Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Reduce starting load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

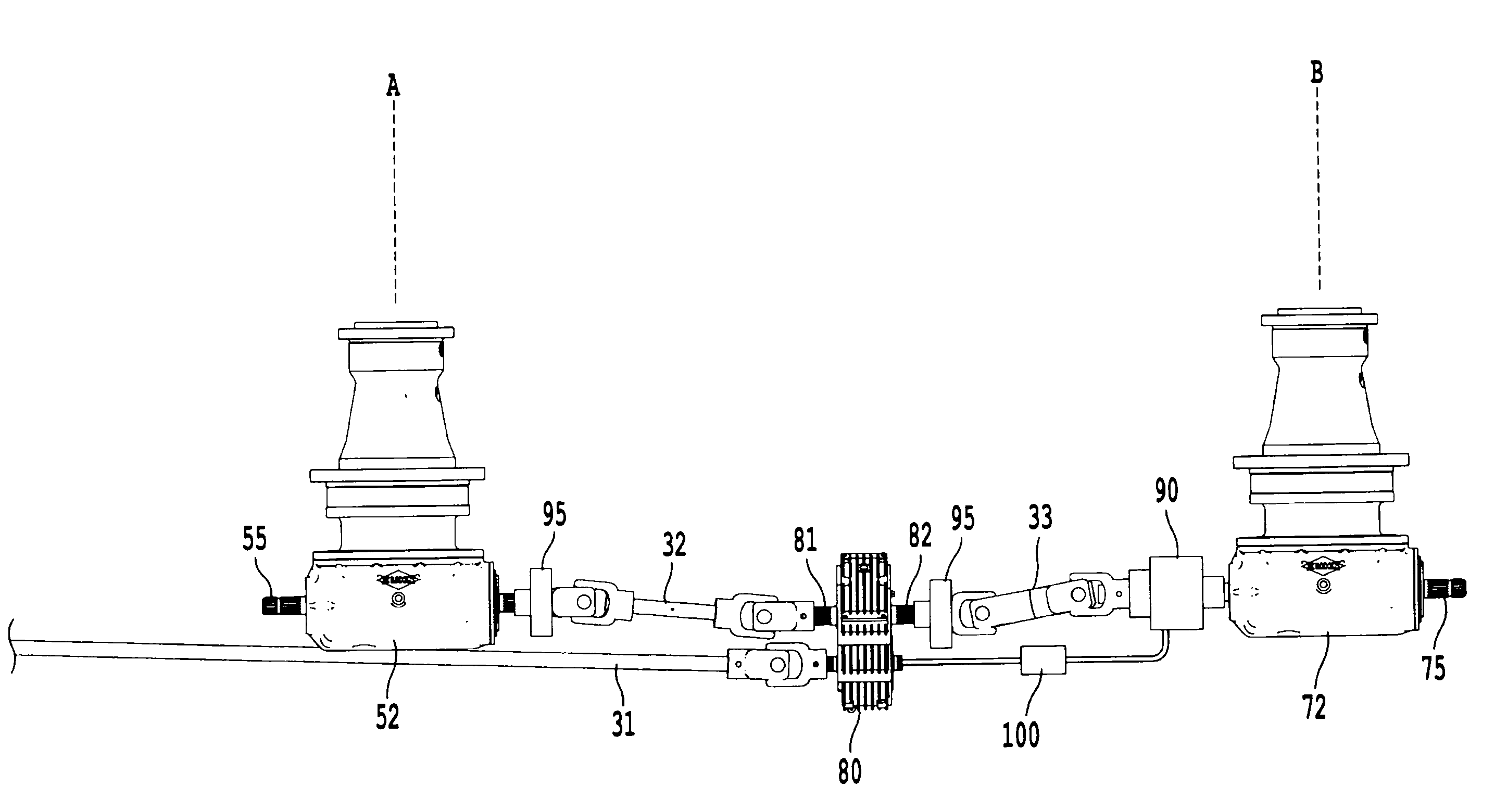

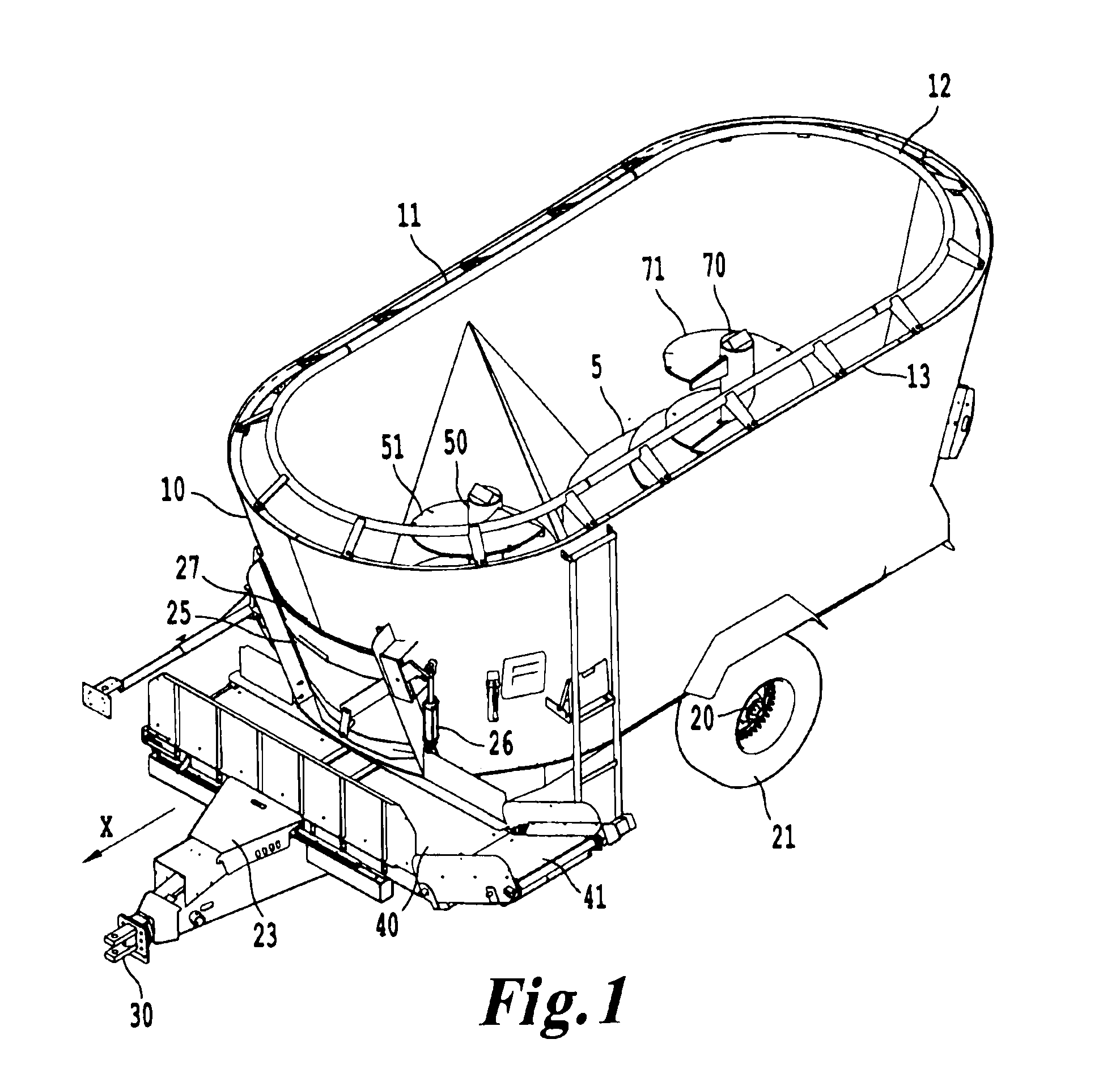

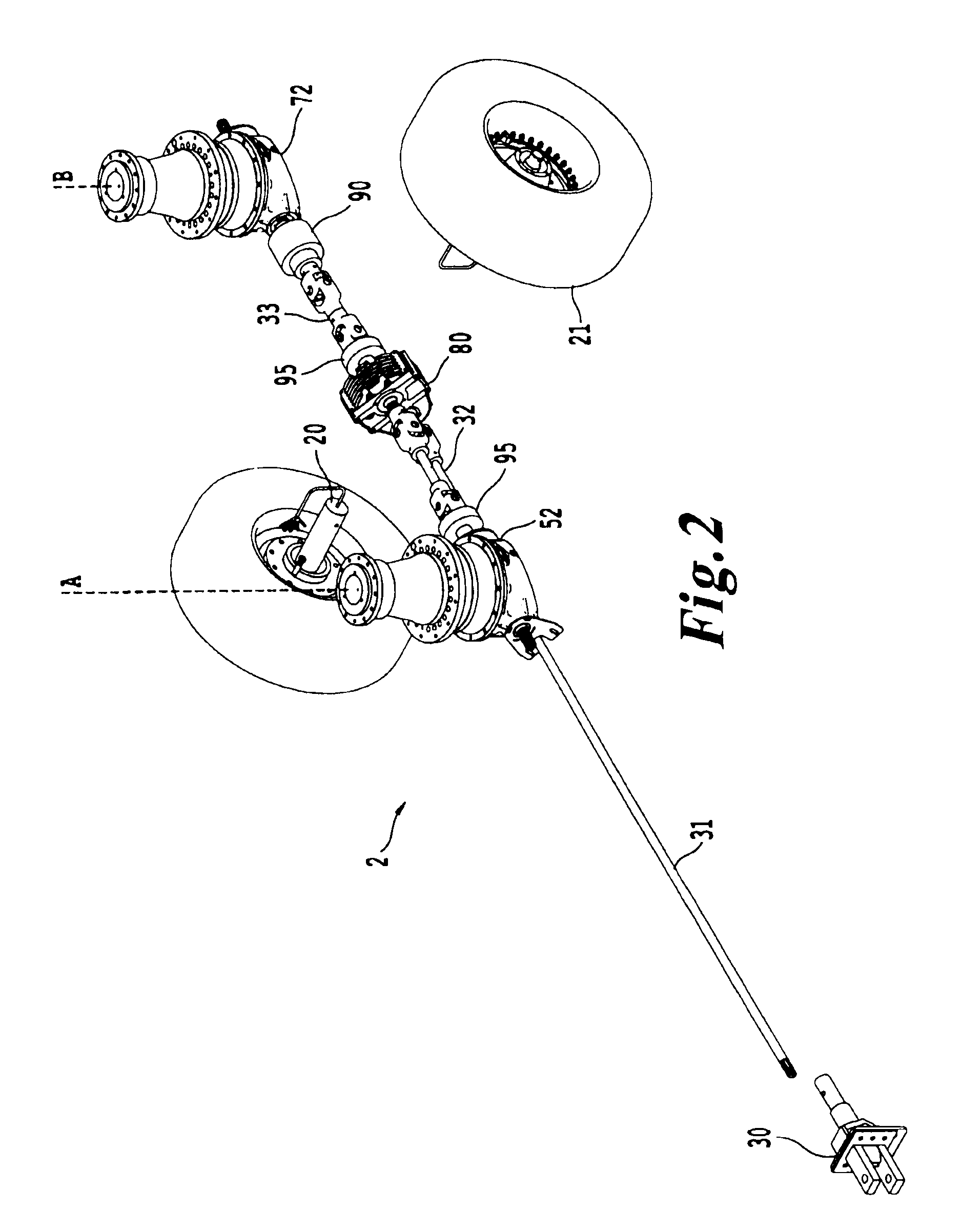

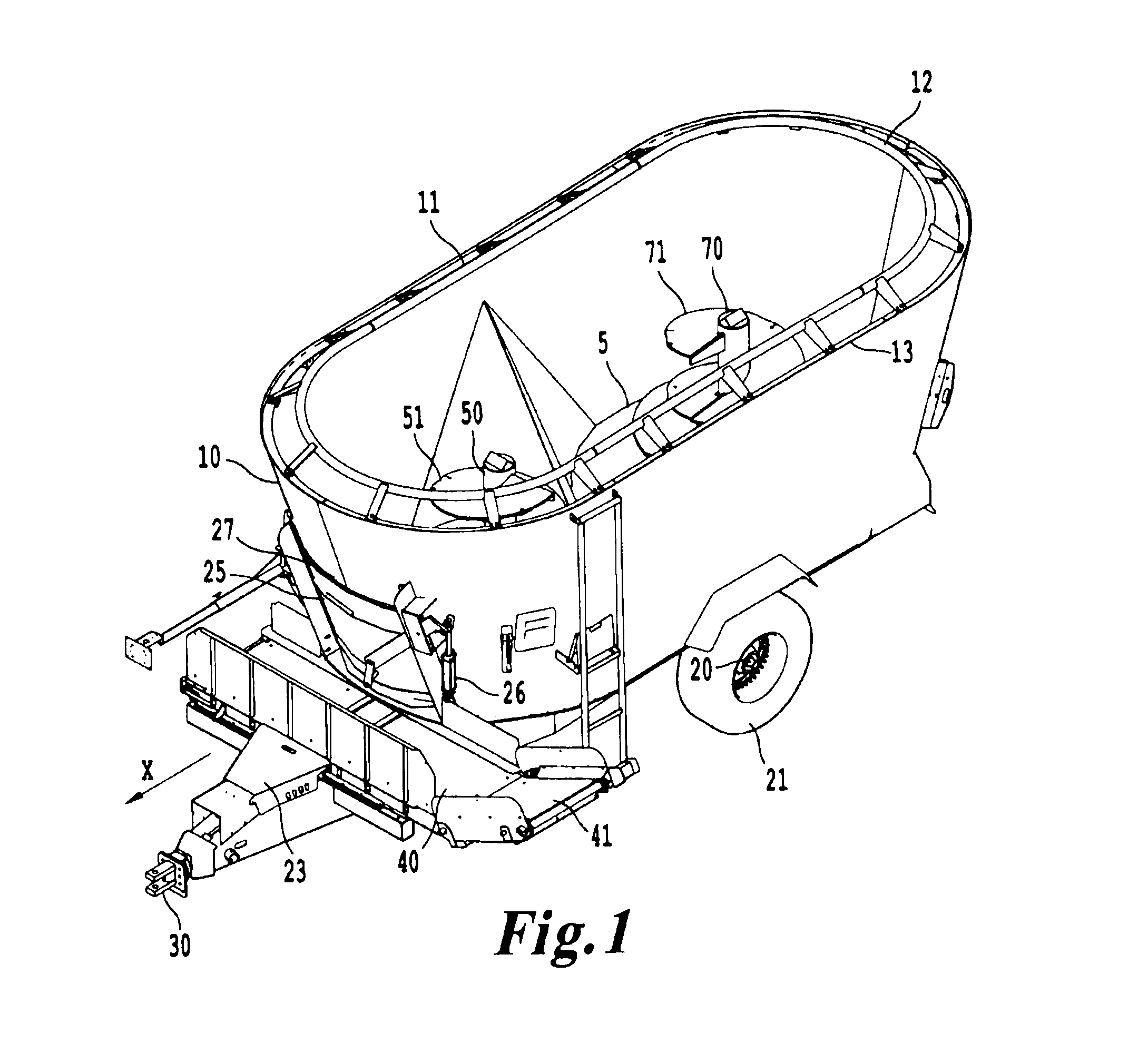

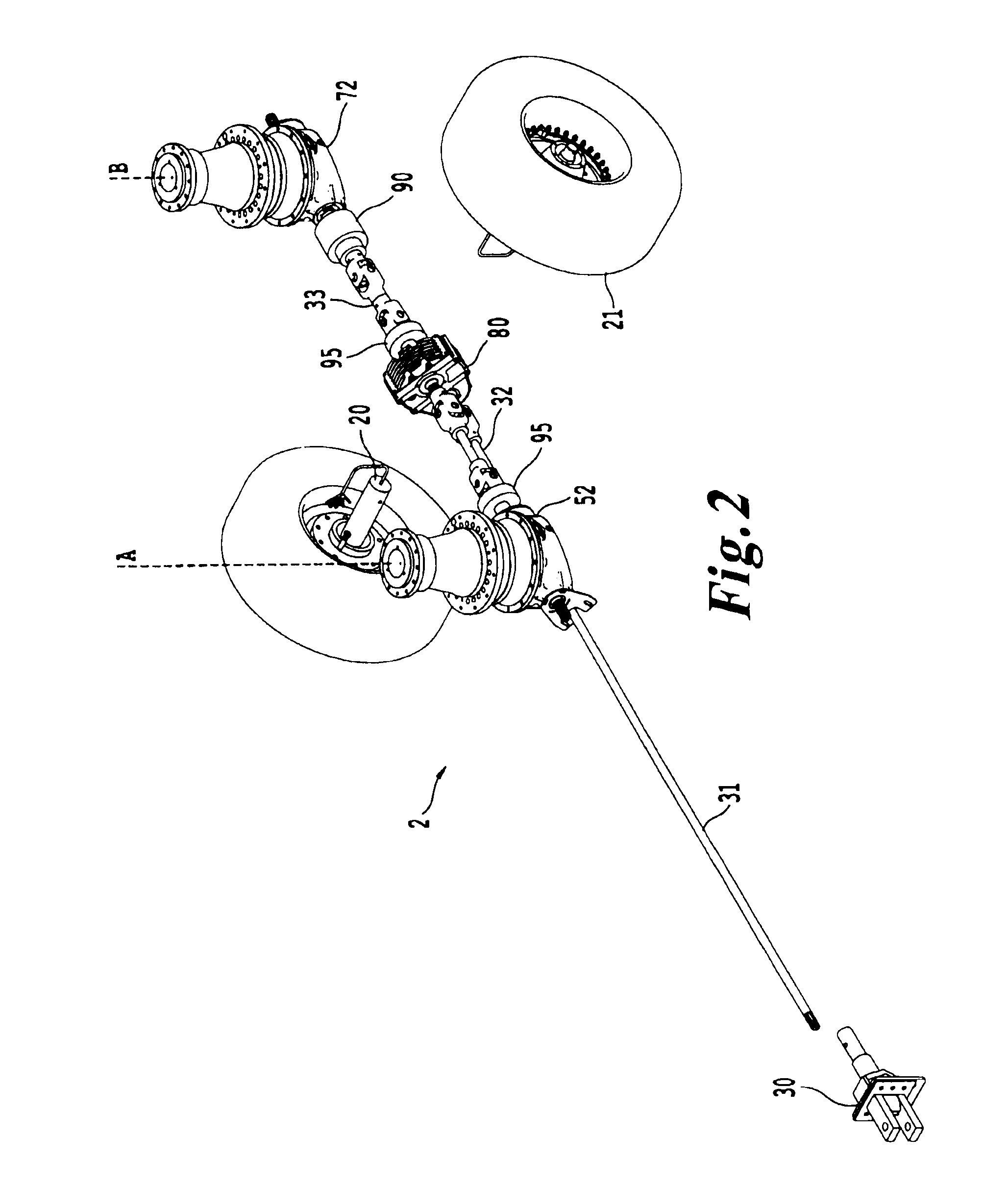

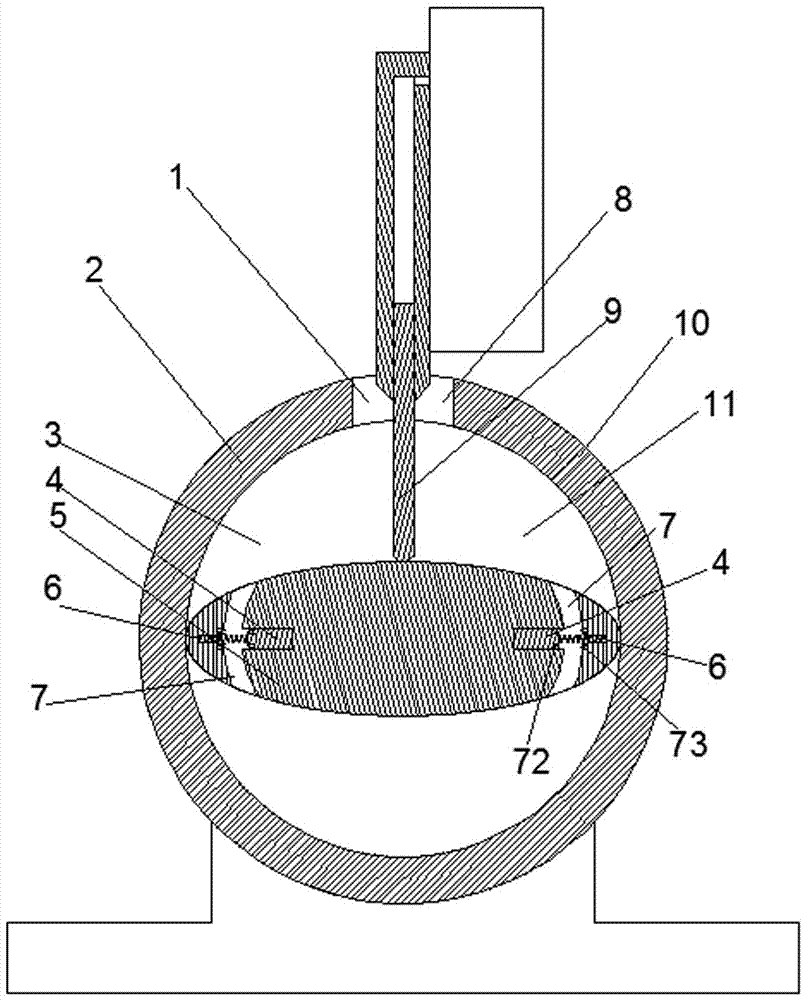

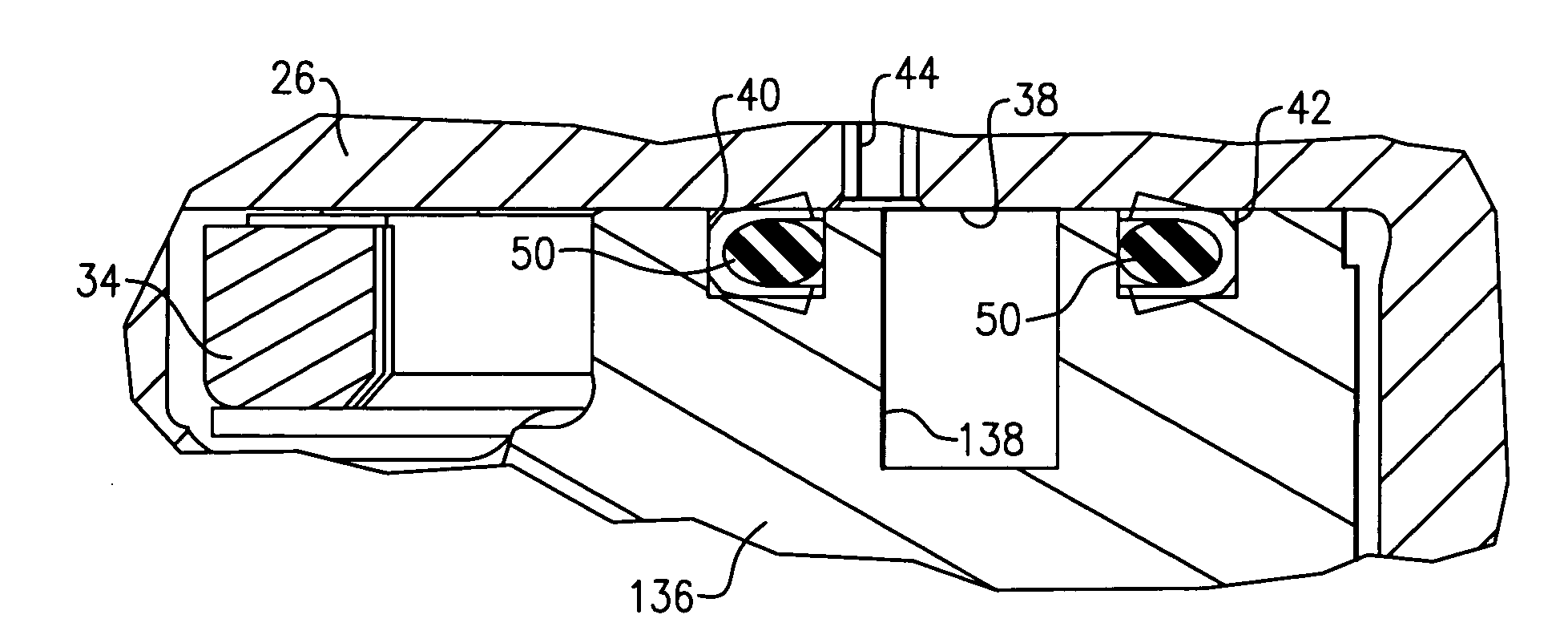

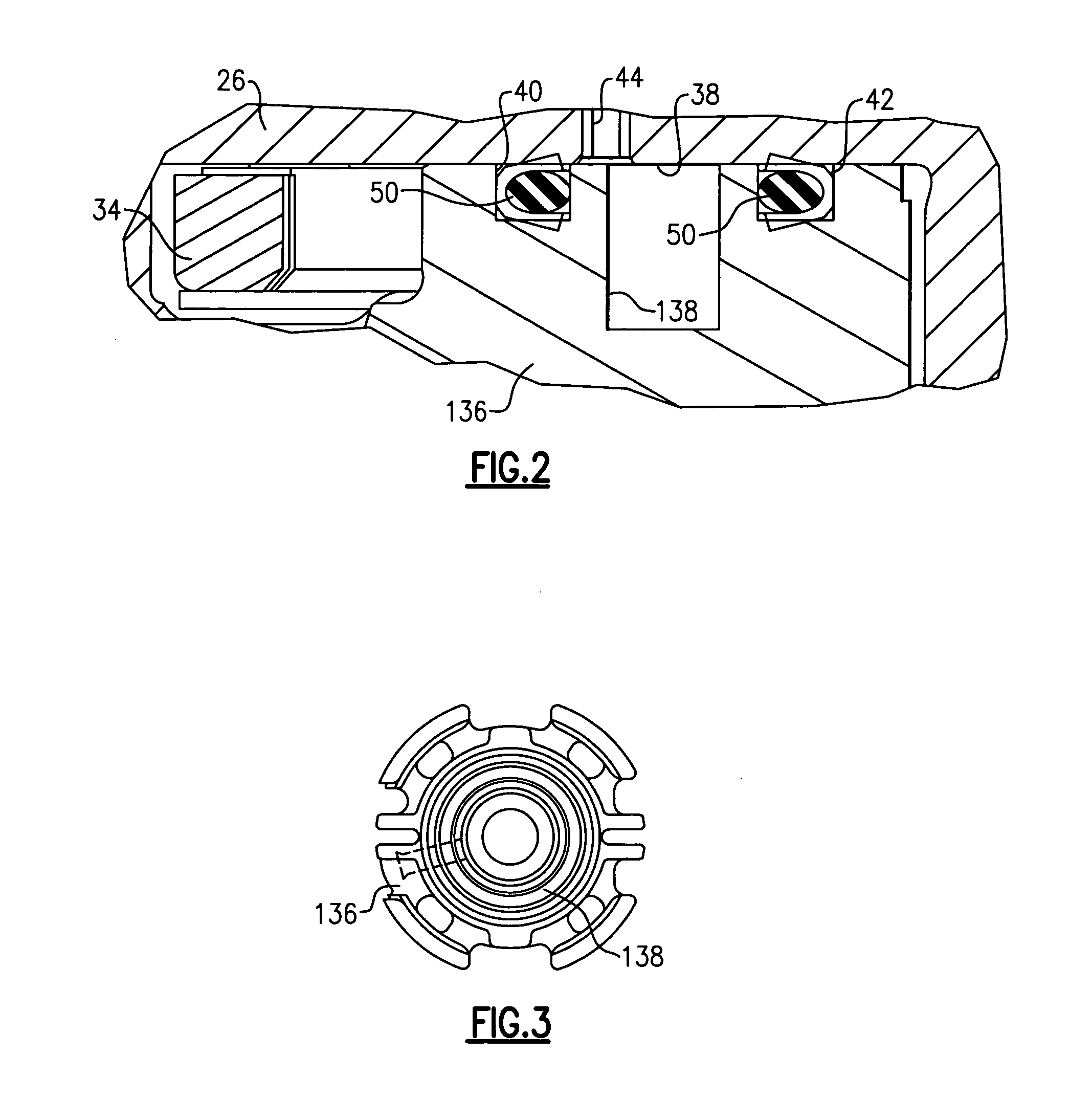

Sequential start clutch for a material mixing machine

ActiveUS20090238032A1Reduce starting loadStagger of over timeClutchesShaking/oscillating/vibrating mixersMixing chamberClutch

A mixer system includes a mixing chamber with a drive panel, open top, discharge opening in a side of the mixing chamber, and door configured to open and close the discharge opening. A first mixing auger is disposed inside the mixing chamber, and a first auger drive is disposed on another side of the drive panel and connected to the first auger through the drive panel and connected to a driveline. A second mixing auger is disposed inside the mixing chamber on the first side of the drive panel, and another auger drive is connected to the second auger through the drive panel. A clutch is connected between the second auger drive and the driveline and configured to mechanically connect and disconnect the second auger drive from the driveline based on an input. A method of sequentially starting different augers within a mixing chamber is provided.

