Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

258results about How to "Guaranteed force balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal management system of water-cooling proton exchange membrane fuel cell and control method of thermal management system

ActiveCN104934619AReduce poisonEasy temperature controlFuel cell auxillariesThermal management systemEngineering

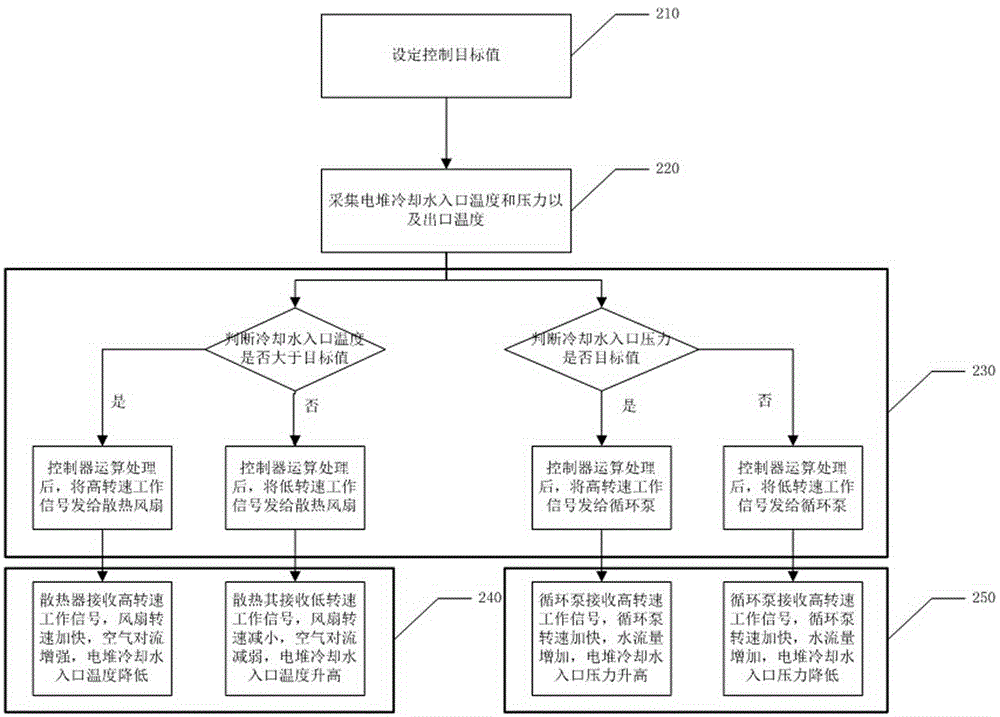

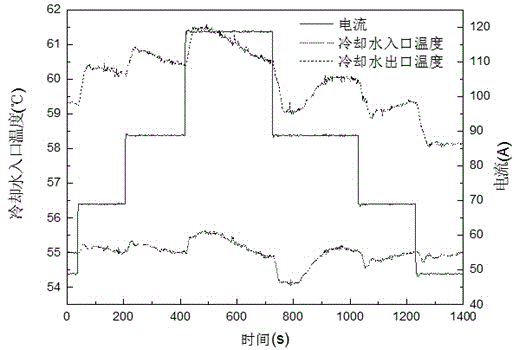

The invention provides a simple and effective thermal management system of a water-cooling proton exchange membrane fuel cell and a control method of the thermal management system. The thermal management system mainly comprises an electric pile, a water tank provided with a heating device, a cooling water circulating pump, a radiator, a cooling water pile inlet temperature sensor, a cooling water pile outlet temperature sensor, a cooling water pile inlet pressure sensor and a controller of the thermal management system. The control method following pressure change is provided to overcome the defects of lag, great overshooting, system coupling and the like caused by temperature change tracking in the traditional control strategy. The radiator is mainly used for controlling the cooling water inlet temperature of the pile and mainly controls the rotating speed of a radiator fan according to the cooling water inlet temperature of the pile of the fuel cell; and the cooling water circulating pump is mainly used for controlling the cooling water flow in the whole thermal management system and mainly controls the rotating speed of the circulating pump according to the cooling water inlet pressure of the pile of the fuel cell.

Owner:SOUTHWEST JIAOTONG UNIV

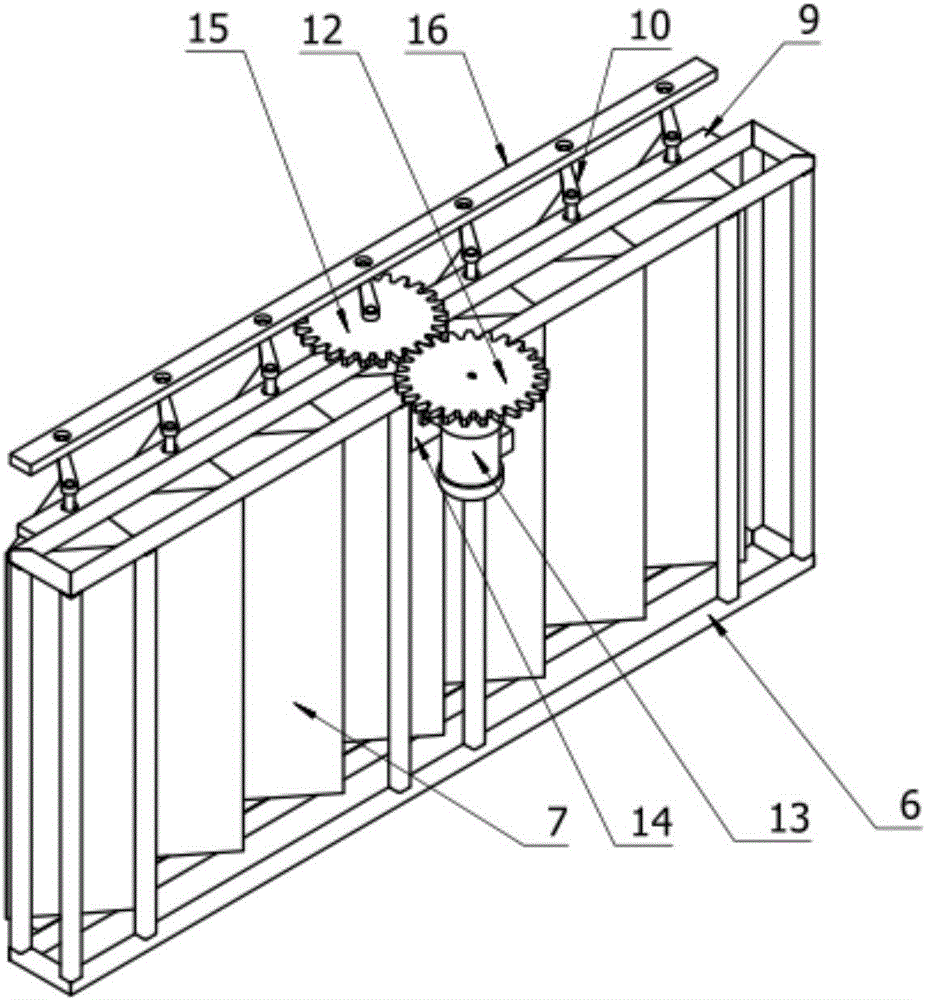

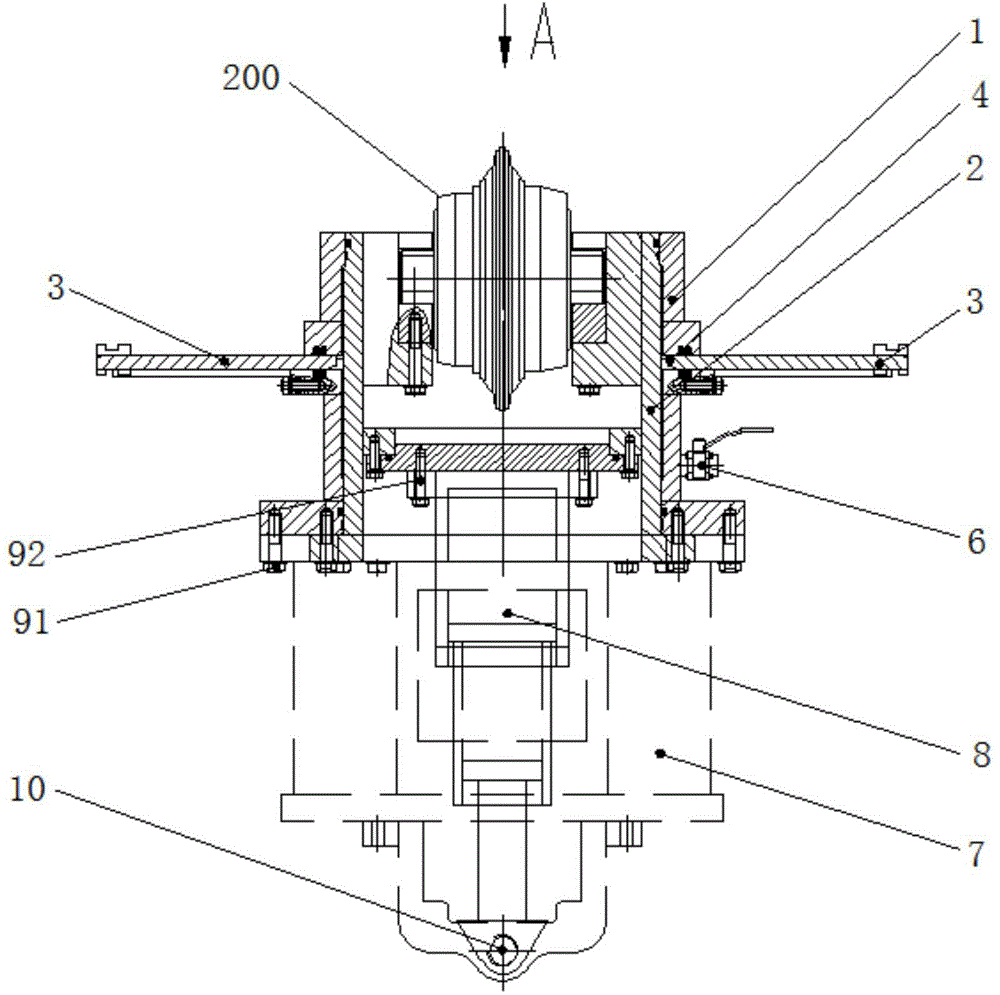

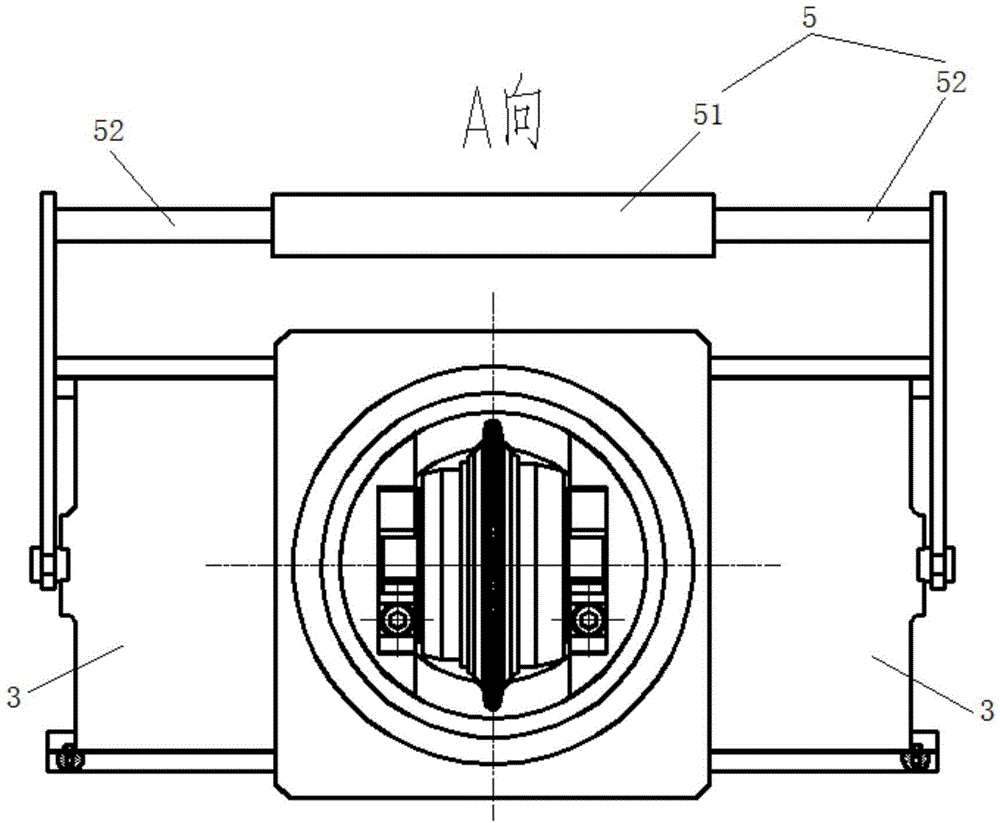

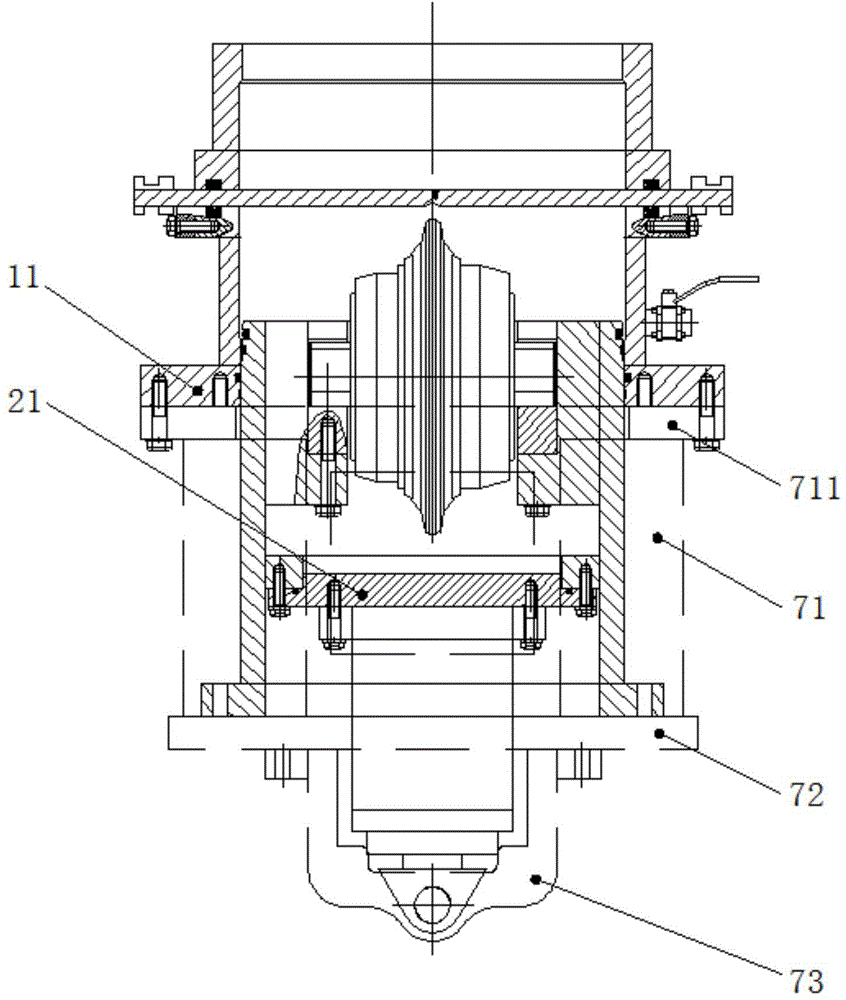

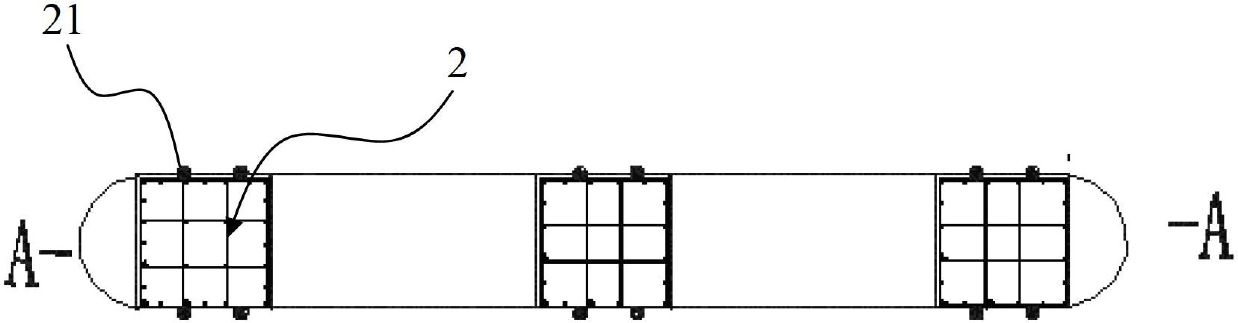

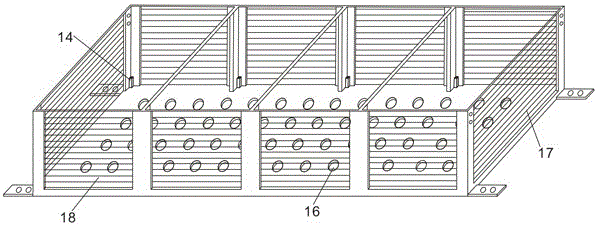

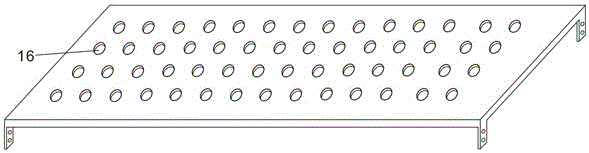

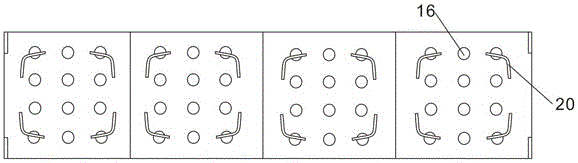

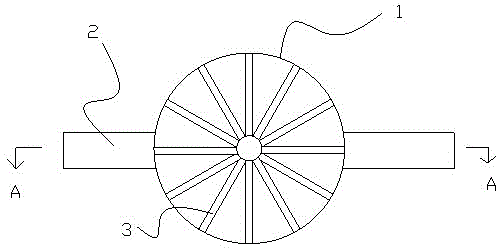

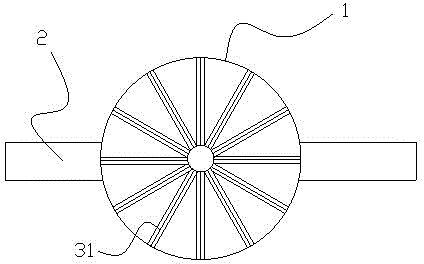

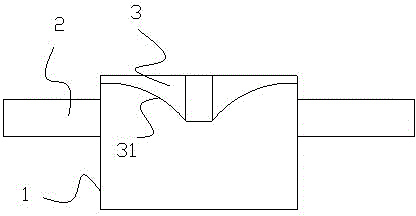

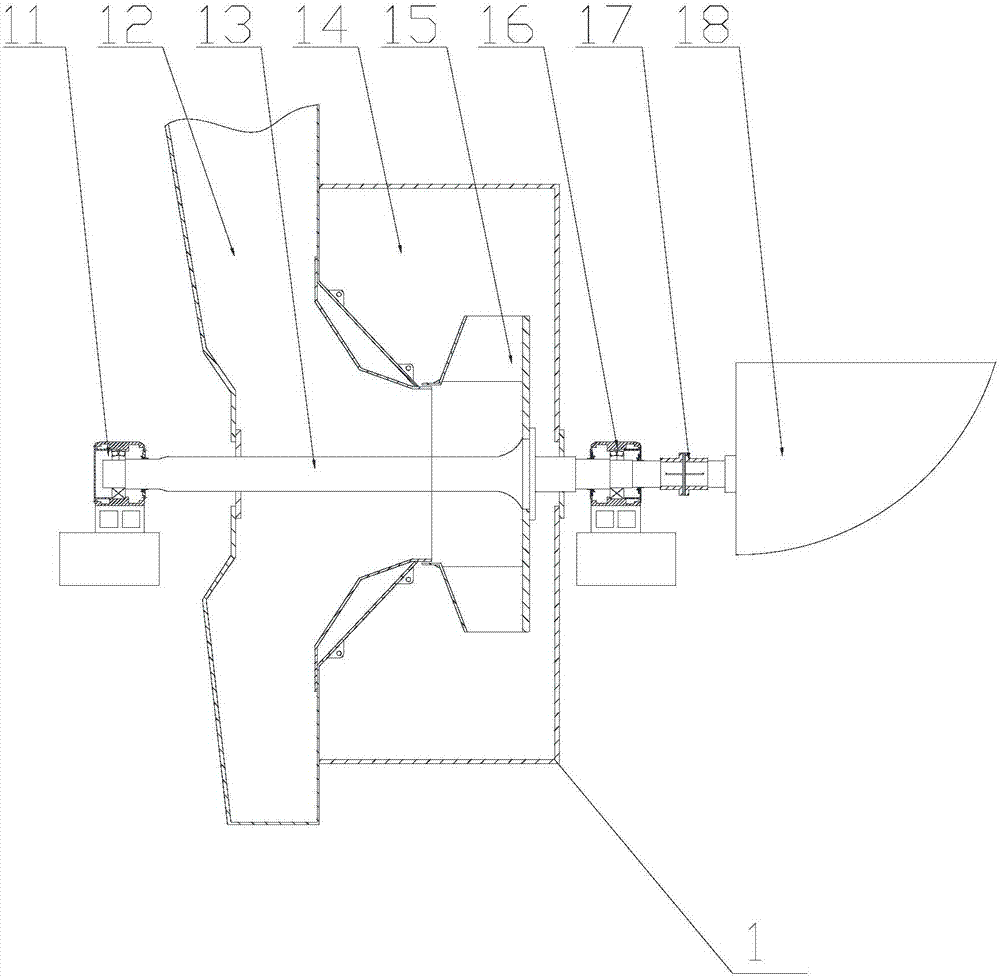

Multi-picture rotatable omnibearing displaying advertising device

InactiveCN106128325AExpansion quantityGuaranteed force balanceIdentification meansMotor driveAgricultural engineering

