Extra-large down-print corrugated case press with suction-assisted sheet feed

A paper feeding device, corrugated box technology, applied in printing presses, general parts of printing machinery, printing and other directions, can solve the problems affecting printing quality, unstable pressure between cardboard and printing plate, etc., to ensure printing quality and pressure stability , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

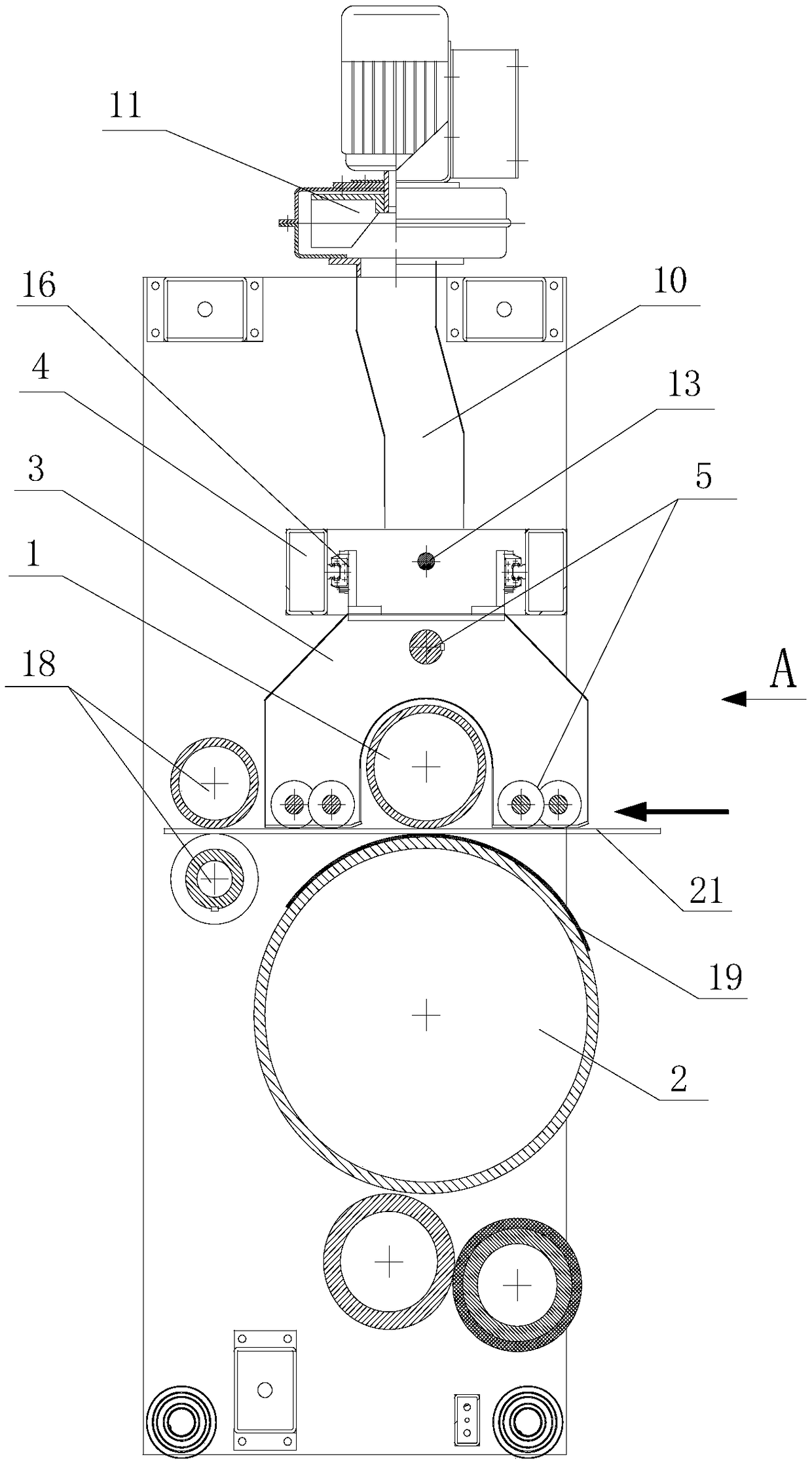

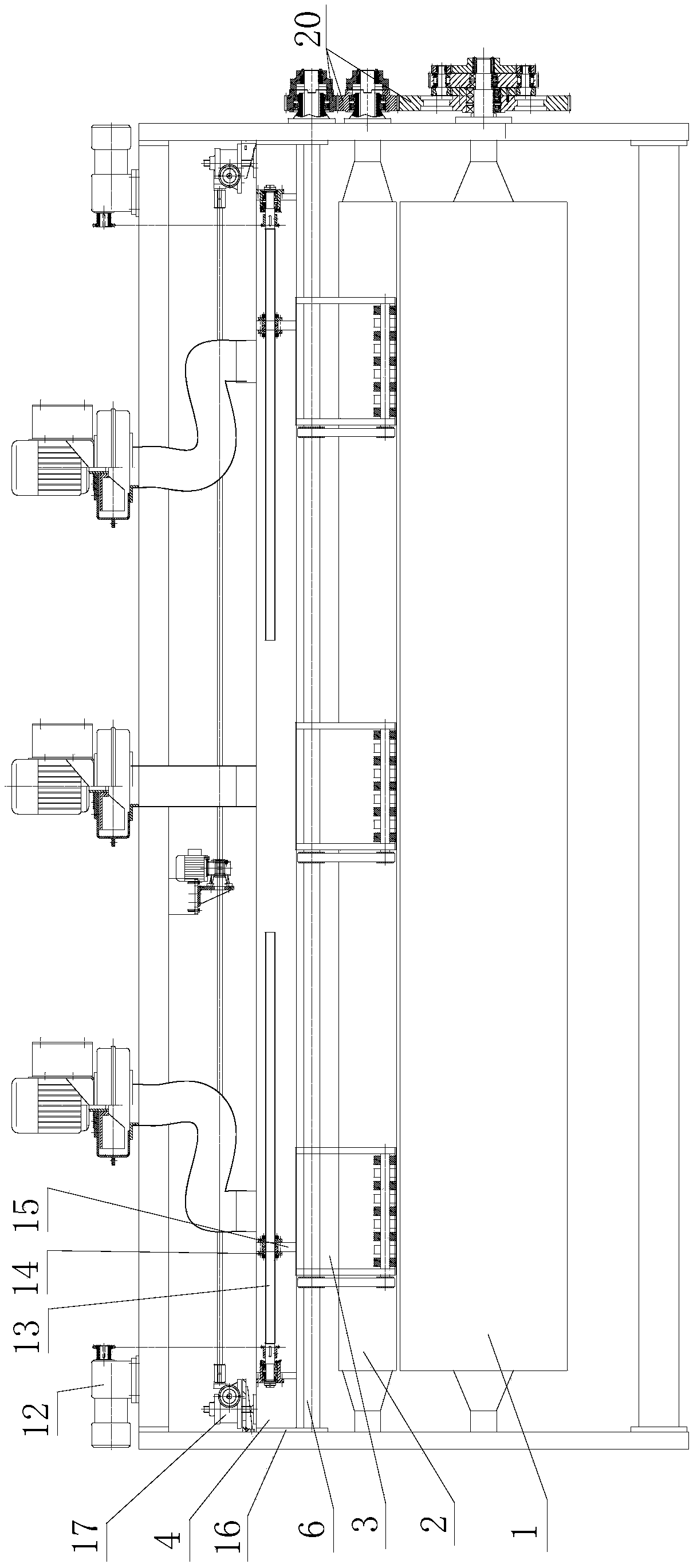

