Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Improve detachment efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

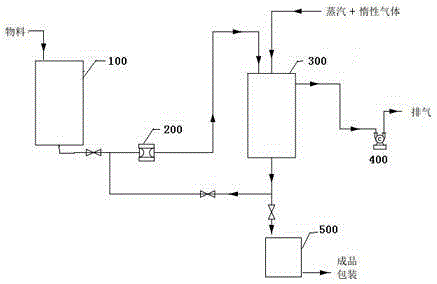

Acrylic emulsion voc (volatile organic compounds) removal method and device therefor

The invention discloses an acrylic emulsion voc (volatile organic compounds) removal method and a device therefor. The method comprises the steps of preheating an acrylic emulsion crude extract, introducing the preheated acrylic emulsion crude extract into an evaporator, and meanwhile, introducing mixed gas of water vapor and inert gas into the evaporator for voc removal, thereby preparing the acrylic emulsion finished product. By the method, the content of voc in the acrylic emulsion crude extract can be greatly lowered, and the quality of the product is greatly improved, so that the product can fully meet environment-friendly requirements; and the method is low in operation cost and high in voc removal efficiency and has little damage to the product high polymer, so that the quality of the product cannot be affected.

Owner:GUANGDONG YINYANG ENVIRONMENT FRIENDLY NEW MATERIALS CO LTD

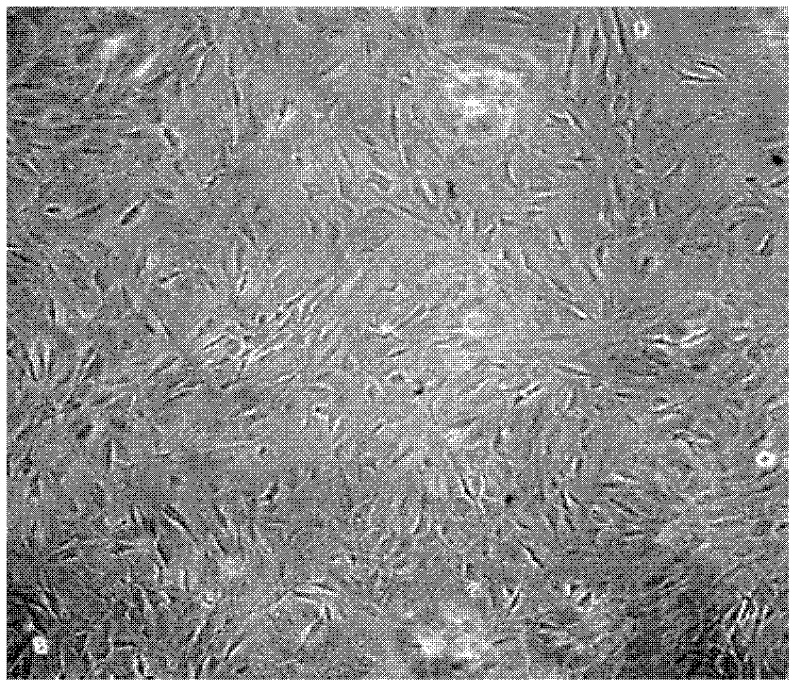

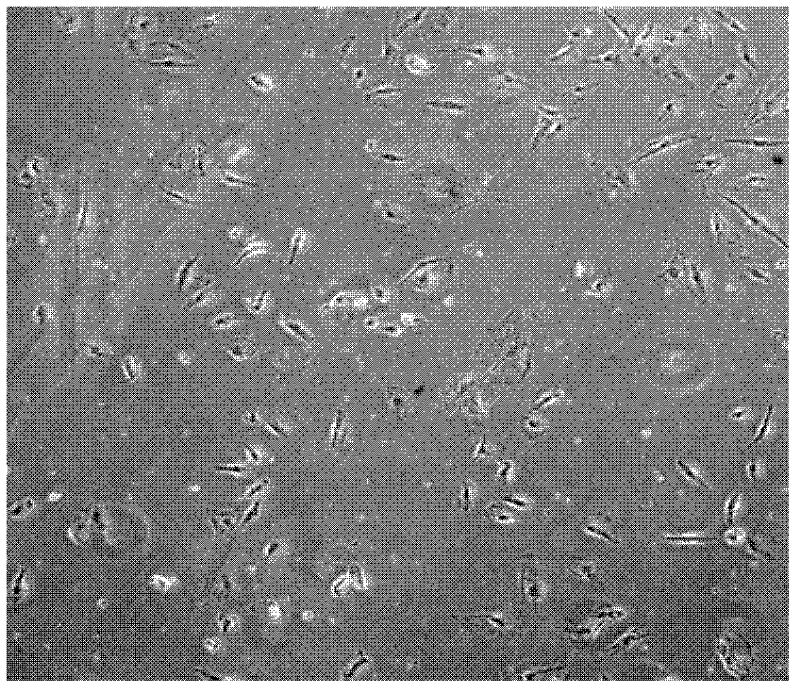

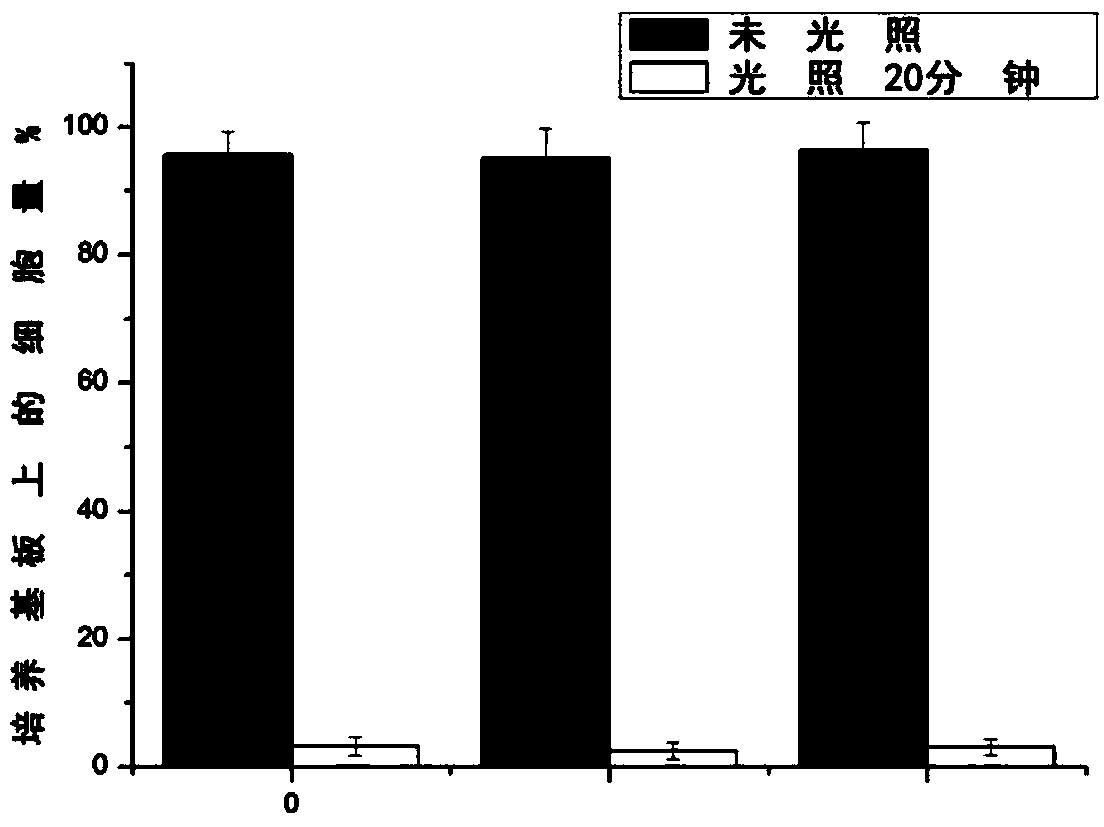

Photon stimulated cell desorption method and cell culture implement used by same

InactiveCN102586169AImprove detachment efficiencyAvoid damageArtificial cell constructsSkeletal/connective tissue cellsDesorptionSemiconductor structure

The invention discloses a photon stimulated cell desorption method and a cell culture implement used by the same. The method comprises the following steps: preparing a photosensitive semiconductor structure layer on the cell contact surface of a cell culture vessel as the cell culture surface; then performing in-vitro cell culture on the cell culture surface of the cell culture vessel; and after completing the in-vitro cell culture, performing ultraviolet light or visible light irradiation treatment to desorb cells growing on the cell culture surface from the cell culture vessel. According to the method disclosed by the invention, injuries to the cells can be reduced to the greatest extent during cell desorption. The cell culture implement used in the method comprises the cell culture vessel, and the photosensitive semiconductor structure layer is prepared on the cell contact surface of the cell culture vessel as the cell culture surface. The implement can be realized by performing very small improvement on the basis of the prior art and has the advantages of low cost and easiness in popularization and application.

Owner:ZHEJIANG UNIV

Processing method for recycling waste packaging paper

InactiveCN112111984AImprove detachment efficiencySpread outWashing/displacing pulp-treating liquorsPaper recyclingFiberWarm water

The invention discloses a processing method for recycling waste packaging paper, and relates to the technical field of waste paper recycling. The processing method comprises the following steps of: 1,conveying waste paper into a cutting machine, and sequentially carrying out twice flattening treatment, cutting treatment and crushing treatment on the waste paper in the cutting machine, 2, pouringa waste paper raw material into a magnetic suction rolling cylinder, rotating the magnetic suction rolling cylinder, supplying power for electromagnet in the magnetic suction rolling cylinder to adsorb metal impurities in the waste paper raw material; and 3, pouring the waste paper raw material into a pulping machine, pouring warm water into the pulping machine, conducting stirring to obtain pulp,pouring a deinking agent, a defoaming agent and a dispersing agent into the pulp, and starting an ultrasonic cleaner in the pulping machine to physically clean the pulp. When paper pulp is stirred, the surfaces of fibers in the paper pulp can be physically cleaned through ultrasonic waves, so that the separation efficiency of the fibers in the paper pulp and ink is improved, ultrasonic cleaning and stirring are mixed and used for 2-3 times, and the deinking quality can be improved.

Owner:界首市鑫华装璜彩印有限公司

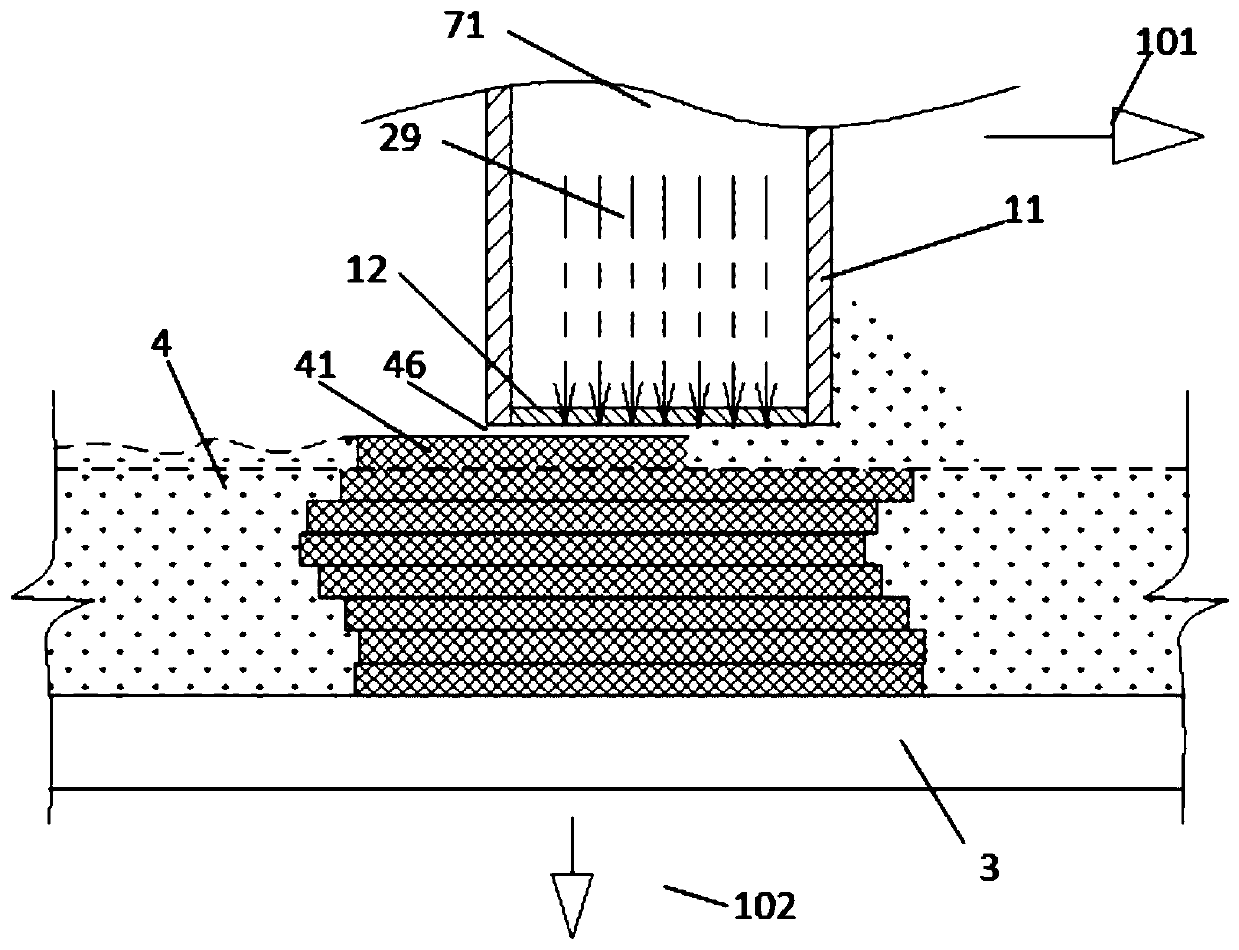

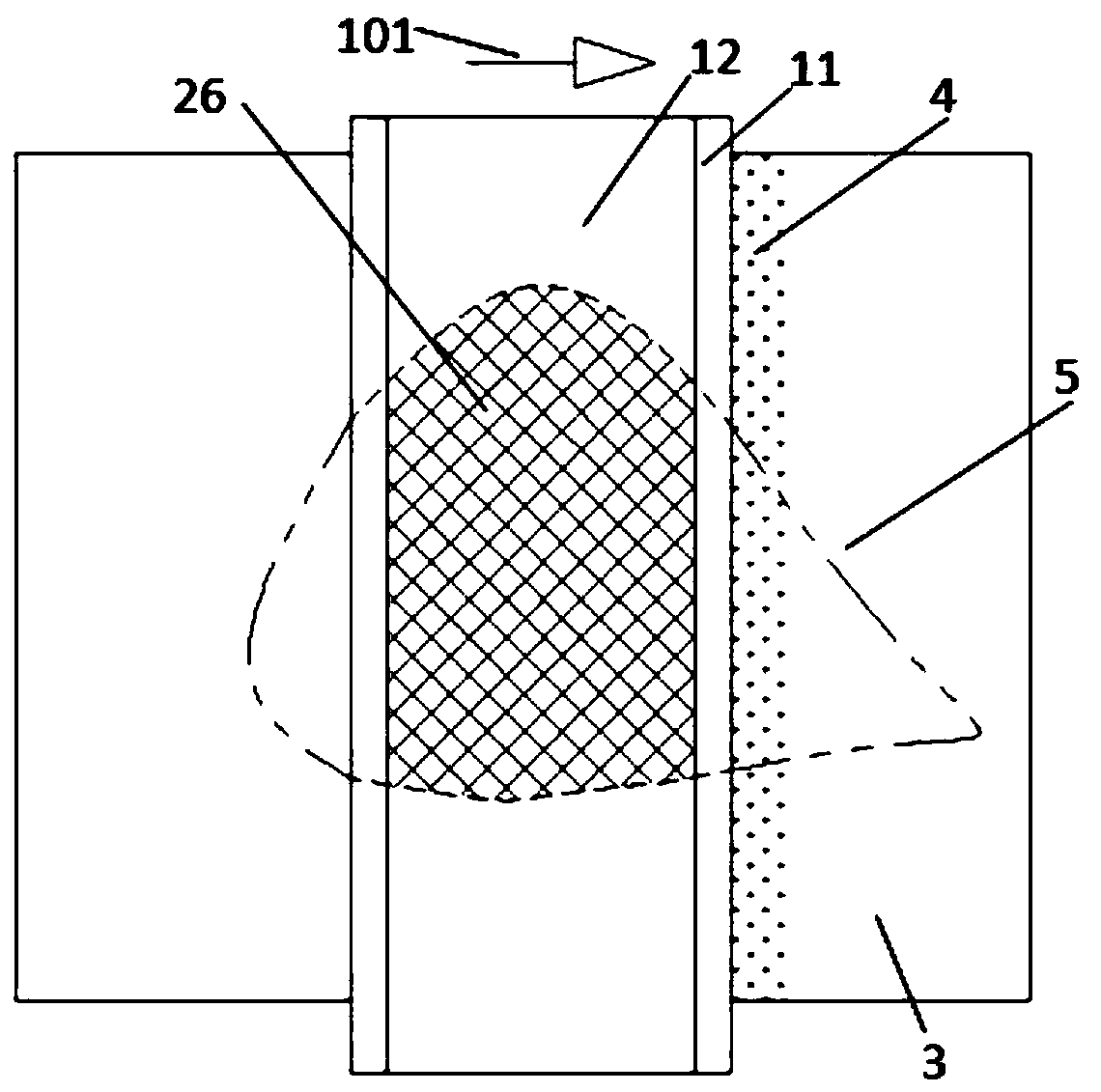

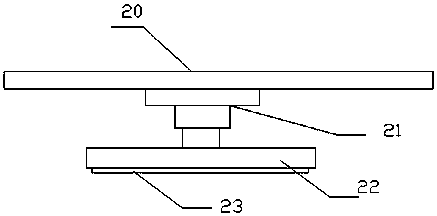

Photocuring 3D printing system and printing method

ActiveCN110901058AFast printingLarge light transmission areaAdditive manufacturing apparatus3D object support structuresLight beam3D modeling

The invention relates to a photocuring 3D printing system and a printing method. The photocuring 3D printing system comprises a material carrier and a spreader. The spreader is of a scraper structure;at least part of the spreading side of the spreader is a light-transmitting area; and the spreader and the material carrier generate relative translation motion to lay a photosensitive printing material on the material carrier opposite to the light transmitting area. When the laid photosensitive printing material is in the extruded state, the light beam transmits through the light transmitting area and selectively irradiates the photosensitive printing material of the spreading side of the light transmitting area according to the information of a three-dimensional model to be printed to forma curing layer. The spreader and the material carrier can move vertically relative to each other, the distance between the spreader and the material carrier is increased in the printing process and the curing layer forms a curing model on the material carrier. Material spreading and illumination curing can be synchronously carried out, the 3D printing speed and printing precision can be improved,the application range is wider and the equipment cost and the production cost can be reduced..

Owner:YUANZHI TECH SHANGHAI CO LTD

Agricultural mechanical soybean thresher

The invention discloses an agricultural mechanical soybean thresher which comprises a shell and a feeding plate. The feeding plate fixedly penetrates the side wall of the shell, a feeding port is formed in the side wall of the shell and positioned on the upper portion of the feeding plate, and a first motor is fixedly connected onto the rear side wall of an inner cavity of the shell. By combination of a flapping strip, a first compression roller and a screen mesh, soybean grains are efficiently separated and can be screened, the flapping strip rotates in a reciprocating manner, soybean stems on a conveying belt are flapped, so that the soybean grains are preliminarily separated, the soybean stems can be further rolled and crushed by the first compression roller and a second compression roller, the soybean grains are repeatedly separated, separation efficiency is improved, the soybean grains can be efficiently and rapidly separated, the whole thresher is small in size and adapts to various landform, and mechanical use efficiency is improved.

Owner:杨翠红

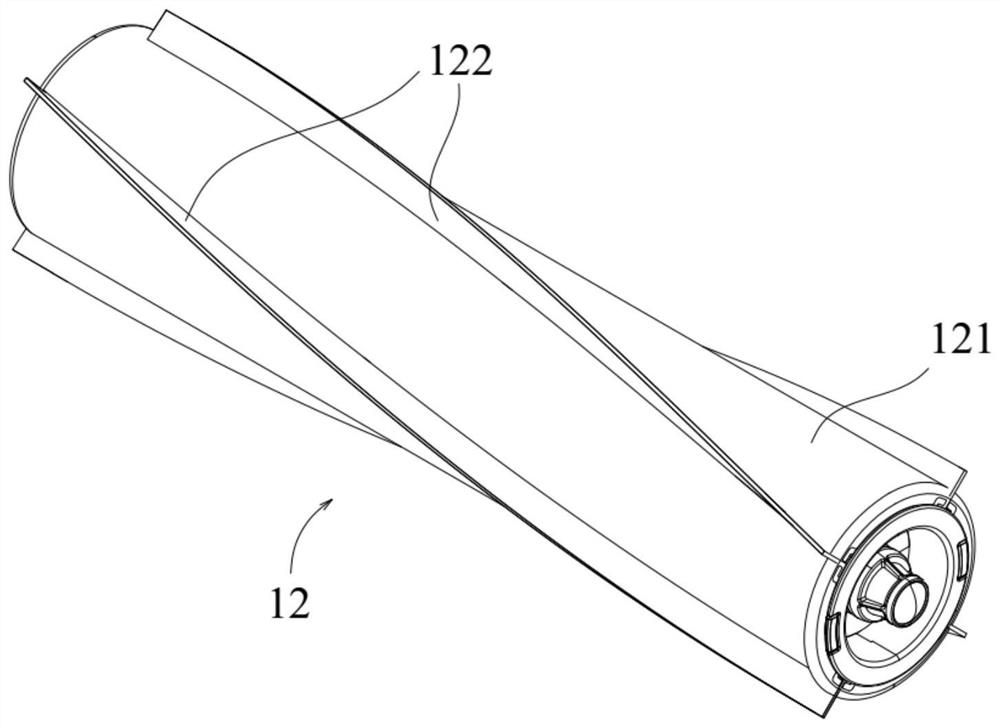

Sweeping and mopping integrated device and scrubber with same

PendingCN112294199AReduce workloadImprove quality of lifeCarpet cleanersFloor cleanersScrubberManufacturing engineering

The invention discloses a sweeping and mopping integrated device and a scrubber with the same. The sweeping and mopping integrated device comprises: a base, a sweeping rolling brush which is rotationally connected to the front end of the base; a mopping rolling brush which is rotationally connected to the rear end of the base; a sweeping driver which is in transmission connection with the sweepingrolling brush; and a mopping driver which is in transmission connection with the mopping rolling brush, wherein a dust collecting box and a sewage box are arranged in the base at intervals, the dustcollecting box is arranged to receive dust carried by the sweeping rolling brush, and the sewage box is arranged to receive sewage absorbed by the mopping rolling brush. According to the invention, the equipment procurement cost and the equipment occupied space are reduced by improving the equipment integration degree, the floor mopping operation is executed while the floor sweeping operation is executed, the workload of a user is reduced, the cleaning efficiency is improved, and the life quality of the user is also improved.