Owner:KUHN NORTH AMERICA

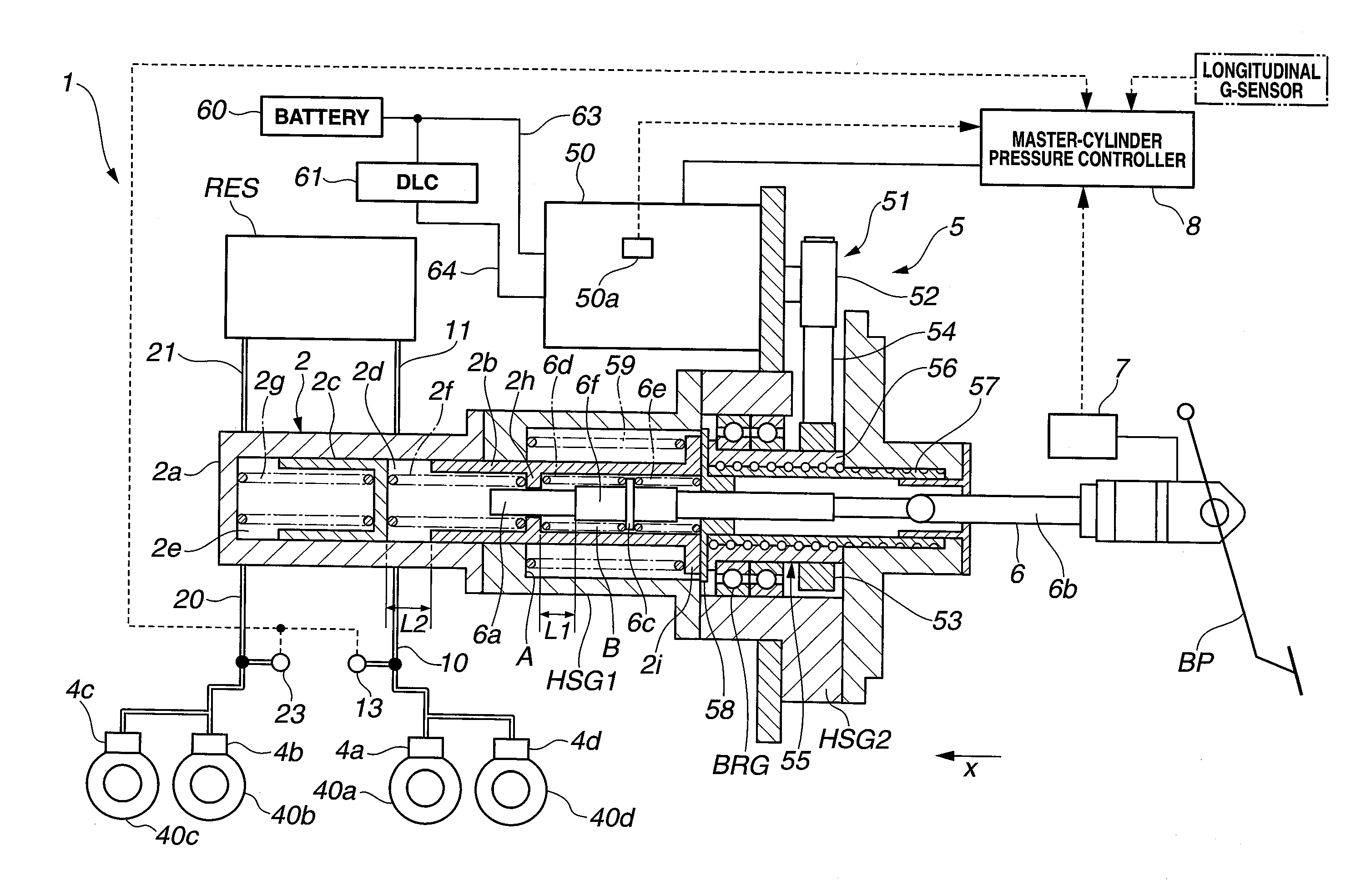

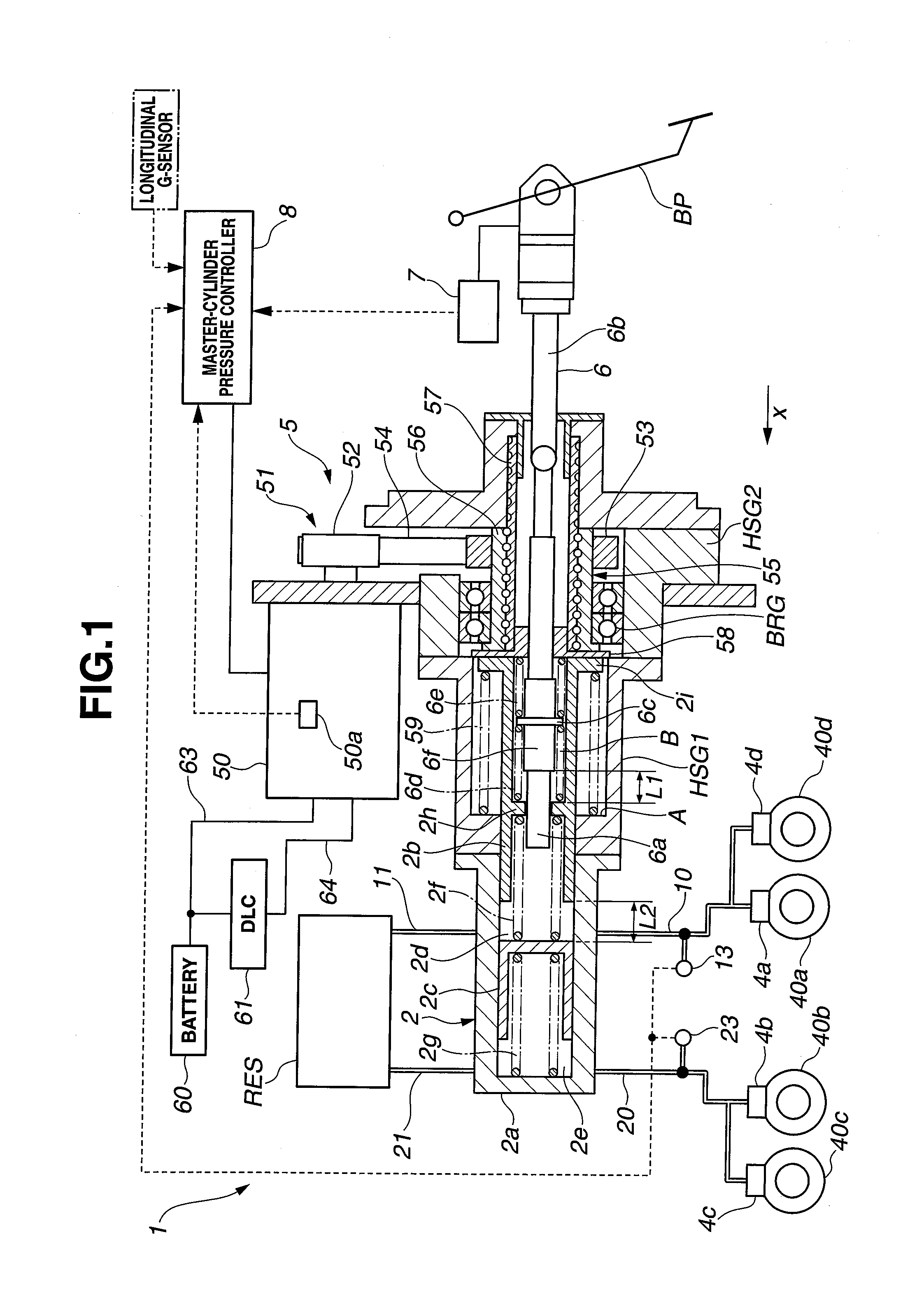

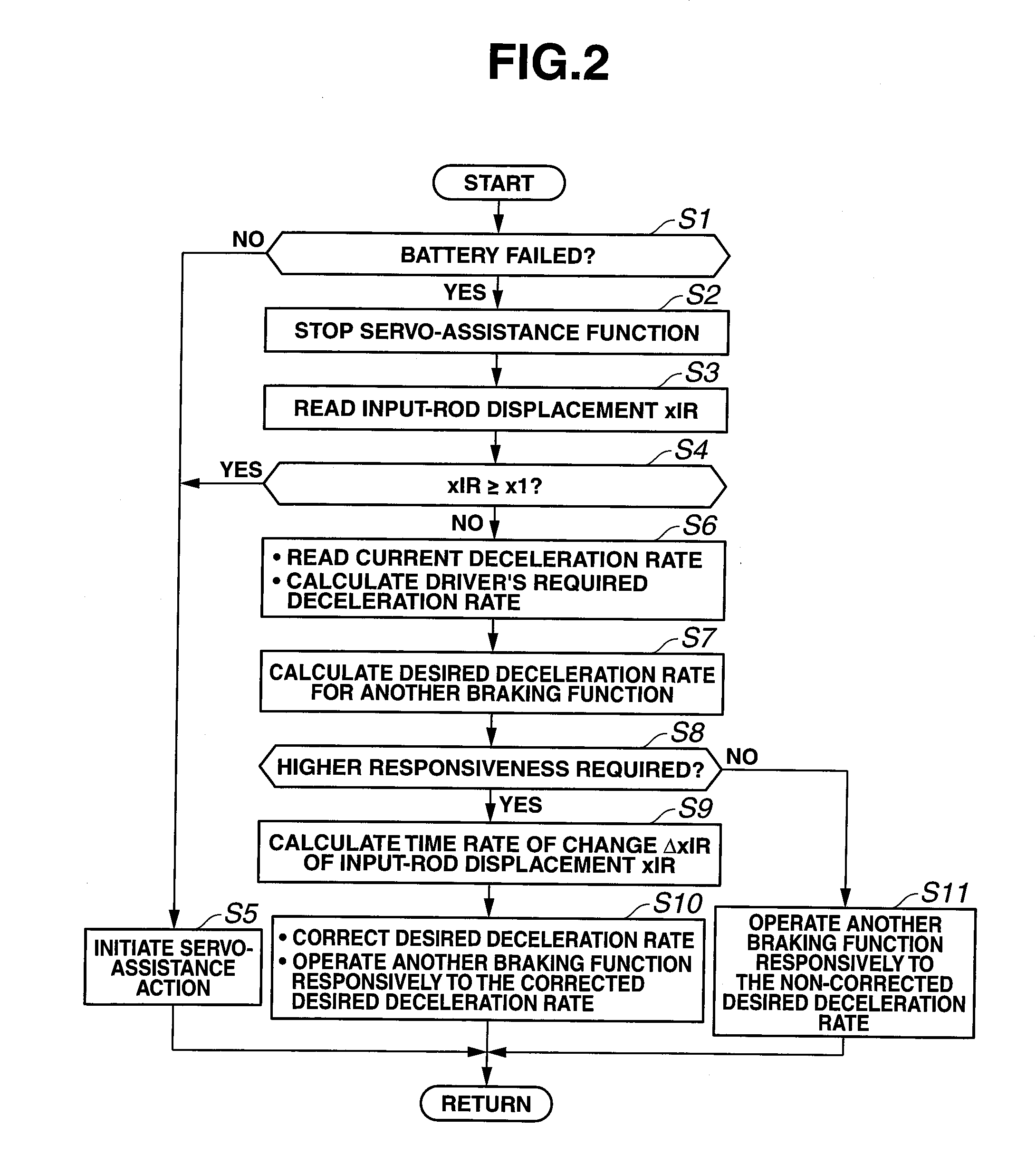

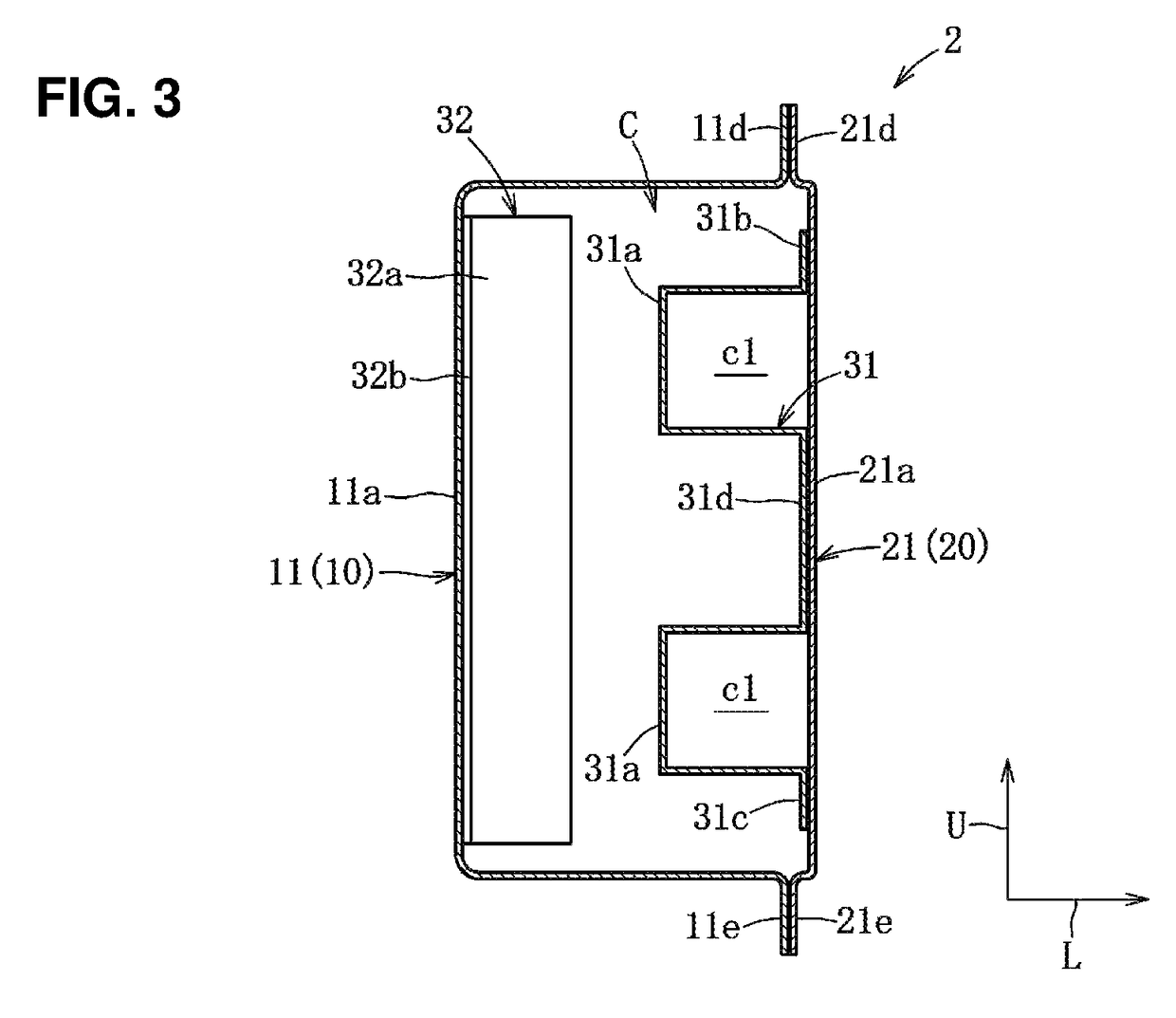

Brake device and method of controlling brake device

InactiveUS20110314806A1Reduce starting loadInhibit currentBraking action transmissionRotary clutchesMaster cylinderControl theory

[TASK] It is an object to provide a brake device and a method of controlling the brake device, capable of suppressing an inrush current during a startup period of an electric booster.[MEANS TO SOLVE] In a brake device having an input rod, a piston for pressurizing a fluid pressure in a master cylinder responsively to a displacement of the input rod, and an electric booster for pushing the piston against a spring bias of a return spring of the piston and for assisting a movement of the piston in a direction for pressurizing of the fluid pressure, an input-rod displacement detection device is provided for detecting the displacement of the input rod. Also provided is an electric-booster controller configured to start up the electric booster, while applying an assisting force to the piston to push the piston against a biasing force, which forces the piston in a direction for reducing of the fluid pressure in the master cylinder, upon detecting that the input rod has been displaced a predetermined displacement at the time when a driver's brake-pedal operation starts.

Owner:NISSAN MOTOR CO LTD

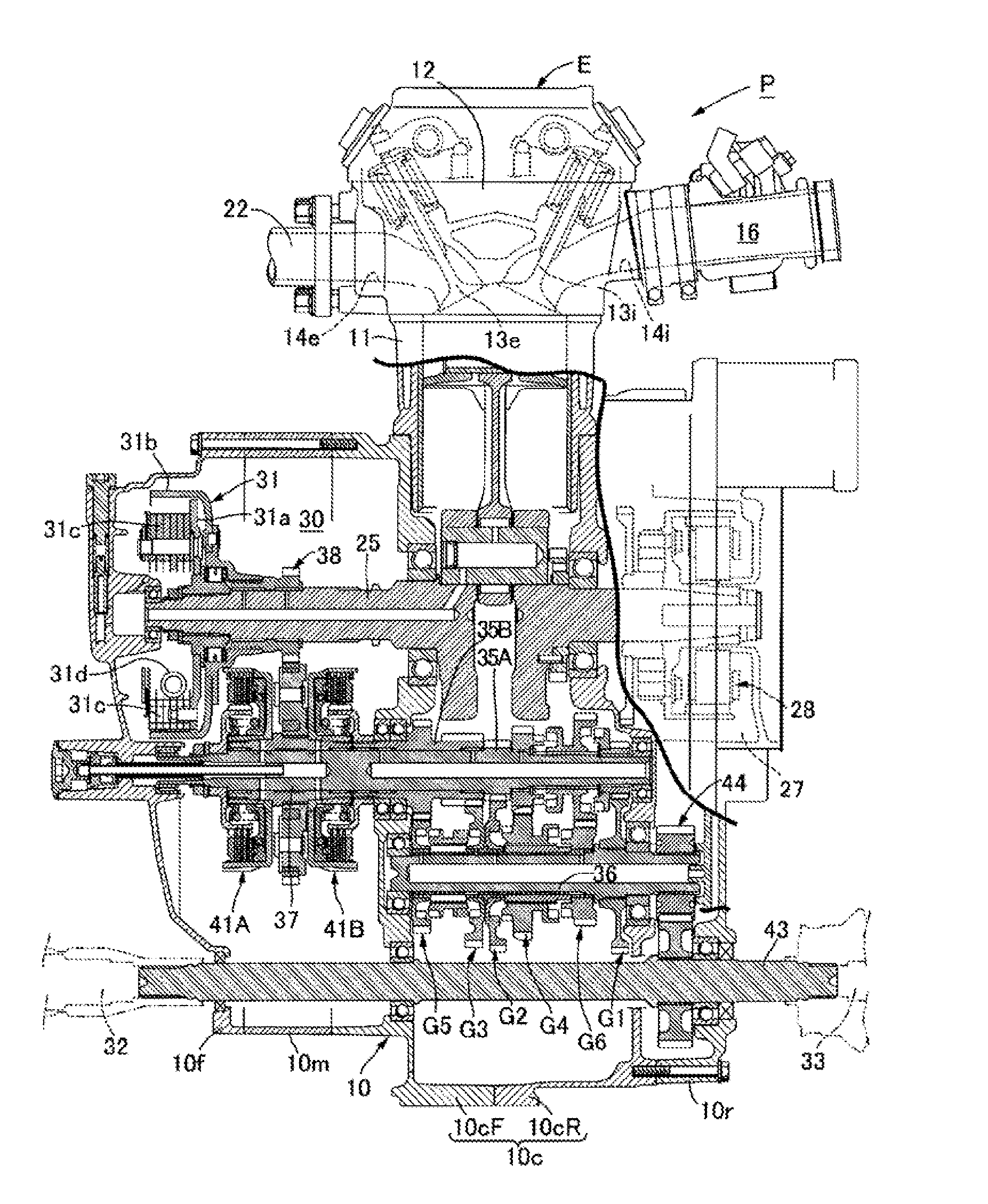

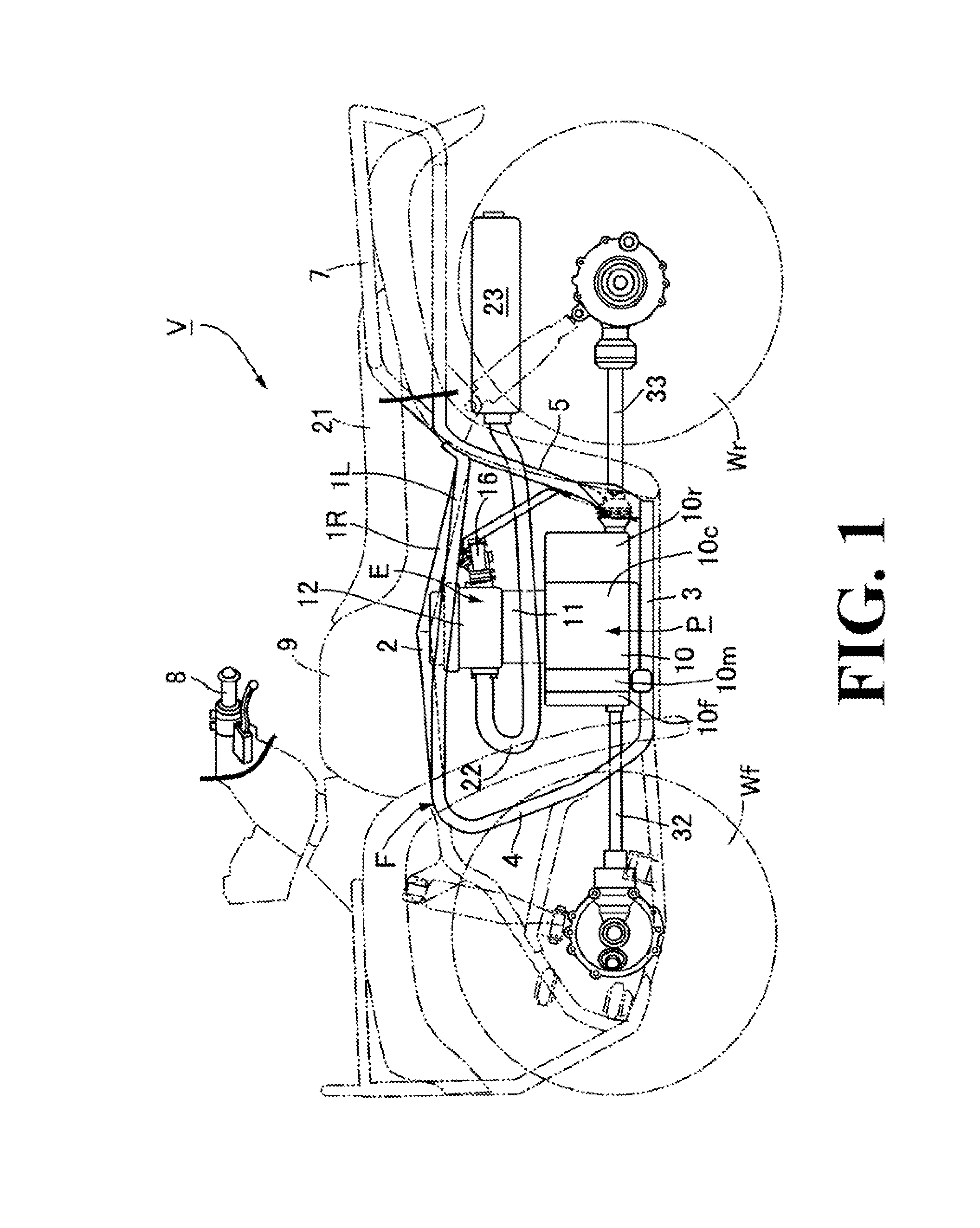

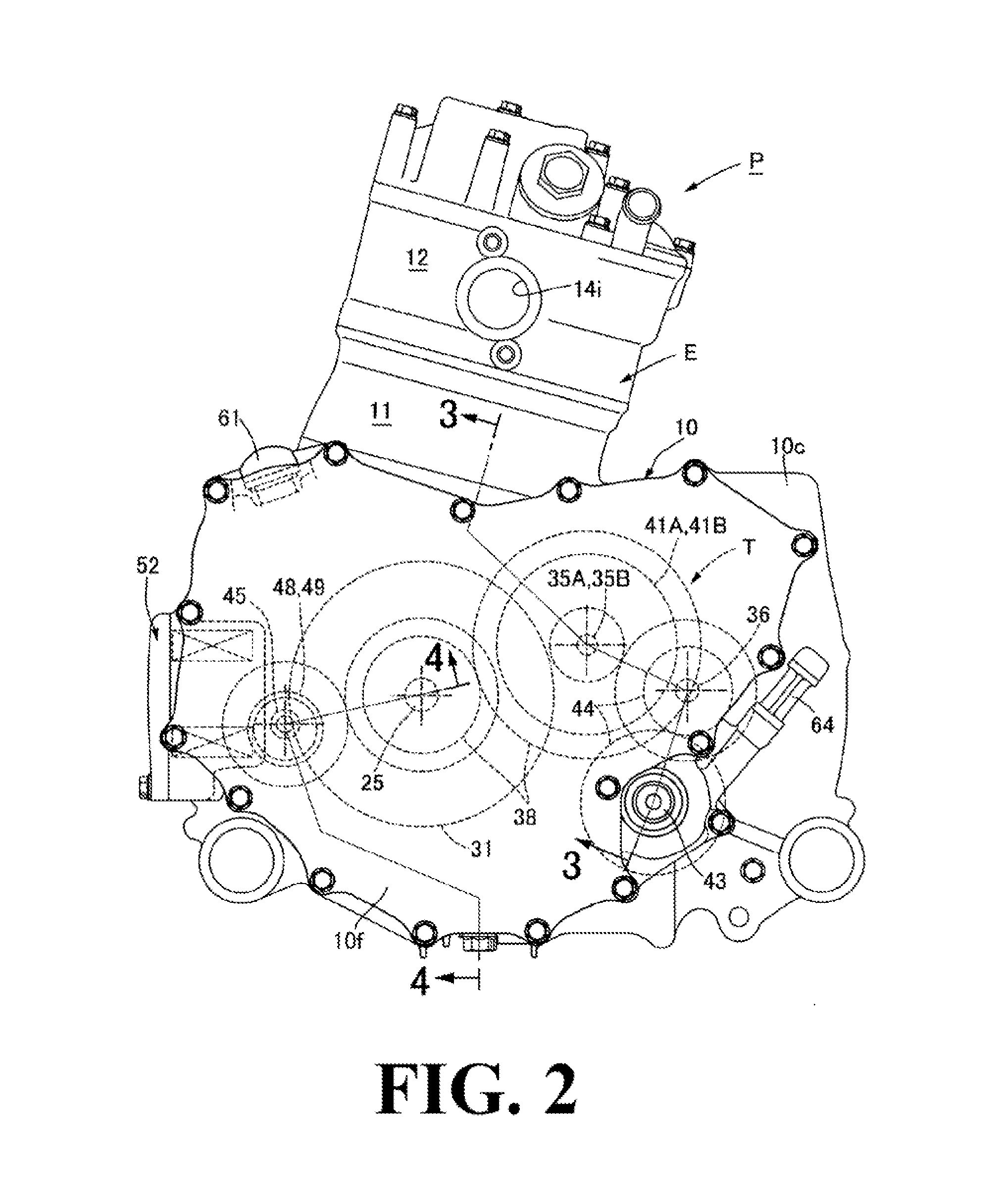

Lubricating device for power unit

ActiveUS20130333980A1Limit power lossReduce starting loadGear lubrication/coolingOilsumpsFuel tankFeeding pumps

A lubricating device for a power unit includes an oil pan, an oil tank being separated from the oil pan, a scavenging pump for circulating the received oil of the oil pan to the oil tank, and a feed pump to feeding oil stored in the oil tank to the engine and the transmission, wherein an oil reservoir for storing a certain amount of oil to immerse a lower part of a clutch that connects and disconnects a transmission route between the engine and the transmission is provided in a power unit case, and a first overflow passage is provided in the oil tank such that when the stored oil in the oil tank is increased beyond a first level, the first overflow passage allows the increased oil to overflow into the oil reservoir side.

Owner:HONDA MOTOR CO LTD

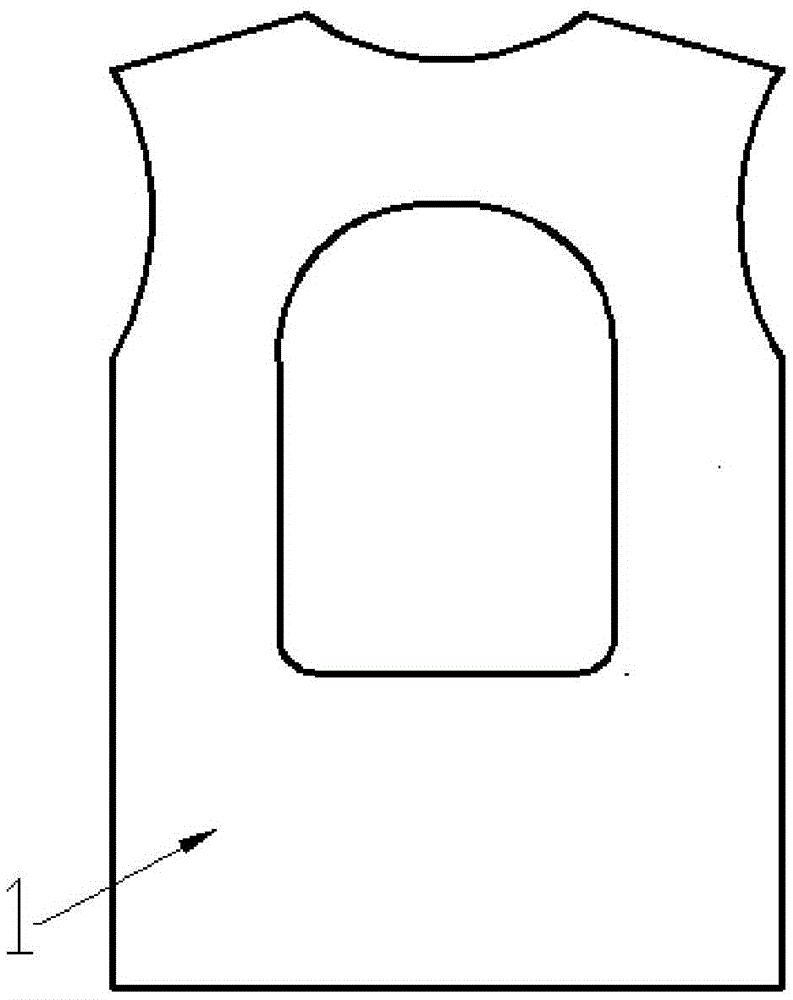

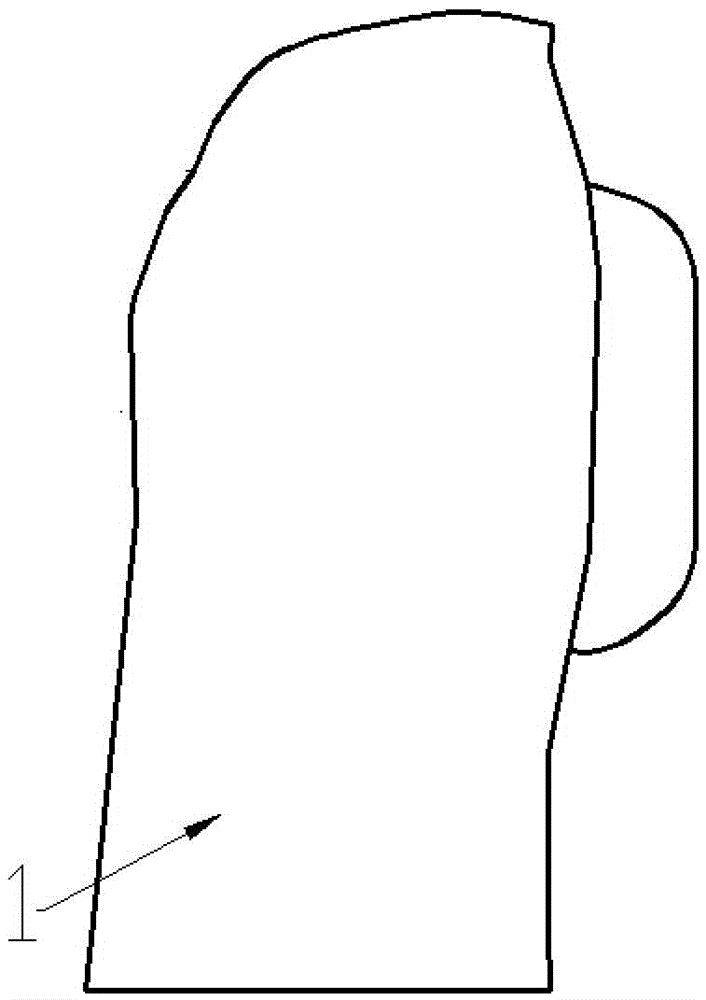

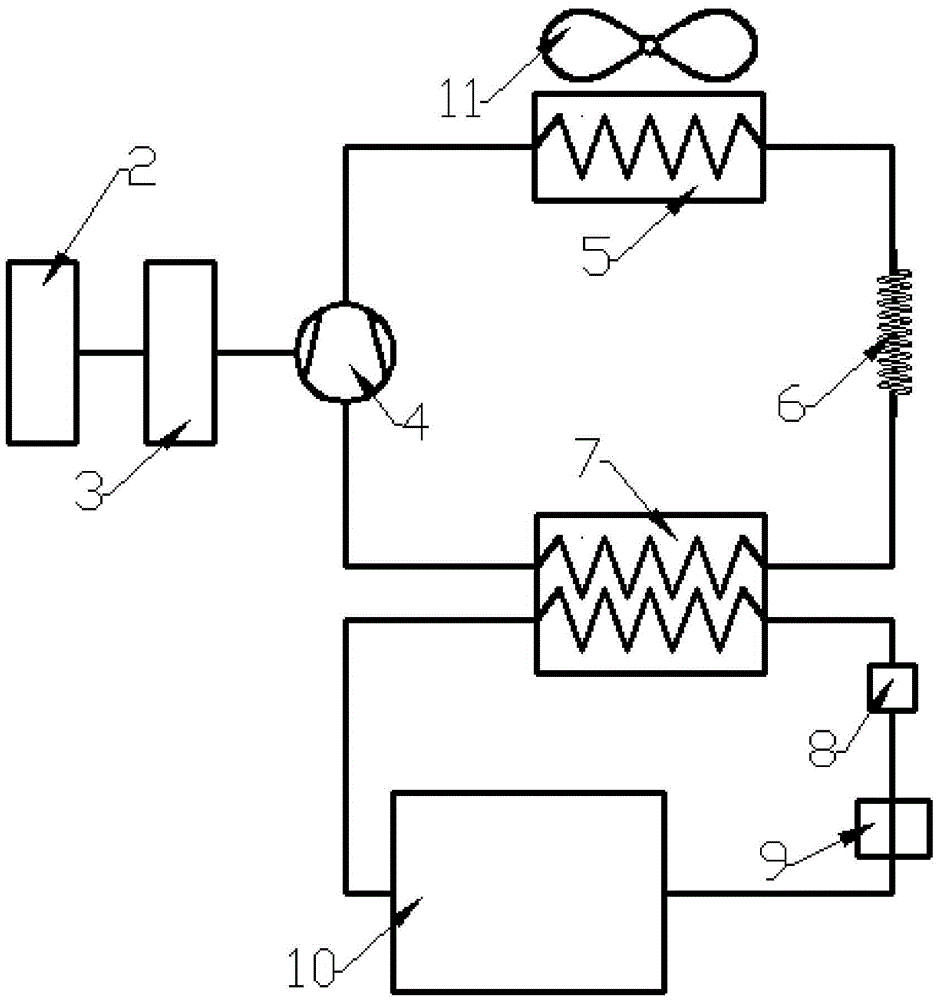

Wearable air conditioning suit based on bionic honeycomb structure

ActiveCN105466057AEasy to deploy in a large areaOptimize layoutCompression machines with non-reversible cycleProtective garmentInsulation layerSurface layer

The invention discloses a wearable air conditioning suit based on a bionic honeycomb structure. A throttling device of the wearable air conditioning suit is respectively connected with a condenser and an evaporator; a miniature compressor is respectively connected with the condenser and the evaporator; the evaporator is also connected with a miniature water pump and a honeycomb structural pipeline, and the miniature water pump is connected with the honeycomb structural pipeline through a small water storage tank; a lithium ion battery pack is connected with a controller; the throttling device adopts a capillary pipe with the diameter of 0.5-0.8mm; a wearing assembly is divided into a plurality of layers; a comfortable layer, a breathable layer, a heat insulation layer and a surface layer are sequentially arranged from inside to outside; the evaporator adopts a plate heat exchanger; a pipe network of a water cooling system is distributed in a net shape by using a honeycomb structure; the condenser adopts a parallel flow heat exchanger; and a small fan is parallel to the parallel flow heat exchanger. By using the wearable air conditioning suit, the temperature of a microenvironment in the suit is maintained within the range of + / -1.5 DEG C based on the temperature set by a user, and therefore, a comfortable microenvironment inside the suit is provided for a human body.

