Multi-mode synchronous advancement and assembly system of shield tunneling machine and control method of multi-mode synchronous advancement and assembly system

A multi-mode, shield machine technology, applied in fluid pressure actuated system components, mechanical equipment, earthwork drilling and mining, etc., can solve the problems of mutual constraints between the advancing process and the assembling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

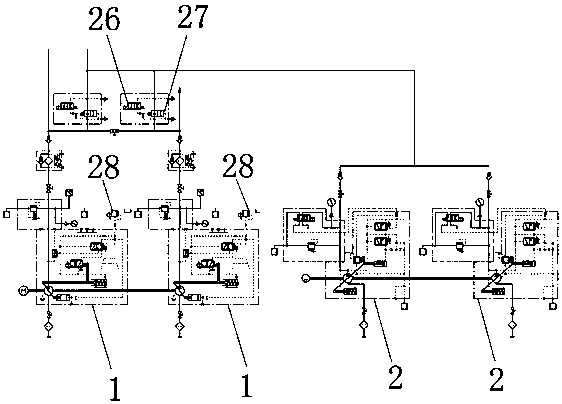

[0047] Embodiment 1, a shield machine multi-mode synchronous propulsion, assembly system, such as figure 2 As shown, it includes a propulsion pump source 1 and an assembly pump source 2 connected to the PLC control unit. The propulsion pump source 1 is used to provide power for shield machine propulsion, and the assembly pump source 2 is used to provide power for assembly.

[0048] like figure 1 As shown, the propulsion pump source 1 and the assembled pump source 2 are connected to the oil cylinder group through the hydraulic valve group, and the oil cylinder group is connected to the oil return circuit 31, and the propulsion pump source 1 and the assembled pump source 2 are connected to the oil cylinder group through the hydraulic valve block. Oil is supplied, and then the extension and retraction of the oil cylinder group are realized. When the oil cylinders of the oil cylinder group are extended and retracted, the corresponding hydraulic oil in the cylinder cavity is retur...

Embodiment 2

[0059] Embodiment 2, a shield machine multi-mode synchronous propulsion and assembly system, the large group of valve blocks 3 is connected with an external control oil source through the external control oil circuit 32, the external control oil circuit 32 includes the first shuttle valve 15, the first shuttle valve One oil inlet end of 15 is connected to the external control oil source, and the other oil inlet end is connected to the assembled mode rodless chamber oil return oil circuit between the rodless chamber of the cylinder group and the rodless chamber oil return valve 13, the first shuttle valve 15 The oil outlet end is connected with the rodless chamber oil return valve 13 through the second electromagnetic reversing valve 14, and the second electromagnetic reversing valve 14 is connected with the PLC control unit.

[0060] When advancing or assembling, the pressure in the rodless chamber of the cylinder group continues to increase, and it is necessary to ensure that ...

Embodiment 3

[0062] Embodiment 3, a shield machine multi-mode synchronous propulsion and assembly system, the external control oil circuit 32 includes a second shuttle valve 25, one oil inlet end of the second shuttle valve 25 is connected with the external control oil source, and the other oil inlet The end is connected on the rodless chamber oil inlet oil path of the assembly mode between the rodless chamber of the oil cylinder group and the second oil inlet valve 17 of the assembly mode, and the oil outlet end of the second shuttle valve 25 is connected with the assembly mode through the third electromagnetic reversing valve 18. The second oil inlet valve 17 is connected to each other, and the third electromagnetic reversing valve 18 is connected to the PLC control unit.

[0063] During assembly, the oil of the assembled pump source 1 needs to enter the rodless cavity of the cylinder group through the second oil inlet valve 17 in the assembled mode. In the pressure maintaining state, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com