Molecular sieve dehydration pry for heating regenerated natural gas with high reliability

A technology of heating regeneration and molecular sieve, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of pollution, poor filtering effect of shale gas, and high regeneration energy consumption, so as to improve the detachment efficiency, improve the filtering and drying effect , enhance the effect of work pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

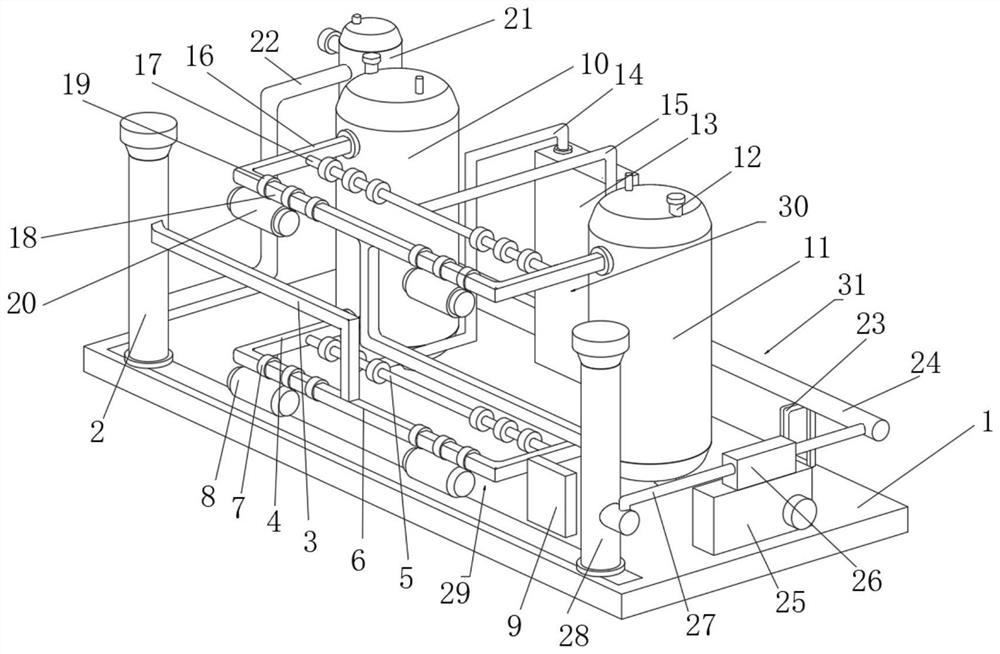

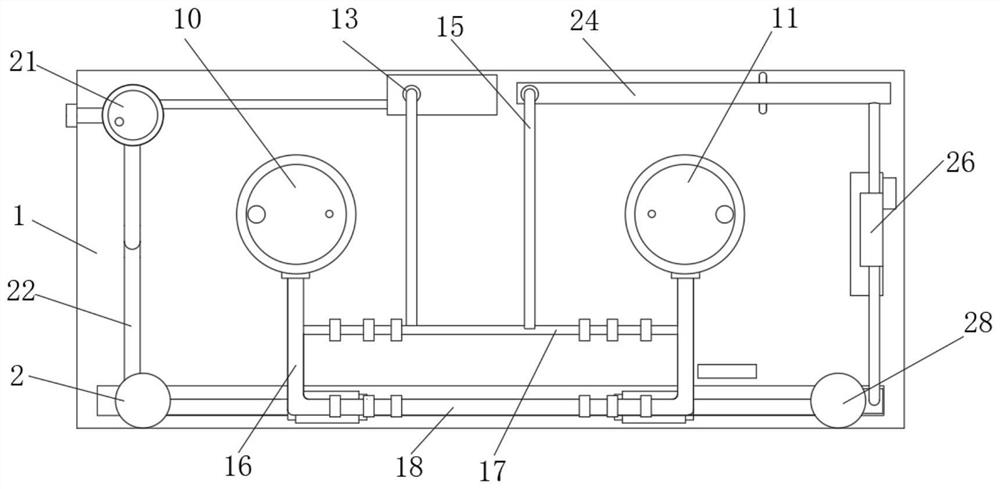

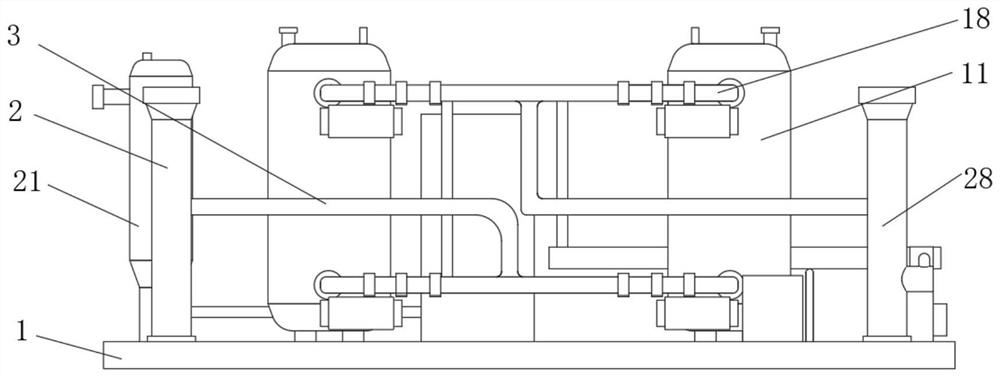

[0028] see Figure 1-6 , the present invention provides a technical solution: highly reliable heating and regenerating natural gas molecular sieve dehydration skid, including a bracket 1, the upper end of the bracket 1 is provided with a molecular sieve dryer 10 and a molecular sieve dryer 2 11 near the middle position, a molecular sieve dryer 10 and a molecular sieve dryer Valves 12 are arranged at the upper end of the second device 11, an exhaust mechanism 30 is arranged at the top of the first molecular sieve dryer 10 and the second molecular sieve dryer 11, and an air intake mechanism 29 is arranged at the bottom of the first molecular sieve dryer 10 and the second molecular sieve dryer 11. A circulation mechanism 31 is provided at the upper end of the support 1 and on one side of the molecular sieve dryer 10 .

[0029] The upper end of the support 1 is provided with a separation filter 2 close to one side corner, the upper end of the support 1 is provided with a dust filt...

Embodiment 2

[0036] see Figure 1-6 , the present invention provides a technical solution: highly reliable heating regeneration natural gas molecular sieve dehydration skid, and also includes a circulation mechanism 31, the circulation mechanism 31 includes a regeneration gas air cooler 13, and the upper end of the regeneration gas air cooler 13 is provided with a circulation pipe-14 near one side , the upper end of the bracket 1 is provided with a regenerative gas heater 25 near one side, the upper end of the regenerative gas heater 25 is provided with a regenerative gas pressurizer 26, and both ends of the regenerative gas pressurizer 26 are provided with pipes 27, and the upper end of the bracket 1 is located at A support frame 23 is provided on the back side, and a feeding pipe 24 is provided at the upper end of the support frame 23. The end of the feeding pipe 24 close to the regeneration air cooler 13 is connected with a circulation pipe 2 15. The side wall of the regeneration air coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com