Exterior wall tile composite structure and method for manufacturing same

A composite structure and production method technology, applied in the direction of chemical instruments and methods, layered products, building structures, etc., can solve the problems of affecting appearance effects, surface cleaning differences, tiles falling off, etc., and achieve good decorative effects and decorative quality. High assembly construction efficiency, safety, reliability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

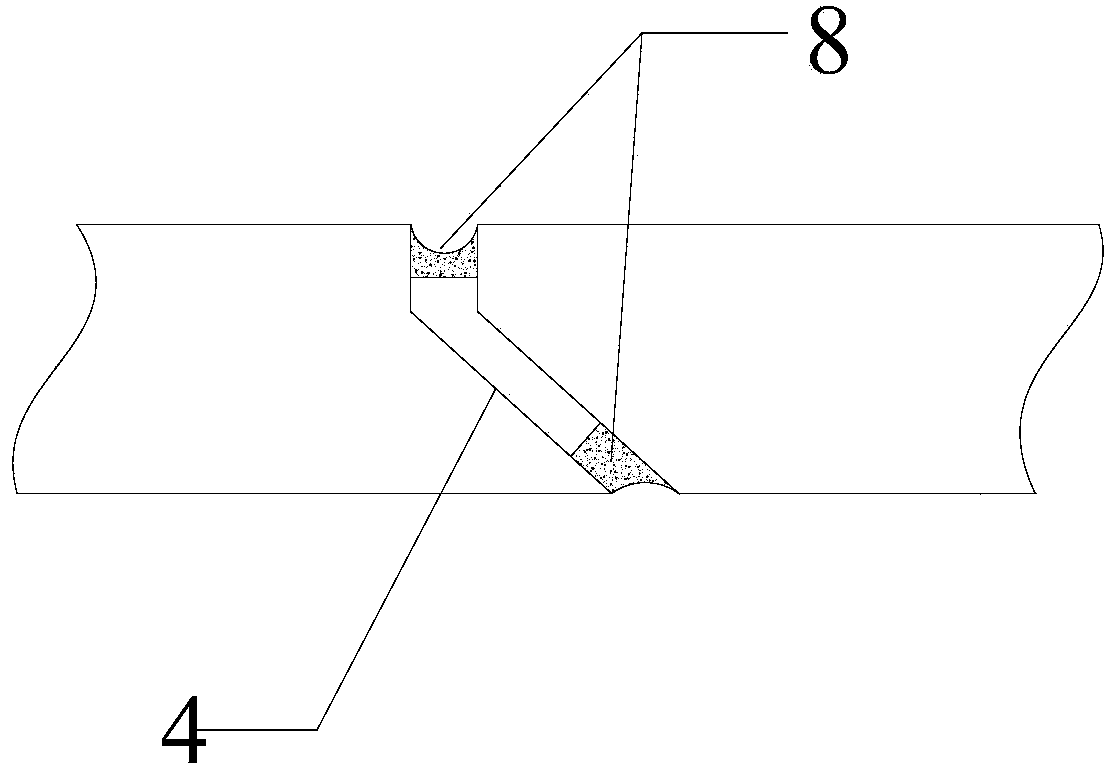

[0017] Such as Figure 1-4 Shown, a kind of production method of exterior wall brick composite structure comprises the following steps:

[0018] Spread mortar on one side of the inorganic board 1, and then scrape the mortar flat;

[0019] The tiles 3 are placed on the mortar surface, after which they are punched and formed.

[0020] A composite structure of exterior wall bricks, comprising an inorganic board 1, one side of the inorganic board 1 is bonded with a ceramic tile 3 through an adhesive layer 2.

[0021] The production method of a composite structure of exterior wall bricks and the composite structure of exterior wall bricks provided by the above-mentioned embodiments are fixed on the wall by dry hanging or a combination of wet sticking and dry hanging, so that the thermal insulation system is no longer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com