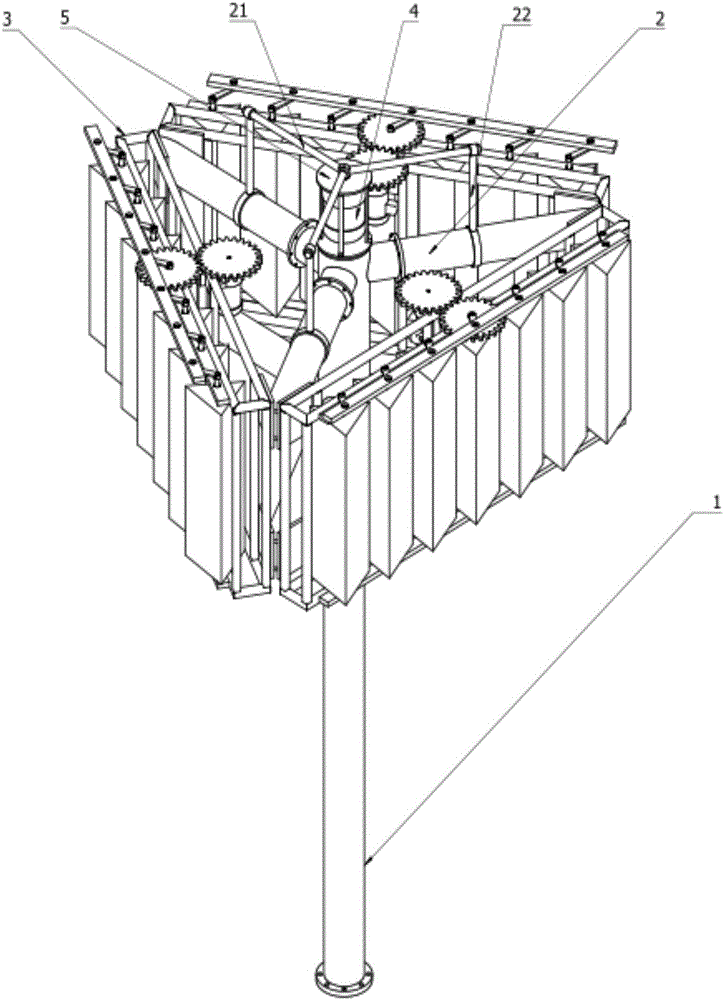

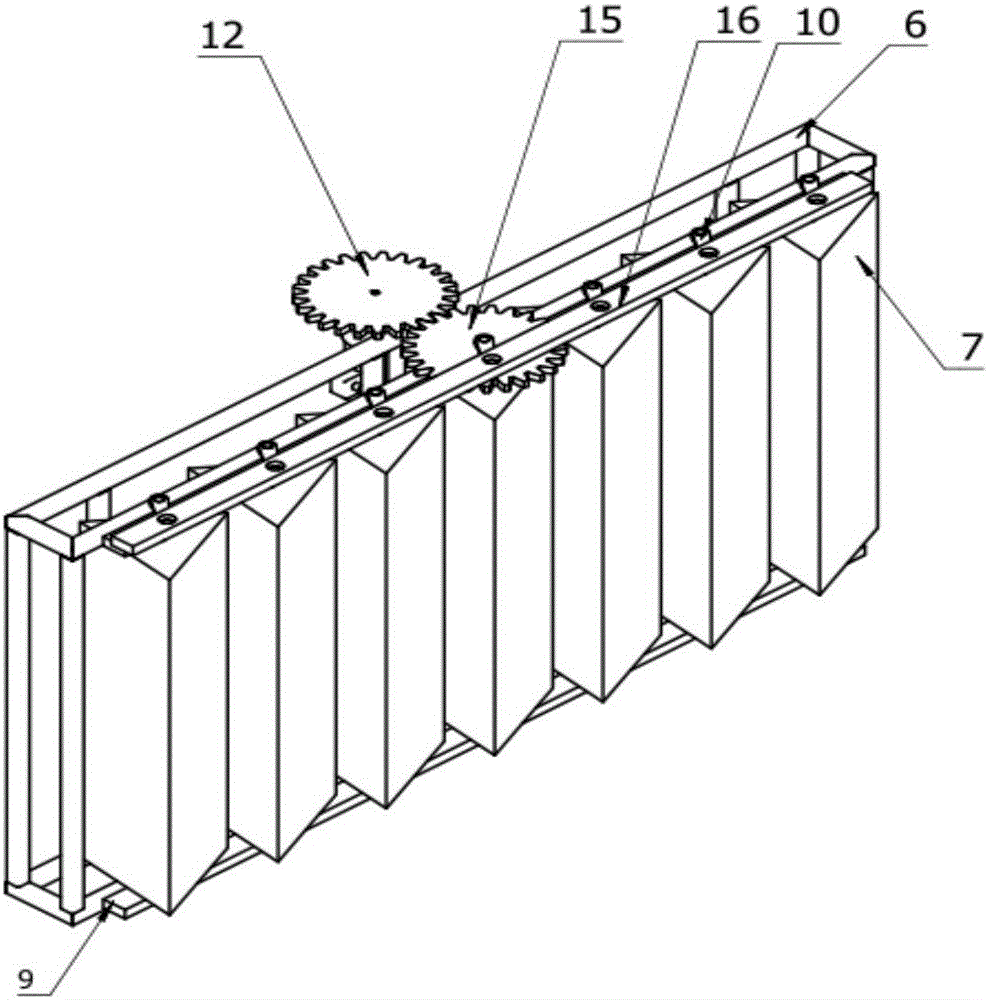

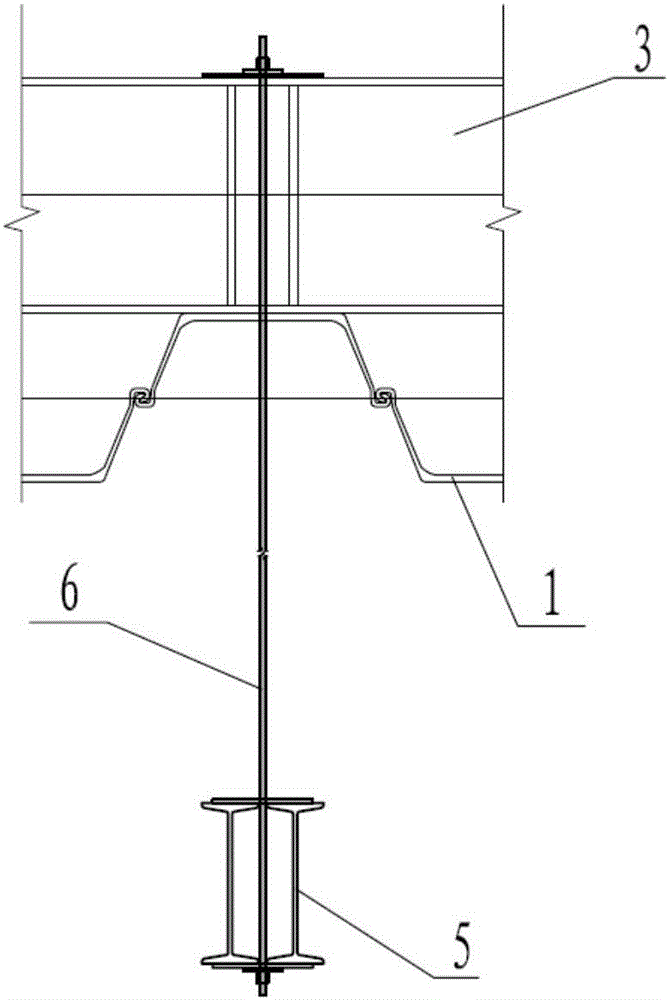

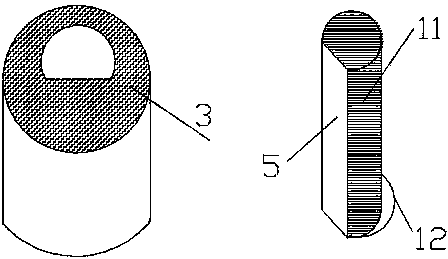

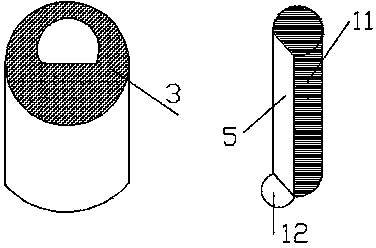

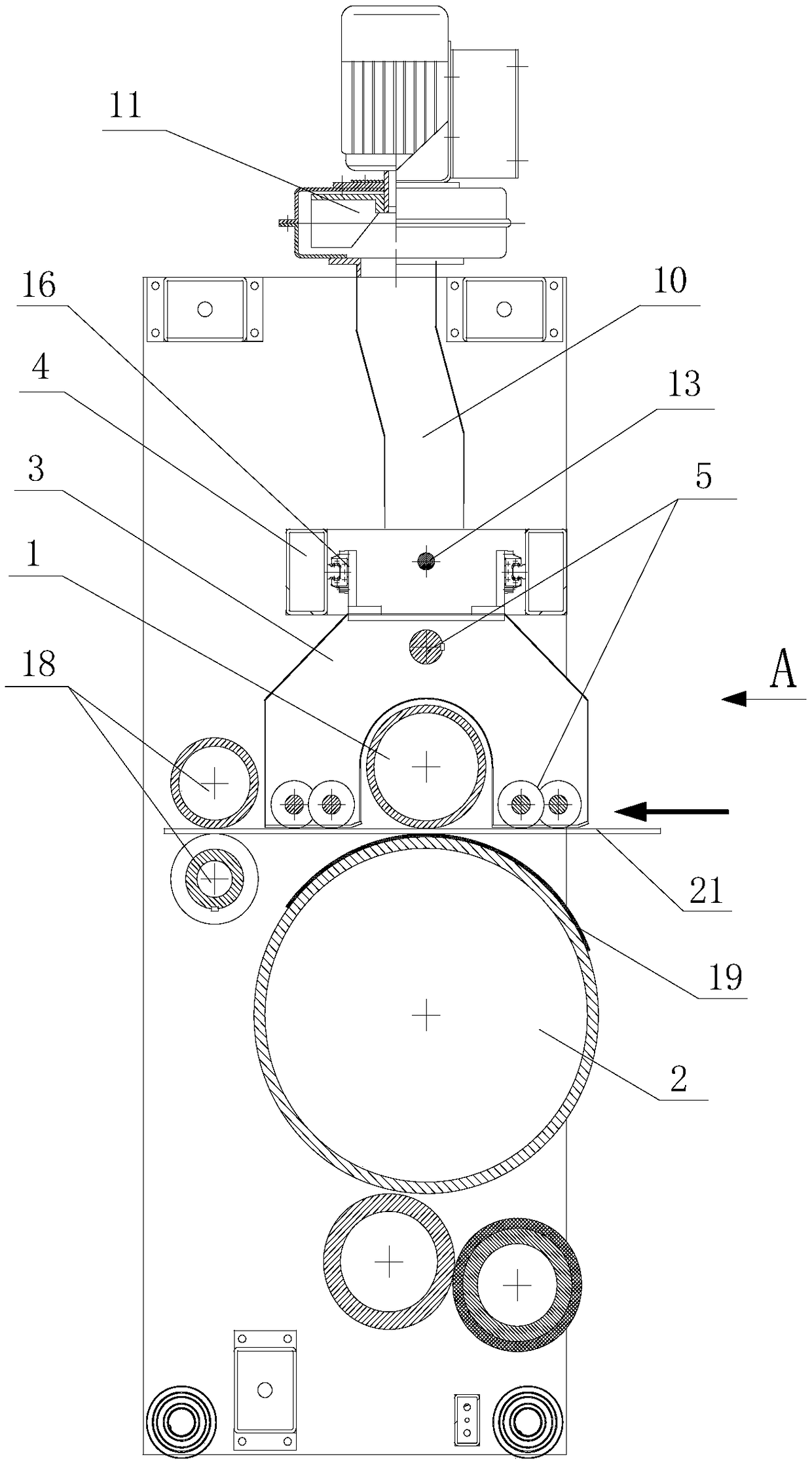

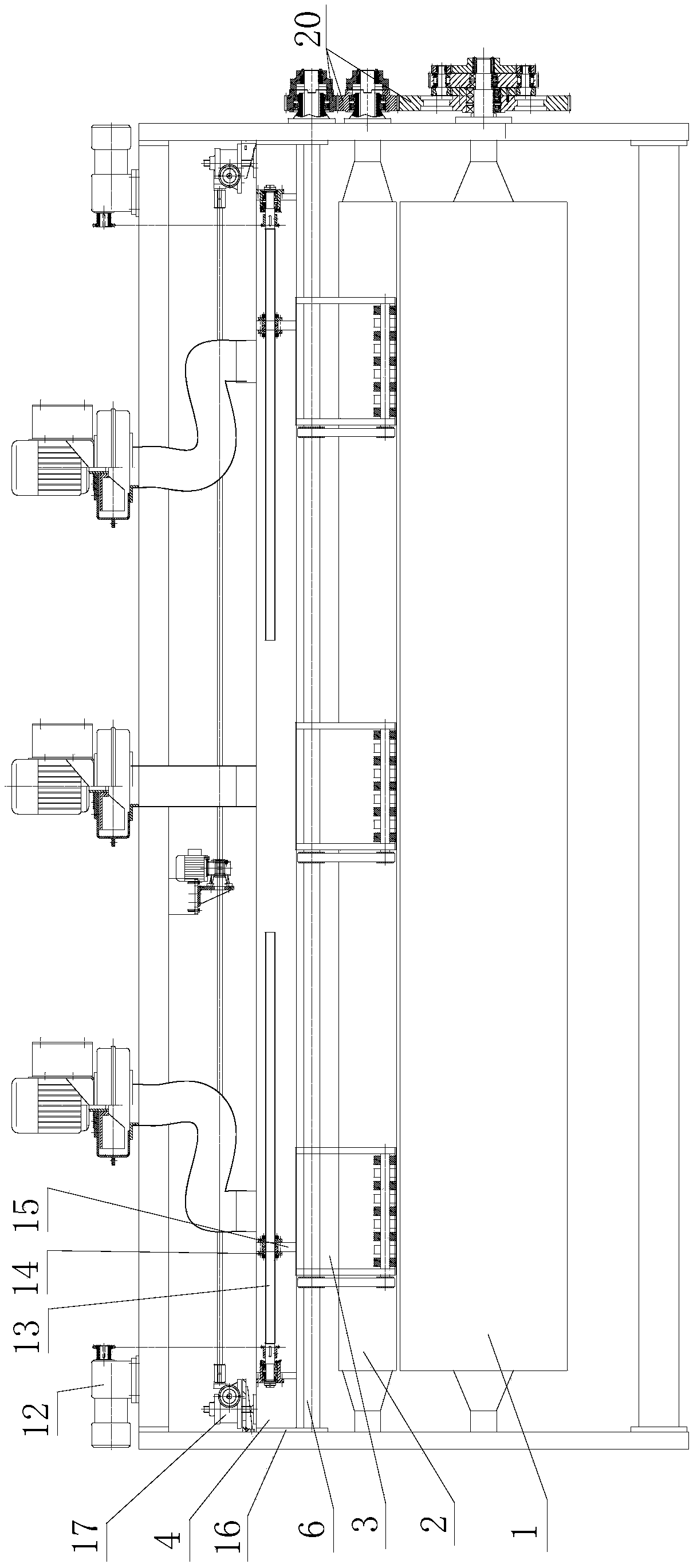

The invention discloses a multi-picture rotatable omnibearing displaying advertising device. The device comprises a single vertical column (1), a rotating framework (2), a turning plate framework (3), a main stepping motor (4), a rotating arm (21) and a shifting lever (22), wherein the bottom of the single vertical column (1) is connected with the foundation; the top of the single vertical column (1) is connected with a fixed shaft (17) of the rotating framework; the main stepping motor (4) is mounted on a main stepping motor base (5); the main stepping motor base (5) is mounted at the top of the fixed shaft (17) through bolts; the output shaft of the main stepping motor (4) is connected with the rotating arm; the rotating arm is connected with the shifting lever through a split flange; the shifting lever and a rotating drum steel framework (18) of the rotating framework are also connected with each other through a split flange, so that the fact that the motor drives the rotating drum steel framework to rotate is realized; a supporting rod of the rotating drum steel framework is connected with the turning plate framework through bolts. The device can deliver the total quantity of advertisements through a single advertising board, and realizes the fact that advertisement pictures are changed through the motion of a turning plate.

Owner:WUHAN UNIV OF TECH

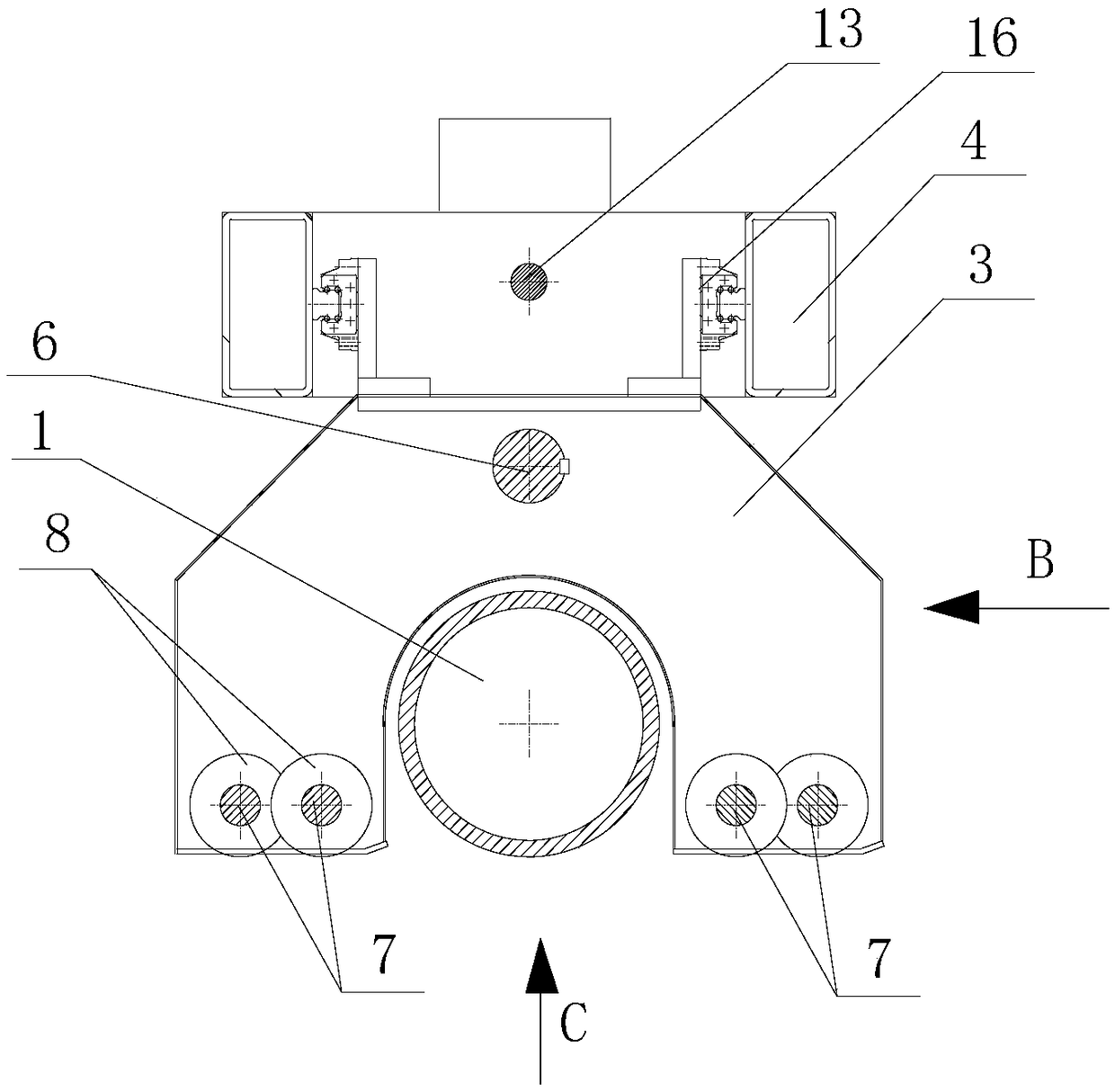

Replacement device for shield cutters

ActiveCN104589266ASave layout spaceGuaranteed StrengthMetal-working hand toolsRelative motionEngineering

Owner:CHINA RAILWAY CONSTR HEAVY IND

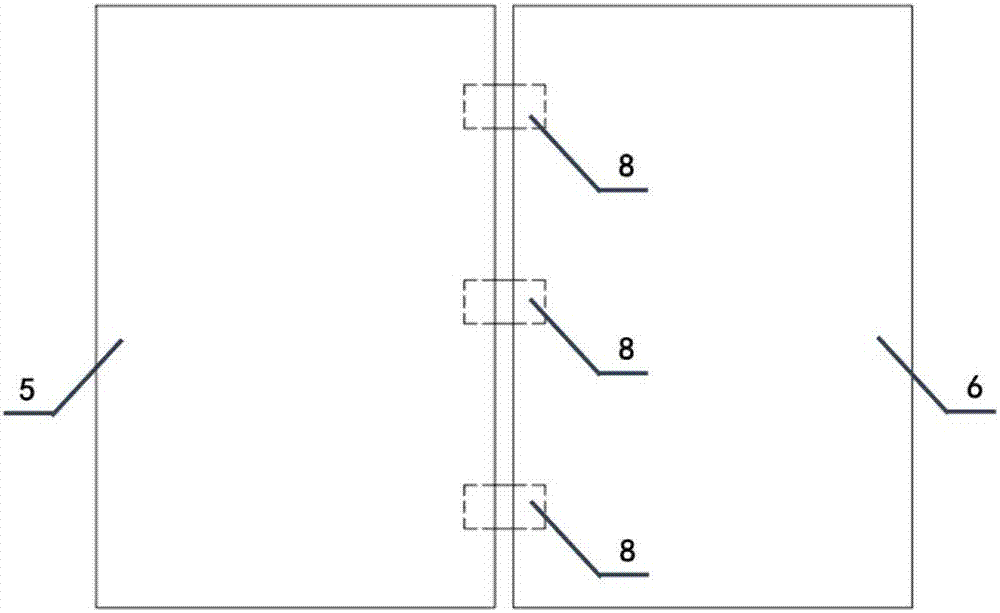

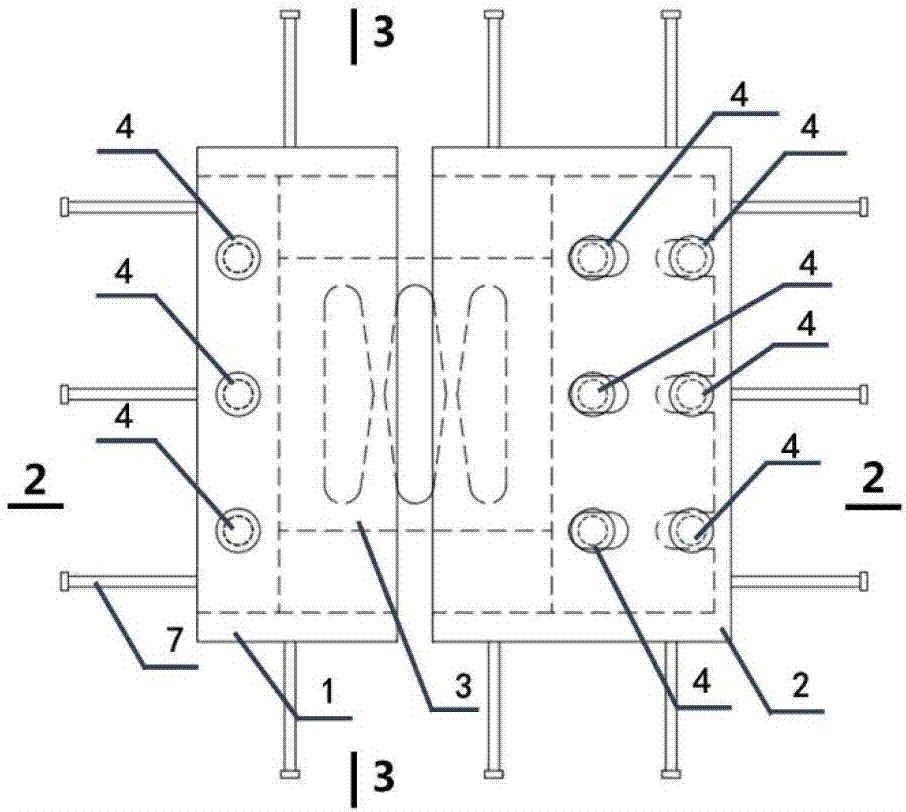

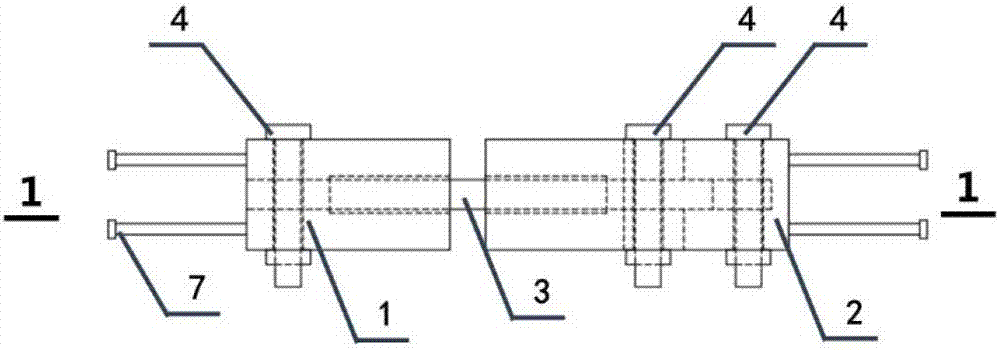

Fabricated shear-wall energy-dissipation vibration-reduction horizontal connecting device and construction method thereof

ActiveCN107178163AGuaranteed durabilityAvoid Out-of-Plane WarpingWallsProtective buildings/sheltersCorrosionCarrying capacity

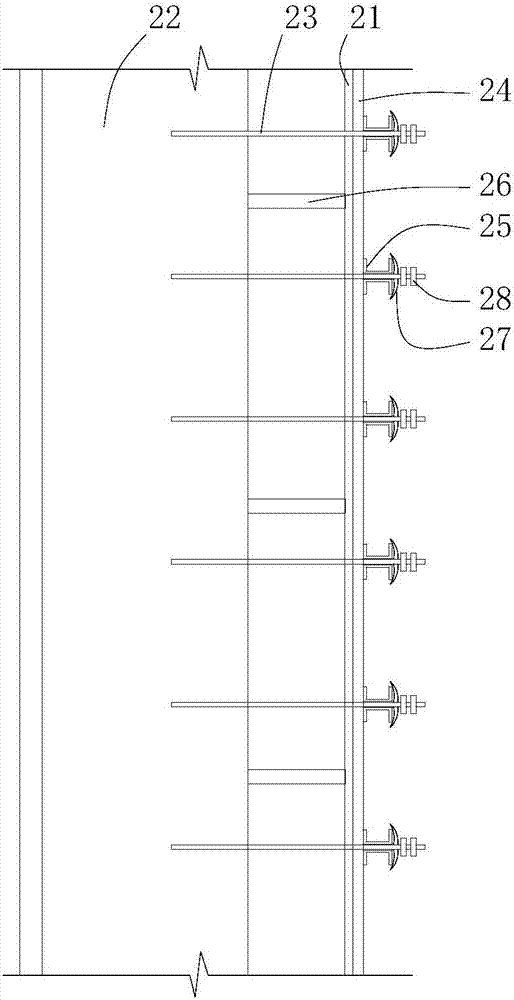

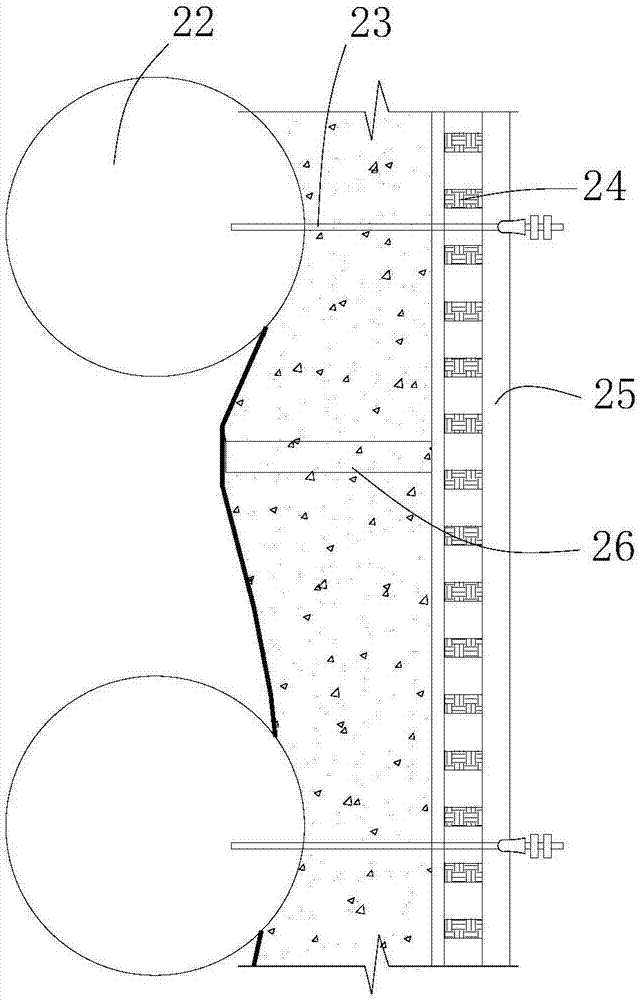

The invention belongs to the field of civil engineering, and relates to a fabricated shear-wall energy-dissipation vibration-reduction horizontal connecting device and a construction method thereof. A pre-embedded part and a connecting part of the fabricated shear-wall energy-dissipation vibration-reduction horizontal connecting device are both arranged in the wall body, changes of performances such as corrosion, erosion and aging can be avoided, the durability of the whole structure is ensured, plane outer warping of an energy-dissipation connecting device is avoided, and the better energy-dissipating capacity can be achieved. The energy-dissipation connecting part is placed in the wall body and coincides with the axis of a horizontal shaft of the section of the wall body, force balance of the wall body, rigidity in the plane and carrying capacity are ensured, and eccentric bending moment can not be generated. With the connecting mode, the efficiency of prefabricated shear-wall on-site assembling construction can be improved substantially, enough initial rigidity supplied to shear-wall to connect under the function of small vibration can be achieved, under the function of big vibration, earthquake energy can be dissipated, and vibration-reduction thoughts of structure and component ductility can be improved, and meanwhile, the whole effect of building beauty and space usage can not be influenced, steel products can be saved, and a certain economic benefit can be achieved.

