Assisted start control method for in-cylinder direct injection engine starter

An in-cylinder direct injection and engine technology, which is used in engine starting, engine motor starting, and engine components, etc., can solve problems such as engine start failure, tooth punching, and resultant force formation, shortening start-up time, reducing system costs, The effect of reducing the startup load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

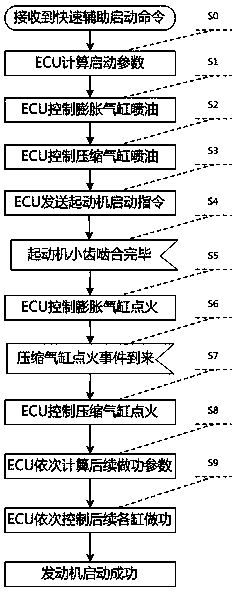

[0029] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0030] The basic idea of the present invention is to make the working moment of the expansion cylinder coincide with the maximum moment of the starting torque of the starter according to the meshing feedback signal of the starter, so as to reduce the starting torque to the greatest extent and make full use of the working torque of the expanding cylinder during the engine starting process, Reduce startup time.

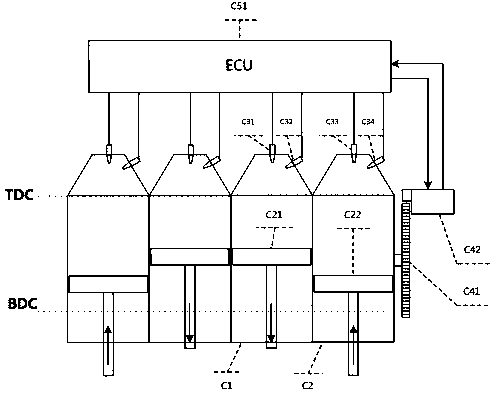

[0031] A schematic diagram of a shutdown state of the engine of this embodiment is as follows Figure 1-2 As shown, the expansion cylinder C1 is a cylinder in which the piston descends and the intake and exhaust valves are closed after the shutdown; the compression cylinder C2 is a cylinder in which the piston ascends and the intake and exhaust valves are closed after the shutdown. In this embodiment, the working conditions of the expansion cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com