Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Improve assembly construction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

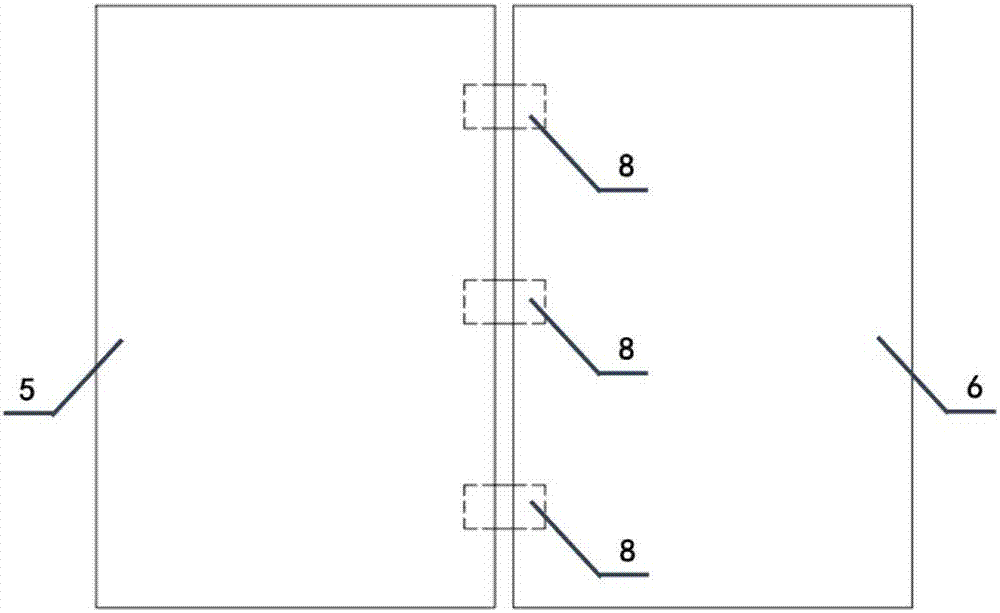

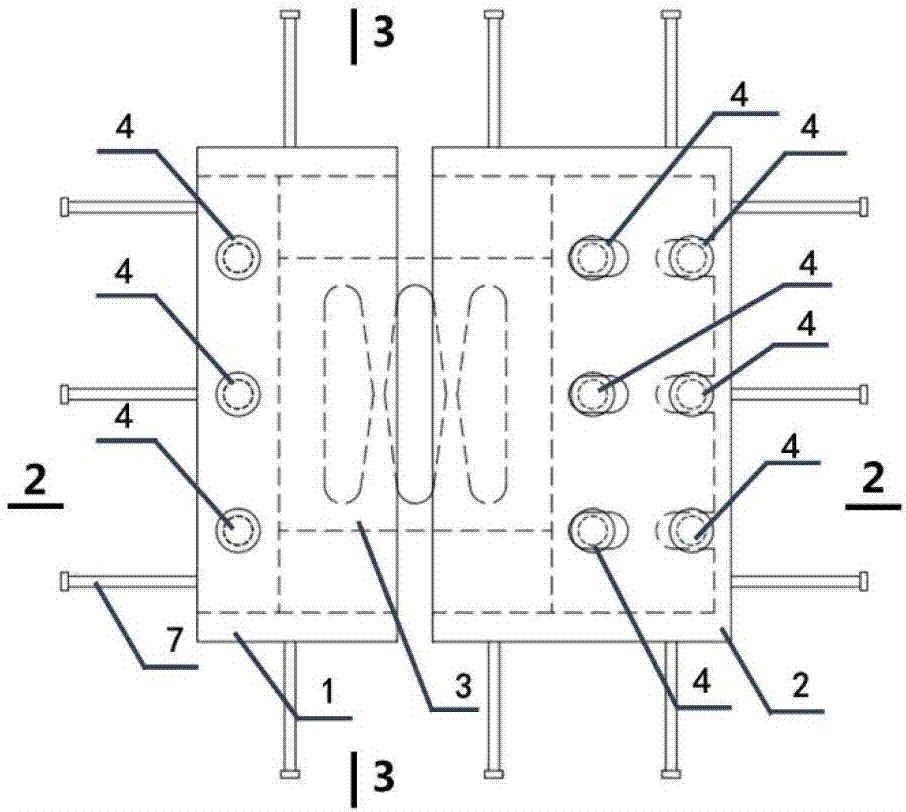

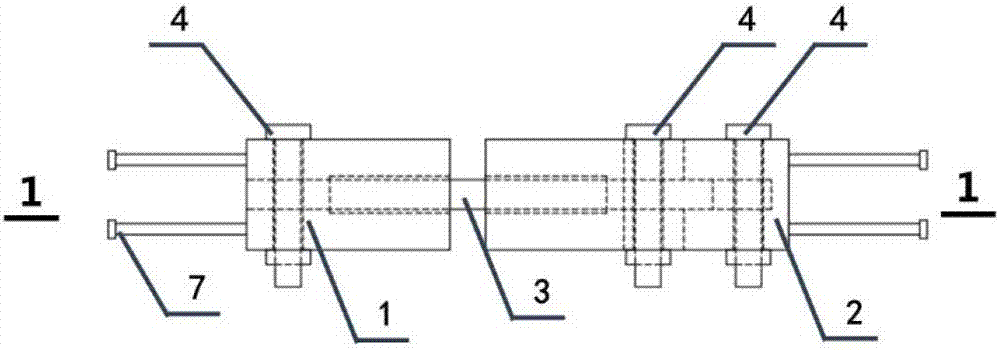

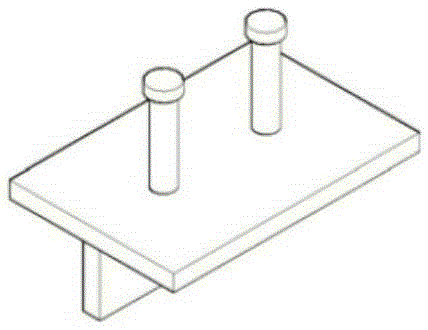

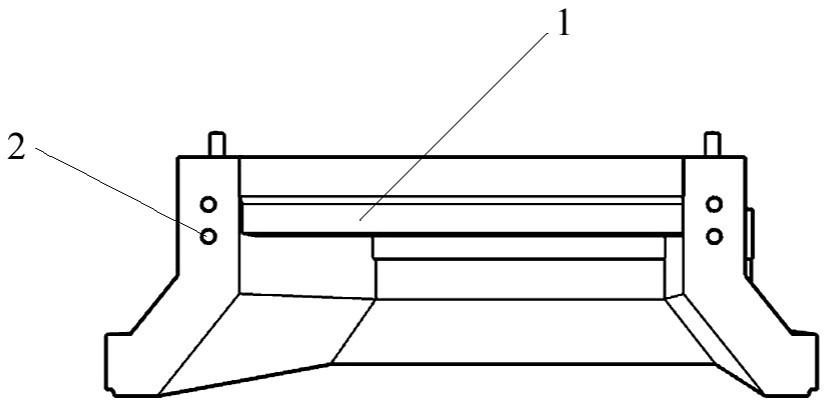

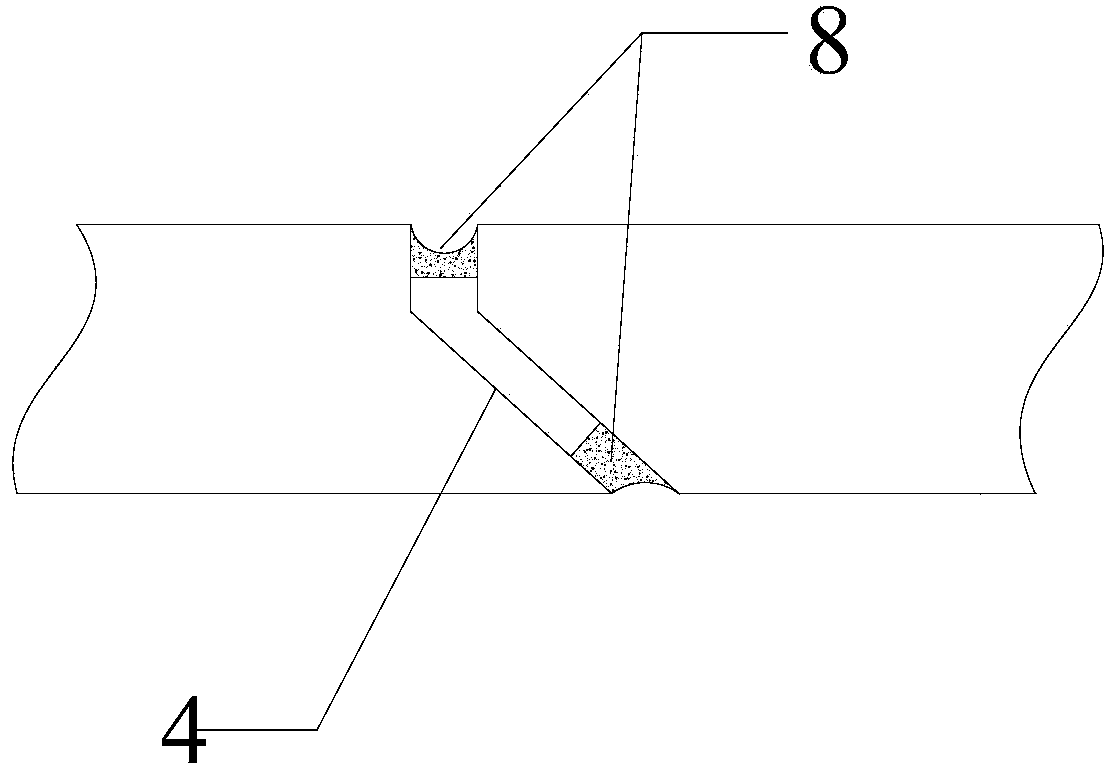

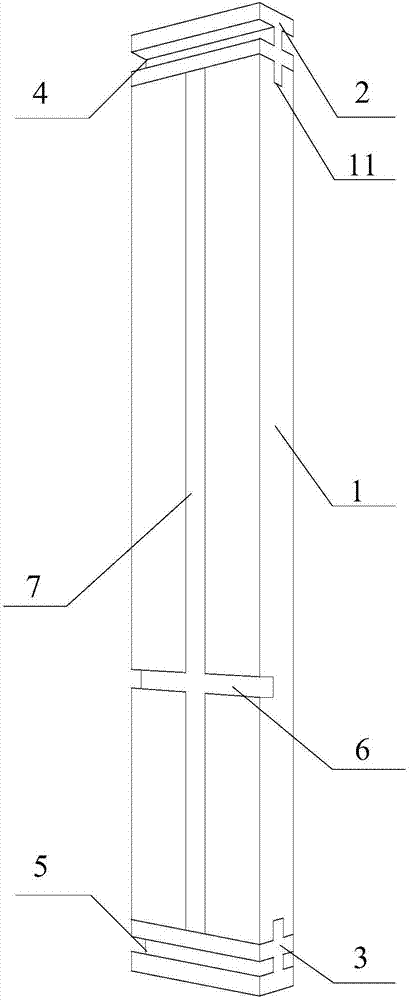

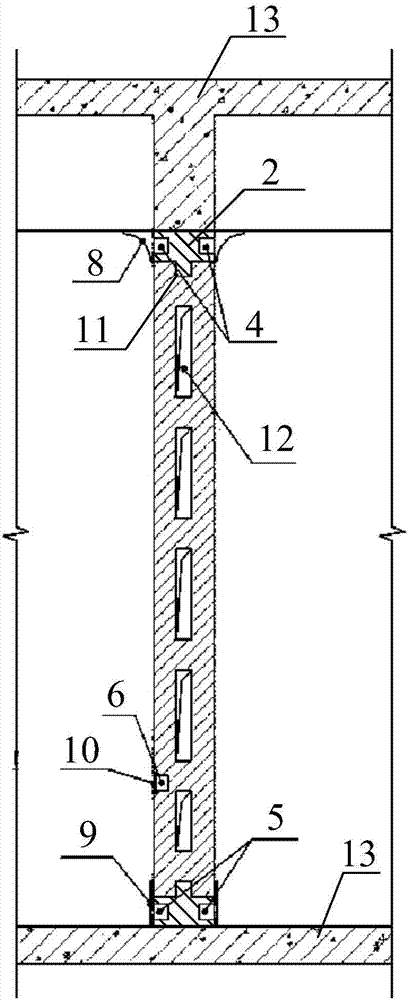

Fabricated shear-wall energy-dissipation vibration-reduction horizontal connecting device and construction method thereof

