Control method and device for reducing starting load of excavator

A control method and technology for excavators, which are applied in the directions of earthmoving machines/shovels, construction, etc., can solve the problems of expensive preheating devices, increase maintenance costs, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

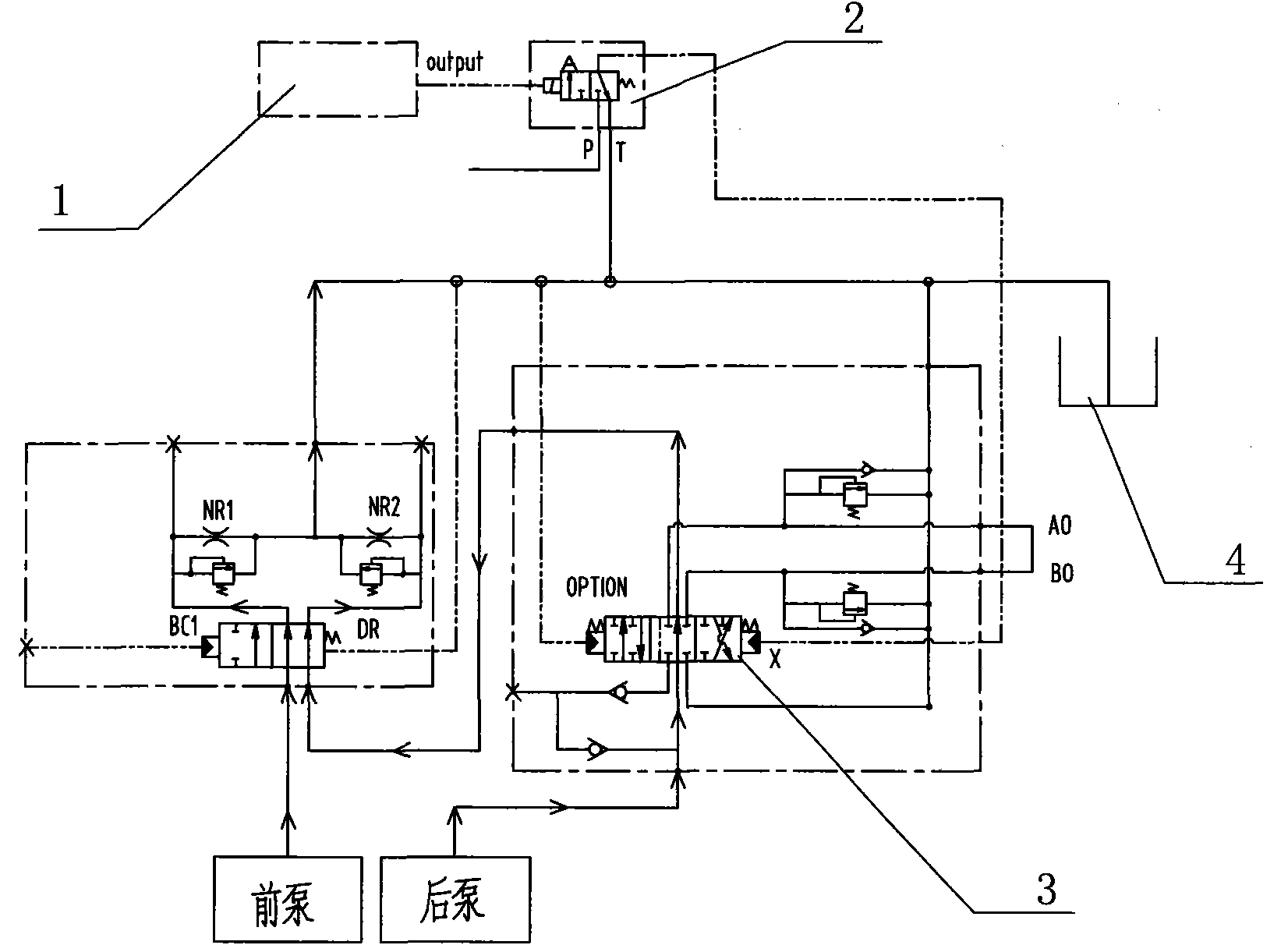

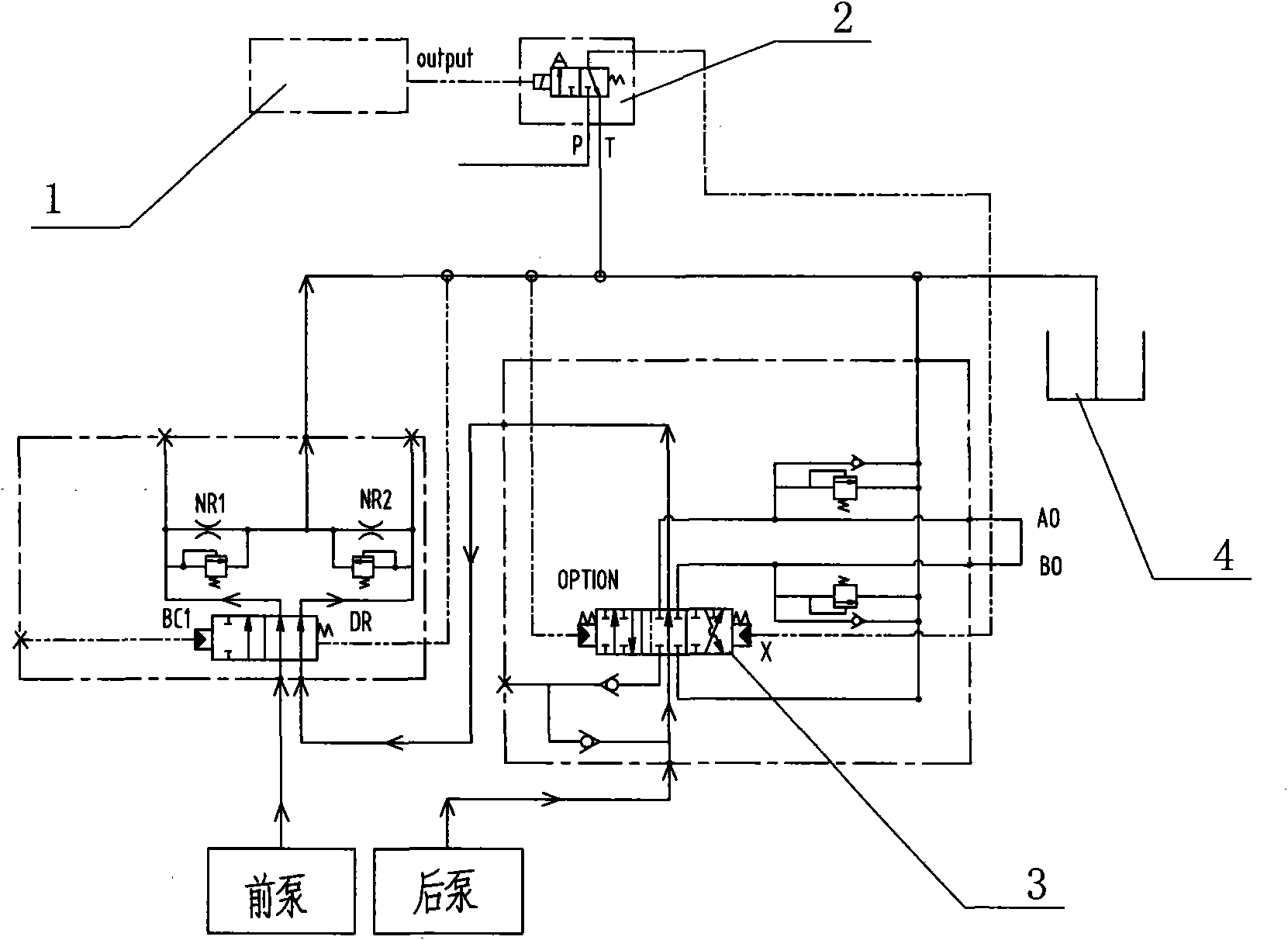

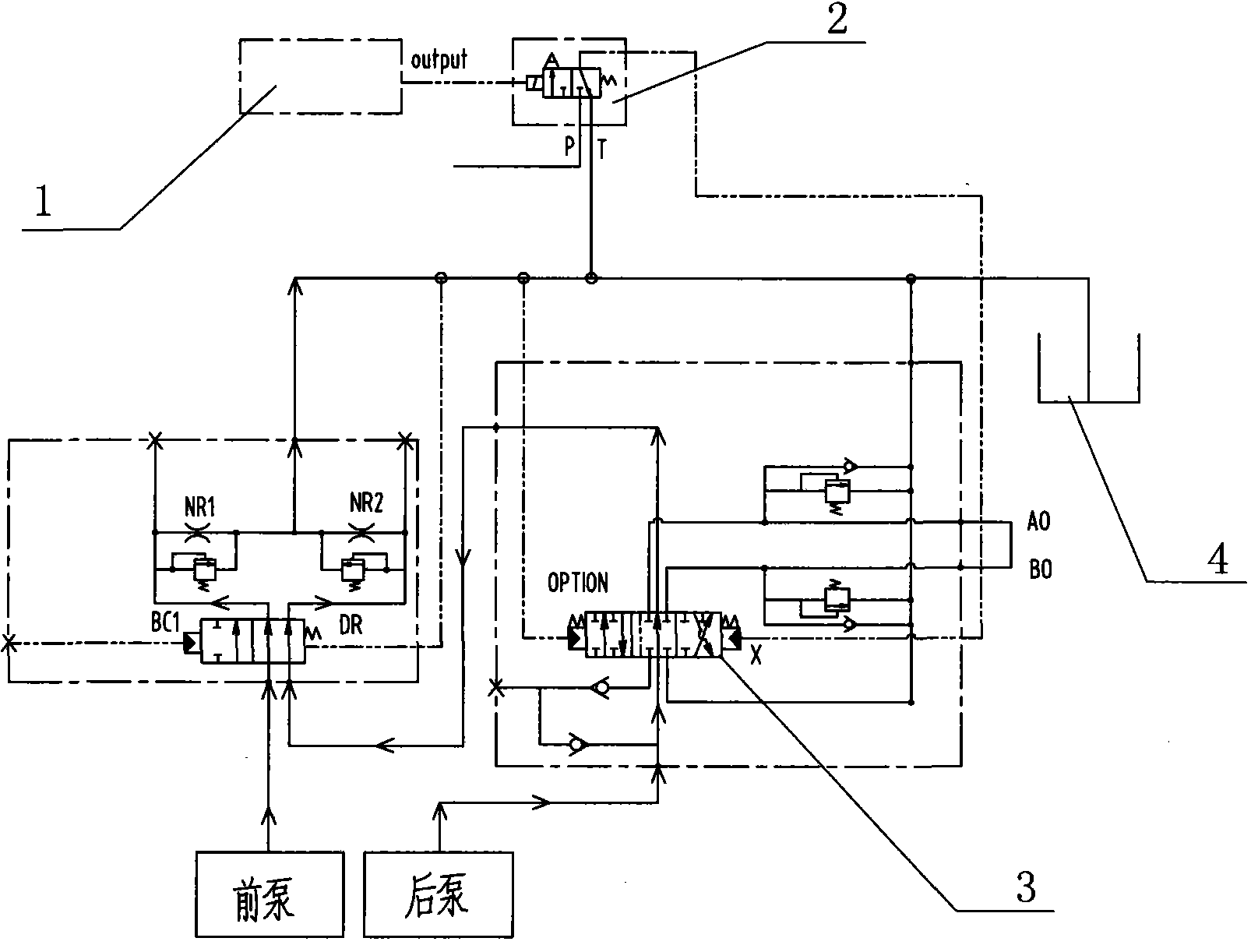

[0017] Embodiment one: see figure 1 , 2 As shown, a device for reducing the starting load of an excavator includes a solenoid valve control switch 1 and a solenoid valve 2, the oil inlet P of the solenoid valve 2 is connected to the oil outlet of the pilot oil pump, and the output of the solenoid valve 2 Port A is connected to the control oil port X of the spare valve 3, and the oil return port T of the solenoid valve is connected to the oil return pipeline.

[0018] see figure 1 As shown, when the solenoid valve control switch 1 is not opened, the solenoid valve 2 is closed. When the engine is started at low speed, because the solenoid valve spool is not opened, there is no pilot pressure to push the backup valve to open, so the flow generated by the pump before the engine starts immediately passes through The bucket confluence valve and negative feedback valve are throttling and then flow back to the fuel tank; the flow generated by the rear pump is throttled by backup val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com