Owner:DALIAN UNIV OF TECH

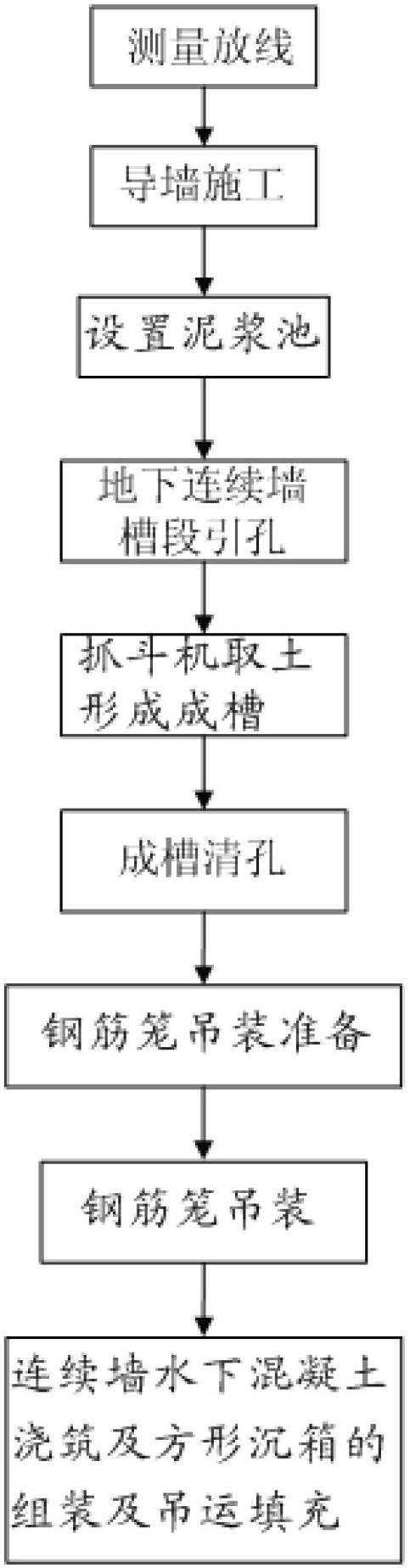

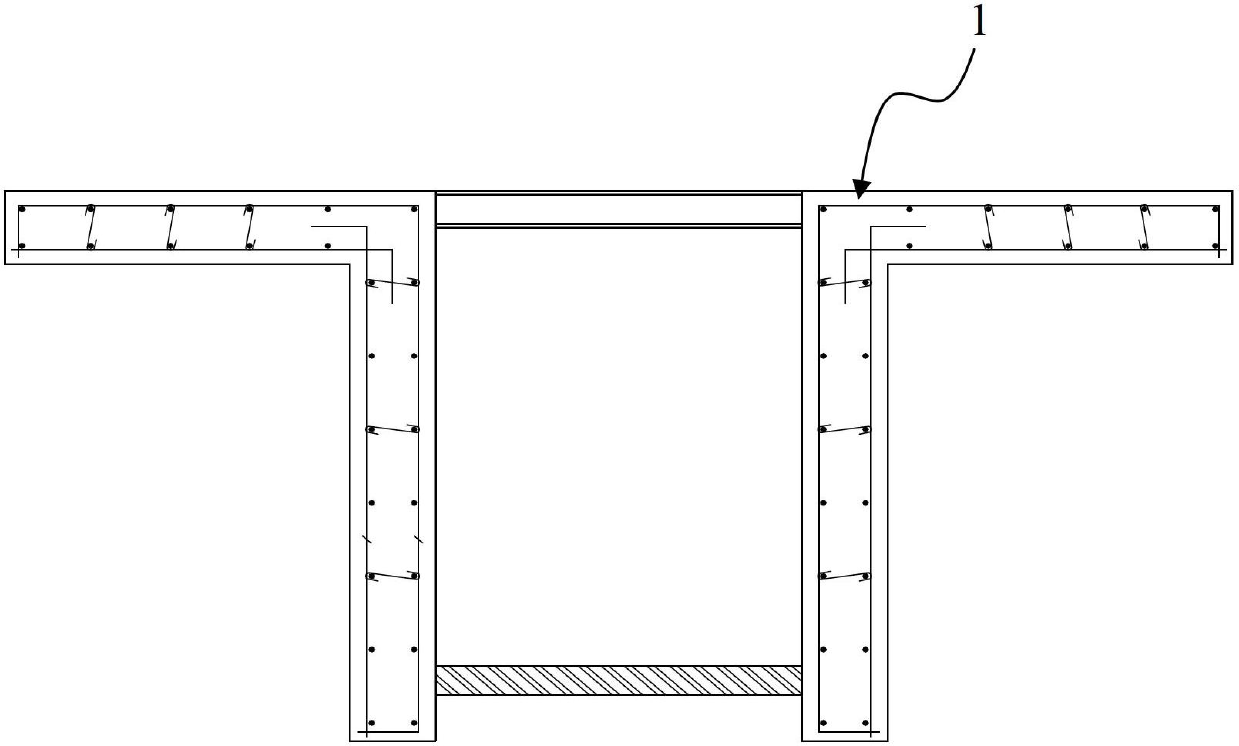

Variable cross section construction method for underground continuous wall

ActiveCN102677653AIncrease the number ofGuaranteed force balanceBulkheads/pilesSlurry wallBuilding construction

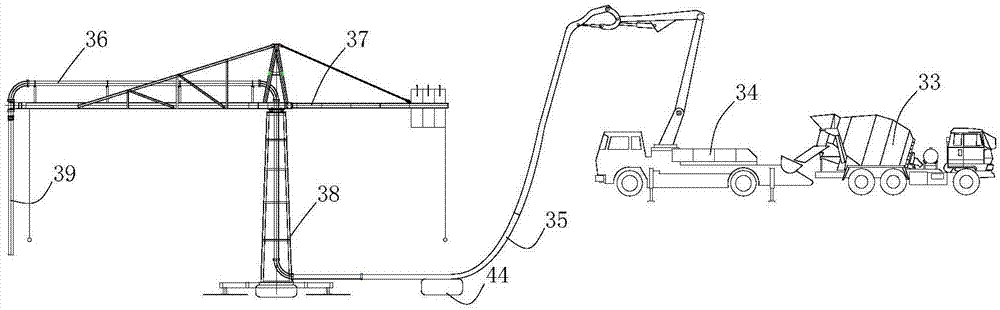

The invention discloses a variable cross section construction method for an underground continuous wall. The method comprises the following steps: surveying and setting out; constructing a guide wall; arranging a mud pit; processing lead holes in the groove segment of the underground continuous wall; taking soil with a grab machine to form a groove; cleaning the formed groove; preparing for hoisting a reinforcing cage; hoisting the reinforcing cage; and casting underwater concrete for the continuous wall, assembling a square caisson, hoisting and filling. The variable cross section construction method for the underground continuous wall has the advantages that the cost is low, the chisel workload of the follow-up construction is reduced, the construction period is short, the construction quality is stable, and the construction is convenient.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

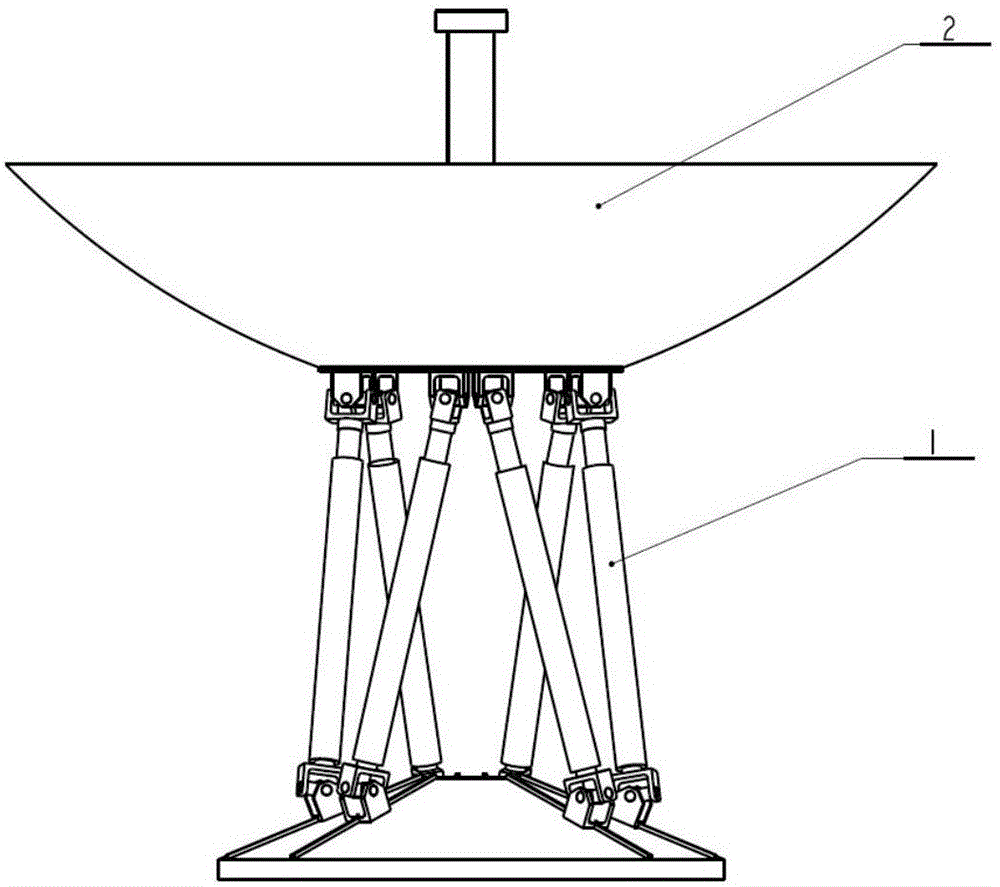

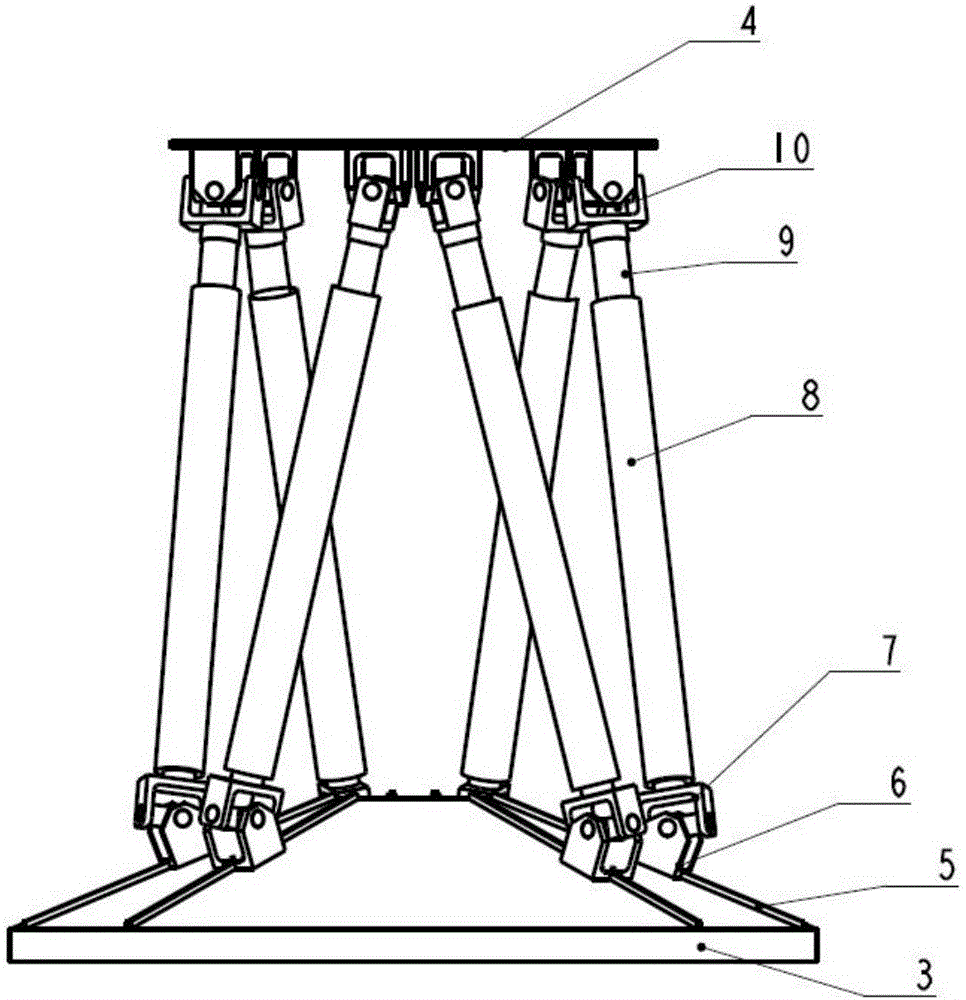

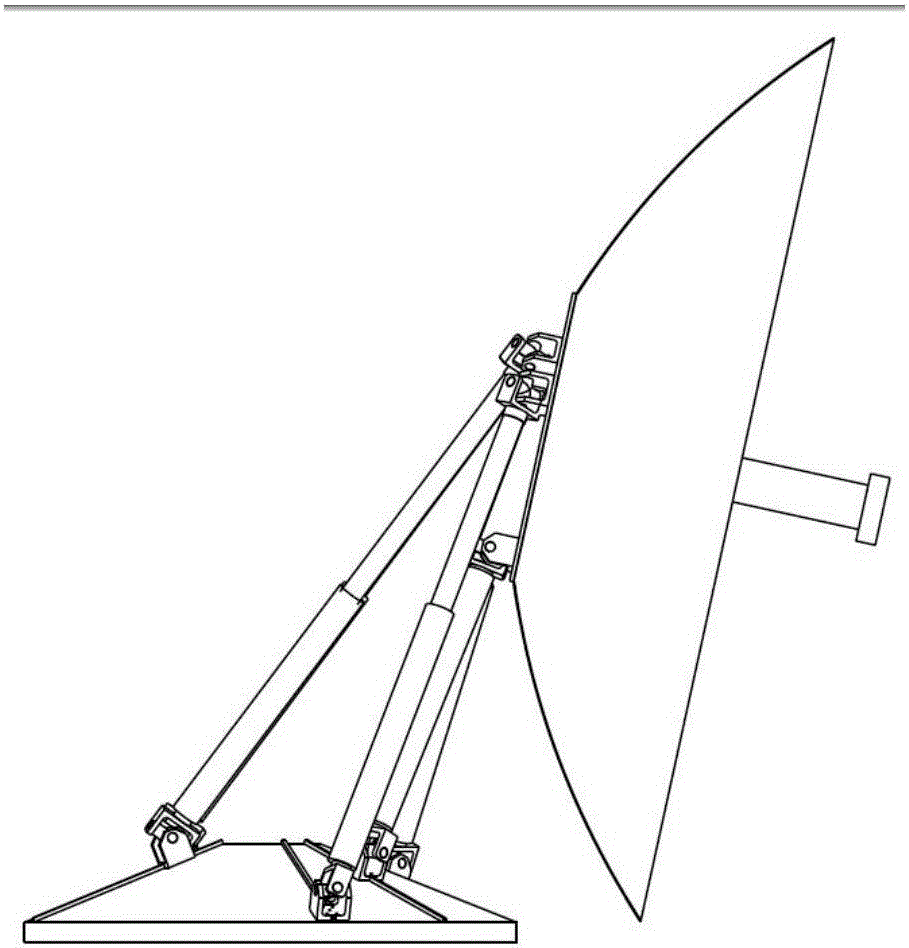

Parallel type six-freedom-degree redundant driving antenna structural system

ActiveCN106450653ASolve the problem of over-the-top "blind zone"Solve the problem that negative angle pitch cannot be achievedAntenna supports/mountingsAntenna adaptation in movable bodiesEngineeringUnit group

Disclosed is a parallel type six-freedom-degree redundant driving antenna structural system. The parallel type six-freedom-degree redundant driving antenna structural system comprises an antenna reflective surface and an antenna pedestal, wherein the antenna reflective surface is linked on the antenna pedestal; the antenna pedestal comprises a fixed platform and a movable platform which are arranged in parallel; the fixed platform is a convex circular table with gradually decreased caliber; three groups of guiding rail units are uniformly distributed on the fixed platform; each guiding rail unit group consists of two guiding rails; each guiding rail is equipped with a driving sliding block; a telescopic unit is hinged on each driving sliding block in a one-to-one correspondence manner; all the telescopic units are hinged to the movable platform; each movement point can perform coordination action by following four movement units, so that special forms and positions can be effectively reduced; the convex circular table shape of the fixed platform is matched with the driving sliding blocks to realize overturn of the antenna; the multiple driving sliding blocks are matched with the telescopic units to perform a coordination operation, so that not only all-around tracking of the antenna, but also negative angle pitching of the antenna can be realized; and consequently, the stability, flexibility and rigidity of the mechanism are highly reinforced.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

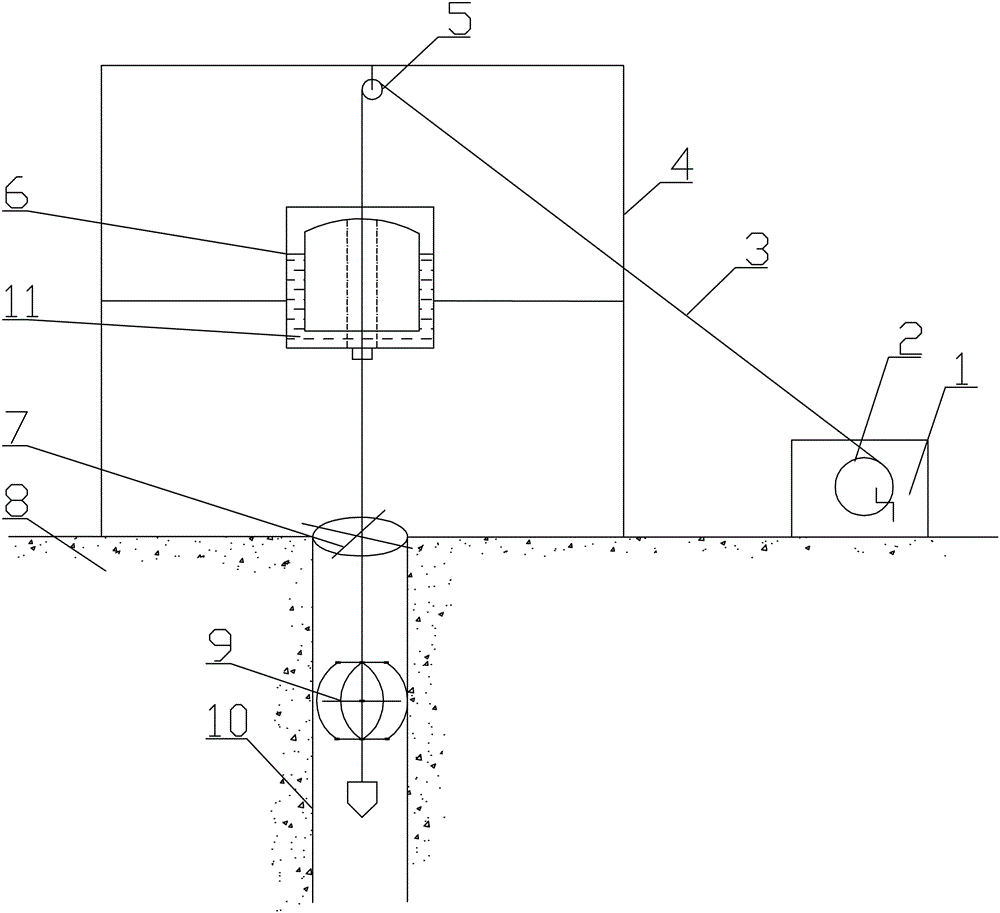

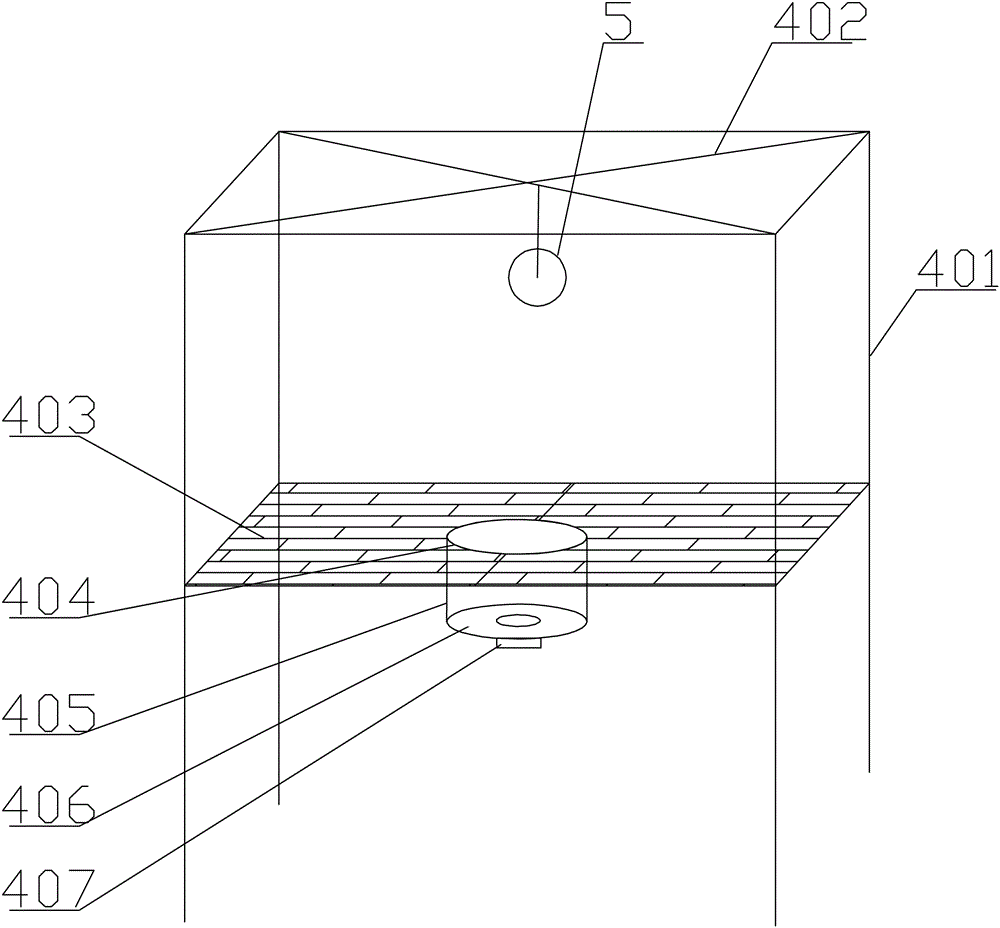

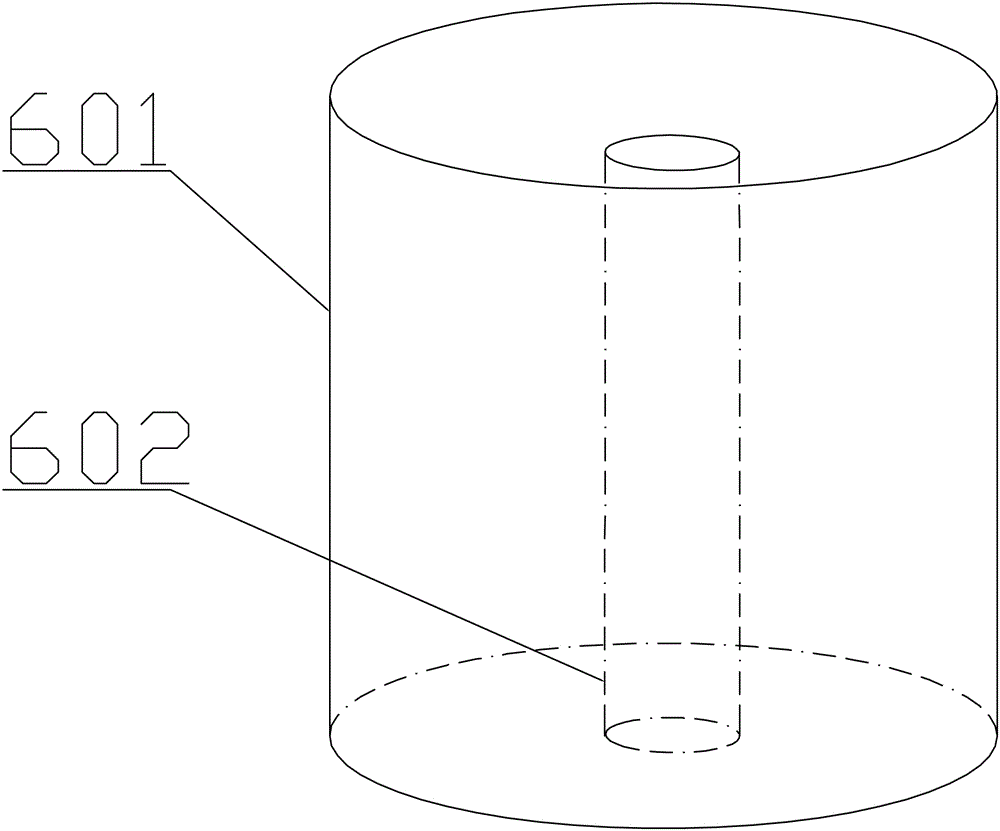

Suspension type counter weight clinometer and measurement method

The invention relates to a suspension type counter weight clinometer and a measurement method. The suspension type counter weight clinometer comprises a winch motor, wherein a steel wire rope winds a winch barrel of the winch motor and penetrates through a fixed pulley fixed at the top of a supporting platform; a floating barrel device is mounted in the middle of the supporting platform; the steel wire rope passes through the floating barrel device; a linear vertical suspension device is connected with the tail end of the steel wire rope and is located in a hole to be detected; and a measuring device is located at an inlet position of the hole to be detected. The clinometer provided by the invention can be used for carrying out high-frequency and high-precision detection in drilling construction with very high perpendicularity requirements; and an efficient and high-precision perpendicularity detection device, which is convenient to mount, has accurate and reliable data and can meet real-time detection requirements, can be provided for a drilling construction site through the clinometer.

