Device for removing MIBK (Methyl Iso Butyl Ketone) from raffinate for MIBK extraction and zirconium and hafnium separation

A raffinate, removal technology, applied in distillation separation, separation method, improvement of process efficiency, etc., can solve problems such as low cost, and achieve the effects of reducing production cost, improving product quality, and accelerating separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

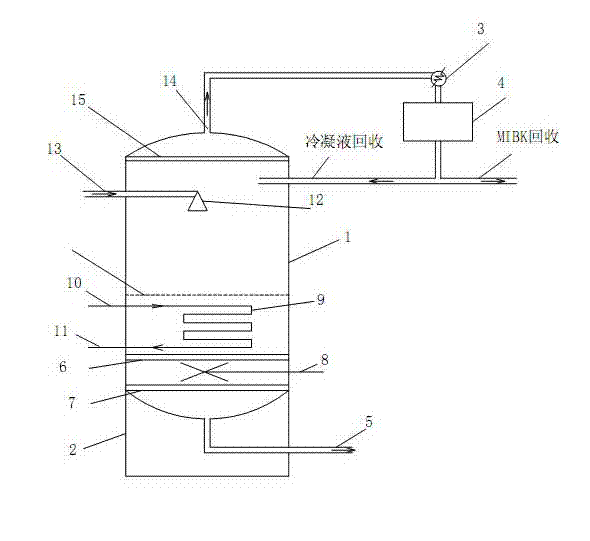

[0022] The cylinder shell 1 has a diameter of 1m and a total height of 3.5m. The skirt support 2 at the lower part of the cylinder is 0.5m high. The upper support grid 6 is installed at a height of 0.5m above the lower support grid 7, and the liquid level Maintain the height at 1m from the heating coil, install a liquid distributor 12 at a height of 0.5m above the liquid level, and communicate with the raffinate inlet, and install a screen partition 14 at a height of 0.5m above the liquid distributor , the water phase enters the deoiling device from 0.3m below the screen partition. After installation, open the feed valve, raise the liquid level to 1m above the heating coil, stop feeding, turn on the steam, and start blowing at the same time After 1 hour, the feed valve and the discharge valve are opened at the same time, and the flow rate of the incoming and outgoing materials is the same. The oil removal device starts to run continuously. After 3 hours, the discharge port is s...

Embodiment 2

[0024] The cylinder shell 1 has a diameter of 1.5m and a total height of 5.5m. The skirt support 2 at the lower part of the cylinder is 1.0m high, and the upper support grid 6 is installed at a height of 1.0m above the lower support grid 7. The level height is maintained at a distance of 1.5m from the heating coil, a liquid distributor 12 is installed at a height of 1.0m above the liquid level, and is connected to the raffinate feed inlet, and a screen separator is installed at a height of 1.0m above the liquid distributor. Plate 14, the water phase enters the shell 1 from 0.4m below the screen partition. Open the feed valve, raise the liquid level to 1.5m above the heating coil, stop the feed, turn on the steam, and start blowing at the same time. After 1 hour, open the feed valve and the discharge valve at the same time, and the flow rate of the incoming and outgoing materials is the same. The degreasing device started to run continuously. After 3 hours, the discharge port w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com