Owner:苏州睿克斯科技有限公司

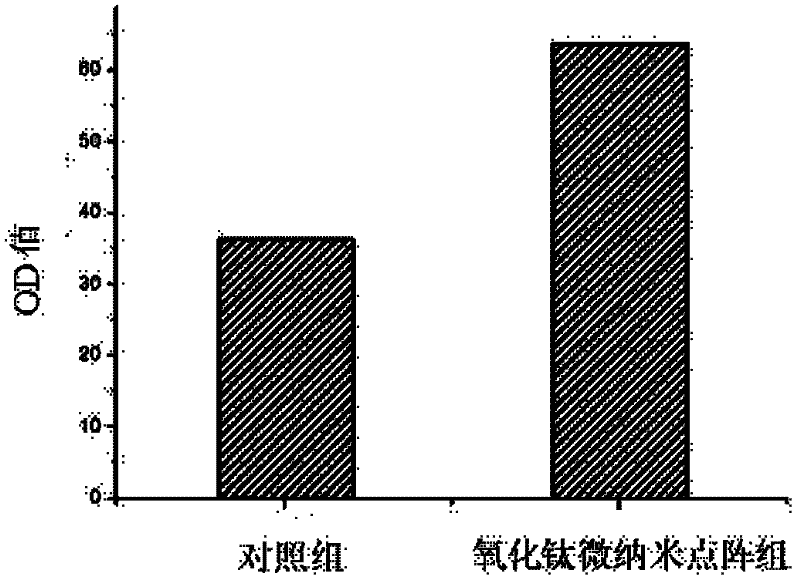

Photoresponsive nanostructure film with high visible light transmittance and application thereof

InactiveCN104087928AImprove efficiencyLess cell damageNanotechnologyTissue cultureTissue engineeringTransmittance

Belonging to the field of tissue engineering, the invention in particular relates to a photoresponsive nanostructure film with high visible light transmittance and application thereof. The preparation method of the photoresponsive nanostructure film comprises the steps of: (1) dispersing photoresponsive nano-particles in water uniformly to form a nano-particle dispersion solution with a mass fraction of 10-20%; preparing the nano-particle dispersion solution, alcohol and an organic solvent into a precursor solution in a proportion of 0.02-0.06:6-9:1-3; and (2) adding the precursor solution onto a polystyrene culture vessel dropwise and evenly according to a concentration of 20-52 microL / cm<2>, and then conducting drying at 40-90DEG C, thus obtaining the photoresponsive nanostructure film with a grain size of 10-30nm, a thickness of 20nm-100nm and visible light transmittance of 89%-98%. Compared with the prior art, the method provided by the invention has the characteristics of high cell detachment efficiency, small cell damage, simple operation and wide applicable cell range, etc., thus having very strong practicability.

Owner:周婧

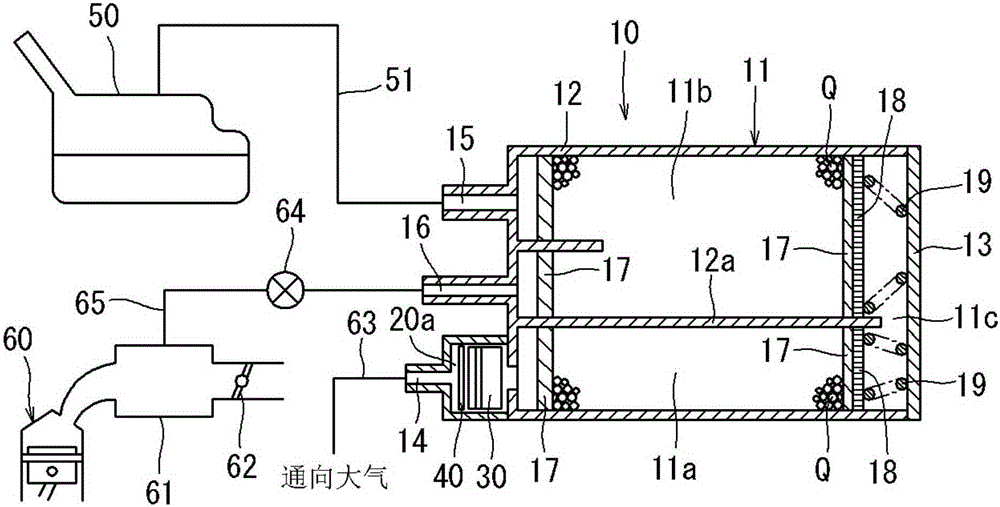

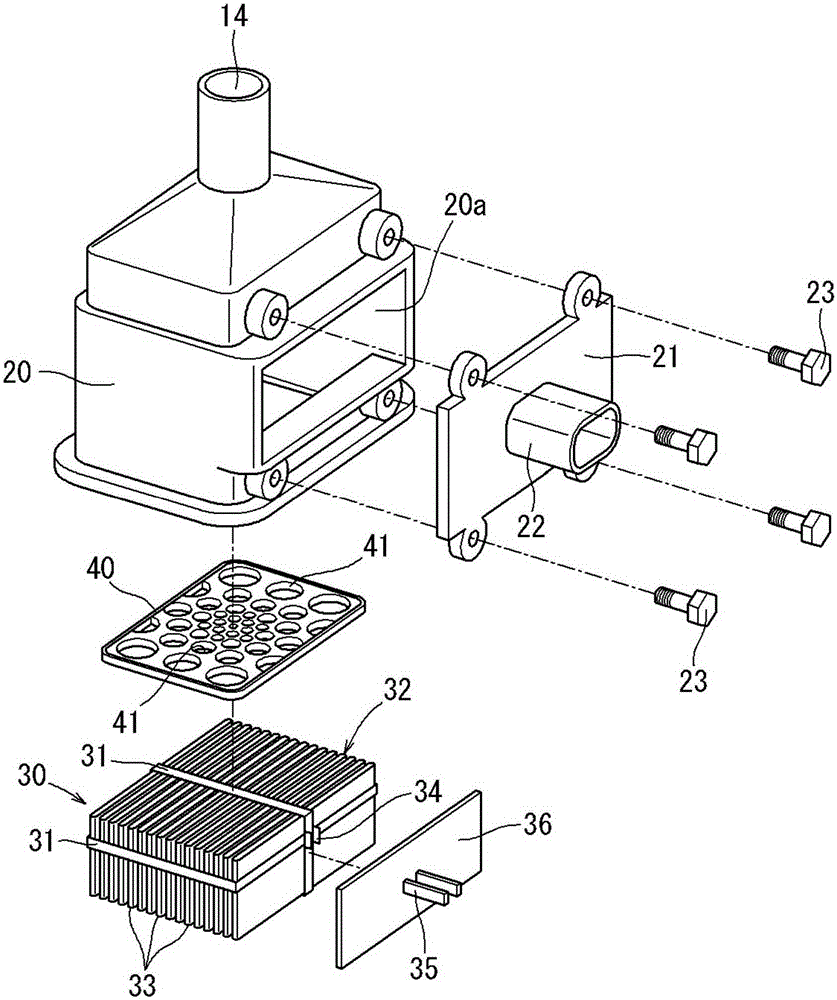

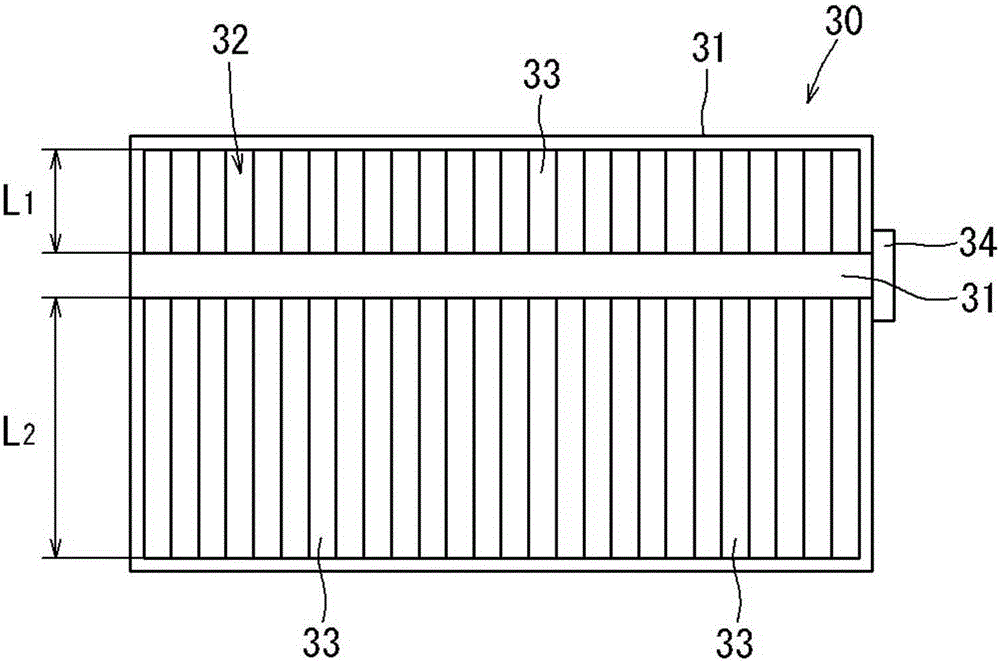

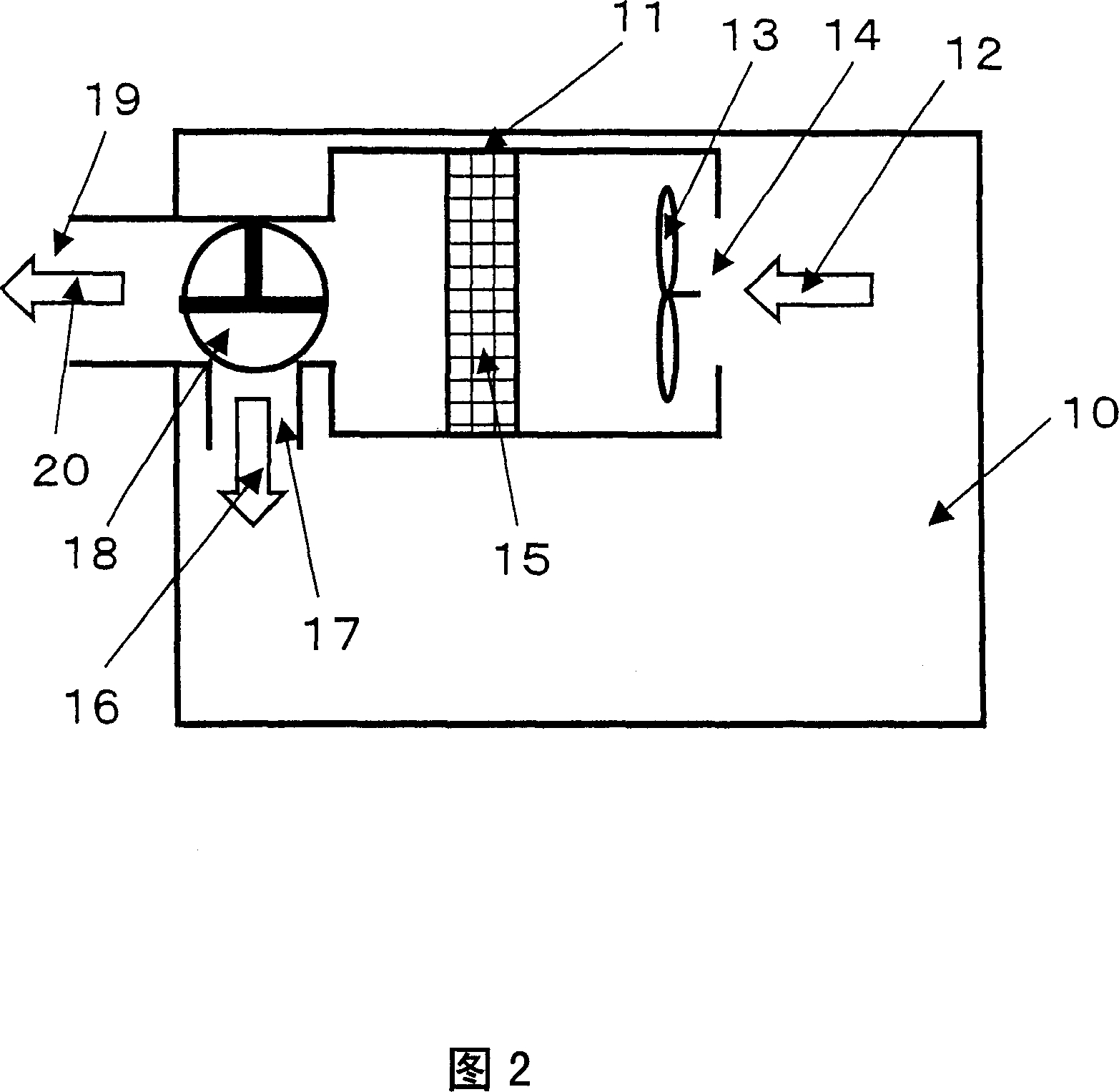

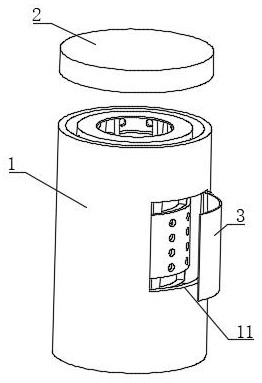

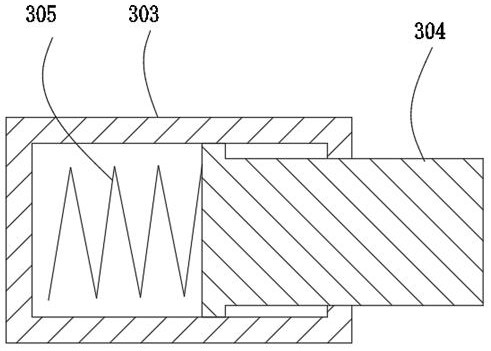

Vaporized Fuel Processing Apparatus

InactiveCN105422322AImprove detachment efficiencyImprove adsorption efficiencyElectrical controlNon-fuel substance addition to fuelElectricityAtmospheric air

A vaporized fuel processing apparatus has a casing defining an adsorption chamber therein and having a tank port, a purge port, and an atmospheric port. The tank port is connected to a fuel tank. The purge port is connected to an internal combustion engine. The atmospheric port is open to the atmosphere. A heater is disposed between the adsorption chamber and the atmospheric port and has a fin heat exchanger and a heating element. The heating element is configured to generate heat by electricity supply. The fin heat exchanger is joined to the heating element. The surface area of the fin heat exchanger between the heating element and the adsorption chamber is larger than the surface area of the fin heat exchanger between the heating element and the atmospheric port.

Owner:AISAN IND CO LTD

Wood peeling device

Owner:临沂海森木业有限公司

Magnetic separator with good separation effect

InactiveCN111570087AGood energy saving effectImprove sorting efficiencyFouling preventionCleaning using toolsFixed bearingDrive shaft

The invention relates to a magnetic separator with a good separation effect. The magnetic separator comprises a conveying belt, a power device, two rotating rollers and two supports. The magnetic separator further comprises a dispersing mechanism and a separating mechanism. The dispersing mechanism comprises a transmission assembly, a driving shaft, a rotary disc, two supporting rods, two supporting plates, two springs, two fixing bearings, two supporting sleeves and at least two protruding blocks. The separating mechanism comprises a sealing box, a magnetic separation device, a discharge port, an air cylinder, an elastic rope, a scraper blade, two notches and two dispersion claws. The transmission assembly comprises a friction disk, a first gear and a second gear. According to the magnetic separator with the good separation effect, raw materials on the conveying belt can be dispersed through the dispersing mechanism, the separation effect of the magnetic separator on the raw materialsis improved, the separation efficiency of the separated raw materials is improved through the separating mechanism, and the separation efficiency of the magnetic separator is improved.