Owner:CHINA GEZHOUBA GRP SURVEY DESIGN CO LTD

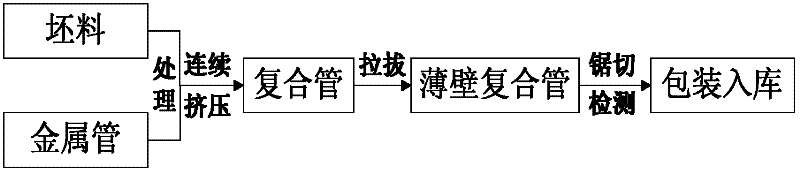

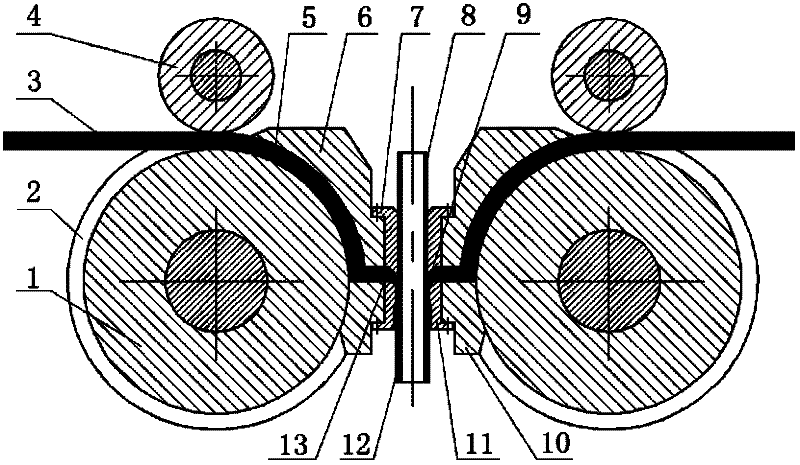

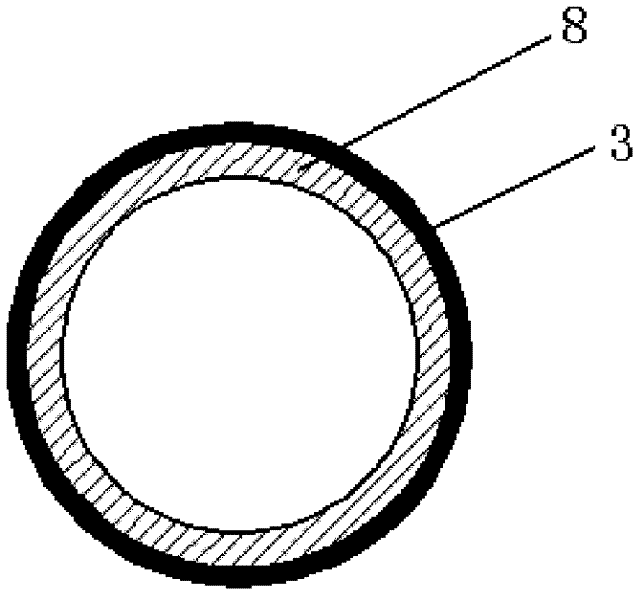

Process for manufacturing bimetal thin-wall composite pipe

The invention relates to a process for manufacturing a bimetal thin-wall composite pipe, which comprises the following steps of: processing a blank; continuously extruding the blank to compound the blank with a metal pipe, and feeding the processed blank bar and the metal pipe into a continuous extruder for compounding, wherein the continuous extruder is provided with two extrusion rollers which are symmetrically arranged and are controlled by a servo motor; keeping the metal pipe not deformed in the extrusion process, pressing the blank in grooves on the extrusion rollers, making the blank enter an extrusion cavity under the drive of friction force, raising the temperature of the blank under the double action of the friction force and extrusion deformation, and making the blank subjected to plastic deformation, extruded to a cavity and coated on the surface of the metal pipe along two symmetrical surfaces; drawing, namely feeding the bimetal composite pipe formed by continuous extrusion into drawing equipment, and designing the deformation size of a coating layer and the metal pipe in the drawing process to make the coating layer and the metal pipe synchronously deformed and have the same deformation; and sawing and finishing. The prepared bimetal thin-wall composite pipe does not have any weld seam, and is short in process flow and high in production efficiency.

Owner:XI AN JIAOTONG UNIV

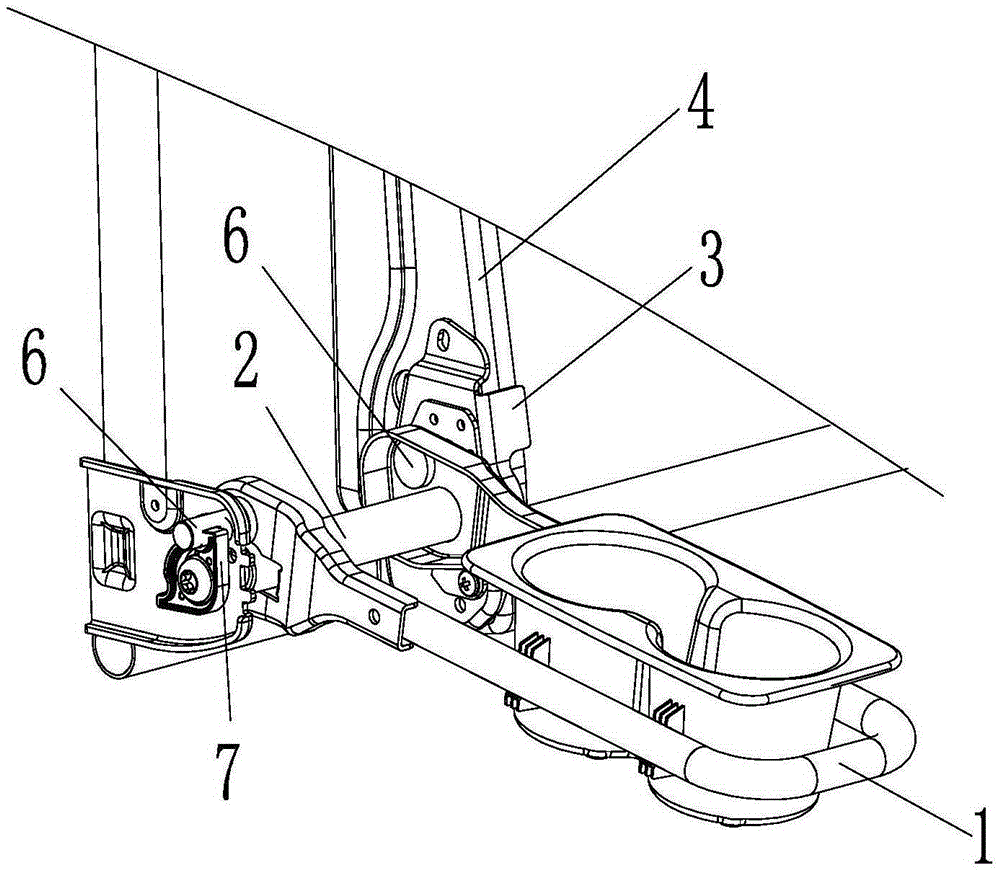

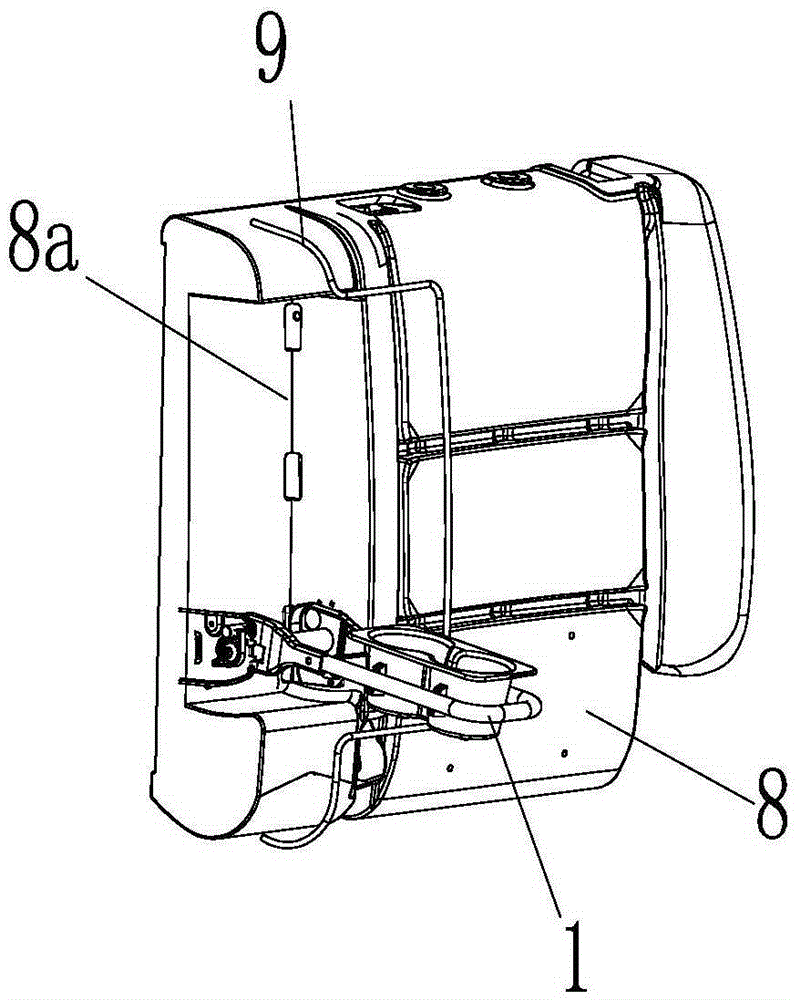

Transformation robot as well as transformation method and combined-steering-engine automatic reset method thereof

PendingCN108371820ASmall driving forceGuaranteed force balanceDollsToy vehiclesEngineeringMetamorphic robots

The invention relates to a transformation robot as well as a transformation method and a combined-steering-engine automatic reset method thereof. The transformation robot comprises a robot-body main body (1), standing components (3) and supporting components (4), wherein the standing components (3) are arranged at the lower part of the robot-body main body (1); the supporting components (4) are arranged on two sides of the upper part of the robot-body main body (1); the standing components (3) and the supporting components (4) are rotationally connected with the robot-body main body (1) respectively; the transformation robot also comprises a work executing component; the work executing component is arranged at the back of the robot-body main body (1). Compared with the prior art, the transformation robot has the beneficial effects that the transformation of an engineering vehicle is realized through the work executing component; the supporting components can be enabled to support the robot-body main body during transformation through the supporting components; the driving power when the standing components are used for carrying out standing is reduced by a wide margin; the stress balance during the transformation is ensured; the quick transformation is realized, and meanwhile, the transformation robot can be also used for realizing the automatic reset of a combined steering engine of the transformation robot.