ActiveCN107178163AGuaranteed durabilityAvoid Out-of-Plane WarpingWallsProtective buildings/sheltersCorrosionCarrying capacity

The invention belongs to the field of civil engineering, and relates to a fabricated shear-wall energy-dissipation vibration-reduction horizontal connecting device and a construction method thereof. A pre-embedded part and a connecting part of the fabricated shear-wall energy-dissipation vibration-reduction horizontal connecting device are both arranged in the wall body, changes of performances such as corrosion, erosion and aging can be avoided, the durability of the whole structure is ensured, plane outer warping of an energy-dissipation connecting device is avoided, and the better energy-dissipating capacity can be achieved. The energy-dissipation connecting part is placed in the wall body and coincides with the axis of a horizontal shaft of the section of the wall body, force balance of the wall body, rigidity in the plane and carrying capacity are ensured, and eccentric bending moment can not be generated. With the connecting mode, the efficiency of prefabricated shear-wall on-site assembling construction can be improved substantially, enough initial rigidity supplied to shear-wall to connect under the function of small vibration can be achieved, under the function of big vibration, earthquake energy can be dissipated, and vibration-reduction thoughts of structure and component ductility can be improved, and meanwhile, the whole effect of building beauty and space usage can not be influenced, steel products can be saved, and a certain economic benefit can be achieved.

Owner:DALIAN UNIV OF TECH

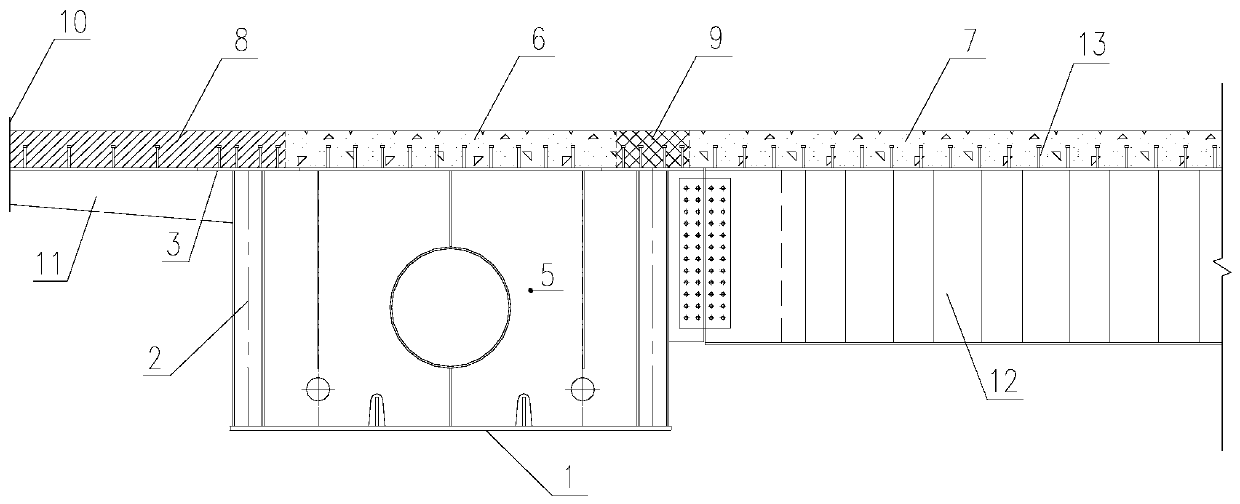

Novel efficient assembly-type reinforced concrete composite beam

InactiveCN105350445ASolve corrosiveSolve Concrete CrackingBridge structural detailsBridge materialsReinforced concreteEconomic benefits

The invention discloses a novel efficient assembly-type reinforced concrete composite beam, and belongs to the technical field of bridge construction. The novel efficient assembly-type reinforced concrete composite beam comprises a concrete bridge deck and a steel girder; the concrete bridge deck is arranged on the steel girder; a top flange plate of the steel girder is fixedly connected with a ribbed plate extending in the vertical direction of the steel girder; the bottom of the concrete bridge deck is provided with a channel extending in the vertical direction of the steel girder; the ribbed plate is arranged in the channel; two side edges of the top flange plate are fixedly connected with rubber sealing strips extending in the vertical direction of the steel girder; the bottom surface of the concrete bridge deck is in lap joint with the rubber sealing strips; the top flange plate, the rubber sealing strips, the bottom surface of the concrete bridge deck, and the channel of the concrete bridge deck defines a grouting channel; and the grouting channel is filled with a high-strength pouring sealant material. According to the invention, a series of problems brought by processing of reinforced concrete connecting pieces and cast-in-place of jointed concrete are effectively avoided, the construction quality is guaranteed, at the same time, the on-site work efficiency is improved, and the novel efficient assembly-type reinforced concrete composite beam is more environmentally friendly, and has good economic benefits.

Owner:CCCC SECOND HARBOR ENG +1

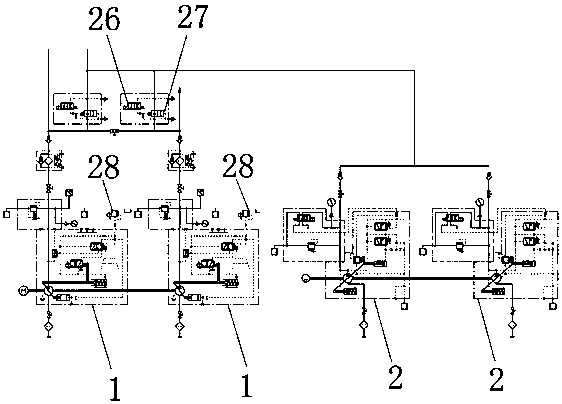

Multi-mode synchronous advancement and assembly system of shield tunneling machine and control method of multi-mode synchronous advancement and assembly system

ActiveCN111102256ASimultaneously promote the assembly functionImprove assembly effectServomotor componentsServomotorsControl cellEngineering

The invention discloses a multi-mode synchronous advancement and assembly system of a shield tunneling machine and a control method of the multi-mode synchronous advancement and assembly system. The multi-mode synchronous advancement and assembly system includes an advancement pump source and an assembly pump source which are connected with a PLC control unit. The advancement pump source and the assembly pump source are both connected with an oil cylinder group through a hydraulic valve group, and the oil cylinder group is connected with an oil return channel. The hydraulic valve group includes at least one large-group valve block, and each large-group valve block includes a fixed group mode rodless cavity oil inlet channel, a fixed group mode rod cavity oil return channel, an analog fixedgroup mode rodless cavity oil inlet channel, an assembly mode rod cavity oil inlet channel, an assembly mode rodless cavity oil return channel and an assembly mode rodless cavity oil inlet channel ofthe oil cylinder group. The multi-mode synchronous advancement and assembly system has a fixed group mode, an analog fixed group mode and an arbitrary group mode. The multi-mode synchronous advancement and assembly system has a plurality of advancement modes including the fixed group mode, the analog fixed group mode, the arbitrary group mode and a weekend pressure maintaining mode, and can realize the functions of synchronous advancement and assembly of a shield.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

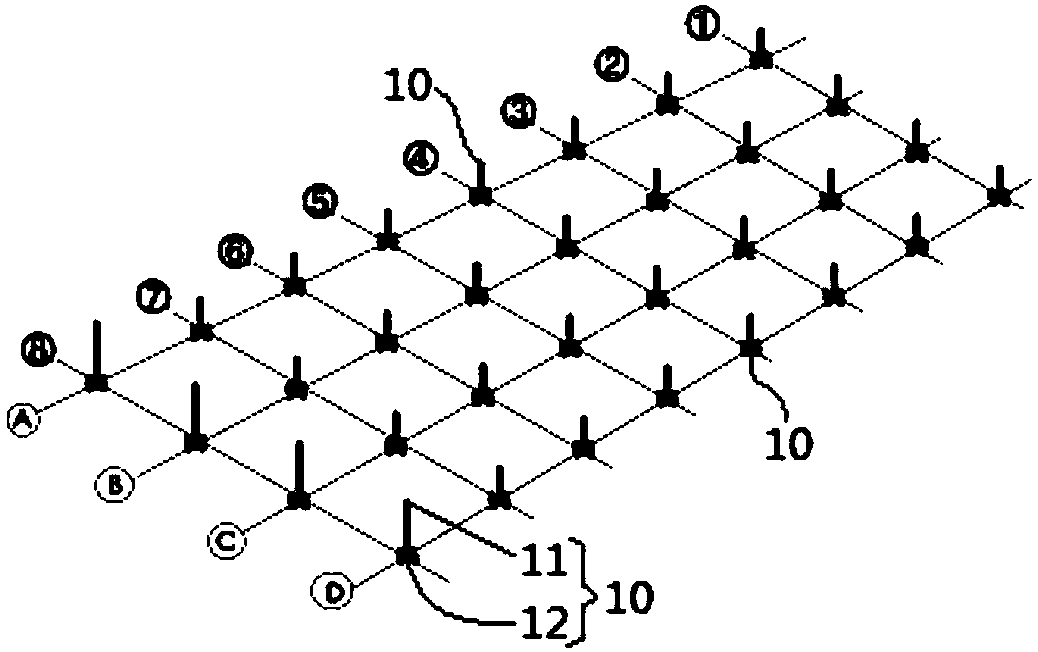

Welding ball net frame assembling construction method

InactiveCN108612187AReduce difficultyImprove assembly construction efficiencyBuilding material handlingEngineeringSmall unit

The invention provides a welding ball net frame assembling construction method. The construction method comprises the following steps that S10, a design coordinate system P1 (X, Y, Z) is set up; S20,an assembling coordinate system P2 (N, E, H) is set up, the coordinate values of each bottom chord welding ball (XS, YS, ZS) are converted into the coordinate value (NS, ES, HS) to be assembled to form a bottom chord welding ball set net; S30, a small assembling unit coordinate system P3 (A, B, 0) is set up, and the coordinate values (XS, YS, ZS) of the corresponding bottom chord welding balls areconverted to the coordinate value (AS, BS, 0) to be assembled to form triangular small units; and S40, modular assembling of the triangular small units and supplementary connection of connecting rodsare carried out. By applying the welding ball net frame assembling construction method, the problem that in the prior art, the construction cost is increased due to the fact that the assembling precision, installation efficiency and construction safety are difficult to balance at the same time in the assembling construction process of a welding ball net frame is solved.

