Fabricated shear-wall energy-dissipation vibration-reduction horizontal connecting device and construction method thereof

A technology of horizontal connection and connection device, applied in the direction of wall, shockproof, protective building/shelter, etc., can solve the problems of unbalanced force on the wall, affecting the durability of the structure, long construction period, etc., to avoid the plane warping The effect of ensuring durability and good energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

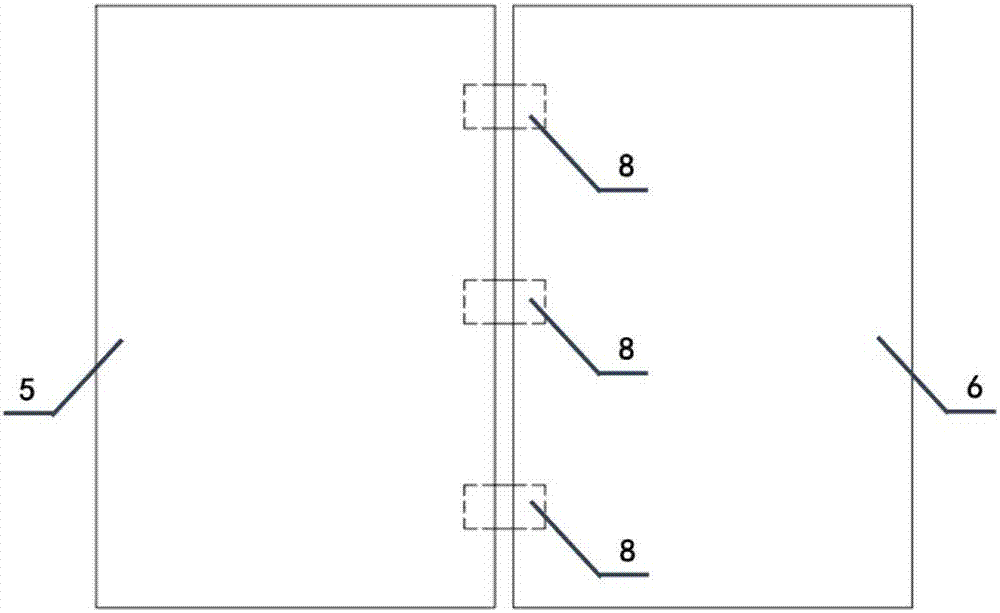

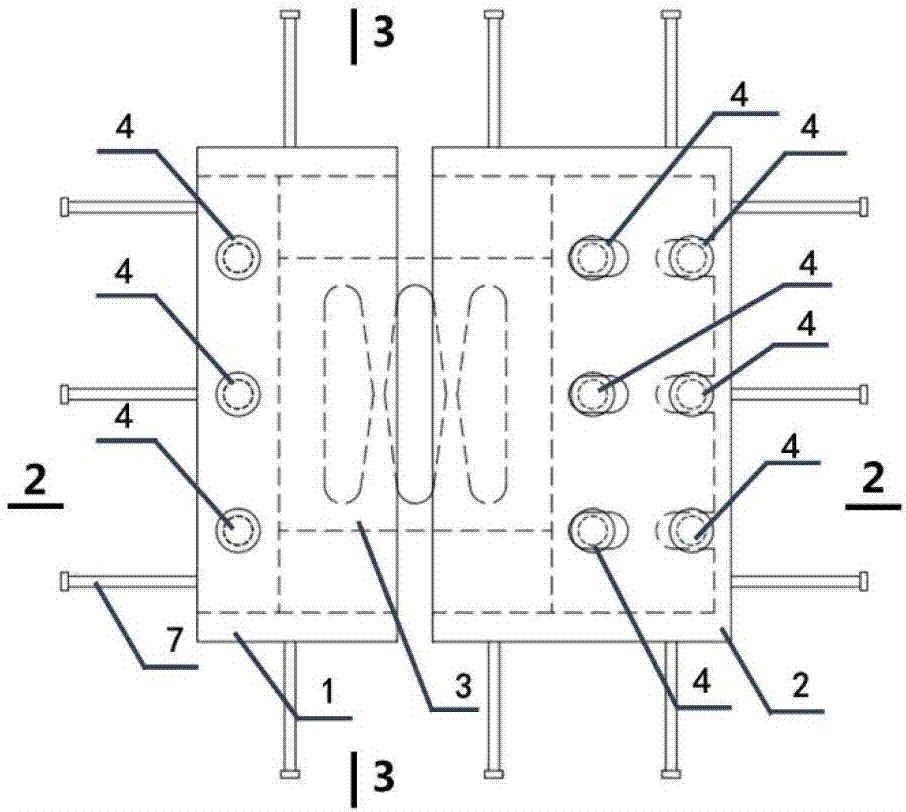

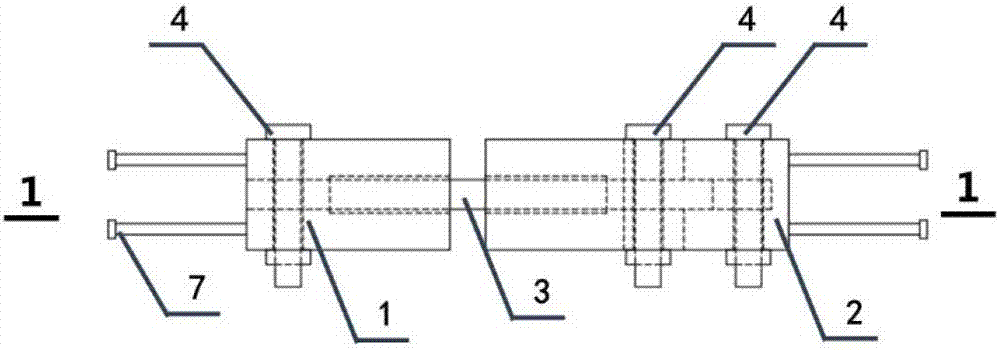

[0036] A prefabricated horizontal connection device for shear wall energy dissipation and shock absorption, including a left shear wall 5, a right shear wall 6 and a pre-embedded connection device 8;

[0037] The embedded connection device 8 includes a left groove 1, a right groove 2, an energy-dissipating shock-absorbing component 3 and a pull bolt 4; the left groove 1 is composed of a left front plate, a left rear plate, a left upper plate and a left lower plate Cavity structure, the left front plate, left rear plate, left upper plate and left lower plate are all welded with pullout bolts 7; 1. The right rear plate, right upper plate and right lower plate are all welded with anti-pull bolts 7; the energy-dissipating shock-absorbing components 3 are placed in the cavity structure of the left cavity 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com