Owner:ROBOSEN ROBOTICS (SHENZHEN) CO LTD

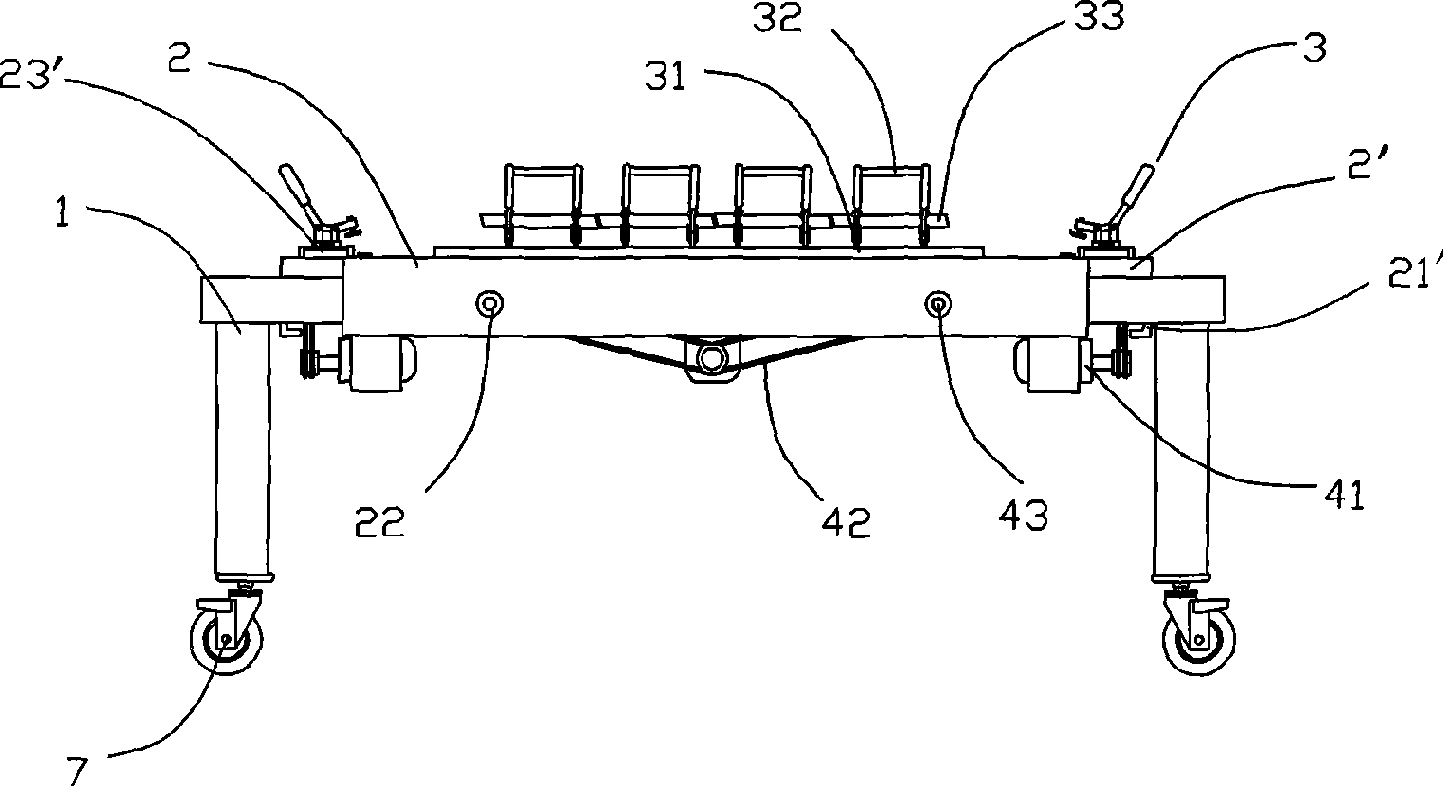

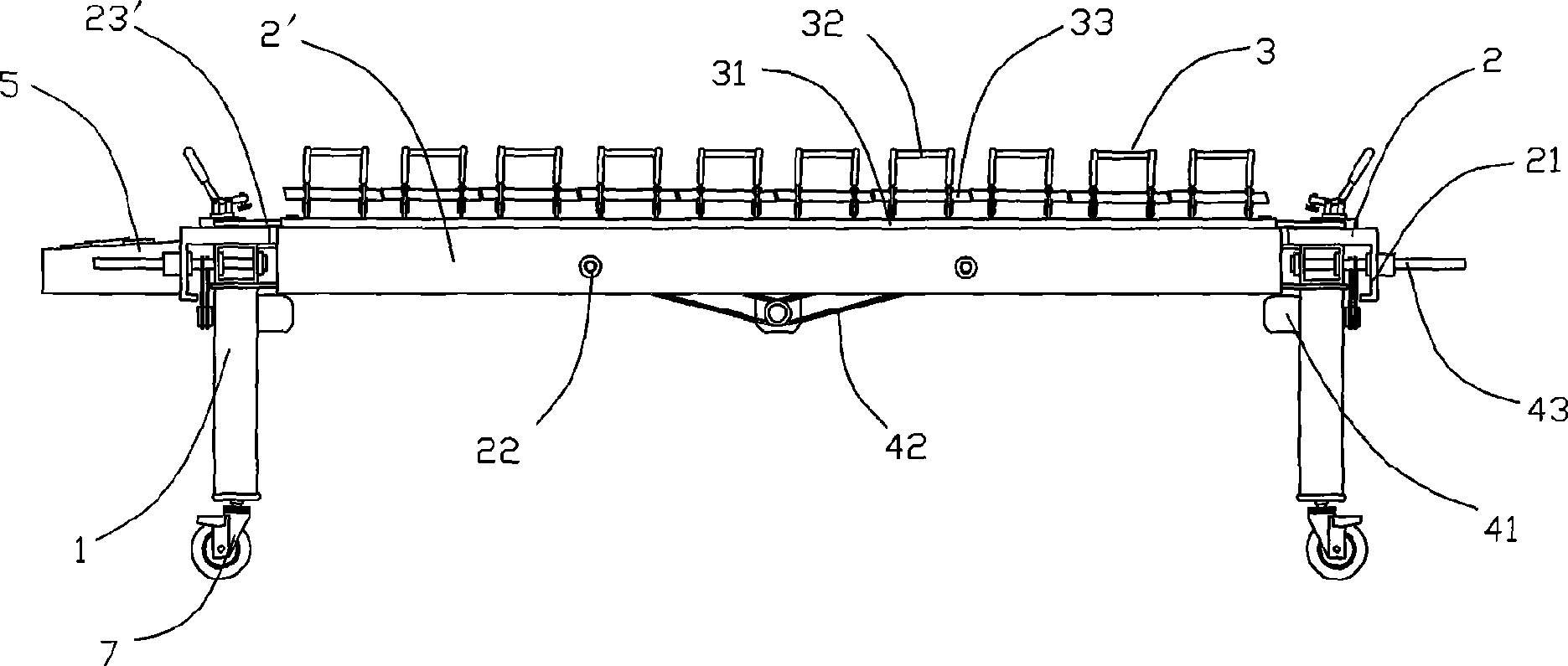

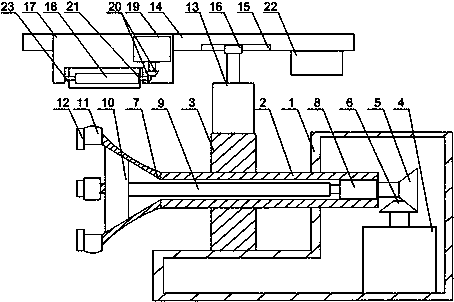

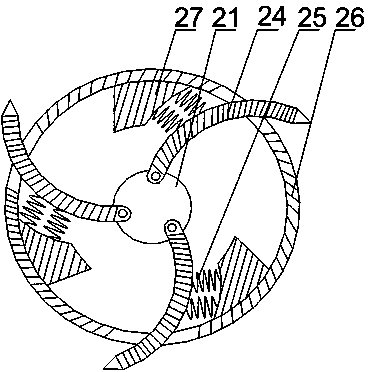

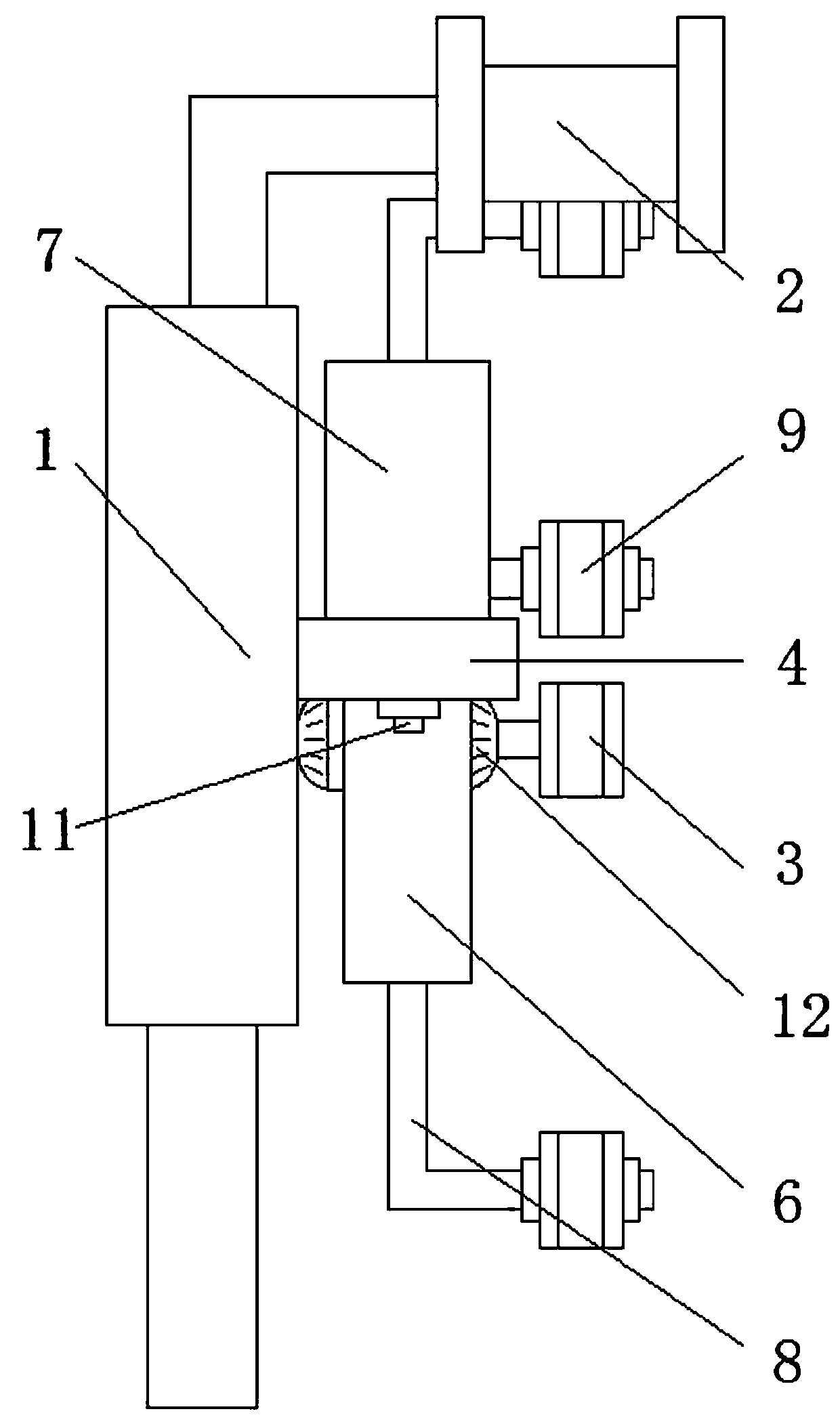

Automatic synchronization net puller and net pulling method

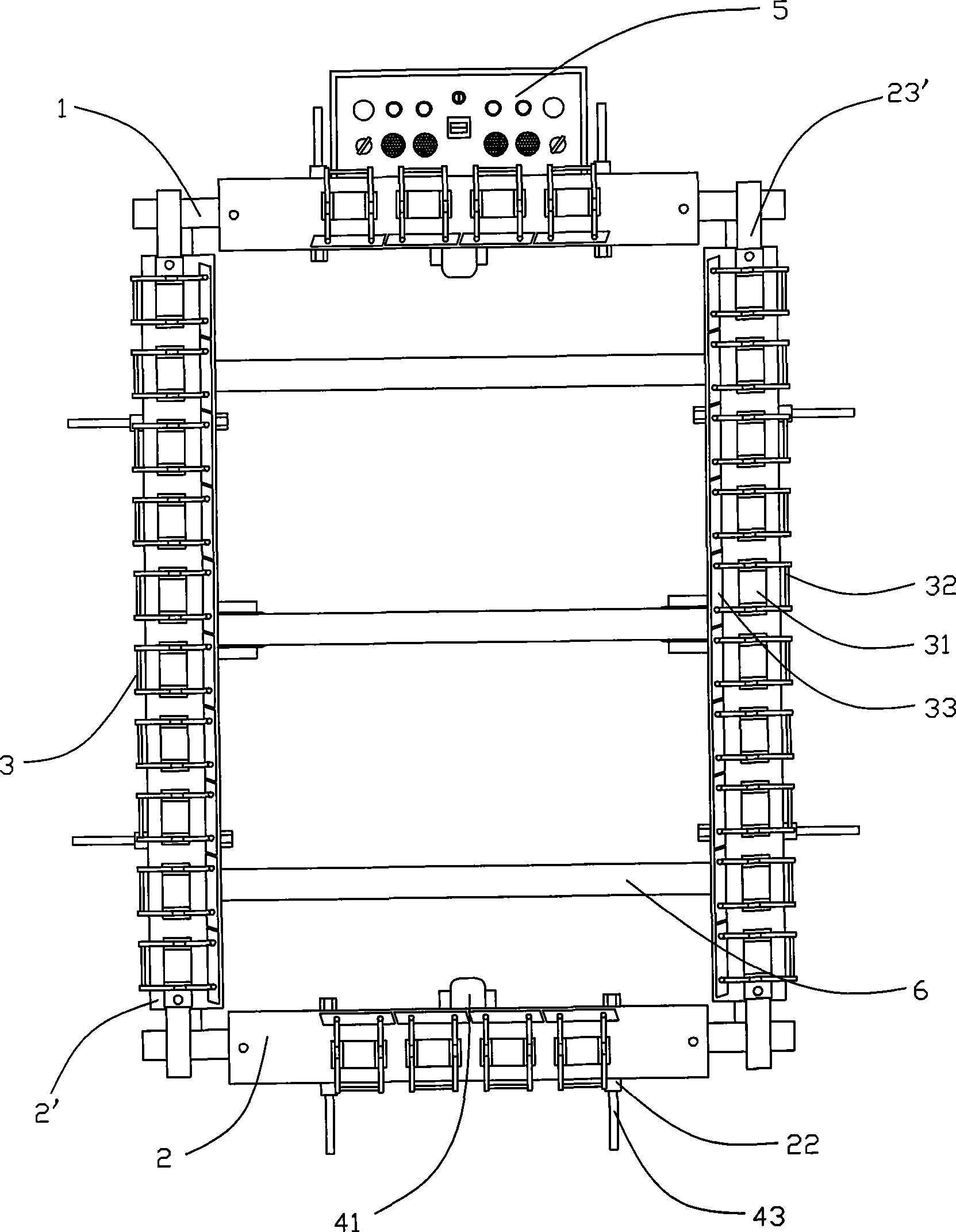

InactiveCN101380840AGuaranteed force balanceHigh precisionScreen printersSynchronous motorEngineering

The invention discloses a self-synchronizing net stretching machine and a stretching method thereof. The net stretching machine comprises a frame, horizontal and vertical line screw mandrel shifting devices arranged around the frame and net stretching collets arranged on the horizontal and vertical line screw mandrel shifting devices, wherein, the frame is provided with a synchronous motor group which controls the synchronous relative inward or outward shift of the horizontal and vertical opposite line screw mandrel shifting devices. While stretching the net, screw mandrel shifting devices at symmetrical sides of the horizontal line or the vertical line are controlled by the synchronous motor group to shift synchronously in succession for pre-stretching, then the mesh cloth is vertically fixed and firmly clamped, and synchronous net stretching from both symmetrical sides is carried out. The method has the advantages that net stretching can be carried out synchronously from symmetrical sides, thus ensuring that the force the mesh bears is balanced; besides, the horizontal lines and vertical lines are ensured to be vertical to each other during the process of synchronous net stretching, thereby largely improving the accuracy of net stretching; moreover, four sides of the mesh cloth can be ensured not to be wasted while stretching, thus improving the utility ratio of the mesh cloth.

Owner:冯兆坚

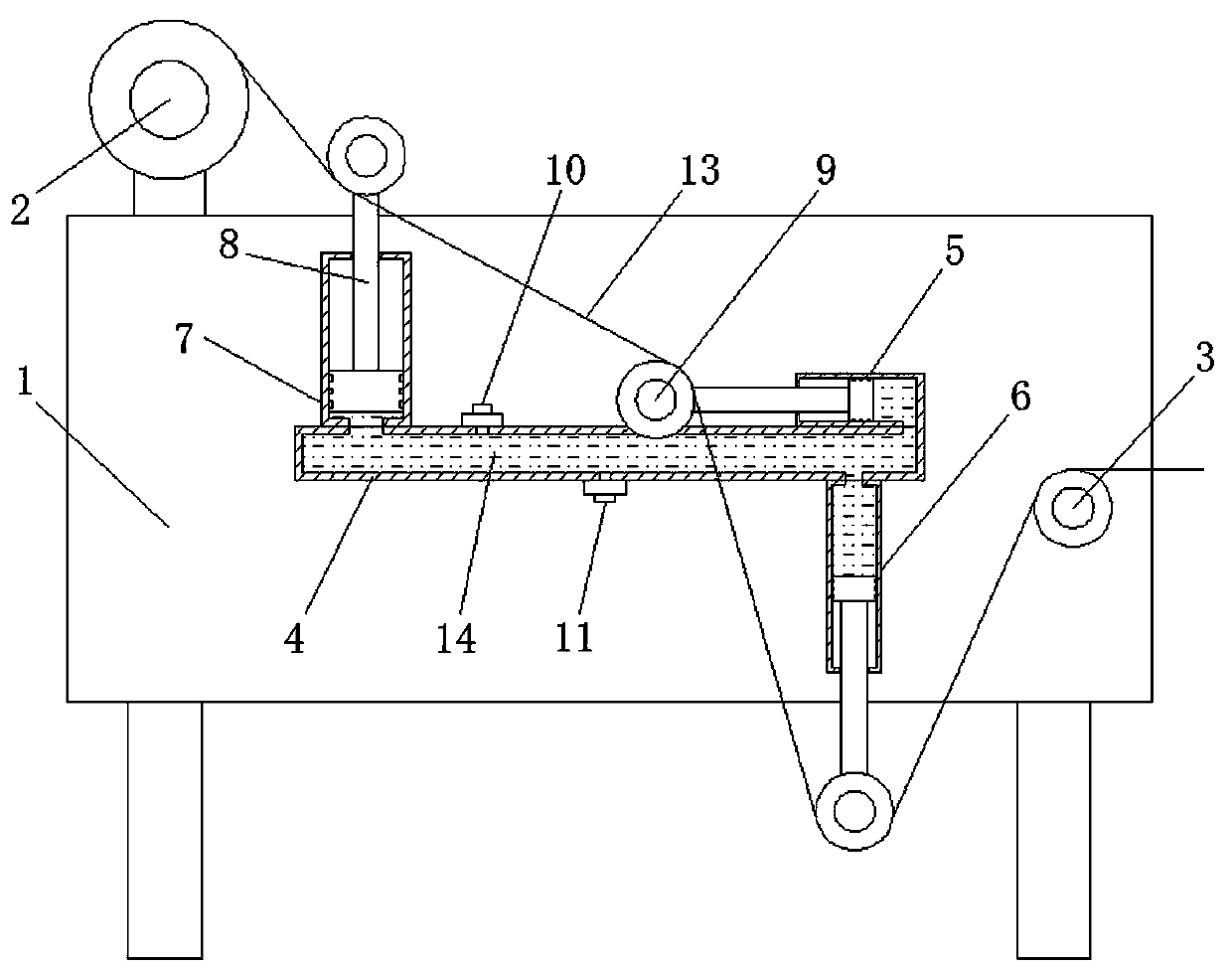

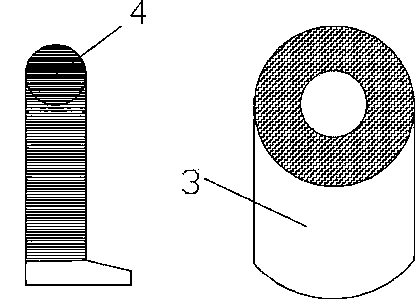

Loading machine tire retreading structure

ActiveCN103921460AImprove work efficiencyGuaranteed force balanceRevolution surface grinding machinesTyresGear wheelEngineering

The invention discloses a loading machine tire retreading structure. The loading machine tire retreading structure comprises an L-shaped support base, wherein a sleeve, a stand column and a direct current motor are arranged on the L-shaped support base, the sleeve penetrates through the stand column, a gear wheel is arranged at the end part of one end of the sleeve, a pinion matched with the gear wheel is arranged at the output end of the direct current motor, an expanded clamping part is arranged at the end part of the other end of the sleeve, a first cylinder is arranged in the sleeve, a connecting rod is connected at the output end of the first cylinder, a sliding block matched with the expanded clamping part is arranged at the end part of the connecting rod, a trapezoid-shaped slot is formed on a support rod, a bulge is formed on the output end of a second cylinder, the bulge is matched with the trapezoid-shaped slot, the second cylinder is arranged on the stand column, a tool support is arranged at one end of the support rod, a tool is rotationally arranged on the tool support, the motor is arranged in the tool support, the end part of the tool and the output end of the motor are both connected with bevel gears which are matched with each other, and a balancing weight is also arranged at the other end of the support rod.

Owner:CHENGDU HAILINGDA MACHINERY

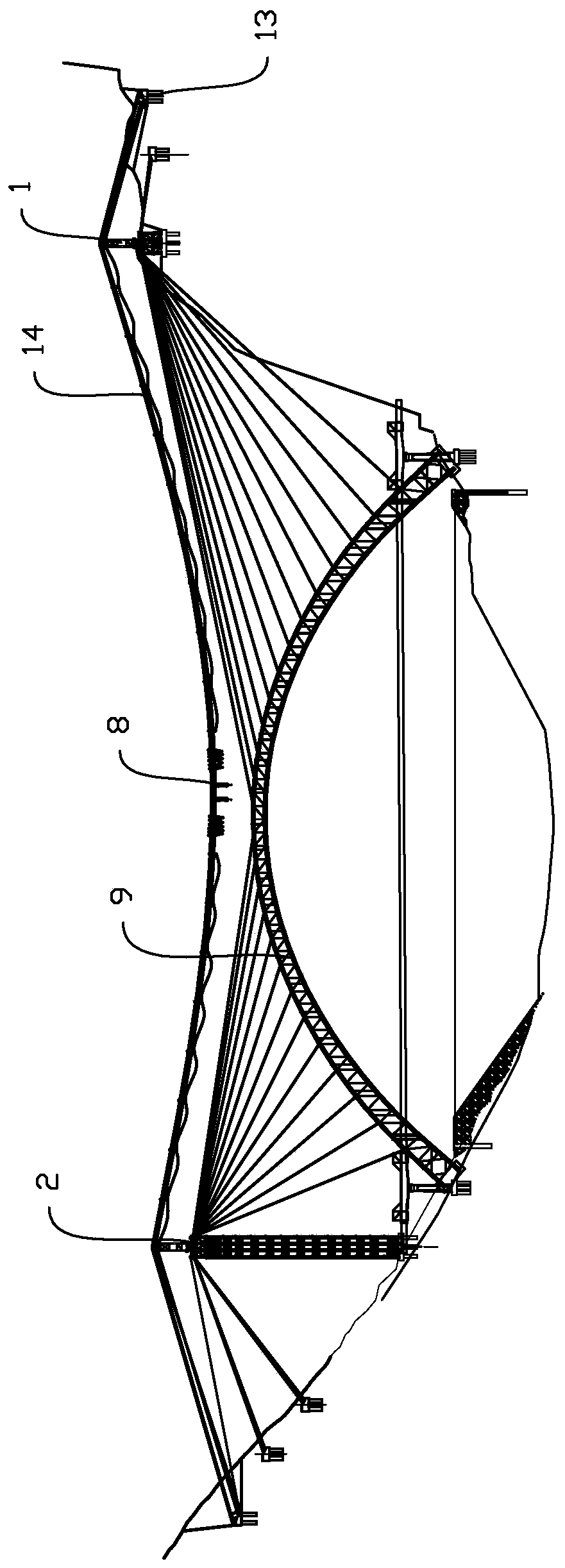

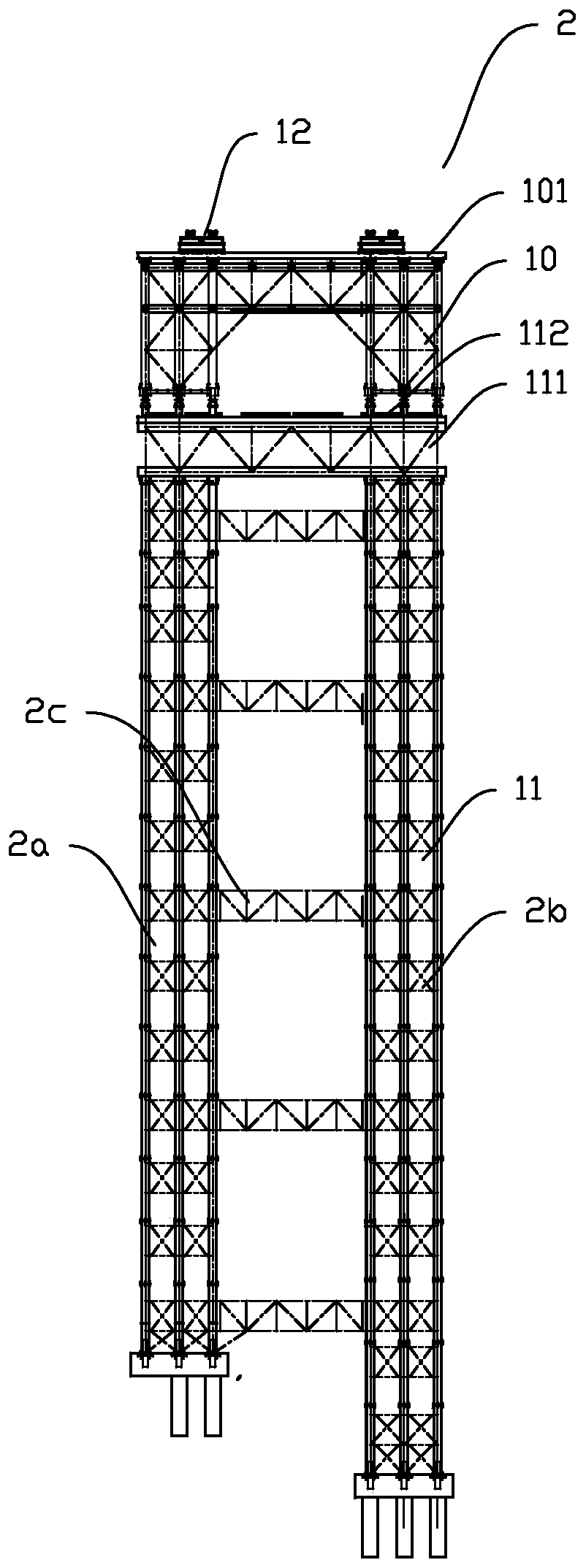

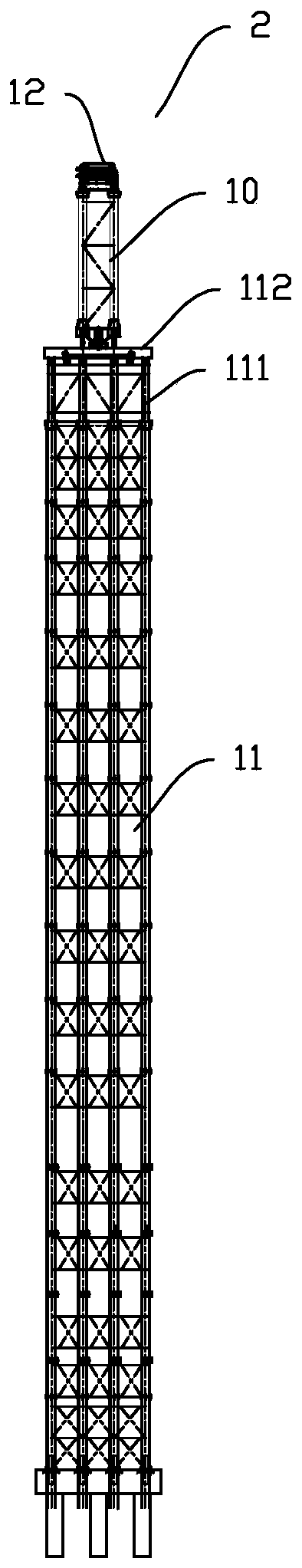

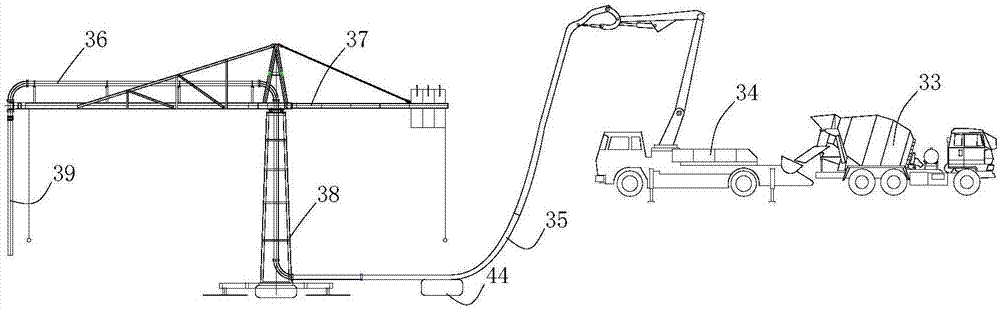

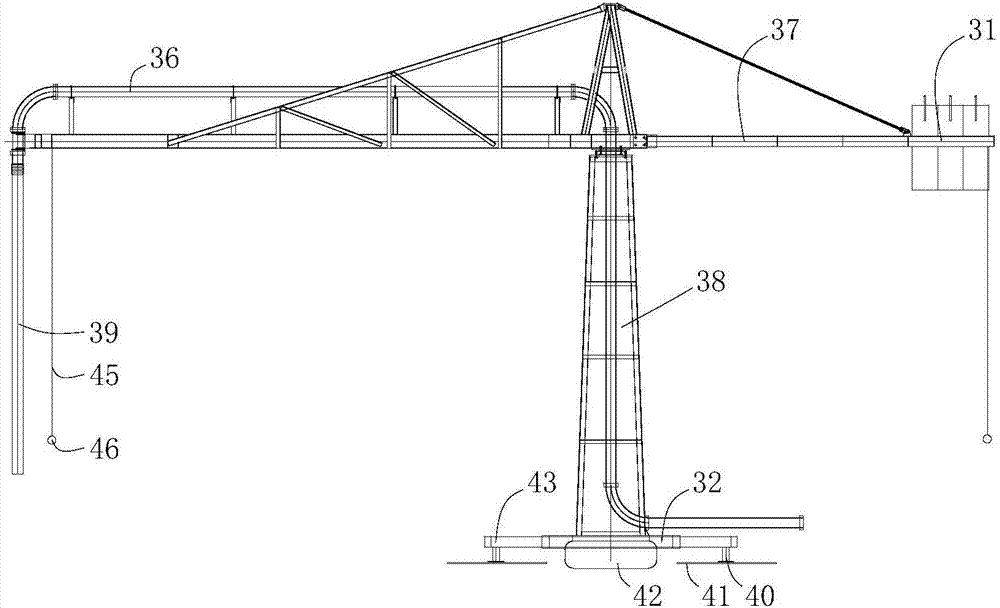

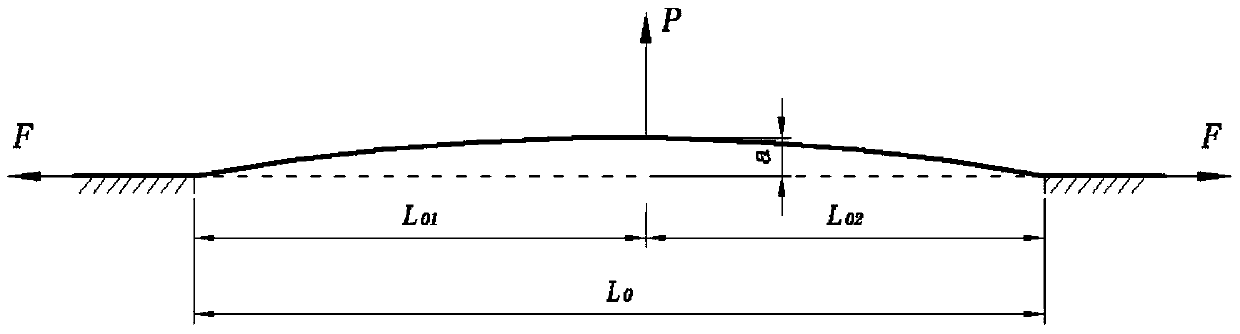

Construction method of asymmetric cable crane

ActiveCN109750600ASave construction materialsGuaranteed force balanceSuspension bridgeBridge structural detailsTerrainHeight difference

The invention discloses a construction method of an asymmetric cable crane. The engineering terrain situation is integrated, the characteristic of craggedness of large-mileage side mountain is utilized, thus a large-mileage side tower frame is arranged on a mountain slope with the precipitous mountain valley, the terrain height difference is reasonably utilized, thus a construction material of thelarge-mileage side tower frame is saved, stable force-bearing of two sides is ensured, the construction difficulty is also lowered, the distance between the large-mileage side tower frame and the center of a bridge is greater than the distance between a small-mileage side tower frame and the center of the bridge, through formed unequal edge span design, force-bearing balance of the large-mileageside tower frame and the small-mileage side tower frame under the unequal elevation situation is ensured, the structural stability is improved, and the construction method is used for the technical field of bridge construction.