Owner:CHINA CONSTR STEEL STRUCTURE CORP LTD

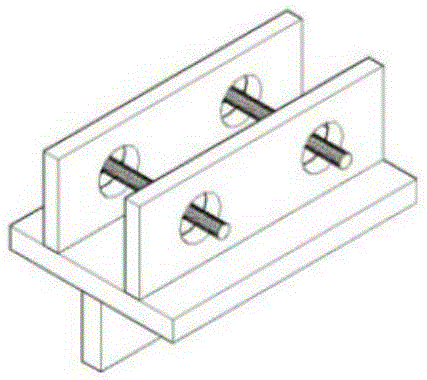

Assembling method for jacketed pipe and its pipe lining apparatus

InactiveCN101463923AGuarantee welding qualityGuaranteed installation qualityPipe laying and repairEngineeringStructural engineering

The invention discloses an assembly method of jacketed pipes and a pipe inserting device. The method comprises the following steps: firstly, welding inner pipes of the jacketed pipes in pairs, and sheathing outer pipes of the jacketed pipes after heat treatment, weld seam detection and a hydraulic test; lifting the welded inner pipes while sheathing the outer pipes, and then lifting the outer pipes to ends of the inner pipes; mounting the pipe inserting device respectively on a front end and a rear end of the outer pipe; translating and sheathing the outer pipes outside the inner pipes one by one; and finally welding various outer pipes, and finishing assembly. The assembly method has the advantages of saving construction materials, having low equipment investment and simple construction steps, being capable of effectively protecting jacketed pipe materials and the like; and the pipe inserting device has the advantages of simple structure, convenient installation and use, less construction materials, lower equipment investment, simplified construction steps and the like.

Owner:五矿二十三冶建设集团有限公司

Fabricated corrugated web steel box-UHPC composite beam bridge and construction method thereof

PendingCN111206489AMeet different design needsReduce welding workloadBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention relates to a fabricated corrugated web steel box-UHPC composite beam bridge and a construction method thereof, the fabricated corrugated web steel box-UHPC composite beam bridge is composed of corrugated web steel boxes and UHPC bridge deck slabs, each corrugated web steel box is of an open box-shaped structure composed of a flat steel bottom plate, corrugated steel webs and a flat steel top plate, and the adjacent corrugated web steel boxes are connected through cross beams between the boxes; the UHPC bridge deck slabs comprise in-box prefabricated UHPC bridge deck slabs, inter-box prefabricated UHPC bridge deck slabs and cantilever cast-in-place UHPC bridge deck slabs, and the adjacent prefabricated UHPC bridge deck slabs are connected through cast-in-place wet joint UHPC bridge deck slabs; and the multiple UHPC bridge decks are correspondingly installed on the multiple corrugated web steel boxes to form the assembly type corrugated web steel box-UHPC composite beam bridge. According to the fabricated corrugated web steel box-concrete composite beam bridge, the steel consumption configuration is optimized, the self-weight of the structure is further reduced, the prefabricated concrete bridge deck is adopted, the fabricated degree is further improved, the construction period is short, the standardization degree is high, remarkable economic and social benefits areachieved, and the fabricated corrugated web steel box-concrete composite beam bridge has important significance in promoting large-scale application of steel structure bridges.

Owner:甘肃省交通规划勘察设计院股份有限公司

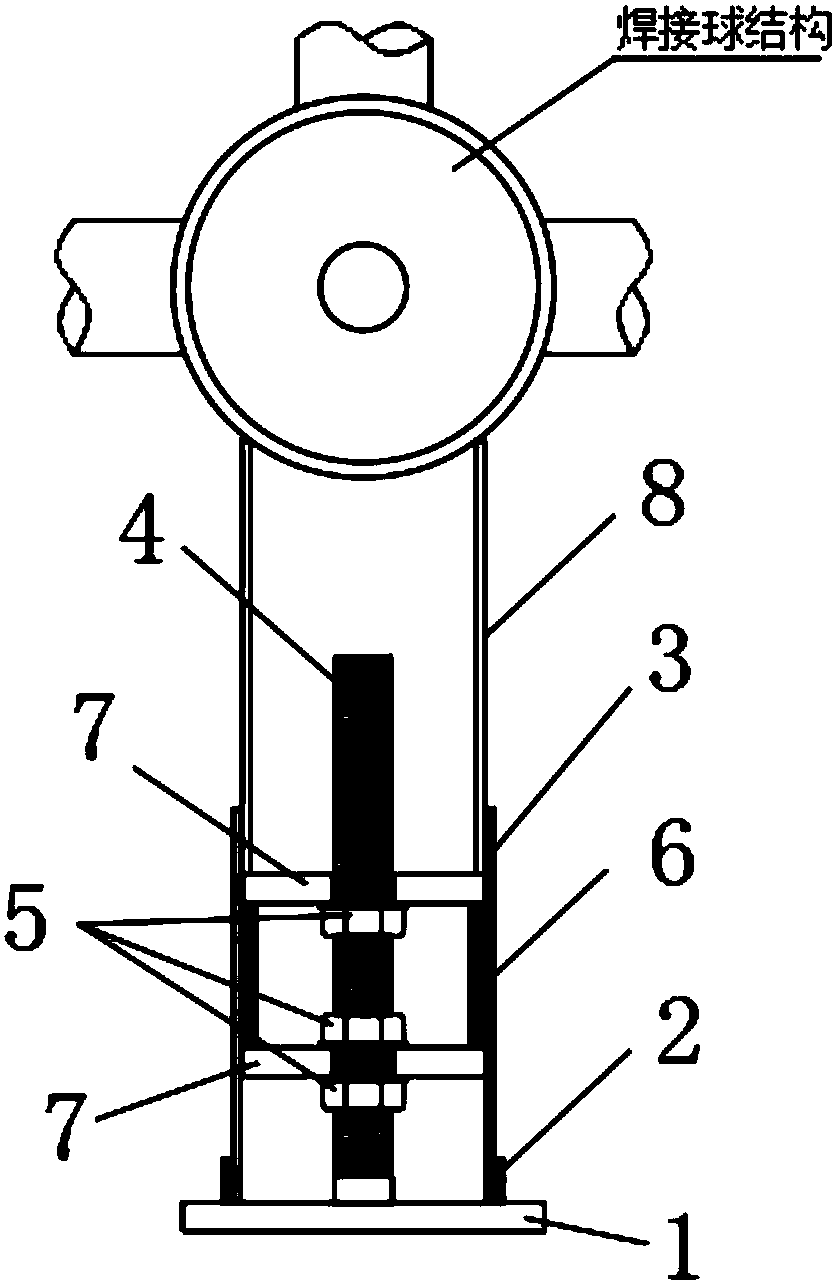

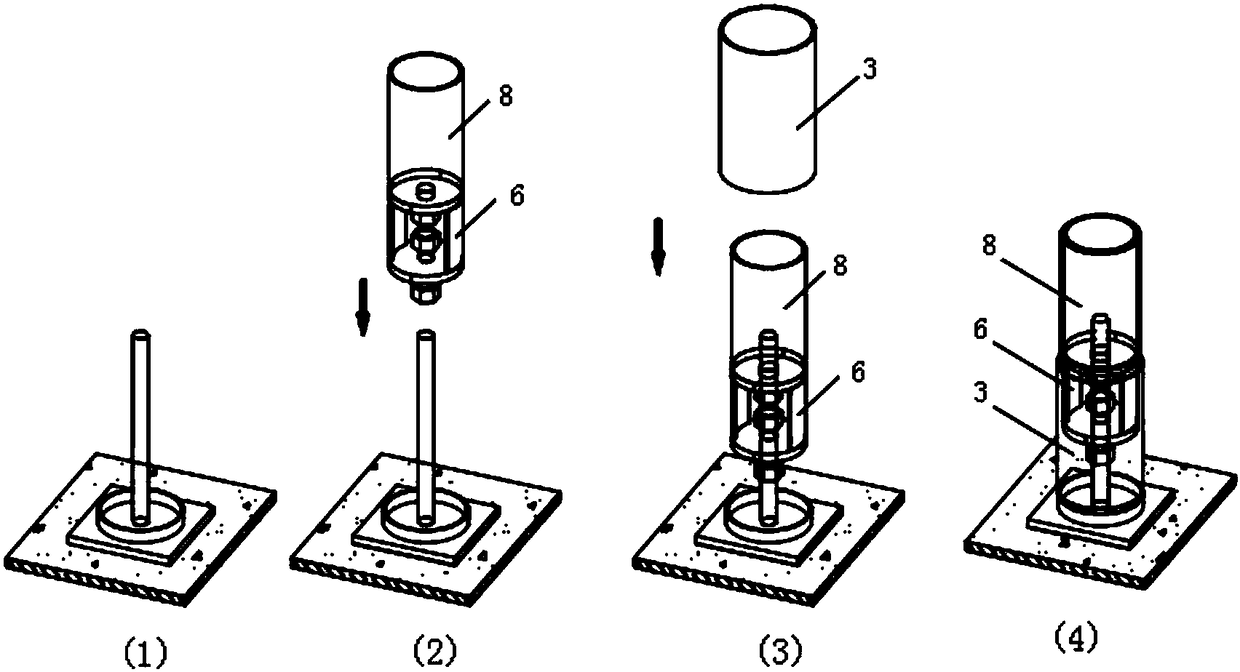

Wire frame sphere joint positioning rapid adjustment device and installation adjustment method thereof

PendingCN108590204ALimits eccentric compressionImprove assembly construction efficiencyBuilding material handlingArchitectural engineeringScrew thread

The invention discloses a wire frame sphere joint positioning rapid adjustment device. The wire frame sphere joint positioning rapid adjustment device comprises a base plate, a threaded round rod anda supporting steel pipe. A circular fixing hoop steel pipe is arranged on the surface of the base plate, and the threaded round rod is fixed to position, in the vertical axis direction of the fixing hoop steel pipe, of the base plate. Two curved plates are arranged on the outer side of the threaded round rod, and force transmitting plates are separately arranged on the upper and lower ends of thecurved plates. The supporting steel pipe is fixed to the force transmitting plate at the upper end. A movable hoop steel pipe is arranged between the supporting steel pipe and the fixing hoop steel pipe. Three hexagonal lock nuts are arranged on the threaded round rod, two of the hexagonal lock nuts are located between the two force transmission plates, another hexagonal lock nut is located belowthe force transmission plate at the lower part, and the hexagonal lock nuts are used for height adjustment and locking. The structural design of the wire frame sphere joint positioning rapid adjustment device is reasonable, and the upper and lower adjustment and rapid positioning and unloading can be realized, the assembly construction efficiency of a sphere joint wire frame is improved, the eccentric compression of the threaded round rod is reduced, the relative offset is not generated, and the fixation reliability is high.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU

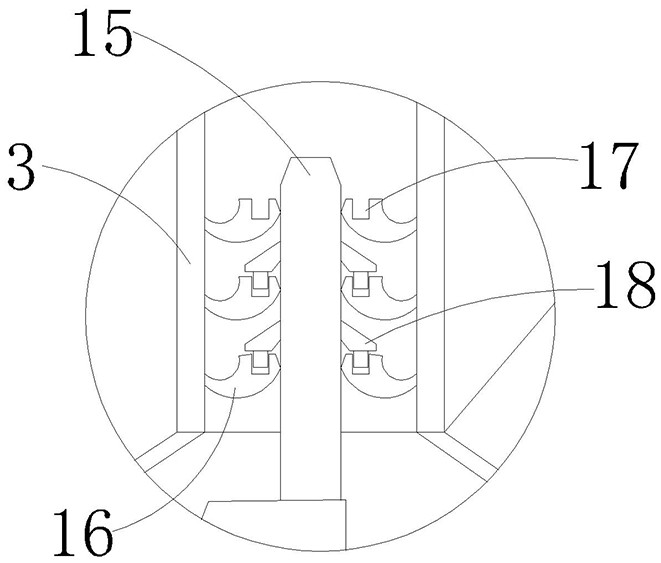

Quick-installation type high-voltage wire harness fixing device and using method thereof

PendingCN109546587ASimple structureEasy to operateElectrical apparatusElectric/fluid circuitEngineeringHigh pressure

The invention relates to a quick-installation type high-voltage wire harness fixing device and an operating method thereof. The quick-installation type high-voltage wire harness fixing device a wire clamping device and a fixing bracket, wherein the fixing bracket is used for fixing the wire clamping device; the wire clamping device comprises a base; one end of the base is rotatably connected withone end of a buckle cover, and the other end of the base is provided with a locking groove; the other end of the buckle cover is provided with a locking bolt matching the locking groove; the base is provided with at least one first wire harness slot, and the buckle cover is provided with a second wire harness slot corresponding to the first wire harness slot; the first wire harness slot and the second wire harness slot form an accommodating cavity for placing the wire harness; and the bottom of the base is provided with a locking structure for fixing the base and the fixing bracket. The quick-installation type high-voltage wire harness fixing device has the advantages of being simple in structure, being convenient for operation, greatly improving the fixing efficiency of the high voltage wire harness, and reducing the labor intensity.