Owner:南京捷达威机电科技有限公司

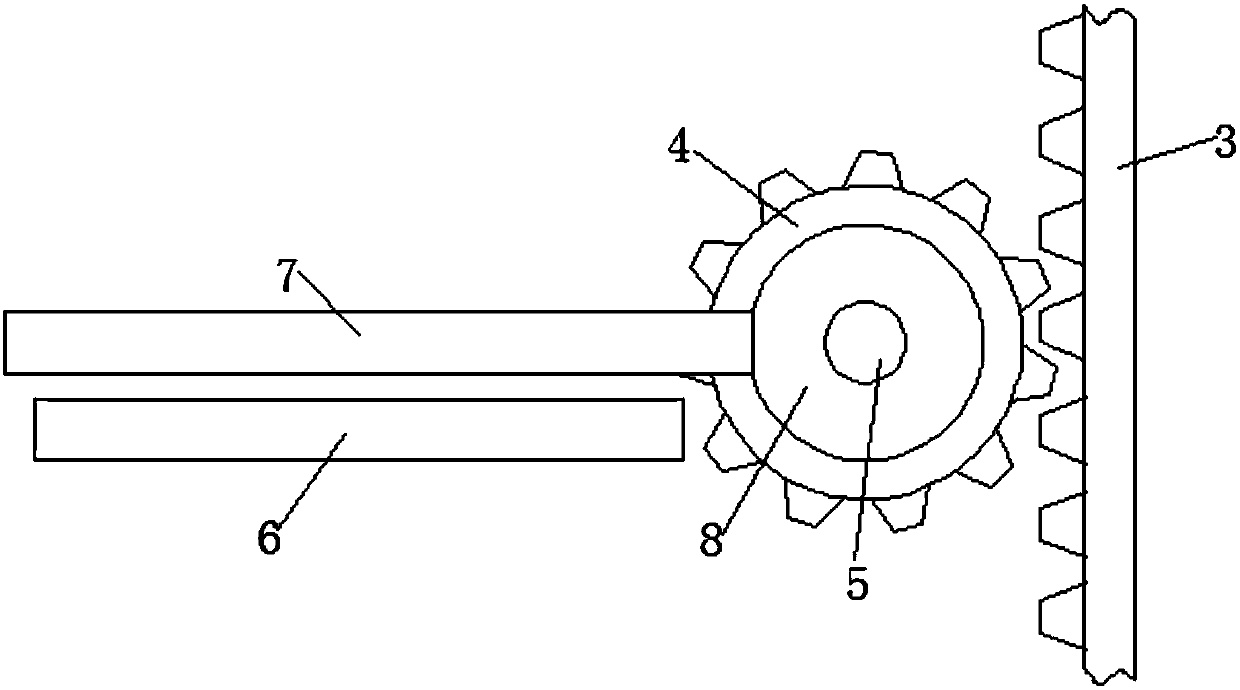

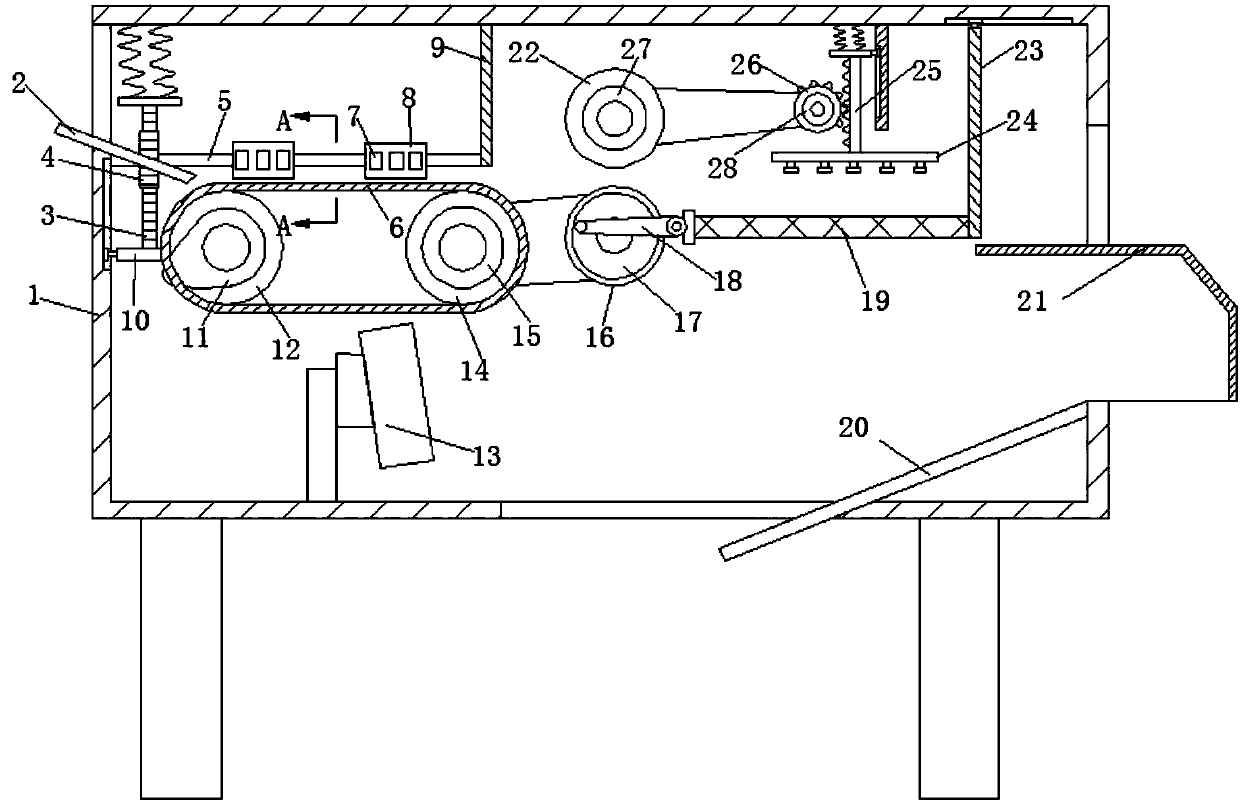

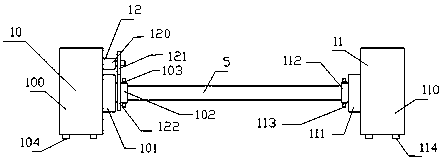

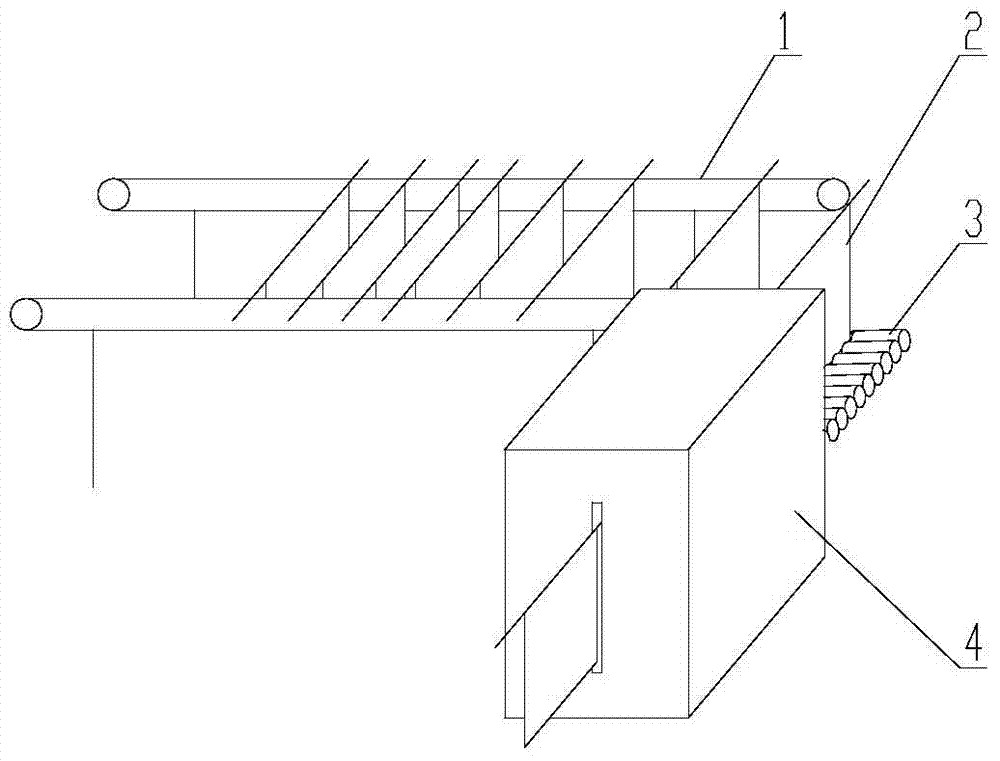

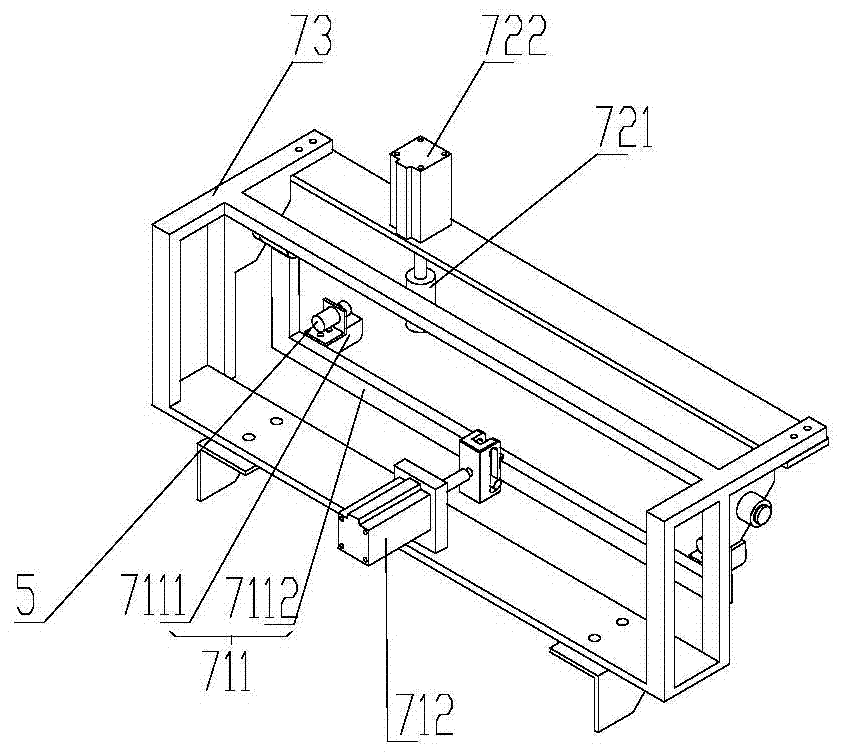

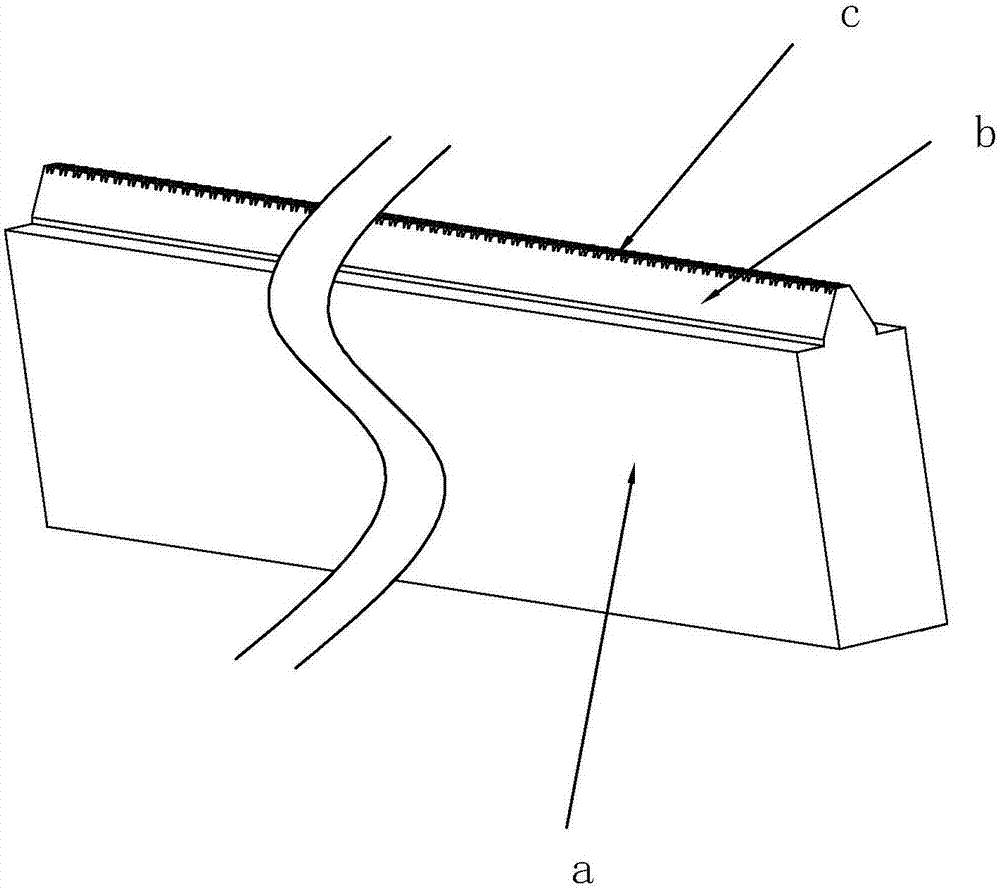

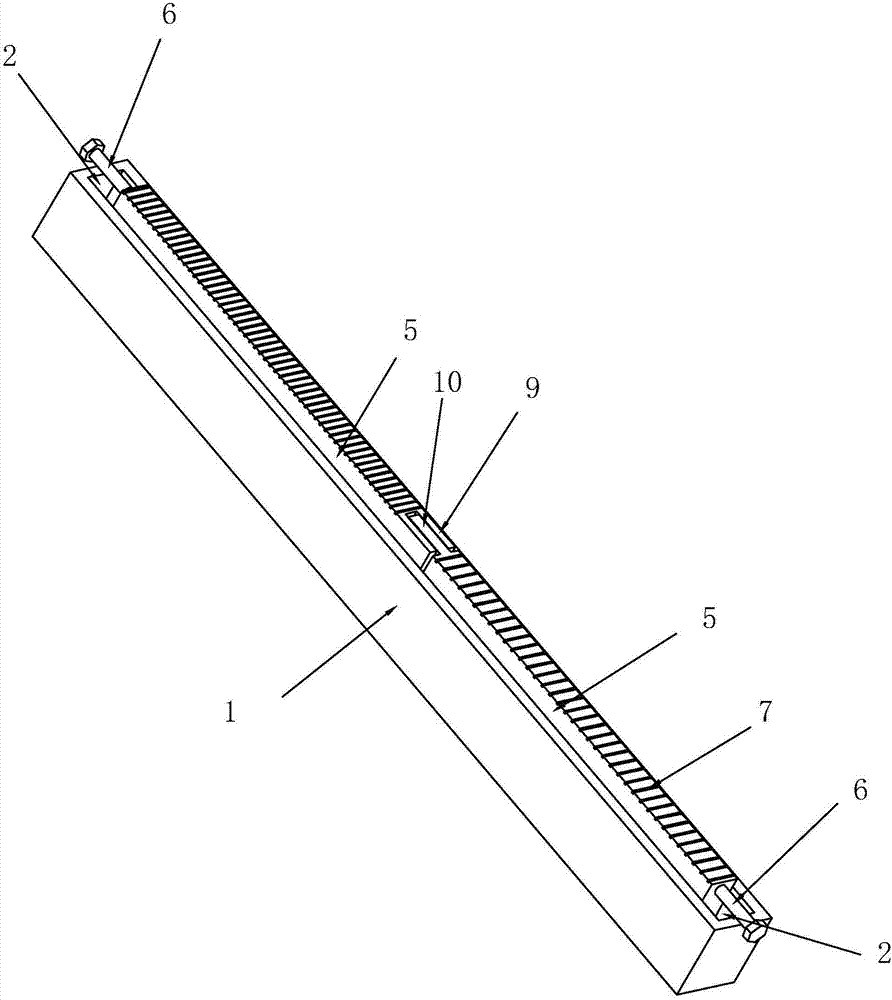

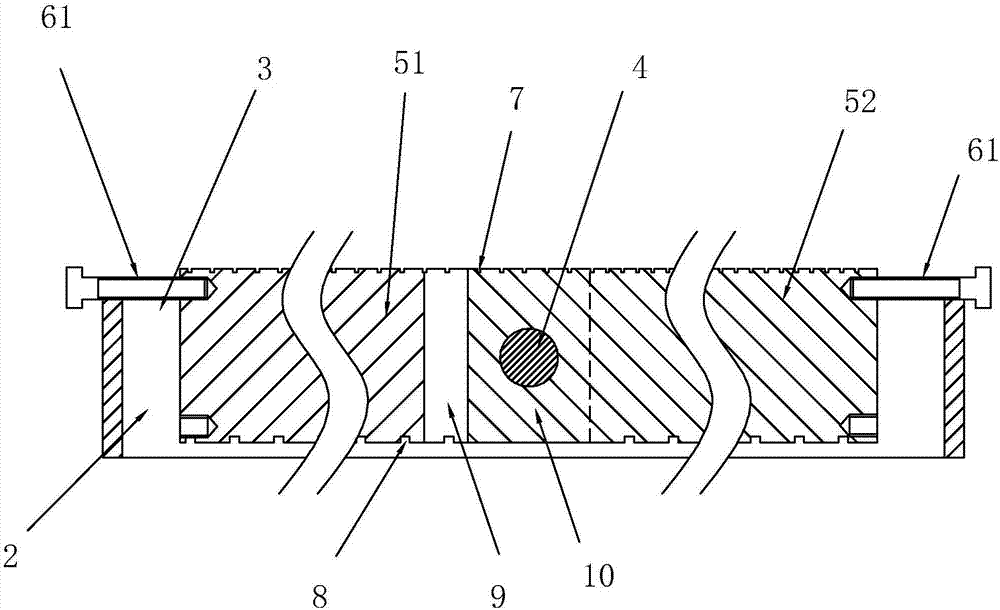

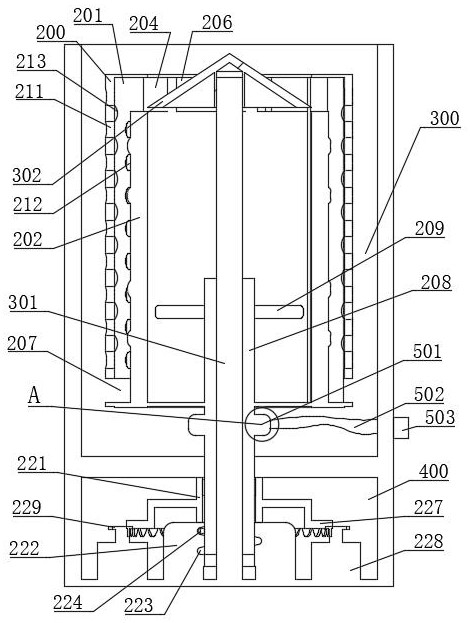

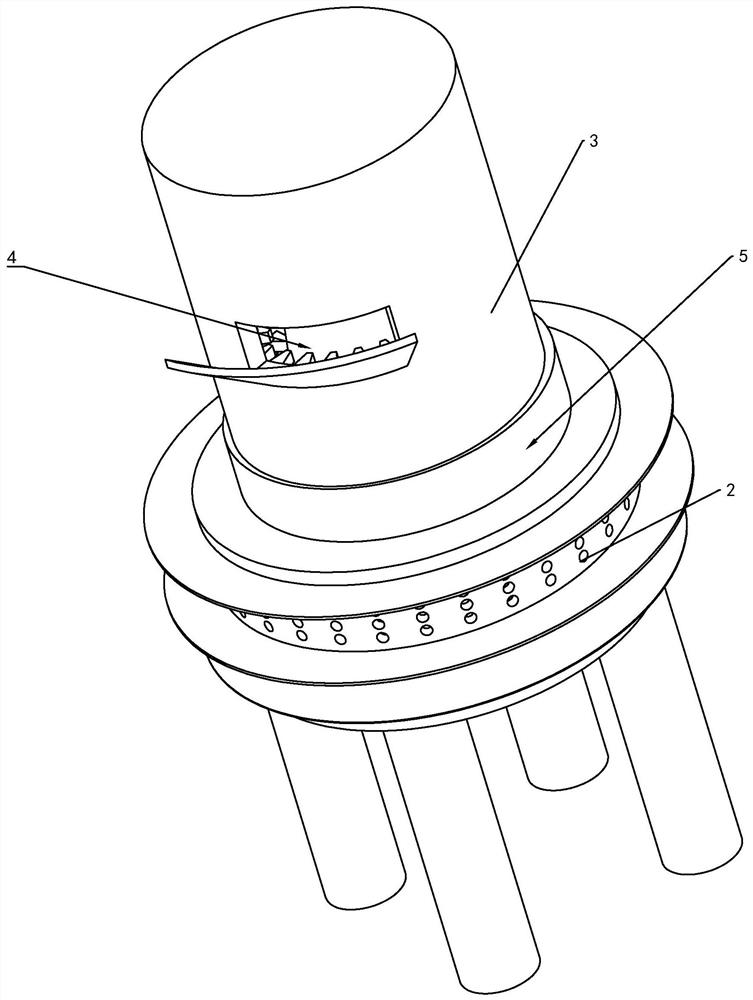

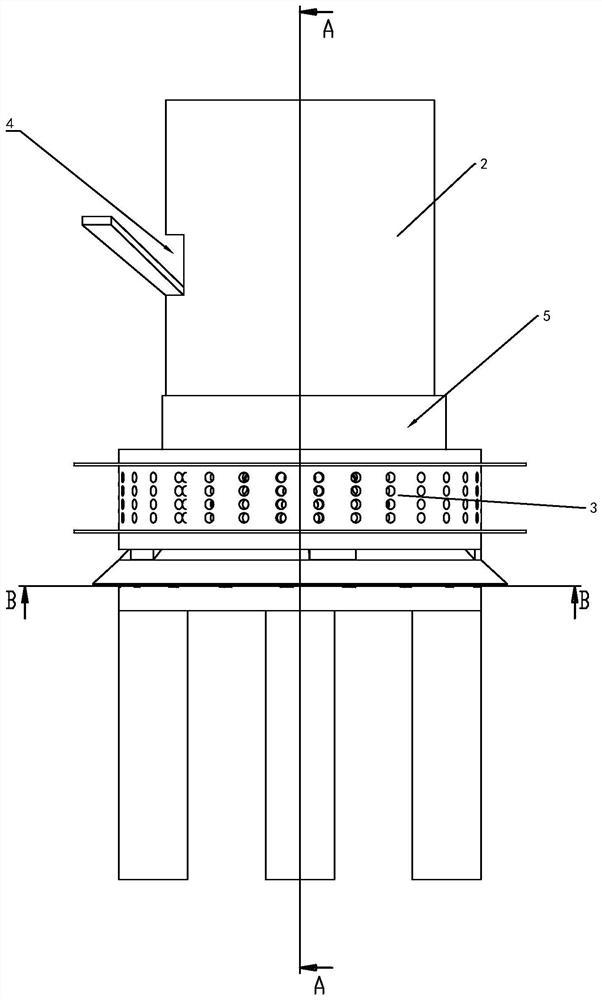

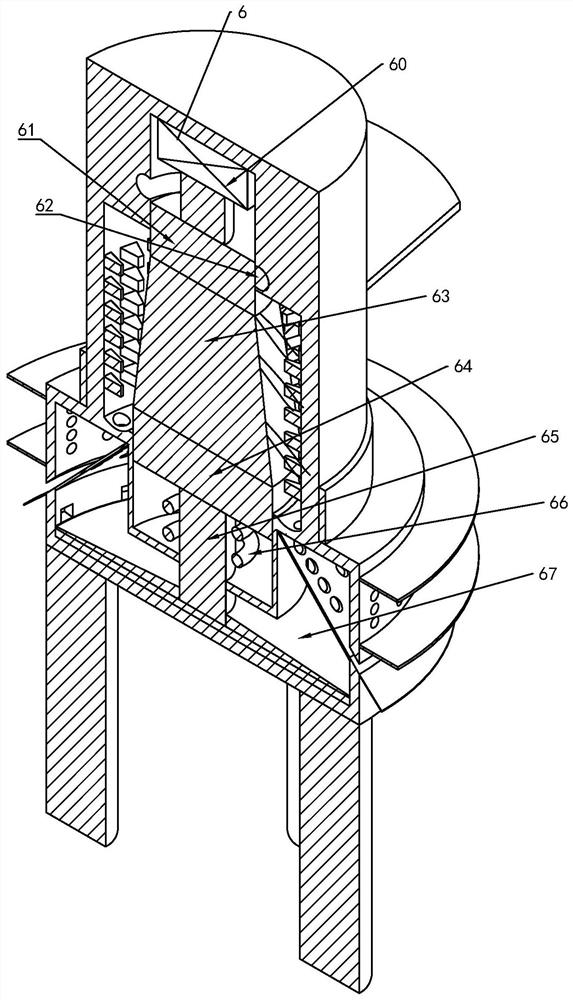

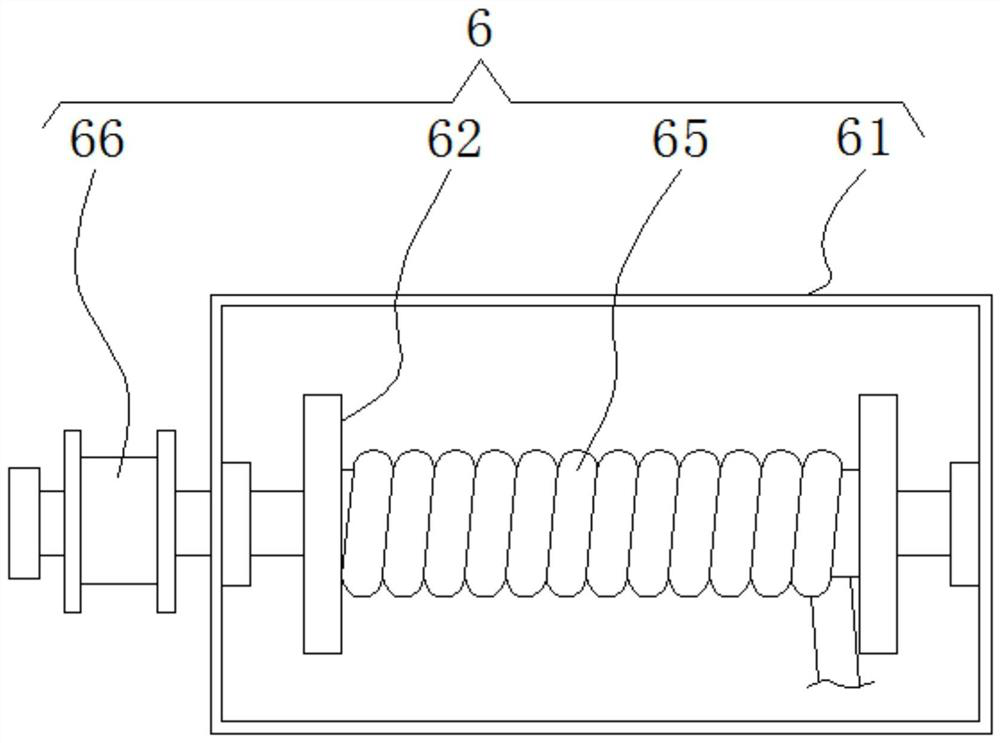

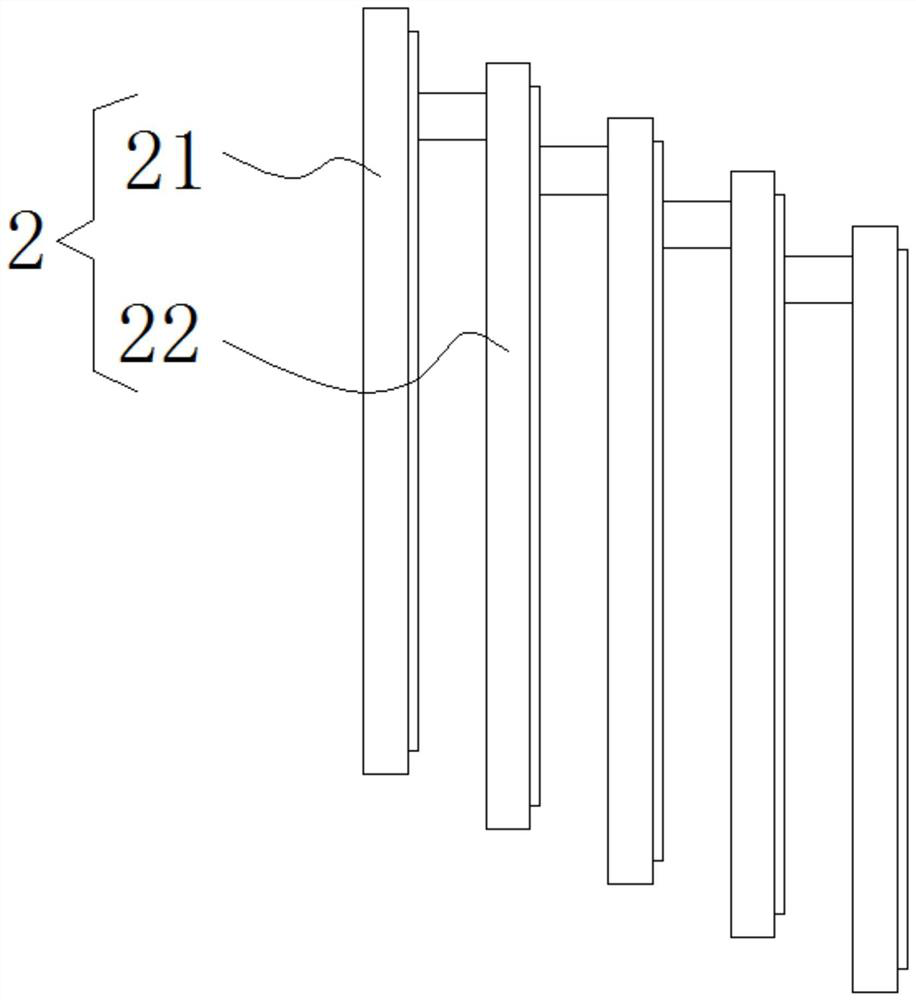

Electrolytic manganese releasing production line and plate distribution device thereof

ActiveCN104499007AAvoid getting stuckEfficient and smooth disengagementPhotography auxillary processesElectrolysis componentsProduction lineElectrolysis

The invention provides an electrolytic manganese releasing production line and a plate distribution device thereof. The plate distribution device comprises a first conveying mechanism (3) for conveying a negative plate (2) to an electrolytic manganese releasing machine (4), and a second conveying mechanism (1) for conveying the negative plate (2) to the first conveying mechanism (3), and further comprises a detection mechanism (5) and a braking mechanism (6); the detection mechanism (5) is used for detecting the negative plate (2) located above the first conveying mechanism (3); the braking mechanism (6) is used for braking the second conveying mechanism (1) when detecting the negative plate (2) located above the first conveying mechanism (3), so that the second conveying mechanism (1) stops conveying the negative plate (2) to the first conveying mechanism (3). By the aid of the plate distribution device provided by the invention, the problems in the prior art that the first conveying mechanism is clamped caused by the fact that the plurality of negative plates are conveyed to the first conveying mechanism by the second conveying mechanism are solved, so that the metal manganese releasing efficiency is improved.