Owner:CHINA RAILWAY GUANGZHOU ENG GRP CO LTD +3

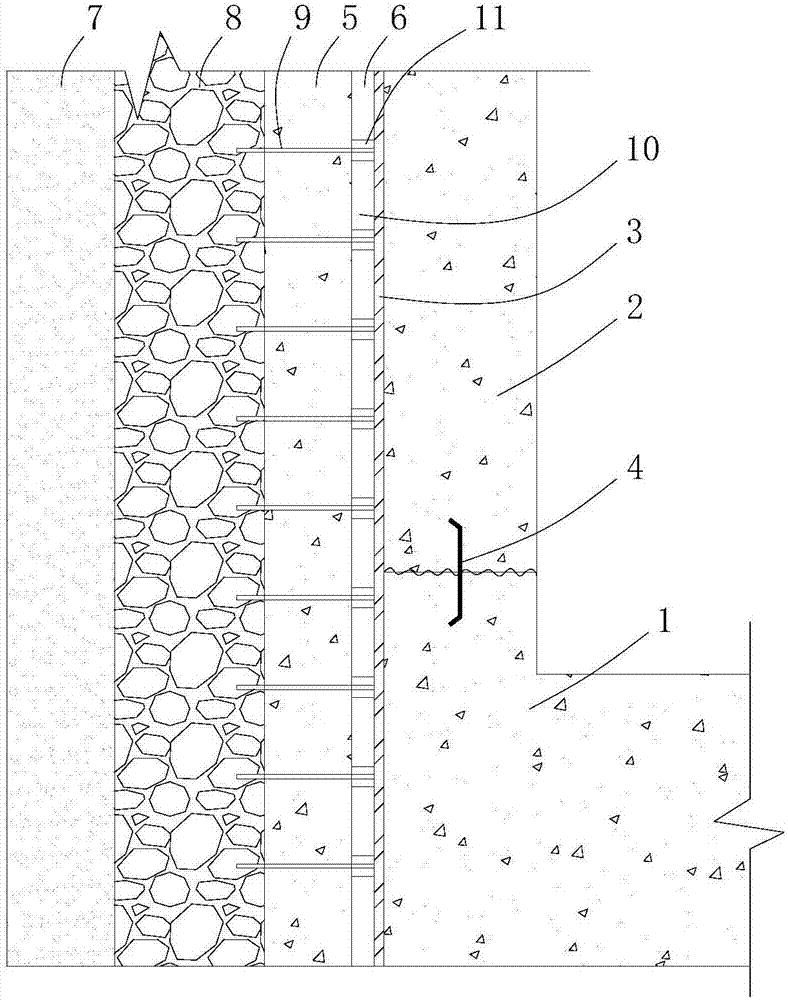

Method for constructing basement retaining wall based on brick base membrane modeling wall

ActiveCN106968269AGood fit and transmissionImprove stabilityArtificial islandsExcavationsBasementBrick

The invention discloses a method for constructing a basement retaining wall based on a brick base membrane modeling wall. The method comprises the following steps that firstly, the modeling wall is arranged on the pit wall of a foundation pit of a basement, then construction of waterproof roll material is conducted on the outside surface of the modeling wall to obtain a waterproof layer of the retaining wall, and the modeling wall and the waterproof layer of the retaining wall form a basement retaining wall outside support to complete pouring of the basement wall retaining wall. The method is characterized in that brick membrane serves as a support, a support pile at the outer side of the pit wall of the foundation pit is placed into a welding screw rod to be connected with the brick membrane, and then the modeling wall is obtained by pouring. The method for constructing the basement retaining wall based on the brick base membrane modeling wall has the advantages of simple construction, a short construction period, low cost, a good waterproofing effect, and the like; and the method is particularly suitable for implementation and application foundation construction of a high-rise building with the deep foundation pit.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

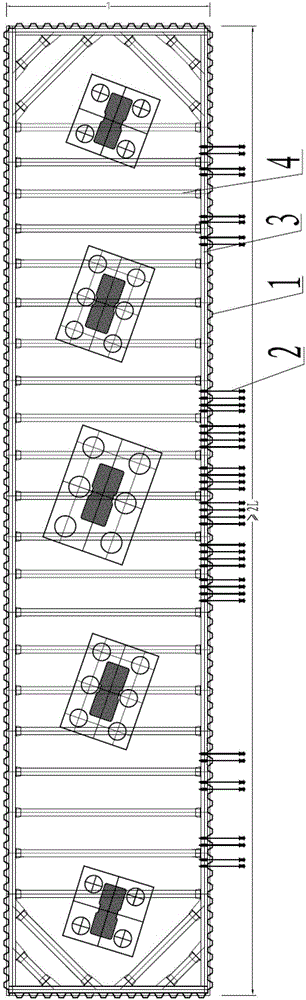

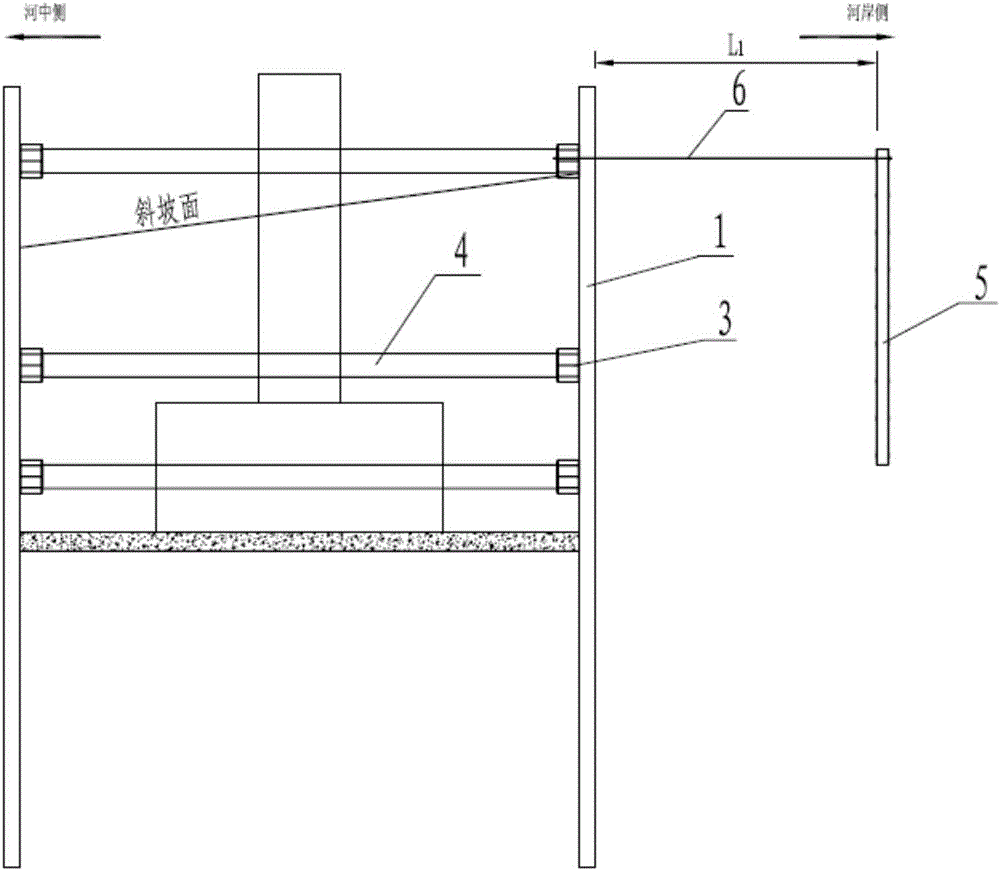

Construction method for small-spacing long-large underwater sheet steel pile cofferdams

InactiveCN106320351ASolve the problem of slow excavation speedSolve the problem of interval asynchronous constructionFoundation engineeringPurlinSheet steel

The invention discloses a construction method for small-spacing long-large underwater sheet steel pile cofferdams. The construction method comprises the steps of underwater guide beam mounting, sheet steel pile inserting and driving, cofferdam closure, reverse anchoring system arrangement, foundation pit excavation, steel enclosing purlin and steel support arrangement, foundation pit monitoring, steel enclosing purlin and steel support dismantling, sheet steel pile removal and the like. The method is applicable to synchronous construction of two or more underwater small-spacing bridge group foundation sheet steel pile cofferdams in rivers, lakes, seas and the like, and a reverse anchoring system adopted in the method can balance active earth pressure on two sides of sheet steel piles on an inclined earth layer; and when the method is selected for construction, synchronous construction of small-spacing bridge group foundations can be realized, so that the construction efficiency and the construction speed are increased, the construction period is guaranteed, the material consumption of temporary structures is reduced and the construction cost is lowered.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

Basement retaining wall construction method based on concrete pouring of modeling wall

ActiveCN107130631AGood fit and transmissionImprove stabilityArtificial islandsProtective foundationBasementEngineering

The invention discloses a basement retaining wall construction method based on concrete pouring of a modeling wall. The basement retaining wall construction method comprises the following steps: the modeling wall is arranged on the wall of a basement foundation pit, waterproof roll construction is performed on the outer side surface of the modeling wall to obtain a retaining water water-proof layer, and a basement retaining wall outer side support is formed by the modeling wall and the retaining wall water-proof layer to finish pouring of a basement retaining wall. The basement retaining wall construction method is characterized in that welding screw rods are embedded into a supporting pile on the outer side of the wall of the foundation pit to realize supporting and pouring of a modeling wall template to obtain the modeling wall. The basement retaining wall construction method has the characteristics that the construction is simple, the construction period is short, the cost is low and the water-proof effect is good, and is particularly suitable for implementation and application in building foundation construction of high-rise buildings with relatively deep foundation pits.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

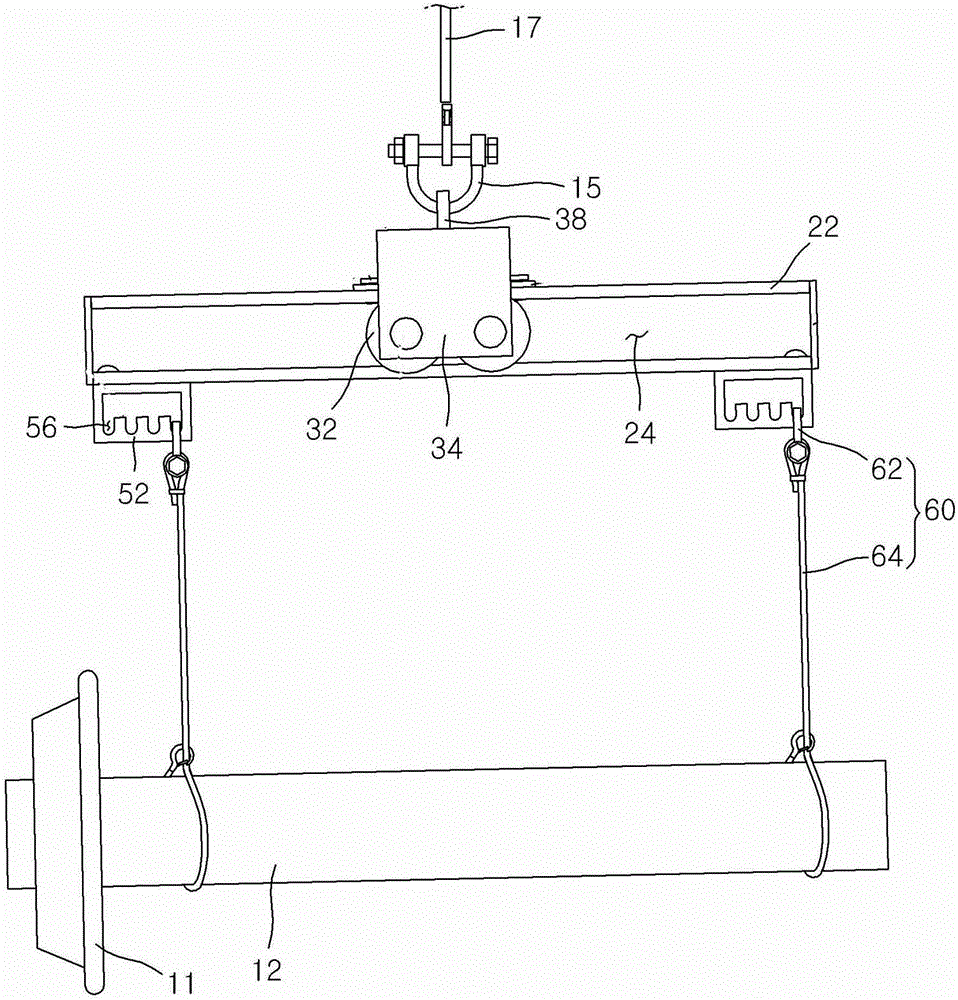

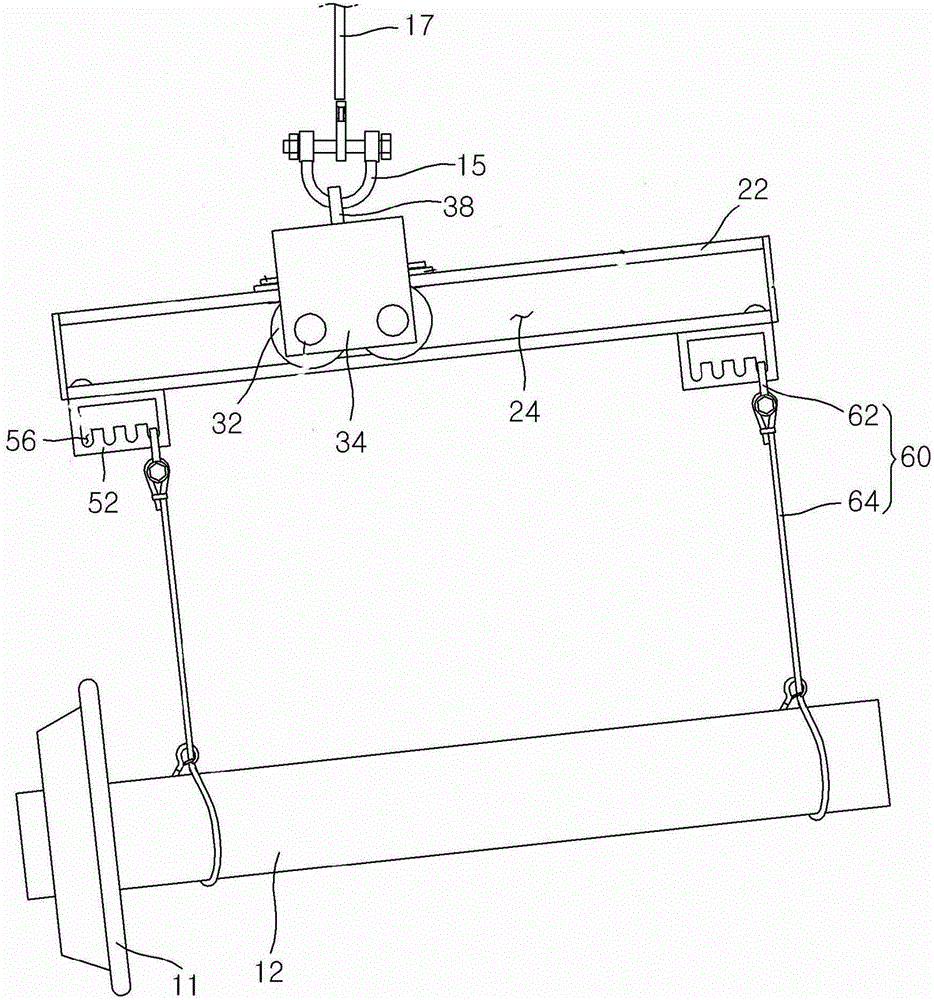

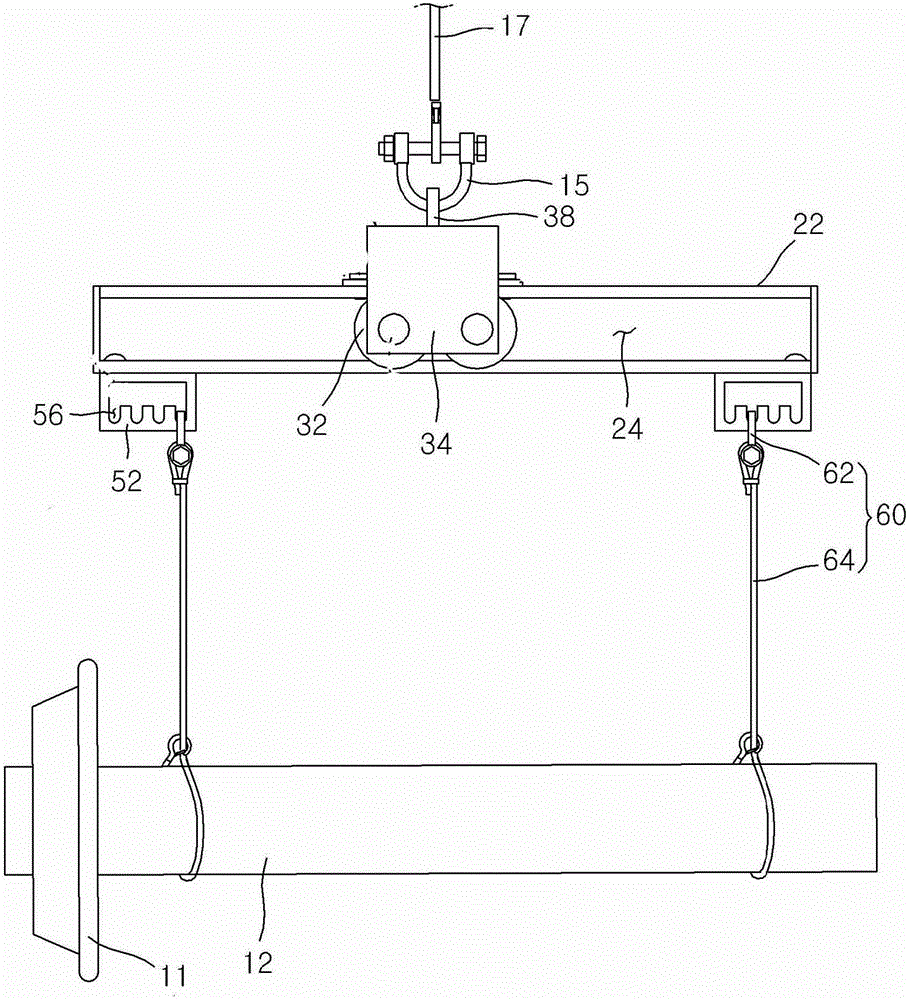

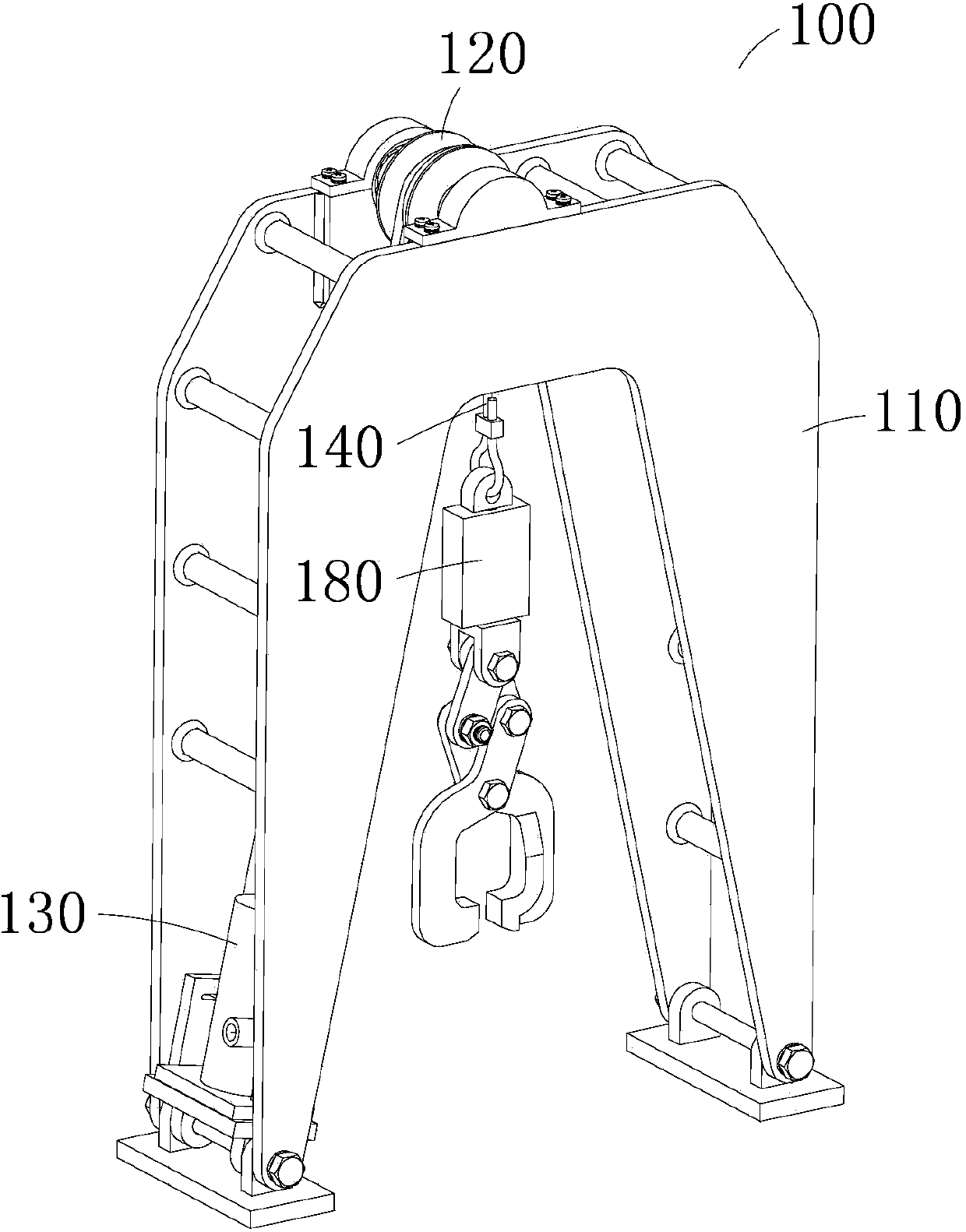

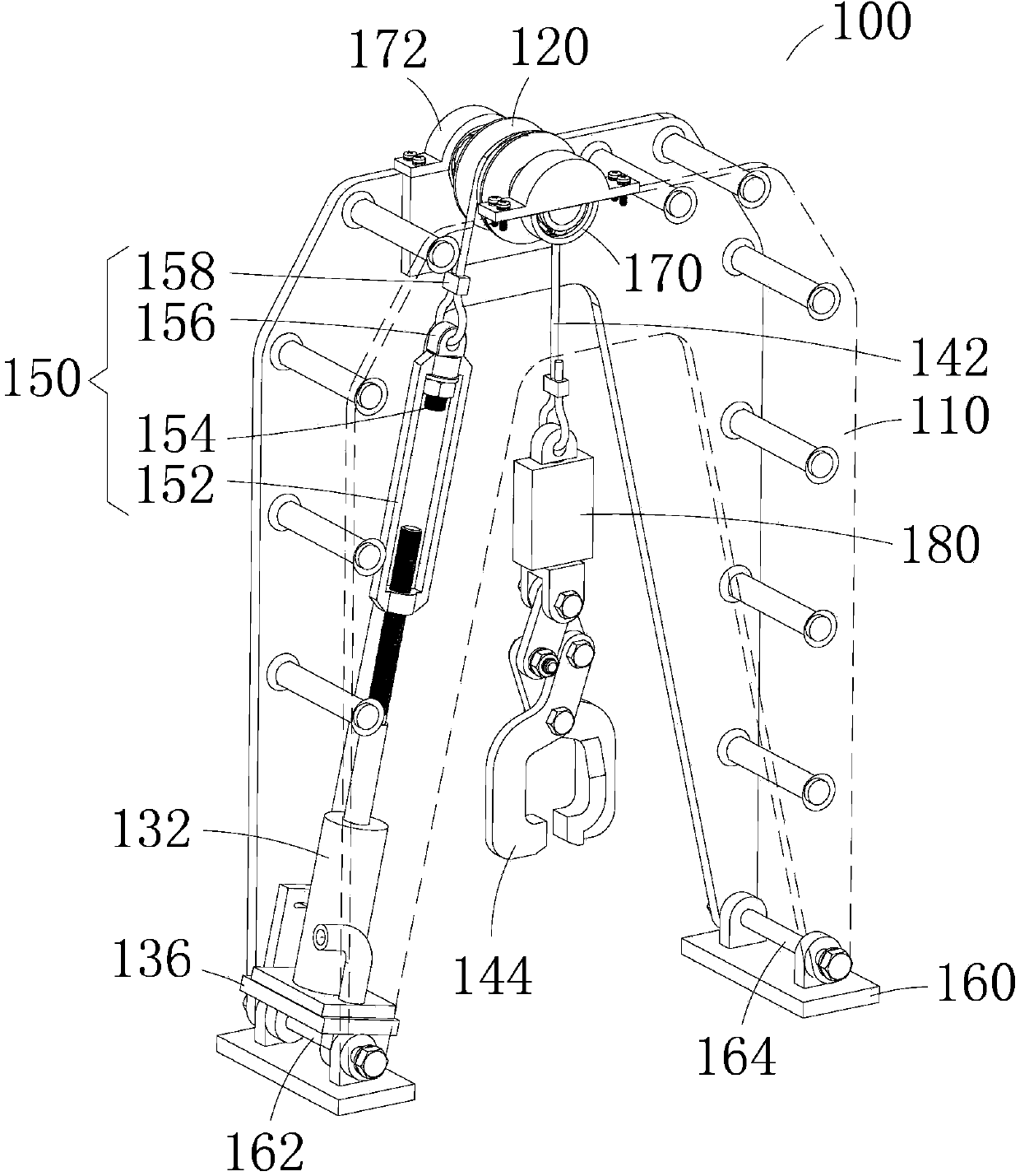

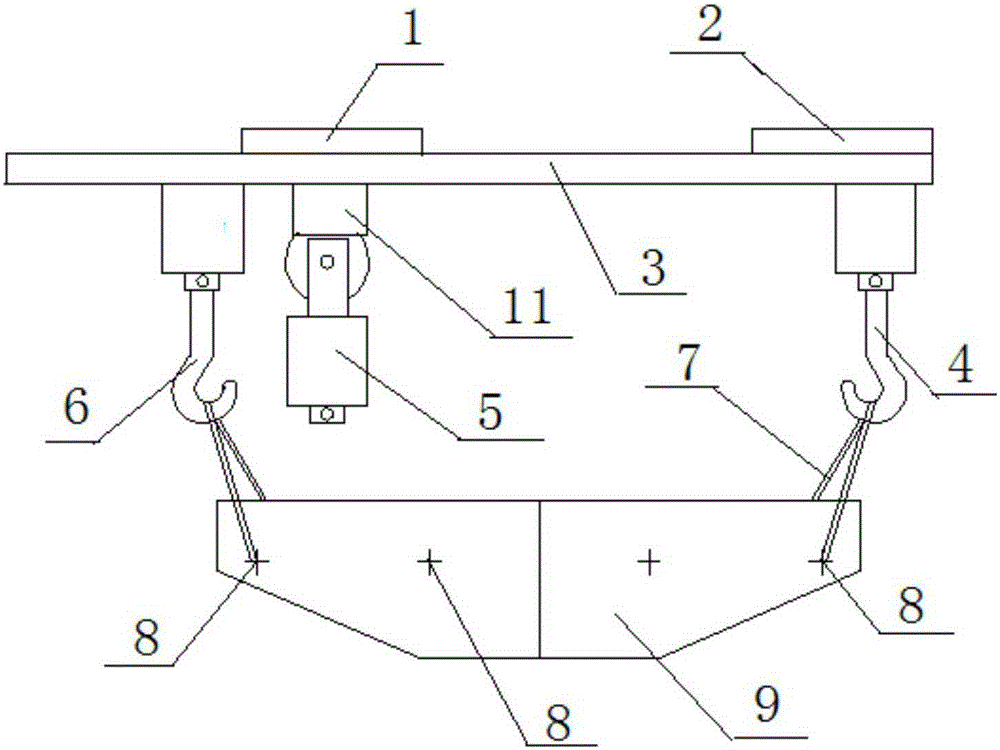

Portable iron core overturning mechanism

InactiveCN105151999AReduce labor intensityEasy to operateInductances/transformers/magnets manufactureLoad-engaging elementsEngineeringUltimate tensile strength

The invention discloses an overturning mechanism, and particularly relates to a portable iron core overturning mechanism. The portable iron core overturning mechanism comprises a hanging and turning assembly connected between a hook and a bearing platform, wherein the hanging and turning assembly comprises hanging ropes, a balanced frame body and a hook ring connected with the hook; hook grooves for allowing the hanging ropes to be connected in a hanging manner are formed in two ends of the balanced frame body; a travelling wheel group is arranged between the balanced frame body and the hook ring and comprises a casing, a travelling wheel connected to the casing in a rotating manner and a two-way motor for driving the travelling wheel, wherein the two-way motor is mounted on the casing, the casing is fixedly connected with hanging rings, guiding rails corresponding to the travelling wheel are arranged on the balanced frame body, the length directions of the guiding rails are consistent with the length direction of the balanced frame body, and the travelling wheel is mounted on the guiding rails. According to the portable iron core overturning mechanism disclosed by the invention, the defect that the operational efficiency is low existing in the prior art is overcome, and the portable iron core overturning mechanism which is low in labor intensity and high in operational efficiency is provided.