Owner:ZHONGTONG BUS HLDG

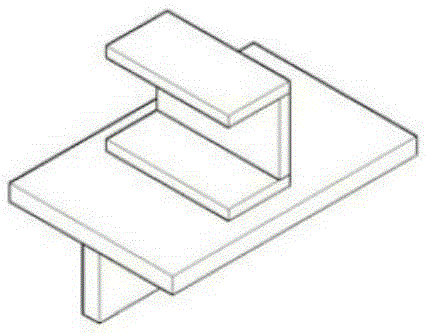

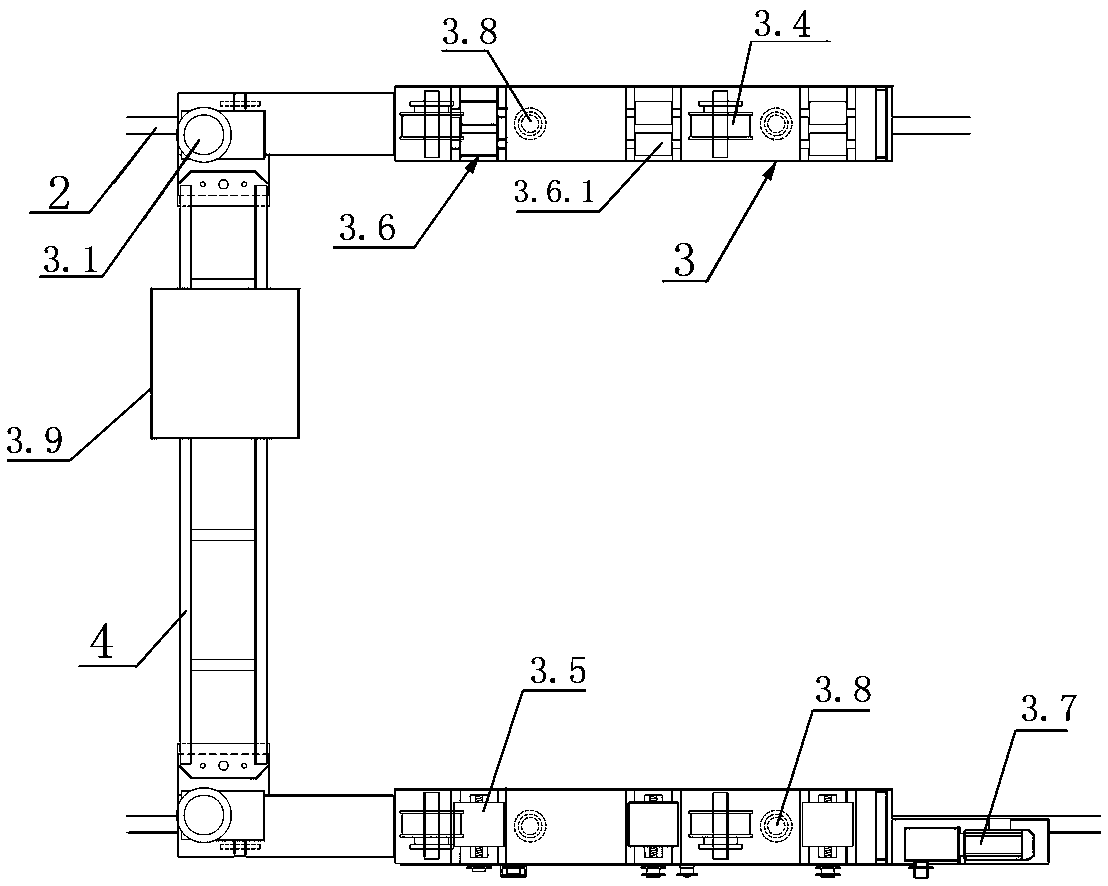

Transportation and assembling equipment system for prefabricated components and construction method of transportation and assembling equipment system

PendingCN108343087AImprove assembly construction efficiencyReduce workloadArtificial islandsUnderwater structuresVertical displacementUltimate tensile strength

The invention provides a transportation and assembling equipment system for prefabricated components and a construction method of the transportation and assembling equipment system. The transportationand assembling equipment system comprises guide rails, transport assembling equipment, at least two vehicle bodies and connecting beams; each vehicle body is connected to the corresponding guide railin a rolling mode and comprises a vehicle body structure, a traveling system and an aligning system; the vehicle body structures comprise top buckling plates and bottom buckling plates, and the top buckling plates and the bottom buckling plates are jointly spliced into a hollow box body with the cross section being rectangular; the traveling systems are mounted on the vehicle body structures fordriving the vehicle body structures to move along the guide rails; the aligning systems are mounted on the vehicle body structures for adjusting vertical displacement and transverse displacement of to-be-transported prefabricated components; and the prefabricated components are placed on the top buckling plates of the vehicle body structures, and transporting and mounting work of the prefabricatedcomponents is completed through the vehicle body structures, the traveling systems and the aligning systems. According to the transportation and assembling equipment system for the prefabricated components, the technical problems that as for a traditional construction method, the heavy hoisting operation quantity is large, many potential safety hazards occur, the occupied space of hoisting operation is large, the labor intensity of aligning splicing operation is high, and splicing precision is poor are solved.