Owner:长沙合利智能装备有限公司

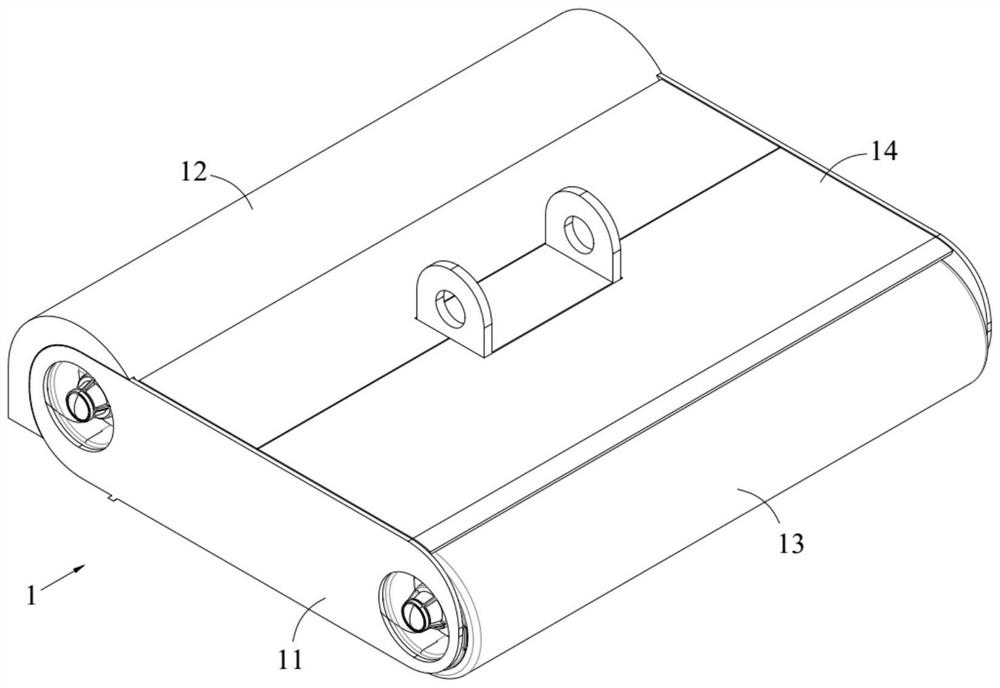

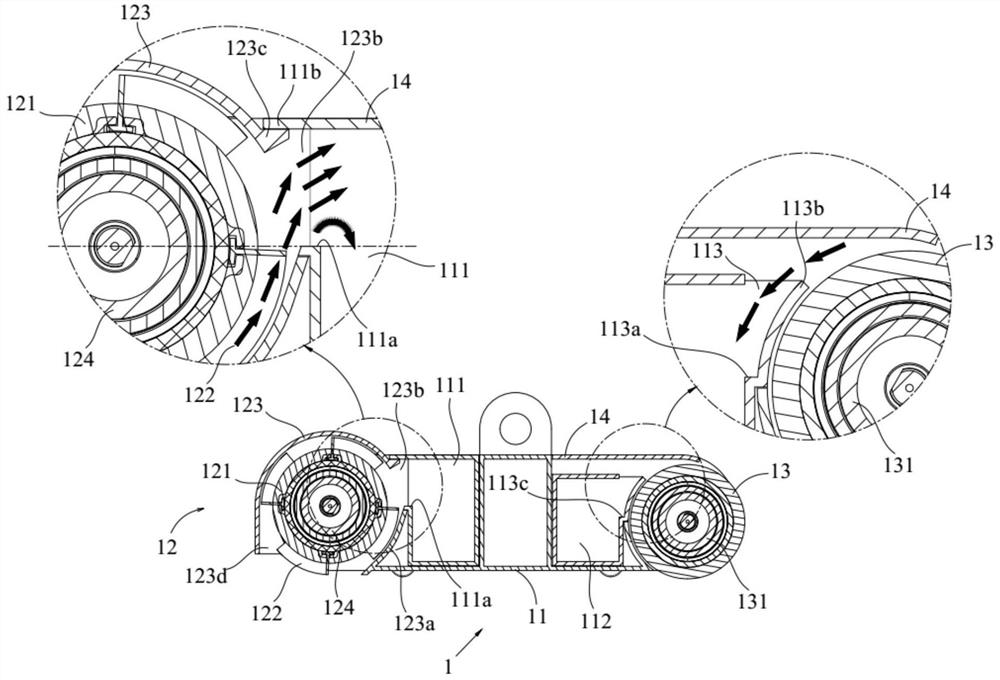

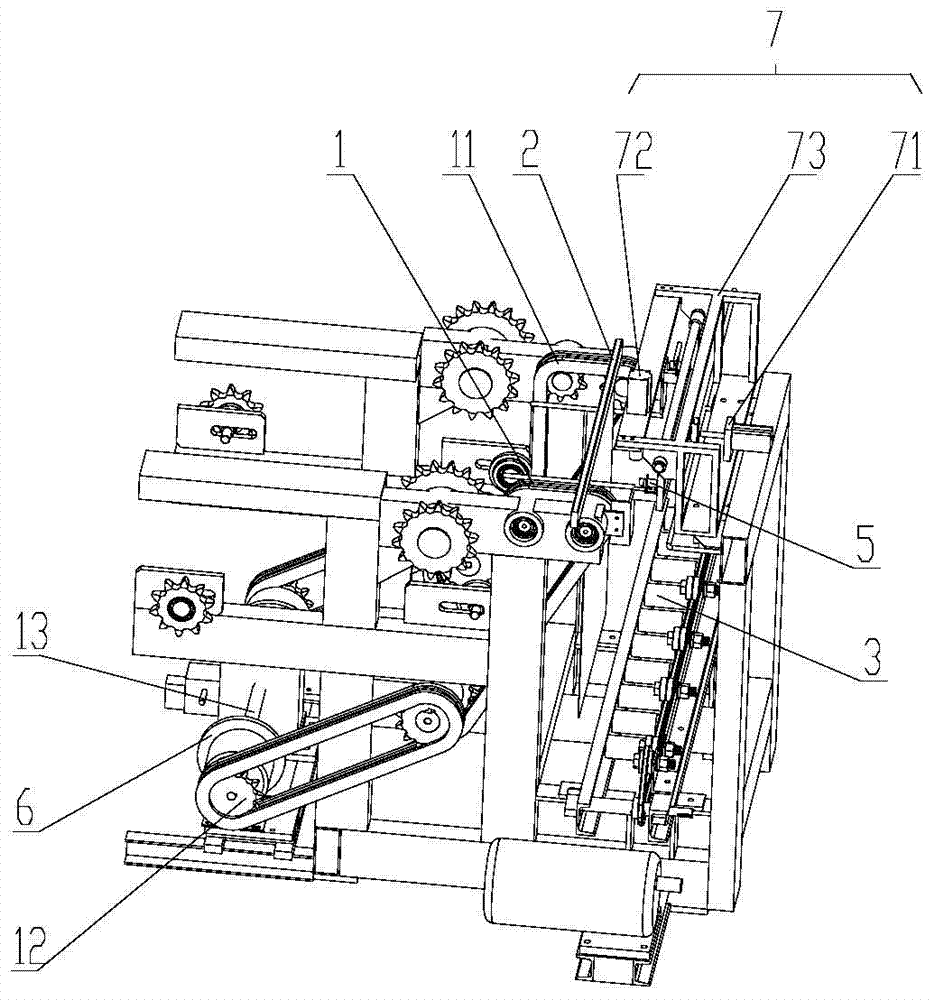

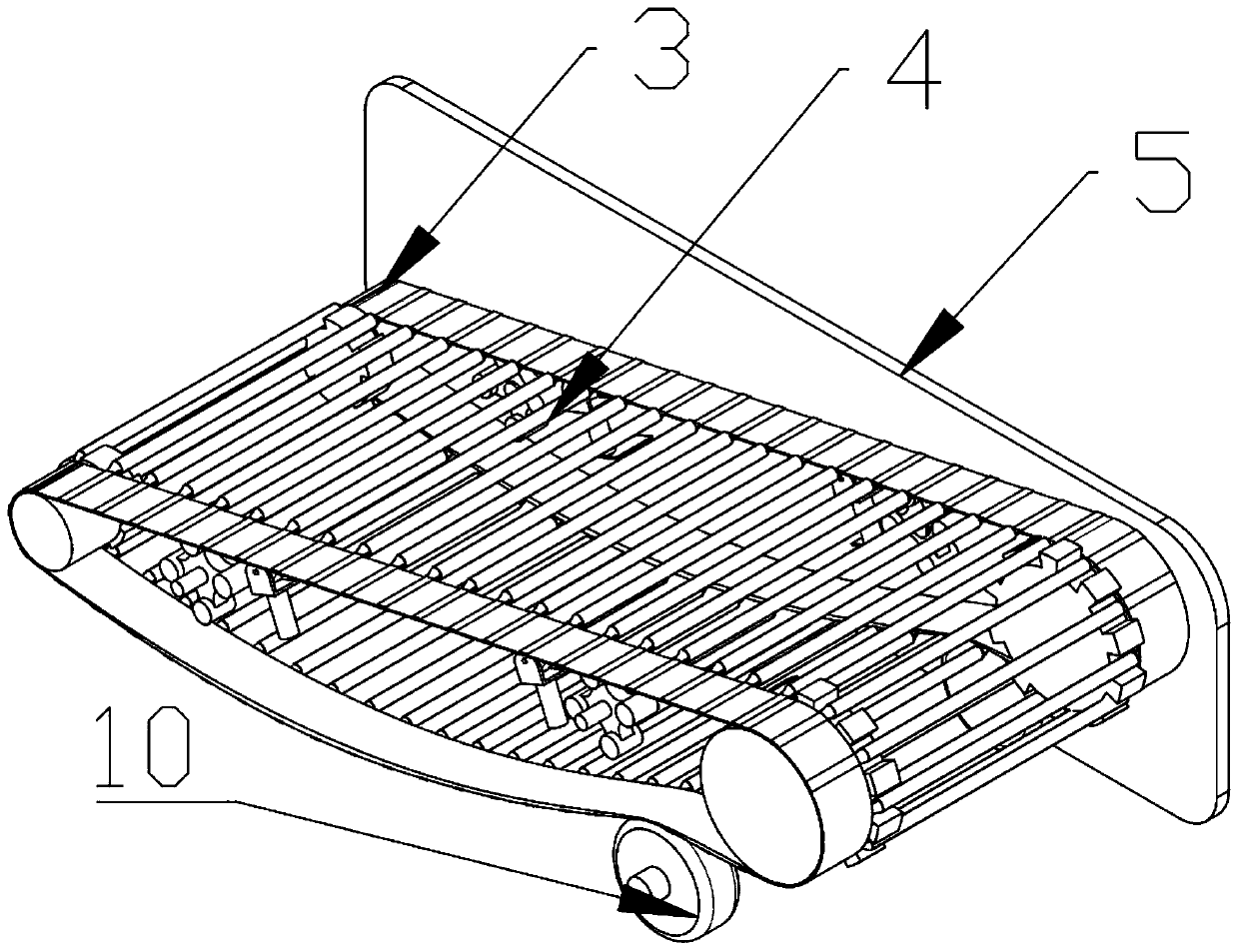

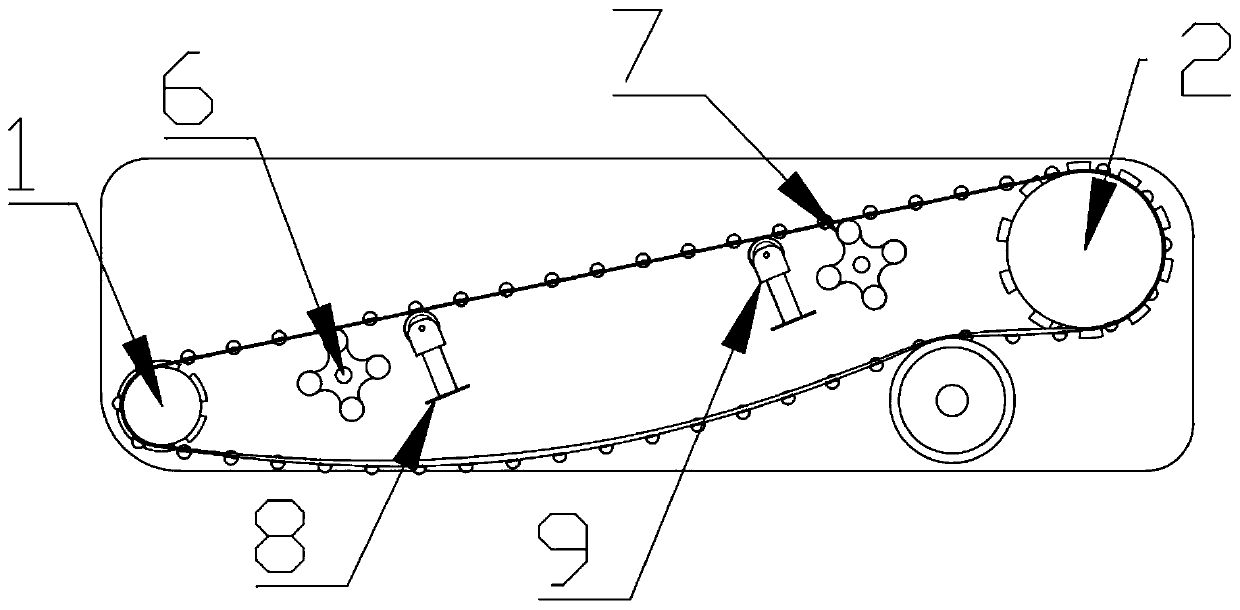

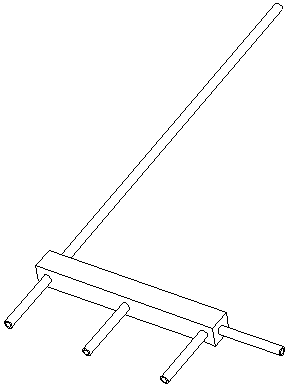

Shaking conveyor belt for potato harvester

PendingCN110214520AHigh vibration frequencyReduce vibration amplitudeDiggersChain conveyorEngineering

The invention discloses a shaking conveyor belt for a potato harvester. The shaking conveyor belt for the potato harvester comprises a chain conveyor belt, wherein the tail part of the chain conveyorbelt inclines upwards, the head part of the chain conveyor belt is provided with a front conveying roller assembly, and the tail part of the chain conveyor belt is provided with a rear conveying roller assembly; the front conveying roller assembly is connected with the rear conveying roller assembly through a group of parallel conveying belts; a plurality of chain rods are connected between the conveying belts; side plates are arranged on two sides of the chain conveyor belt separately; two vibration devices are arranged on the side plates at intervals along the conveying direction, and each vibration device comprises a rotating shaft; one end of each rotating shaft is connected with the corresponding side plate while the other end of the rotating shaft is connected with a plum blossom-shaped shaking wheel; and the outer walls of the plum blossom-shaped shaking wheels are abutted to the inner walls of the conveying belts. A support plate is connected with the inner walls of the side plates, a support roller is connected to the support plate, and the outer wall of the support roller is abutted to the inner walls of the conveying belts. Collision damage of potatoes is relieved by increasing shaking frequency and reducing shaking amplitude.

Owner:DANYANG RONGJIA PRECISION MACHINERY

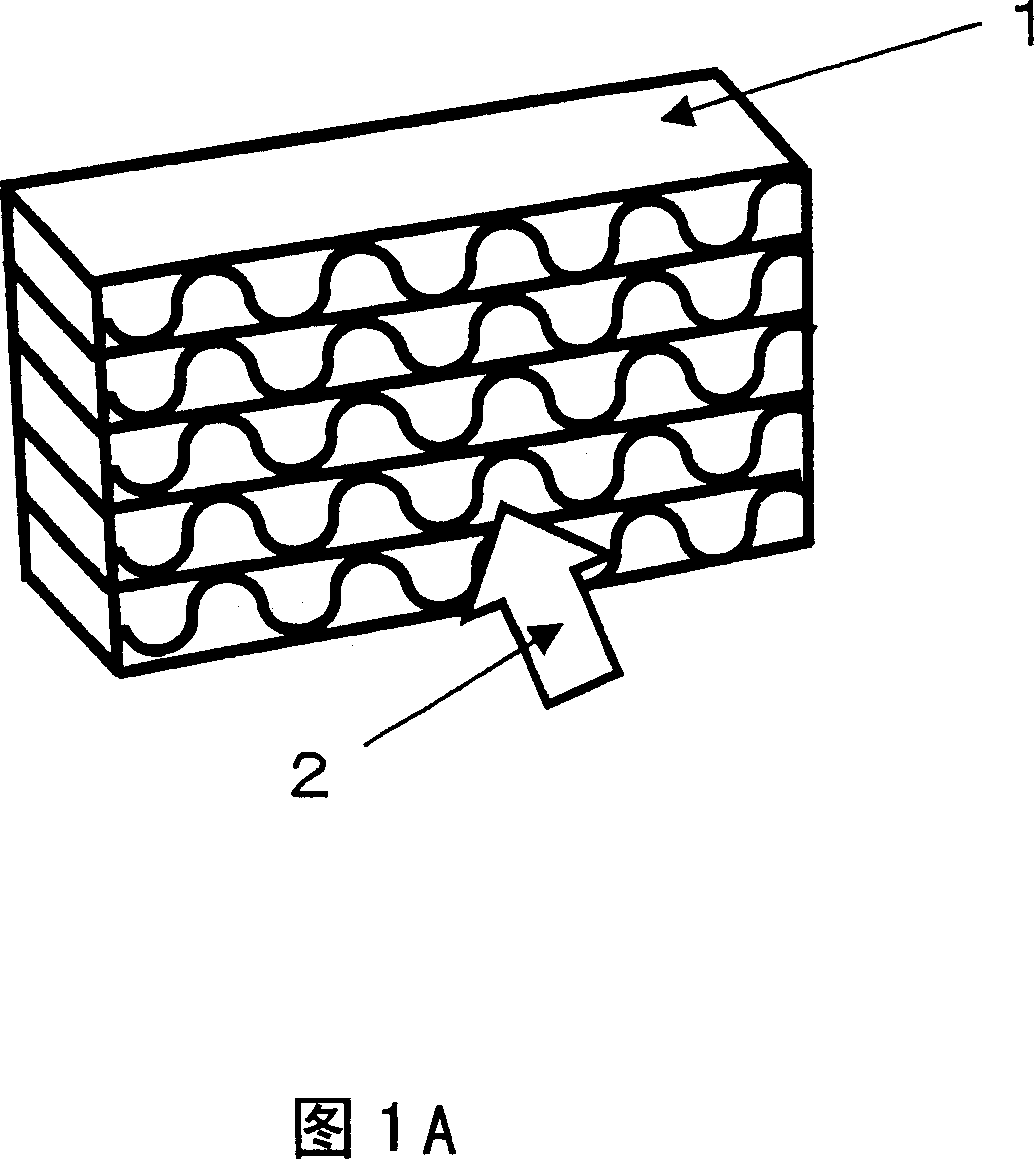

Deodorising composition, device and air conditioner using the same

ActiveCN1947799AImprove impact resistanceReduced ventilation resistanceLighting and heating apparatusSpace heating and ventilation detailsSorbentCarboxylic acid

A deodorizer includes an adsorbent (4) having a physical adsorption capability, an oxide (5) containing cobalt and having a catalytic activity, and a carrier (3) for carrying the adsorbent (4) and the oxide (5). The oxide (5) transforms aldehydes to carboxylic acids, and the adsorbent (4) removes the carboxylic acids by adsorption.

Owner:PANASONIC CORP

Vibration air screen device applied to metal parts

InactiveCN114798195APromote sheddingShedding achievedGas current separationGrinding machinesEngineeringVibration treatment

The invention is applicable to the technical field of screening devices, and provides a vibrating air screening device applied to metal parts, which comprises a shell, a vibrating screen barrel which is positioned in the shell, rotates automatically and vibrates up and down along the axis of the vibrating screen barrel, and a driving mechanism for driving the vibrating screen barrel to move; the vibrating screen barrel comprises an inner barrel and an outer barrel which are fixedly connected with each other; a plurality of sub storage spaces are uniformly distributed between the inner cylinder and the outer cylinder; the inner barrel is provided with a screen barrel inlet; a screen barrel outlet is formed in the outer barrel; a plurality of filter holes are formed in the outer wall of the outer cylinder, and bulges are arranged in the filter holes; a blowing nozzle is arranged on the outer wall of the outer cylinder; in this way, metal parts can be subjected to pile-dividing vibration treatment, the rust layer separation effect can be further promoted, and the rust layer separation efficiency is higher; centrifugal force generated by the vibrating screen barrel is matched with a vibrating effect to realize efficient separation of a rust layer; and during vibration, separated rust layers are blown out by utilizing airflow, so that the metal parts are treated more cleanly.

Owner:潍坊市凯隆机械有限公司

Automatic taking-off personal protective equipment robot

PendingCN111660308AReasonable structural designReduce infectionApparel holdersSurgical glovesPhysical medicine and rehabilitationRobot hand

The invention discloses an automatic taking-off personal protective equipment robot which comprises a platen. Four corners at the bottom end of the platen are all fixedly connected with supporting legs. A glove taking-off device is installed on the left side of the upper end face of the platen. A mask taking-off device is installed on the right side of the glove taking-off device. A goggle taking-off device is installed on the right side of the mask taking-off device. An unzipping mechanism is installed on the right side of the goggle taking-off device. A zipper front clamping mechanism is installed on the right side of the unzipping mechanism. A sleeve pulling-down mechanism is arranged between the unzipping mechanism and the zipper front clamping mechanism. The overall automation degreeof the robot is high, manpower is replaced by mechanical arms to take off the dirtiest equipment on the outermost layer such as gloves, masks, goggles and protection suits, infection of medical workers is effectively reduced, safety of the medical workers is effectively guaranteed, in addition, the taking-off efficiency is improved, the prospect is good, and popularization is easy.

