COF film, preparation method, transfer method and application thereof, and chip containing same

A transfer method and substrate sheet technology, applied in the field of COF membranes, can solve the problems of large pores during bombardment, difficulty in industrial application, and influence on film selectivity, and achieve high ion permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The COF membrane is synthesized by the following steps:

[0060] In step (1), 0.01 mmol (0.564 mg) of ammonium hexahydrochloride triptycene salt was dissolved in 100 mL of water, and a few drops of sulfuric acid was added thereto to adjust its pH value to <7 to obtain solution A;

[0061] In step (2), 0.015 mmol (0.56 mg) of di-tert-butylpyrene-4,5,9,10-tetraketone was dissolved in 100 mL of chloroform, and the solution was placed in a beaker to obtain solution B;

[0062] In step (3), solution A is slowly dripped into solution B within 30 minutes, and the polymerization reaction is carried out under undisturbed conditions. The temperature of the polymerization reaction is 50 ° C, and the time of the polymerization reaction is 15 hours. After the reaction is completed, the COF membrane.

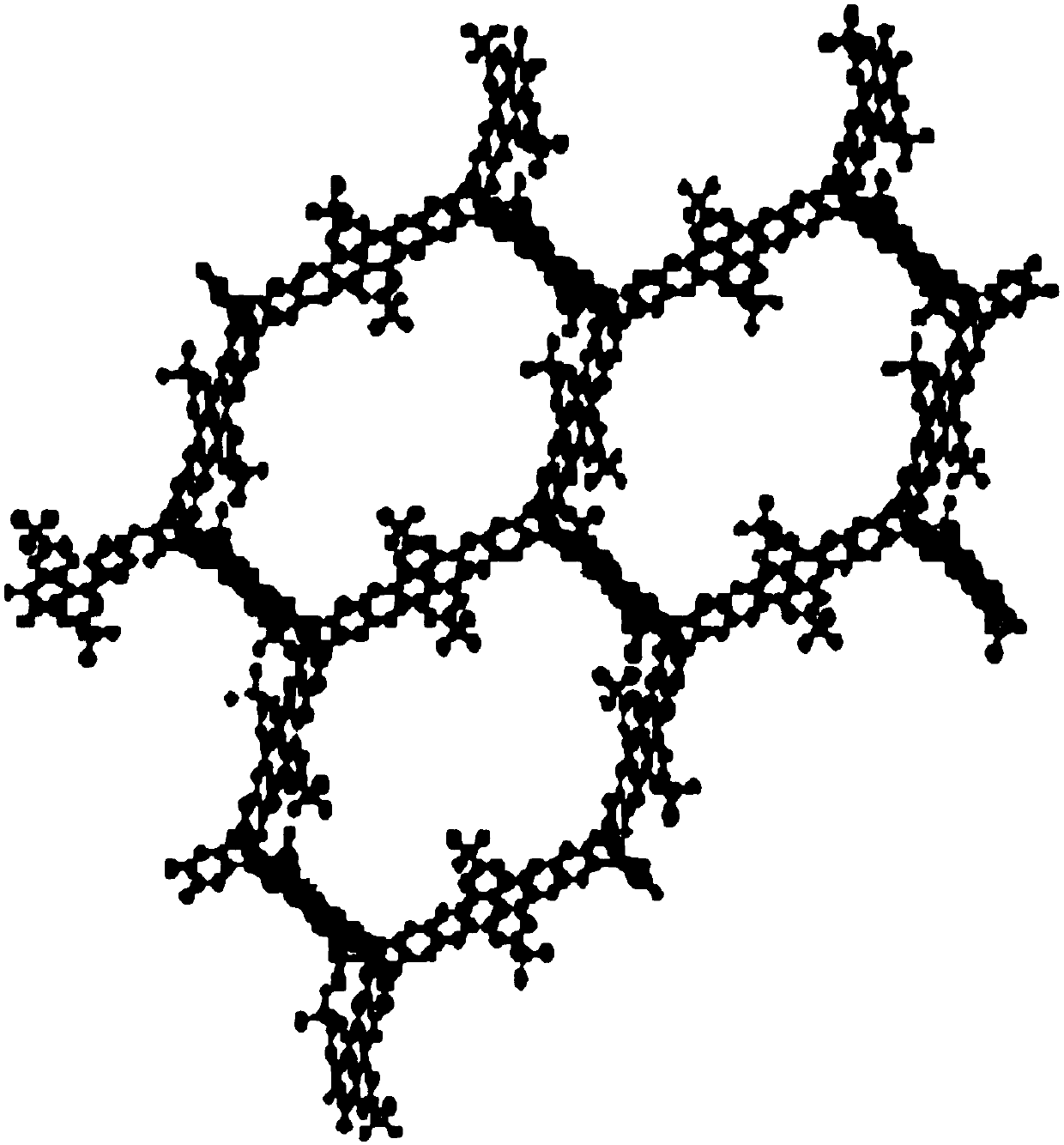

[0063] The ammonium hexahydrochloride triptycene salt has a structure as shown in formula 3:

[0064]

[0065] The di-tert-butylpyrene-4,5,9,10-tetraketone has a structure as show...

Embodiment 2

[0069] The only difference from Example 1 is that the amount of ammonium hexahydrochloride triptycene salt added is 0.012 mmol.

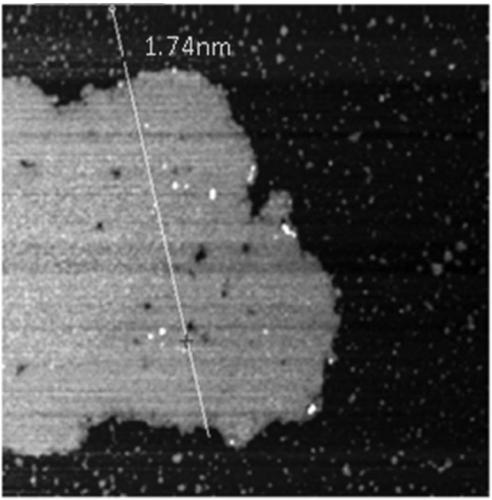

[0070] The COF film obtained in Example 2 is a 1-2 layer film with an average thickness of about 3 nm.

Embodiment 3

[0072] The only difference from Example 1 is that the temperature of the polymerization reaction described in step (3) is 60° C., and the time of the polymerization reaction is 10 h.

[0073] The structure and morphology of the COF membrane obtained in Example 3 are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com