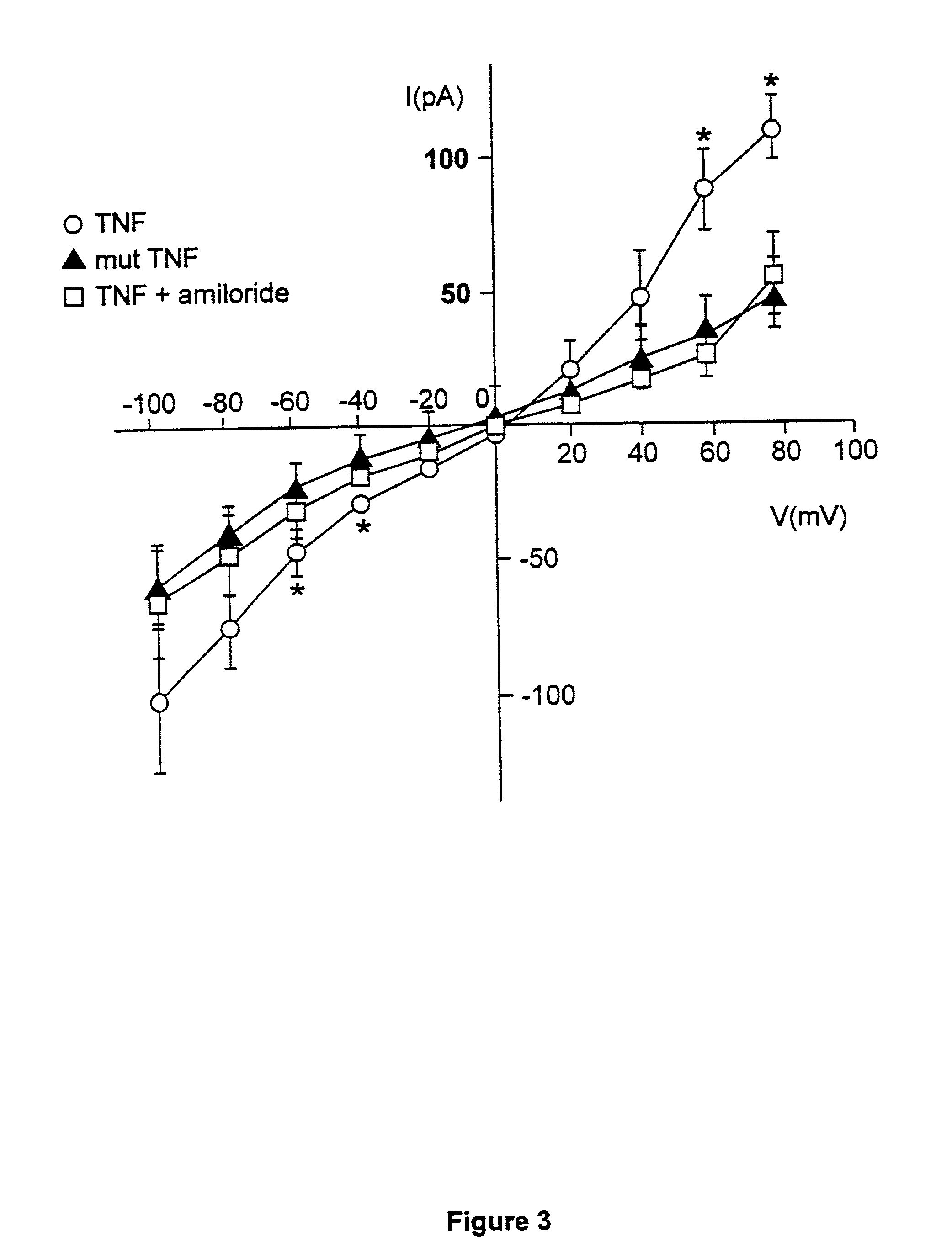

TNF-derived peptides for use in treating oedema

InactiveUS20030105021A1Improve ion permeabilitySimilar in inductionMetabolism disorderTumor necrosis factorTumor necrosis factor alphaAmino acid

The present invention relates to the finding that peptides derived from a specific domain of tumor necrosis factor-alpha (TNF-alpha) can efficiently be used to treat oedema. More specifically, the present invention relates to the usage of peptides derived from the region of human TNF-alpha from Ser100 to Glu116 to treat pulmonary oedema. Moreover, the present invention concerns a circularized peptide having amino acid sequence CGQRETPEGAEAKPWYC which is very efficient in inducing oedema resorption.

Owner:INNOGENETICS NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com