Mold special for decorative lighting wiring harness winding and using method thereof

A technology of winding and wire harness, which is applied in the field of special mold for lighting wire harness winding, which can solve the problems of low separation efficiency of wire harness and winding mold, low production efficiency, cumbersome operation steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

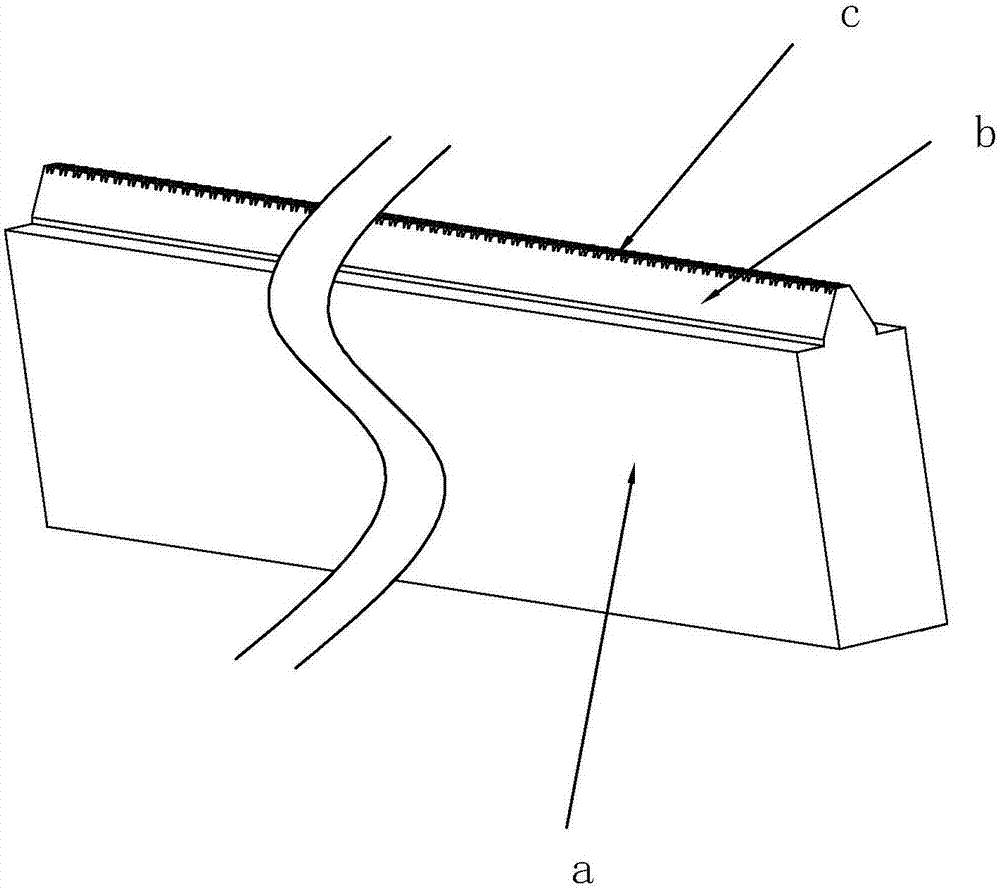

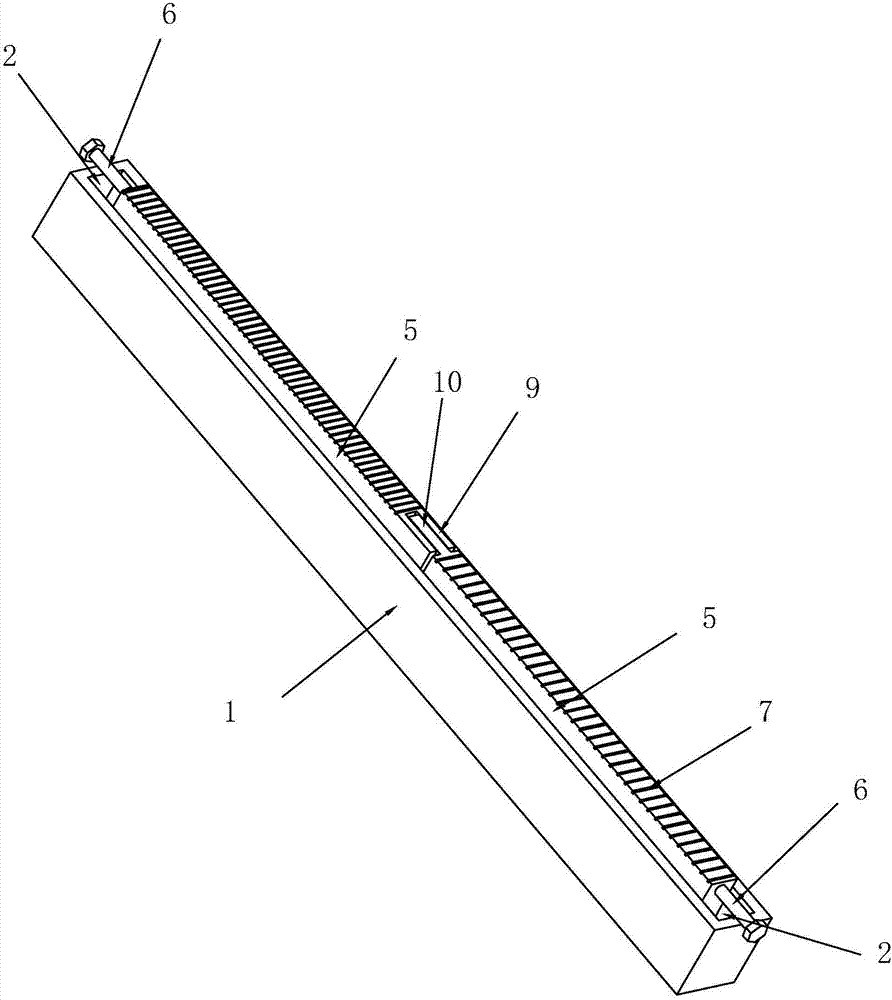

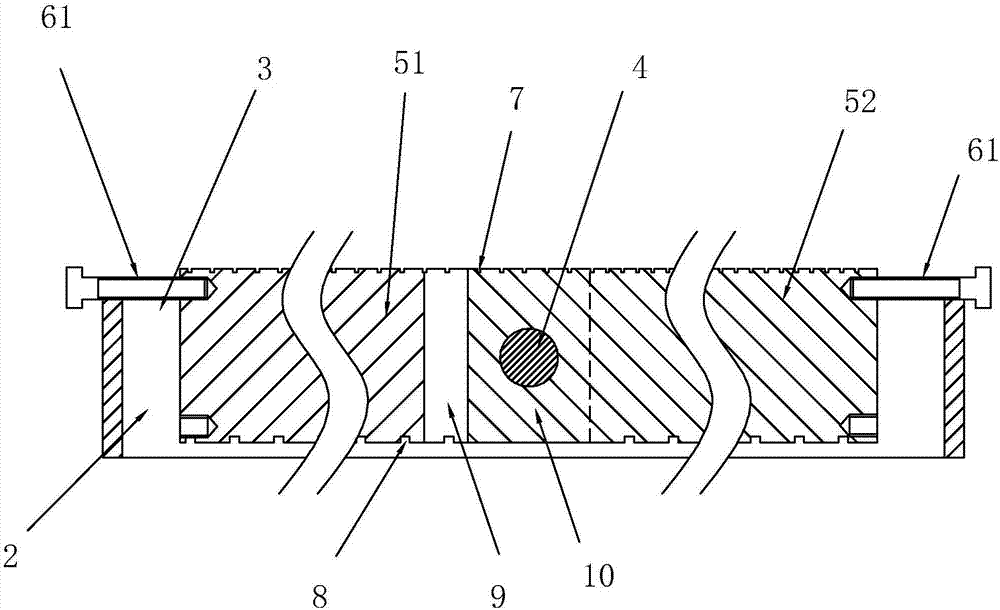

[0039] A special mold for lighting wiring harness winding, comprising a rectangular parallelepiped frame body 1, a square through-groove 2 is arranged inside the frame body 1, the through-hole groove 2 runs through two upper and lower opposite end surfaces of the frame body 1, and the upper side of the through groove 2 The notch is the winding port 3, and the hinge shaft 4 and two strip-shaped wire harness coils 5 are arranged in the through slot 2. The hinge shaft 4 is located in the middle of the frame body 1, and the hinge shaft 4 is horizontally arranged. The ends of the wire harness winding sheets 5 are hinged to the hinge shaft 4 at the same time, and the ends of the two wire harness winding sheets 5 facing away from the hinge shaft 4 are provided with a fixing part 6, which is used to hinge the two wire harness winding sheets 5 away from the hinge One end of the shaft 4 is fixed to the frame body 1 , and a plurality of first wire embedding grooves 7 are arranged at inter...

Embodiment 2

[0048] A method for using a special mold for winding lighting harnesses, including the following steps:

[0049] Winding spot welding steps:

[0050] S1: Unscrew the fixing bolt 61 from the end of the wire harness winding sheet 5, set the fixing bolt 61 on the frame body 1, and the first embedding groove 7 protrudes from the side of the winding port 3;

[0051] S2: The winding wires are respectively wound on the first embedding groove 7 and the outer side wall of the frame body 1;

[0052] S3: Spot welding the lamp beads on the winding wire until the spot welding of the lamp beads is completed;

[0053] Harness removal steps:

[0054] S4: Unscrew the fixing bolt 61 from the wire harness coil 5;

[0055] S5: the first winding sheet 51 and the second winding sheet 52 rotate around the hinge shaft 4 to the side away from the winding port 3;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com