Owner:CHONGQING WANGBIAN ELECTRIC GRP CORP

Double-layer shock-resistant new energy automobile storage battery installation box

PendingCN106654106AImprove seismic performanceImprove the safety of useElectric propulsion mountingCell component detailsElectrical batteryNew energy

The invention discloses a double-layer shock-resistant new energy automobile storage battery installation box. At least one battery box containing cavity is arranged in the box body; at least one first support shock absorption component is arranged at the bottom of each battery box containing cavity; at least one first downward pressure shock absorption component is arranged on the lower head face of a cover plate corresponding to the battery box containing cavity; a storage battery containing cavity is arranged in the battery box; at least one second support shock absorption component is arranged at the bottom of the storage battery containing cavity; at least one second downward pressure shock absorption component is arranged on the top of the storage battery containing cavity; a storage battery is put in the battery box; the battery box is put in the box body; furthermore, each of the battery box and the box body is provided with the support shock absorption component and the downward pressure shock absorption component; therefore, the double-layer shock-resistant effect is realized; vibration of vehicular movement on the storage battery is greatly reduced; simultaneously, the storage battery can be prevented from being struck and pricked by external force; the working stability, security and reliability of a new energy automobile storage battery can be improved; and the complex environment responding capability of a new energy automobile is also improved.

Owner:成都因纳维特科技有限公司

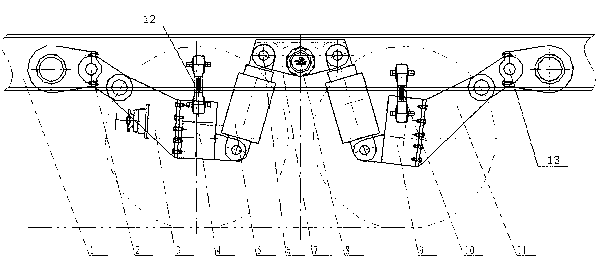

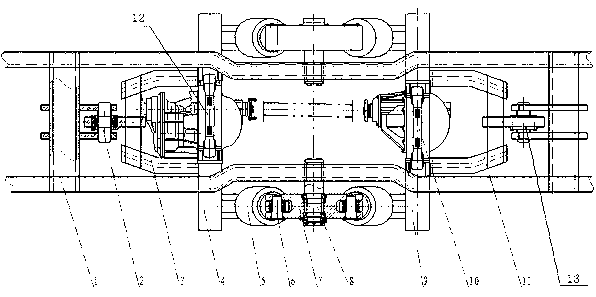

Rear suspension system of mining dump vehicle

InactiveCN103342089ASolve balance puzzlesOutstanding FeaturesInterconnection systemsResilient suspensionsFailure rateVehicle frame

The invention discloses a rear suspension system of a mining dump vehicle. The rear suspension system of the mining dump vehicle is characterized by comprising a frame (1), a front support (3), a medium axle (4), a hydro-pneumatic suspension cylinder (5), a balance beam (7), a balance shaft (8), a rear axle (9), distance rods (10) and a rear support (11). The front support (3) is connected with the frame (1). The medium axle (4) and the front support (3) are in rigid connection. The medium axle (4) and the frame (1) are connected through the second distance rod (12). The rear support (11) is connected with the frame (1). The rear axle (9) and the rear support (11) are in rigid connection. The rear axle (9) and the frame (1) are connected through the first distance rod (10). The balance shaft (8) and the frame (1) are in rigid connection. The hydro-pneumatic suspension cylinder (5) and the balance shaft (8) are connected through the balance beam (7). The medium axle (4) and the rear axle (9) are connected with the hydro-pneumatic suspension cylinder (5) respectively. The rear suspension system can improve bearing capacity of the vehicle, reduces the failure rate of a rear suspension, and solves the balance problem of arranging a plurality of hydro-pneumatic springs among the multiple axles.

Owner:SHANDONG PENGXIANG AUTOMOBILE

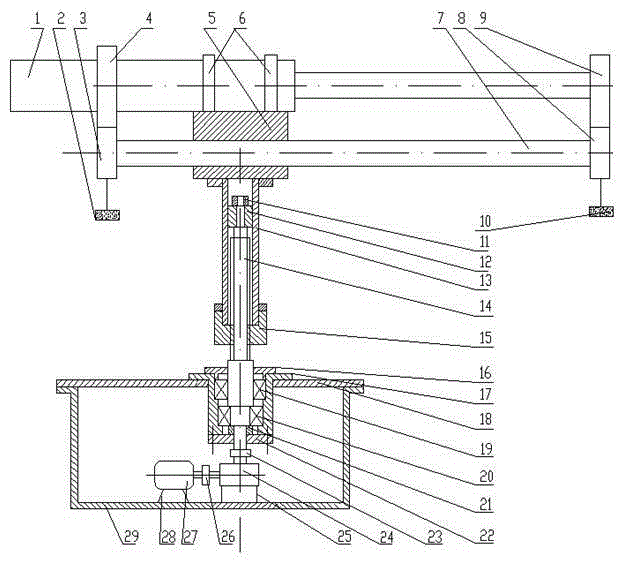

Lifting force measuring device and equipment and method for measuring actual locking rail temperature of jointless track

ActiveCN104149815AThe actual locked rail temperature is safely obtainedThe actual locked rail temperature is obtainedRailway auxillary equipmentRailway profile gaugesIndustrial engineering

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

Lightweight loading and unloading machine

ActiveCN105197787AReduce work intensityImprove work efficiencyWinding mechanismsTrolleysThrust bearingReducer

The invention discloses a lightweight loading and unloading machine. The lightweight loading and unloading machine comprises a linear motor, a left electric hoist, a guide sleeve, a sliding guide block, fixing sleeves, a sliding guide rod, a right electric hoist, an adapter sleeve, a guide pillar, a lifting sleeve, a stand column, a lifting nut, a bearing block, a box cover plate, a radial bearing, a thrust bearing, a worm gear reducer, an electrical motor and a box. The lightweight loading and unloading machine has no special requirements for the use place, is convenient to operate, simple in structure, easy to manufacture and convenient to mount and maintain; the labor intensity of an express delivery worker can be reduced; the working efficiency of loading and unloading of express delivery articles is improved, and damage of the express delivery articles due to throwing and falling in the loading and unloading process is prevented; double electric hoist structures are arranged, one electric hoist is used for lifting goods, the other one is used for unloading the goods, the assisting time is shortened, and the working efficiency is improved.

Owner:江苏华普泰克石油装备有限公司

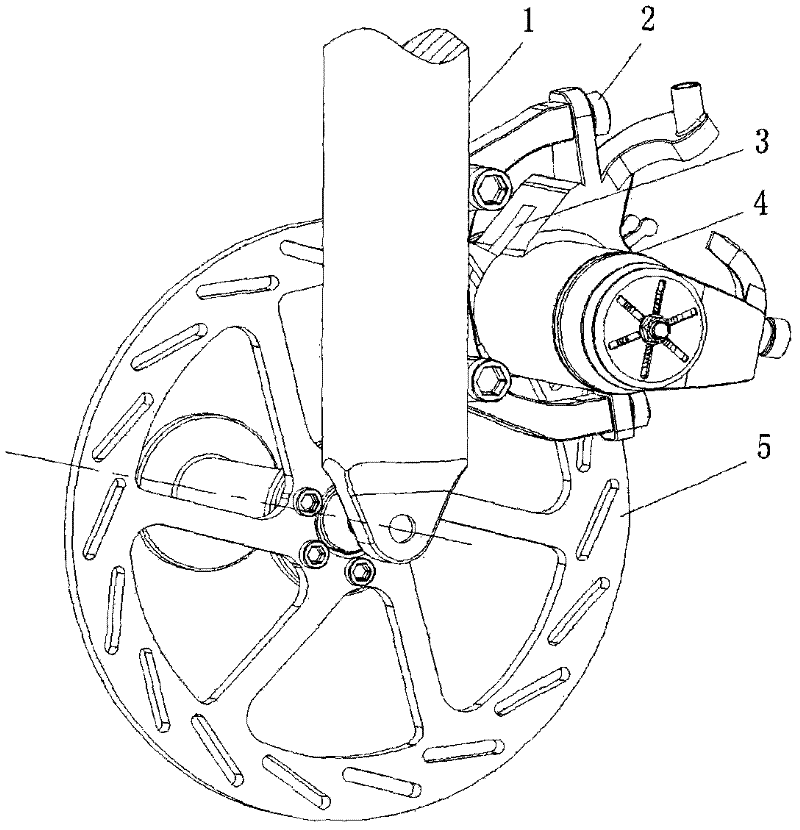

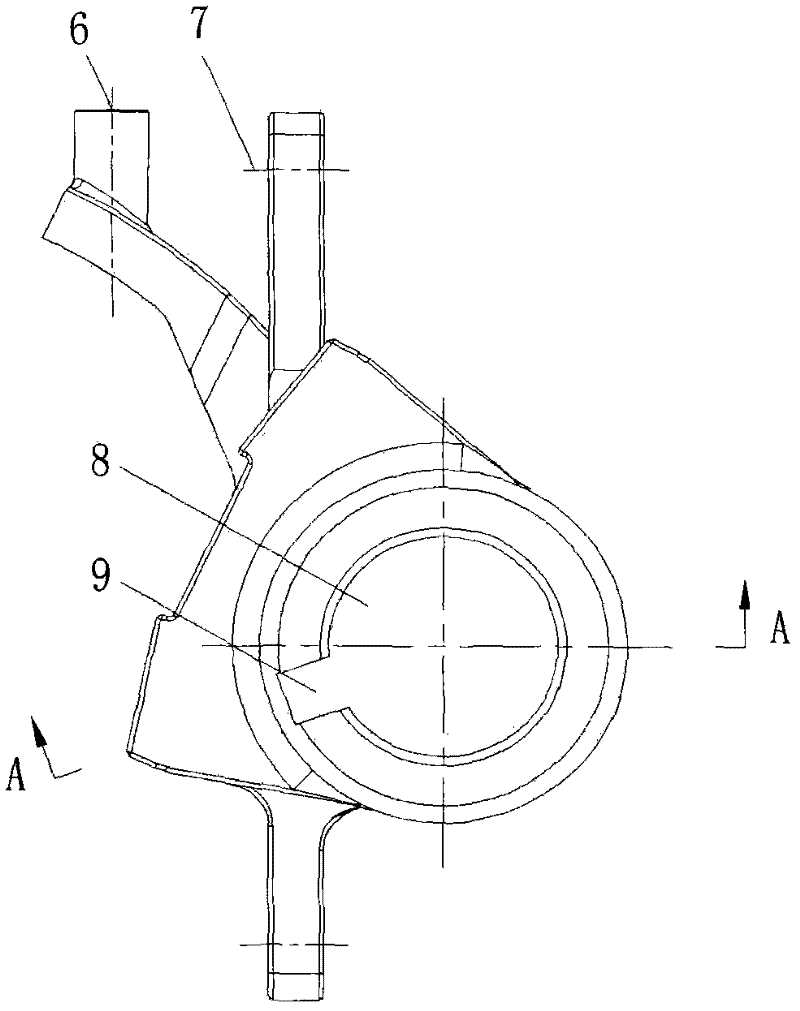

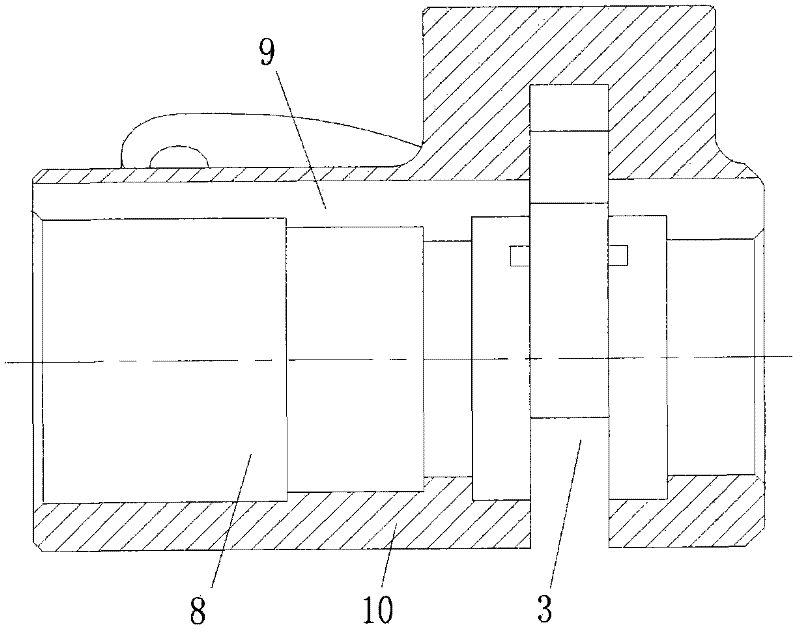

Double-acting bicycle disk brake device

InactiveCN102501935AGuaranteed force balanceAvoid deformationAxially engaging brakesCycle brakesVehicle frameEngineering

The invention relates to a double-acting bicycle disk brake device and belongs to the field of design and manufacturing of bicycle part products. The double-acting bicycle disk brake device consists of a shell, a double-acting brake mechanism and brake pad position regulating mechanisms. The double-acting bicycle disk brake device is arranged on a disk brake seat of a bicycle frame and a front fork and can synchronously extrude two sides of a disk, so that double acting and synchronous brake can be realized, brake efficiency is improved, the disk can be forced uniformly, and the problem that the brake disk is easy to deform after being used for a long time is solved. Meanwhile, the double-acting bicycle disk brake device is provided with brake pad position regulating devices which are arranged on the left and right sides, so that distance between the device and the disk can be regulated simply and easily under the conditions that the disk brake device is installed and brake pads are abraded.

Owner:时利

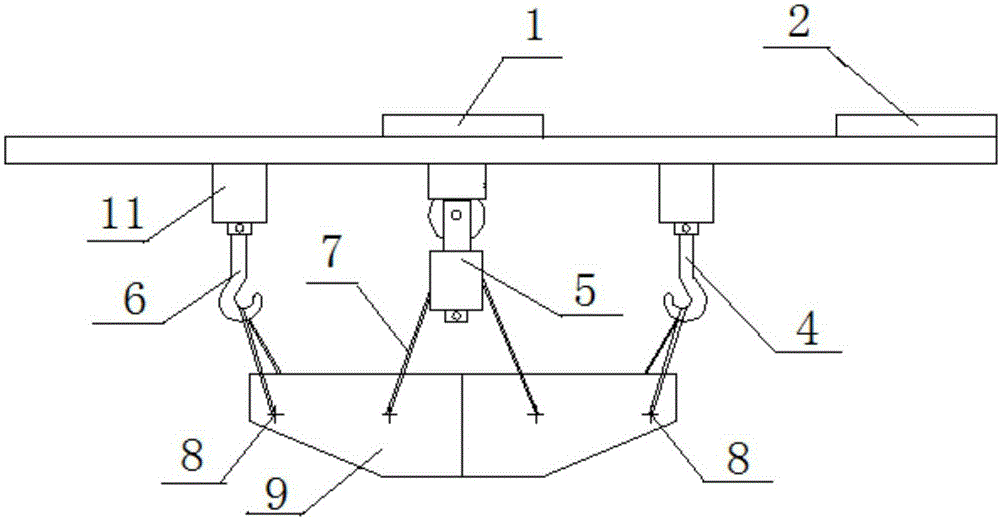

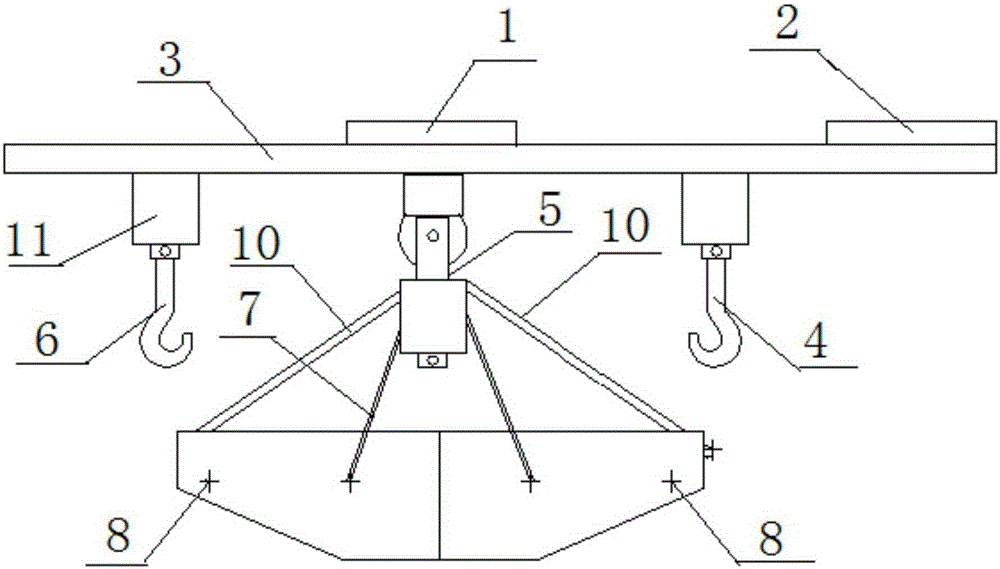

Method for replacing ladle turret rotary arm of continuous casting machine

The invention discloses a method for replacing a ladle turret rotary arm of a continuous casting machine, and belongs to the technical field of maintenance of ladle turrets of large-tonnage continuous casting machines. The method comprises the steps of mounting of fixed pieces, hoisting between two spans, horizontal movement, molten steel below-span hoisting, balance locking, hoisting landing, reassembling and the like. The ladle turret rotary arm of the continuous casting machine is moved to the position where a molten steel span crane main hoist can operate through a continuous casting crane main hoist and a molten steel span crane auxiliary hoist of existing facilities on site; a chain block is used for balance locking before molten steel span crane hoisting, and the situation that the rotary arm loses balance after the molten steel span crane auxiliary hoist is loosened is avoided; and after steel wire rope hanging of the molten steel span crane main hoist, balance locking of the chain block and stressing of the molten steel span crane main hoist, the molten steel span crane auxiliary hoist and the continuous casting crane main hoist are loosened, and then the molten steel span crane main hoist is used for hoisting landing. The aims of safely and effectively replacing the ladle turret rotary arm of the continuous casting machine, reducing the influence on production and improving maintenance efficiency are achieved.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

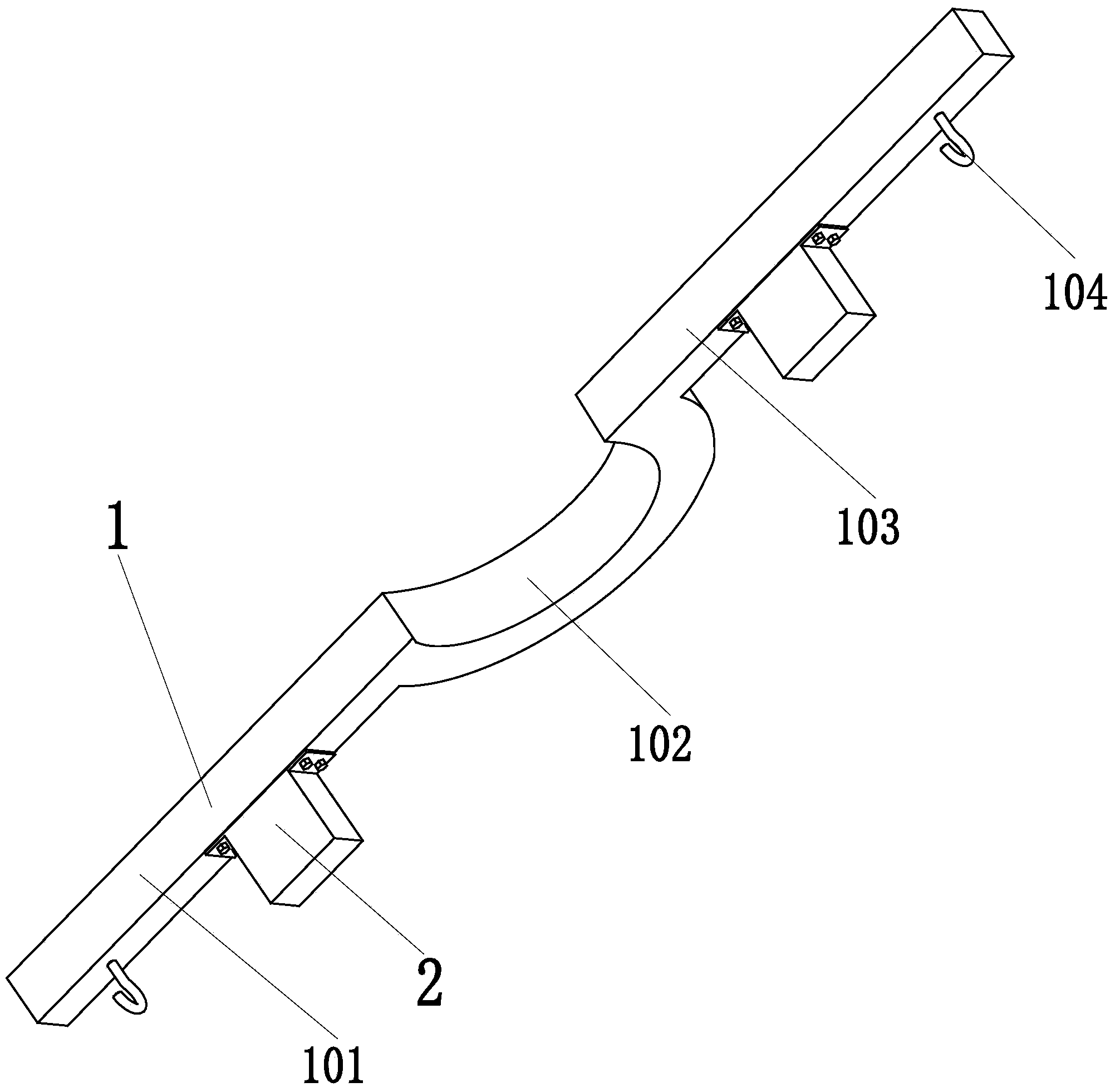

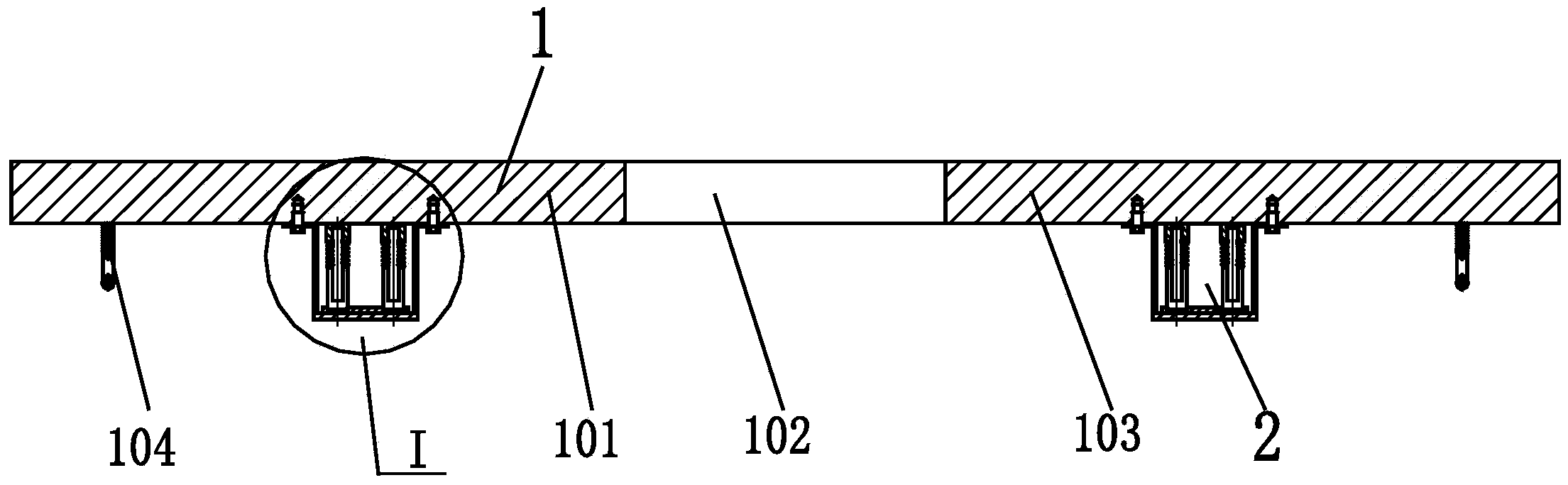

Shoulder pole unit for shouldering system

ActiveCN104249903AEliminate jitter conditionsGuaranteed force balanceManual conveyance devicesPhysical medicine and rehabilitationRight shoulder

The invention relates to a shoulder pole unit for a shouldering system. The shoulder pole unit comprises a pole body and two shoulder damping mechanisms. The pole body comprises a left shoulder portion, a neck portion, a right shoulder portion and two upper hooks. Two ends of the neck portion are fixedly connected with the left shoulder portion and the right shoulder portion. The upper hooks are symmetrically and fixedly connected to the lower end of the left shoulder portion and the lower end of the right shoulder portion. Each shoulder damping mechanism comprises two damping support chains, a holder and a damping cover; the upper ends of the damping support chains are mounted at the lower end of the pole body; the lower ends of the damping support chains are mounted on the holder; the holder is fixedly connected with the inner wall of the damping cover; two ends of the damping cover are mounted on the pole body through screws. Shake of material can be eliminated by the damping support chains when the material is being carried, and shoulders bear balanced stress. The shoulder pole unit has the advantages such that shake of the material during carrying is eliminated, balanced stress is ensured for the shoulders, and work efficiency is high.