Owner:CHILDRENS HOSPITAL OF FUDAN UNIV

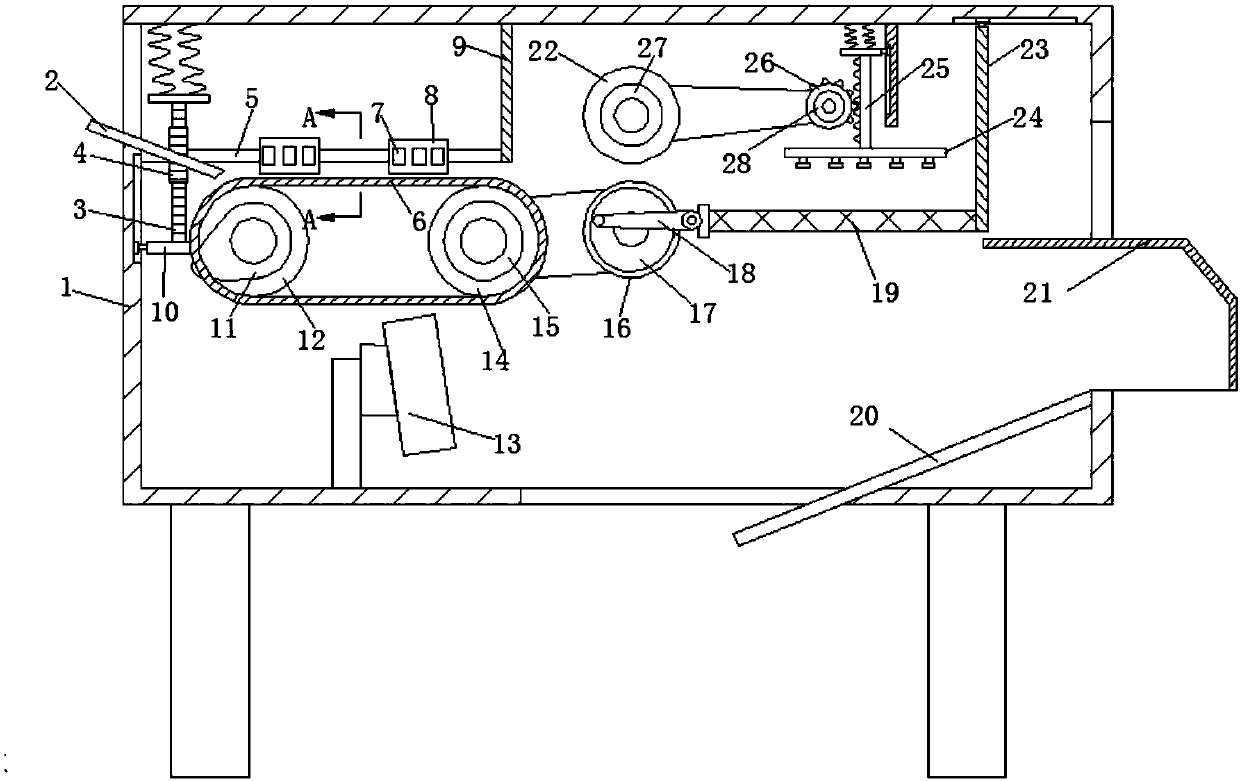

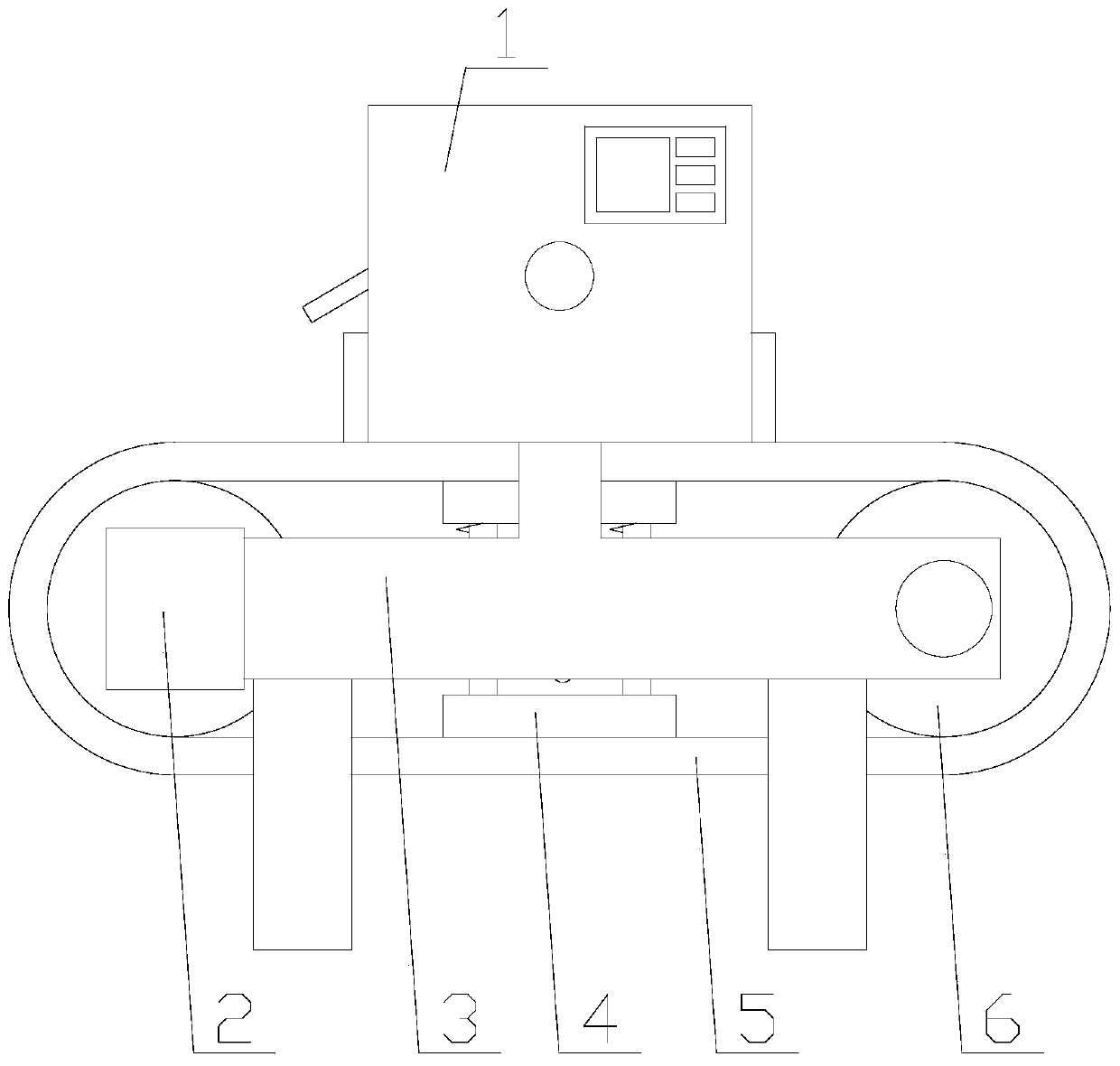

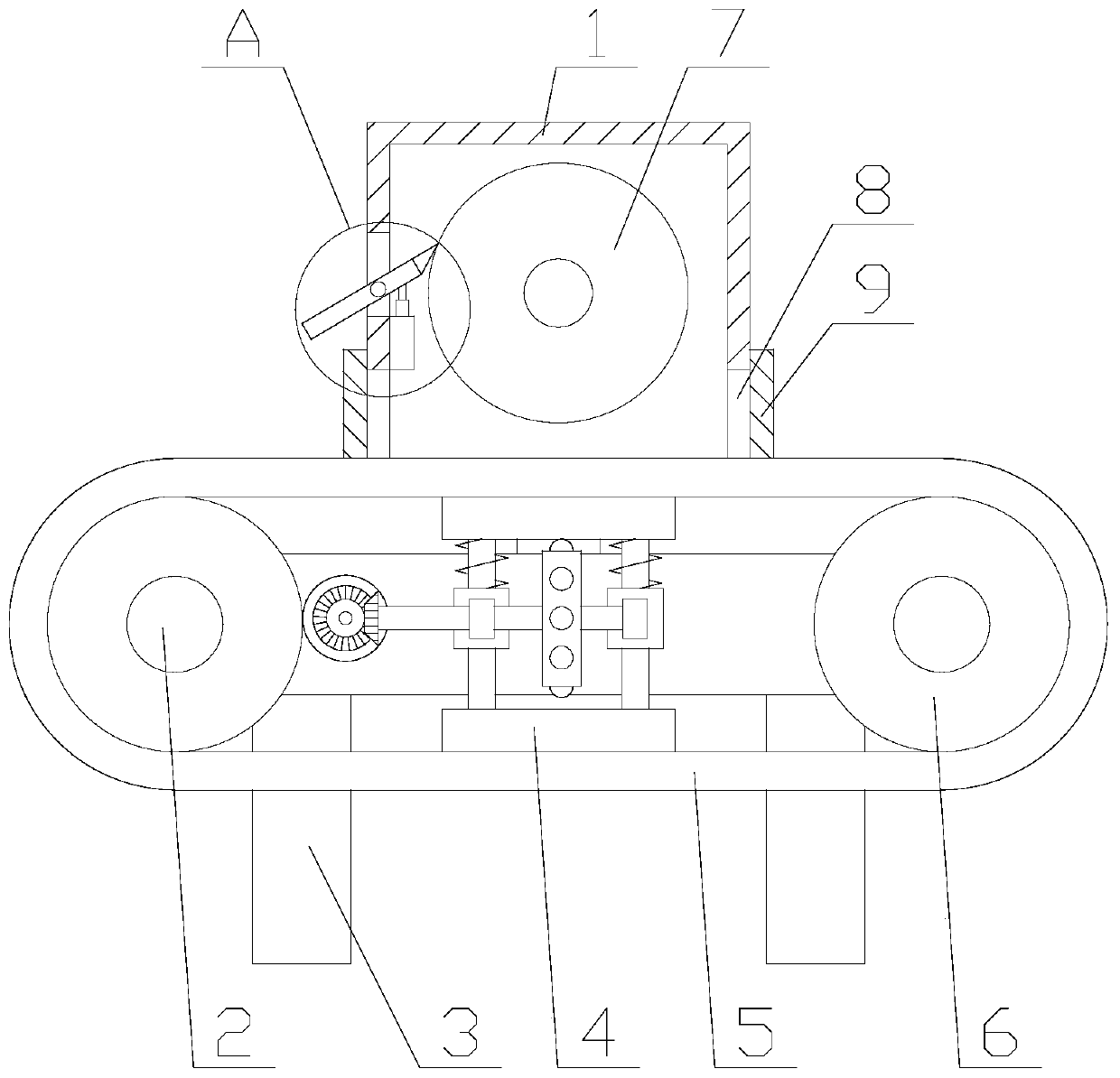

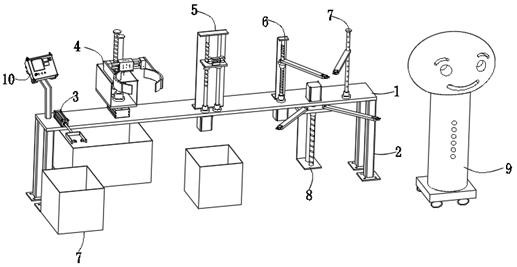

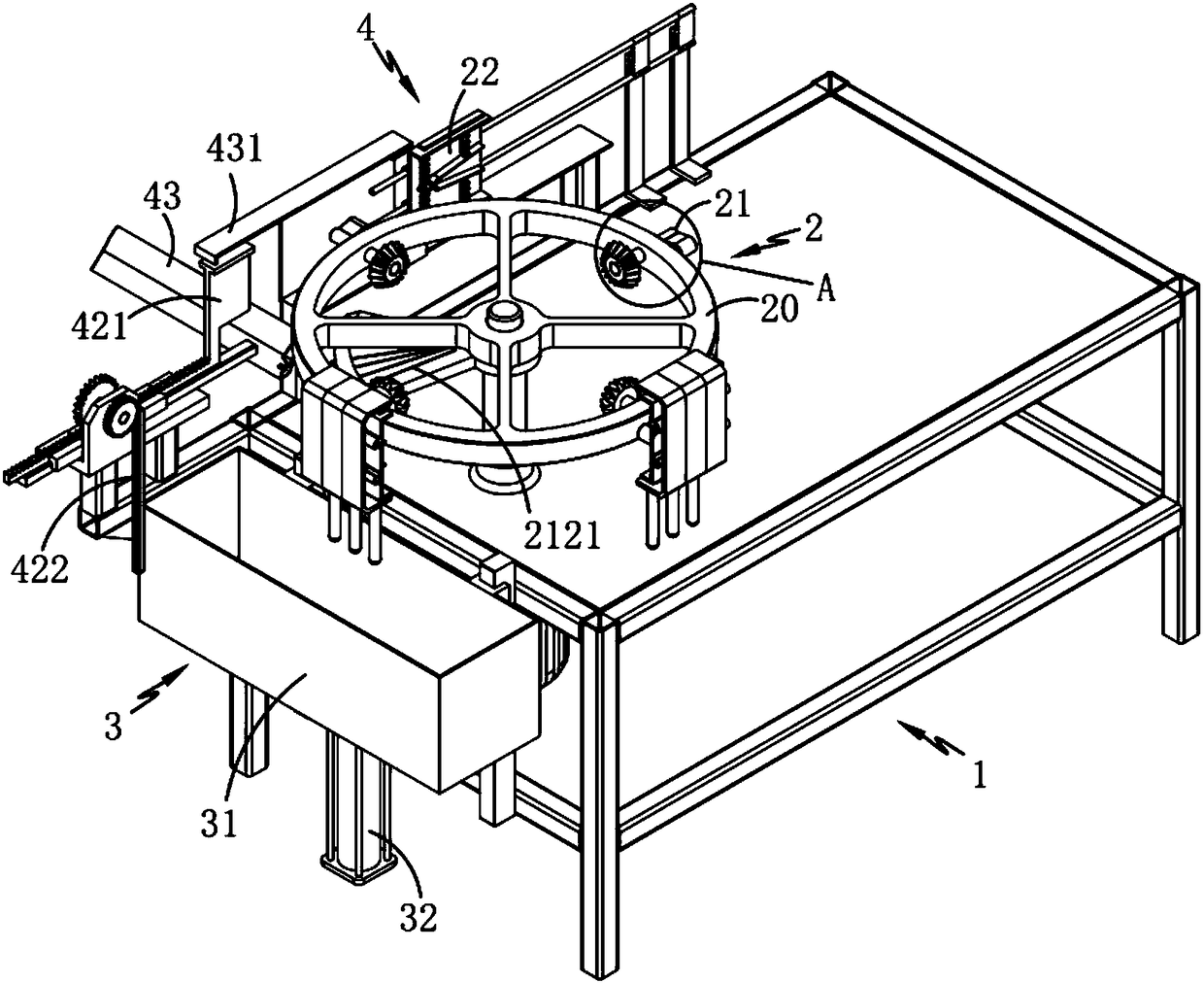

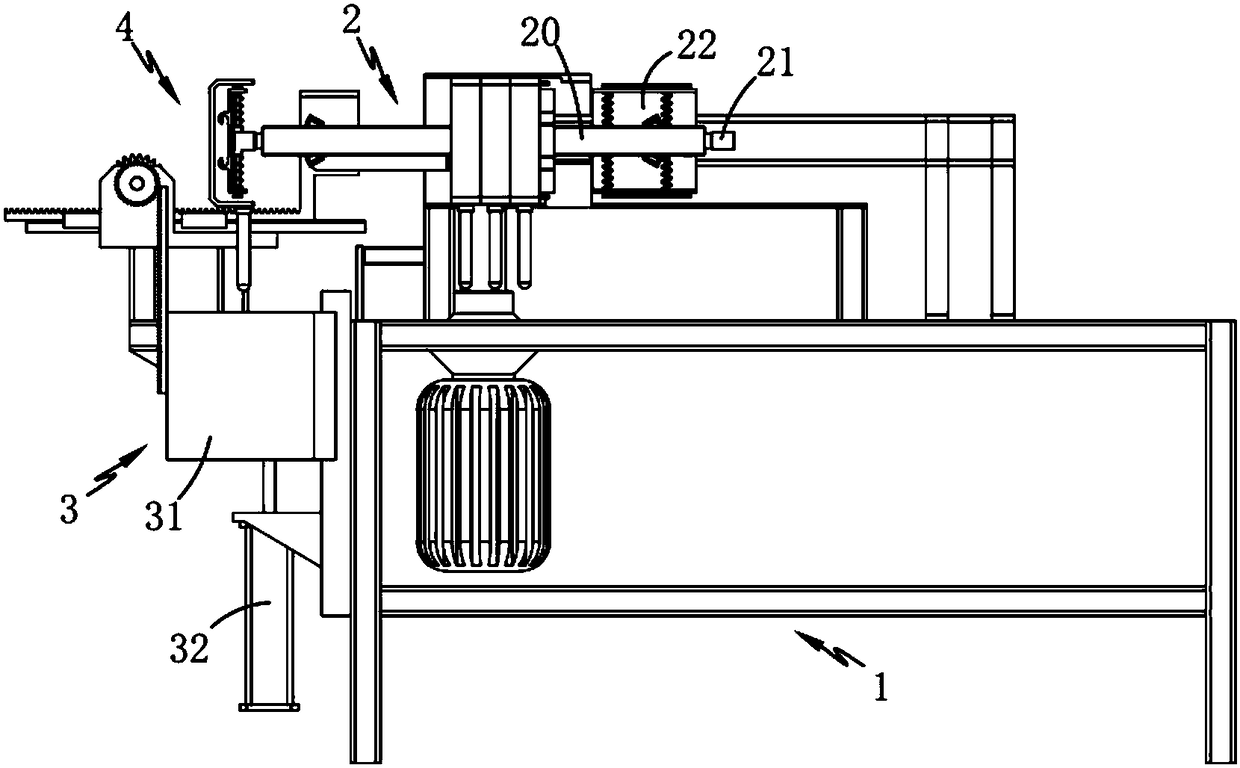

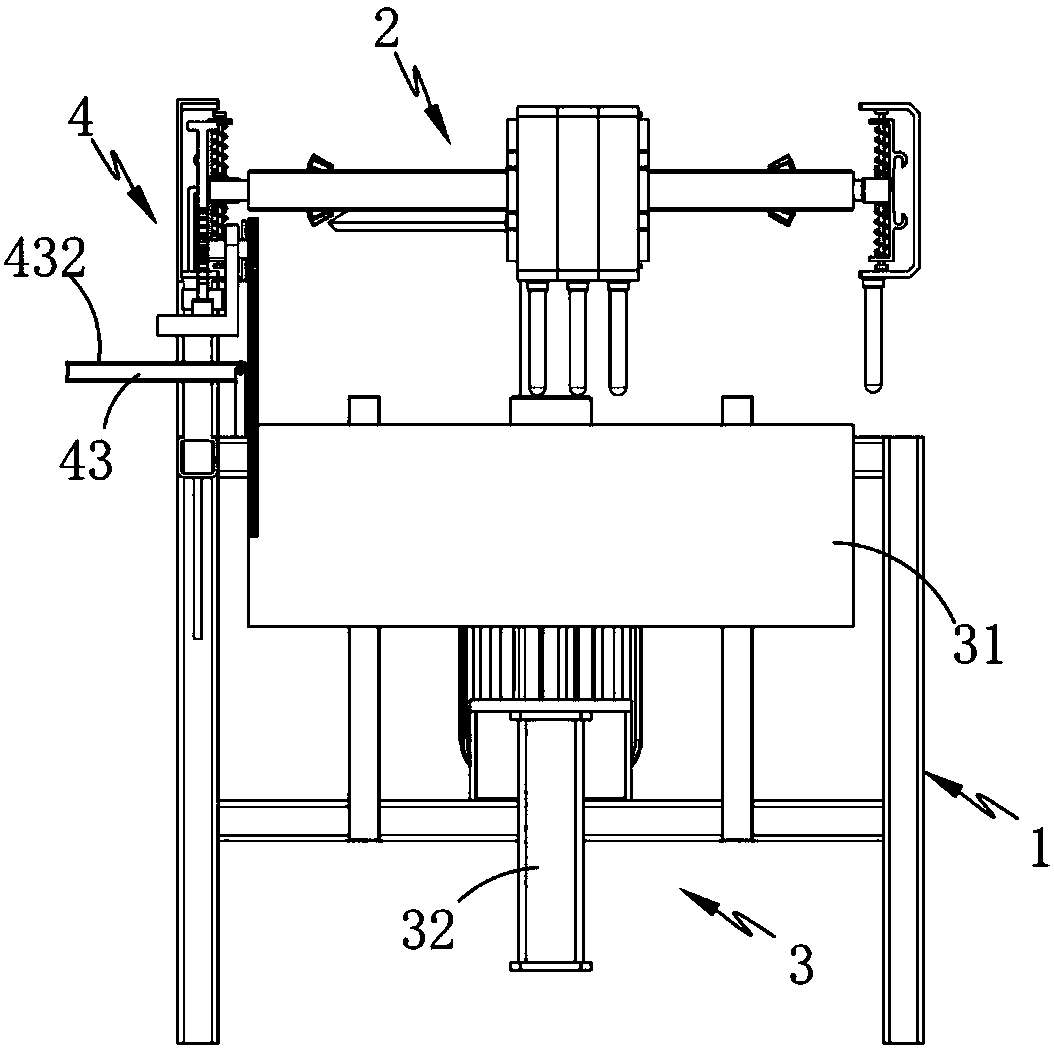

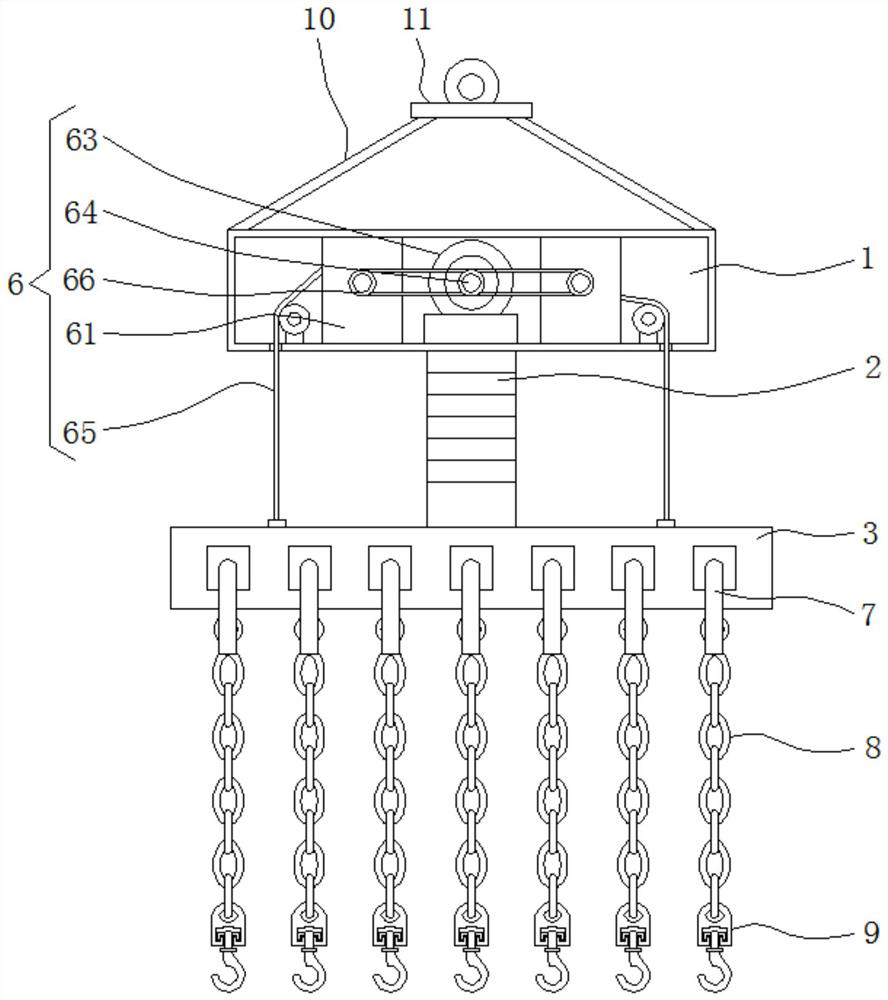

Automatic plastic dipping production line for metal products

ActiveCN108525957AAvoid drippingImprove detachment efficiencyLiquid surface applicatorsCoatingsProduct PartMetal

The invention relates to the technical field of plastic dipping production, and in particular relates to an automatic plastic dipping production line for metal products, the automatic plastic dippingproduction line comprises a frame, a transfer assembly, a plastic dipping assembly and an output assembly, wherein the transfer assembly is mounted on the frame, and comprises a conveying portion, a fixing portion and a clamping assembly, the conveying portion is used to transfer a work station of a to-be-dipped part, the fixing portion is used for placing the to-be-dipped part, the clamping assembly is mounted on the fixing portion and is used for holding the to-be-dipped part, the plastic dipping assembly is arranged on one side of the transfer assembly, and includes a plastic dipping chamber containing a plastic dipping liquid inside, and a driving portion for driving the plastic dipping chamber to move up and down, the output assembly includes a discharging portion for separating the clamping assembly from the fixing portion, a separating part and an output part, the separating part is in driving connection with the plastic dipping chamber, and is used for transferring the clampingassembly and a finished product part, the output part is used to transfer and output a finished product machine, the conveying portion is used to transfer the to-be-dipped part located on the fixingportion, and meanwhile flip and quickly output to realize automatic discharging of a concave jig; and the automatic plastic dipping production line solves the technical problem that the plastic dipping production in the prior art is in inefficient.

