Construction method for rapidly installing pipelines in pipe gallery

A construction method and technology for inner pipes, which are applied in the directions of pipe laying and maintenance, pipes/pipe joints/pipes, artificial islands, etc., can solve the problems of narrow space, slow welding speed, heavy pipe sections, etc., and achieve easy assembly and disassembly, The effect of improving transportation speed and speeding up construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

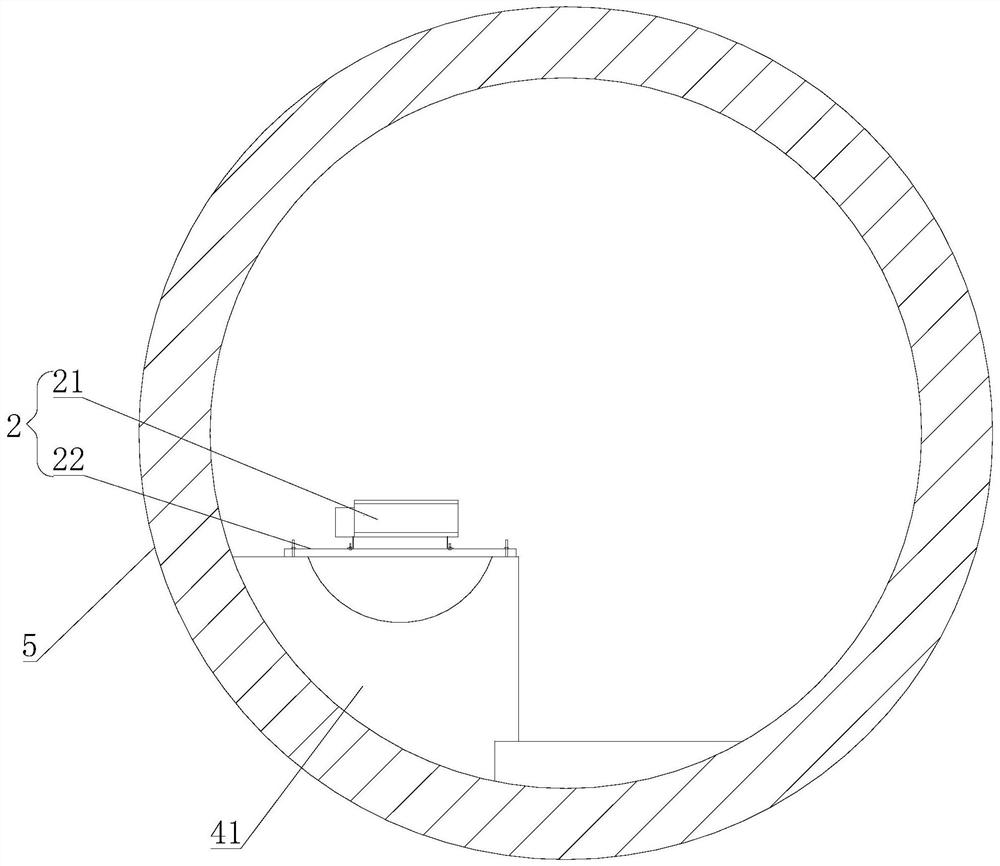

[0030] Such as Figure 1 to Figure 9As shown, a construction method for quick installation of pipelines in a pipe gallery provided in this embodiment, in order to facilitate the transportation and assembly of pipe joints, and speed up the construction efficiency of pipeline assembly. Further, the construction method for quick installation of pipelines in the pipe gallery includes step A of group welding of pipelines outside the gallery, step B of pipeline transportation in the gallery, step C of welding between groups of pipelines in the gallery, and step D of pipeline assembly. In the group welding step A, a plurality of pipe joints are welded into a pipe group 6 outside the pipe gallery 5, and then the pipeline transportation step B is adopted in the gallery, and a plurality of pulley blocks 1 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com