Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134results about How to "Guaranteed repeat positioning accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plane wing titanium alloy thin-wall web efficient numerical control machining technology

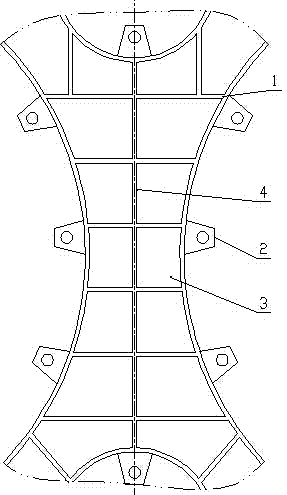

A plane wing titanium alloy thin-wall web efficient numerical control machining technology comprises the following steps that (1) blanking is carried out; (2) web outer contour machining is carried out, and an ear piece for locating is machined; (3) a web is clamped, and a cavity on the front face of the web is machined; (4) a web side wall is machined; (5) web quick converting is carried out, and a cavity on the back face of the web is machined; (6) the locating ear piece is removed by milling; and (7) quality testing is carried out. The rigidity of a machining technology system is improved, unstressed machining is achieved, by optimized design of a feed track, the stability of a machining process is improved, machining speed is increased, titanium alloy shallow cutting large feeding milling technology parameters are used, heat deforming during machining is lowered, rectifying processes are omitted, the metal removing rate is improved by 30%-50%, finally, machining efficiency is obviously improved, the clamping time of workpieces is obviously shortened through a quick-reloading technology, the repeated locating accuracy of clamping is guaranteed, and accordingly numerically-controlled machine tool machining efficiency is greatly improved.