Owner:阜阳汇中芯自动化技术有限公司

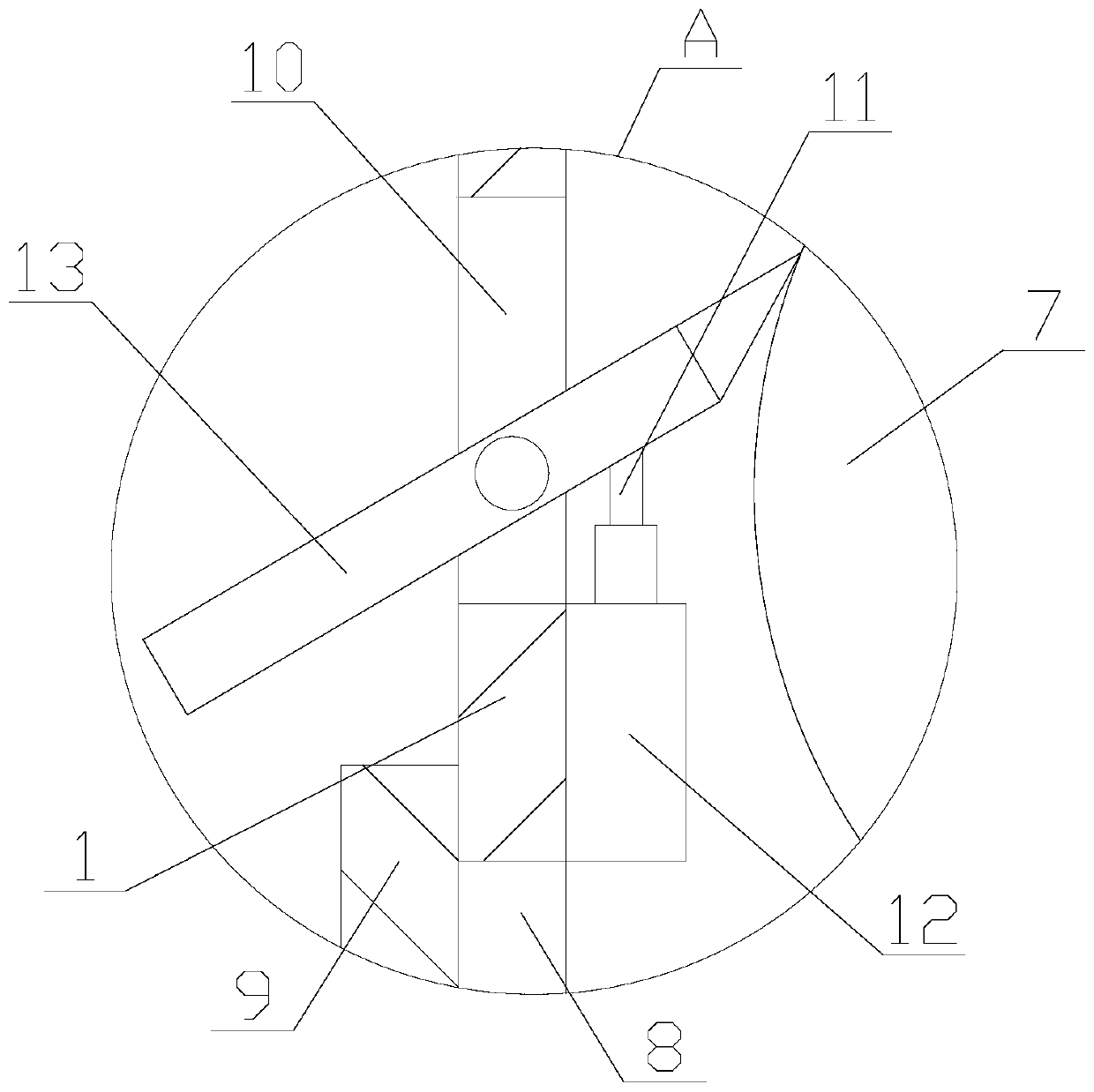

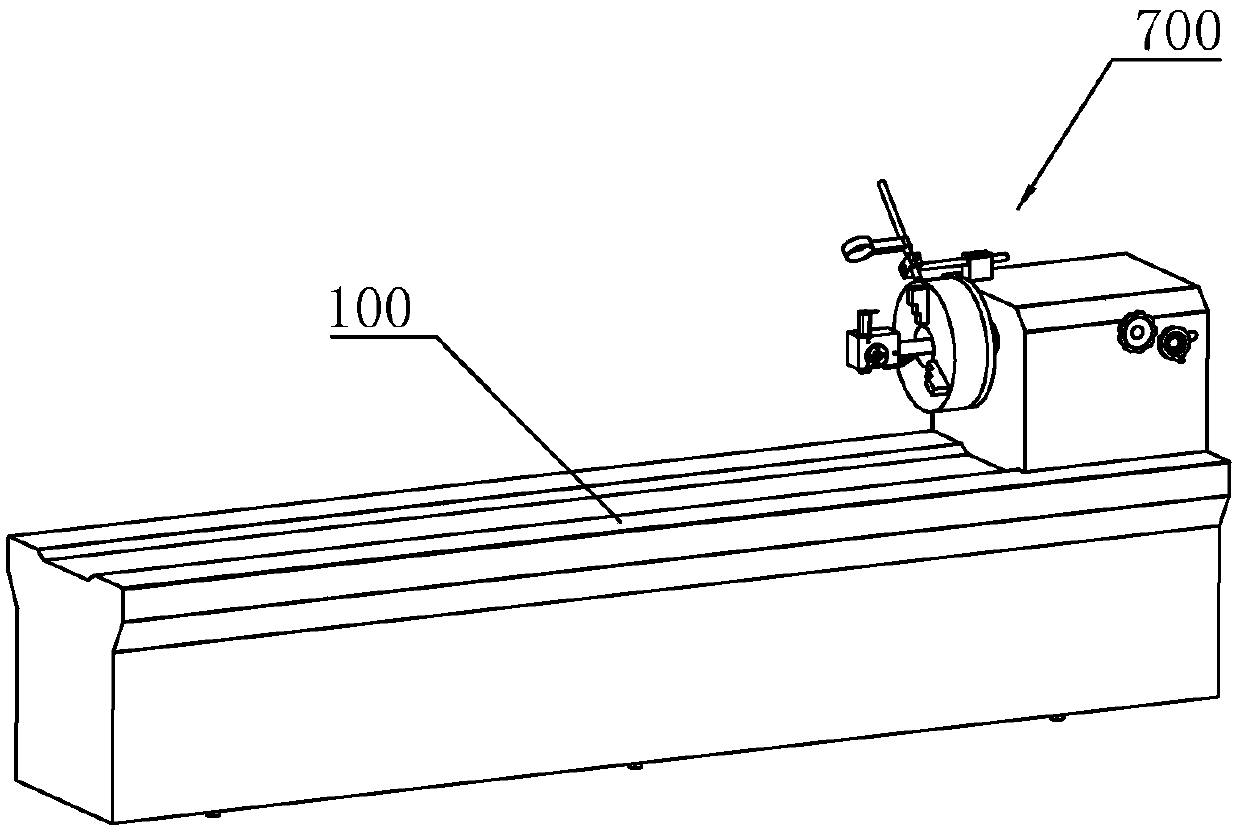

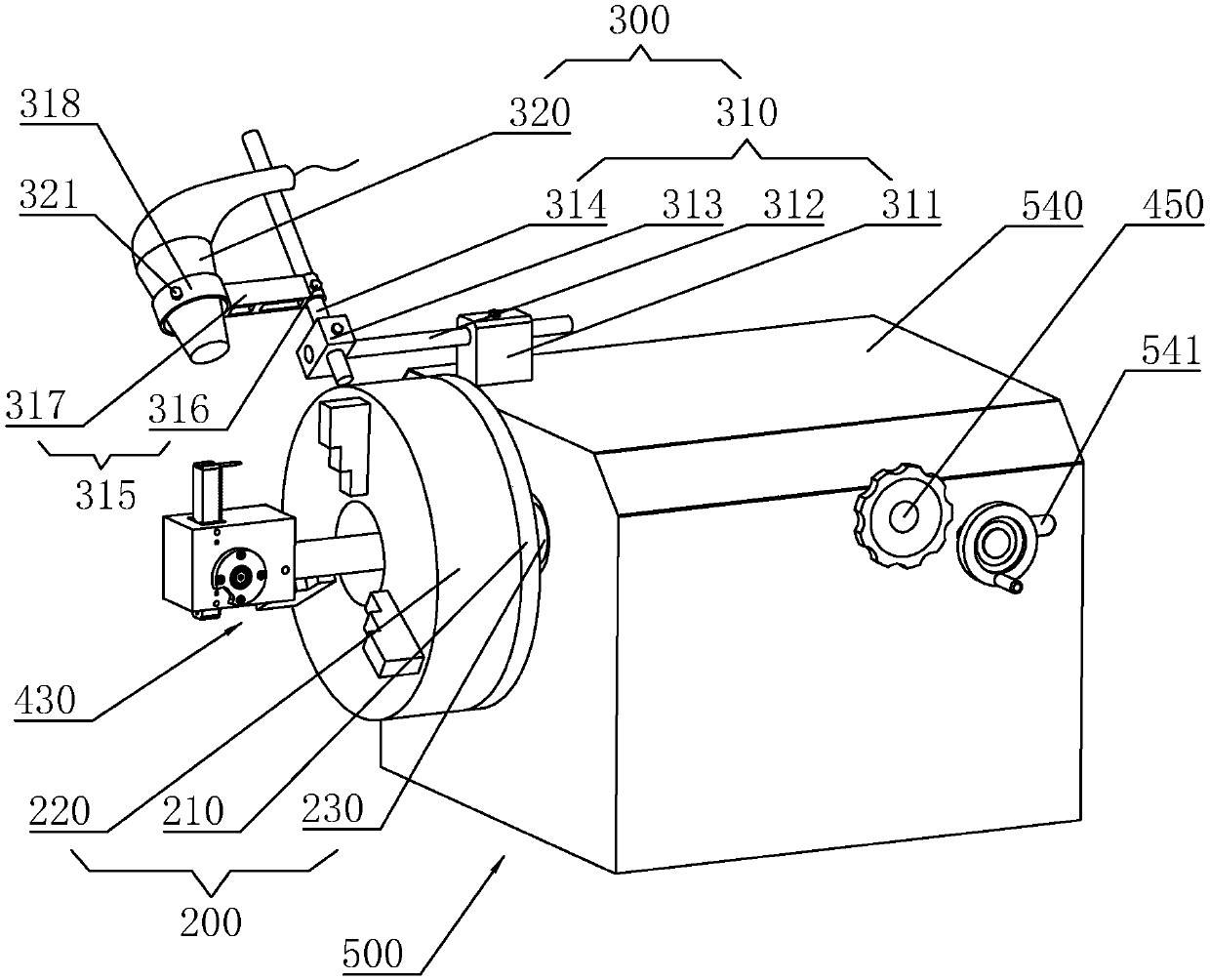

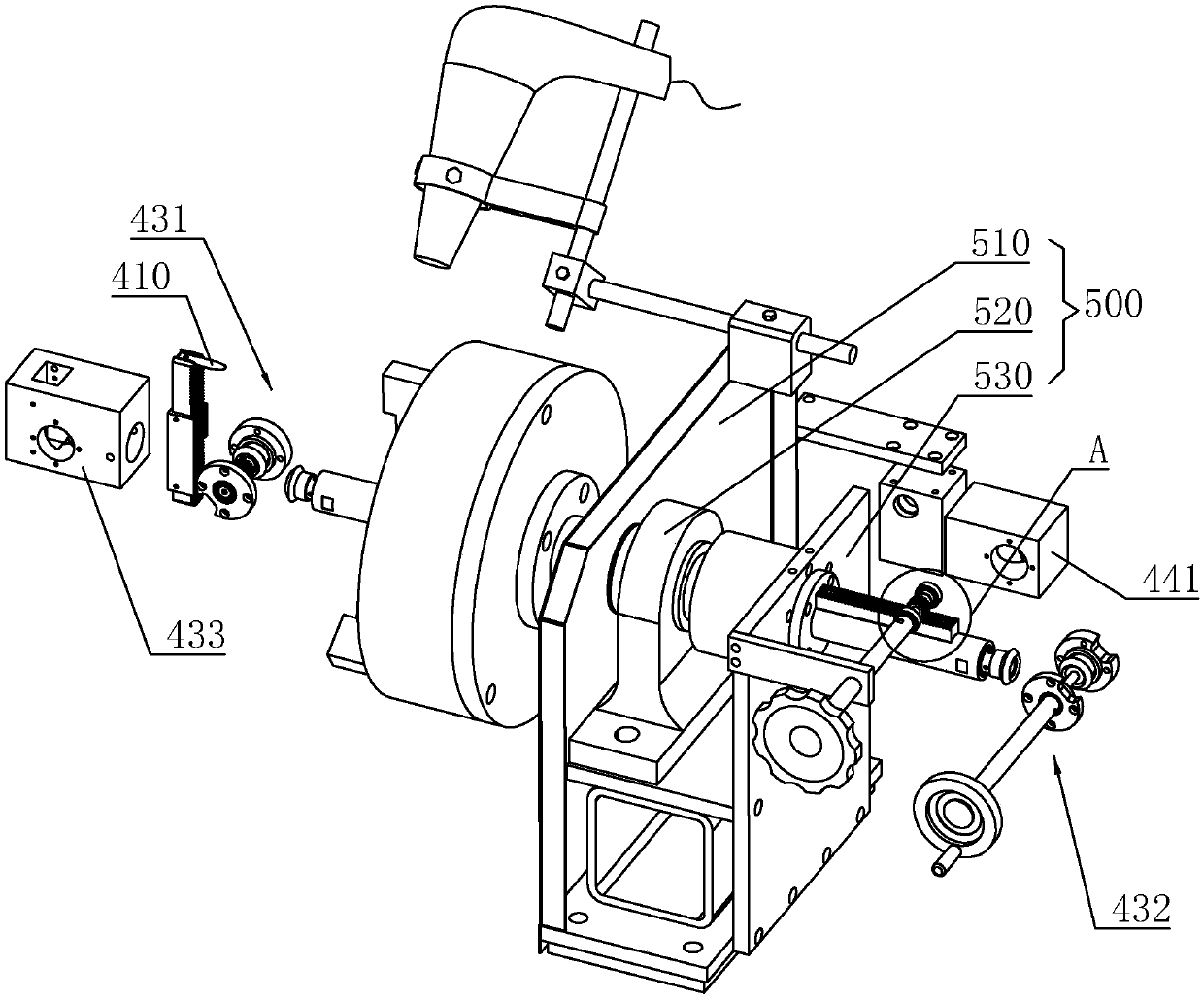

Circular net choke plug removing machine

ActiveCN109624503AReduced soaking stepsImprove the efficiency of de-boiling headPrinting press partsPulp and paper industryThe chokes

The invention discloses a circular net choke plug removing machine, and relates to the technical field of matching equipment of a circular net washing machine. The circular net choke plug removing machine comprises a workbench, wherein at least one end of the workbench is provided with a choke plug separating device, the choke plug separating device comprises a mounting plate set, a choke plug clamping mechanism, a heating mechanism and a stripping mechanism, the mounting plate set is fixedly connected to one end of the workbench, the choke plug clamping mechanism is rotationally connected tothe mounting plate set, the heating mechanism is connected to the connecting position of a choke plug and a circular nickel net and is connected to the mounting plate set, and the stripping mechanismis used for stripping the choke plug and the circular nickel net; and the stripping mechanism comprises a stripping blade and a position adjusting assembly, the position adjusting assembly is connected with the stripping blade and used for adjusting the relative position between the stripping blade and the choke plug, and the position adjusting assembly is connected to the mounting plate set. Theadhesive between the choke plug and the circular nickel net is subjected to hot melting through the heating mechanism, the stripping blade is used for separating the choke plug and the circular nickelnet, and the soaking work of the choke plug stripping agent is not needed, so that the soaking step is reduced; and by utilizing the equipment, the action of removing the choke plug can be completedonly by about 10 minutes, and the efficiency of removing the chock plug is greatly improved.

Owner:SHAOXING XINCHANG PRINTING MACHINERY TECH CO LTD

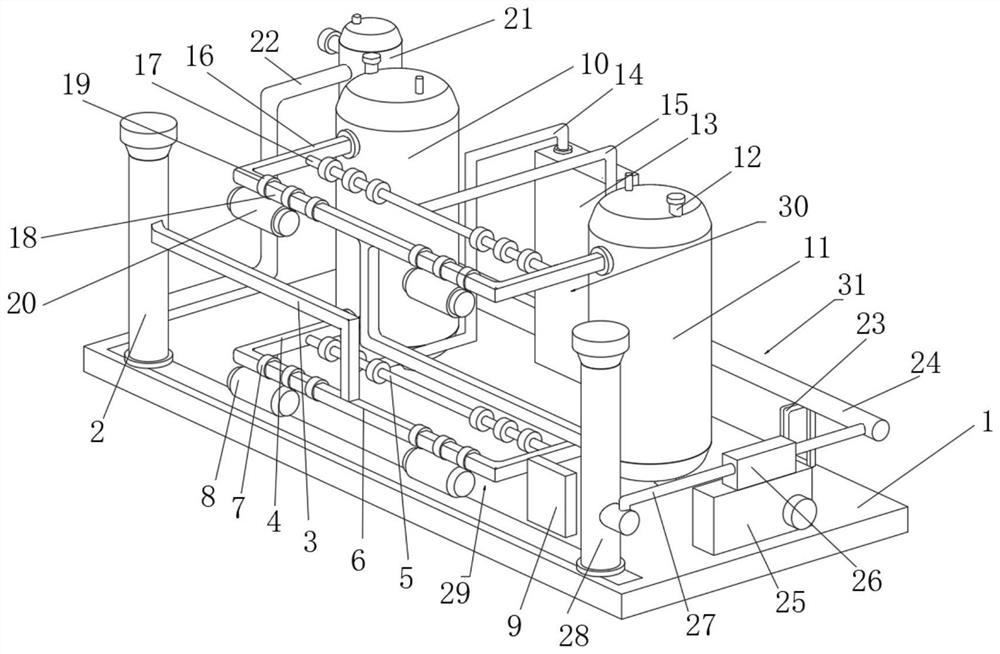

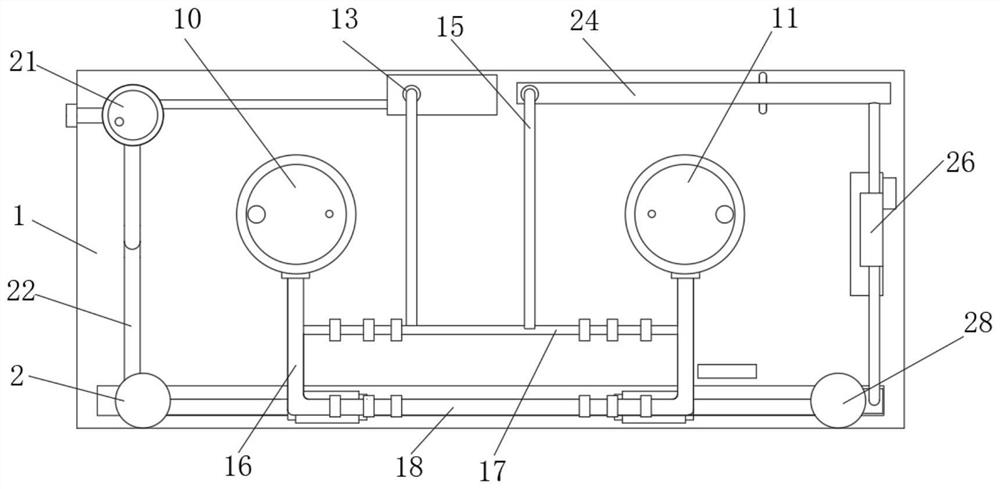

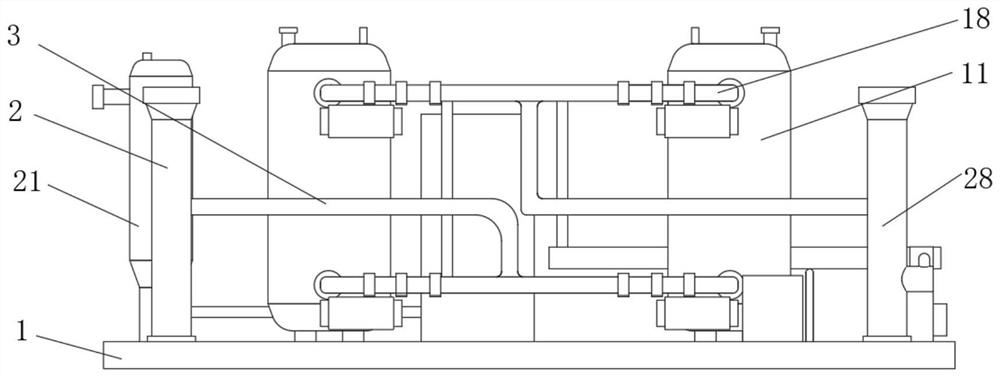

Molecular sieve dehydration pry for heating regenerated natural gas with high reliability

The invention discloses a high-reliability heating regenerated natural gas molecular sieve dehydration pry, and relates to the field of raw gas exploitation treatment, the high-reliability heating regenerated natural gas molecular sieve dehydration pry comprises a support, a first molecular sieve dryer and a second molecular sieve dryer are arranged at the upper end, close to the middle position, of the support, and valves are arranged at the upper ends of the first molecular sieve dryer and the second molecular sieve dryer; exhaust mechanisms are arranged at the tops of the first molecular sieve dryer and the second molecular sieve dryer, air inlet mechanisms are arranged at the bottoms of the first molecular sieve dryer and the second molecular sieve dryer, and a circulating mechanism is arranged at the position, located on one side of the first molecular sieve dryer, of the upper end of the support; a separation filter is arranged at the upper end, close to one side corner, of the bracket; according to the shale gas filtering and drying device, shale gas can be filtered and dried in a multi-stage mode, the shale gas filtering and drying effect can be effectively improved, the device forms a circulating system through the circulating mechanism, the device can be circularly used for multiple times, and waste of the shale gas cannot be caused.

Owner:浙江机电职业技术学院

Apparatus achieving dynamic vacuum degassing and use method of same

InactiveCN110870989AEnsure consistencyIncreased dissipation rateComponent separationLiquid degasification by filtrationMechanicsElectromagnetic valve

The invention provides an apparatus achieving dynamic vacuum degassing and a use method of same. The apparatus includes a five-way connection pipe, four two-way electromagnetic valves, a degassing cylinder and a passive cylinder, wherein the two-way electromagnetic valves have a two-position connection structure; four ways of the five-way connection pipe are connected respectively to four oil inlet / outlet pipes of the four two-way electromagnetic valves, the rest one way of the five-way connection pipe is connected to the oil inlet / outlet of the degassing cylinder through a connection pipe; the degassing cylinder also has a sample gas outlet; a telescopic rod of the degassing cylinder is telescoped under driving by a driving device; a limit switch for controlling the movement of the telescopic rod is arranged on the degassing cylinder; the oil inlet / outlet of the passive cylinder is connected to one of the two-way electromagnetic valves through an oil path connection pipe. By means ofthe precise cooperation of the driving device and the degassing cylinder, precise metering of detection oil is achieved. The detection oil flows forth and back between the degassing cylinder and the passive cylinder, so that escape rate and separation efficiency of gas are improved, and extremely high degassing efficiency is achieved.

