Chip integrated boiling enhancement heat exchange structure and preparation method thereof based on MEMS (Micro Electro Mechanical System) technology

A technology for strengthening heat exchange and chips, applied in electrical components, electric solid devices, circuits, etc., can solve problems such as dry burning, and achieve the effect of strengthening heat dissipation, boiling heat exchange, and bubble detachment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

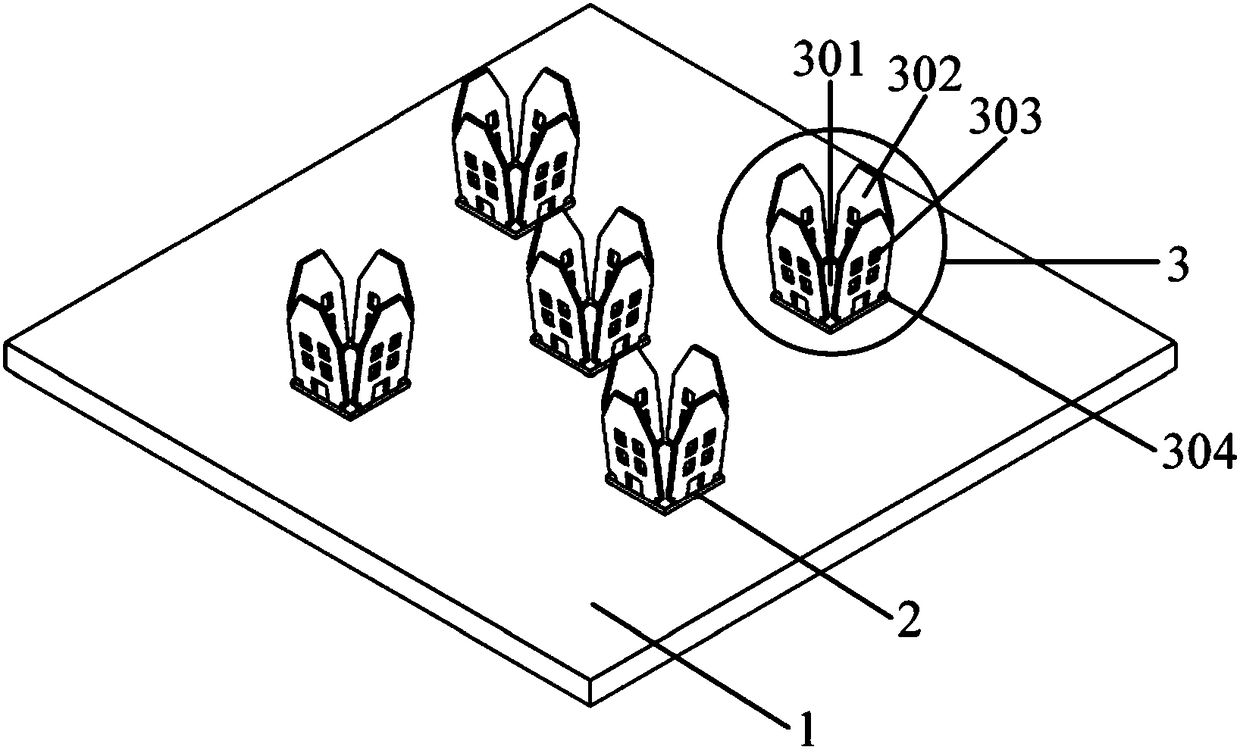

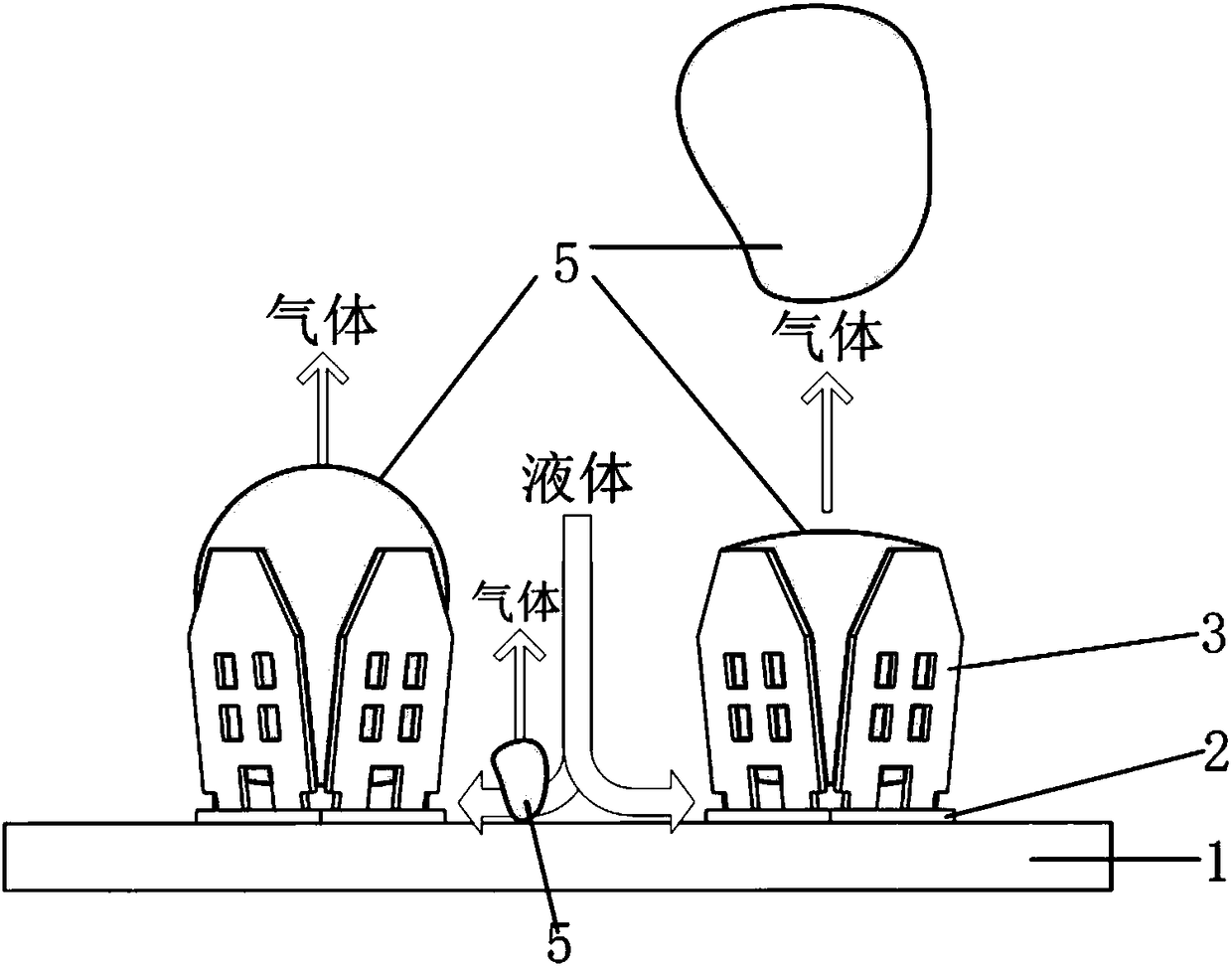

[0055] Such as figure 1 As shown, this embodiment provides a chip-integrated boiling-enhanced heat transfer structure based on MEMS technology, including: a heat-conducting substrate 1, a support layer 2, and a claw-shaped structure 3, wherein:

[0056] The heat-conducting substrate 1 is made of AlN material, and the support layer 2 and the claw structure 3 are made of copper material.