Owner:HUANGHE S & T COLLEGE

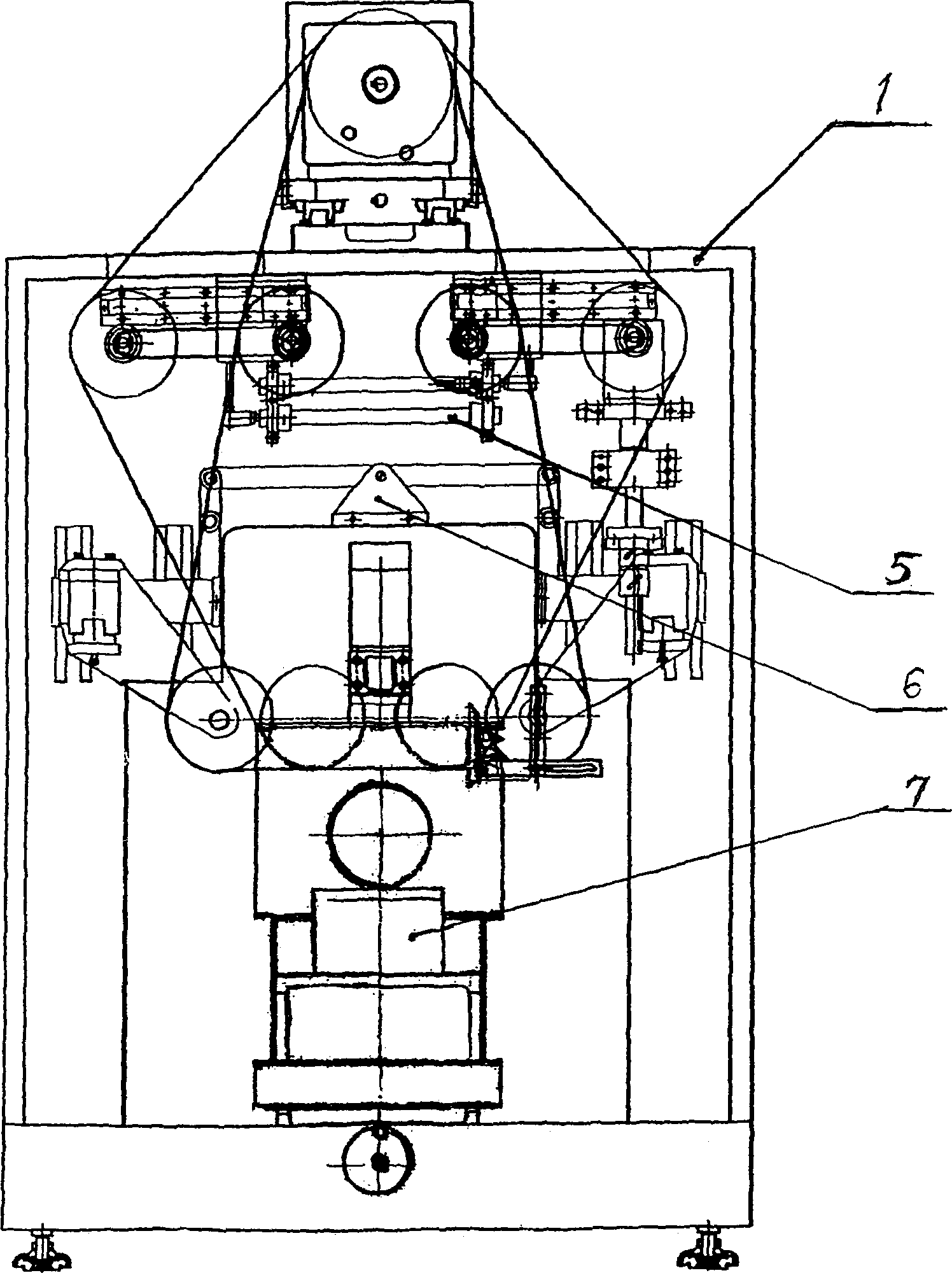

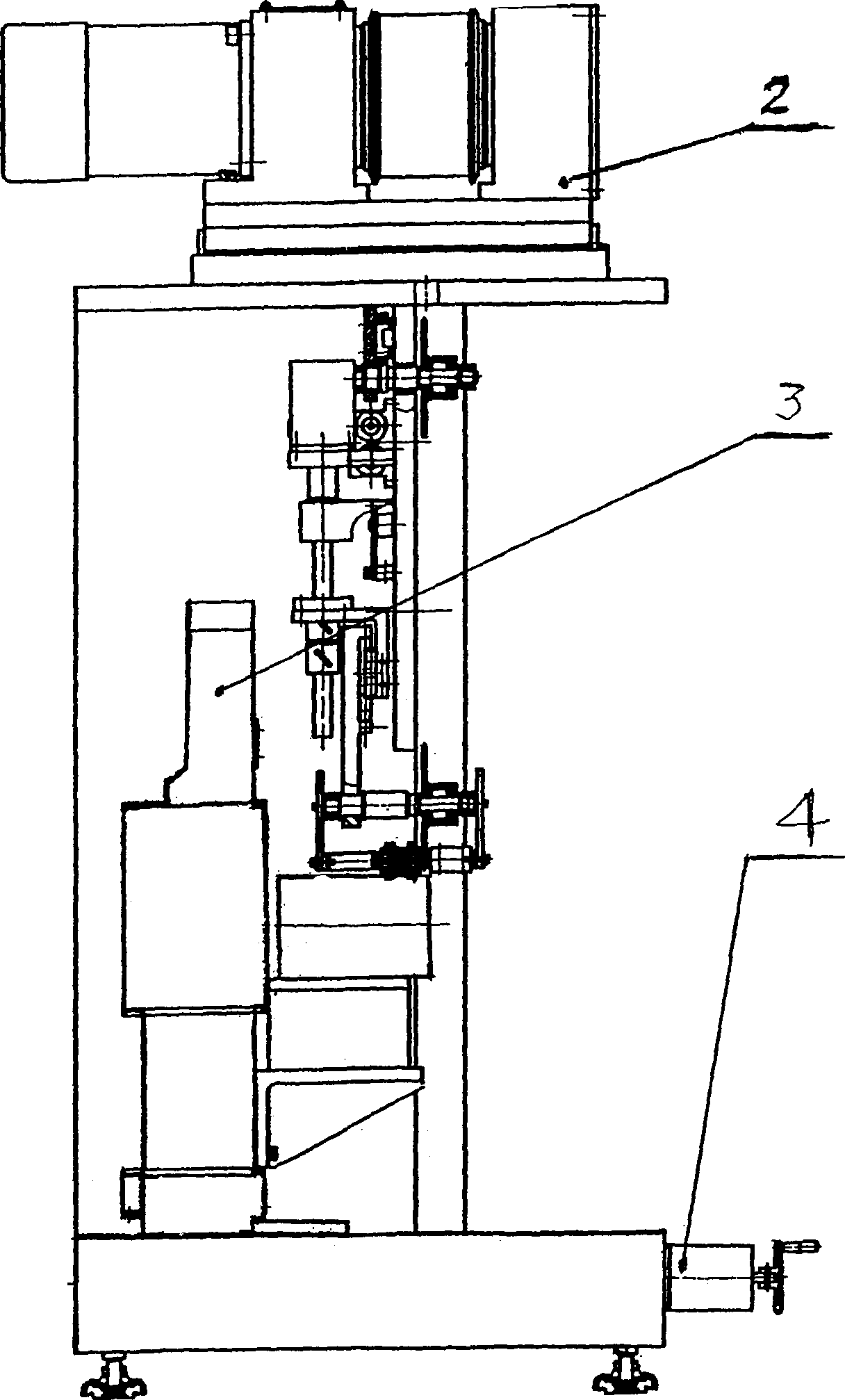

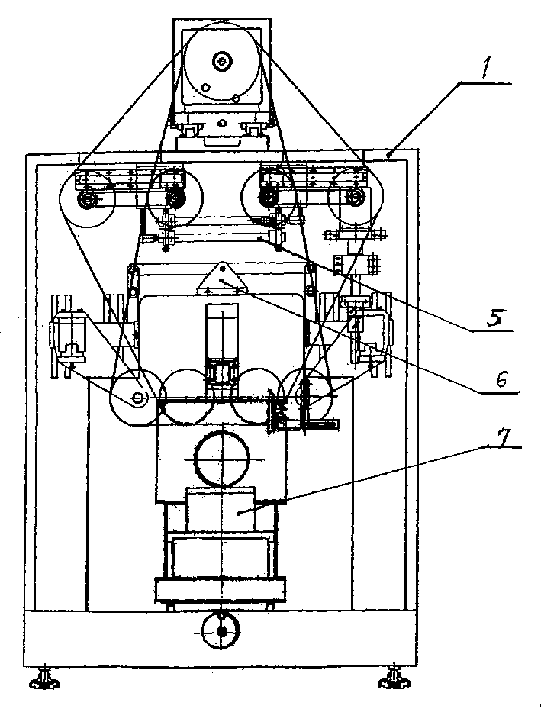

Automatically controlled high-precision crystal wire electrode cutting machine

InactiveCN1387979AImprove rigidityAvoid deformationFine working devicesMetal working apparatusEngineeringMechanical engineering

The present invention relates to cutting equipment and is especially one computerized efficient and high-precision wire electrode cutting machine. The cutting machine consists of frame, winding cylinder driven by one DC motor to rotate in either right direction or reverse direction, Z-axis bench, Y-axis bench, tension mechanism with one pair of tension wheels controlled by one pair of micro cylinders to support the cutting wire, oscillating mechanism with one pair of oscillating support wheels and fixture. The cutting machine is used mainly for cutting silicon wafer, quartz glass, ceramic, jewel, magnesia and other hard and fragile material.