Owner:福建和盛高科技产业有限公司

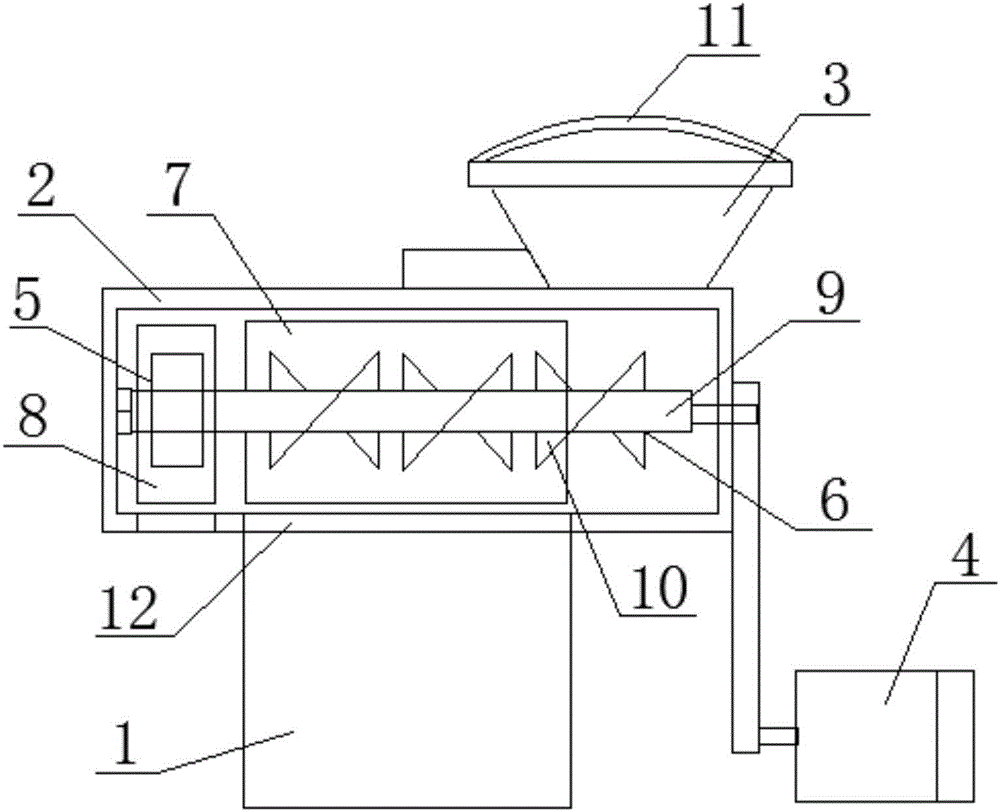

Smashing corn thresher

The invention relates to a smashing corn thresher. The smashing corn thresher comprises a corn storage box, a threshing box, a feeding box and a motor. The threshing box is arranged at the upper end of the corn storage box, the feeding box is disposed on one side of the upper end of the threshing box, a rotary blade assembly is arranged in the threshing box, one end of the rotary blade assembly extends out of the threshing box and is connected with an output shaft of the motor through a belt, the output shaft of the motor drives the rotary blade assembly to rotate through the belt, the threshing box is disposed outside the rotary blade assembly, the bottom of the threshing box is communicated with the corn storage box, a corncob discharge chamber is arranged at the tail end of the rotary blade assembly, and a corncob guide opening is formed in the bottom of the corncob discharge chamber; a smashing device is arranged in the corncob discharge chamber and used for smashing corncobs. Compared with the prior art, the structure is simplified, the corncobs can be smashed, and the threshing efficiency is improved.

Owner:苏怀

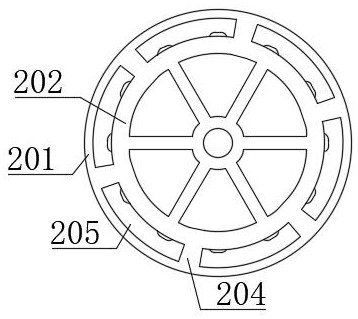

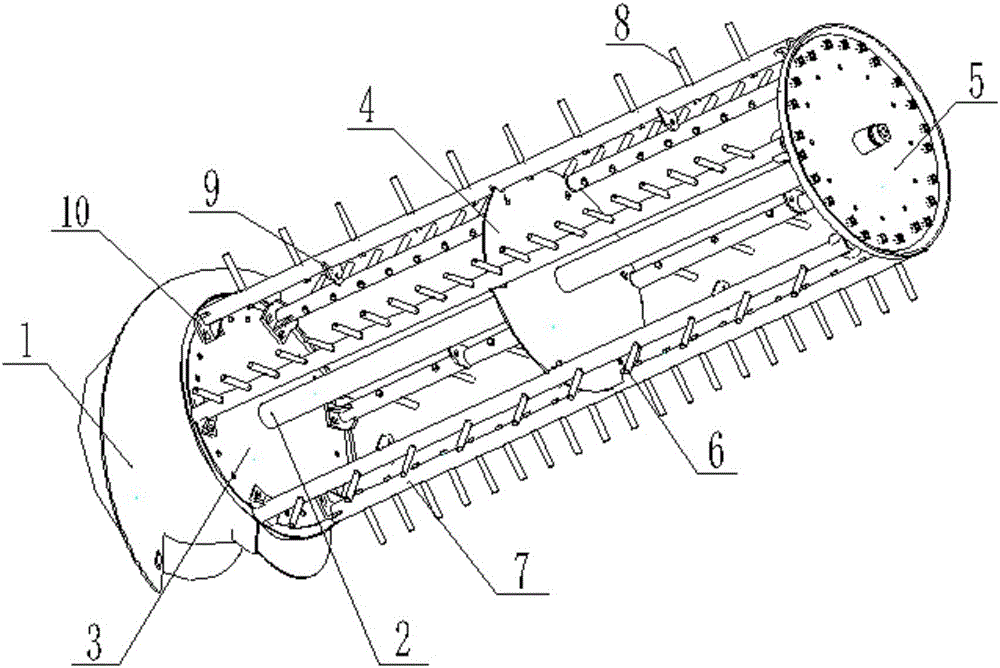

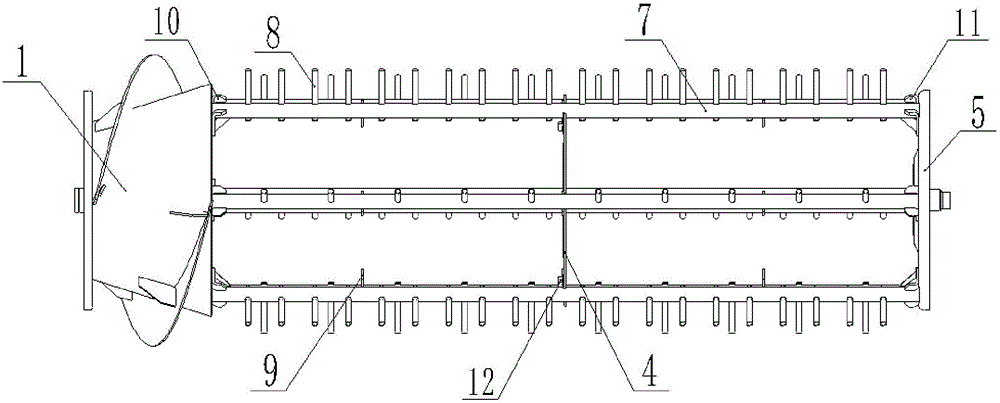

Combine harvester threshing cylinder assembly

InactiveCN104996071ASimple structureEasy to install and maintainMowersThreshersControl engineeringCombine harvester

The invention discloses a combine harvester threshing cylinder assembly. The combine harvester threshing cylinder assembly comprises a front assembly, a main shaft, a front main shaft connecting plate, a middle main shaft connecting plate, a rear main shaft connecting plate, installation holes, connecting rods, grain beating teeth, installation sheets, front installation seats, rear installation seats and bolts. The front assembly is fixedly installed on the front main shaft connecting plate, the front end of the main shaft is fixedly installed in the installation hole of the front assembly, the rear end of the main shaft is fixedly installed in the center hole of the rear main shaft connecting plate, the connecting rods are radially provided with the plurality of grain beating teeth, the front installation seats are fixedly installed in clamping grooves at the front ends of the connecting rods, the rear installation seats are fixedly installed in camping grooves at the rear ends of the connecting rods, the connecting rods are fixedly provided with the installation sheets, the front installation seats are installed at the front main shaft connecting plate, the rear installation seats are installed at the rear main shaft connecting plate, and the middle main shaft connecting plate is installed on the installation sheets of the connecting rods. The combine harvester threshing cylinder assembly is simple in structure, convenient to install and maintain and low in cost; and the combine harvester threshing cylinder assembly is provided with the six connecting rods, the disengagement effect is good, and the disengagement efficiency is high.

Owner:DANYANG RONGJIA PRECISION MACHINERY

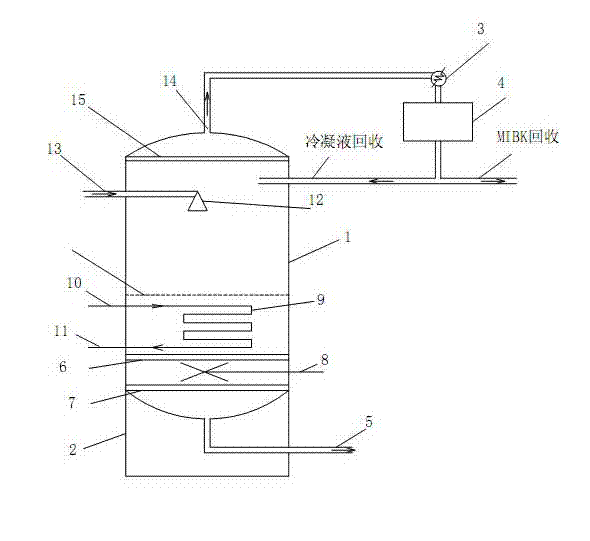

Device for removing MIBK (Methyl Iso Butyl Ketone) from raffinate for MIBK extraction and zirconium and hafnium separation

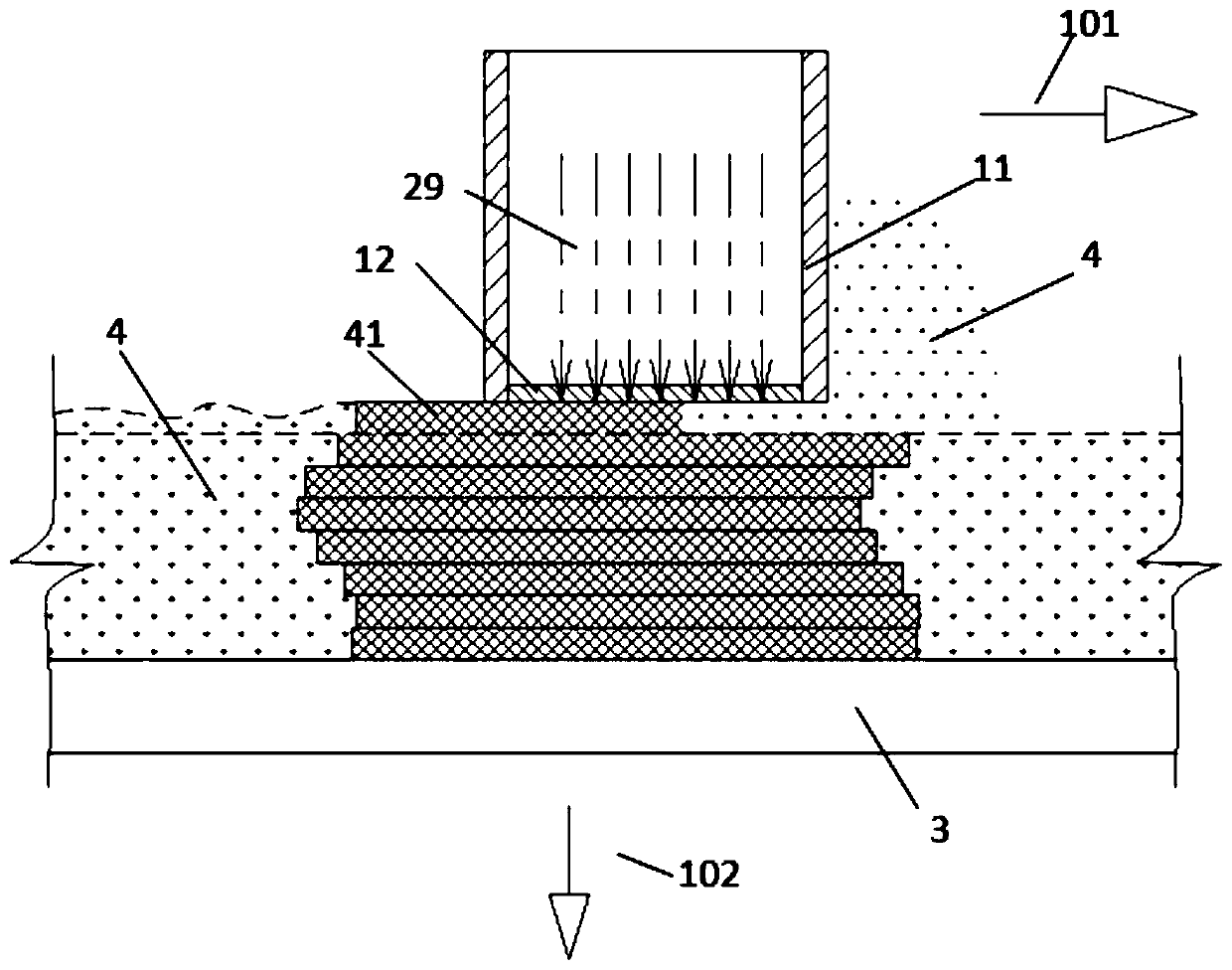

InactiveCN102389642AImprove detachment efficiencyIncrease contact areaDistillation separationProcess efficiency improvementGas phaseKetone

The invention discloses a device for removing MIBK (Methyl Iso Butyl Ketone) from a raffinate for MIBK extraction and zirconium and hafnium separation. The device comprises a shell, a condenser and a phase-separating barrel, wherein a removed organic raffinate outlet is formed at the bottom inside the shell; an upper supporting grid plate and a lower supporting grid plate are crosswise arranged on a lower part inside the shell; a gas inlet is formed on a side wall of the shell between the upper supporting grid plate and the lower supporting grid plate; a heating device is arranged on the upper supporting grid plate; a liquid distributor with a raffinate feeding port is arranged at the top inside the shell; a steam overflow port is mounted at the top of the shell and is connected to the condenser; the phase-separating barrel is used for separating an organic phase from a water phase; the organic phase is recycled; and an output pipeline of the phase-separating barrel is connected to the shell. The device provided by the invention is beneficial to increasing a contact area between a gas phase and a liquid phase and promoting a MIBK removing efficiency, thereby achieving a purpose of quickly removing oil. The device is simple in structure, convenient and practicable, and is characterized by capabilities of increasing production efficiency, lowering production cost, promoting product quality, and the like.

Owner:JIANGXI KINGAN HI TECH

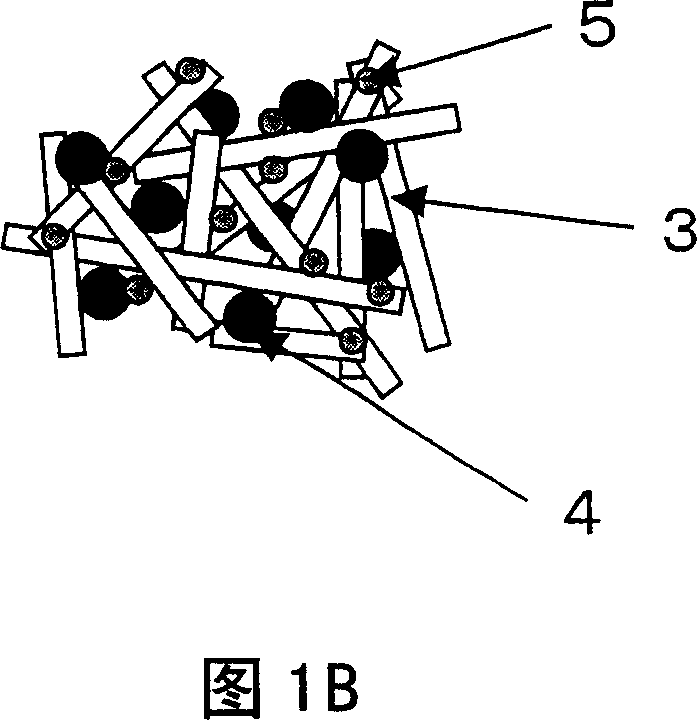

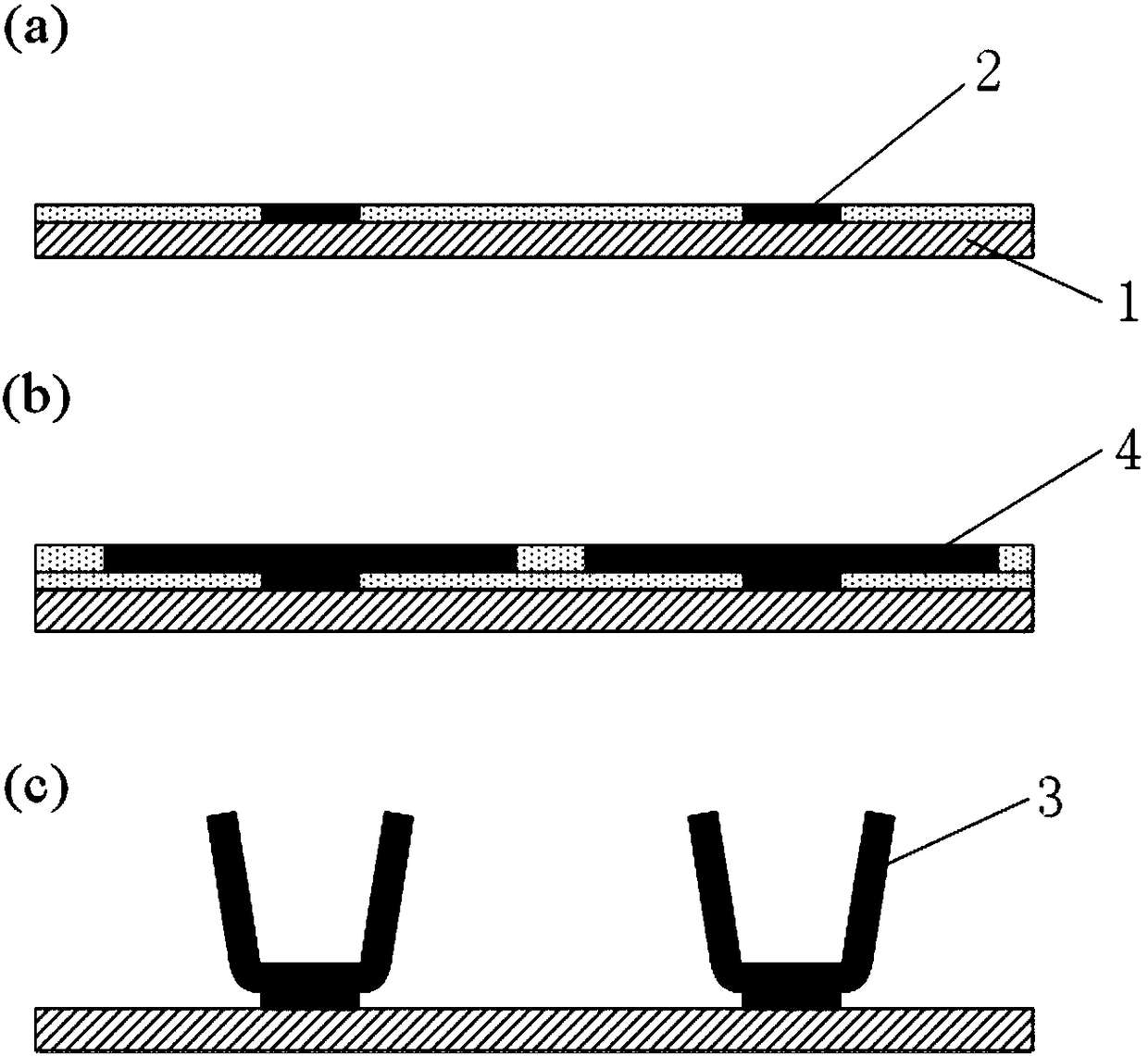

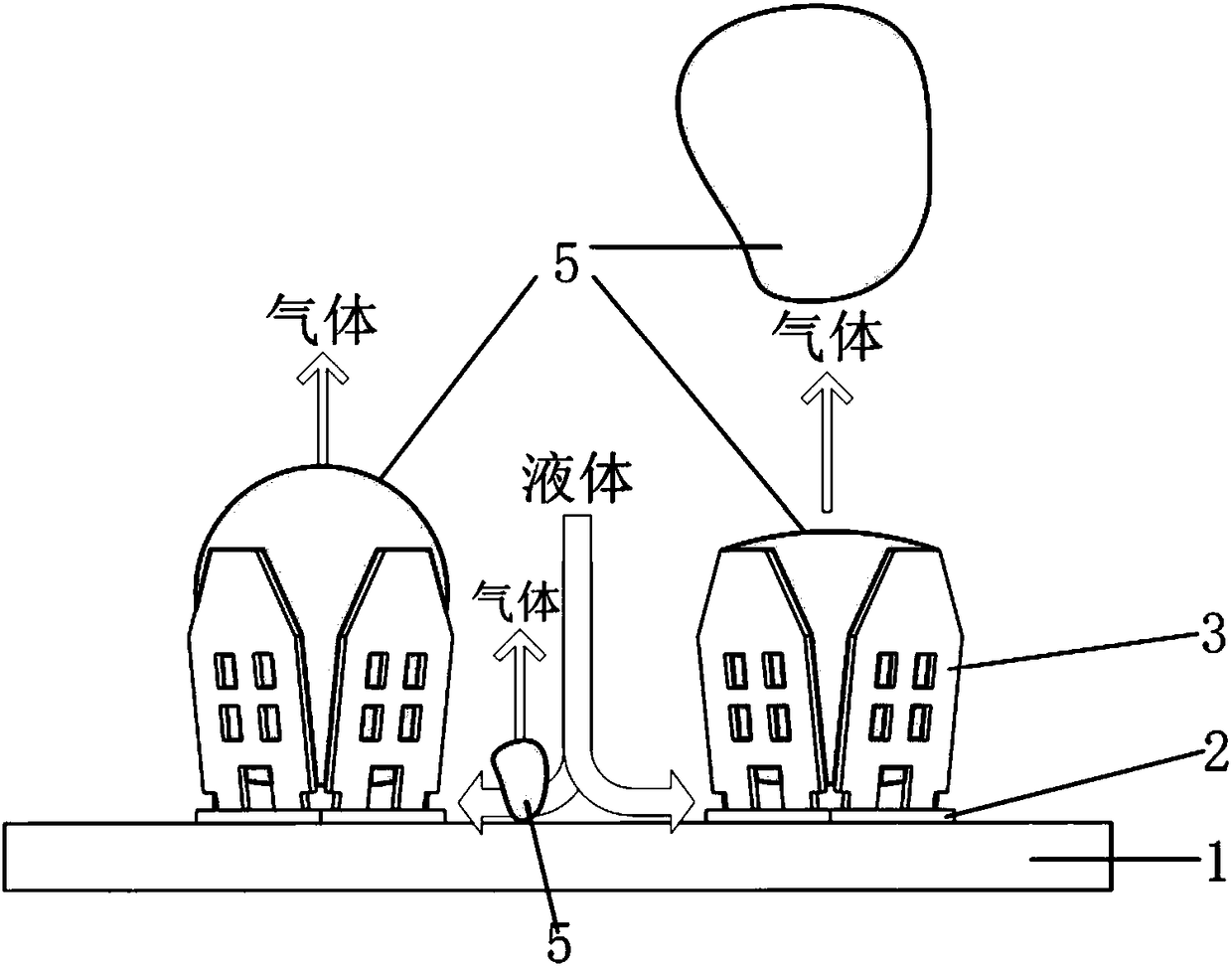

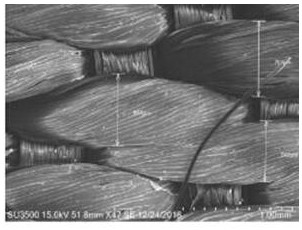

Chip integrated boiling enhancement heat exchange structure and preparation method thereof based on MEMS (Micro Electro Mechanical System) technology

ActiveCN108231712AEnhanced disengagement rateImprove detachment efficiencySemiconductor/solid-state device detailsSolid-state devicesHeat conductingEngineering

The invention provides a chip integrated boiling enhancement heat exchange structure and a preparation method thereof based on an MEMS (Micro Electro Mechanical System) technology. The chip integratedboiling enhancement heat exchange structure comprises a heat conducting substrate, wherein a supporting layer is arranged on the surface of the heat conducting substrate; a plurality of claw type structures are arranged on the supporting layer; the claw type structures are obtained by preparing suspended metal sheet structures by adopting a surface micro-machining method, and folding the suspended metal sheet structures along plane normal thereof. According to the chip integrated boiling enhancement heat exchange structure disclosed by the invention, a path of combining and growing a large amount of surface bubbles into an air film is blocked off by the array claw type structures, so that the dry burning risk is avoided; porous structures can be prepared in the side walls of the claw typestructures so as to ensure liquid supply below the bubbles in the cavity and intensify the separating efficiency of the bubbles; the effects of increasing the heat exchange area by the claw type structures and further intensifying heat exchange by using bubble turbulence and convection of the metal side wall can be realized. Besides, the designed substrate material and a processing mode are derived from a chip integration technology, and application of the structure in integrated heat dissipation of electronic devices is favorably realized.