Owner:BCEG CIVIL ENG +1

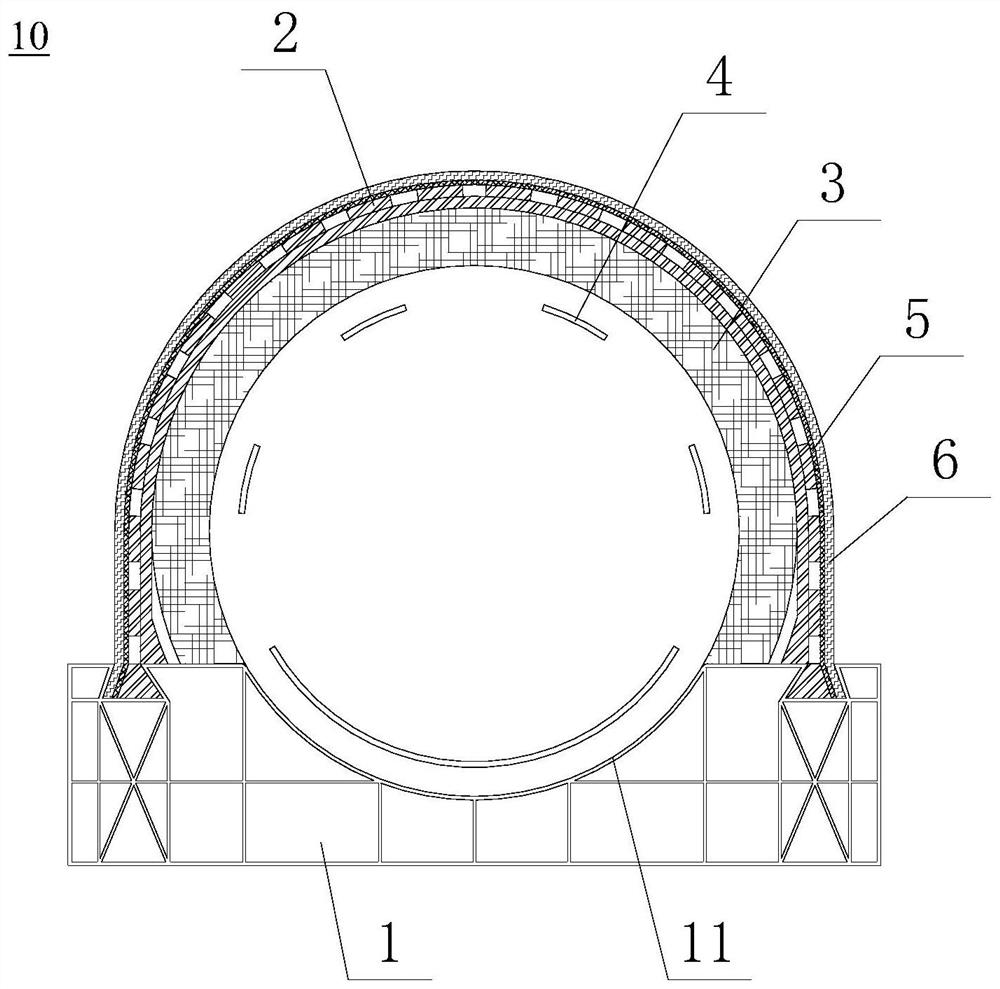

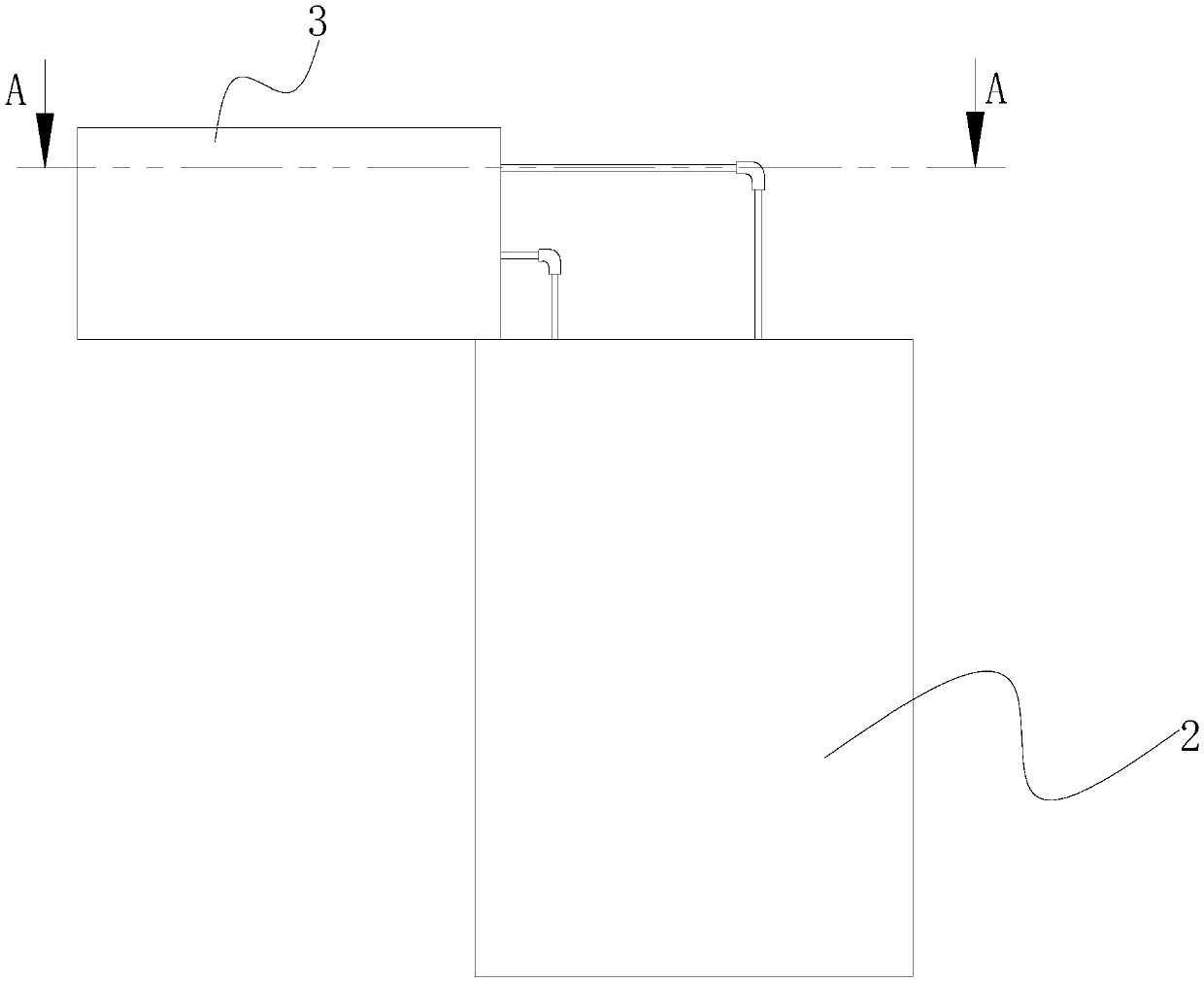

Subgrade seepage and drainage blind ditch

ActiveCN110747874AImprove assembly construction efficiencyImprove structural strengthBallastwayFoundation engineeringStructural engineeringDitch

The invention provides a subgrade seepage and drainage blind ditch. The subgrade seepage and drainage blind ditch comprises a base, a frame body detachably mounted on the base and configured as a semi-circular, and a corrugated tube arranged between the base and the frame body, wherein a plurality of water seepage holes are uniformly formed in the frame body; an arc-shaped groove is formed in thearea of the middle of the upper end surface of the base, the lower part of the outer wall of the corrugated tube is closely installed in the arc-shaped groove, the upper part of the outer wall of thecorrugated tube is in close contact with the inner wall of the frame body, a through hole is formed in the trough position where the corrugated tube in close contact with the frame body, and the groundwater in a subgrade can penetrate into the corrugated tube and be discharged from the subgrade through seepage holes and the through hole

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Construction method of prefabricated fair-faced concrete exterior wall cladding connecting structure

ActiveCN113833220AImprove the forceEasy to disassembleCovering/liningsBuilding material handlingFloor slabArchitectural engineering

The invention discloses a construction method of a prefabricated fair-faced concrete exterior wall hanging plate connecting structure, which comprises a building exterior wall hanging plate, an upper connecting plate, a bracket connecting piece and an adjustable bolt, a floor slab at the top of the exterior wall hanging plate is connected with a plate top chain block, and the middle of the exterior wall hanging plate is detachably connected with an in-plate chain block; a jack is detachably connected to the top face of the lower floor. By arranging the hoisting holes, the buried anchorage devices and the special hoisting devices in the exterior wall hanging plate, convenient and fast installation and hoisting can be achieved when the externally-hung wall plate is hoisted, and overall stress and convenient and fast disassembly are facilitated due to the arrangement of the buried anchorage devices and the internal threaded sleeves; through the comprehensive application of the in-plate chain block, the jack and the plate top chain block, the exterior wall cladding can be accurately positioned and adjusted in the hoisting process, the plate top chain block can accurately position the vertical direction, and the in-plate chain block and the jack can accurately position the horizontal direction, so that the installation quality of the exterior wall cladding is improved.

Owner:BEIJING FOURTH CONSTR & ENG

Exterior wall tile composite structure and method for manufacturing same

InactiveCN103669778AGood decoration quality and decoration effectImprove assembly construction efficiencyCovering/liningsLaminationBuilding materialComposite structure

The invention relates to the field of building materials, in particular to an exterior wall tile composite structure and a method for manufacturing the same. The method for manufacturing the exterior wall tile composite structure includes steps of fully laying mortar on a side surface of an inorganic plate and then leveling the mortar; placing ceramic tiles on the surface of the mortar and pressing and forming the exterior wall tile composite structure. The exterior wall tile composite structure comprises the inorganic plate. The ceramic tiles are adhered on the side surface of the inorganic plate by an adhesion layer. The exterior wall tile composite structure and the method for manufacturing the exterior wall tile composite structure have the advantages that the exterior wall tile composite structure is fixed onto a wall body in a dry hanging mode or a wet adhesion and drying hanging combined mode, so that a heat-insulation system is not stressed any more and is safe, the exterior wall tiles do not need to be manually adhered in a wet manner in a field, accordingly, a decorative effect and the decorative quality are good, and the assembly construction efficiency is high; the ceramic tiles can be prevented from falling off, leakage of an exterior wall can be prevented, and accordingly an integral exterior wall system is safe, reliable and durable.

Owner:吕国兵

Column prefabricated member and manufacturing method and installation construction method thereof

PendingCN111456326AReduce workloadReliable deliveryStrutsMouldsArchitectural engineeringStructural engineering

The invention discloses a column prefabricated member and a manufacturing method and installation construction method thereof, and belongs to the technical field of prefabricated buildings. The columnprefabricated member comprises a column die sleeve, a plurality of inner diaphragms, a plurality of longitudinal steel bars and a protective layer, the longitudinal steel bars are arranged on the inner wall of the column die sleeve, the inner diaphragms are arranged in the column die sleeve, the protective layer is arranged on the outer side wall of the column die sleeve, the inner diaphragms areconnected to the column die sleeve and the longitudinal steel bars, a hole communicating with a structural beam is formed in the middle part of the column die sleeve, end plates are arranged at the two ends of the column die sleeve, and connecting sections at the two ends of the column die sleeve comprise the end plates used for vertically splicing column prefabricated member bodies of the uppersection and the lower section on site. According to the column prefabricated member and the manufacturing method and installation construction method thereof, the workload of on-site installation construction of the column prefabricated member can be reduced, the defect that the longitudinal steel bars are prone to get bent firstly under stress can be overcome, and the overall bearing capacity ofa structural column can be improved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Prefabricated wall integrated with mechanical and electrical pipelines and construction method thereof

PendingCN106958309AReduce the impact of holesImprove assembly construction efficiencyWallsFloor slabLine tubing

The invention provides a prefabricated wall integrated with mechanical and electrical pipelines and a construction method thereof. The wall comprises a main wall body; the upper end and the lower end of the main wall body are in sliding connection with an upper layer floorboard and a lower layer floorboard through an upper connecting piece and a lower connecting piece correspondingly; end plates used for being fixedly connected with the floorboards are arranged at the ends, away from the main wall body, of the upper connecting piece and the lower connecting piece; the ends, facing the main wall body, of the upper connecting piece and the lower connecting piece are each provided with a convex rail; the upper end and the lower end of the main wall body are provided with grooves matched with the corresponding convex rails; and the main wall body can move relative to the floorboards along the upper connecting piece and the lower connecting piece, and main pipeline grooves or a main pipeline groove are / is pre-buried in the upper connecting piece and / or the lower connecting piece. On the one hand, the civil engineering and mechanical-electrical integrated prefabricated wall can be achieved, punching influences of mechanical and electrical pipeline construction on civil engineering can be reduced to a great extent, and the prefabrication construction efficiency is improved. On the other hand, free moving and splicing of the prefabricated wall can be achieved, and the wall can be recycled.

Owner:上海市建工设计研究总院有限公司 +1

Deep foundation pit water leakage emergency rescue cofferdam and construction method thereof

The invention discloses a deep foundation pit water leakage emergency rescue cofferdam and a construction method thereof. The cofferdam comprises a plurality of linear water injection box bodies and corner type water injection box bodies, each of the linear water injection box bodies and corner type water injection box bodies is provided with a water injection hole, water leakage positions of an underground diaphragm wall are enclosed by the linear water injection box bodies and the corner type water injection box bodies to be mutually spliced and assembled layer by layer, inserting body structures are correspondingly arranged between the vertical adjacent upper and lower layers of linear water injection boxes, between the vertical adjacent upper and lower layers of corner type water injection boxes, between the horizontal adjacent linear water injection boxes, and between the horizontal adjacent linear water injection box and the corner type water injection box, and the bottom of the linear water injection box body on the bottom layer and the bottom of the corner type water injection box body on the bottom layer are each provided with insertion feet inserted into a deep foundation pit soil body. According to the deep foundation pit water leakage emergency rescue cofferdam and the construction method thereof, when a deep foundation pit leaks water, the purpose of rapidly assembling the deep foundation pit water leakage emergency rescue cofferdam can be achieved, and control over the water leakage danger is facilitated; and the cofferdam is reliable and stable in connection and not prone to collapse.

Owner:SHANGHAI CONSTR NO 1 GRP

Diagonal bar supporting device and construction method thereof

InactiveCN110005214AAchieve recyclingReduce wasteBuilding material handlingArchitectural engineeringThreaded rod

The invention discloses a diagonal bar supporting device. The diagonal bar supporting device comprises a connector, a connecting sleeve and a supporting frame, the supporting frame is provided with asupporting ring and a threaded rod, the connector is in a rod shape and used for being assembled with hanging nails in a superposed beam; external threads are arranged at the two ends of the connector, the first end of the connector is used for being connected with internal threads of the hanging nails in a matching mode; the connecting sleeve is provided with the internal threads and is used forbeing connected with the second end of the connector in a matching mode through threads; the supporting frame is used for supporting a diagonal bar; the supporting frame is provided with the supporting ring which is annular and used for supporting the diagonal bar; and the threaded rod is connected with the outer edge of the supporting ring and used for being connected with the connecting sleeve in a matching mode through the threads. The diagonal bar supporting device can be split, split parts can be recycled, and the problem of low construction efficiency is solved. In addition, the invention further discloses a construction method of the diagonal bar supporting device.

Owner:SHANGHAI BAOYE GRP CORP

Construction method for rapidly installing pipelines in pipe gallery

InactiveCN111609213AImprove assembly construction efficiencyReduce the amount of welding workArtificial islandsPipe laying and repairConstruction engineeringPipe

The invention discloses a construction method for rapidly installing pipelines in a pipe gallery, and belongs to the technical field of pipeline engineering. An operator welds a plurality of pipe joints into a pipeline set outside the pipe gallery, then the pipeline sets are conveyed to preset assembling positions in the pipe gallery through a pulley set and a winch set, between-group welding is carried out the pipeline sets in the pipe gallery, finally, conveying pipes are jacked through a jacking unit, the pulley set and the winch set are dismantled, and the conveying pipelines are assembledon a buttress set. According to the construction method for rapidly installing the pipelines in the pipe gallery, the advantages of the speed and process stability of welding outside the pipe galleryare fully utilized, the welding work amount in the pipe gallery is reduced, the transportation speed in pipe joint holes is increased, and the pipeline assembling construction efficiency is improved.