Owner:沈阳科晶设备制造有限公司

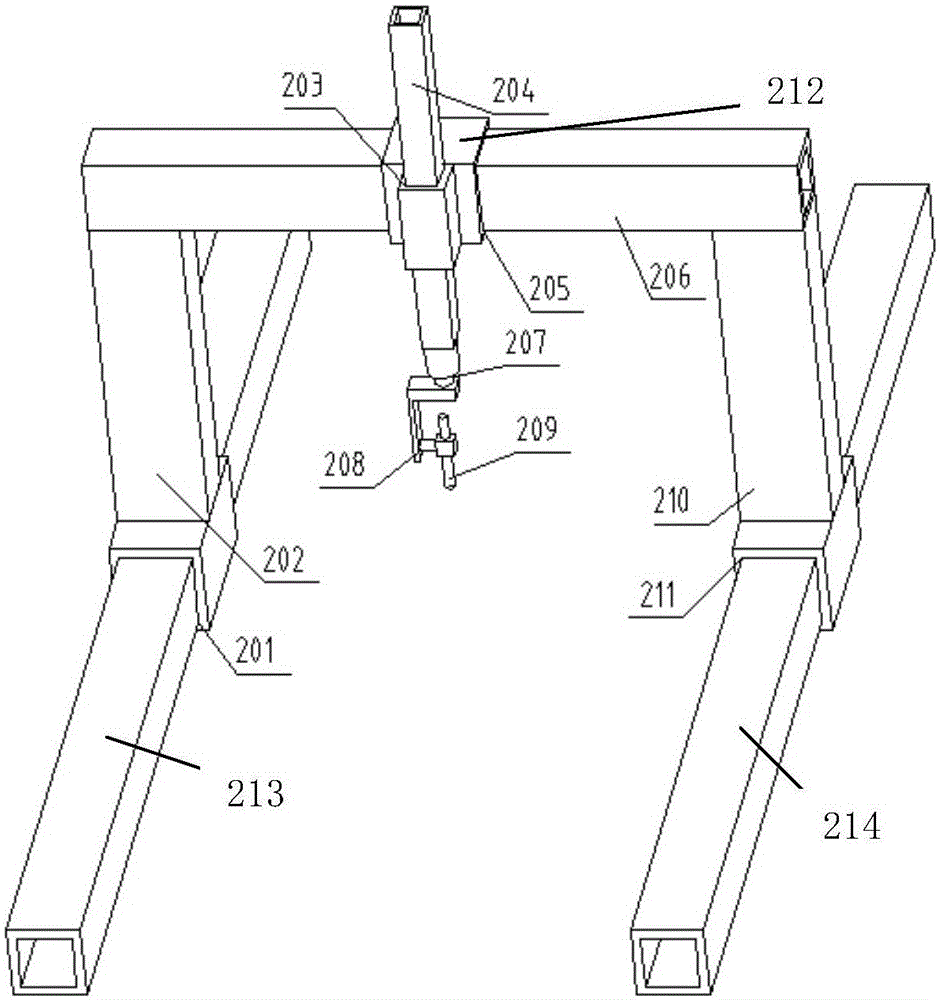

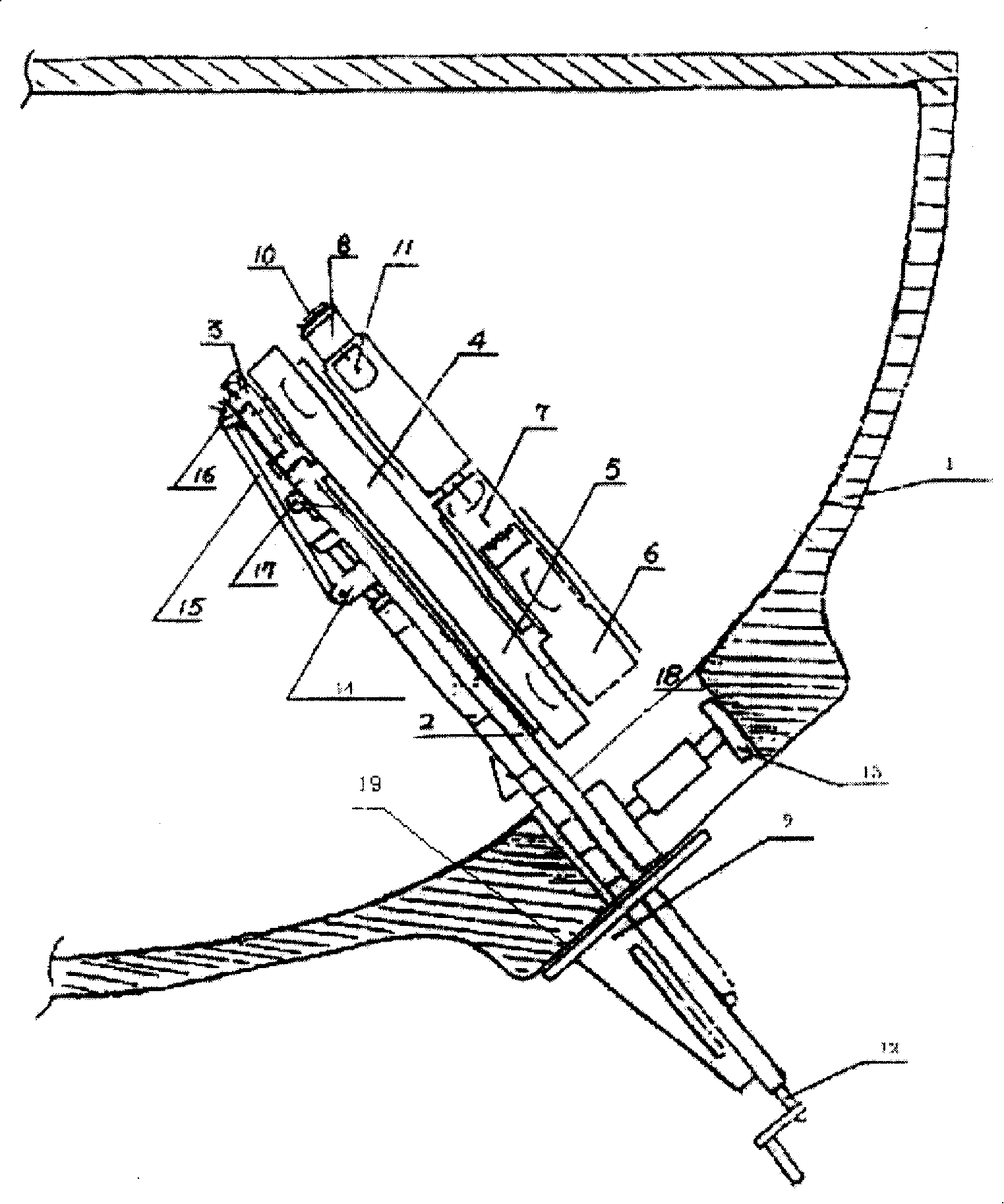

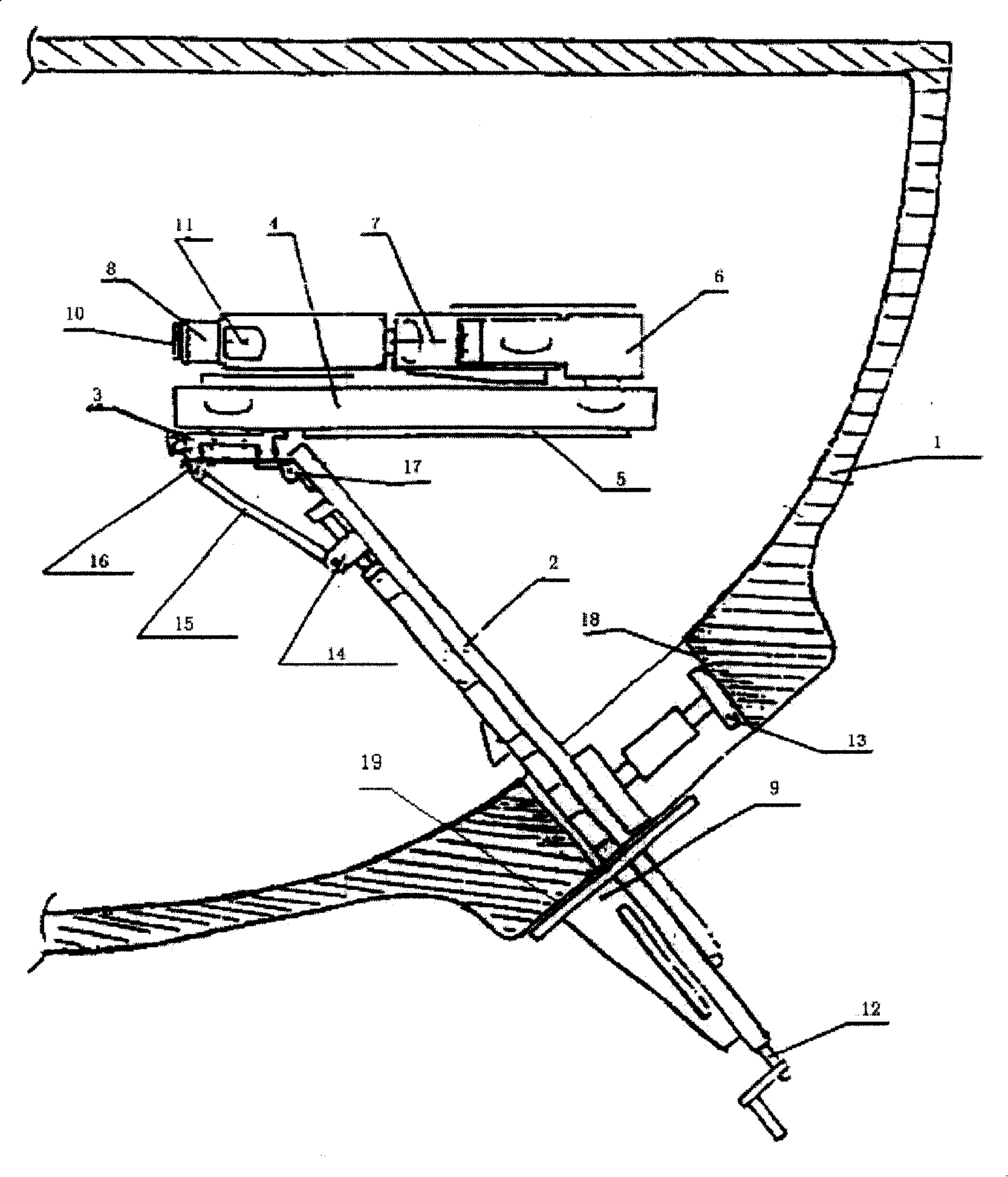

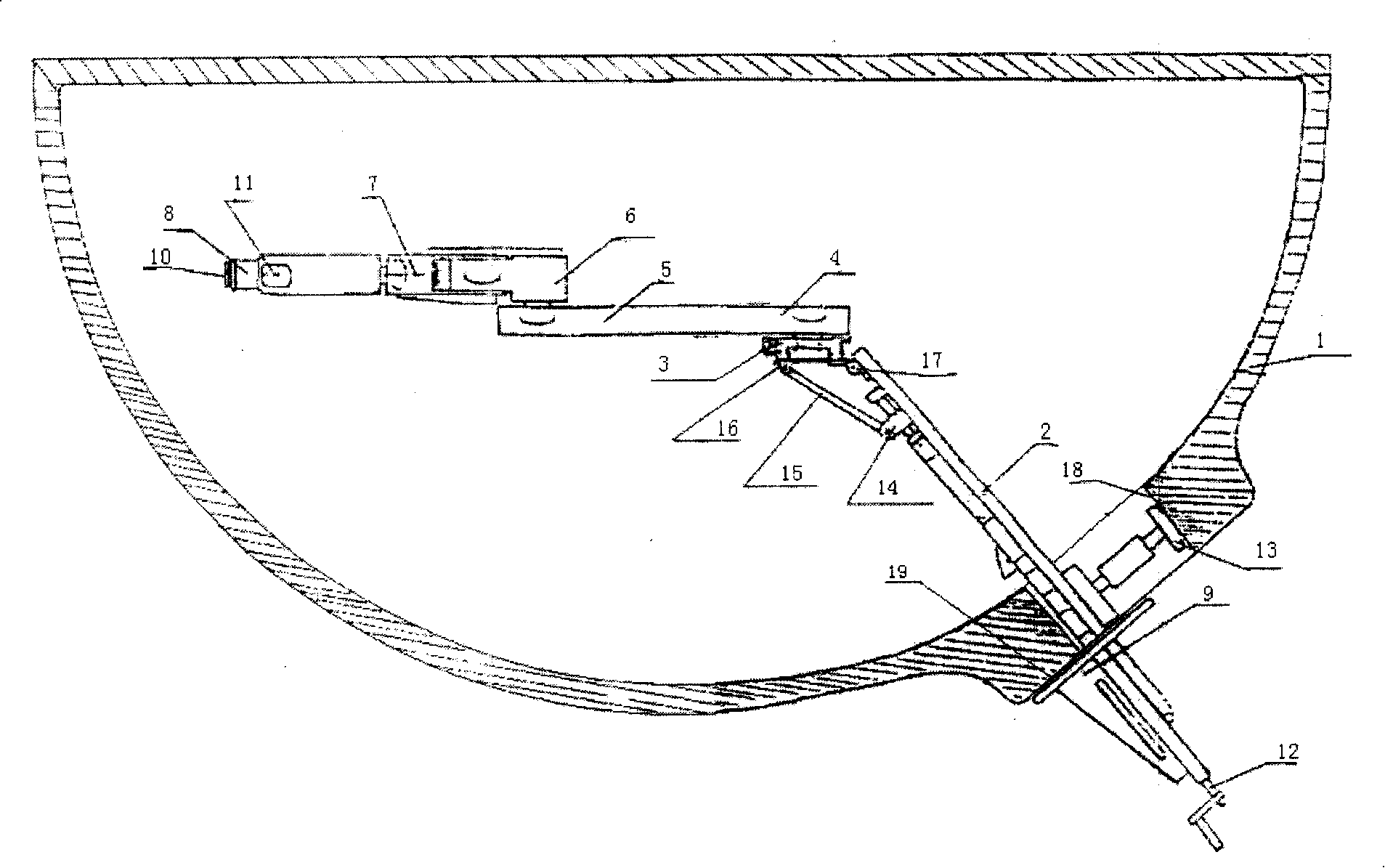

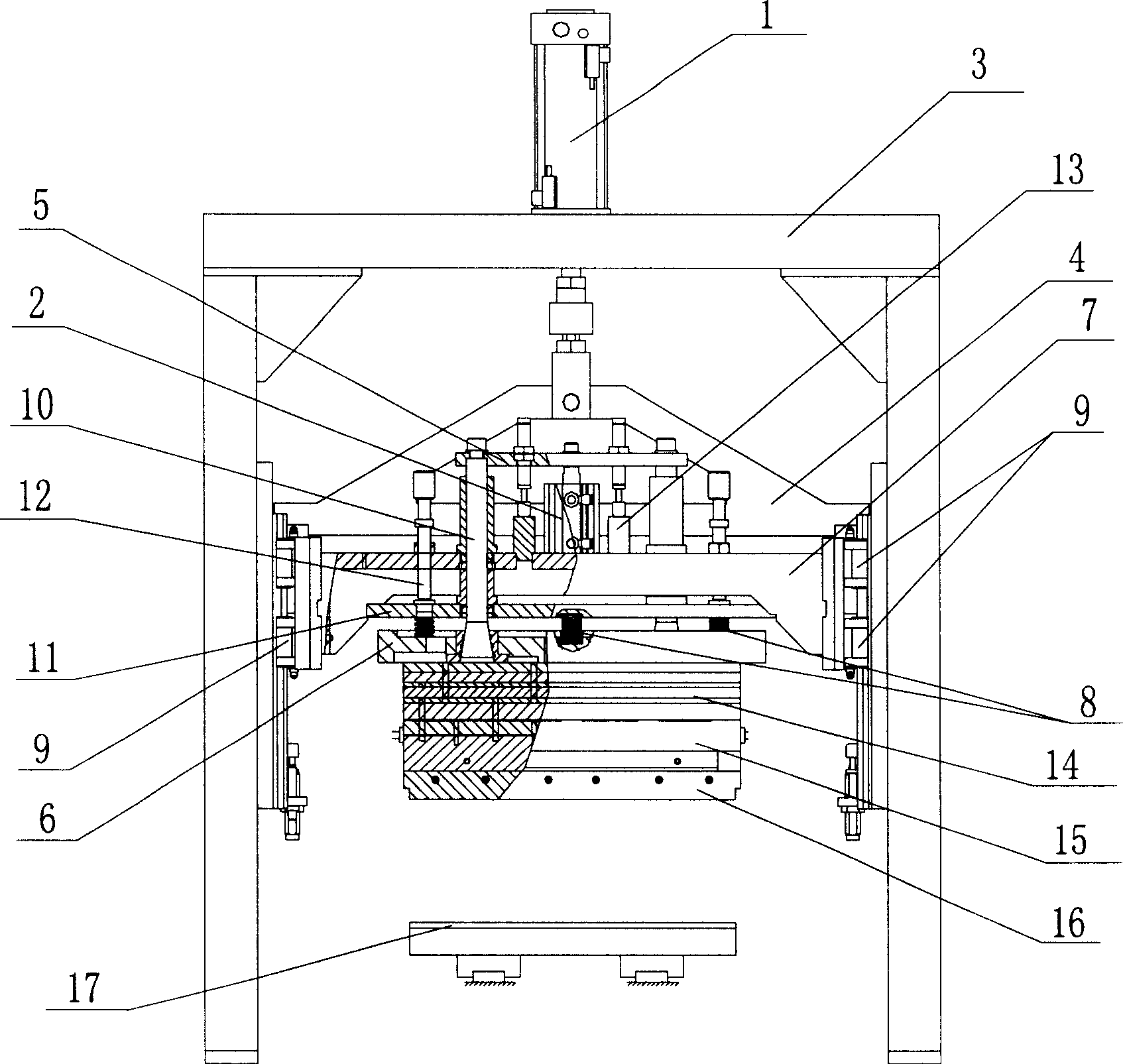

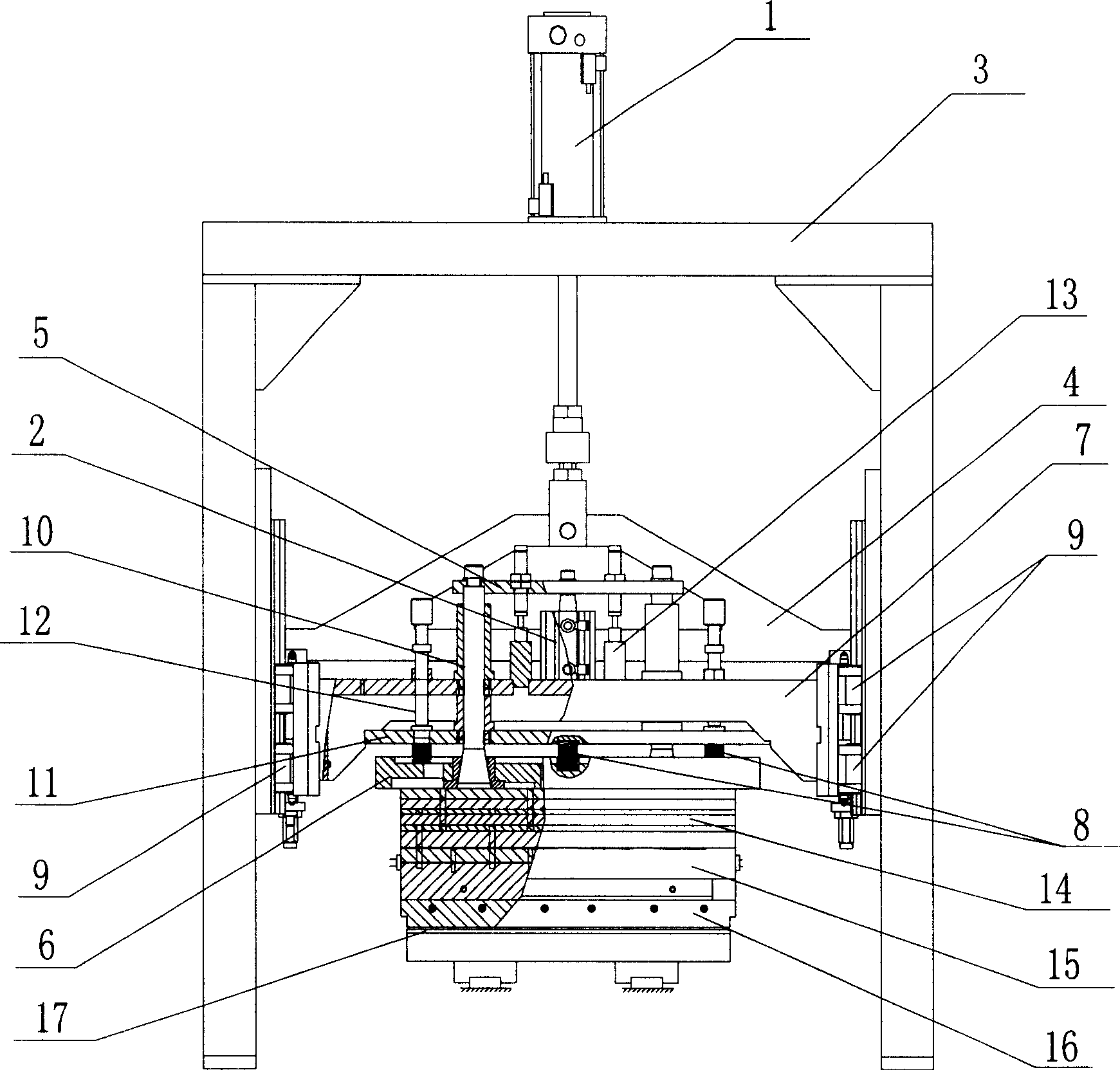

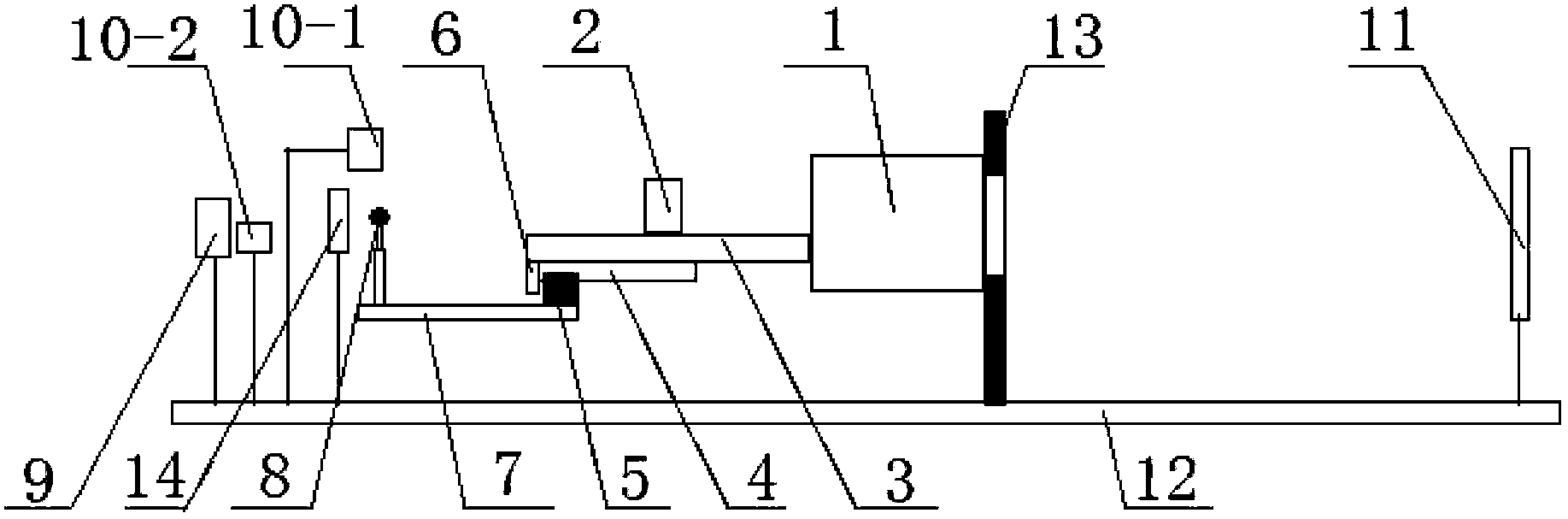

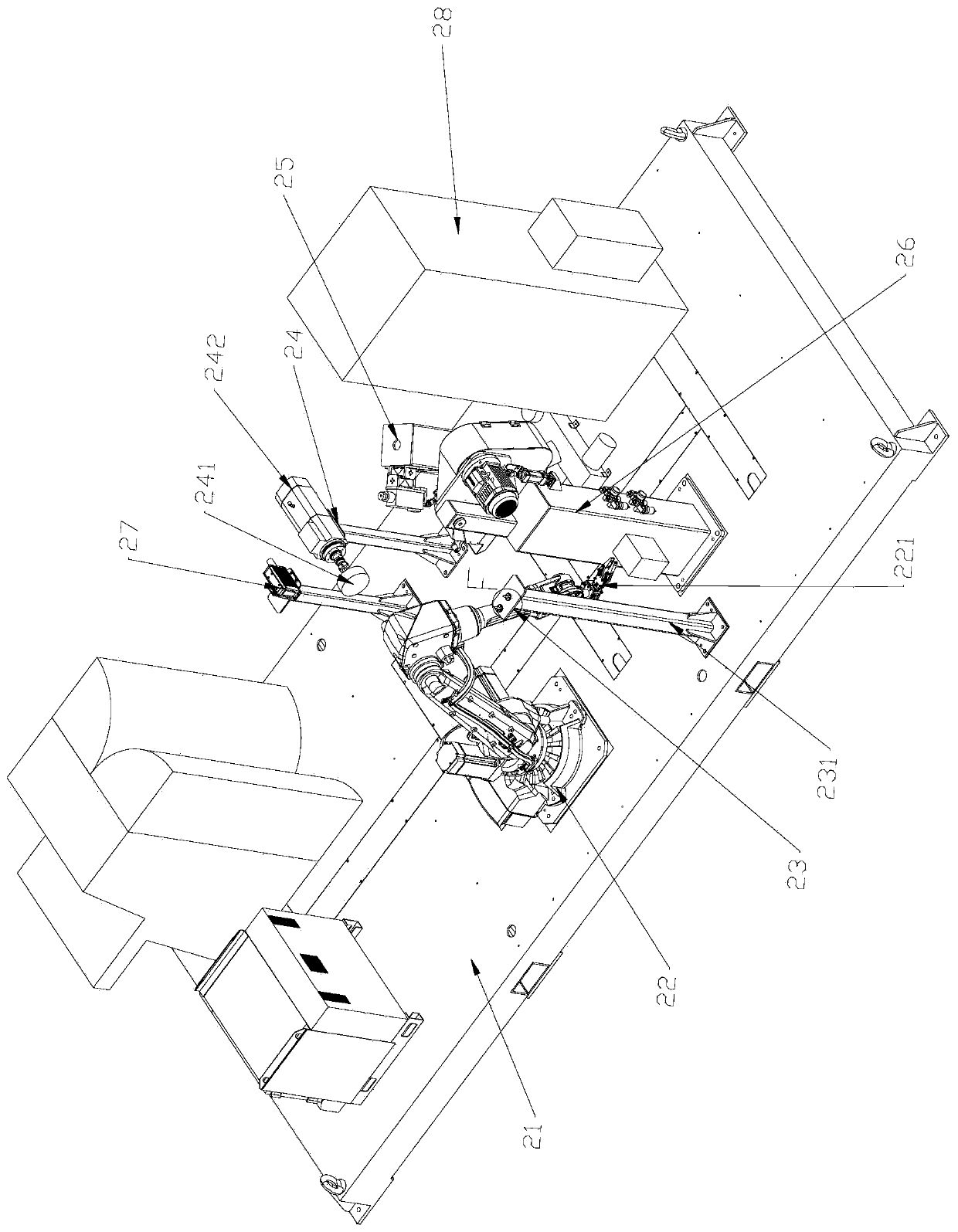

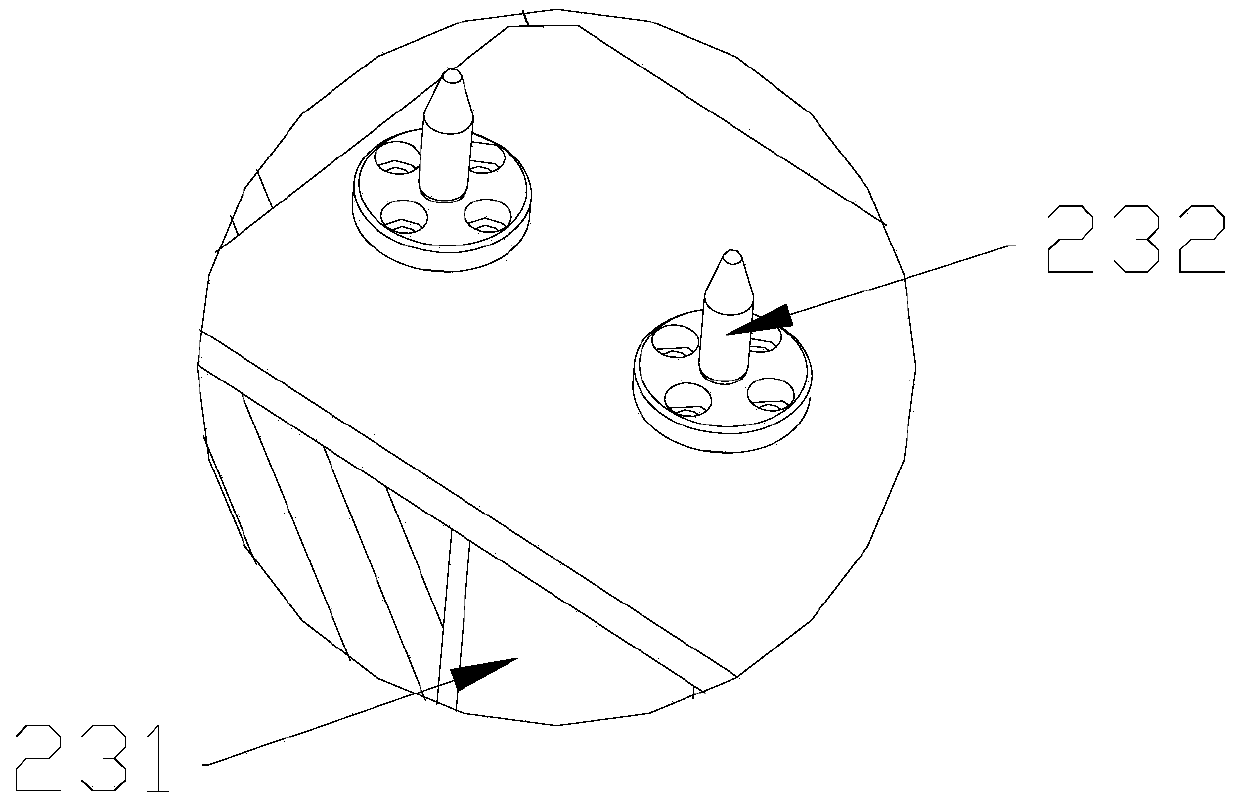

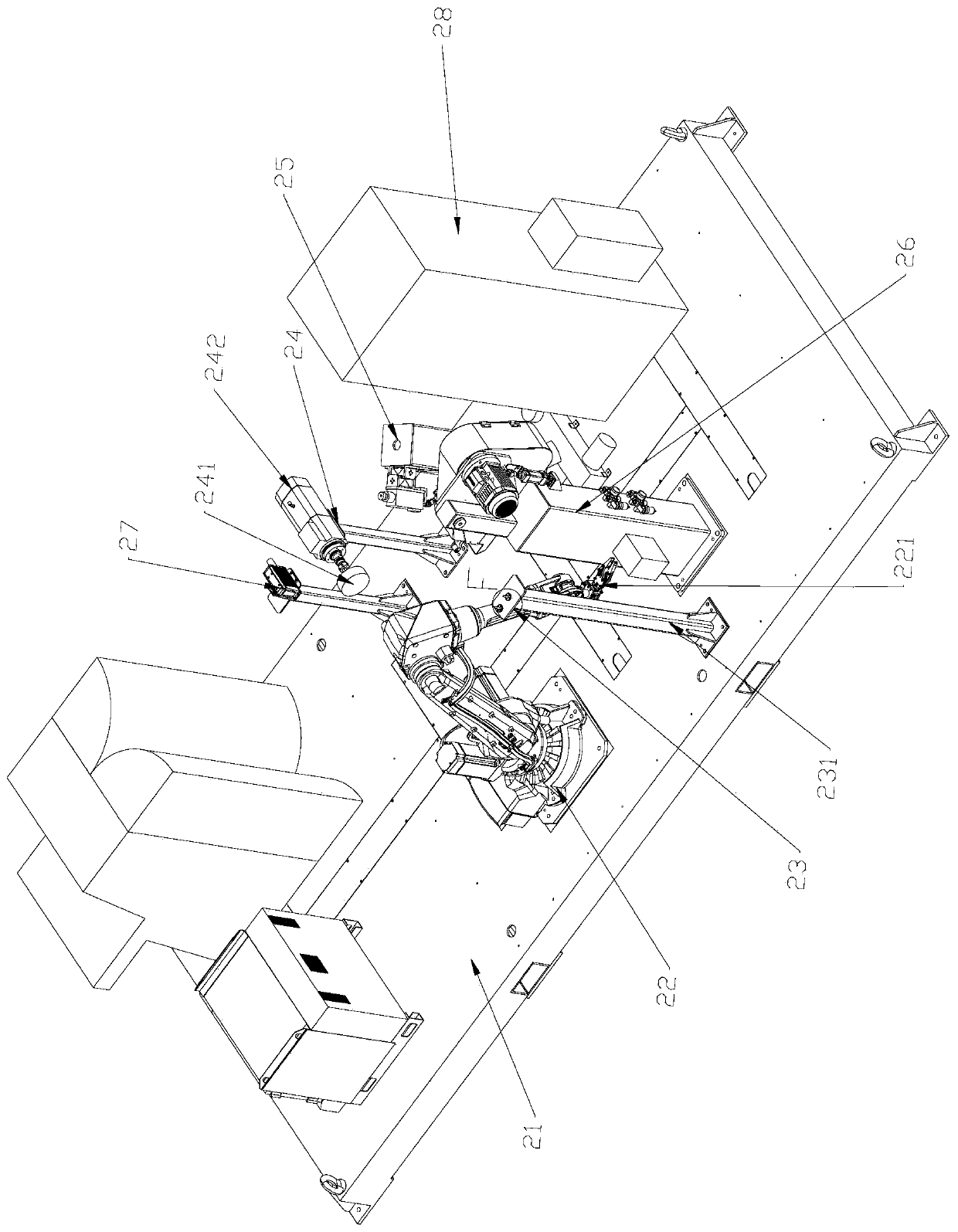

