Bamboo splitter

A body and blade technology, applied in mechanical equipment, sugarcane machining, etc., can solve problems such as unfavorable processing, low efficiency, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

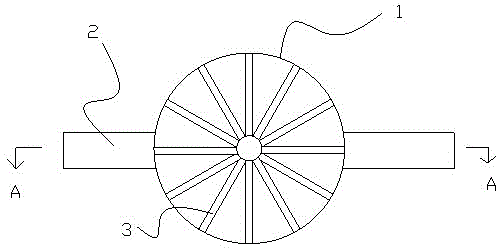

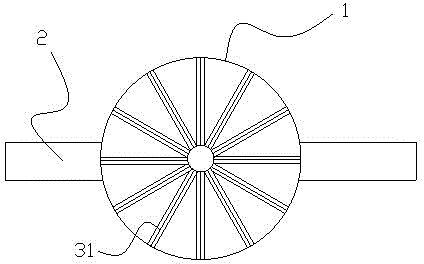

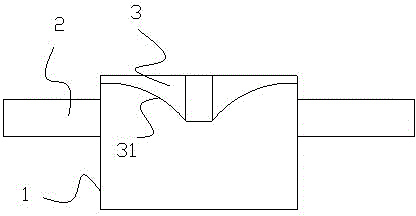

[0015] Such as figure 1 , 2 , 3, 4, the bamboo opener of the present invention comprises the handle 2 that the cylindrical body 1 of two ends through-hole and body 1 peripheral wall is arranged, is provided with 12 blades 3 that the center radially distributes outwards in the body 1, and blade 3 The direction of the knife edge 31 is consistent with the length direction of the body 1, and the knife edge 31 is arc-shaped. Wherein, the blades 3 are uniformly distributed in gaps. The blade 3 is disposed on the side of the through hole at one end of the cylindrical body 1 . There are two handles 2 arranged symmetrically.

[0016] During use, the sectioned bamboo is placed vertically, and then the end of the cylindrical body 1 of the bamboo opener close to the knife edge 3 is entangled with the bamboo, as Figure 4 as shown, Figure 4 The dotted line part of represents section bamboo, and then exerts force on the handle 2 of the bamboo opener, the bamboo can be broken into even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com