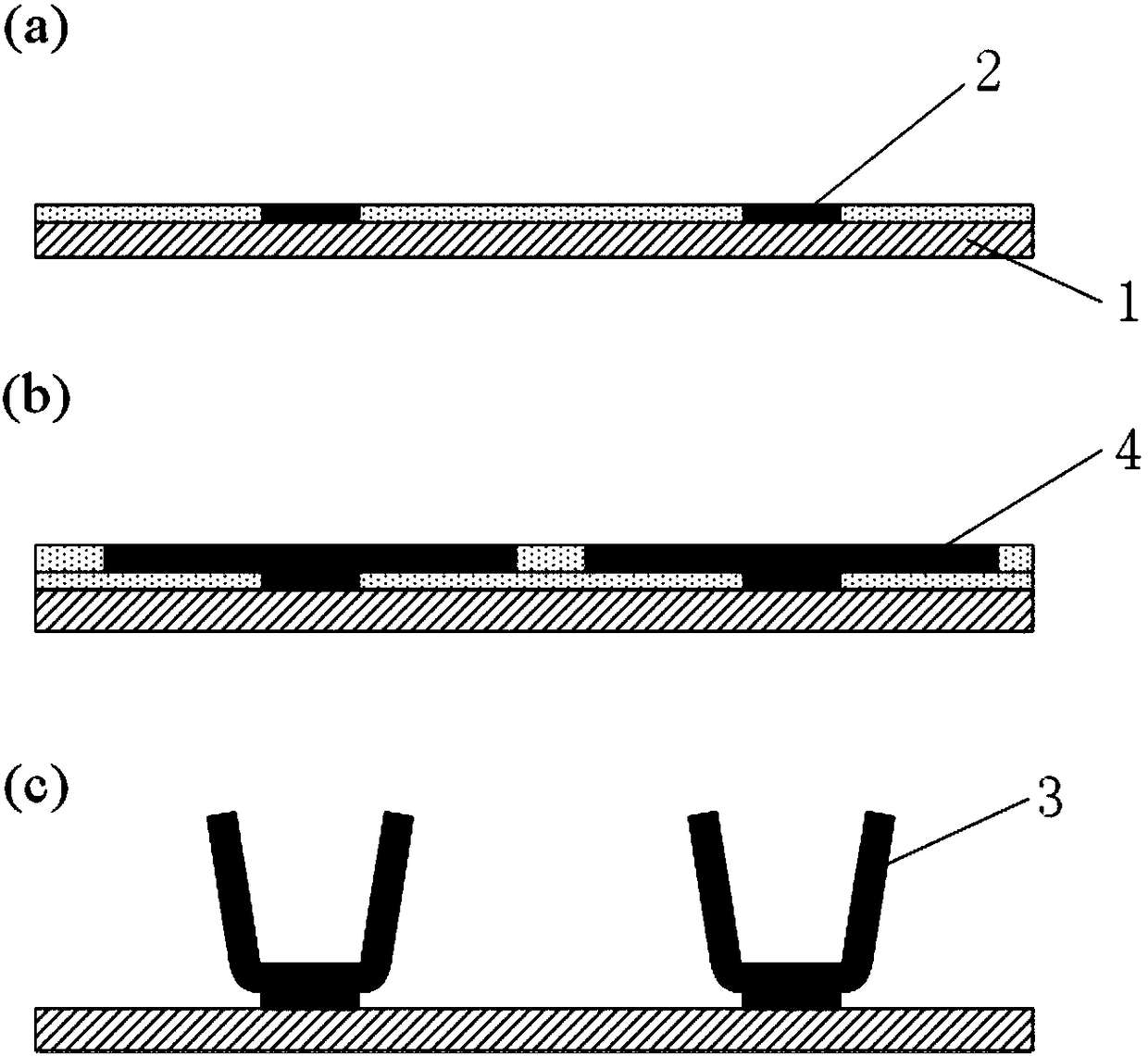

[0057] The support layer 2 is evenly distributed on the surface of the heat-conducting substrate 1, and the bottom heat-conducting metal layer 301 of each claw structure 3 is connected and fixed to the support layer 2;

[0058] The claw-shaped structure 3 is composed of a bottom heat-conducting metal layer 301 and a plurality of sidewall metal sheets 302, the bottom heat-conducting metal layer 301 is arranged on the support layer 2, and one end of the plurality of sidewall metal sheets 302 is fixed On the bottom heat-conducting metal layer 301 , the other ends of the plurality of sidewall met...

Embodiment 2

[0073] Such as Figure 4 As shown, this embodiment provides a chip-integrated boiling-enhanced heat transfer structure based on MEMS technology. Compared with Embodiment 1, this embodiment changes the material of the heat-conducting substrate and the size and distribution density of the claw structure. Specifically, the chip integrated boiling enhanced heat transfer structure includes: a thermally conductive substrate 1, a support layer 2, and a claw structure 3, wherein:

[0074] The heat-conducting substrate 1 is cut from a silicon wafer, and the support layer 2 and the claw structure 3 are both made of copper. The support layer 2 is evenly distributed on the surface of the heat conduction substrate 1, and the bottom heat conduction metal layer 301 of each claw structure 3 is connected and fixed to the copper support layer 2; the side wall metal layer of the claw structure 3 The sheet 302 has holes 303, and gaps are left between the sidewall metal sheets 302 to ensure the l...

Embodiment 3

[0081] Such as Figure 5 As shown, the appearance of the chip-integrated boiling-enhanced heat transfer structure based on MEMS technology provided by this embodiment is the same as that of Embodiment 1, including: a thermally conductive substrate 1, a support layer 2, and a claw-shaped structure 3, wherein:

[0082] The heat-conducting substrate 1 is made of AlN material, and the support layer 2 and the claw structure 3 are made of copper material. The structure and size of each component of the chip integrated boiling enhancement are also the same as those in Example 1.

[0083] Different from Embodiments 1 and 2, in this embodiment, a patterned layer is added to the chip-integrated boiling enhanced heat transfer structure process to make micropores on the inner wall of the claw-shaped structure 3 and increase the nucleation sites there. Such as Figure 5 As shown, in this embodiment, the overall processing flow of the boiling enhanced heat transfer structure is as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com