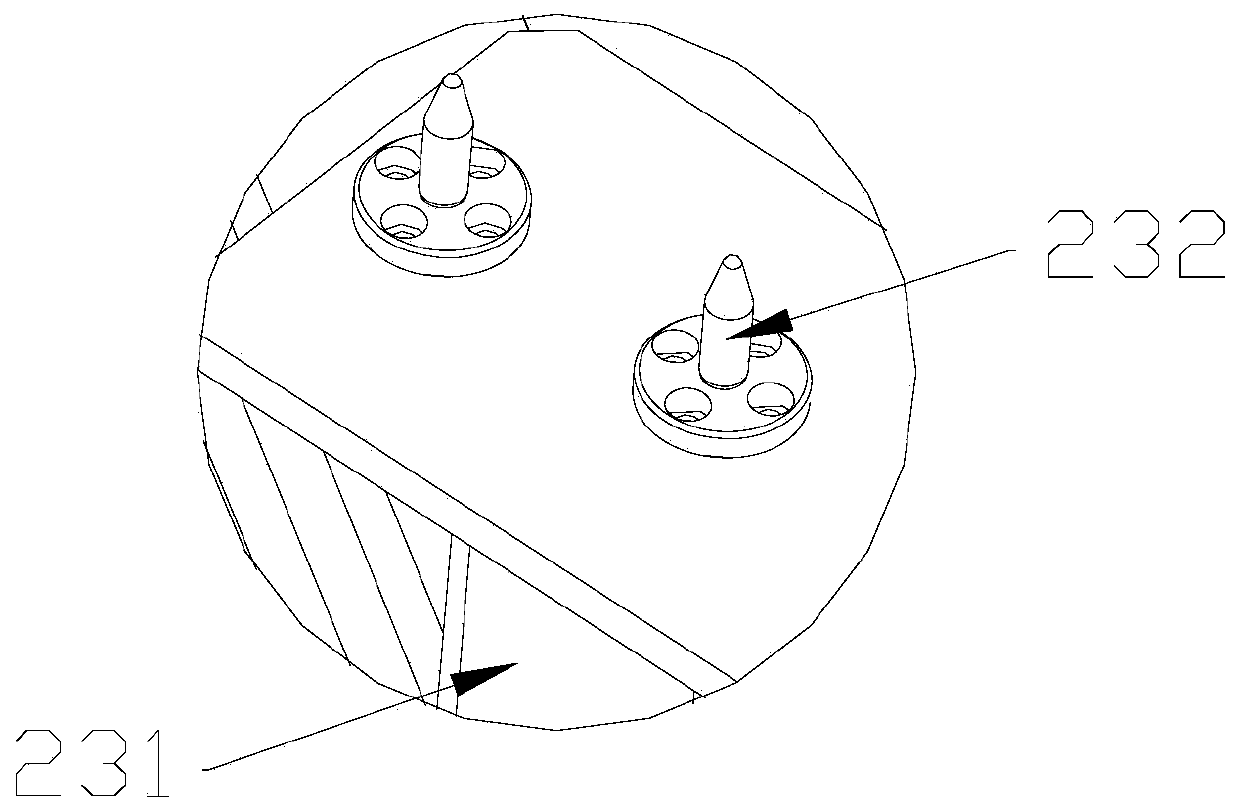

Multifunctional five-axis gantry type integrated welding robot

ActiveCN105149831AEasy to carryRealize high-precision welding operations in large spacesProgramme-controlled manipulatorWelding/cutting auxillary devicesThree-dimensional spaceEngineering

The invention provides a multifunctional five-axis gantry type integrated welding robot. A first upright post and a second upright post are respectively mounted on a first steel rail and a second steel rail through a first X moving joint and a second X moving joint; a cross beam is mounted between the first upright post and the second upright post; a moving arm is mounted on the cross beam through a Y moving joint; a lifting arm is mounted on the moving arm through a Z moving joint; a U-shaped rotating mechanism is arranged at the end part of the lifting arm; a V-shaped rotating mechanism is arranged at the end part of the U-shaped rotating mechanism; and a welding tool or a cutting tool is connected with the end part of the V-shaped rotating mechanism. The multifunctional five-axis gantry type integrated welding robot provided by the invention can be applicable to various space cutting of large-sized spherical crowns, curved plates, pressure vessels, cones, barrels and the like, and multilayer multiple-time welding of three-dimensional space connecting parts of two metals.

