Fatigue test stand for torsion damper and fatigue test method thereof

A technology of torsional shock absorber and fatigue test, which is applied in the testing of machine/structural parts, testing of mechanical parts, instruments, etc. It can solve the problems of poor durability and difficulty of the test bench, and achieve convenient operation, guaranteed durability, Effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

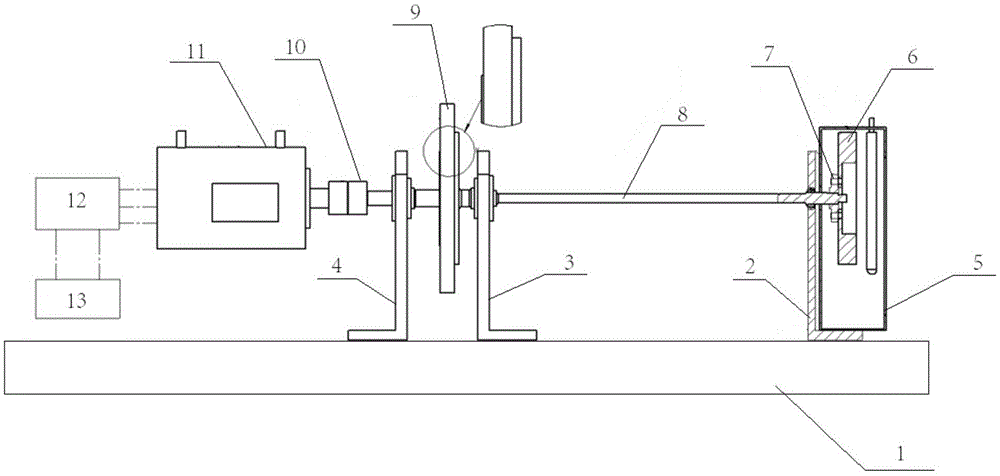

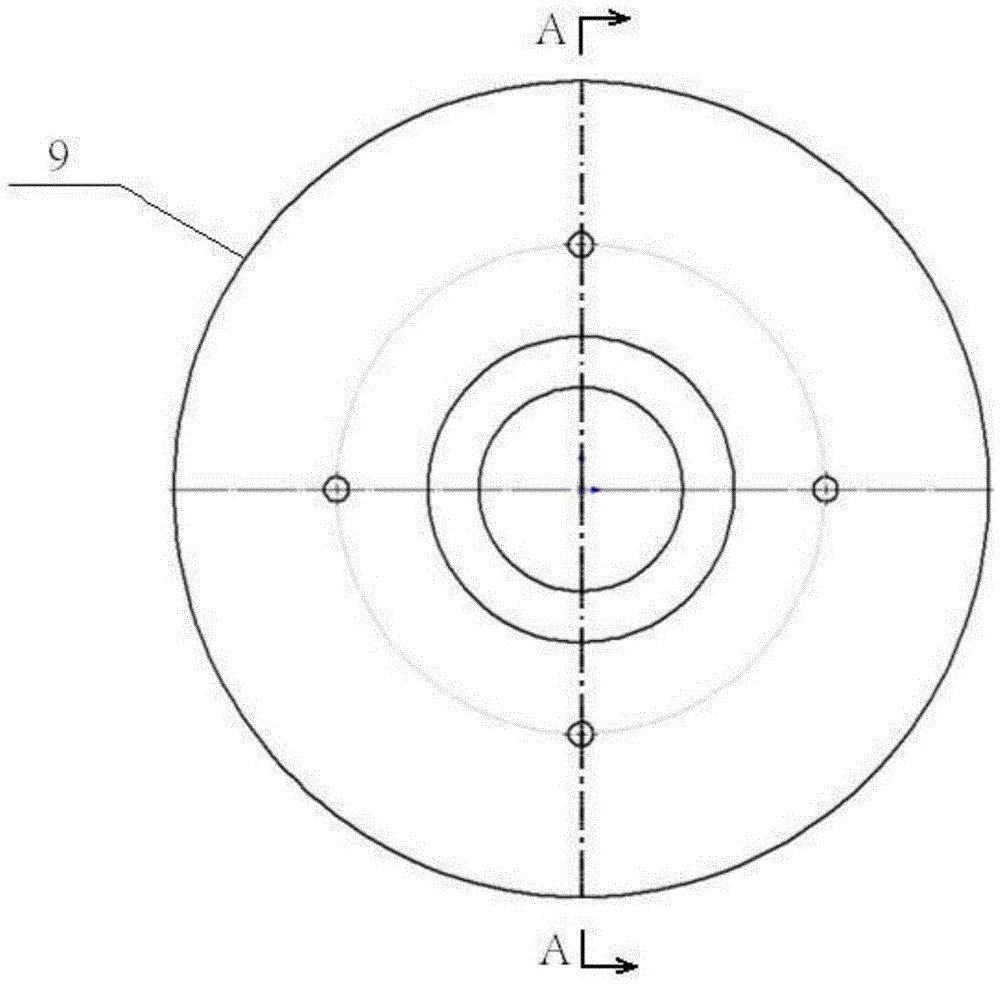

[0030] Such as Figure 1 to Figure 4 As shown, a fatigue test bench for torsional shock absorbers includes an experimental platform 1, a torsional shock absorber 6, a torsional vibration shaft 8 and a permanent magnet synchronous motor 11 with a controller 12 connected to a signal Generator 13, the first base 2, the second base 3 and the third base 4 are installed on the experimental platform 1 by bolts, ribs can be added on the three bases according to the actual situation to enhance the stability of the test bench;

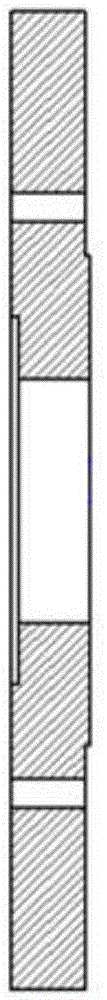

[0031] On the first base 2, a constant temperature box 5 is installed by bolts, and the bottom of the constant temperature box 5 is provided with a bolt hole 52 corresponding to the first base 2, in order to fix the constant temperature box 5 on the experimental platform 1; Vibrator 6 is installed in the incubator, and the top of incubator 5 has at least tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com