Owner:SOUTH CHINA UNIV OF TECH

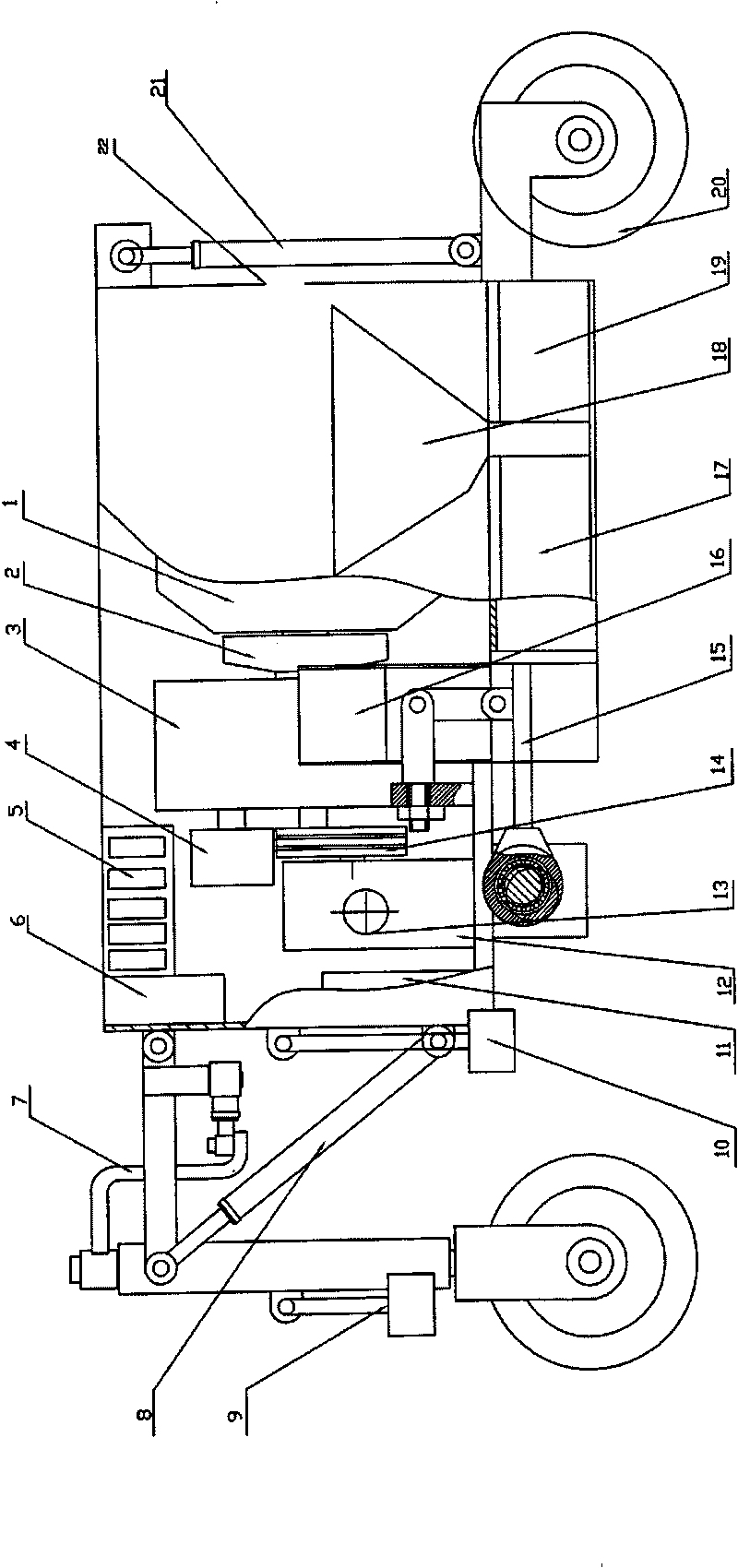

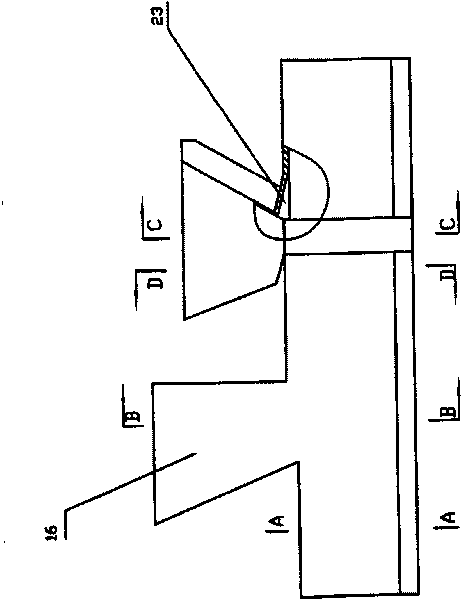

Automatic control reverse pushing-type multilayer color concrete slip-form paver

InactiveCN101691734AGuaranteed compactnessReduce starting loadRoads maintainenceAutomatic controlEngineering

The invention discloses an automatic control reverse pushing-type multilayer color concrete slip-form paver. One side of a frame (22) is installed with an eccentric feeding mechanism (15), a base material hopper (16) and a color material hopper (18); the lower parts of the base material hopper (16) and the color material hopper (18) are communicated with a base material molding mould (17) and a multilayer color material molding mould (19); the output shaft of the multiple output shaft gear box (3) on an engine (1) is connected with the eccentric shaft of the eccentric feeding mechanism (15) through a driving belt (14) and a driving chain (13); the front part of the frame (22) is installed with an elevation adjustment oil cylinder (8), a steering adjustment oil cylinder and a steering arm (7); the rear part of the frame (22) is installed with a back wheel (20) and a back wheel-supported adjustment oil cylinder (21). The invention has compact structure and simple and convenient operation, can realize multilayer color concrete continuous paving by operating once, and can improve the construction quality, construction efficiency and appreciation of curbs.

Owner:万红华 +1

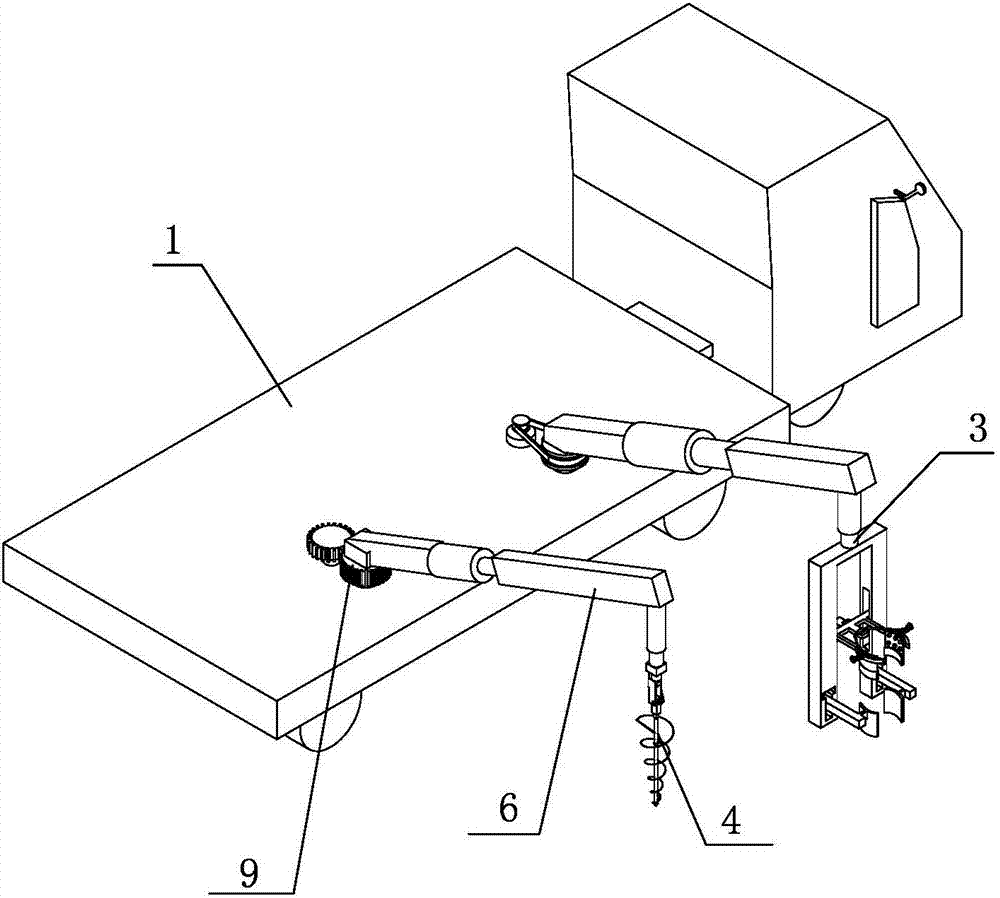

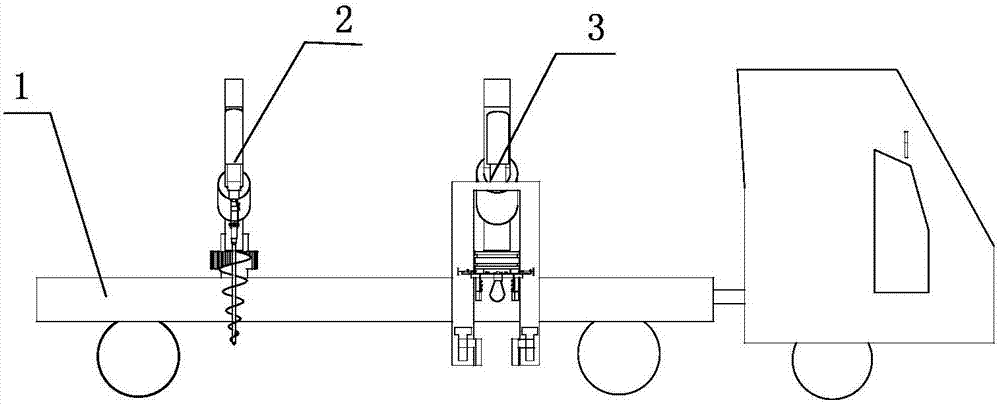

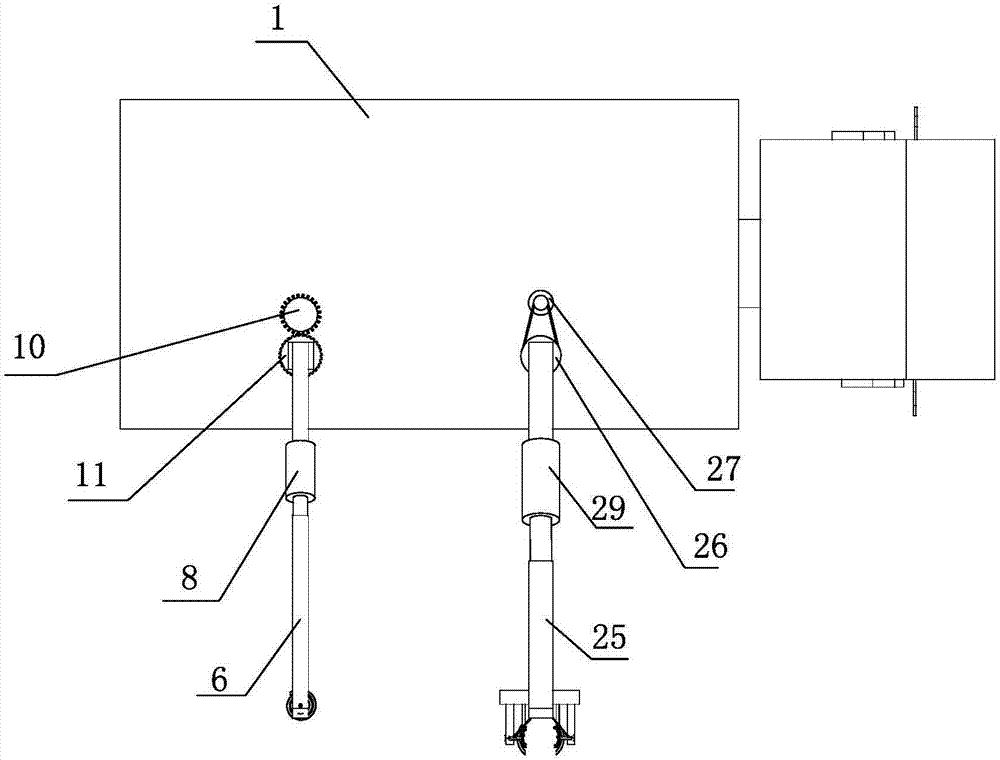

Device for telegraph pole installation

The invention provides a device for telegraph pole installation so achieve the technical purpose of telegraph pole installation. The device comprises a carrying mobile vehicle on a compartment chassis, a hydraulic station and an excavating system. The hydraulic station is installed on the carrying mobile vehicle; the excavating system comprises an excavating mechanism, an excavating supporting cantilever, an excavating stretchable hydraulic cylinder and an excavating supporting arm driving mechanism; the bottom end of the excavating supporting cantilever is rotationally installed on the carrying mobile vehicle, and the excavating supporting arm driving mechanism drives the excavating supporting cantilever through a transmission mechanism to rotate; the device further comprises an excavating turnover mechanism and a ramming system. The device has the advantages that the hole digging and piling functions are integrated, labor is greatly saved, and the working efficiency of telegraph pole embedding and installation is improved.

Owner:JINAN CITY CHANGQING DISTRICT POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

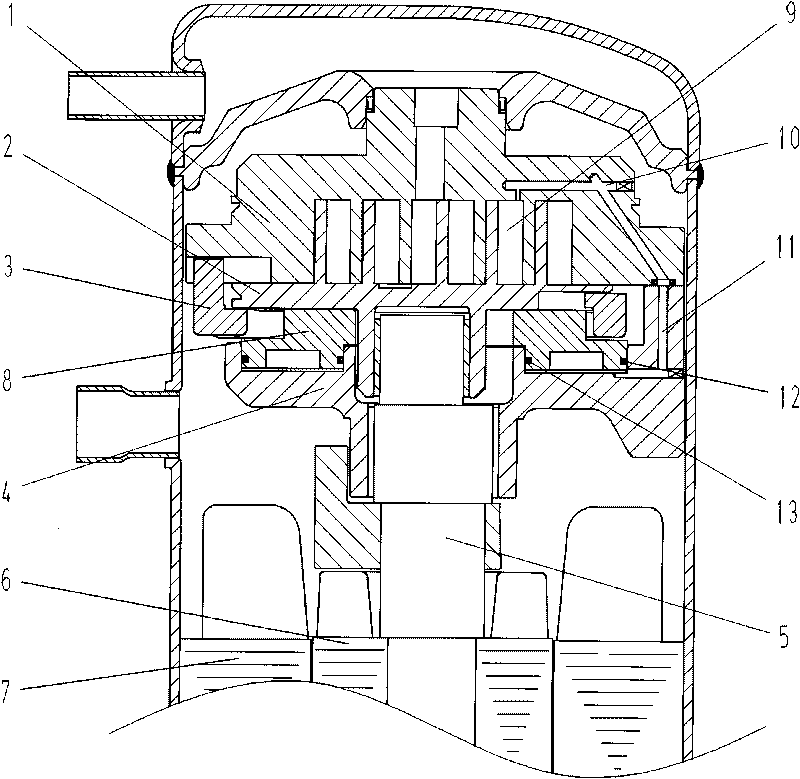

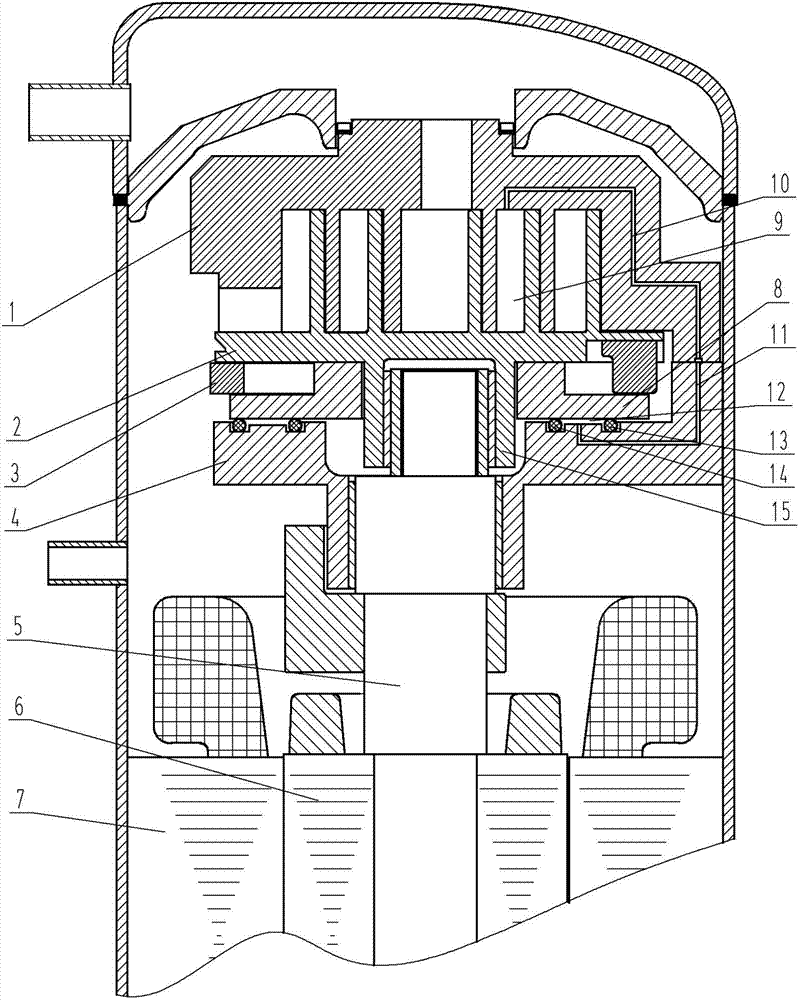

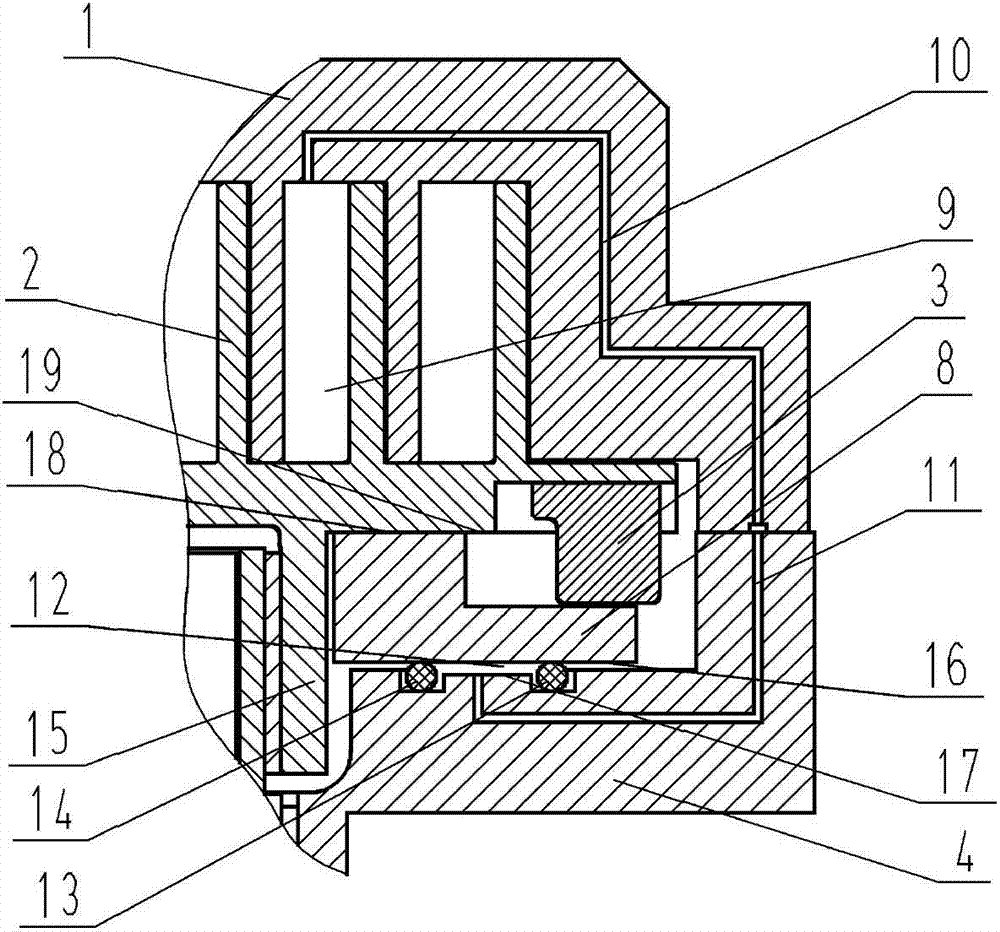

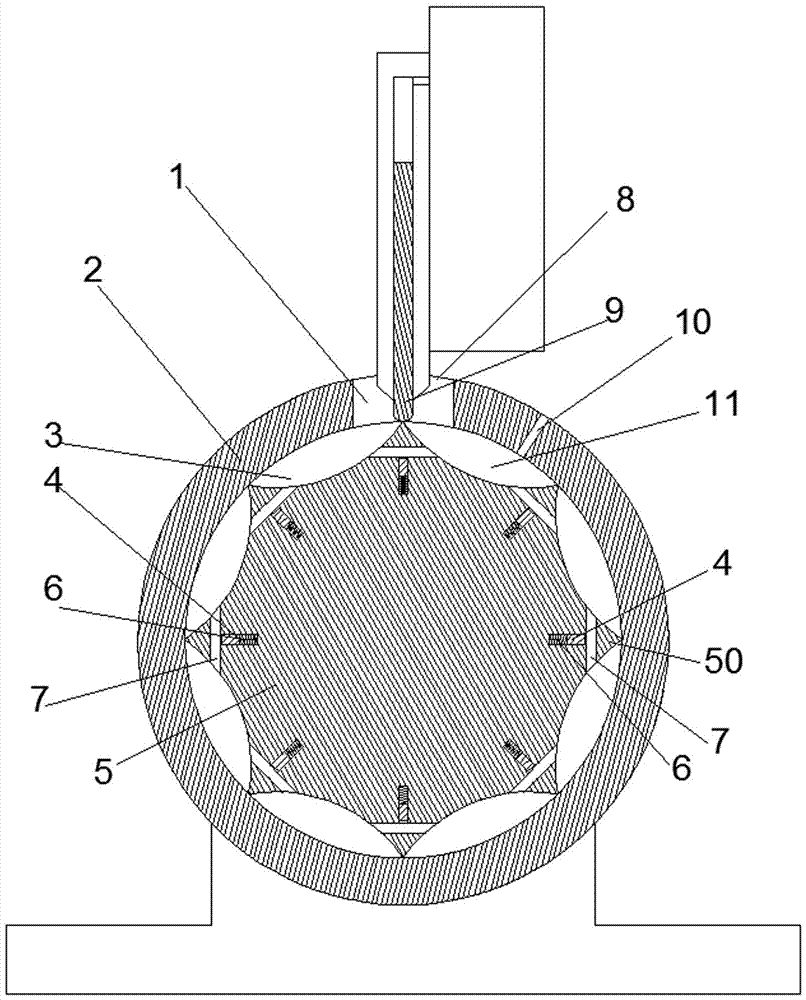

Scroll compressor

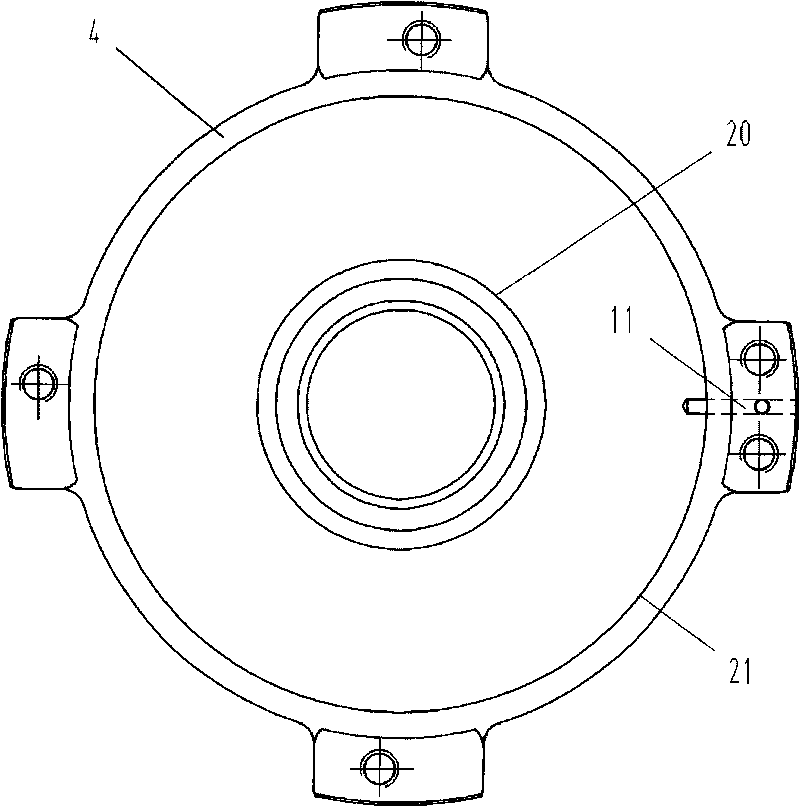

ActiveCN101761477APrevent leakageGood and reliable sealingRotary piston pumpsRotary piston liquid enginesAxial displacementCircular disc

The invention discloses a scroll compressor. A floating disc is arranged between a movable scroll and an upper supporter of the compressor, the floating disc is a circular disc with two layers of steps, a crossed ring is positioned between the movable scroll and the upper surface of the second step of the circular disc of the floating disc, pressure guide passages are arranged on the upper supporter and the fixed scroll, and the pressure guide passages are communicated with a compression cavity of the compressor and the lower surface of the floating disc for forming a sealed cavity between pressure guide passages and the bottom surface of grooves formed on the upper supporter. The invention has the advantages that all sealing parts adopt static sealing, good and reliable sealing can be realized, the crossed ring moves flatly between the movable scroll and the step surface of the floating disc, the fit gap of the flat movement maintains unchanged, the problems of moving stability loss, vibration enhancement and the like of the crossed ring can not occur, the sealing effect of the sealing between the floating disc and the upper supporter can be ensured during large axial displacement, the movement gap of the crossed ring can not be changed after the floating of the movable scroll, the distance between the movable scroll and a fixed scroll can be longer, and the starting load can be reduced to the maximum degree.

Owner:DALIAN SANYO COMPRESSOR

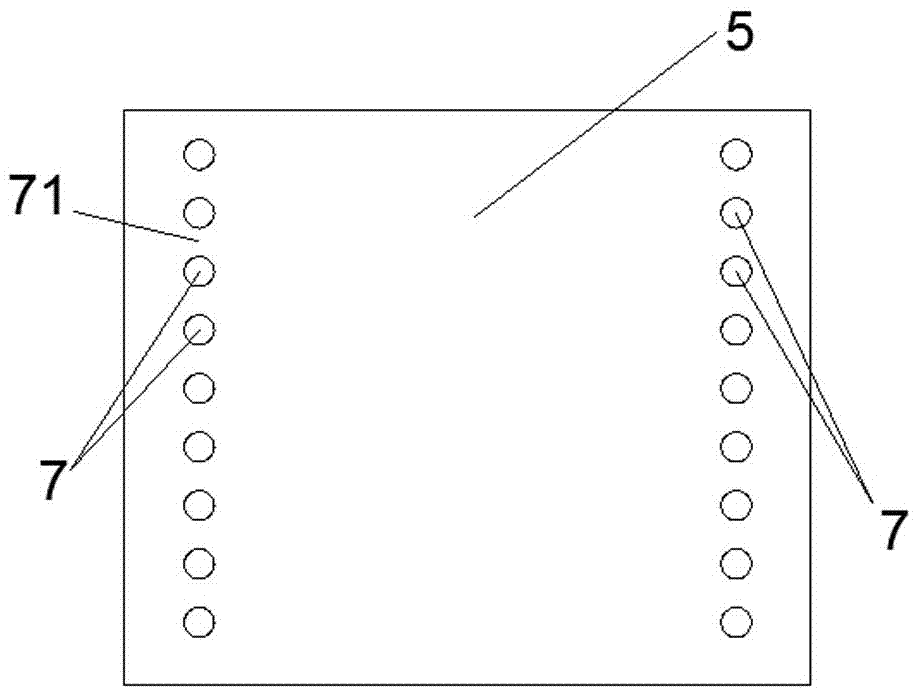

Sequential start clutch for a material mixing machine

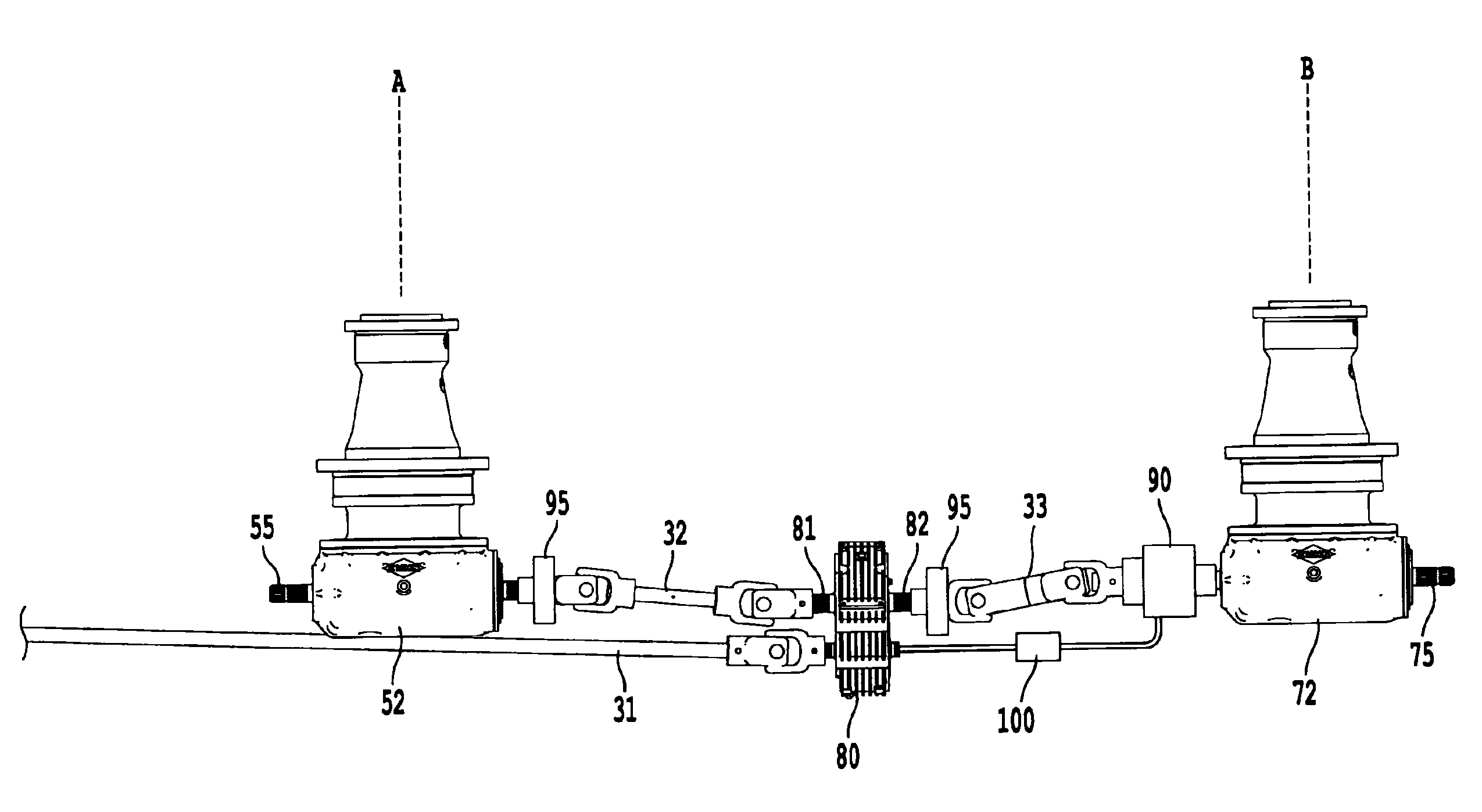

ActiveUS9010991B2Reduce starting loadStagger of over timeClutchesShaking/oscillating/vibrating mixersEngineeringMixing chamber

A mixer system includes a mixing chamber with a drive panel, open top, discharge opening in a side of the mixing chamber, and door configured to open and close the discharge opening. A first mixing auger is disposed inside the mixing chamber, and a first auger drive is disposed on another side of the drive panel and connected to the first auger through the drive panel and connected to a driveline. A second mixing auger is disposed inside the mixing chamber on the first side of the drive panel, and another auger drive is connected to the second auger through the drive panel. A clutch is connected between the second auger drive and the driveline and configured to mechanically connect and disconnect the second auger drive from the driveline based on an input. A method of sequentially starting different augers within a mixing chamber is provided.

