Calcium acetate raw material medicine and preparation method and application thereof

A technology of calcium acetate and raw materials, which is applied in the field of medicine, can solve the problems of poor taste and large residues, and achieve the effects of less acetic acid residues, good taste, and increased crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

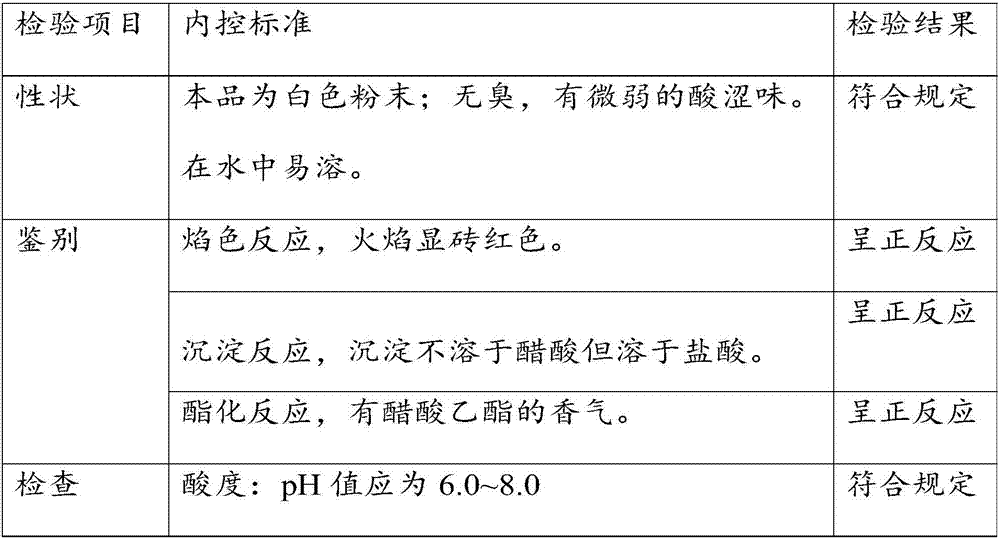

Image

Examples

preparation example Construction

[0025] The preparation method of calcium acetate bulk drug includes the following steps:

[0026] Step S1: Distill the aqueous calcium acetate solution below 90°C, and then collect the concentrate.

[0027] Acetic acid will evaporate in this process. Although the temperature does not reach the boiling point of acetic acid during this process, the process is not a boiling process, so there is no need to reach the boiling point. Even if it is below 90°C, there is always evaporation.

[0028] Among them, the material-to-liquid ratio of the calcium acetate aqueous solution is 0.2 to 0.36 g / mL. The calcium acetate aqueous solution is preferably a clear calcium acetate aqueous solution. The material-to-liquid ratio refers to the ratio of the mass of calcium acetate solid matter to the volume of the aqueous solution.

[0029] When distilling, it needs to be distilled until the collected distillate is 40-70% of the volume of calcium acetate aqueous solution added. Collecting too much or to...

Embodiment 1

[0053] The method for preparing calcium acetate bulk medicine provided in this embodiment includes the following steps:

[0054] a. Take a calcium acetate aqueous solution with a material-to-liquid ratio of 0.2g / mL, distill the calcium acetate aqueous solution, and keep the calcium acetate aqueous solution at 90°C while distilling, until the collected distillate is the calcium acetate aqueous solution added to the volume of 40 %, then collect the concentrate;

[0055] b. Stir the concentrate for 3h in a water bath cooling environment at 15°C;

[0056] c. Vacuum filtration of the substance obtained in step b;

[0057] d. Under the condition of a temperature of 80°C, the substance obtained in step c is dried to a moisture content of 6 wt% to obtain a calcium acetate bulk drug.

[0058] This embodiment also provides a calcium acetate drug prepared by the above preparation method, and the residual amount of acetic acid in the calcium acetate drug is 0.1 wt%.

Embodiment 2

[0060] The method for preparing calcium acetate bulk medicine provided in this embodiment includes the following steps:

[0061] a. Take a calcium acetate aqueous solution with a material-to-liquid ratio of 0.36g / mL, distill the calcium acetate aqueous solution, and keep the calcium acetate aqueous solution at 85°C while distilling, until the collected distillate is the calcium acetate aqueous solution added to the volume of 70 %, then collect the concentrate;

[0062] b. Stir the concentrate for 6h in a water bath cooling environment at 25°C;

[0063] c. Vacuum filtration of the substance obtained in step b;

[0064] d. Under the condition of a temperature of 50°C, the substance obtained in step c is dried to a moisture content of 8% by weight to obtain a calcium acetate bulk drug.

[0065] This embodiment also provides a calcium acetate drug prepared by the above preparation method, and the residual amount of acetic acid in the calcium acetate drug is 0.08 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com