Owner:HARBIN ENG UNIV

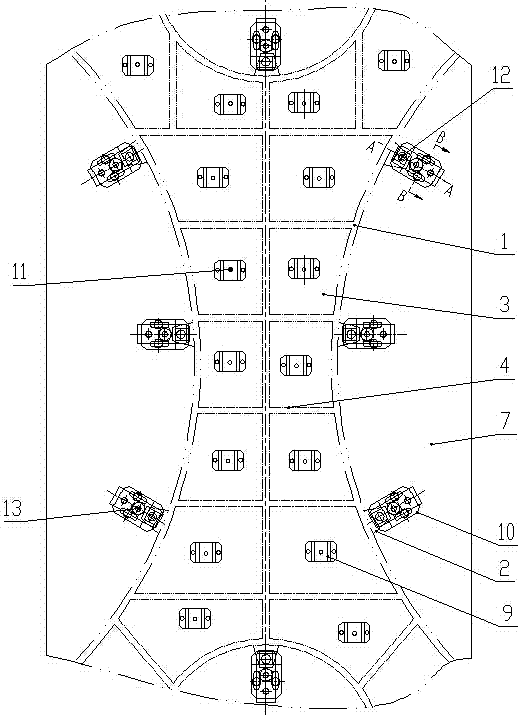

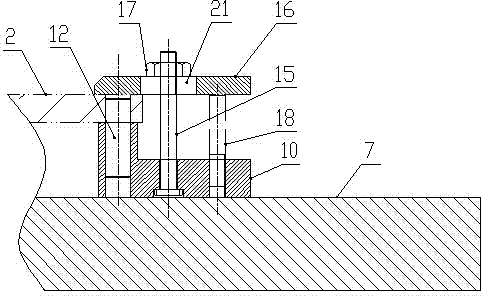

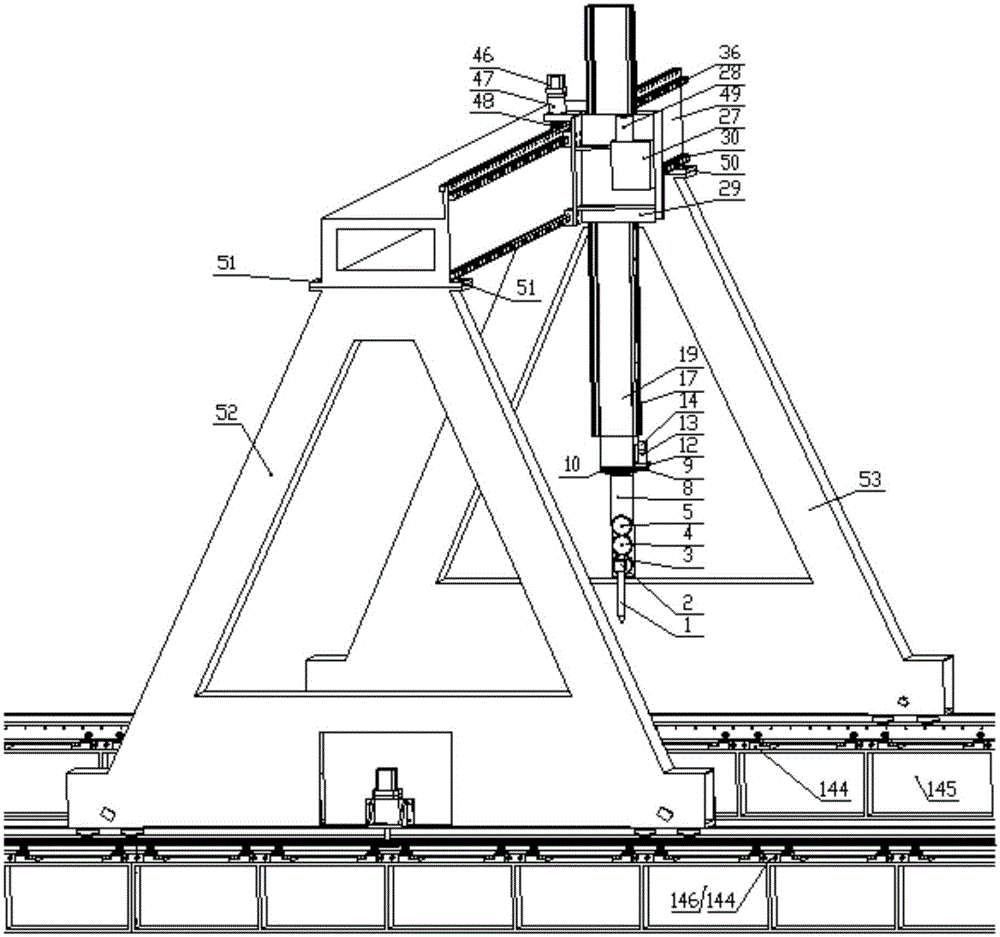

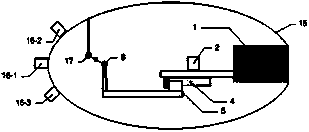

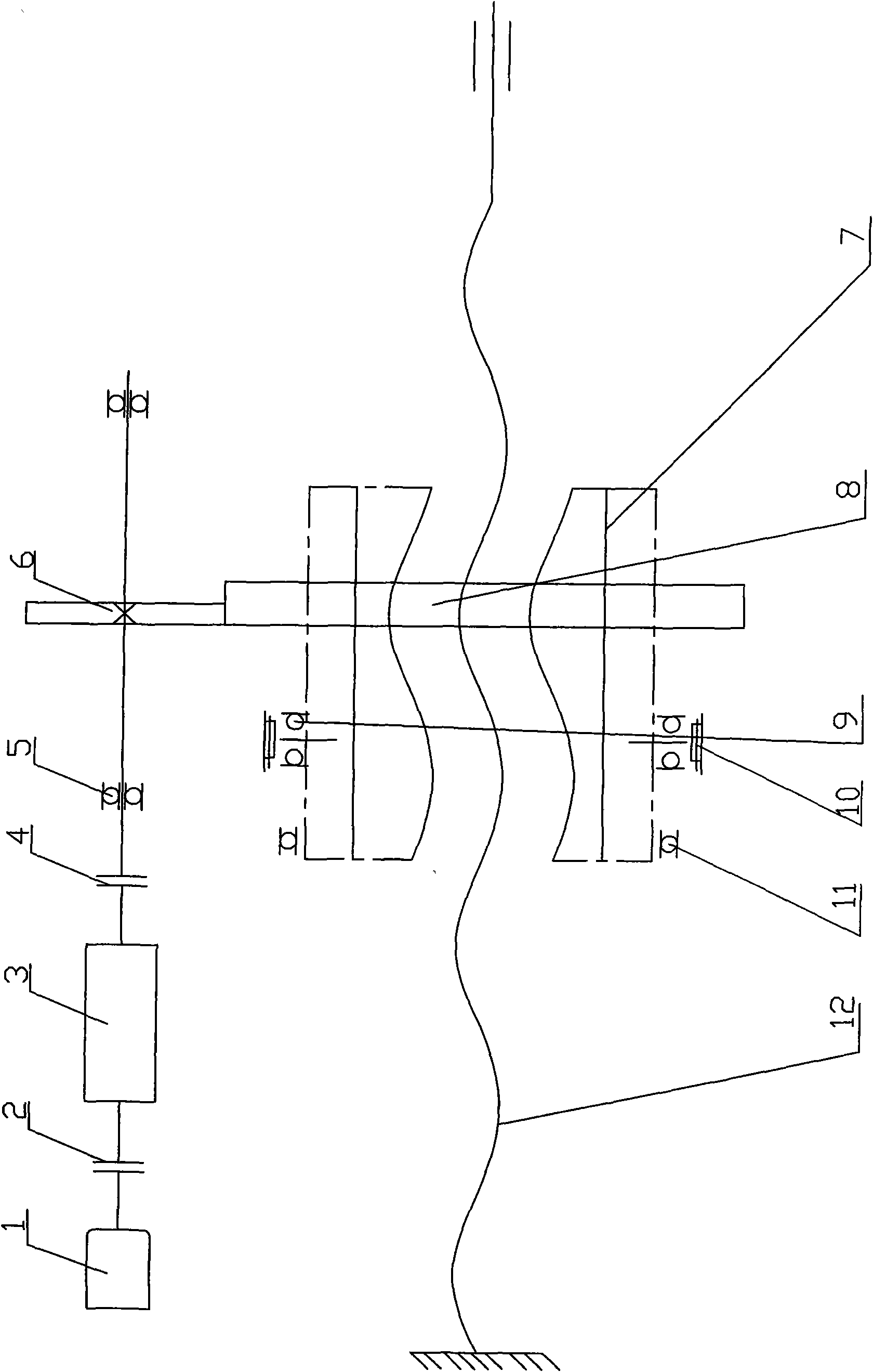

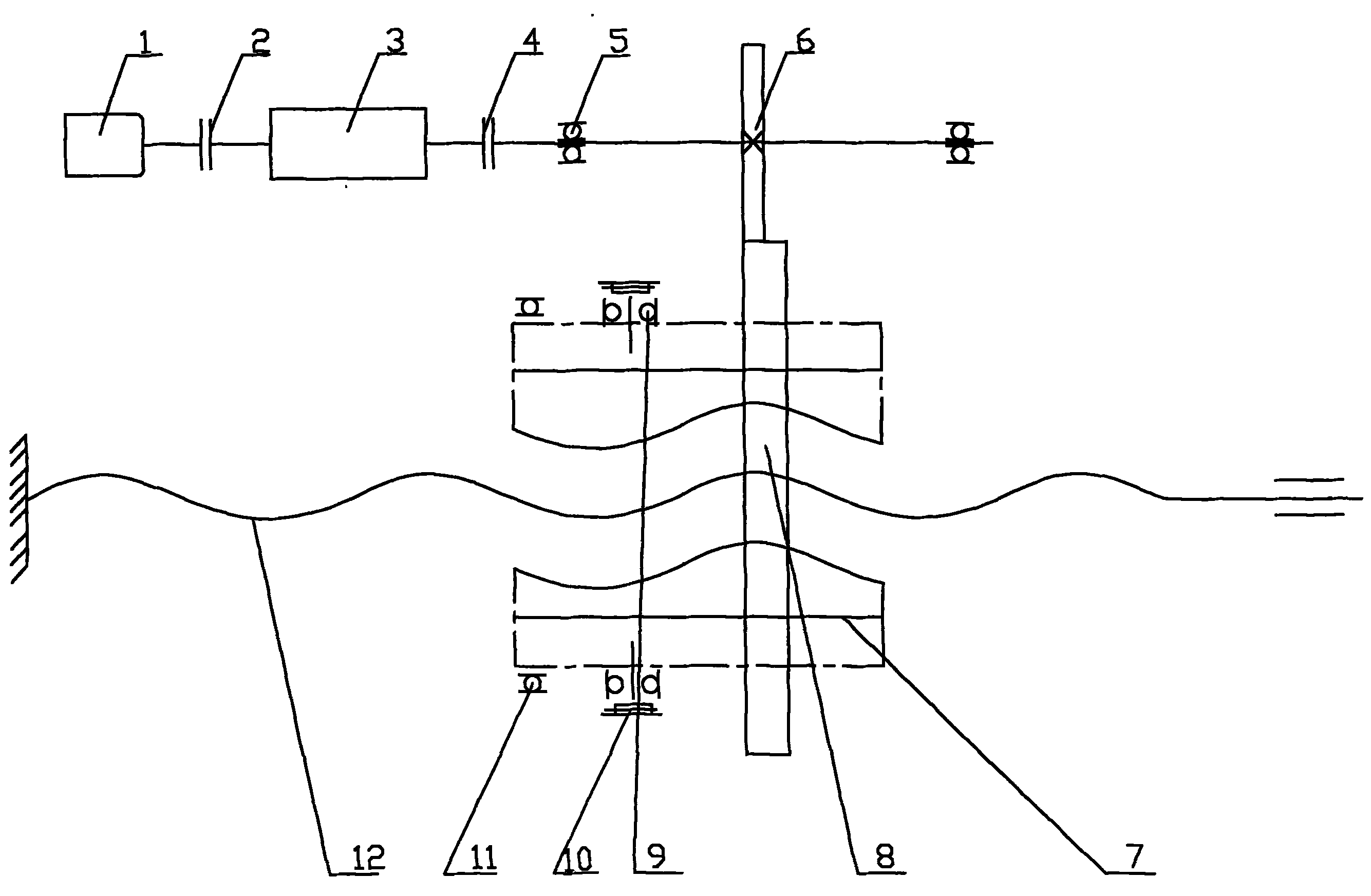

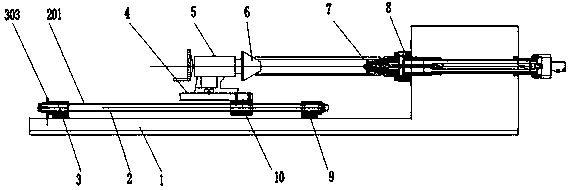

Nuclear boiler water indoor surface television set automatic checking device

ActiveCN101162617AGuaranteed repeat positioning accuracyAdjustable lengthNuclear energy generationNuclear monitoringSheet steelMonaural

The invention provides an TV automatic checkout equipment for the water chamber inner surface of a nuclear steam generator, comprising a guide rail, a support platform, a large arm, a telescopic boom, a forearm, a rotating arm, a yawing arm, a ribbed slab, a support and a steel plate; two ends of the support are supported on the surface of the guide rail and the inner surface of a manhole