Owner:KUHN NORTH AMERICA

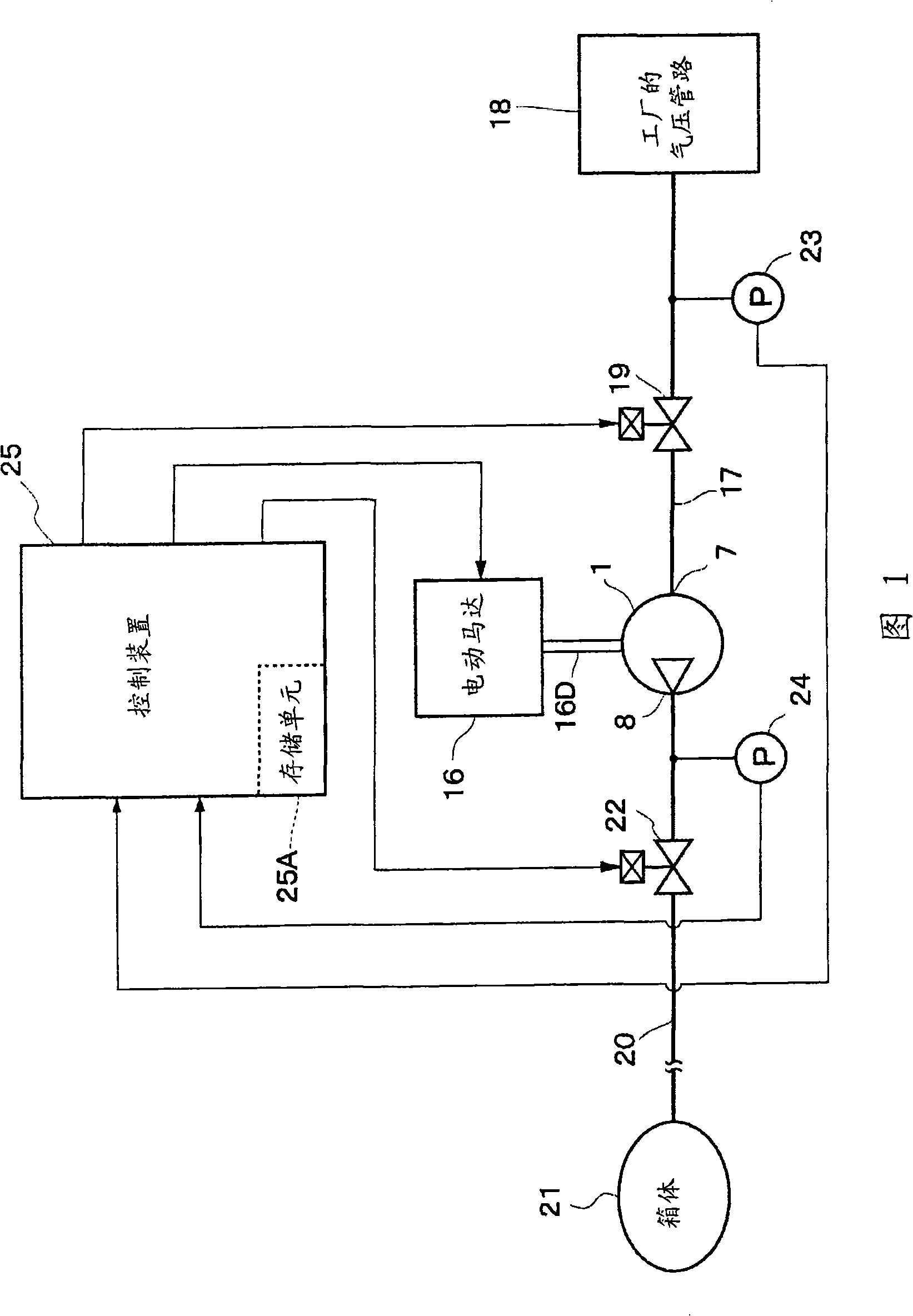

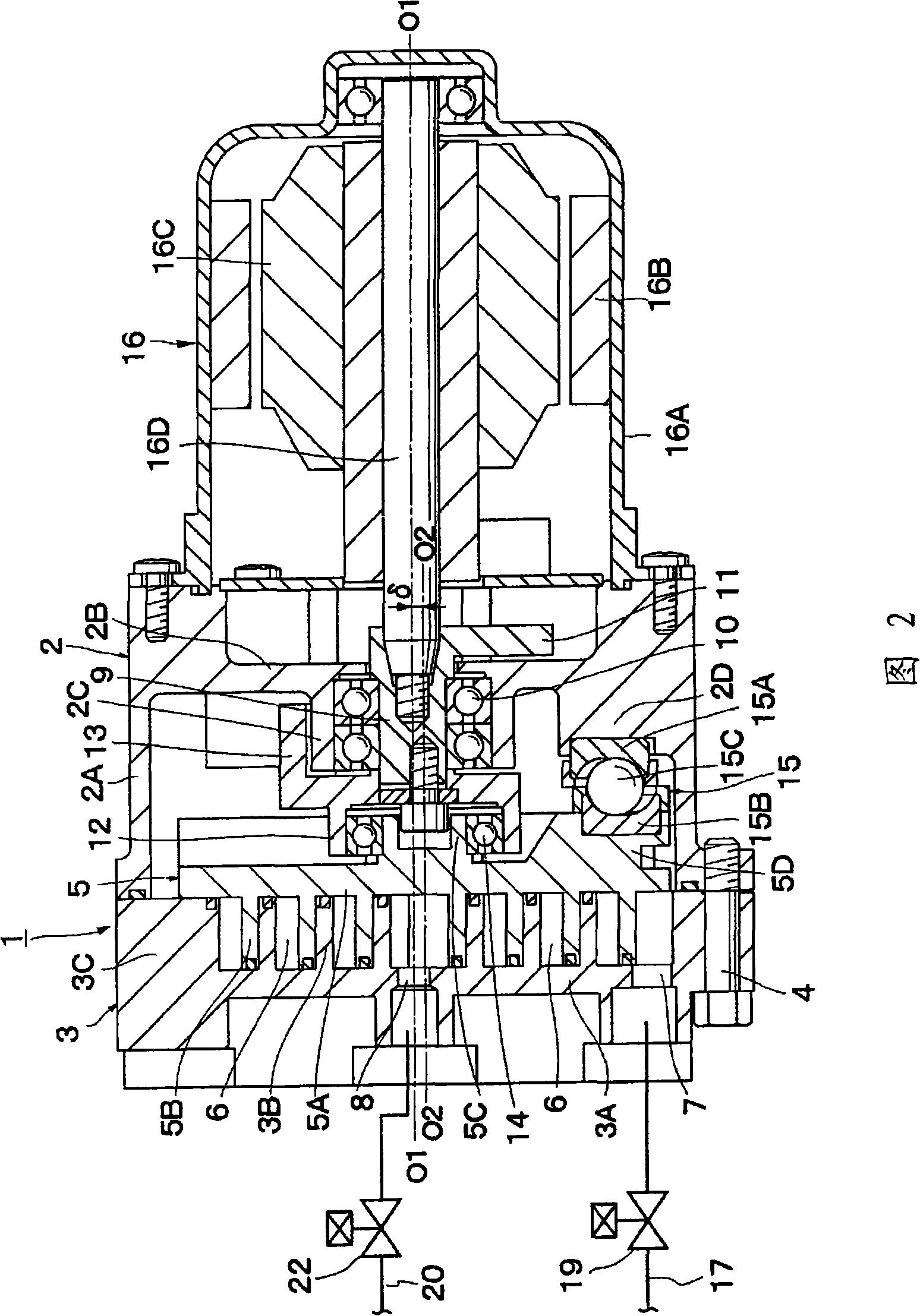

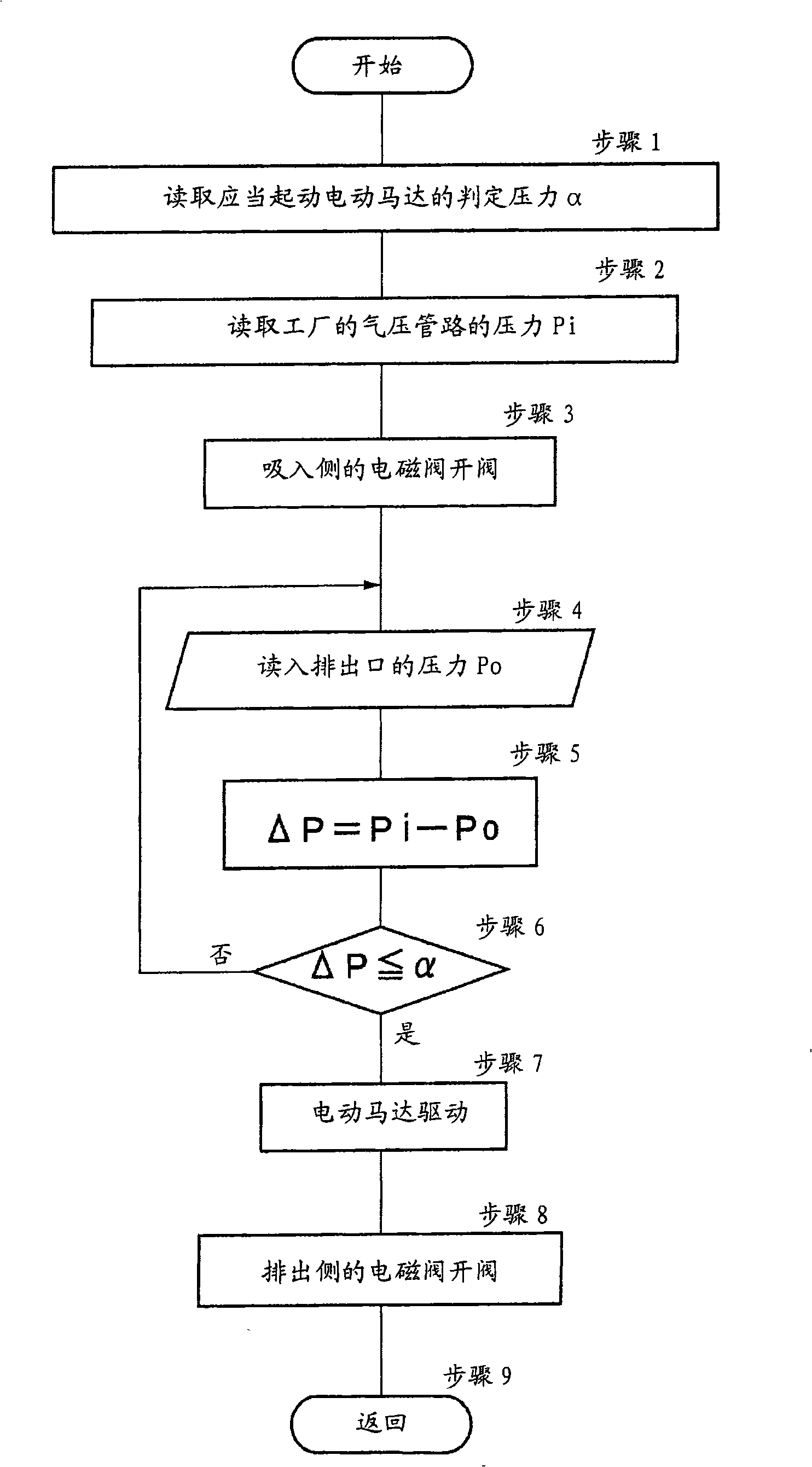

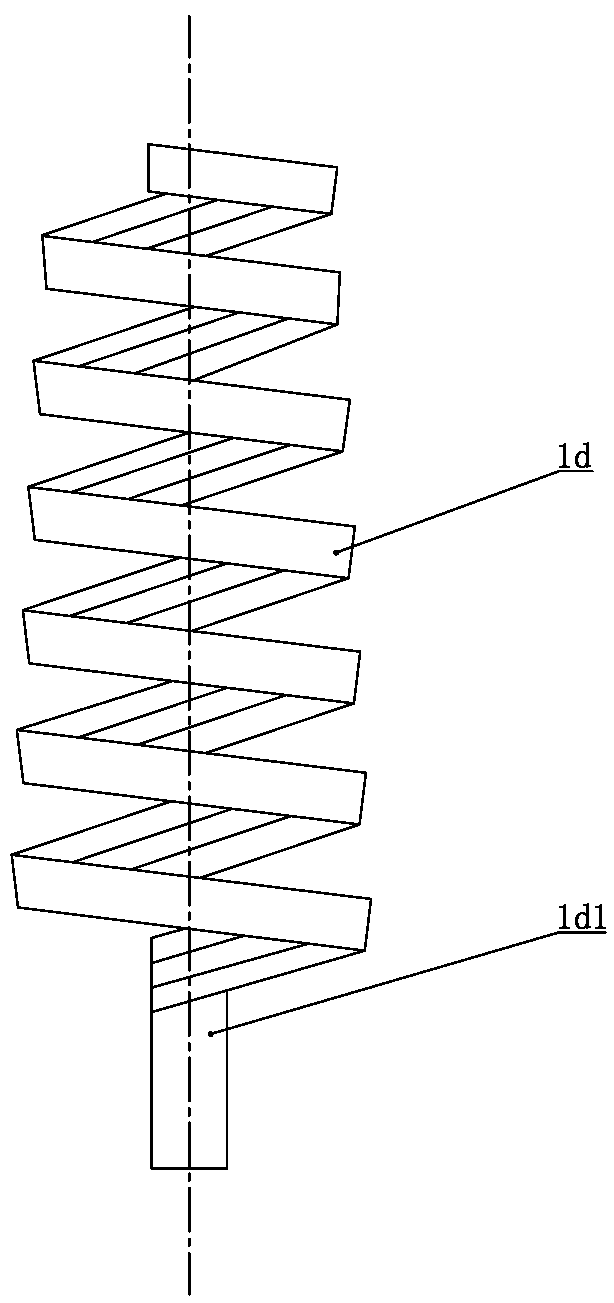

Scroll type booster

InactiveCN101354036AEasy to startShake suppressionRotary piston pumpsFluid-pressure convertersSolenoid valveEngineering

A scroll type booster ensures a noiseless structure by reducing operation sound using a scroll type compressor as a booster and an easy start-up operation. An electromagnetic valve at an intake side is provided between an intake port of a compressor body and a pneumatic line at an intermediate position of an intake pipe. The electromagnetic valve is opened / closed by the control unit. When the valve is opened, a communication of the intake port of the compressor body and the pneumatic line is allowed. When the valve is closed, the communication between the intake port and the pneumatic line is blocked. Under a start-up control of the compressor body, the electromagnetic valve at the intake side is opened to communicate the pneumatic line in the plant with the intake port of the compressor body for power supply to an electric motor to drive an orbiting scroll. The rattle of the orbiting scroll by an amount equal to the axial gap (play) is suppressed before starting a compression operation.

Owner:HITACHI LTD

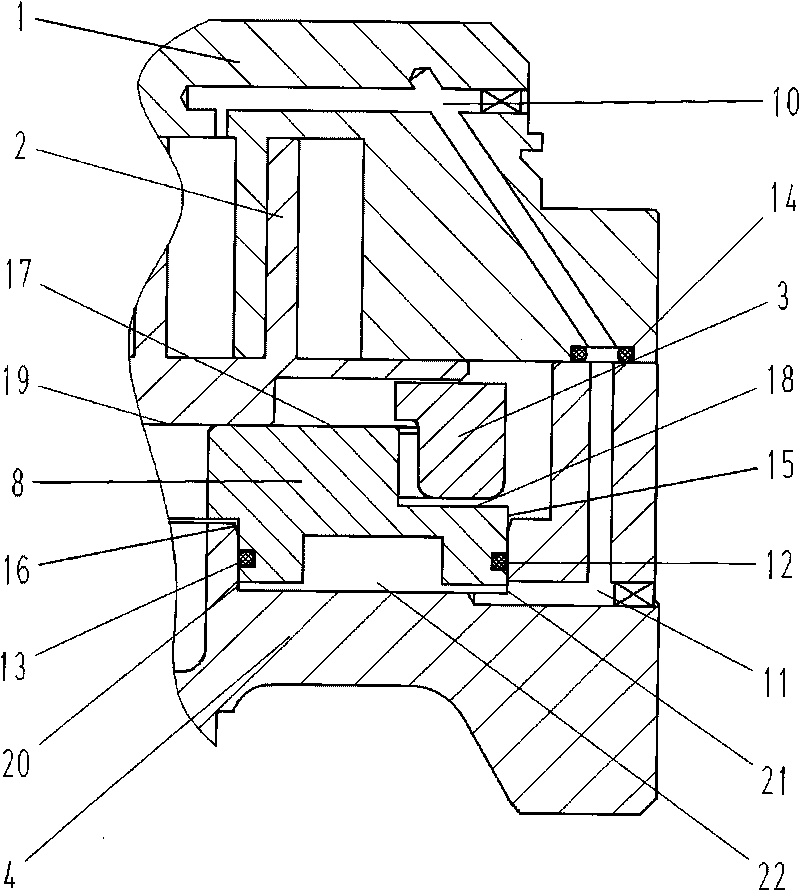

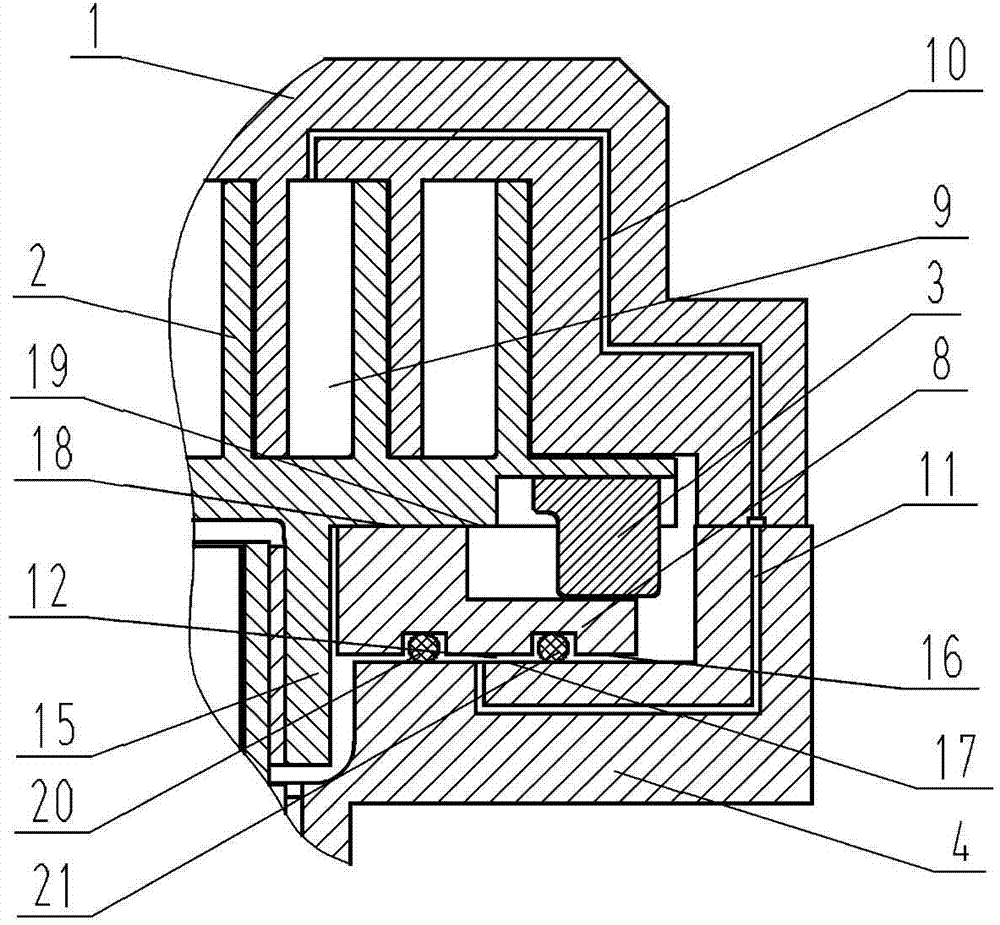

Floating scroll compressor

ActiveCN102953989ALarge choiceSimple structural designSealing arrangement for pumpsRotary piston pumpsEngineeringHigh pressure chamber

The invention discloses a floating scroll compressor. The floating scroll compressor comprises a fixed scroll, a movable scroll, a cross ring, an upper support, a crankshaft, a motor rotor, a motor stator and a floating disk which are arranged in a compressor casing, wherein the floating disk is arranged between the movable scroll and the upper support; an annular pressure chamber is arranged between the bottom surface of the floating disk and the upper surface of the upper support; the floating disk moves along the movable scroll; and a pressure enclosing channel communicated with a compression chamber or a high-pressure chamber is arranged in the annular pressure chamber. The floating scroll compressor disclosed by the invention has the beneficial effects that the pressure chamber is sealed by a sealing element; the structural design is simple and the sealing element is wide in selective range; in the starting process of the compressor, a starting load can be reduced; and the floating disk and the movable scroll move together, so that the reducing effect of the radial distance is remarkable and the tooth side leakage is remarkably reduced.

