A motor reciprocating drive linear pumping machine

A reciprocating drive and drainage technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of adjustment, maintenance and repair of beam pumping units, low pumping unit system efficiency, and installation costs. The problem of large space is needed to achieve the effect of easy maintenance and repair, small wellhead operation area, and improved mechanical efficiency and system efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

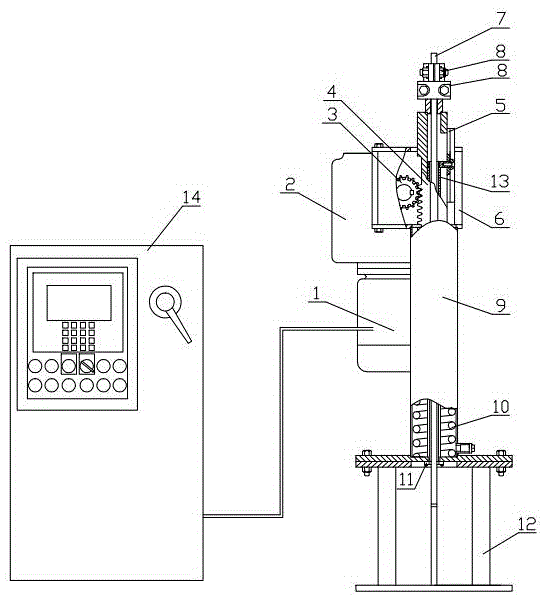

[0013] The motor reciprocating drive linear extraction machine of the present invention mainly comprises control box and extraction machine, and control box comprises control box main body 14, display screen 15, control button 16, and display screen 15 is installed on control box main body 14, and display screen 15 There is a control button 16 on the side, and the extraction machine includes a drive motor 1, a precision reducer 2, a pinion 3, a rack 4, a sliding track 5, a gear box 6, a sucker rod polished rod 7, a fixed clamp 8, and a support cylinder 9 , buffer spring 10, guide copper ring 11, support 12, sleeve pipe 13, drive motor 1 is a three-phase asynchronous induction drive motor 1 controlled by a frequency converter, and is installed and fixed on the lower end of precision reducer 2. The gear transmission mechanism is composed of a pinion 3 and a rack 4 that cooperate with each other. The pinion 3 is directly installed at the output end of the reducer, the rack 4 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com