Owner:中铁二十二局集团第三工程有限公司

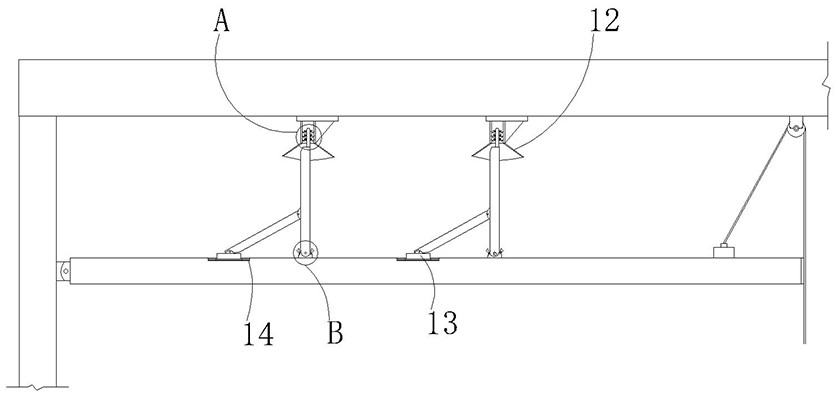

Height-adjustable bridge pier hoisting machine, construction method and overpass passing method

PendingCN111675112AImprove convenienceIncrease the scope of applicationBase supporting structuresBraking devices for hoisting equipmentsPierArchitectural engineering

The invention provides a height-adjustable bridge pier hoisting machine, a construction method and an overpass passing method. The height-adjustable bridge pier hoisting machine comprises a frame beamassembly including a cross beam, a hoisting mechanism arranged on the frame beam assembly and used for hoisting a prefabricated pier to be assembled and a supporting leg assembly used for supportingthe frame beam assembly; and the supporting leg assembly comprises splitting parts and support leg parts, the upper ends of the splitting parts are connected with the cross beam and penetrate throughthe end part of the cross beam, the lower ends of the splitting parts are detachably connected with the support leg parts, and the cross beam is suitable for moving on the splitting parts and the support leg parts. According to the height-adjustable bridge pier hoisting machine, the construction method and the overpass passing method, by arranging the supporting leg assembly with the splitting part and the support leg part, the height of the hoisting machine can be adjusted, and the convenience of transportation of the hoisting machine when the hoisting machine passes through height-limited terrains such as bridge holes of an overpass is improved.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD

Connecting part for connecting light wall body with steel framework, connecting structure and construction method

ActiveCN111472475AImprove assembly construction efficiencyStable supportWallsShock proofingSteel frameMechanical engineering

The invention provides a connecting part for connecting a light wall body with a steel framework, a connecting structure and a construction method and relates to the technical field of building structures. The connecting part comprises an L-shaped connecting plate, a first supporting block, a second supporting block and limiting parts, wherein the first supporting block is connected to an internalcorner portion of the L-shaped connecting plate in a welded manner, the second supporting block is detachably connected to the L-shaped connecting plate and arranged on the outer side of the first supporting block, and the limiting parts are arranged at intervals and fixedly connected to the upper surface of a horizontal support of the L-shaped connecting plate. Each limiting part comprises a cylindrical locating pin, a damping spring fixedly connected to the top face of the locating pin, and a cushion plate fixedly connected to the upper end of the damping spring. The connecting structure comprises the light wall body, a steel beam and connecting parts for connecting the light wall body with the steel beam. The connecting parts are fixedly installed on four corner portions of the light wall body. The four corner portions of the light wall body and the steel beam can be fixed through the connecting parts. According to the connecting part, the connecting structure and the constructionmethod, the problems that force bearing of an existing connecting part is weak, when a framework and a wall body shake, the steel framework and the wall body are in rigid connection, there is no buffering force, and thus the wall body cracks easily are solved.

Owner:TIANYUAN CONSTR GROUP +1

Fabricated concrete structure beam-column dry-wet combination connection structure and implementation method

PendingCN111255066ASave process linksLow construction costBuilding constructionsRebarTransverse beam

The invention discloses a fabricated concrete structure beam-column dry-wet combination connection structure and an implementation method, and belongs to the technical field of fabricated buildings. Acylindrical cavity structure is arranged at the intersection of a transverse beam and a longitudinal beam, the cylindrical cavity structure comprises an outer cylinder and an inner cylinder, and a square ring-shaped cavity is formed by enclosing the outer cylinder and the inner cylinder; column corner part longitudinal reinforcement bars I and column corner part longitudinal reinforcement bars IIare arranged at four corners of the square ring-shaped cavity, transverse beam longitudinal reinforcement bars and longitudinal beam longitudinal reinforcement bars in the transverse beam and the longitudinal beam penetrate through the outer cylinder and the inner cylinder in sequence; and anchoring heads are connected to the inner ends of the transverse beam longitudinal reinforcement bars and the longitudinal beam longitudinal reinforcement bars. According to the fabricated concrete structure beam-column dry-wet combination connection structure and the implementation method, a modular beam-column joint core area connection structure is formed through the construction method of the inner cylinder and outer cylinders, the problems of multi-directional reinforcement bar anchoring connection of a beam body, complex intersection anchoring connection of column body longitudinal reinforcement bars of and stirrups crossing and installation are solved, the process link and construction costof a formwork and a support are saved, and the fabricated concrete structure beam-column dry-wet combination connection structure has the advantages and characteristics of modularization, integration,integration and informatization.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

Multipurpose steel structure decorative suspended ceiling and assembly construction method thereof

ActiveCN114482389AAesthetic impactEasy to operateCeilingsBuilding material handlingClassical mechanicsAssembly (construction)

The multipurpose steel structure decorative ceiling comprises an inner wall and a steel structure top frame, a limiting cylinder is installed at the bottom end of the steel structure top frame, the inner wall is located on one side of the limiting cylinder, a guide pulley is installed at the position, on the other side of the limiting cylinder, of the bottom end of the steel structure top frame, and a top plate is rotationally installed on the upper surface of the inner side wall of the inner wall. An inserting rod is movably installed at the top end of the top plate in a limiting mode through a limiting component, an inserting mechanism is installed between the inserting rod and the limiting cylinder, a multipurpose half hole is formed in the surface of the end, away from the inner wall, of the top plate, a traction mechanism is cooperatively installed between the multipurpose half hole and the guide pulley, and a lamp frame is installed at the bottom end of the top plate below the multipurpose half hole. According to the ceiling and the assembly construction method thereof, by arranging a series of structures, the assembly direction can be changed, construction is facilitated, meanwhile, hole body covering is flexibly conducted by means of the lamp frame, the attractiveness is improved, the construction steps are saved, assembly construction is conducted by means of a semi-hoisting mode, and follow-up overhauling, wiring and other operations are facilitated.

Owner:河南省大方起重设备服务有限公司

A system and method for intelligent management of building formwork based on cloud intelligence technology

InactiveCN104268708BUniqueness guaranteedEasy to assembleData processing applicationsSpecial data processing applicationsTerra firmaComputer science

The invention discloses a building template intelligent managing system and method based on the cloud intelligence technology. The system is characterized by comprising a building template system, a cloud intelligence label, a template sorting system, a template delivery system, a cloud intelligence channel identification system and a data processing center. By means of the integrated management mode of the cloud intelligence technology application of the systems, information management of production, packaging, delivery, out-put and in-put of warehouse, construction site entering, construction installation, detachment, sending back and tracking of various building templates can be achieved. By the adoption of the system and method, construction labor intensity is relieved, labor is saved, labor efficiency is improved, construction period is shortened, and a firm foundation is provided for future unmanned construction, building intelligentization, work standardization and information-based management.

Owner:HUNAN PUYUN INTELLIGENT TECH

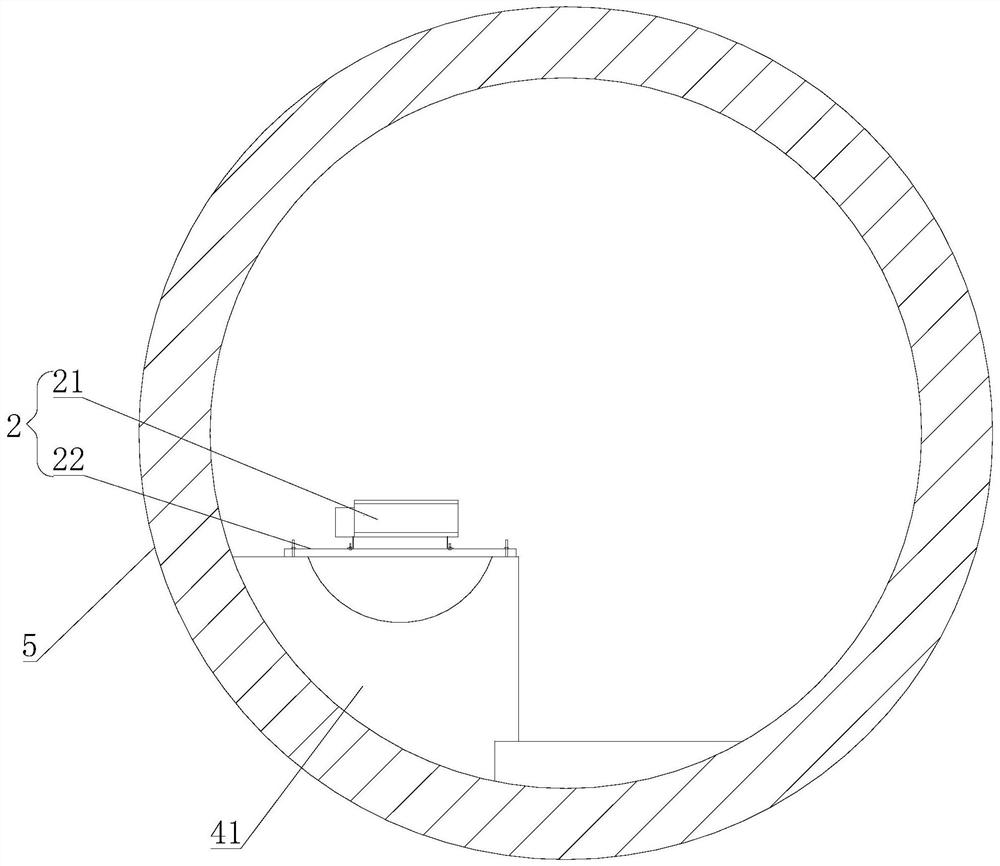

A roadbed seepage drainage blind ditch

ActiveCN110747874BImprove assembly construction efficiencyImprove structural strengthBallastwayFoundation engineeringStructural engineeringClose contact

The invention provides a roadbed seepage and drainage blind ditch, comprising: a base; a frame body detachably mounted on the base and configured as a semicircular ring; the frame body is evenly distributed with a number of seepage holes; and A bellows between the base and the frame body; wherein, the middle area of the upper end surface of the base is provided with an arc-shaped groove, and the lower part of the outer wall of the bellows is closely mounted on the arc-shaped groove Inside, the upper part of the outer wall of the bellows is in close contact with the inner wall of the frame body, and a through hole is provided at the trough position of the bellows in close contact with the frame body, and the groundwater in the subgrade can pass through the seepage The holes and the through-holes penetrate into the bellows and out of the roadbed.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Manufacturing method of driver fence rear enclosure and manufacturing method of driver fence driver door

InactiveCN112536966ASimple structureImprove consistencyPedestrian/occupant safety arrangementStructural engineeringUltimate tensile strength

The invention discloses a manufacturing method of a driver fence rear enclosure and a manufacturing method of a driver fence driver door. The manufacturing method of the rear enclosure comprises the steps of 1) preparing a mold, and specifically, manufacturing a foaming mold meeting requirements according to the shape and structure requirements of the rear enclosure; 2) selecting a surface material and placing the surface material in a lower mold body, and adsorbing or suspending and tensioning an inner surface base material on the surface of an upper mold body; 3) laying a reinforcing material layer zone 1b in the lower mold body of the mold, so that the reinforcing material layer zone 1b is large in density and high in strength; 4) injecting a polyurethane foaming material through high-pressure foaming, assembling the upper mold body and the lower mold body, carrying out maintaining pressure and curing, and completing integral forming of the rear fence; and 5) taking out of a productafter the product is cured, and carrying out edge cutting and trimming. For the manufacturing method of the driver door, the manufacturing method is the same, and a different mold is used. The overall structure is simple, the assembly efficiency is high, the final assembly time is 67% of that of a split structure product, the number of assembly parts is small, no gap exists, the strength is high,stability is achieved, no abnormal sound exists, the inner surface and the outer surface are formed in place at a time, and the cost is low.