Owner:冰山松洋压缩机(大连)有限公司

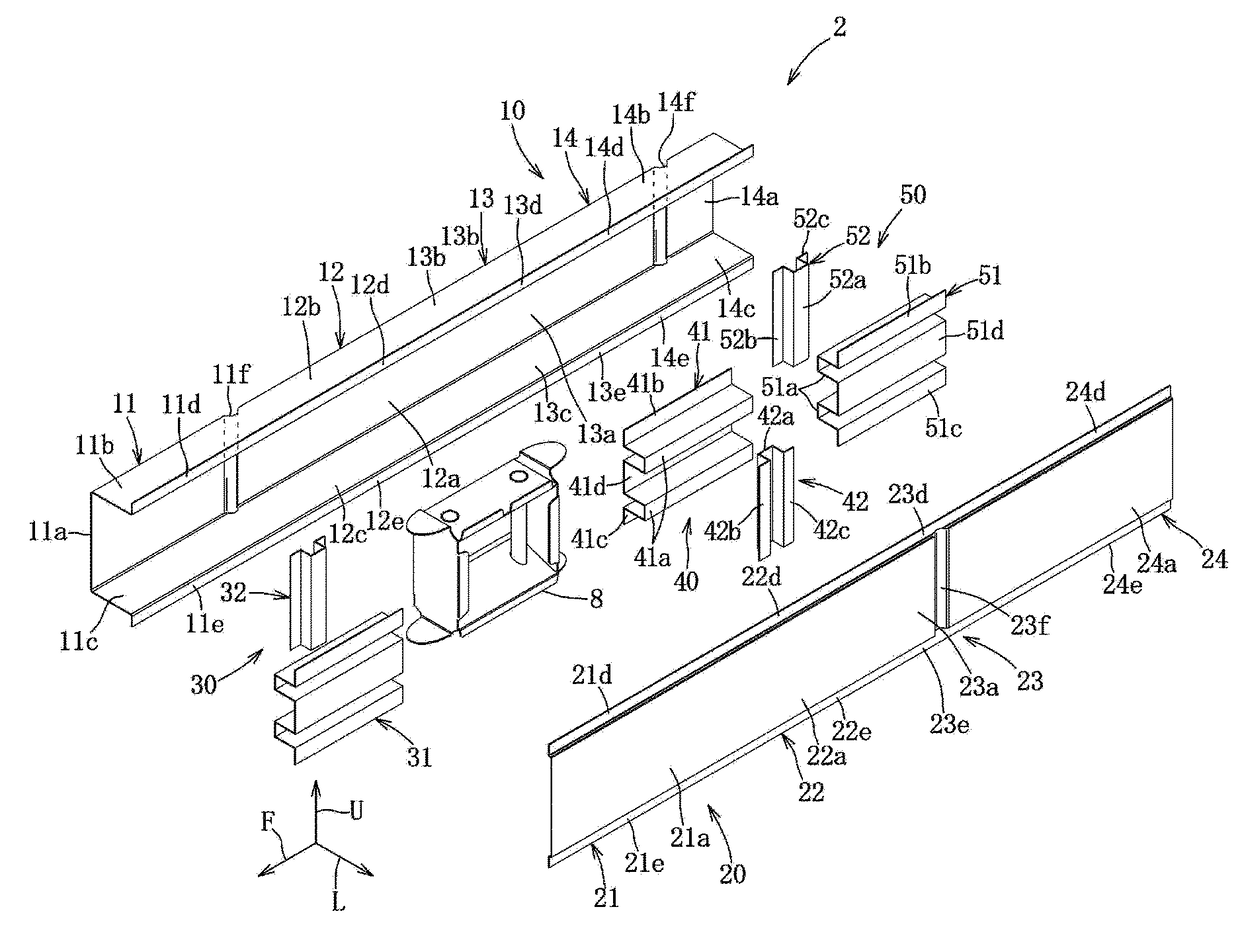

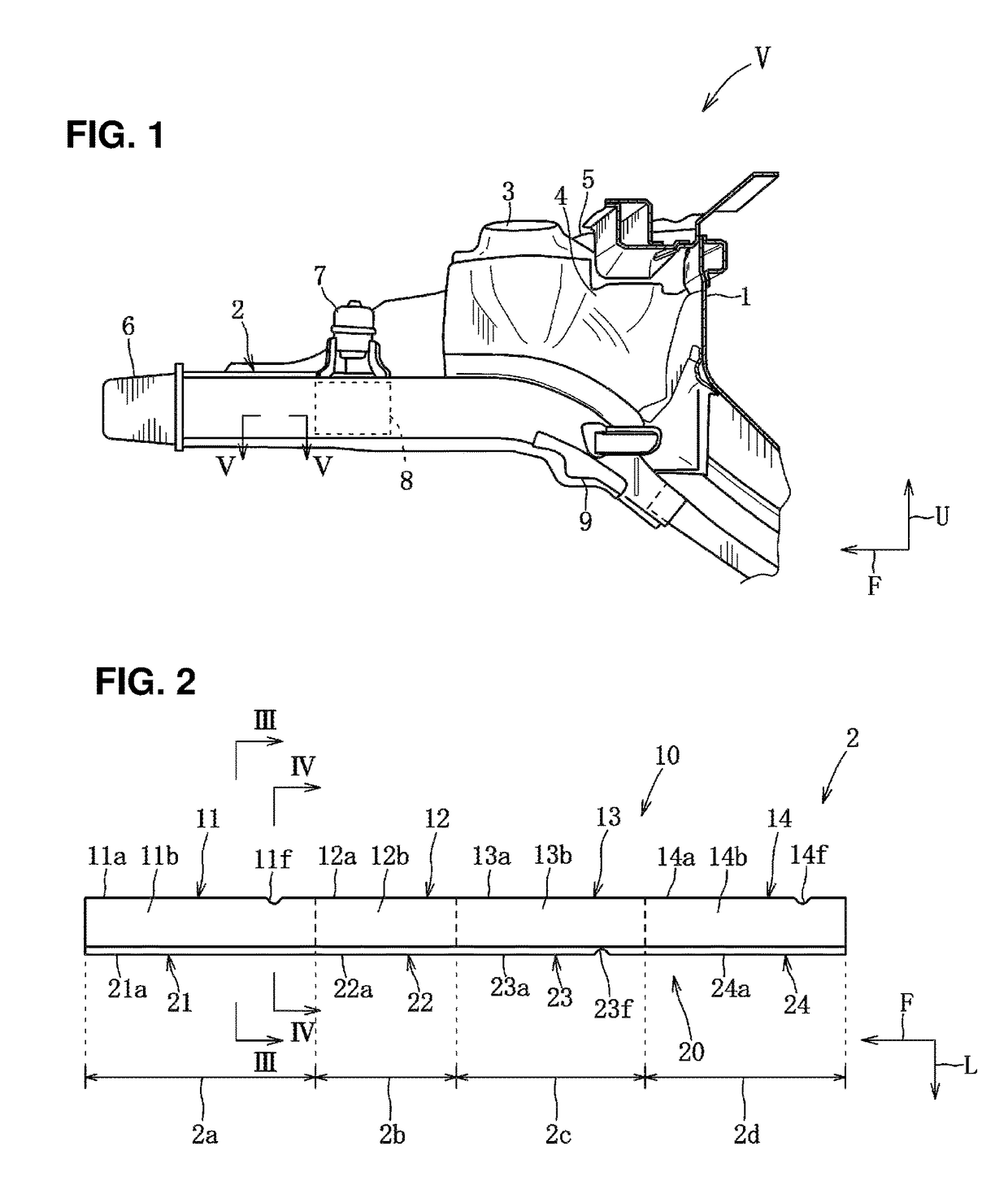

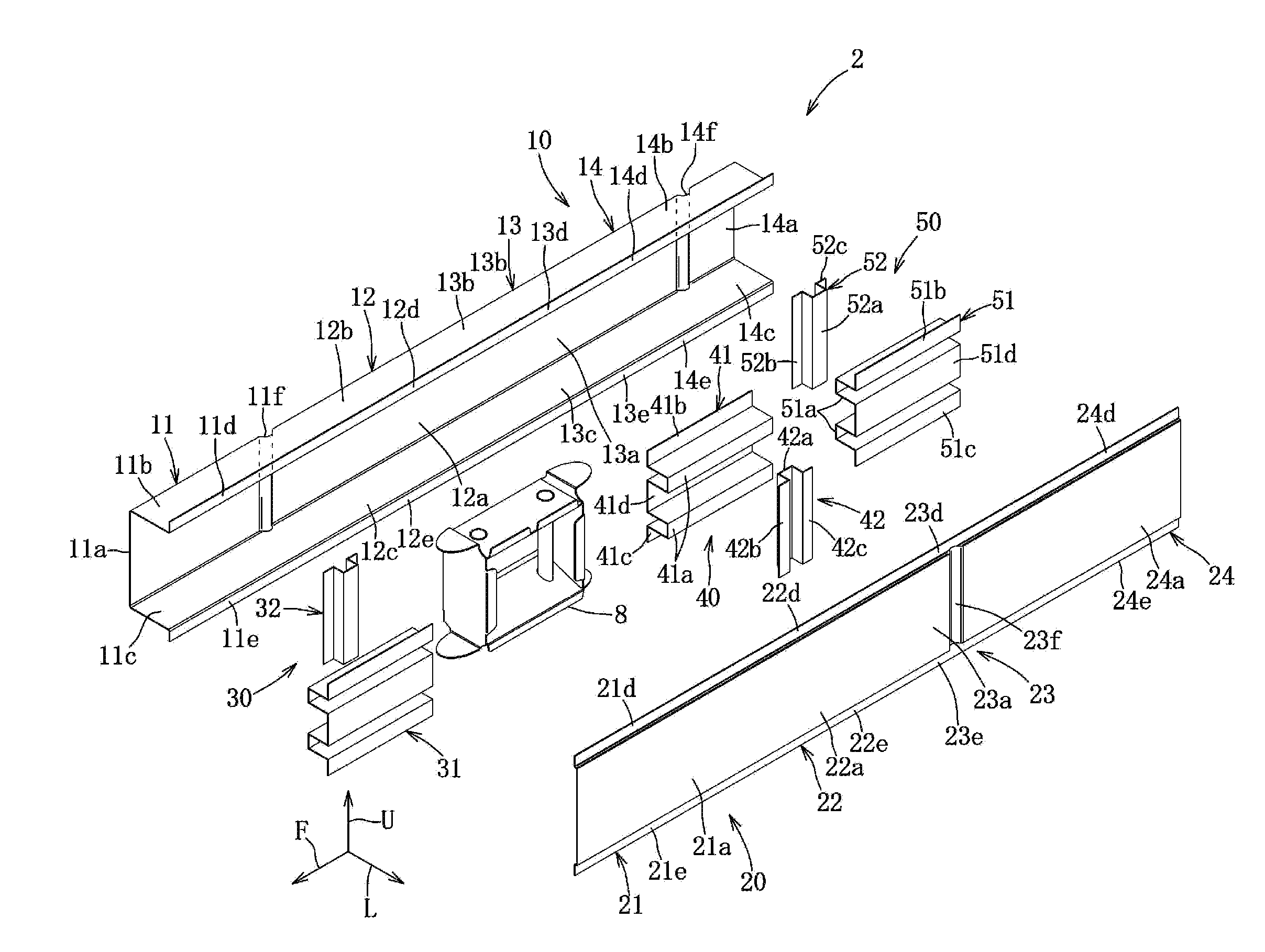

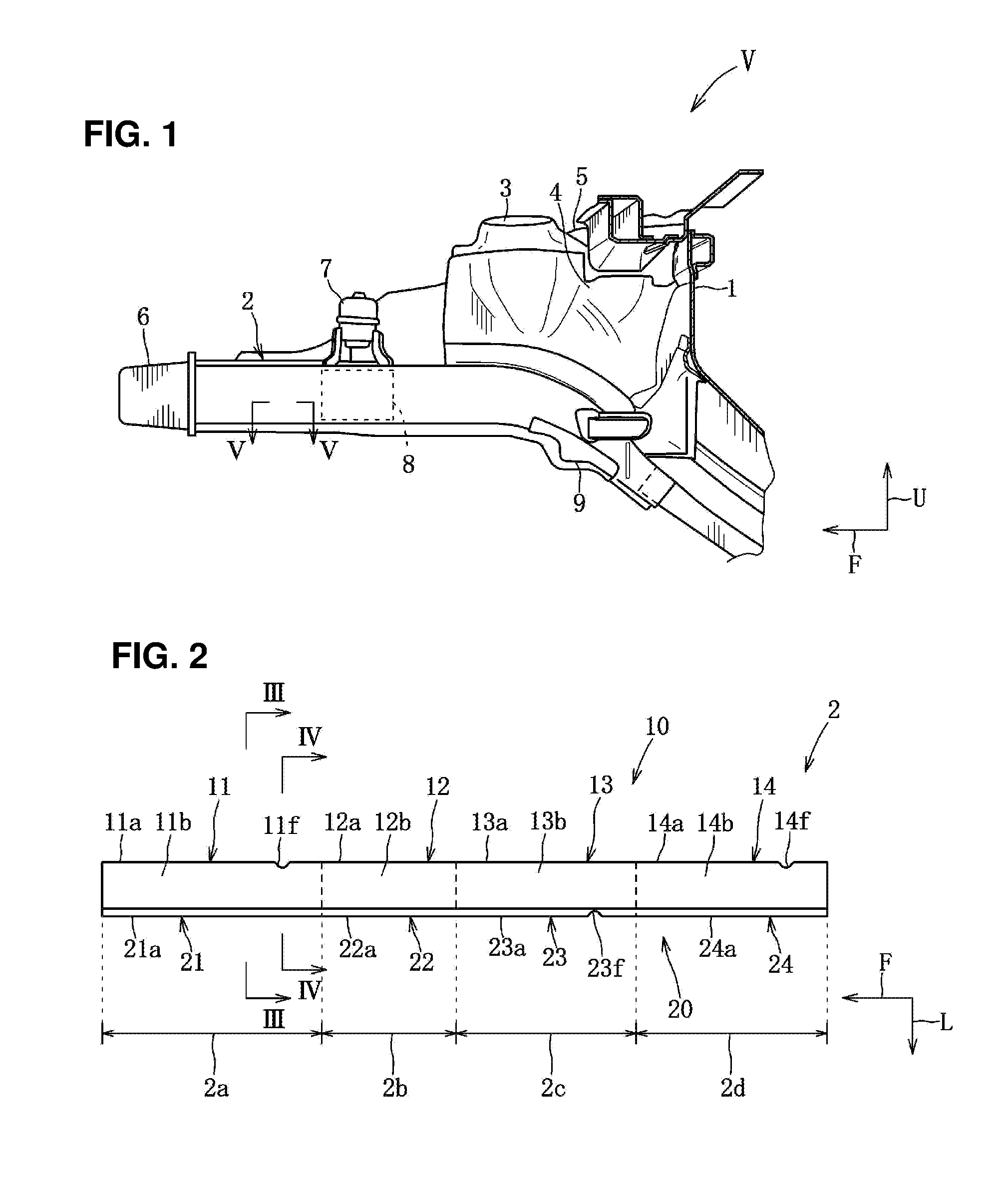

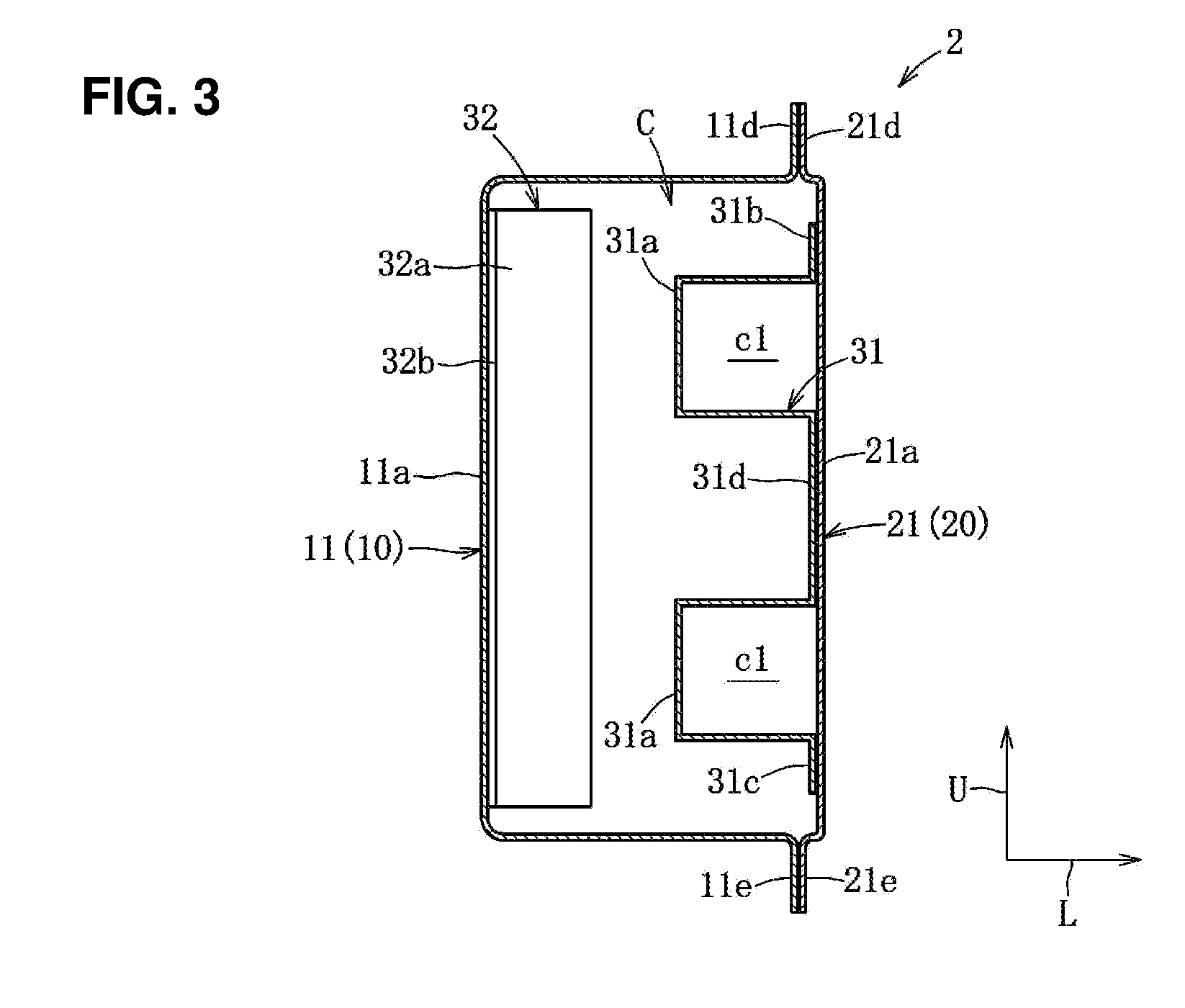

Frame structure for vehicle

ActiveUS9701344B2Increase the EA (Energy Absorption)Reduce starting loadUnderstructuresEngineeringMechanical engineering