Owner:SHANGHAI JIAO TONG UNIV

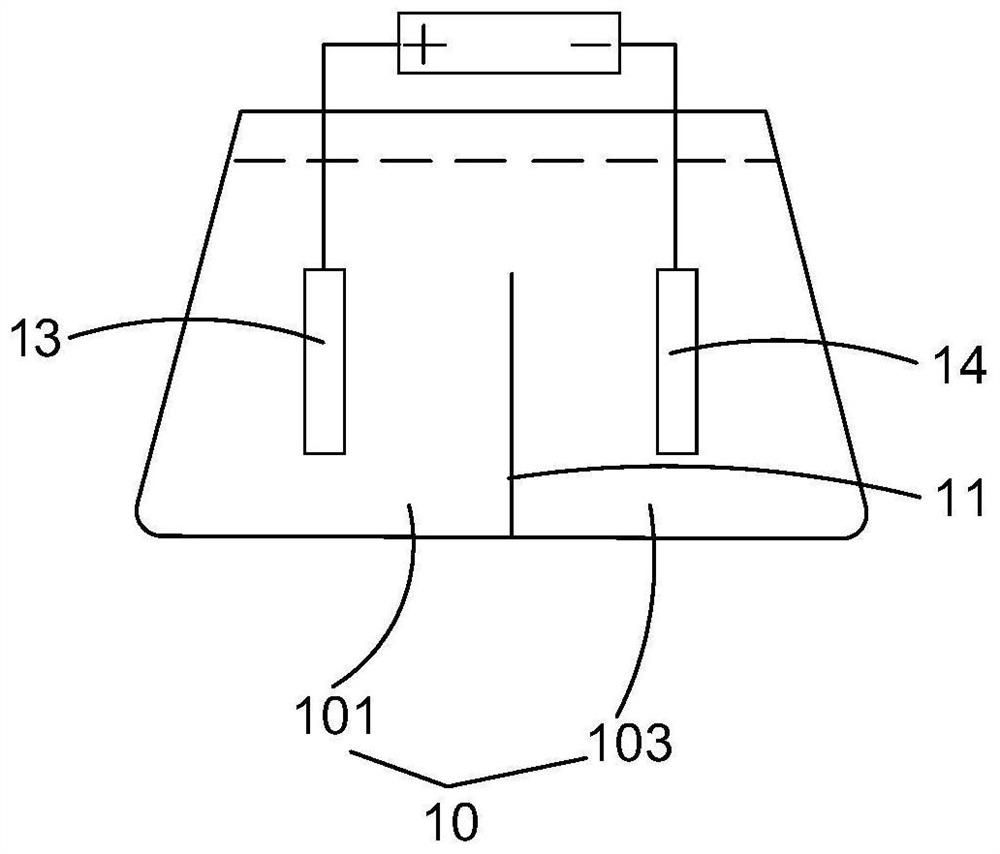

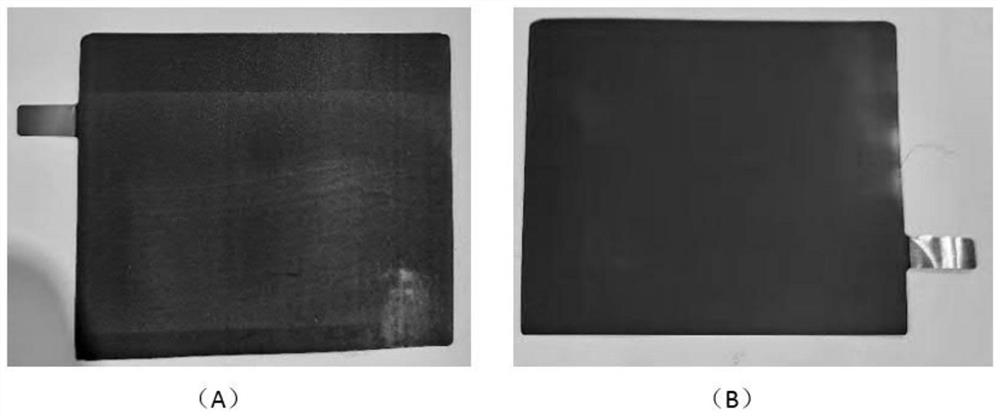

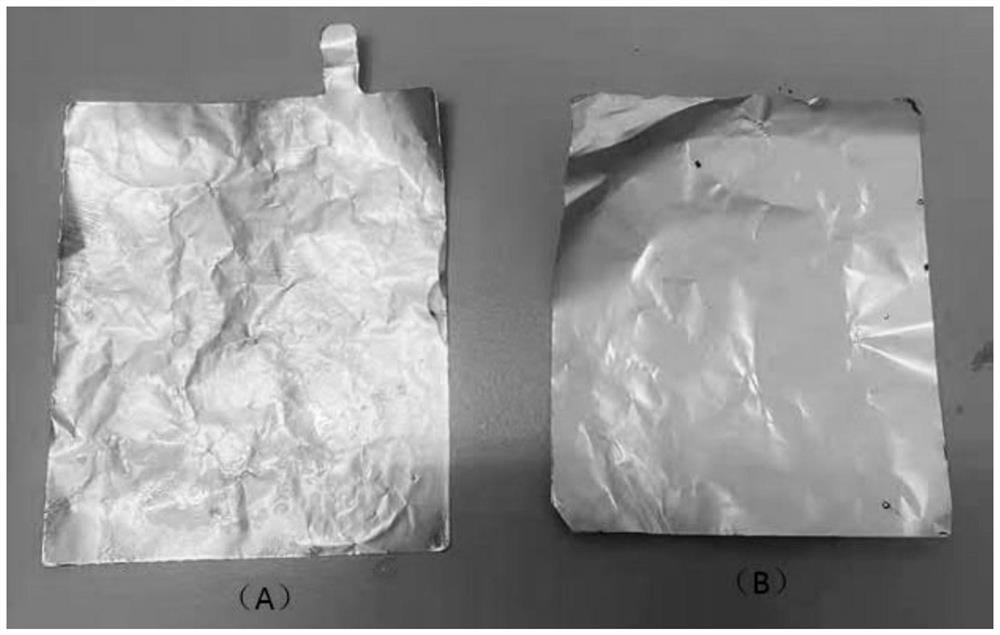

Method for separating and recycling waste lithium battery pole piece material

ActiveCN113904014AAchieve separationAchieving processing powerWaste accumulators reclaimingNon-aqueous electrolyte accumulator electrodesPole pieceProcess engineering

The invention discloses a method for separating and recycling a waste lithium battery pole piece material, and belongs to the field of lithium battery recycling. The method for separating and recycling the waste lithium battery pole piece material comprises the following steps that: S1, a pole piece of a waste lithium battery is obtained, wherein the pole piece comprises a current collector and a coating layer formed on the surface of the current collector; and S2, an anode and a cathode are provided, a positive plate in the pole piece is taken as the anode, and / or a negative plate in the pole piece is taken as the cathode, in an alkaline electrolyte aqueous solution, the anode and the cathode are electrified to perform high-current pulse charge-discharge cycle treatment to electrolyze water, and then the anode and the cathode are soaked in an acidic aqueous solution, at least part of the coating layer on the pole piece is separated from the current collector, the current in the high-current pulse charge-discharge cycle treatment is 2-10 C, and the charge-discharge interval is 5-60 s. On the premise of simplifying the recovery process, the fluid and the coating can be effectively separated and recovered, the recovery and separation efficiency is high, and the purity of a final product is high.

Owner:SONGSHAN LAKE MATERIALS LAB +1

Threshing device for corn harvesting

ActiveCN113273390AImprove detachment efficiencyAvoid damageThreshersAgricultural engineeringAgricultural science

The invention relates to a threshing device for corn harvesting. The threshing device comprises a screening and dust removal module, a corn threshing module and a power mechanism. The screening and dust removal module is fixedly connected with the corn threshing module; the power mechanism is arranged between the screening and dust removal module and the corn threshing module in a penetrating mode; and one side of the power mechanism is slidably connected with the interior of the screening and dust removal module, and the other side of the power mechanism is fixedly connected with the corn threshing module. According to the threshing device for corn harvesting, corn is gradually threshed in a linear friction and rotation mode, so that corn threshing efficiency is improved, and damage to corn kernels in the corn threshing process is reduced; dust, impurities and the corn can be automatically separated in the corn threshing process, so that the dust and impurities are prevented from remaining on the corn kernels, and subsequent tedious work for impurity removal is omitted; and lifting exchange can be continuously carried out in the operation process, so that blockage is reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

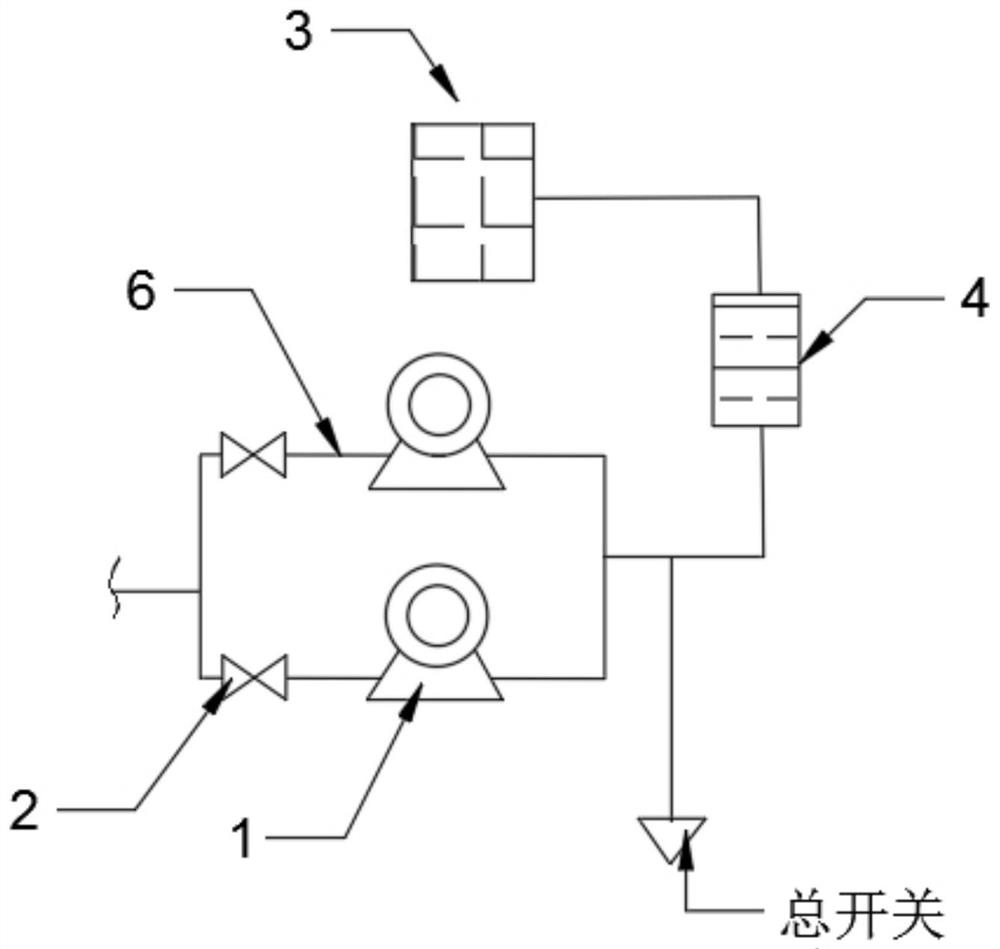

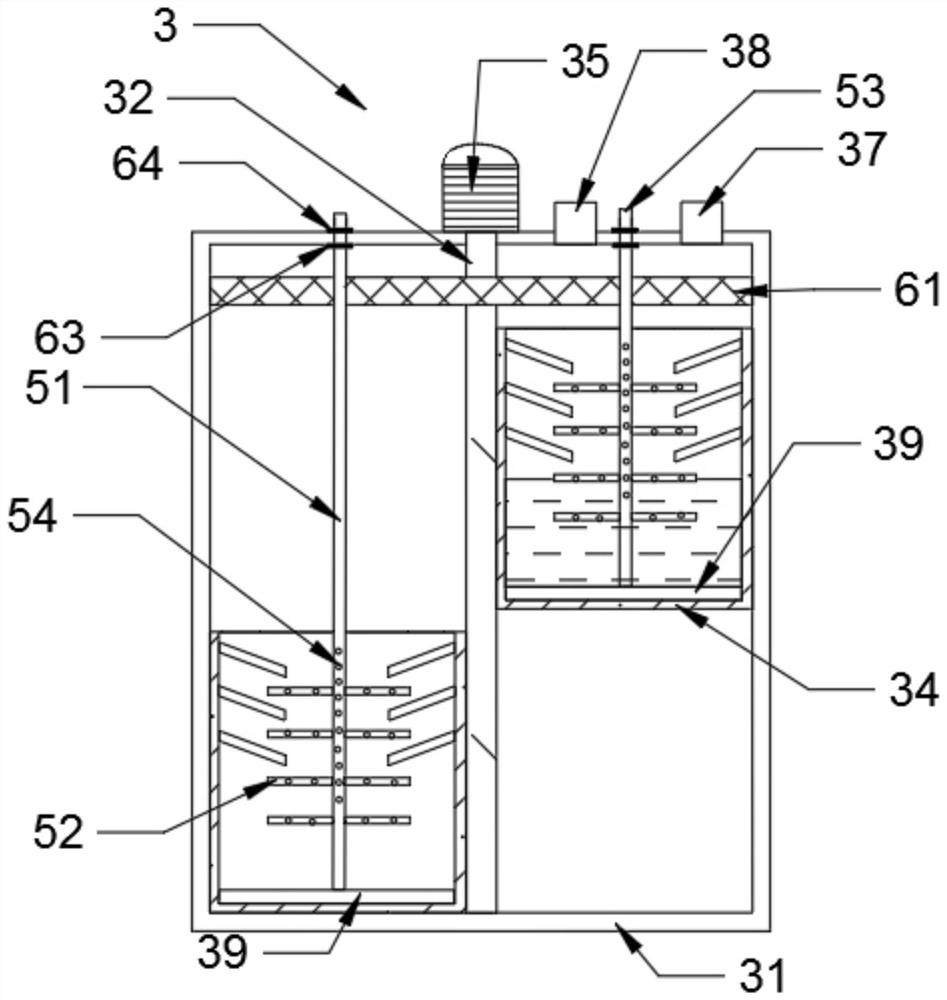

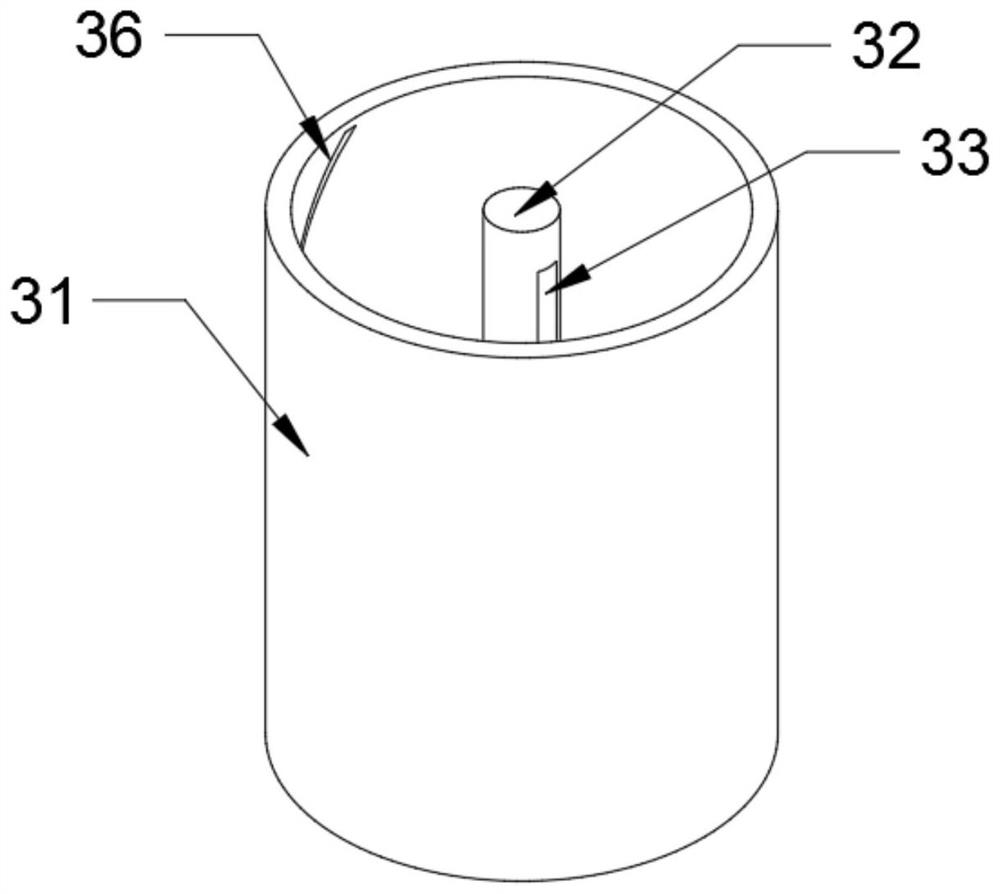

Unattended oil-gas mixed transportation process device

PendingCN113188042AReduce investmentReduce pollutionSludge treatment by de-watering/drying/thickeningLiquid hydrocarbon mixture productionAutomatic controlControl system

The invention discloses an unattended oil-gas mixed transportation process device which comprises a mixed transportation assembly and an intelligent sensing control system. The mixed transportation assembly is used for realizing oil-gas mixed transportation, the mixed transportation assembly comprises a plurality of oil-gas mixed transportation pumps and dirty oil recovery assemblies, the plurality of oil-gas mixed transportation pumps are communicated in series through pipelines, and the multiple oil-gas mixed transportation pumps are all provided with control valves; and the intelligent sensing control system is used for controlling the control valves to enable the oil-gas mixed transportation pumps to operate, the pipelines are further provided with the dirty oil recovery assemblies and buffer tanks, and the buffer tanks are used for oil-gas separation. The unattended oil-gas mixed transportation process device is scientific and reasonable in structure and safe and convenient to use, large-displacement and high-oil-gas-ratio oil-gas mixed transportation can be achieved through the oil-gas mixed transportation pumps 1, the oil and gas directly enter the oil-gas mixed transportation pumps to be transported outwards, technological processes and capital investment are reduced, automatic control is achieved, stations are unattended, labor cost is reduced, oil-gas mixed transportation is achieved, and emission pollution of associated gas can be effectively reduced.

Owner:JIANGSU HONGSHENG PUMP TECH

Industrial filter cloth cleaning process

InactiveCN112007430ARestore filter effectImprove removal effectFilter regenerationProcess engineeringEnvironmental geology

The invention discloses an industrial filter cloth cleaning process and relates to the technical field of industrial filter cloths. The preparation method comprises the following steps: (1) washing with clear water, (2) preparing sludge liquid, (3) carrying out sludge liquid treatment, (4) carrying out fumigation, and (5) carrying out alkali washing. When the sludge liquid is prepared, large-particle solid impurities in the sludge liquid can be removed through filtering treatment, and the sludge liquid is prevented from blocking filter holes of industrial filter cloth. The industrial filter cloth is soaked in the prepared sludge liquid, microorganisms in the sludge liquid can decompose greasy dirt on the surface of the industrial filter cloth to generate easily-dissolved substances, the adhesive force between the greasy dirt and the industrial filter cloth can be reduced, then ultrasonic treatment is conducted, the greasy dirt can be promoted to be separated from the industrial filtercloth, and especially the greasy dirt separation efficiency in filter holes of the industrial filter cloth is higher.

Owner:界首万昌新材料技术有限公司

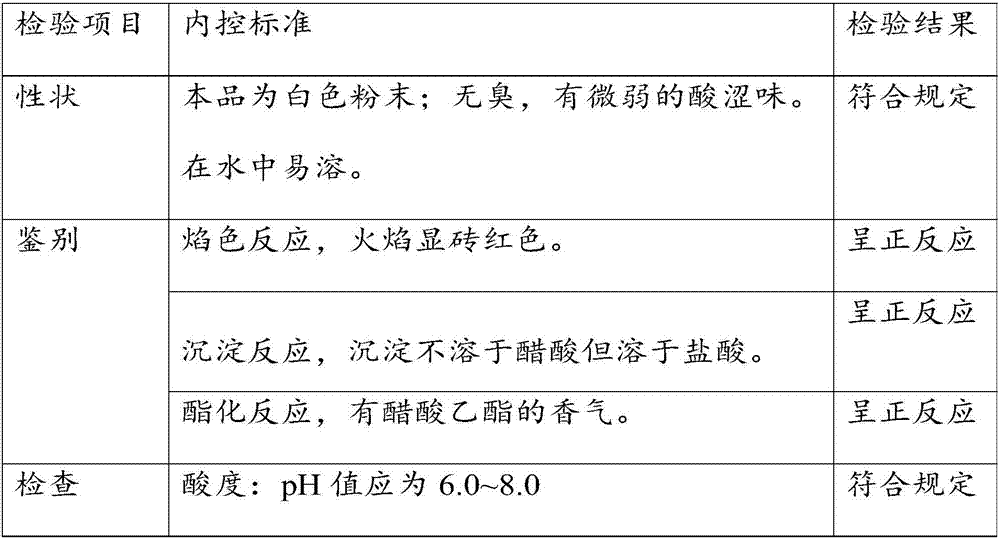

Calcium acetate raw material medicine and preparation method and application thereof

InactiveCN107021880AAvoid decompositionImprove detachment efficiencyMetabolism disorderSkeletal disorderAcetic acidAqueous solution

The invention provides a calcium acetate raw material medicine and a preparation method and application thereof. The preparation method of the calcium acetate raw material medicine comprises the following steps: distilling a calcium acetate aqueous solution, maintaining the calcium acetate aqueous solution at 90 DEG C or below and collecting a concentrate; mixing the concentrate, and meanwhile maintaining the concentrate at 15 to 25 DEG C; and filtering the concentrate, and drying until the moisture content is 6-8wt% to obtain the calcium acetate raw material medicine. The preparation method of the calcium acetate raw material medicine has the advantages of simple operation, and can produce a calcium acetate product with less residual acetic acid and better taste.

Owner:刘晓凯

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com