Owner:湖南亚太实业有限公司

Connecting structure of prefabricated building

InactiveCN111424815AShorten the construction periodAvoid WeldingBuilding reinforcementsArchitectural engineeringStructural engineering

Owner:周兆弟

Connector for prefabricated members

InactiveCN111424816AFirmly connectedEfficient connectionBuilding reinforcementsStructural engineeringMechanical engineering

Owner:周兆弟

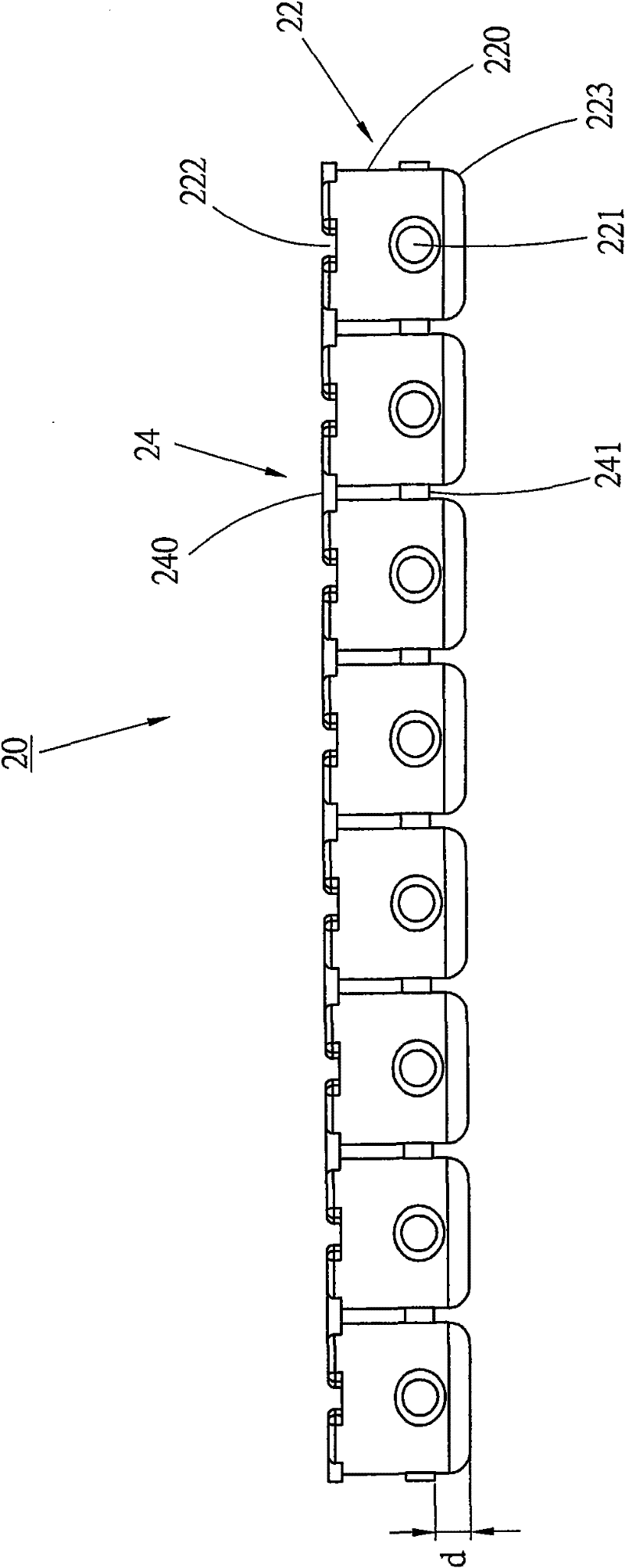

Series type fastening assembly and impact device using same

InactiveCN102011774BImprove assembly construction efficiencyImprove construction efficiencyPortable percussive toolsSheet joiningEngineeringWorking hours

The invention discloses a series type fastening assembly and an impact device using the same. The series type fastening assembly comprises a plurality of fasteners and a plurality of connecting members, wherein the plurality of fasteners are staggered with the plurality of connecting members, and the fasteners and the connecting members are linearly arrayed; a combining hole and a groove are radially arranged in each fastener, wherein the groove is depressed on the top surface of the fastener and has the same direction as the combining hole; the series type fastening assembly is arranged in the impact device, the fasteners can be respectively impacted into a preset hole of a plate by the impact device, thereby the impact device is capable of continuously impacting and embedding the fasteners into the corresponding plate, shortening working hours for assembling the fasteners and increasing the assembling efficiency of the plate.

Owner:蔡登录

Trolley capable of crossing steel support assembled subway station

ActiveCN113668536AImprove assembly construction efficiencyAvoid assembly and disassemblyArtificial islandsRailway transportStructural engineeringSubway station

The invention relates to the technical field of fabricated subway station construction, in particular to a trolley capable of crossing a steel support assembled subway station. The trolley comprises a plurality of bottom plate assembling racks; walking mechanisms are arranged at the lower parts of the bottom plate assembling racks; a middle plate assembling mechanism used for turning over a middle plate is arranged on each bottom plate assembling rack; a cross supporting mechanism is further arranged on each bottom plate assembling rack; each cross supporting mechanism comprises a rack body and an adjustable supporting mechanism connected with the rack body; the adjustable supporting mechanisms are connected with the bottom plate assembling racks and is fixedly connected with or separated from the rack bodies in an adjustable mode; and a top plate assembling mechanism is further arranged above the cross supporting mechanisms. The trolley capable of crossing the steel support assembled subway station can stride over a steel support structure in the advancing construction process, frequent assembly and disassembly are avoided, the efficiency of subway station splicing construction is greatly improved, meanwhile, supporting force is kept in the steel support striding process, and safety guarantee is improved.