Owner:MAZDA MOTOR CORP

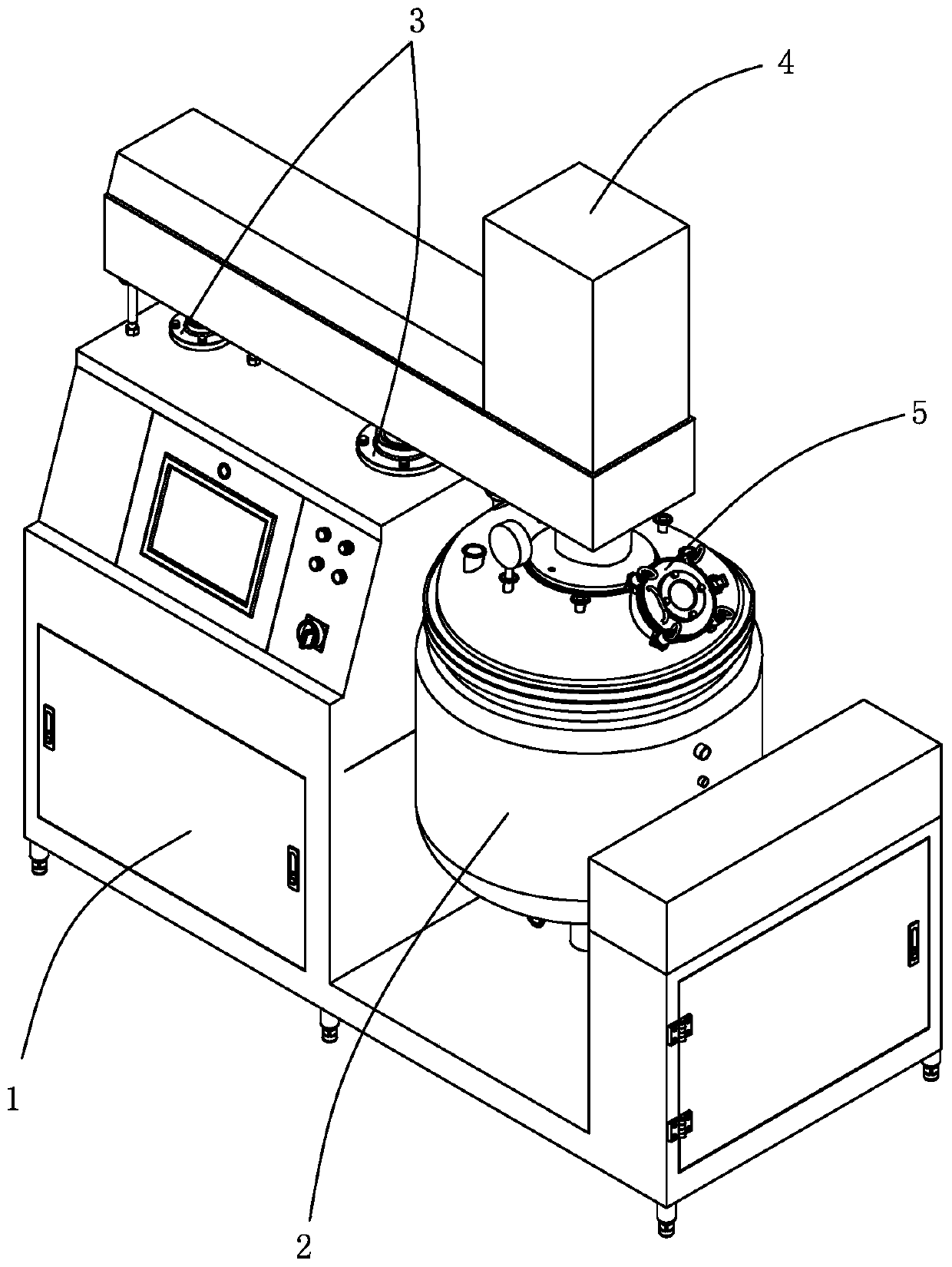

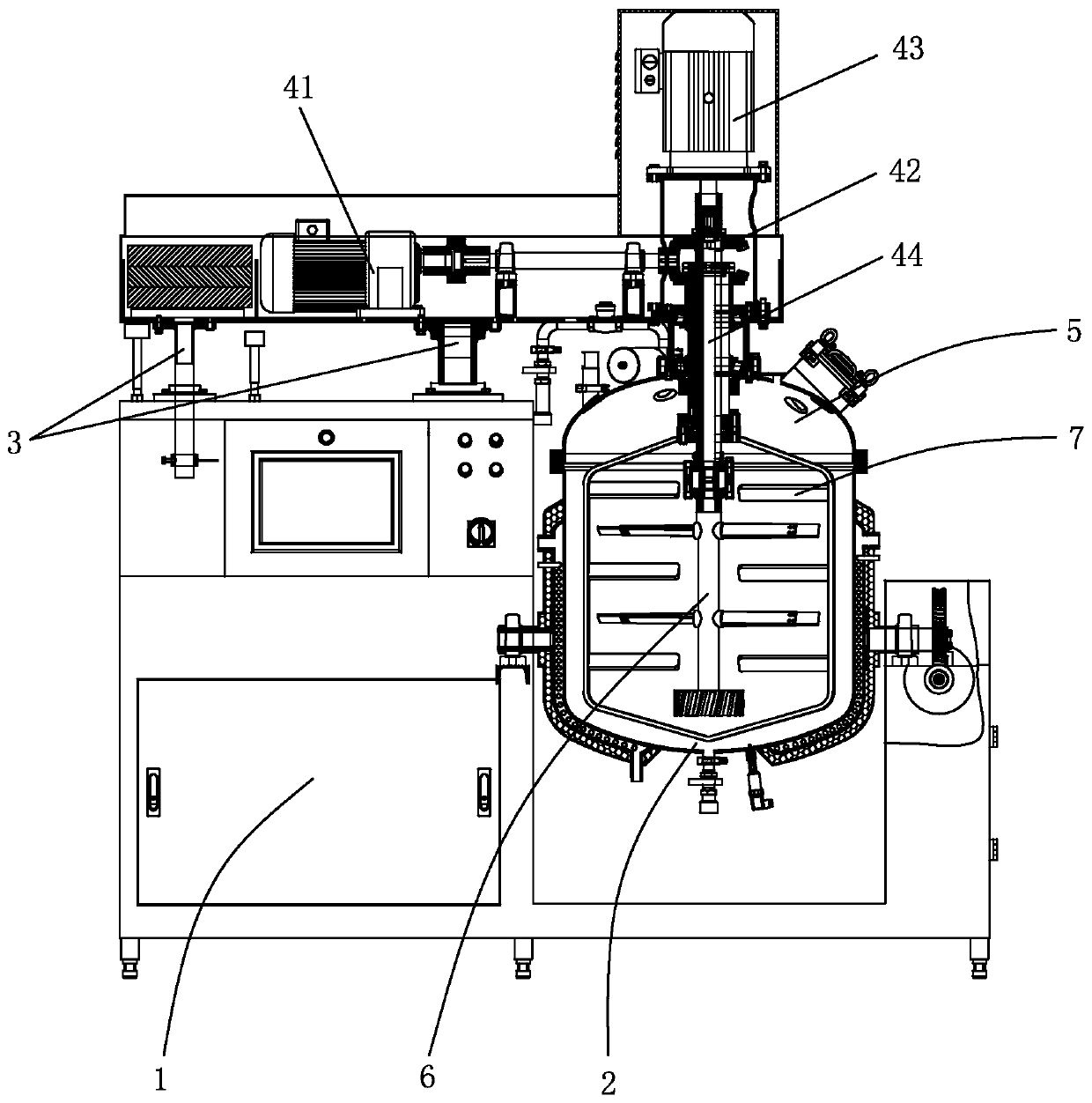

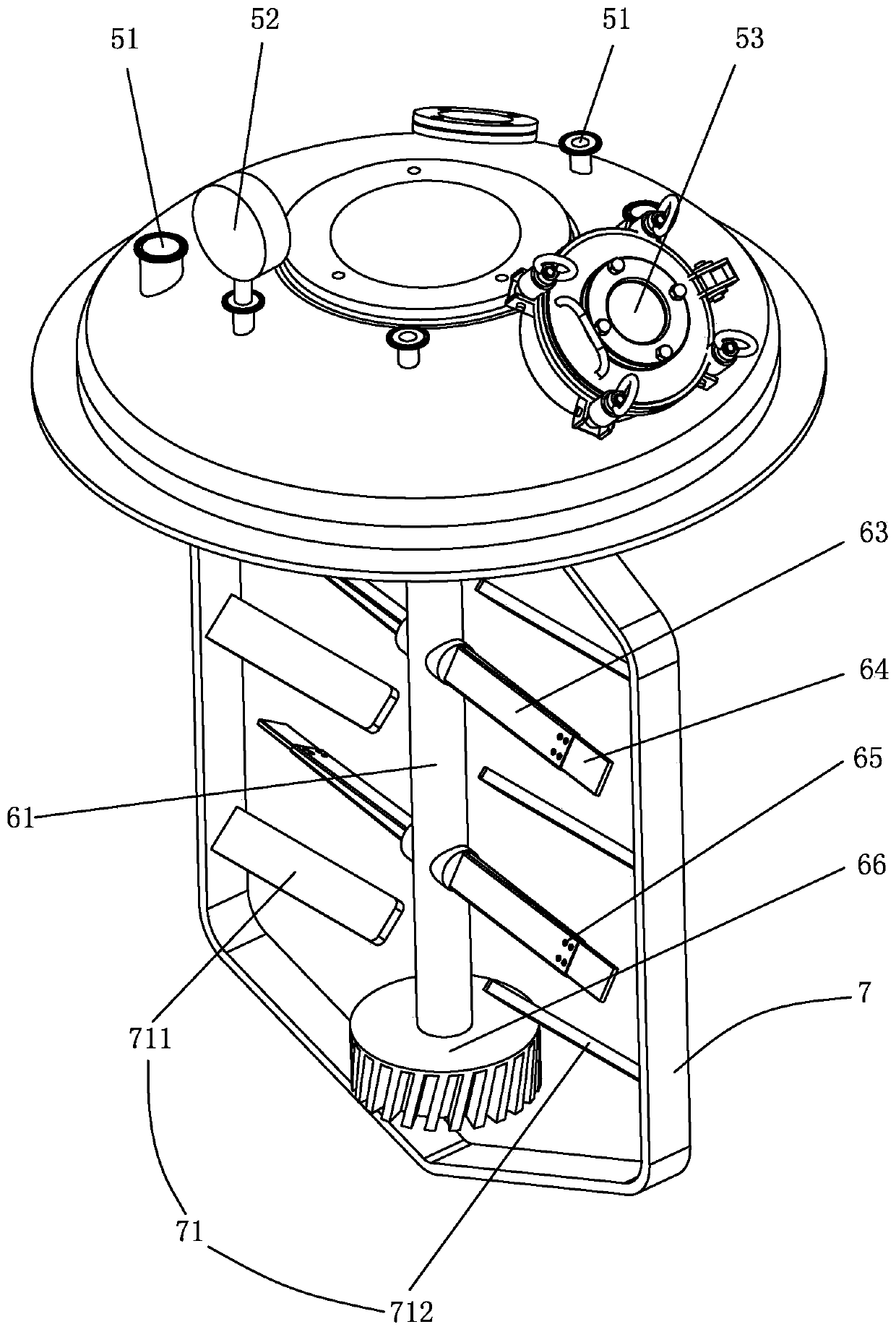

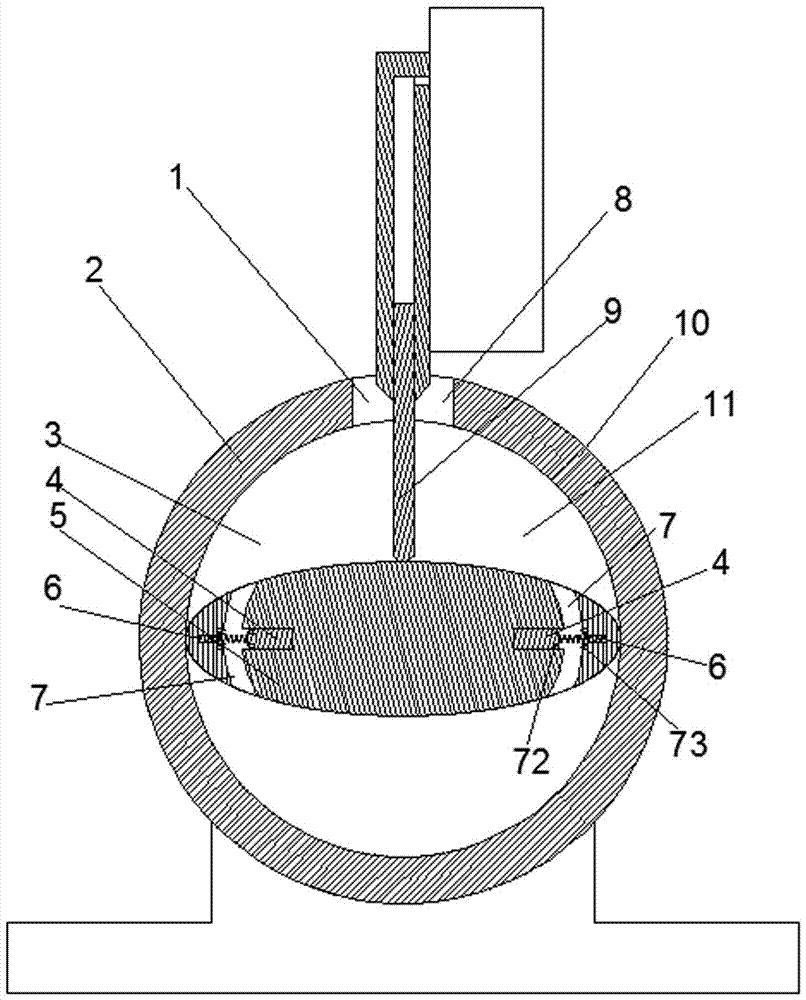

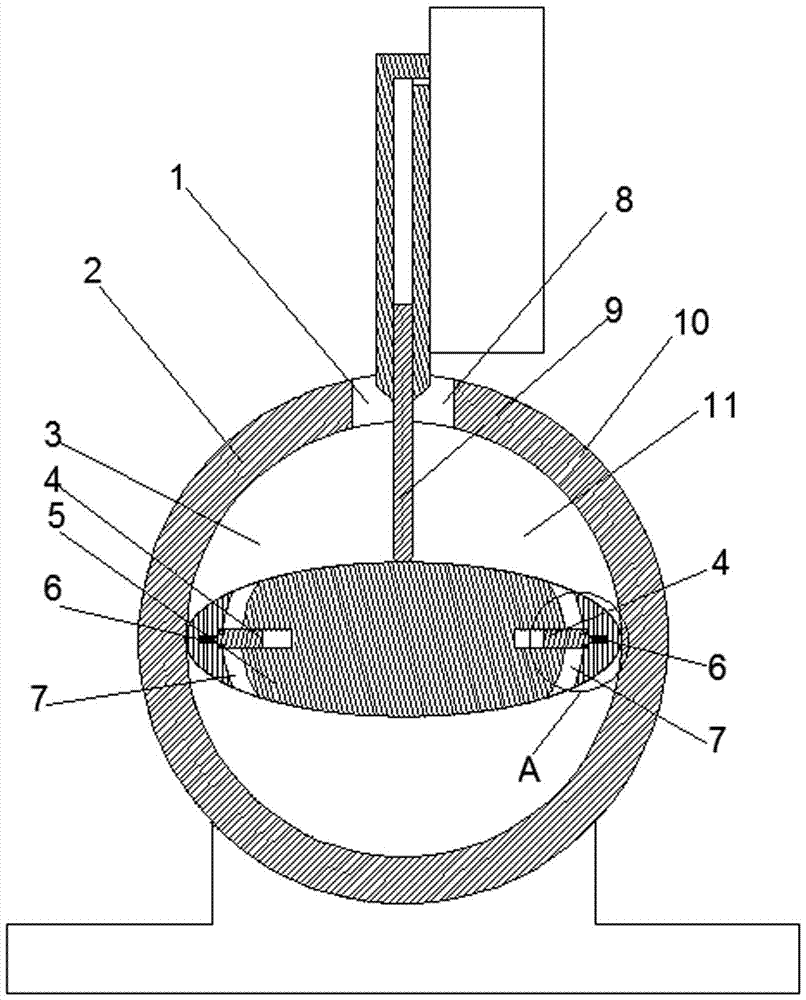

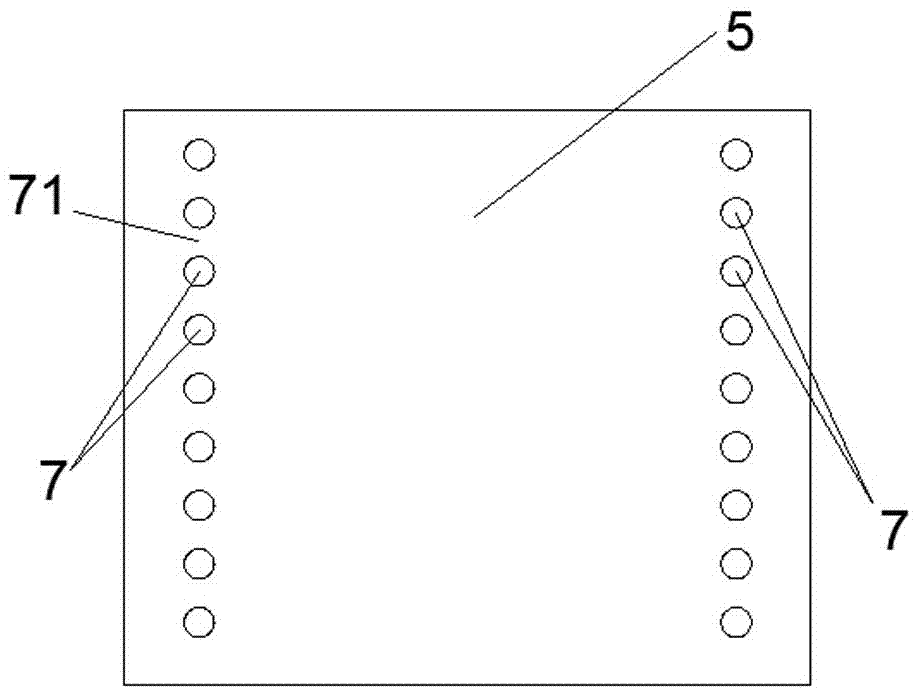

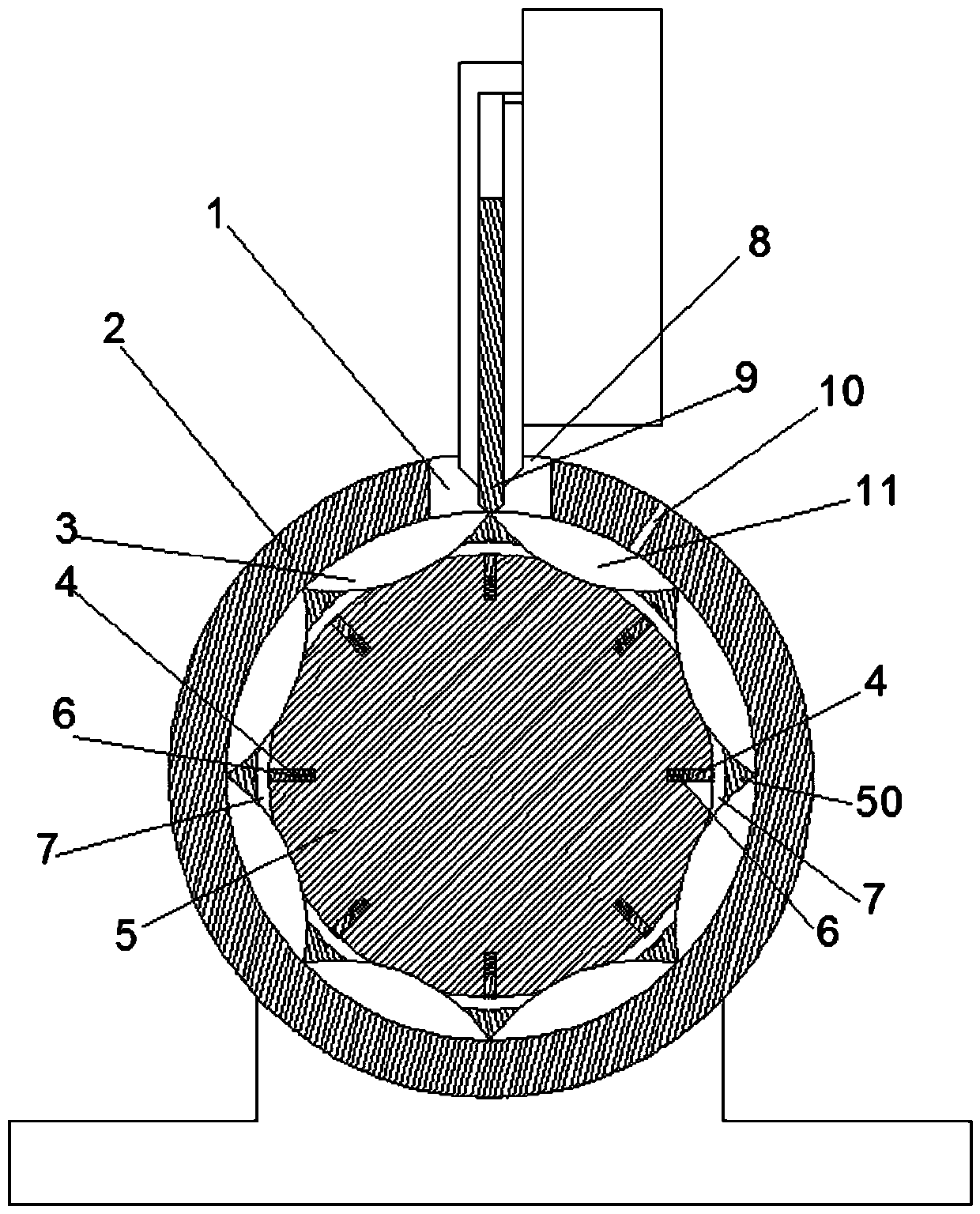

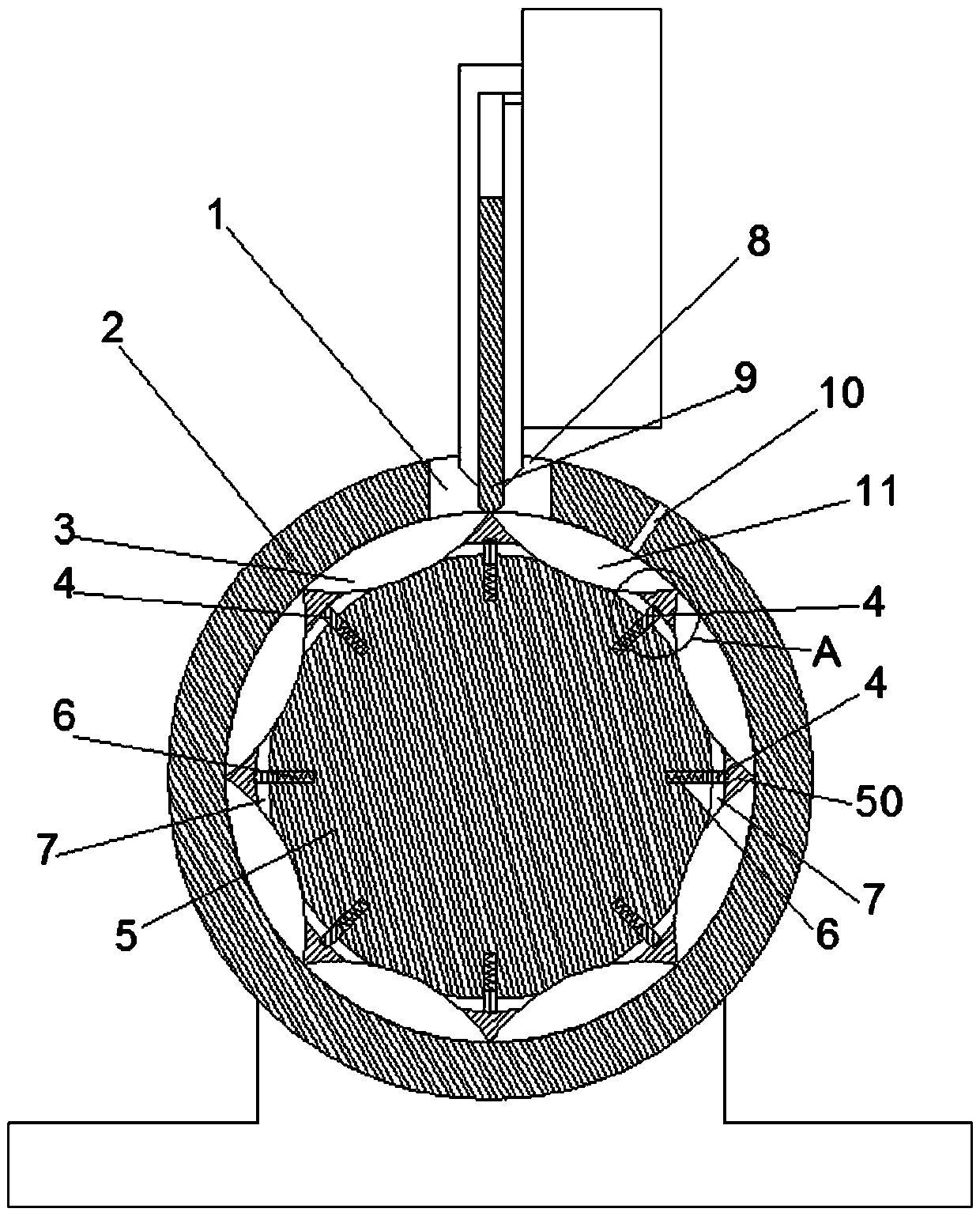

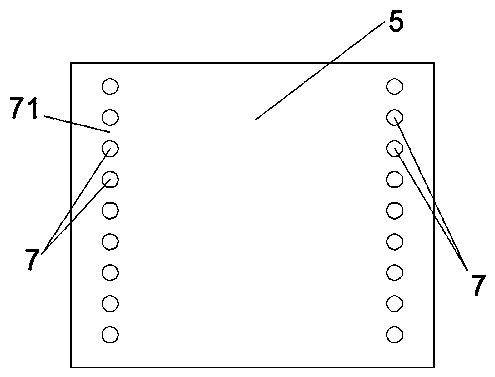

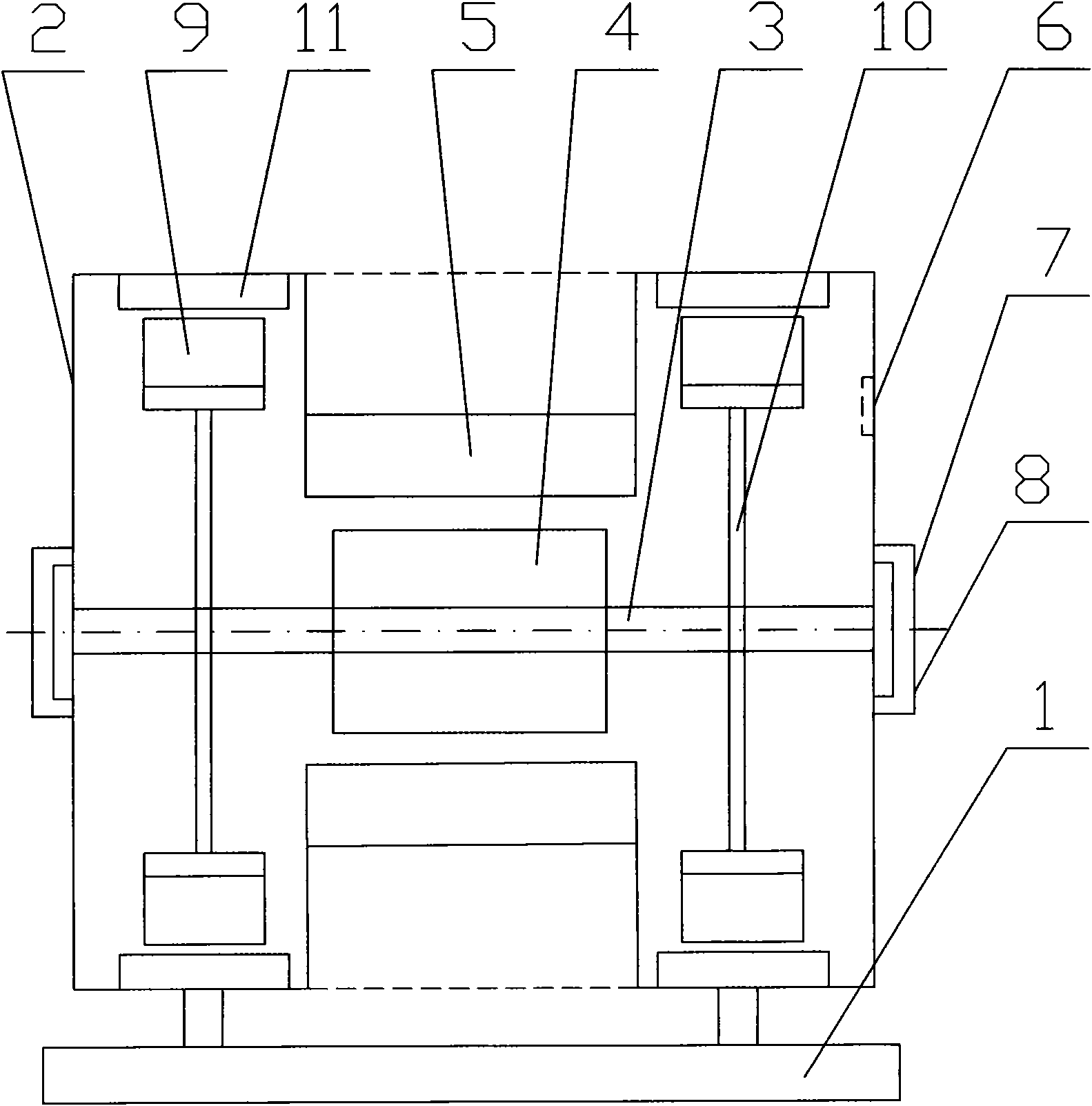

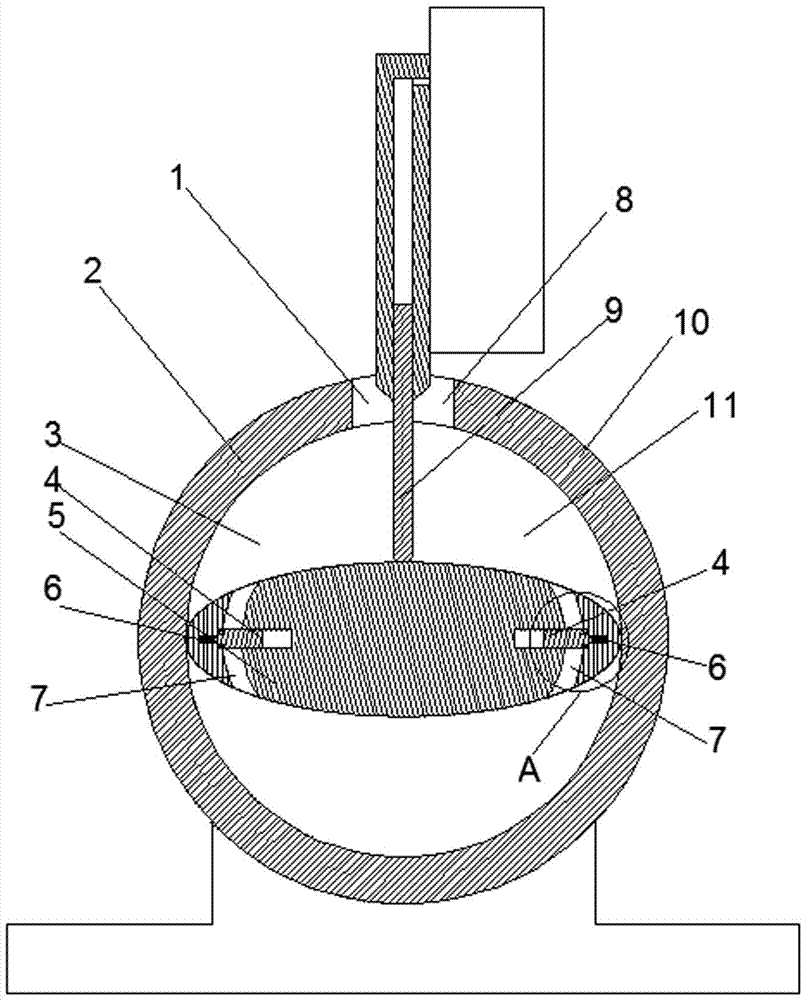

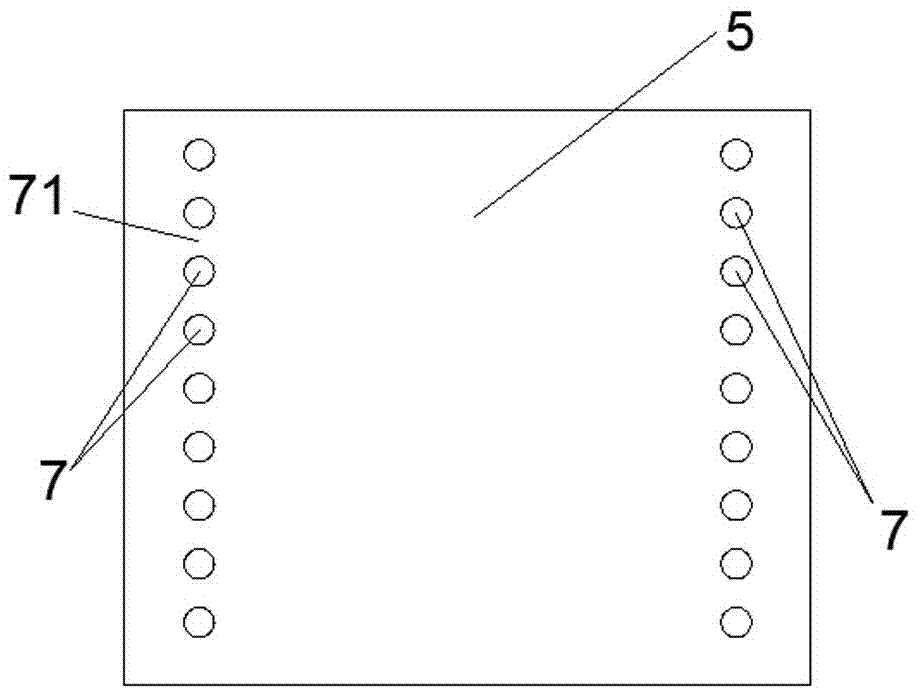

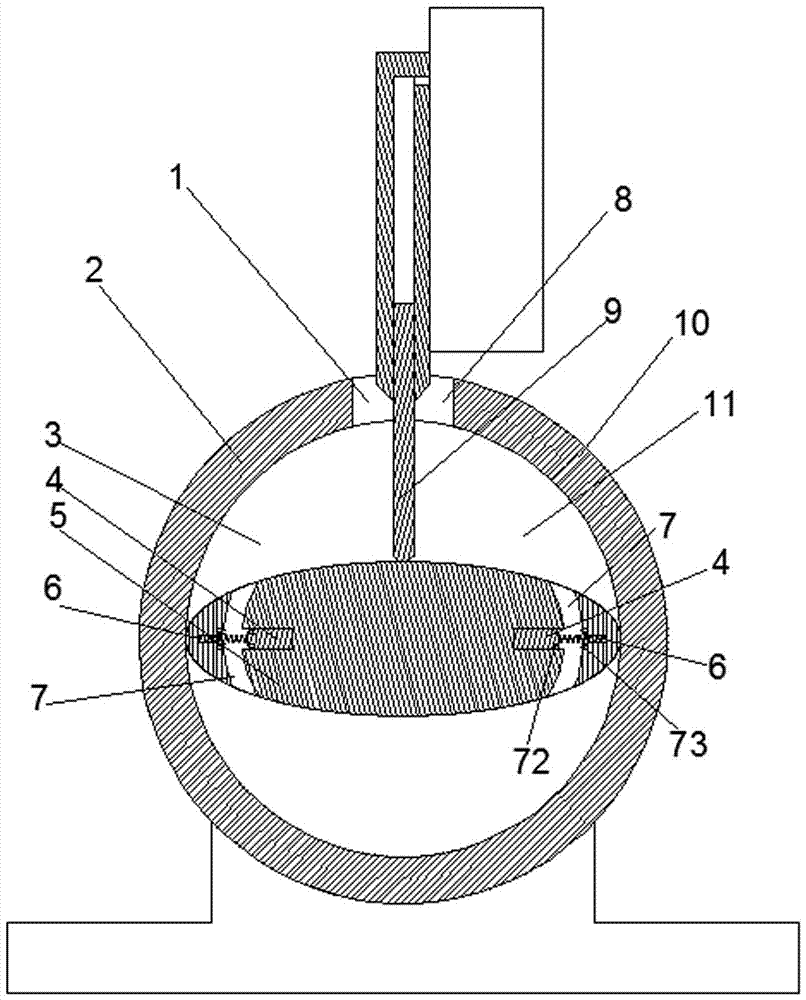

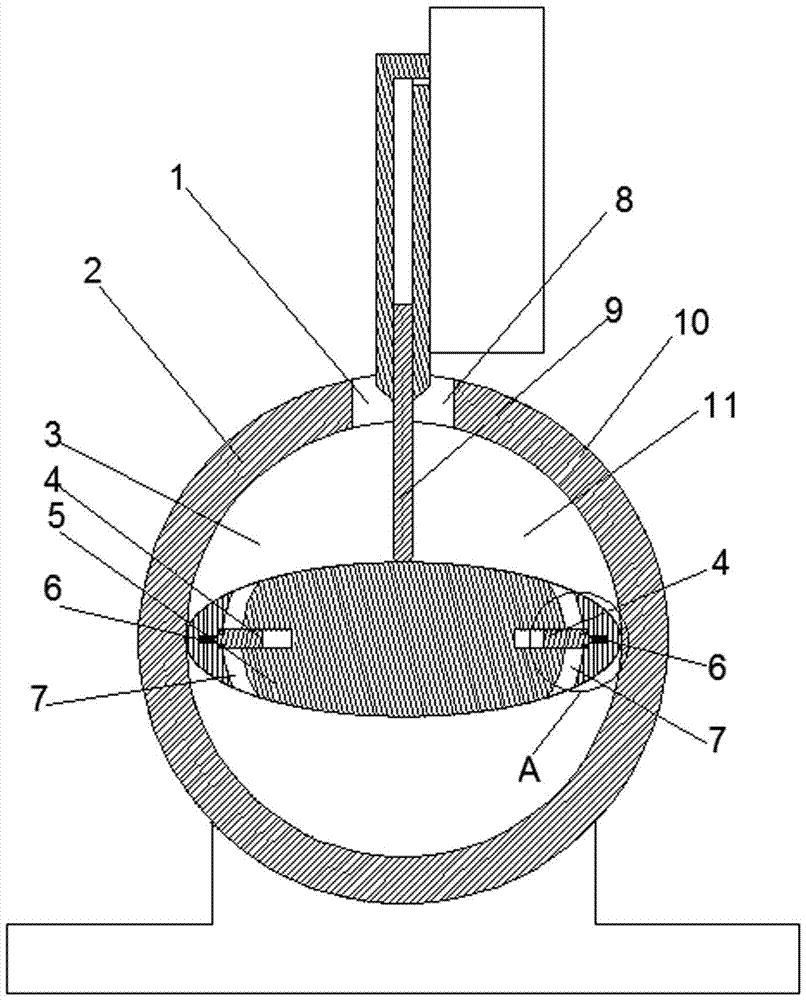

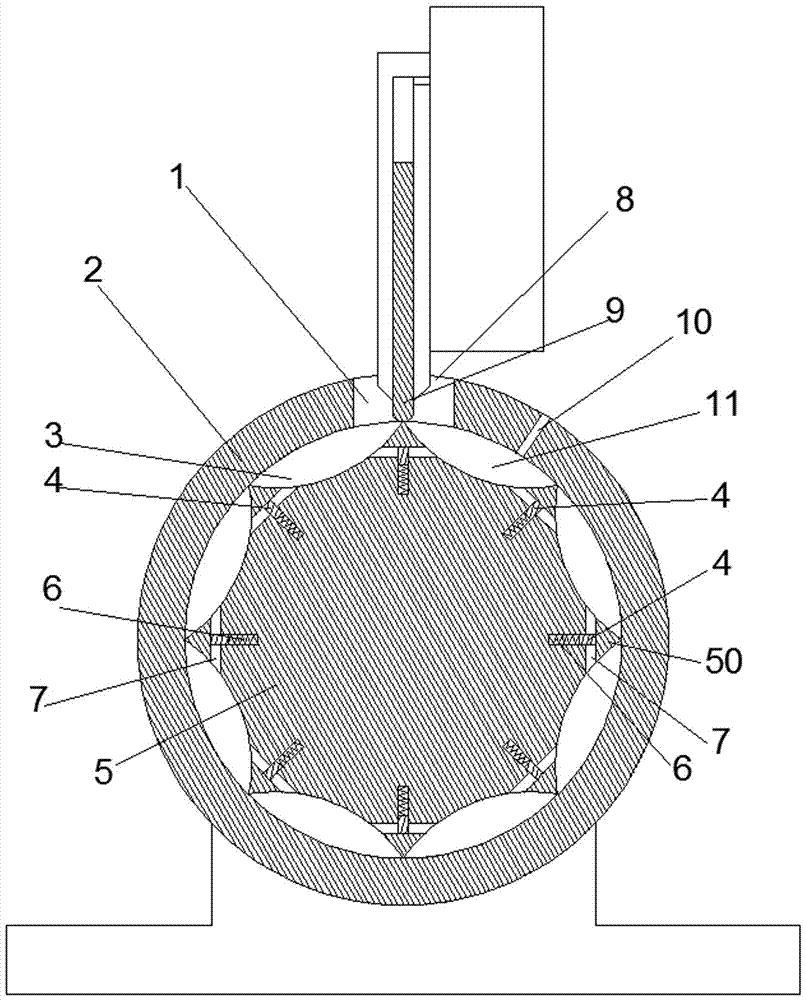

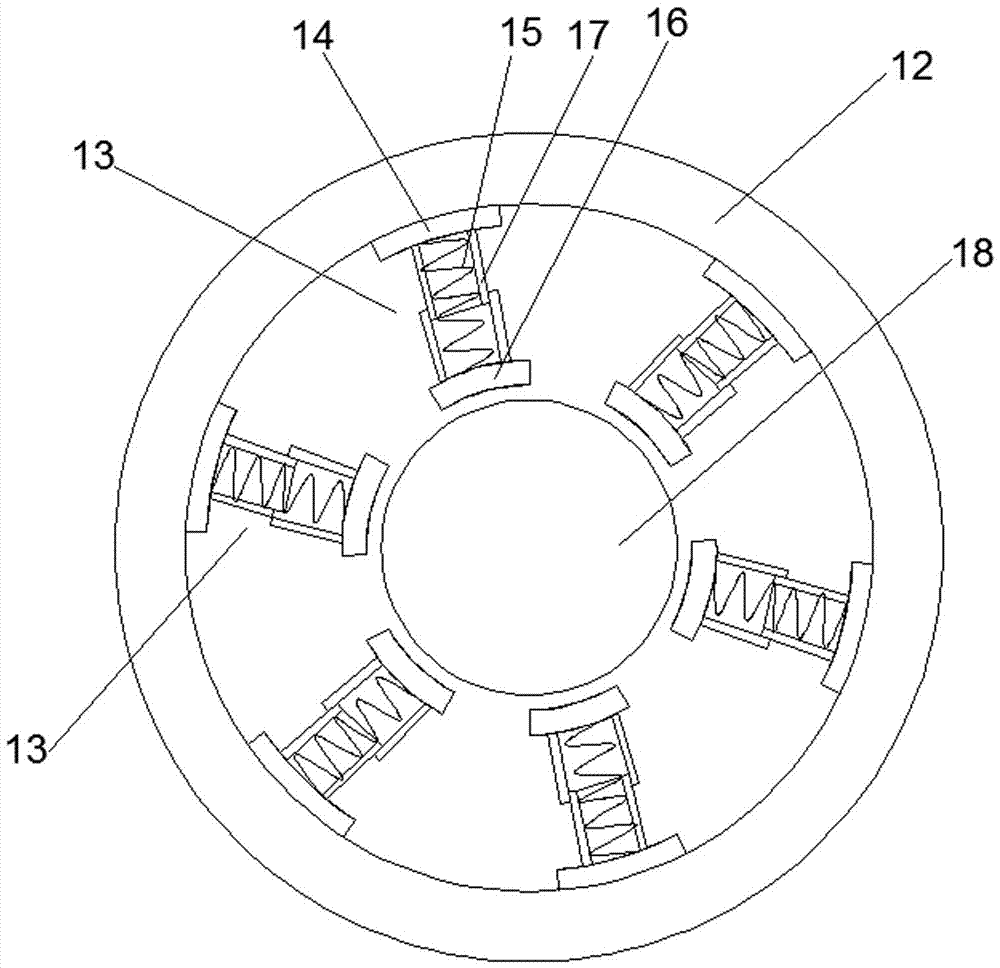

Emulsifying equipment with adjustable stirring blades

PendingCN109847605ALarge Stirring AngleReduce starting loadMixing methodsTransportation and packagingLocking mechanismHigh-speed grinding

The application discloses emulsifying equipment with adjustable stirring blades. The emulsifying equipment comprises a machine frame, an emulsifying tank, a lifting driving group, a rotating driving group, an emulsifying tank cover and an adjustable rotating group, wherein the adjustable rotating group comprises a connecting stirring shaft, an angle adjusting driving component, mother-stirring blades, sub-stirring blades, locking mechanisms and a high-speed grinding working head. According to the equipment, the emulsifying tank cover is driven to move downward to cover the emulsifying tank bythe rotating driving group driven by the lifting driving group, and then the adjustable rotating group is driven to rotate to perform the stirring and emulsifying work by the rotating driving group. Aiming at an emulsified material with the high viscosity, the mother-stirring blades are driven to rotate to increase the inclination angle by the angle adjusting driving component, so that the mother-stirring blades have relatively large stirring cutting-in angles to facilitate the initial stirring of the emulsified material, and the service life of the rotating driving group is improved. When different emulsifying tanks need to be replaced, the telescopic length of the sub-stirring blades can be adjusted to meet use needs of different sizes, so that the practicability, applicability and flexibility are improved.

Owner:中山翰华锡业有限公司

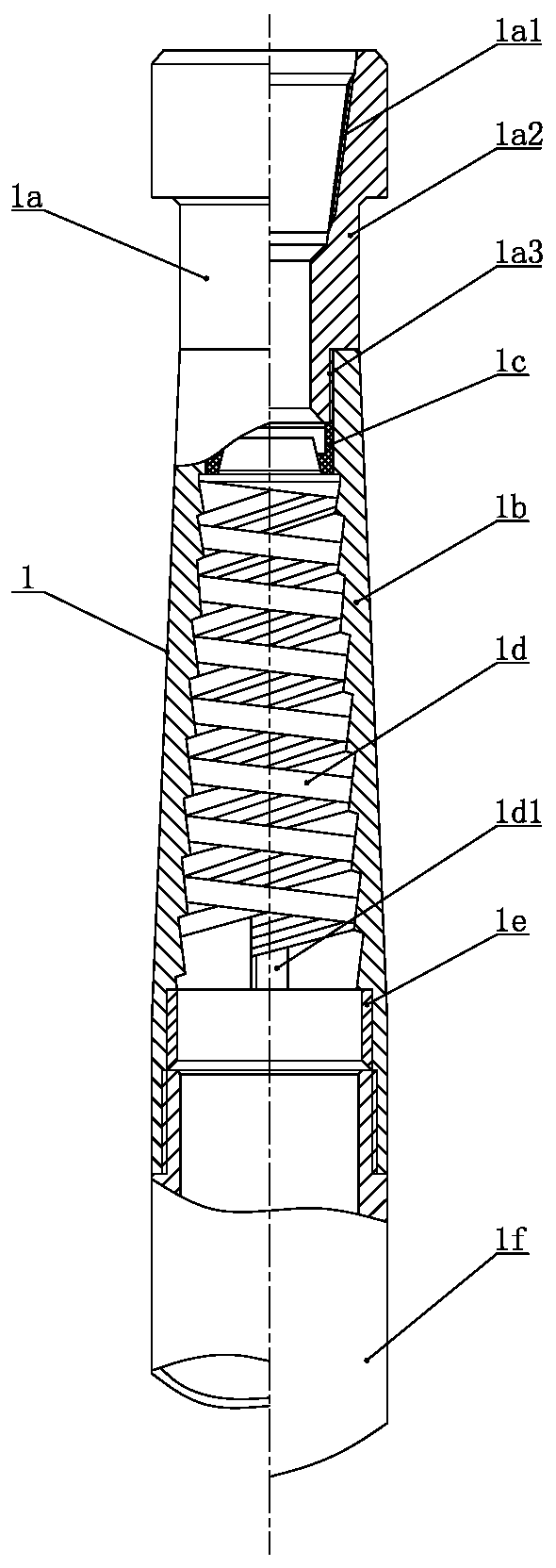

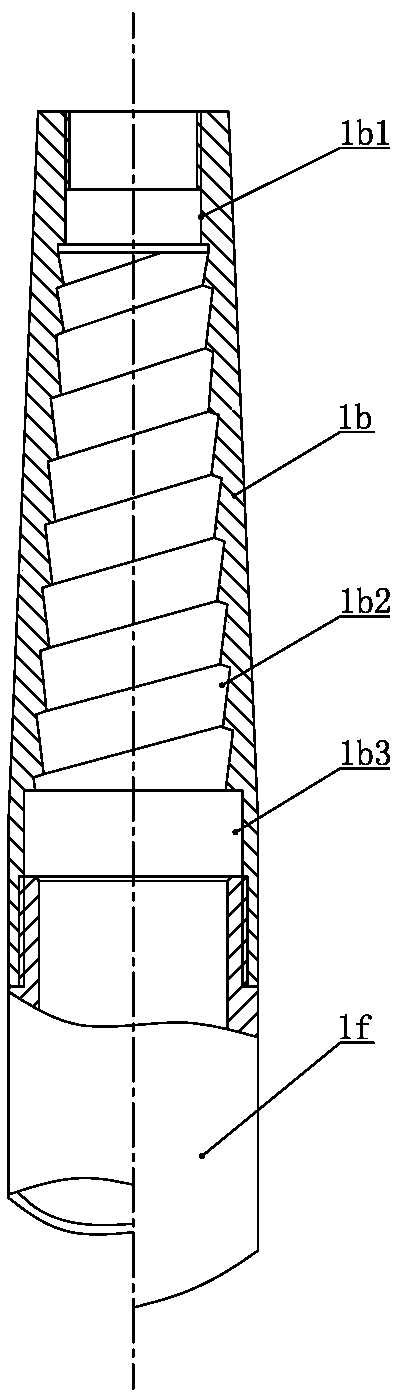

Pump and hydraulic power assembly using same

InactiveCN107288872AReduce starting loadReduce resistanceRotary piston pumpsRotary piston liquid enginesEngineeringCentrifugal force

The invention relates to a pump and a hydraulic power assembly using same. The pump comprises a pump body in which a cylindrical inner cavity is formed. A rotor of which the rotation axis extends back and forth and the cross section is elliptoid is arranged in the pump body. The two ends in the major axis direction of the rotor are provided with oil guide channels for being communicated with the two sides in the circumferential direction of the rotor. The longitudinal sections of the oil guide channels are of arc-shaped structures. The circle centers of the arc-shaped structures are located between the oil guide channels at the two sides. A plugging block is arranged in the rotor in the major axis direction in a director motion mode and has a first position and a second position in the shift motion of the plugging block; the plugging block avoids the oil guide channels at the first position; under the impact of centrifugal force, the plugging block moves outwards to block the oil guide channels at the second position. A spring which applies acting force to the plugging block to force the plugging block to be located at the first position is arranged on the rotor. The invention provides the pump capable of reducing the starting load and the hydraulic power assembly using the same.

Owner:HENAN MECHANICAL & ELECTRICAL VOCATIONAL COLLEGE

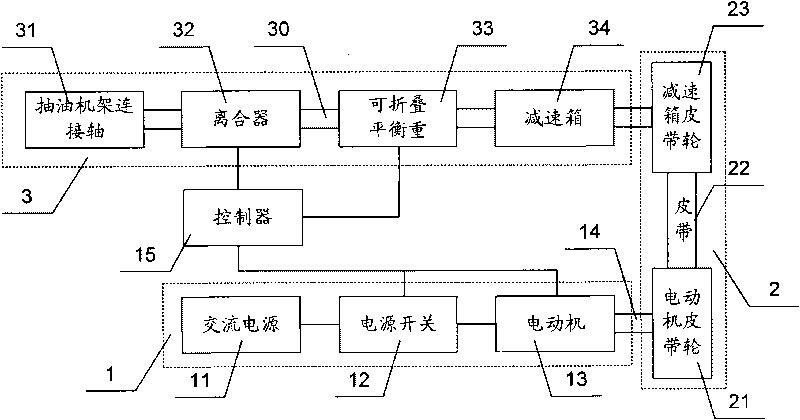

Beam-pumping unit

InactiveCN101748994AImprove efficiencyEvenly distributed inertiaFlexible member pumpsFluid removalClutchPower grid

The invention relates to a beam-pumping unit, which includes a motor, an actuating device and a pumping unit device connected in sequence; the pumping unit device comprises the connection shaft of the frame of the pumping unit, a foldable balancing weight, and a clutch which disconnects the connection shaft of the frame of the pumping unit and the foldable balancing weight when starting the motoras well as reconnects the connection shaft of the frame of the pumping unit and the foldable balancing weight when starting the pumping unit. The foldable balancing weight is set to be under an unfolded state when starting the motor, and under the folded state when starting the pump unit. The beam-pumping unit breaks through the design concept of the current pumping unit, sets the balancing weight of a 'monolithic block' pumping unit into the foldable balancing weight, and uses a mechanical energy storing principle to improve the efficiency of the motor of the pumping unit. The beam-pumping unit not only can reduce the installed power of the motor of the pumping unit to radically solve the technical defect of 'big Marathi car' of the motor of the pumping oil in the oil field, and also canimprove the efficiency of the motor during the running process of the pumping unit, and reduce the impact on power systems.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