Owner:ZHANGJIAGANG DONGDA IND TECH RES INST

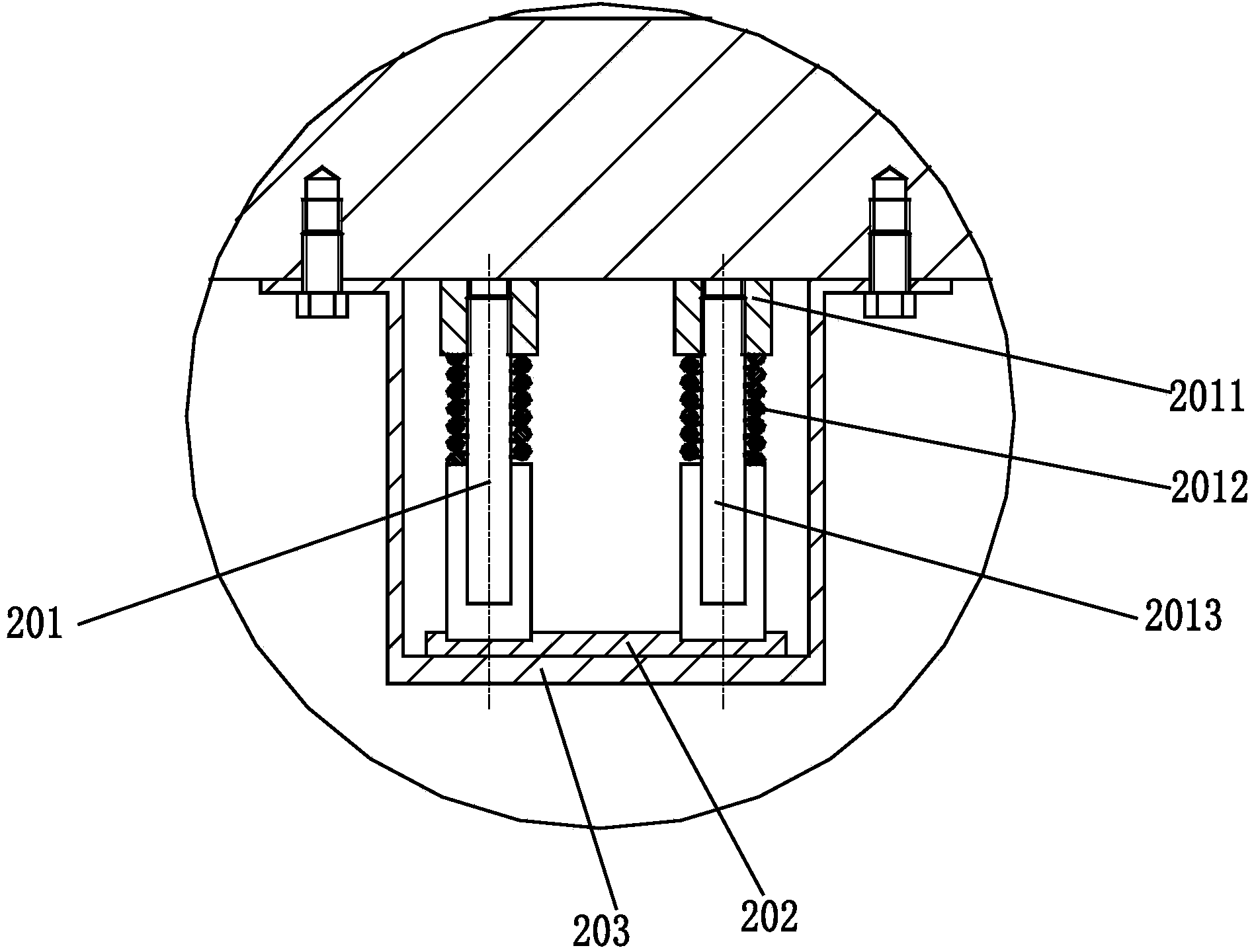

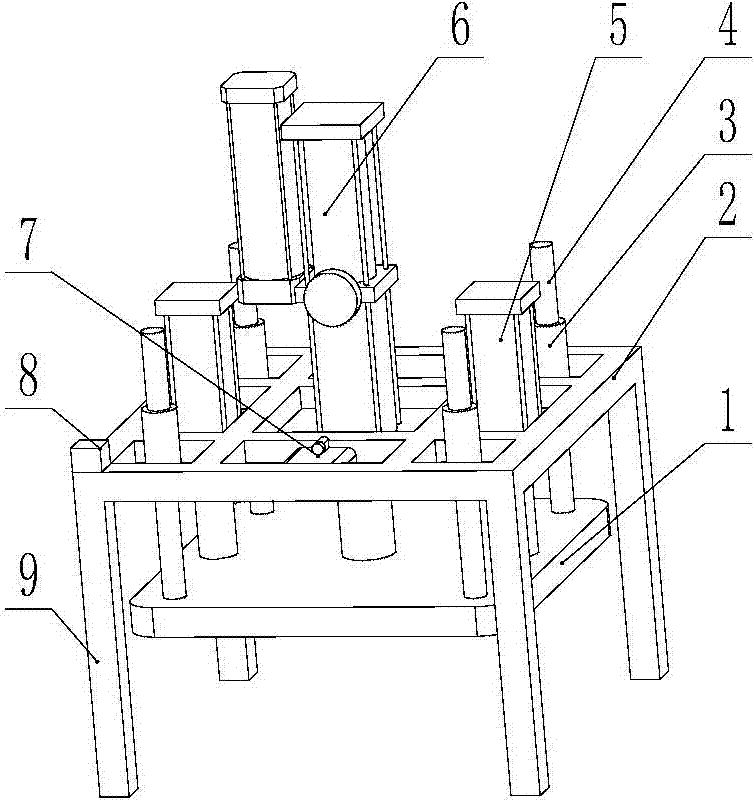

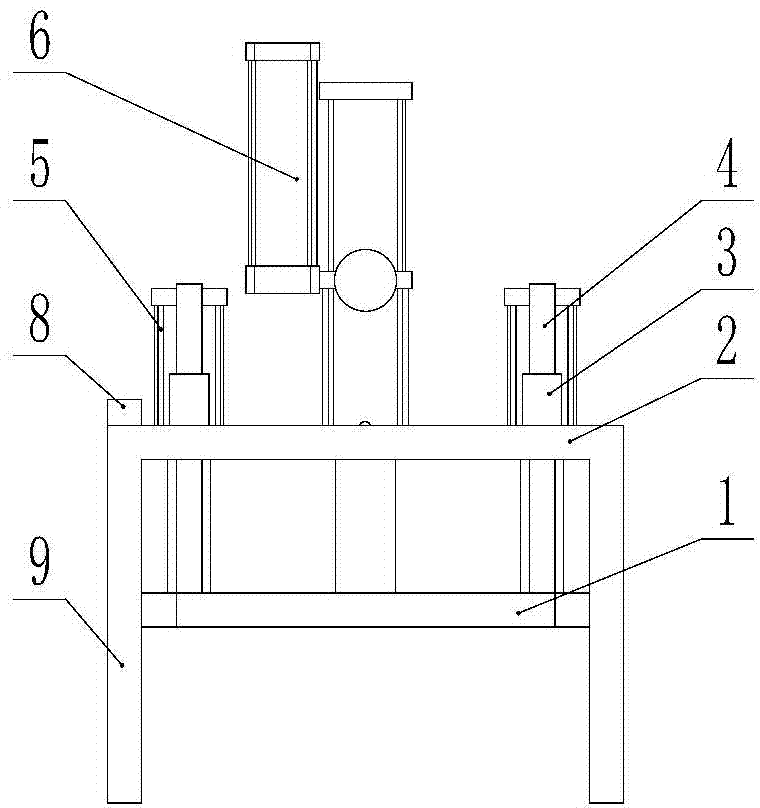

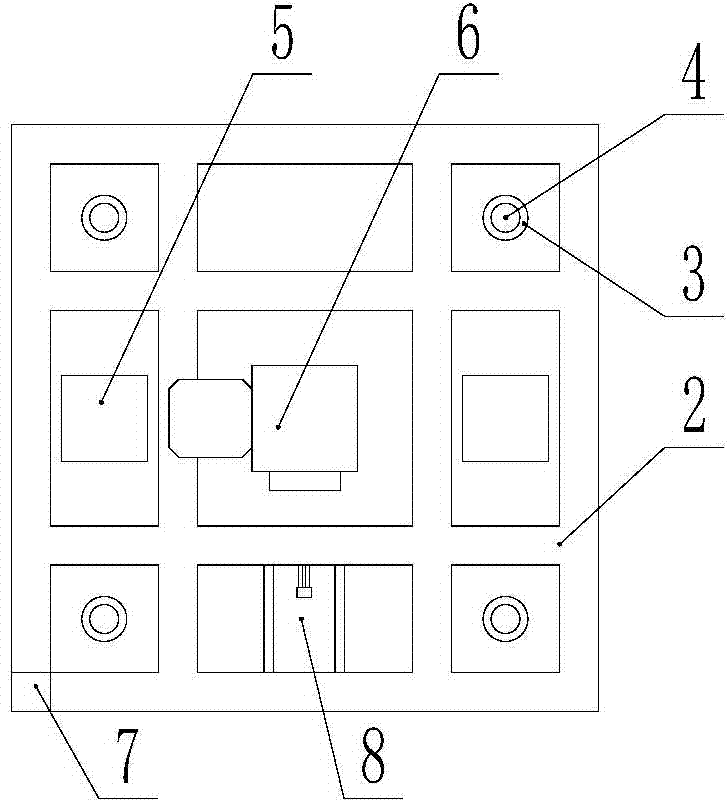

Pressurizing structure

ActiveCN104708841AGuaranteed force balanceGuarantee product qualityPress ramEngineeringMechanical engineering

The invention relates to the field of automobile accessory production, in particular to a pressurizing structure. The structure comprises a main frame, a lifting cylinder and a moulded plate. The lifting cylinder is fixedly arranged above the main frame, the moulded plate is arranged below the main frame, and the lifting cylinder is connected with the moulded plate and can drive the moulded plate to ascend and descend. According to the pressurizing structure, the cylinder is adopted to serve as a lifting power device of the moulded plate and provides power for lifting and downwards pressing the moulded plate, and under the situation that a hydraulic machine is not needed to press a die, the die pressing function is guaranteed, and resources and cost are saved.

Owner:东风佛吉亚汽车内饰有限公司

Bamboo splitter

The invention provides a time-saving and labor-saving bamboo splitter. The bamboo splitter can remarkably improve the quality of split bamboo pieces and facilitate subsequent processing. The bamboo splitter comprises a cylindrical body and a handle on the circumferential wall of the body, wherein through holes are formed in the two ends of the body, a plurality of blades are distributed in the body in the shape of radiating from the center, the direction of the knife edges of the blades is coincident with the length direction of the body, and the knife edges are arc. When the bamboo splitter is used, a bamboo section to be split is placed vertically and sleeved with the end, close to the knife edges, of the cylindrical body of the bamboo splitter, force is applied to the handle of the bamboo splitter, then the bamboo can be split into bamboo pieces uniform in size, time and labor are saved, the quality of split bamboo pieces is high, and subsequent processing is facilitated.

Owner:何理生

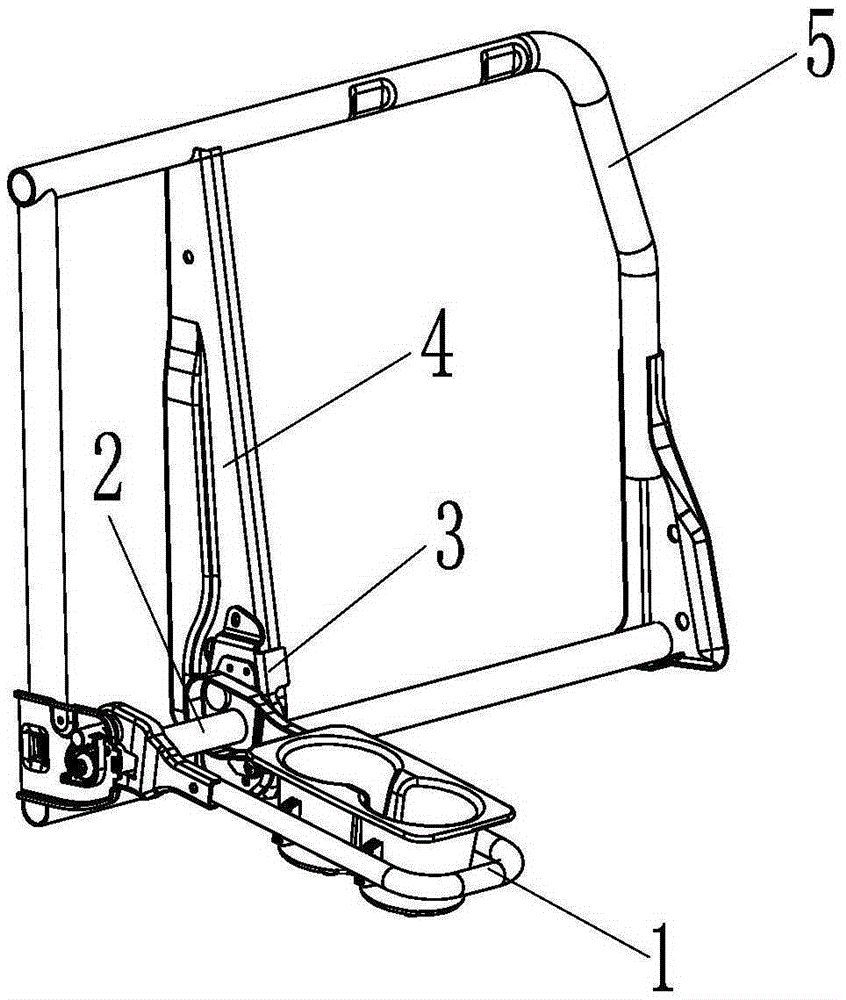

Automobile seat backrest with middle armrest

Owner:CHONGQING ZONGSHEN HONGLI CUSHION MFG

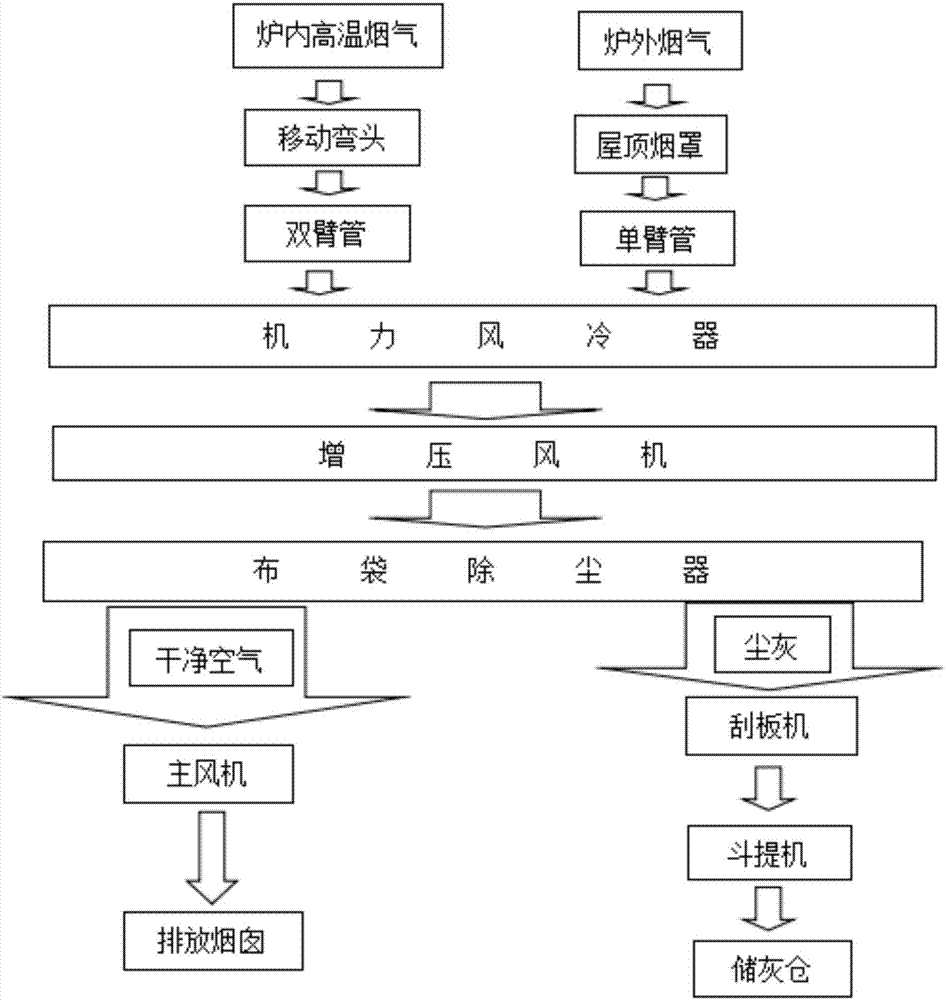

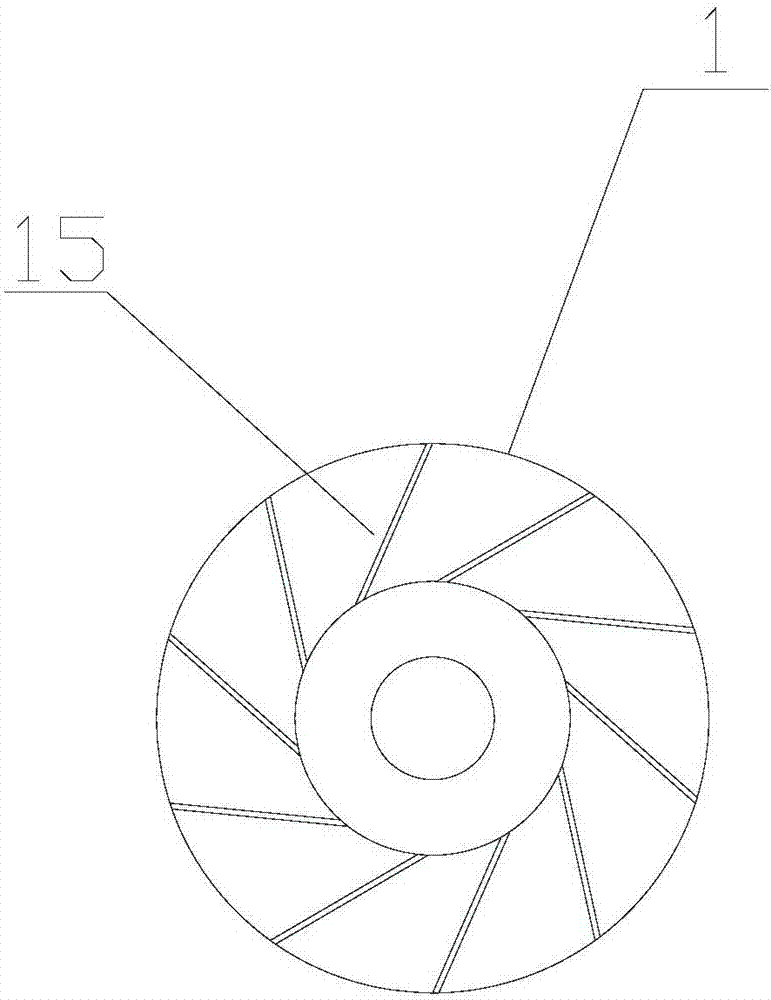

Large centrifugal blower

InactiveCN107100862AReduce starting loadGuaranteed force balancePump installationsNon-positive displacement fluid enginesImpellerEngineering

The invention provides a large centrifugal blower which comprises a shell. An impeller shaft penetrates through the center of the shell and is embedded into an impeller. A connecting plate is fixedly arranged on the side, close to the impeller, of the inner side wall of the shell. A spraying and blowing mechanism is fixedly arranged on the connecting plate and communicates with a stable-pressure gas storage tank. The spraying and blowing mechanism comprises an annular airflow distributor and a plurality of nozzles uniformly arranged on the circular surface of the annular airflow distributor. Compared with the prior art, the large centrifugal blower has the following beneficial effects that compressed air is sprayed and blown onto blades of the blower, so that the whole impeller of the blower is driven to rotate, then the blower is started after the speed is uniform, and accordingly, a starting load of the blower is reduced; and the annular distributor sprays and blows the impeller of the blower to generate couple, so that stress equilibrium of the impeller of the blower during starting is guaranteed.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Yarn guide device for production of socks

The invention relates to a yarn guide device for production of socks. The yarn guide device comprises a vertical plate, a yarn frame and a yarn outlet wheel are fixedly arranged on the vertical plate,the side wall of the vertical plate is provided with a pressure liquid cavity, and the vertical plate is provided with piston cavities which are communicated with the pressure liquid cavity. A pistonrod is arranged in each piston cavity, one end of each piston rod is slidably connected in the corresponding piston cavity, the other end of each piston rod penetrates the side wall of the corresponding piston cavity to be arranged freely, and a free end of each piston rod is provided with a guide wheel. The piston cavities include a first piston cavity in transverse arrangement and a second piston cavity in longitudinal arrangement, and the free end of the piston rod in the second piston cavity is arranged downwards. By arrangement of the pressure liquid cavity and the piston cavities, a gapof the guide wheels on the piston rods can be regulated, and accordingly the yarn length can be changed to adapt to deviation in spinning drive and guarantee yarns in a stable state constantly. The yarn guide device has advantages of simple structure, convenience in operation, extensive applicability and the like.

Owner:湖南莎丽袜业股份有限公司

Bolt combination installation device and application method

The invention discloses a bolt combination installation device and an application method. The bolt combination installation device comprises a screw rod, a nut and a positioning piece matched with the rod body; the screw rod consists of a rod body (the rod body is a cylindrical threaded rod body, or a threaded rod body with a plane section, or a threaded rod body with a notch), a countersunk head; the countersunk head is completely or partially protruded outside the combination formed by the rod body and the positioning piece. By arranging the positioning piece matched with the rod body and the countersunk head, the bolt combination installation device disclosed by the invention can be effectively fixed on a wall body or a decorative panel to realize the functions of the conventional back bolt; the bolt combination installation device is simple in structure and convenient to construct and operate, and has great practicability.

Owner:深圳市伟宝田五金制品有限公司

Extra-large down-print corrugated case press with suction-assisted sheet feed

ActiveCN106985508BStable pressureImprove stabilityPrinting press partsPulp and paper industryPrinting press

Owner:GUANGZHOU KESHENGLONG CARTON PACKING MACHINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com