Owner:KUNMING RAILWAY CONSTR COMPANY OF CHINA RAILWAY NO 8 ENG GRP +3

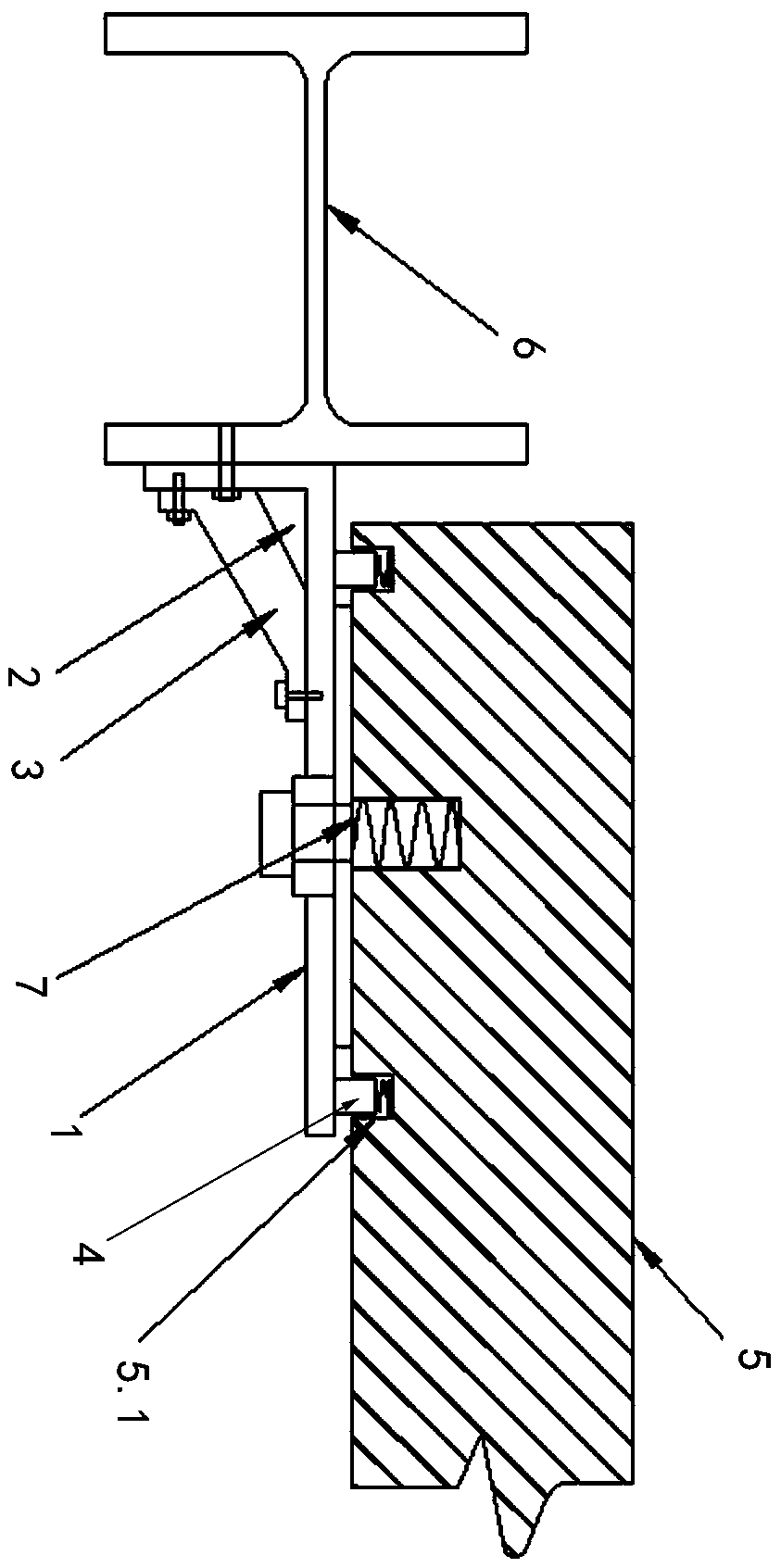

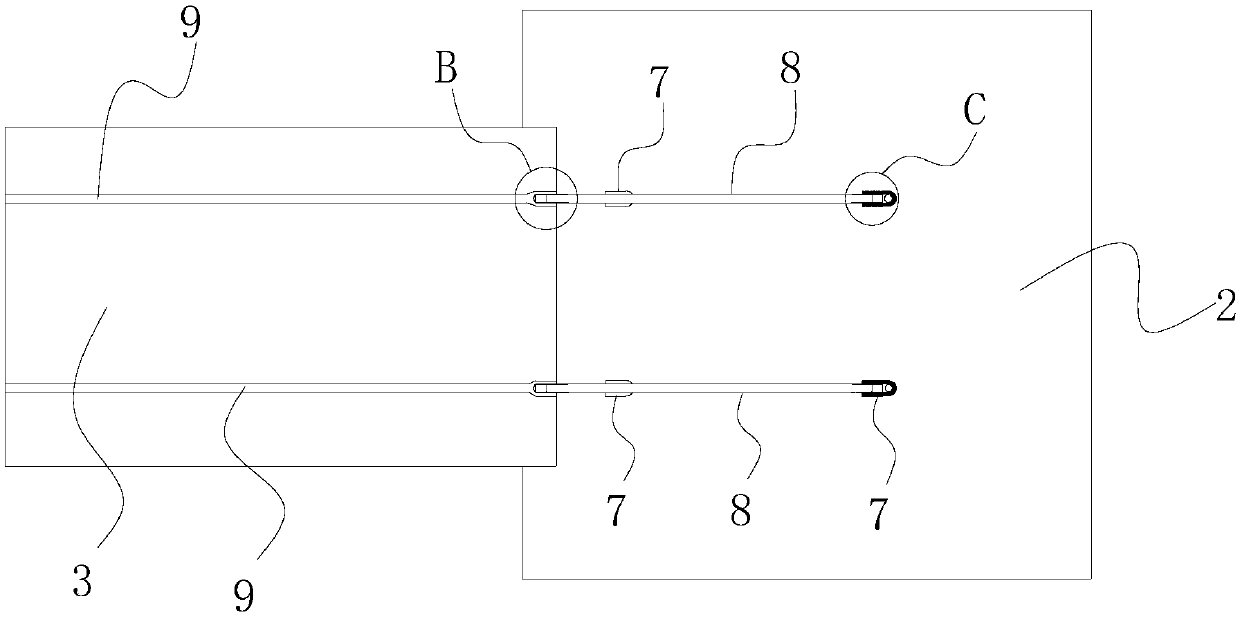

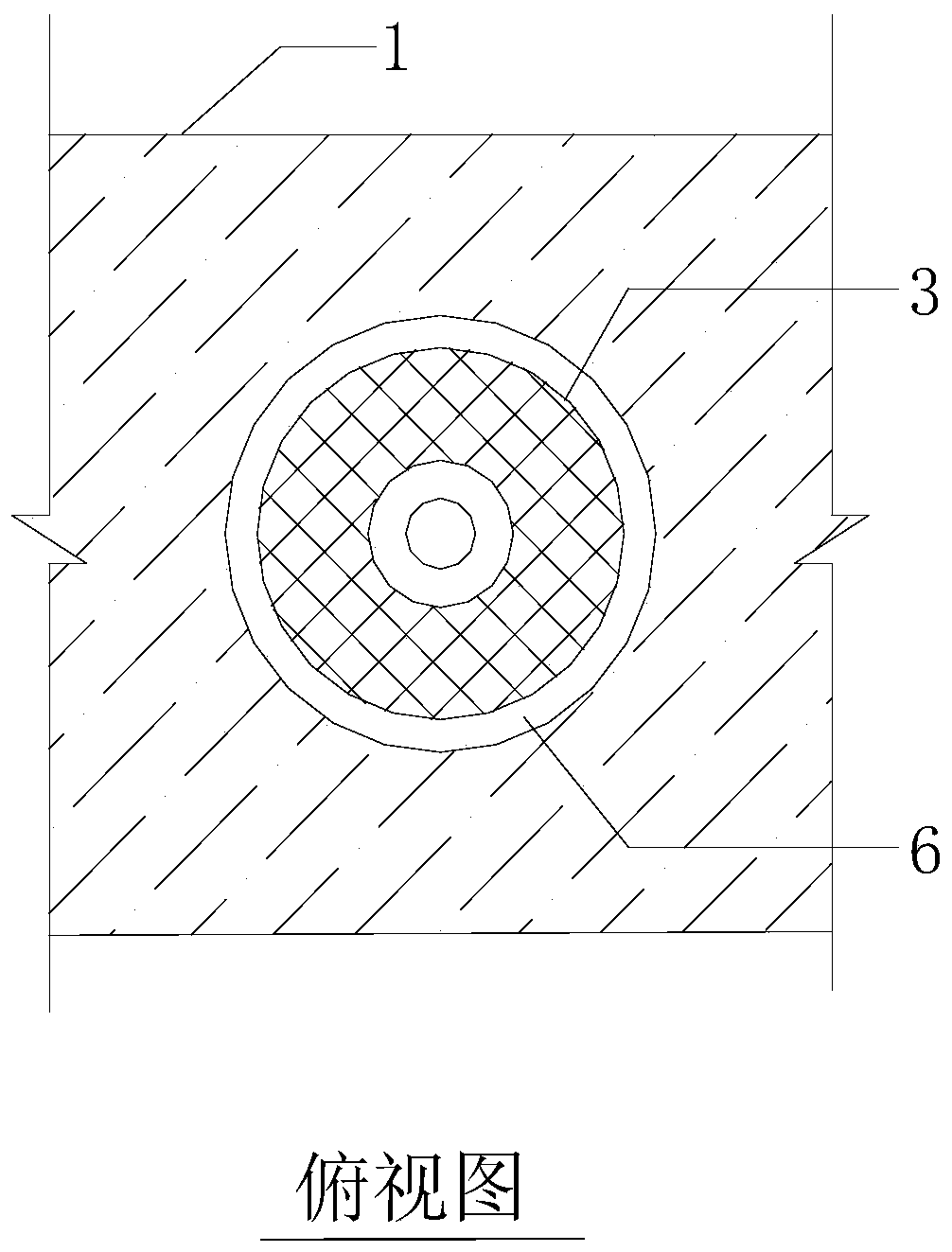

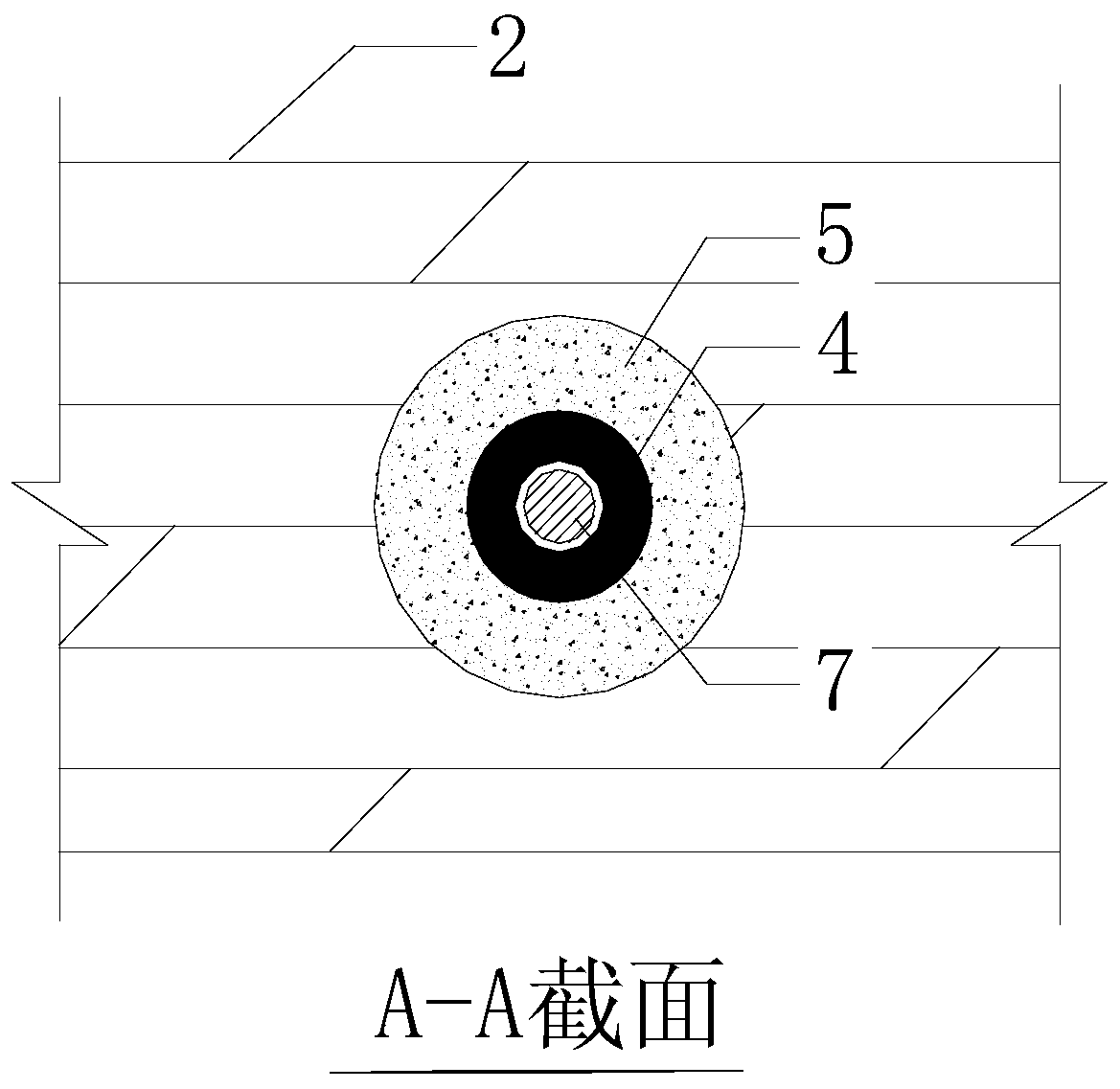

A prefabricated bamboo wood-concrete composite beam

The invention discloses a fabricated bamboo-wood-concrete combination beam. The fabricated bamboo-wood-concrete combination beam is characterized in that a prefabricated concrete plate (1) and a bamboo-wood beam (2) are combined through steel tube-ultra high performance concrete composite shear connector (3); the steel tube-ultra high performance concrete composite shear connector (3) is characterized in that a steel tube (4) is externally wrapped with ultra-high-performance concrete (5), one end of the steel tube is the connecting end, the shape of the connecting end is a circular column, the other end of the steel tube is the anchoring end, and the shape of the anchoring end is a circular truncated cone; the prefabricated concrete plate (1) is characterized in that a preformed hole (6) is formed, and the conicity of a hole channel is the same with the conicity of the anchoring end of the steel tube-ultra high performance concrete composite shear connector (3); and the fabricated bamboo-wood-concrete combination beam is characterized in that the thread end of a tapping screw (7) is anchored in the bamboo-wood beam (2) through a hole channel in the steel tube (4), and the nut end of the tapping screw (7) is supported at the top of the steel tube (4). The fabricated bamboo-wood-concrete combination beam has the advantages of being simple in assembly way, high in construction efficiency, high in flexural rigidity, good in stretchability and the like, the good application prospect in modern bamboo-wood building and existing building reform.

Owner:HUNAN UNIV

Multi-petal combinable anchor rod centering support device and construction method thereof

PendingCN113235586ASolve the problem of not being able to effectively centerSolve the problem that the spacing is difficult to meet the engineering requirementsBulkheads/pilesAgricultural engineeringRebar

The invention discloses a multi-petal and combinable anchor rod centering support device, and relates to the field of reinforcement treatment of water conservancy and hydropower, roads, bridges and geotechnical engineering. The multi-petal and combinable anchor rod centering support device comprises an anchor rod and a centering support, wherein the centering support comprises a first centering support petal, a second centering support petal and a centering ridge frame; the anchor rod is wrapped by the first centering support petal and the second centering support petal, the first centering support petal and the second centering support petal are connected through a fixing device, and the fixing device comprises a first buckling tooth, a first buckling door, a second buckling door and a second buckling tooth. According to the multi-petal and combinable anchor rod centering support device, the problems that the production quality is uncontrollable, and anchor rod steel bars cannot be effectively centered due to the fact that most traditional centering supports are directly machined by field workers in the current anchor rod construction process are solved. The invention further relates to a construction method of the multi-petal combinable anchor rod centering support device.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com