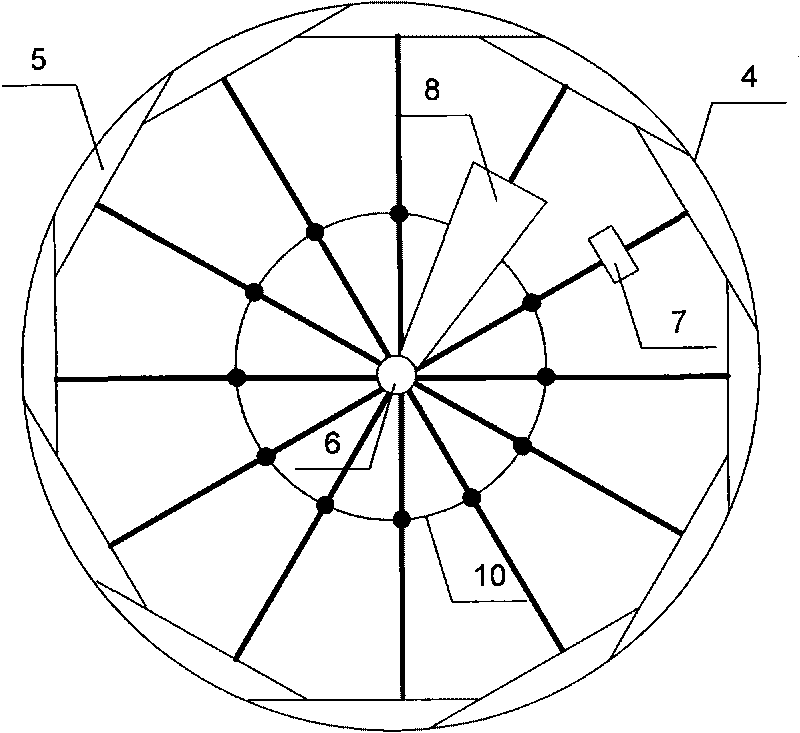

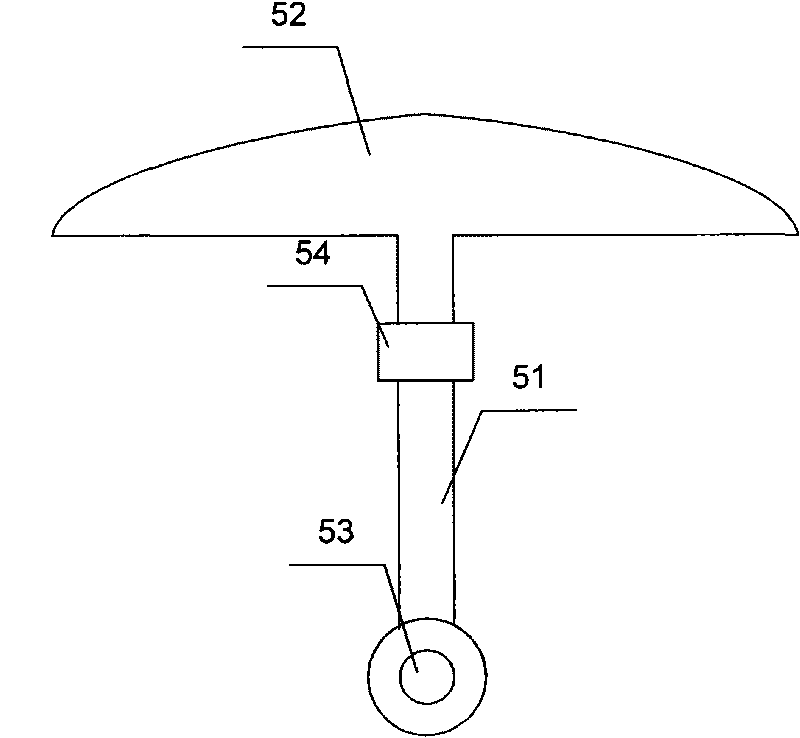

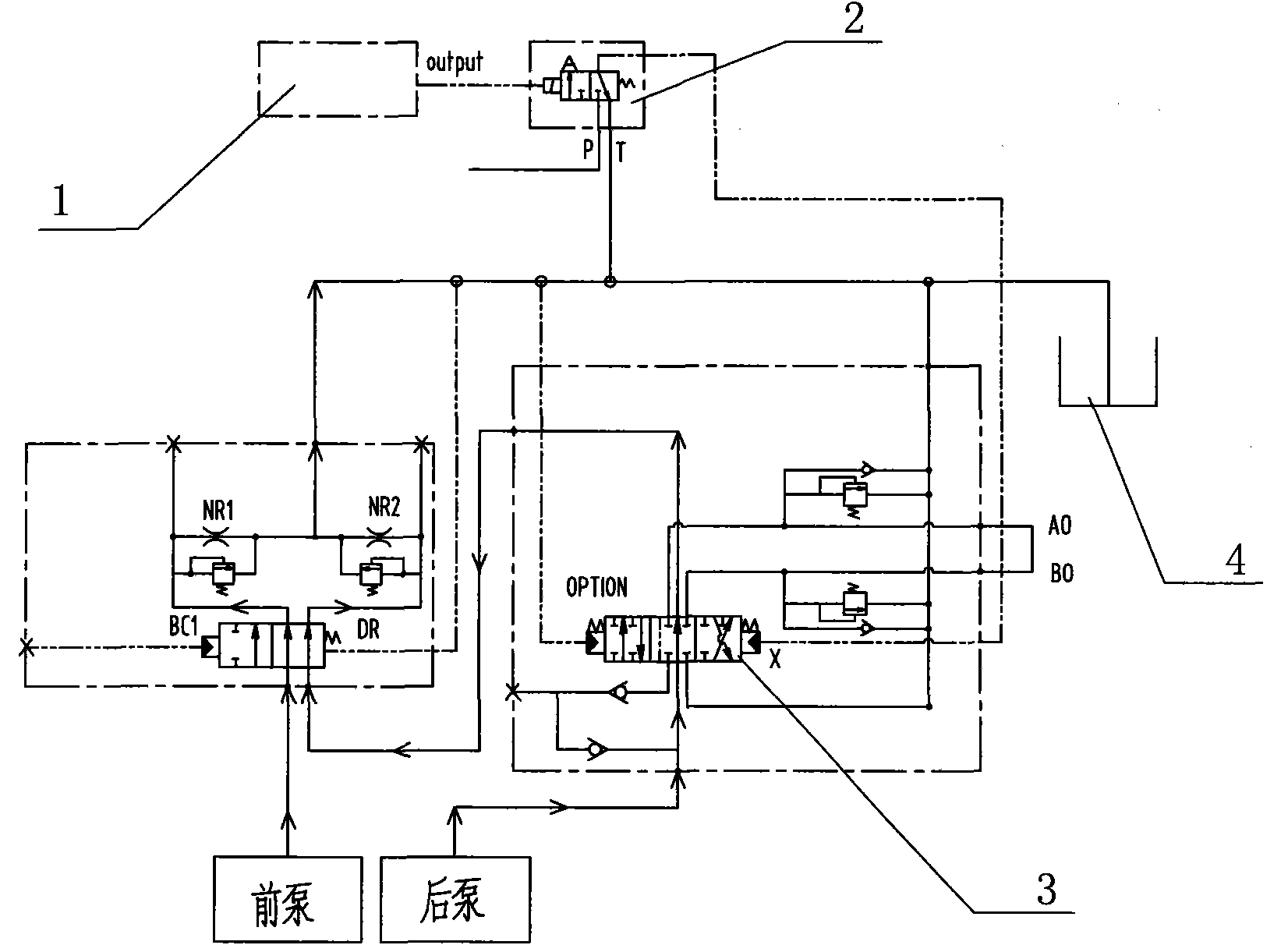

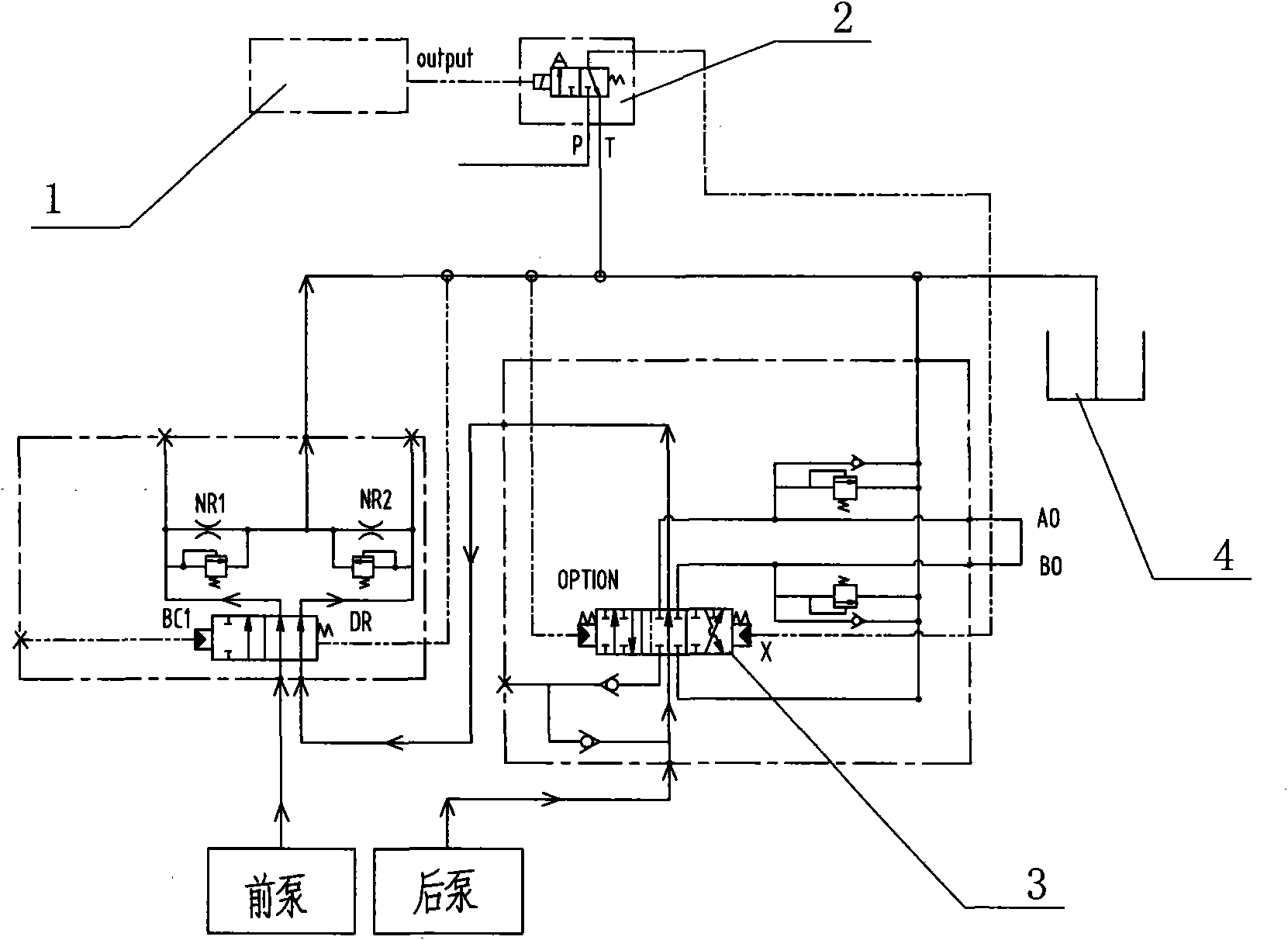

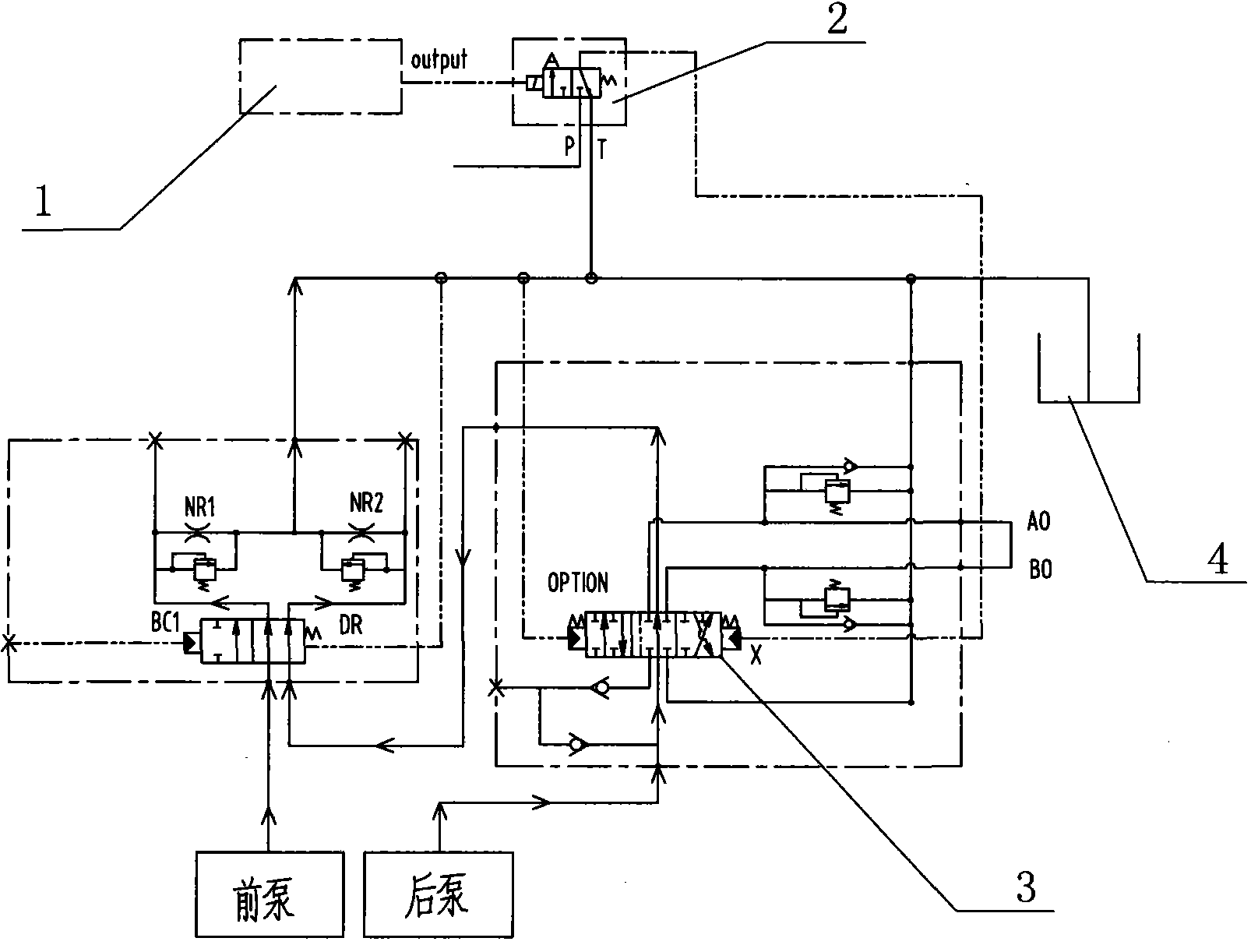

Control method and device for reducing starting load of excavator

The invention discloses a control method for reducing the starting load of an excavator, which is characterized in that: an electromagnetic valve control switch is turned on, when the excavator starts; a pilot oil pump outputs pilot pressure oil from an electromagnetic valve port A and the pilot pressure oil flows into a standby valve to push the standby valve to start; a rear pump outputs hydraulic oil to an oil port BO of the standby valve through the standby valve; a bypass oil return pipeline is formed by communicating the oil port BO and an oil port AO of the standby valve; the hydraulic oil flows back to the standby valve from the oil port AO and then flows back to an oil tank to complete the starting process; the device for reducing the starting load of the excavator comprises the electromagnetic valve control switch and an electromagnetic valve, wherein an oil inlet P of the electromagnetic valve is connected to an oil outlet of the pilot oil pump; an output port A of the electromagnetic valve is connected with a control oil port X of the standby valve; and an oil return port T of the electromagnetic valve is connected to the oil return pipeline. By arranging the bypass oil return pipeline, the hydraulic oil bypasses an oil return box when the device is started, so the loss of the pressure and the starting load of an engine are reduced and the starting is realized at the low temperature.

Owner:SANY HEAVY MACHINERY

Frame structure for vehicle

ActiveUS20160251035A1Increase the EA (Energy Absorption)Reduce starting loadUnderstructuresEngineeringMechanical engineering

Owner:MAZDA MOTOR CORP

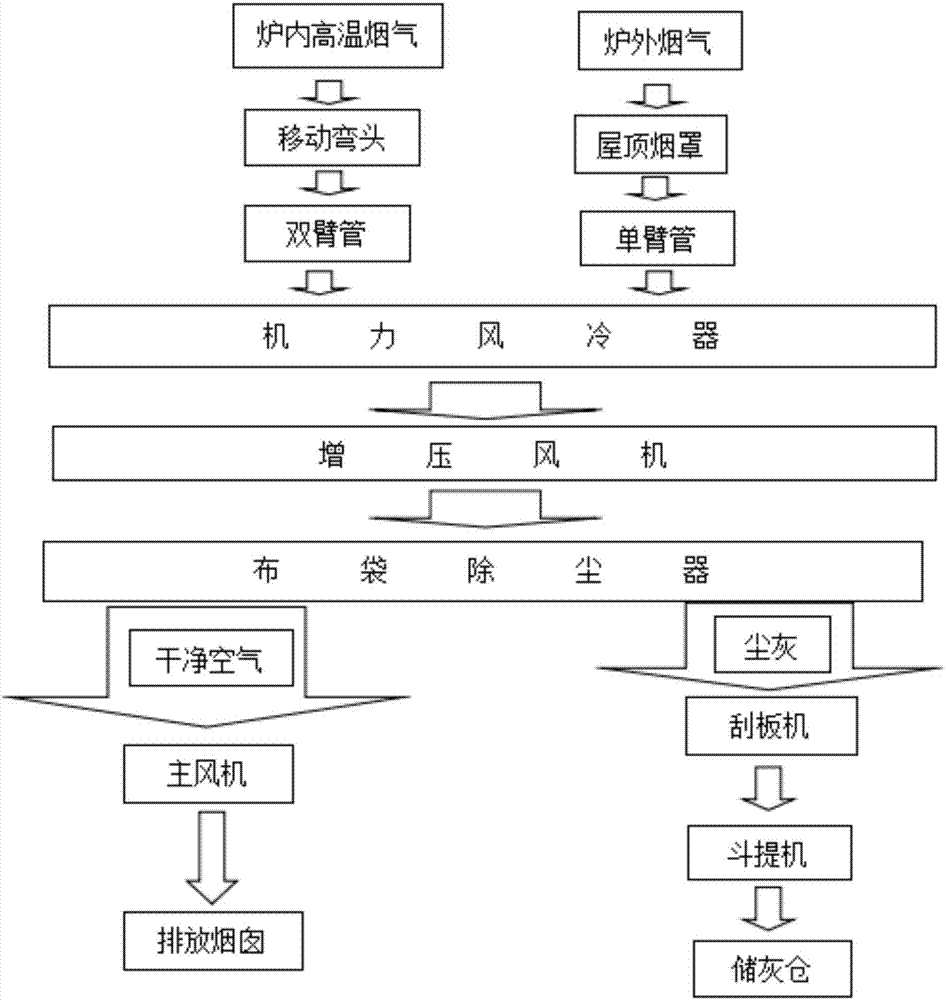

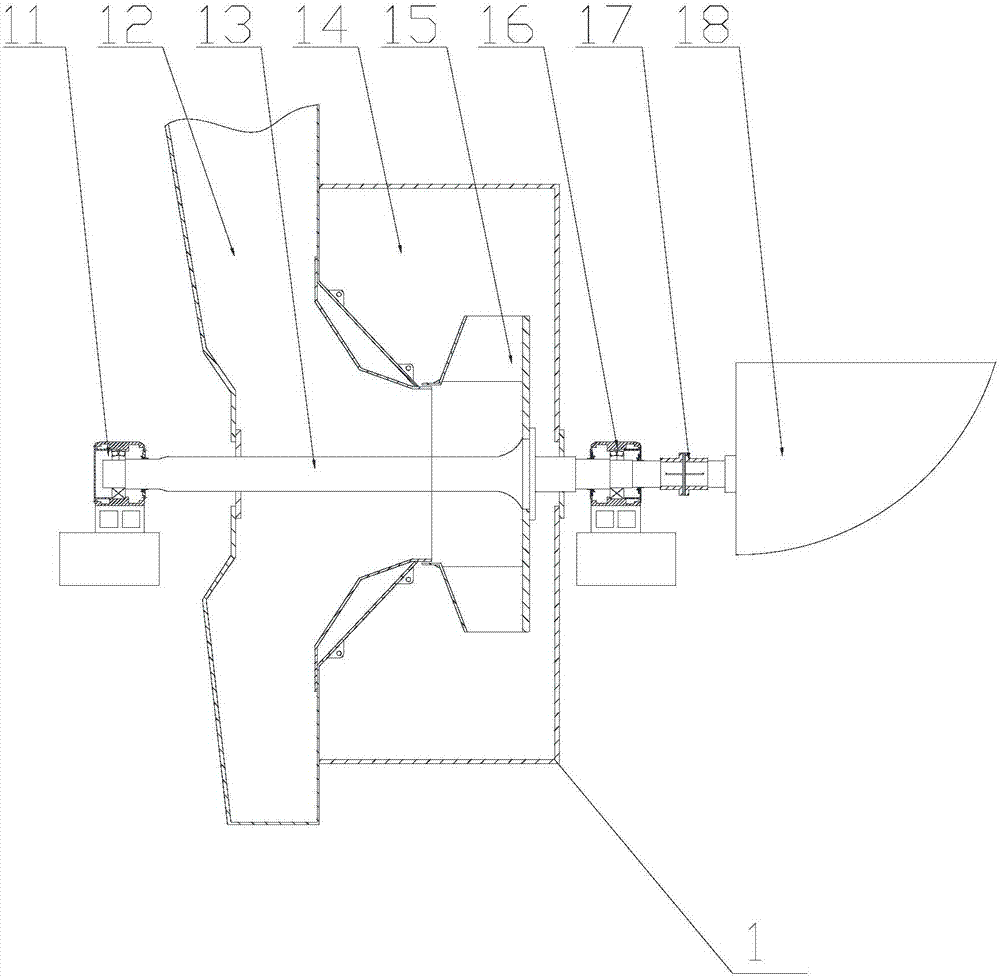

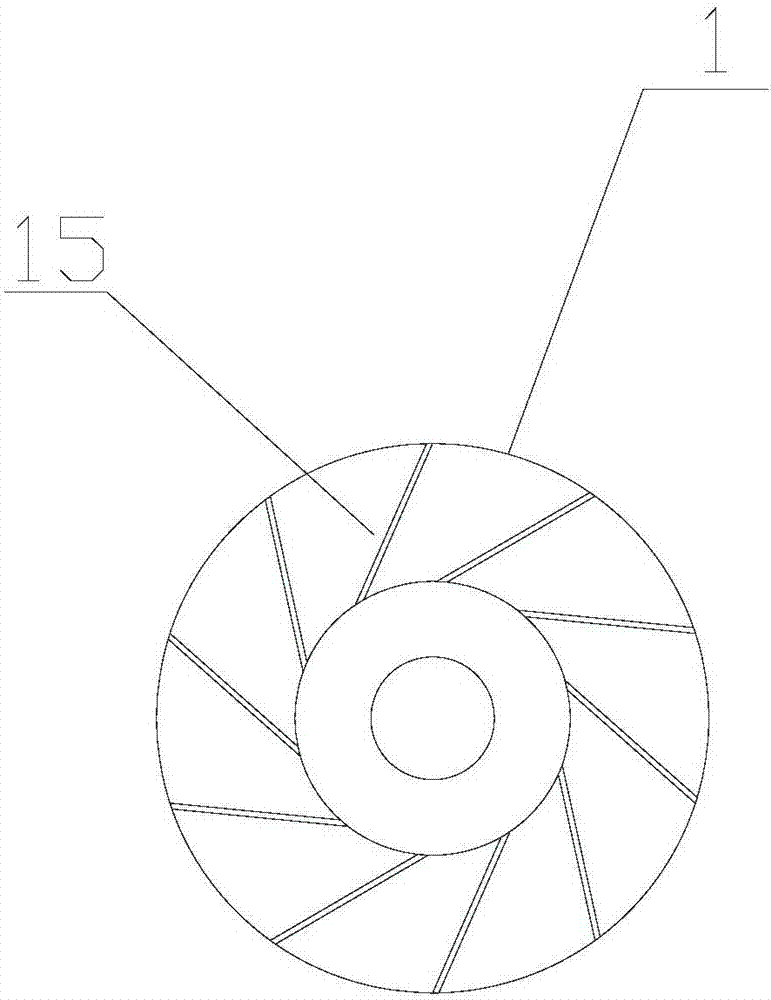

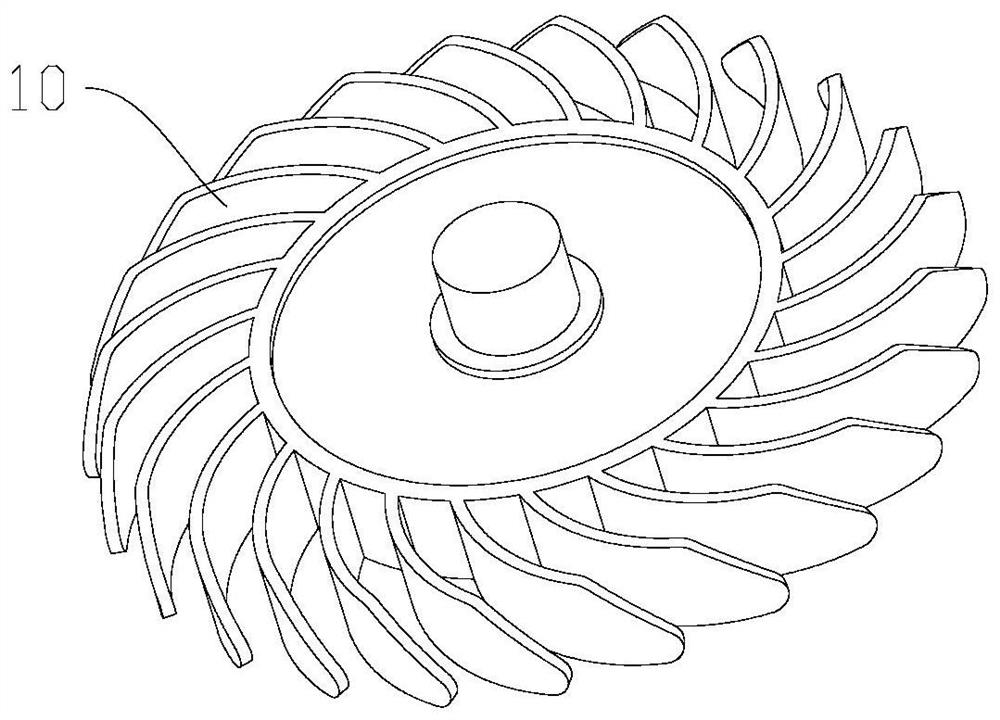

Large centrifugal blower

InactiveCN107100862AReduce starting loadGuaranteed force balancePump installationsNon-positive displacement fluid enginesImpellerEngineering

The invention provides a large centrifugal blower which comprises a shell. An impeller shaft penetrates through the center of the shell and is embedded into an impeller. A connecting plate is fixedly arranged on the side, close to the impeller, of the inner side wall of the shell. A spraying and blowing mechanism is fixedly arranged on the connecting plate and communicates with a stable-pressure gas storage tank. The spraying and blowing mechanism comprises an annular airflow distributor and a plurality of nozzles uniformly arranged on the circular surface of the annular airflow distributor. Compared with the prior art, the large centrifugal blower has the following beneficial effects that compressed air is sprayed and blown onto blades of the blower, so that the whole impeller of the blower is driven to rotate, then the blower is started after the speed is uniform, and accordingly, a starting load of the blower is reduced; and the annular distributor sprays and blows the impeller of the blower to generate couple, so that stress equilibrium of the impeller of the blower during starting is guaranteed.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

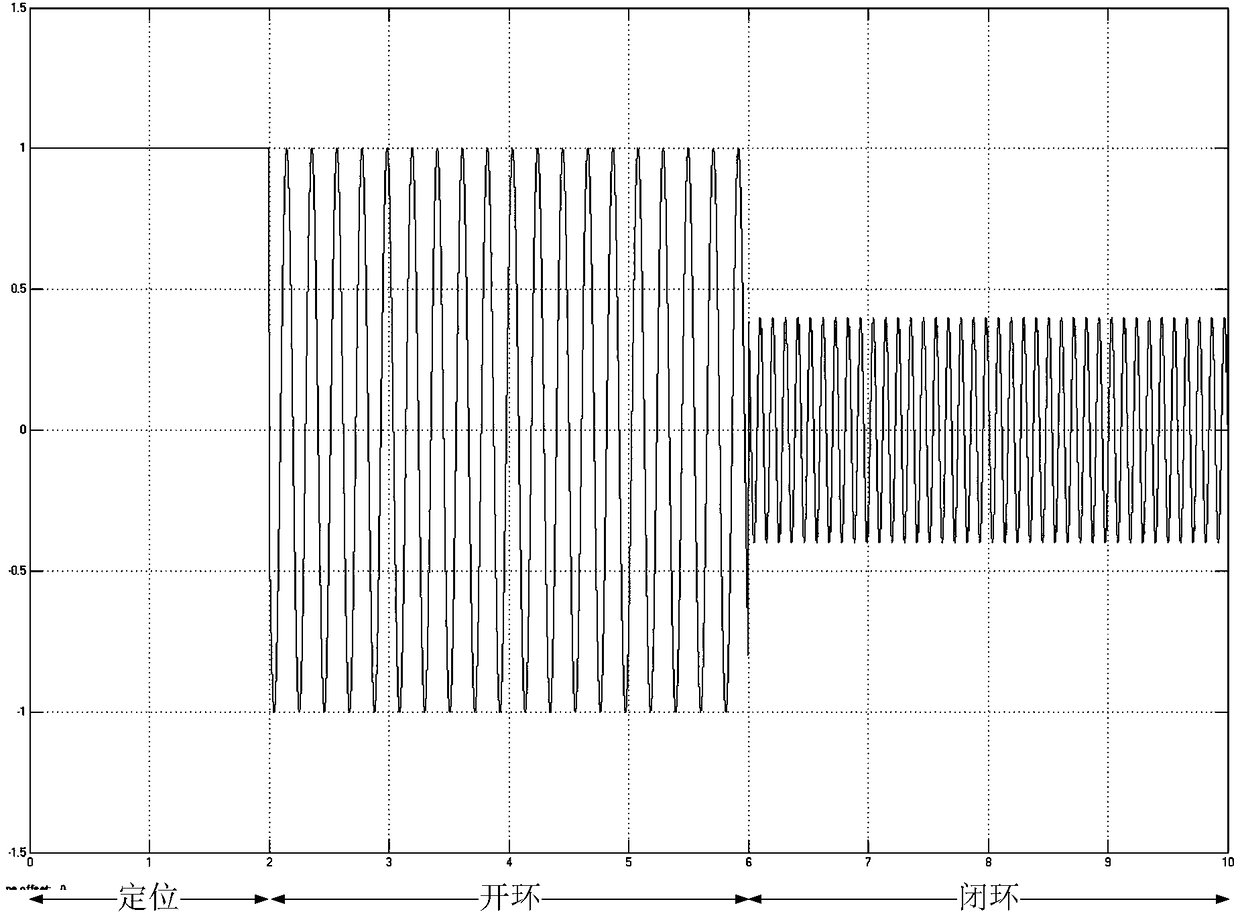

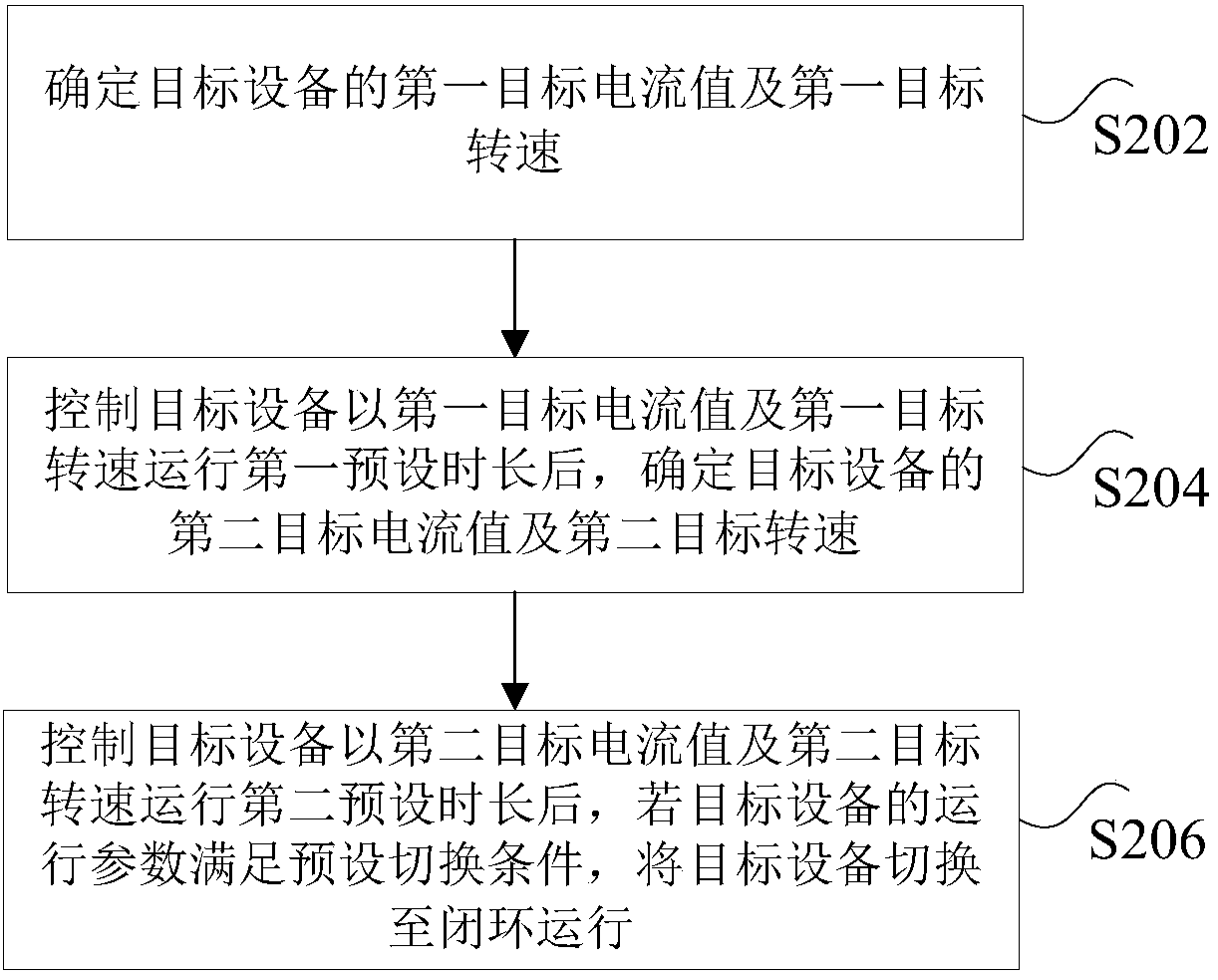

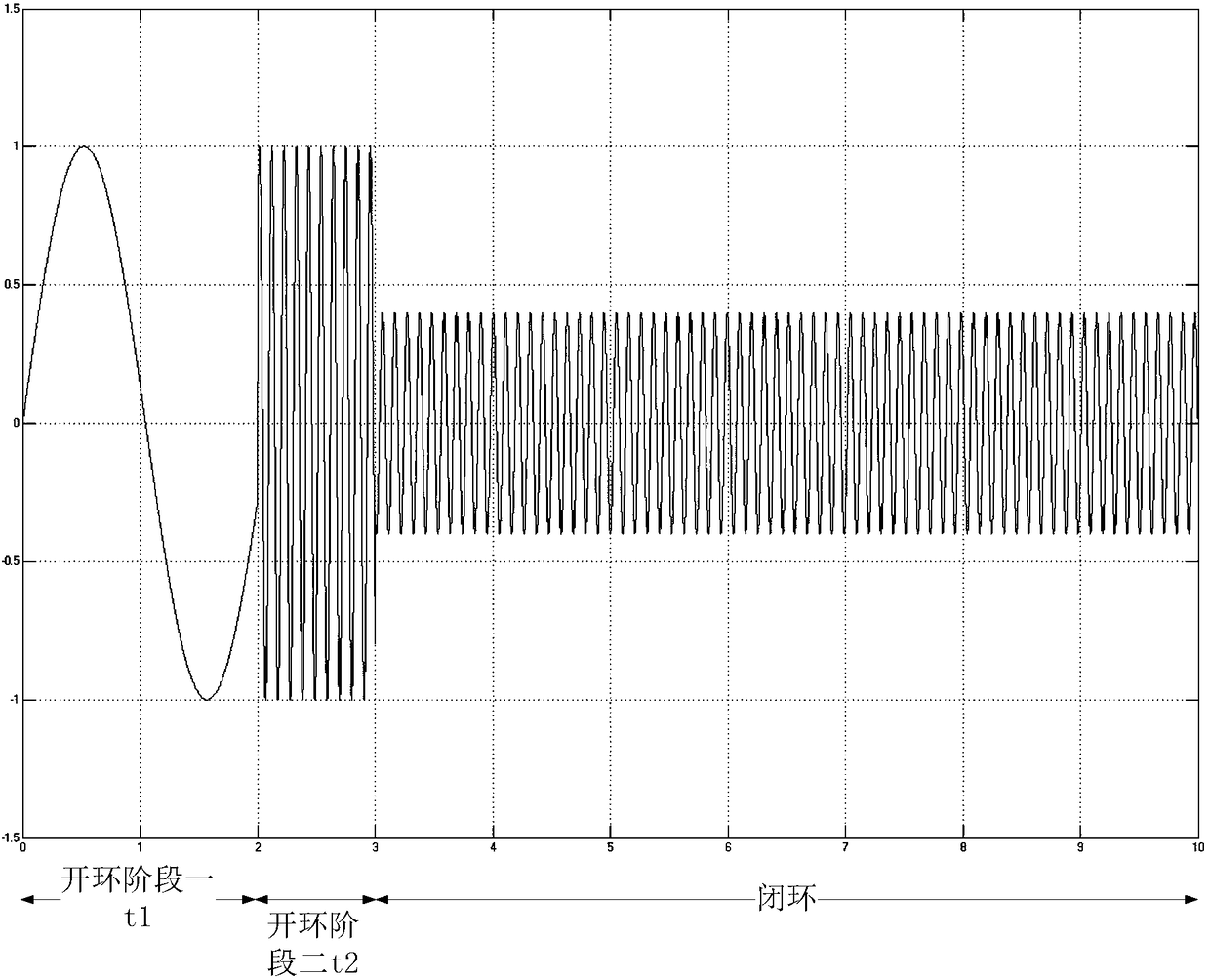

Start-up control method and device, processor

The invention discloses a startup control method and a device, a processor. The method comprises the following steps: determining a first target current value and a first target rotational speed of atarget device; Determining a second target current value and a second target rotational speed of the target device after controlling the target device to operate at the first target current value andthe first target rotational speed for a first preset time, wherein the second target rotational speed is greater than the first target rotational speed; After controlling the target device to run thesecond preset time with the second target current value and the second target rotational speed, if the operation parameters of the target device satisfy the preset switching condition, the target device is switched to the closed-loop operation. The invention solves the technical problems of demagnetization and vibration of motor and compressor caused by long-time large direct current electric positioning.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

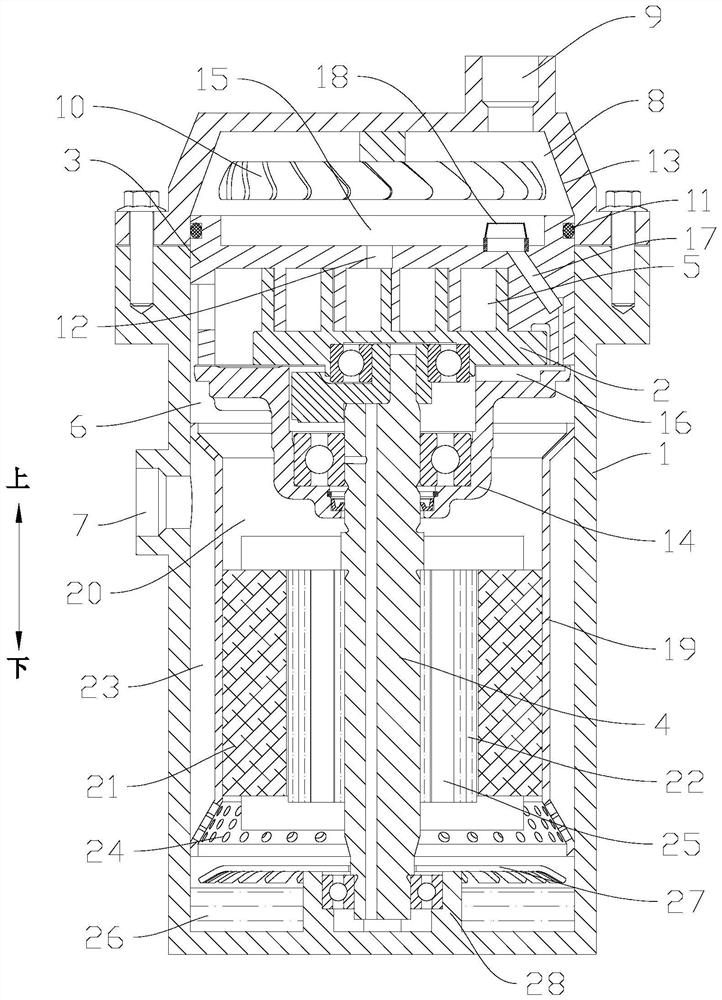

Scroll compressor and temperature regulating equipment

ActiveCN112065715AReduce oil outputReduce starting loadRotary piston pumpsRotary piston liquid enginesElectric machineryEngineering

The invention discloses a scroll compressor and temperature regulating equipment. The scroll compressor comprises a housing, a movable scroll plate, a stationary scroll plate, a crankshaft and a motorassembly. The movable scroll plate, the stationary scroll plate, the crankshaft and the motor assembly are arranged in the housing, the movable scroll plate and the stationary scroll plate are matched to form a compression cavity, a suction cavity is formed in a suction side of the compression cavity in the housing, a suction pipe communicating to the suction cavity is arranged on the housing, anexhaust cavity is formed in an exhaust side of the compression cavity in the housing, an exhaust pipe communicating to the exhaust cavity is arranged on the housing, a wind wheel is arranged in the exhaust cavity, and the wind wheel is used for guiding a refrigerant discharged from the compression cavity to collide with the inner wall of the exhaust cavity to achieve oil-gas separation. Accordingto the scroll compressor, the oil content of suction can be reduced, the oil spitting amount of the compressor can be reduced and the heat exchange capacity of a heat exchanger can be improved, so that the scroll compressor is more suitable for a compressor of special gas which has a strict limit on oil spitting amount.