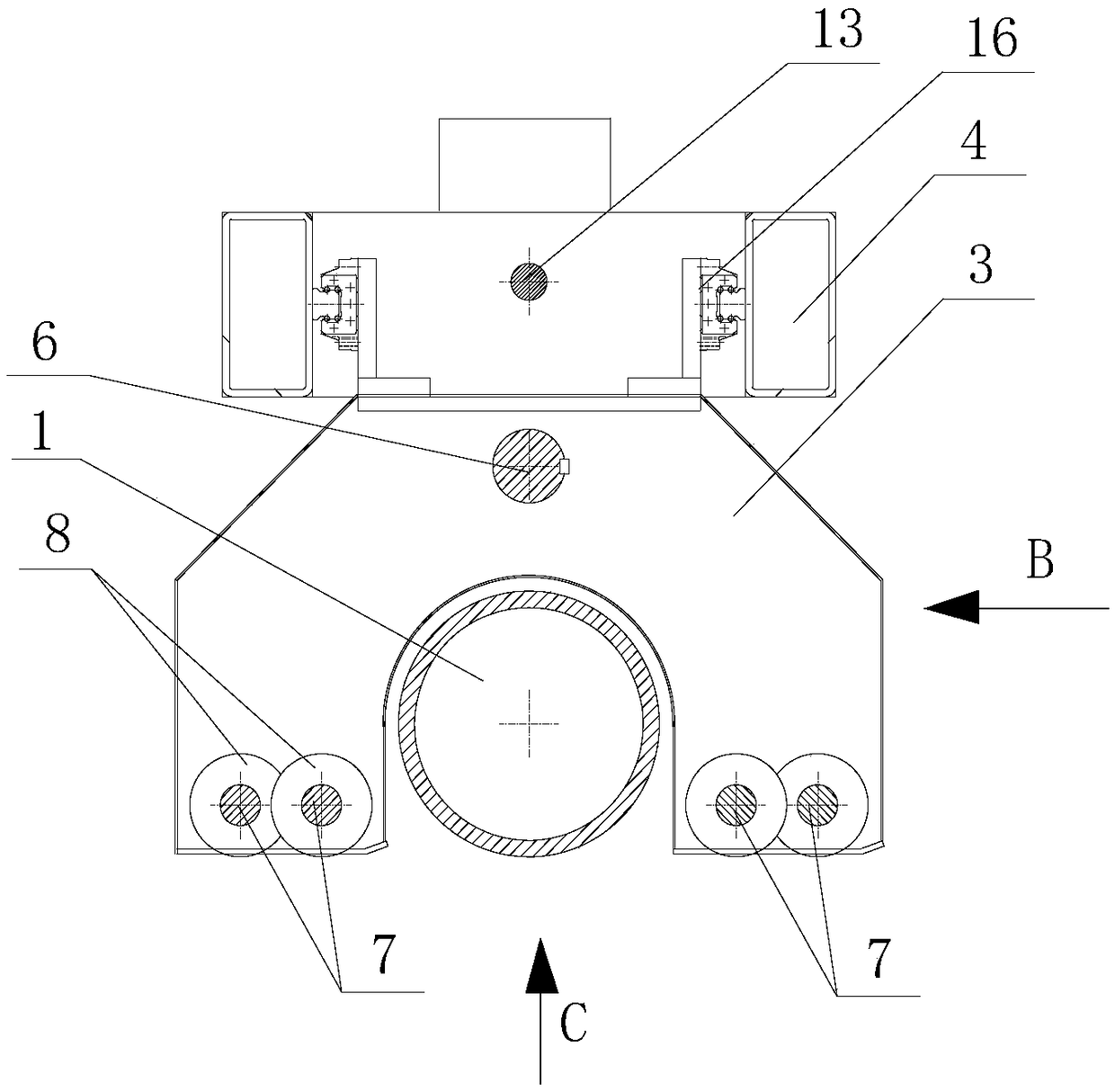

[0028] In this embodiment, a super-large down-print corrugated box printing machine with a suction auxiliary paper feeding device, such as figure 1 or figure 2 As shown, it includes embossing roller 1 and printing roller 2 respectively arranged on the upper and lower sides of the corrugated paper. The printing length of the printing roller is 4.5-6 meters. There is also a suction auxiliary paper feeding device above the corrugated paper; suction auxiliary paper feeding The device includes a suction chamber 3, a suction chamber mounting frame 4 and an auxiliary paper feeding mechanism 5. The suction chamber is installed on the printing machine through the suction chamber mounting frame, and the suction chamber is arranged on the outside of the embossing roller. Auxiliary feeding mechanism. Among them, the length of the embossing roller is the length of the printing platform. Compared with traditional small and medium-sized printing machines, the extension of this length will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com