Owner:WANBAO GROUP COMPRESSOR CO LTD

Hydraulic operation mechanism

InactiveCN107689304AReduce starting loadNormal oil supplySwitch power arrangementsEngineeringCentrifugal force

The invention relates to a hydraulic operation mechanism. A power part of the hydraulic operation mechanism comprises a pump, wherein the pump comprises a rotor; the rotating axial line of the rotor extends in the front and back direction; the cross section of the rotor is of a polygonal structure; convex edges tangential with a cylindrical hole are formed between the two adjacent edges; a liquidinlet hole and a liquid outlet hole which are separated by a separation plate are formed in the pump body; one end of the separation plate is matched with the outer peripheral surface of the rotor ina slide jacking and pushing manner. The hydraulic operation mechanism is characterized in that an oil guide passage communicating with the peripheral two sides of the convex edge is arranged in the position of each convex edge; a sealing and blocking block is assembled on the rotor in the radial direction of the rotor in a guide moving way; the sealing and blocking block has a first position for avoiding the oil guide passage in the moving stroke and a second position for sealing and blocking the oil guide passage through the outward movement under the effect of centrifugal force; a spring enabling the sealing and blocking block to be positioned in the first position through the acting force exertion on the sealing and blocking block is arranged on the rotor. The invention provides the hydraulic operation mechanism capable of reducing the motor starting load.

Owner:HENAN MECHANICAL & ELECTRICAL VOCATIONAL COLLEGE

Double-flywheel battery

InactiveCN101667762AIncrease limit speedReduce starting loadPower network operation systems integrationMechanical energy handlingElectric machineFast charging

The invention relates to an improved technique of a flywheel battery, in particular to a double-flywheel battery with high performance. The double-flywheel battery comprises a sealed outer enclosure arranged on an engine base, a rotating shaft, a bearing, a main motor rotor connected with the rotating shaft, a main motor stator arranged on the inner surface of the outer enclosure and correspondingto the main motor rotor, a vacuum nozzle and an electric power electron switching device. The double-flywheel battery is characterized in that two sides of the rotating shaft are provided with a flywheel component respectively, each flywheel component comprises a pair of flywheel bodies and support frames for mounting the flywheel bodies, and the support frames are fixedly connected with the rotating shaft. The double-flywheel battery not only can increase the accumulation energy of the flywheel, but also can improve the limit rotating speed of the flywheel, thereby having the advantages of large accumulation energy capacity, good effect, fast charging, low energy consumption, high efficacy, long service life and no pollution.

Owner:福建宇力高新能源开发有限公司

Vehicle generator control method and system thereof

ActiveUS20200072138A1Increase capacityAvoid interferenceElectrical controlInternal combustion piston enginesIn vehicleControl system

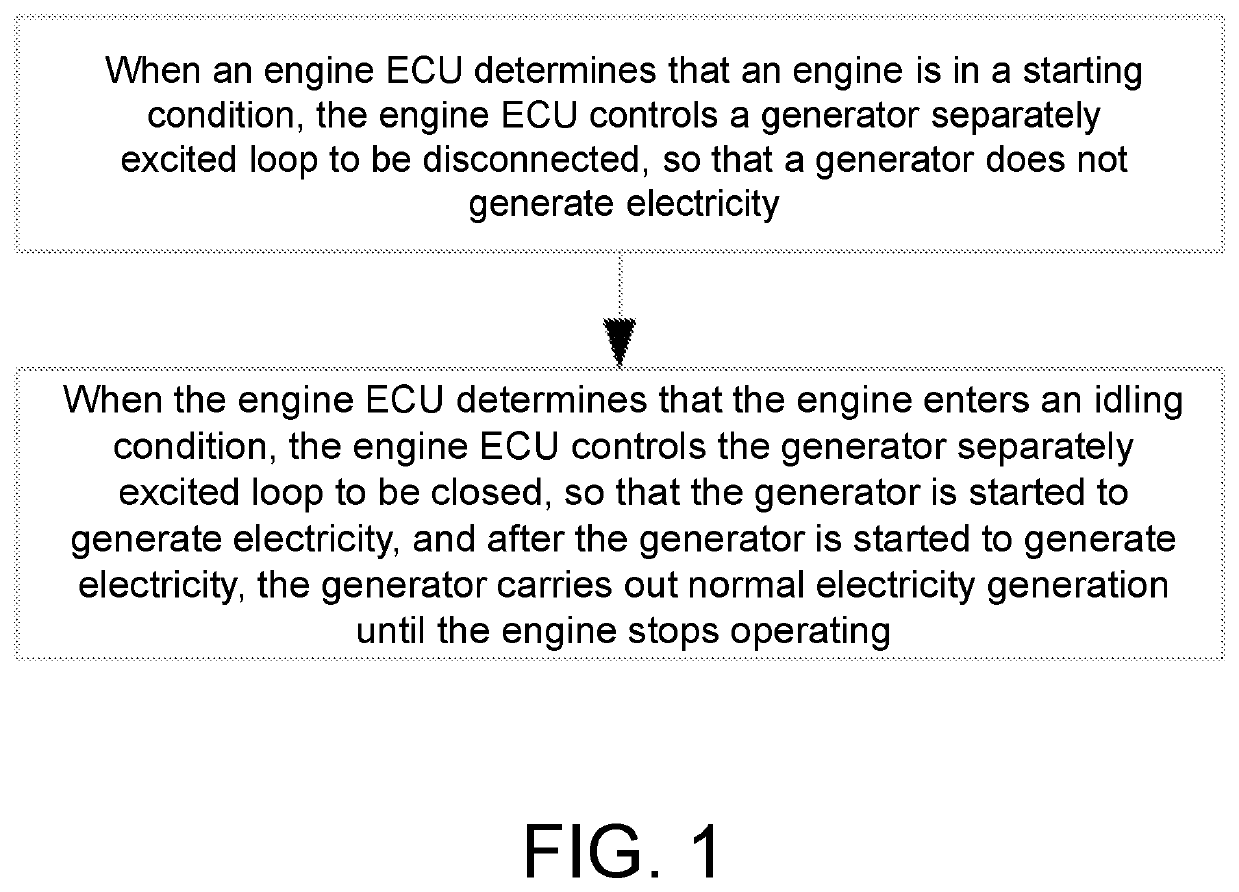

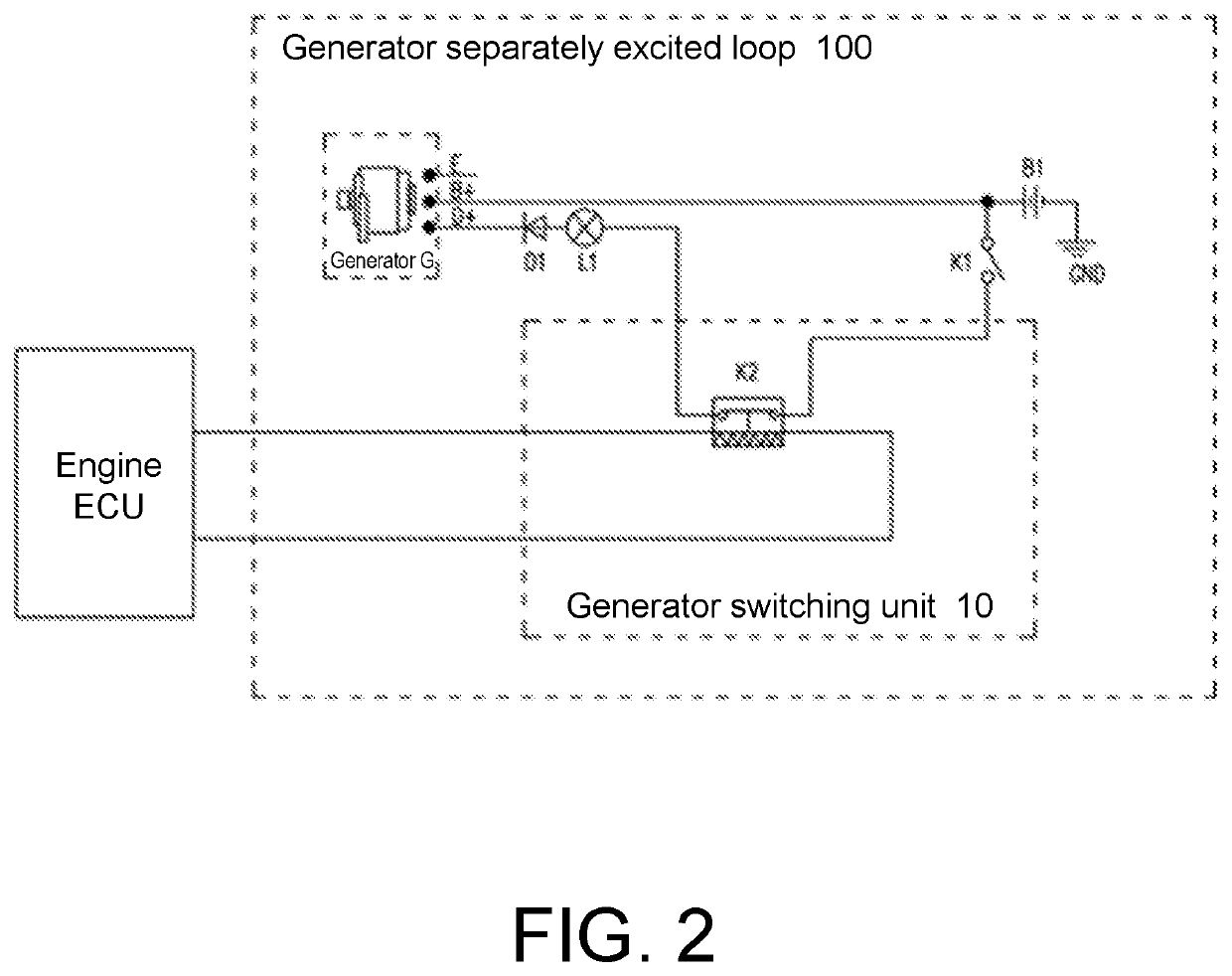

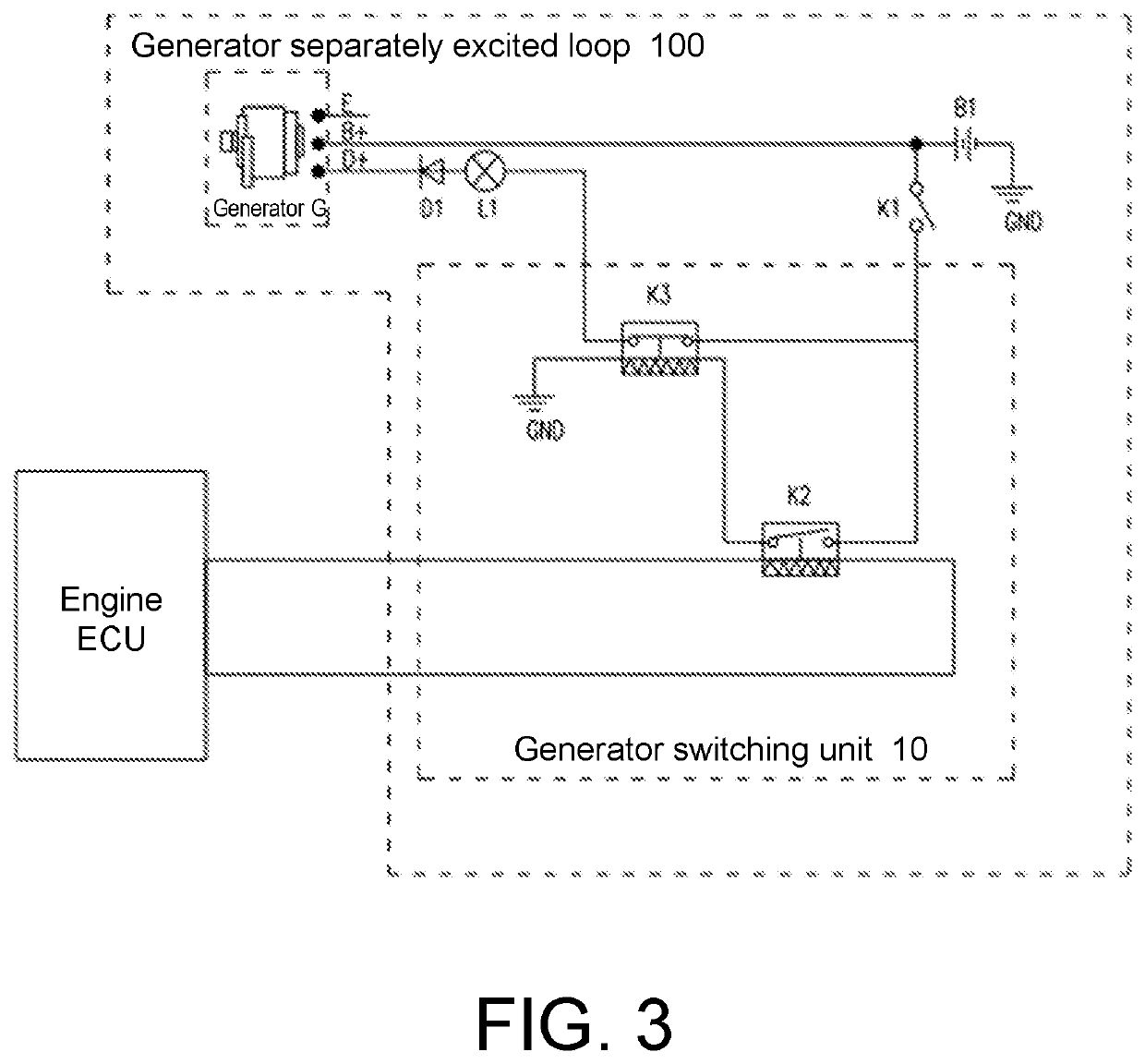

Provided is a vehicle generator control method. An engine ECU controls the generator according to an operating condition of the engine, and the control process is as follows: when the engine ECU determines that the engine is in a starting condition, the engine ECU controls a generator separately excited loop to be disconnected, so that the generator does not generate electricity; and when the engine ECU determines that the engine enters an idling condition, the engine ECU controls the generator separately excited loop to be closed, so that the generator is started to generate electricity, and after the generator is started to generate electricity, the generator carries out normal electricity generation until the engine stops operating. Through the vehicle generator control method, the starting load of the engine can be effectively reduced, and cold starting capacity is improved. Also provided is a vehicle generator control system.

Owner:GUANGXI YUCHAI MASCH CO LTD

Power device

InactiveCN107448381AReduce starting loadAvoid stickingRotary piston pumpsRotary piston liquid enginesLongest DiameterEngineering

The invention relates to a power device. The power device comprises a pump which comprises a pump body; a rotor is arranged in the pump body; the two ends of a long diameter direction of the rotor are provided with a plurality of oil guiding channels communicated with the two sides of the peripheral direction of the rotor; the oil guiding channels at each end are arranged at intervals in the axial direction of the rotor; a partitioning part located between every two adjacent oil guiding channels at the same end of the rotor is used for being in supporting fit with a partition plate; a sealing block is movably assembled in the rotor in the long diameter direction in a guiding manner; the sealing block is provided with a first position avoiding the oil guiding channels and a second positioning moving outwards under the effects of the centrifugal force to block the oil guiding channels in the movement travel of the sealing block; and the rotor is provided with a spring applying the acting force onto the sealing block to make the sealing block located at the first position. The power device can reduce the starting load of a motor.

Owner:HENAN MECHANICAL & ELECTRICAL VOCATIONAL COLLEGE

A motor reciprocating drive linear pumping machine

InactiveCN105370246AReduce starting loadShort mechanical transmission lineFluid removalElectric machineryTop dead center

The invention provides a motor reciprocating drive linear pumping machine comprising a control box and a pumping device. Control buttons are arranged on the lower side of a display screen. The pumping device comprises a drive motor, a precision reducer and a pinion. A polish rod of a sucker rod penetrates a central hole of a rack and extends out to the upper end surface of the rack. During ascend, the rack drives the sucker rod to move upward from a bottom dead center to finish a travel and reach a top dead center. At the beginning of operation start, a buffer spring at the bottom of a support cylinder releases stored energy to reduce the start current of the drive motor and increase the start torque. During descend, under the effect of the gravity of a load, the rack drives the sucker rod to move downward from the top dead center to finish a travel and reach the bottom dead center; when approaching the bottom dead center, the energy storage buffer spring begins to absorb energy and reduces the impact generated when the rack reaches the bottom dead center. The motor reciprocating drive linear pumping machine is high in efficiency, simple in structure, easy to install and transport, and small in noise, and is especially suitable for cities and regions with complex terrain and inconvenient traffic.

Owner:DINKUM TIANJIN

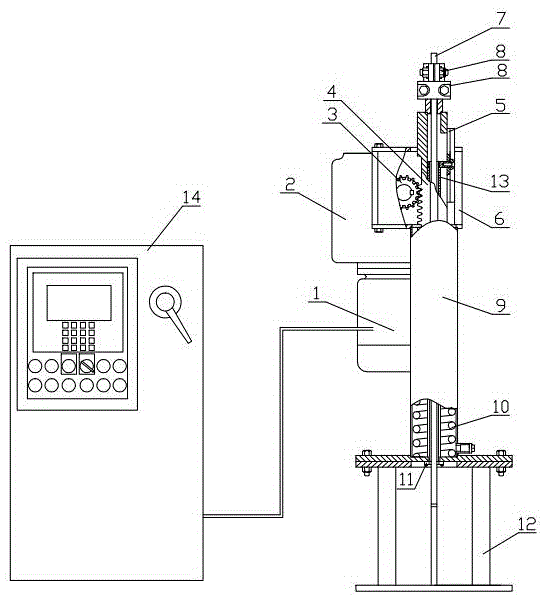

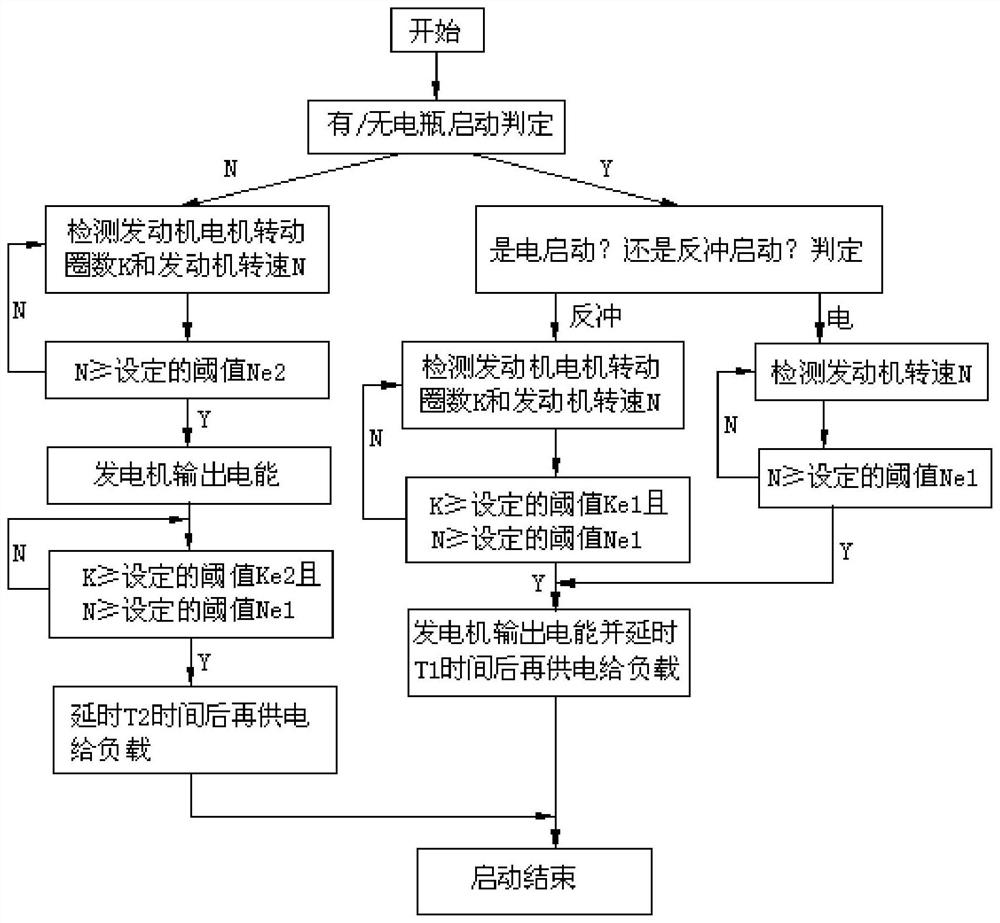

Control method for reducing starting load of engine

InactiveCN112922762AReduce starting loadImprove startup success rateMuscle operated startersElectric motor startersElectric machineControl theory

The invention discloses a control method for reducing the starting load of an engine. The control method comprises the following control steps that a controller judges the starting mode of the engine, if the engine adopts an electric starting mode, and when the rotating speed N of the engine is greater than or equal to the threshold Ne1, the controller controls a generator to output electric energy, and controls the generator to supply power to the load after time delay T1; if the engine adopts a storage battery recoil starting mode, when the number of rotation turns K of an engine motor is larger than or equal to the threshold Ke1 and the rotation speed N of the engine is larger than or equal to the threshold Ne1, the controller controls the generator to output electric energy, and the generator is controlled to supply power to the load after time delay T1; and if the engine adopts a battery-free recoil starting mode, when the rotating speed N of the engine is larger than or equal to the threshold Ne2, the controller controls the generator to output electric energy, and when the number of rotation turns K of the engine motor is larger than or equal to the threshold Ke2 and the rotation speed N of the engine is larger than or equal to the threshold Ne1, power is supplied to the load after time delay T2. According to the control method, the starting load of the engine at the initial starting stage can be reduced, and the starting success rate of the engine is greatly increased.

Owner:苏州巩诚电器技术有限公司

Scroll compressor with back pressure chamber cavity for assisting in start-up

ActiveUS20070297929A1Reduce loadSmall compressionEngine of arcuate-engagement typeOscillating piston enginesEngineeringRefrigerant

A scroll compressor is provided with a cavity in its back pressure chamber to increase a volume of the back pressure chamber. In this manner, at start-up, the back pressure chamber will not be effective to bias the two scroll members together until this enlarged volume is filled with a compressed refrigerant. This reduces the load on the electric motor at start-up.

Owner:DANFOSS (TIANJIN) CO LTD

Switch cabinet

InactiveCN107317252AImprove oil pressure resistanceReduce starting loadSwitchgear detailsSwitch power arrangementsLongest DiameterEngineering

The invention relates to a switch cabinet which comprises a cabinet. Moving contacts, static contacts and hydraulic operating mechanisms for driving the moving contacts to act are arranged in the cabinet, power portions of the hydraulic operating mechanisms comprise motors and pumps, the pumps comprise pump bodies, rotors are arranged in the pump bodies, the cross section of each rotor has two tangent points with a cylindrical inner hole, liquid inlet holes and liquid outlet holes which are separated from one another by partition plates are formed in the pump bodies, one end of each partition plate is in slide pushing fit with the peripheral surface of the corresponding rotor, oil guide channels are arranged at two ends of the long-diameter direction of each rotor, two peripheral sides of each rotor are communicated with each other via the corresponding oil guide channels, plugging blocks are further movably assembled in the rotors in a guide manner along the long-diameter directions of the rotors and have first locations and second locations in movement stroke of the plugging blocks, the oil guide channels can be avoided by the plugging blocks at the first locations, the plugging blocks at the second locations can move outwardly under the effect of centrifugal force to plug the oil guide channels, springs are arranged on the rotors, and acting force can be applied to the plugging blocks by the springs, so that the plugging blocks can be forced to be positioned at the first locations. The switch cabinet has the advantage that starting load of the motors can be reduced.

Owner:HENAN MECHANICAL & ELECTRICAL VOCATIONAL COLLEGE

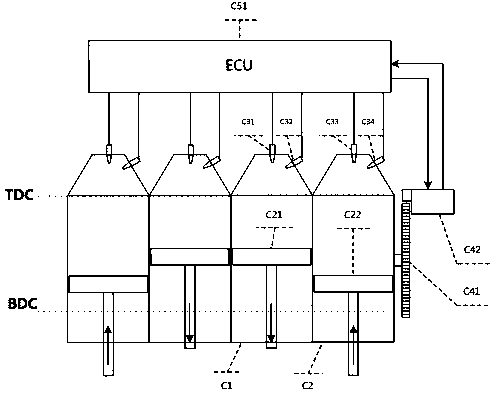

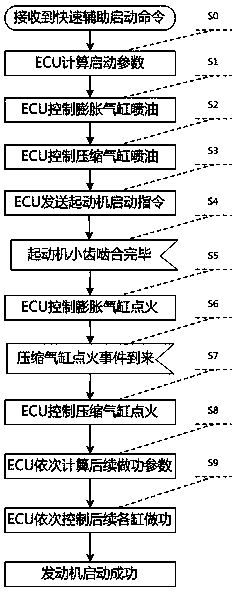

Assisted start control method for in-cylinder direct injection engine starter

InactiveCN109340011AReduce starting loadSmall starting currentElectric motor startersMachines/enginesStart timeTime duration

The invention relates to an assisted start control method for an in-cylinder direct injection engine starter. The method is characterized by comprising the specific steps that a starter assisted startmodule in an ECU receives a quick assisted start command; an engine start parameter is calculated according to a precise stop phase position stored in the ECU; under the circumstance that the engineis stationary, the ECU controls an oil atomizer of an expansion cylinder to inject fuel into the expansion cylinder according to the fuel injection time duration of the expansion cylinder; and the ECUcan achieve effective matching of acting of the expansion cylinder with a starting torque of the starter through an engaged feedback signal of the starter, so that the starting load of the starter isreduced to the maximum extent and the starting currents of the starter and a storage battery are reduced. As the starting process is directly started from the expansion cylinder, a process of recognizing engine synchronization by the ECU is cancelled, so that the starting time is shortened.

Owner:CHINA FIRST AUTOMOBILE

Hydraulic-pressure power device and pump thereof

ActiveCN107288870AReduce starting loadAvoid forceRotary piston pumpsRotary piston liquid enginesEngineeringCentrifugal force

The invention relates to a hydraulic-pressure power device and a pump thereof. The pump includes a pump body with a cylindrical-hole inner cavity, a rotor of which the rotation axis extends in the front-and-rear direction is arranged in the pump body, the section of the rotor is of a polygon structure, ribs tangent to a cylindrical hole are formed between every two adjacent edges, a liquid inlet hole and a liquid outlet hole which are separated by a partition plate are formed in the pump body, one end of the partition plate is matched with the peripheral face of the rotor in a sliding and pushing mode, each rib is provided with an oil guide channel communicated with the two sides of the circumference of the rib, and plugging blocks are mounted on the rotor in a guiding and moving mode in the radial direction of the rotor; in the movement range of the plugging blocks, each plugging block has a first position and a second position, wherein when at the first positions, the plugging blocks step aside from the oil guide channels, and when at the second positions, the plugging blocks move outward under the effect of centrifugal force to plug the oil guide channels; springs are arranged on the rotor, wherein the springs are used for exerting acting force on the plugging blocks to force the plugging blocks to be located at the first positions. The pump capable of reducing a starting load and the hydraulic-pressure power device using the pump are provided.

Owner:DALIAN HERMETIC PUMP

Method for replacing producing well shaft casing pipe

PendingCN109798081AHigh precisionImprove reliabilityDrilling rodsSealing/packingButt jointWell cementing

The invention relates to a method for replacing a producing well shaft casing pipe. The method sequentially includes the steps of firstly, using a packer to block the inner cavity of a residual casingpipe; secondly, using a hydraulic inner cutter to cut off the abraded casing pipe on the upper portion of the residual casing pipe; thirdly, pulling out the cut casing pipe; fourthly, mounting a casing pipe mill shoe at the bottom of a drilling tool to mill a fish top outer chamfer at the fish top of the residual casing pipe; fifthly, mounting a float collar and a new casing pipe at the upper endof a cementing tool; sixthly, lowering the drilling tool to allow the fish top to smoothly enter an externally-inserted guide shoe, continuously lowering the drilling tool to allow the fish top to reach a lengthening cylinder, and starting a pump to circulate workover fluid; seventhly, injecting cement slurry after the circulation is normal to allow the cement slurry to enter the annulus throughcement injection holes; eighthly, putting in a rubber plug, and pushing the rubber plug to the top of the float collar to achieve setting; ninthly, lowering the drilling tool again until the fish topouter chamfer and a butt joint connector inner chamber are connected in an embedded manner, and pressing down 500kN to achieve casing pipe butt joint and sealing. The method is simple, practicable, convenient to operate, low in production cost and downhole risks, simple in butt joint and setting operation and high in sealing reliability.

Owner:SINOPEC SSC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com