respectively; the guide rail is connected with a flange; one end of the guide rail is arranged on the ribbed slab; a monaural on the side wall of the other end of the guide rail is connected with one end of the steel plate; the other end of the steel plate is connected with a monaural on the other location of the corresponding side of the support platform; the other side of the support platform is connected with one end of the large arm, the other end of the large arm is connected with the telescopic boom, the forearm, the rotating arm and the yawing arm in sequence. The device of the invention can have an overall inspection on the stainless overlaying layer of the water chamber surface of the steam generator so as to find if crackles, collision tracks, scratches, corrosive defects, abnormal indication or foreign objects exist.

Owner:RES INST OF NUCLEAR POWER OPERATION

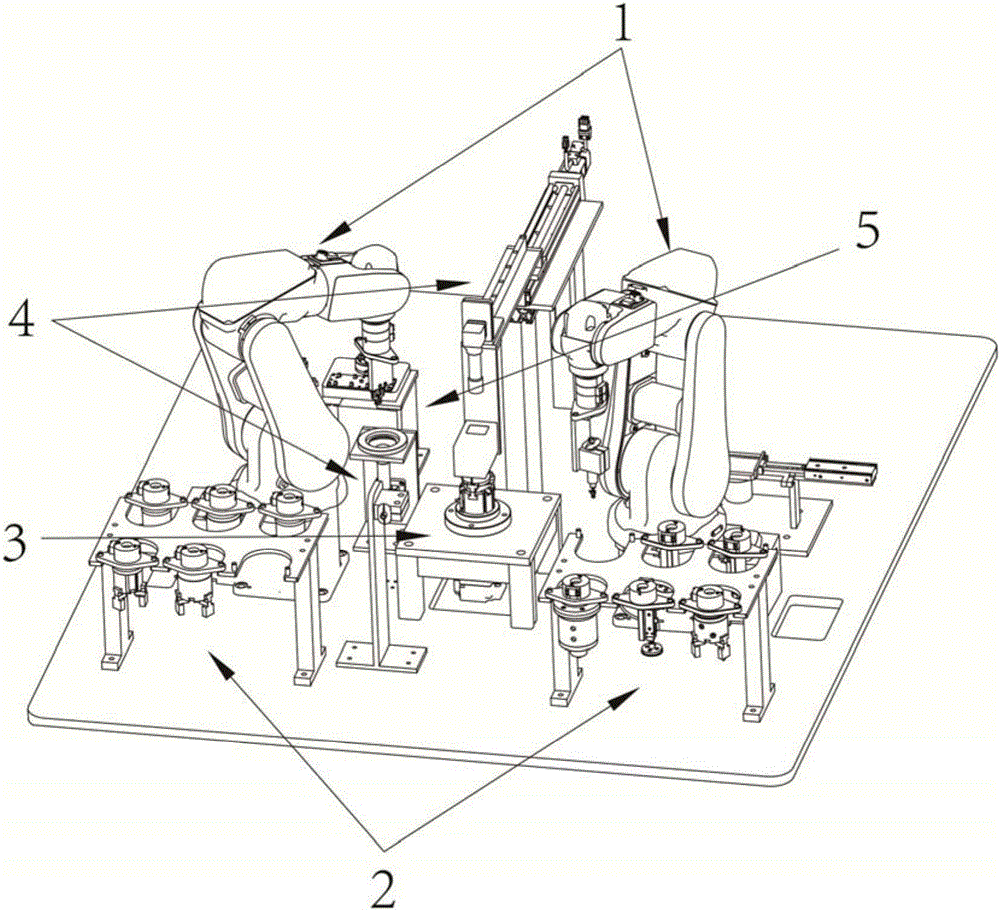

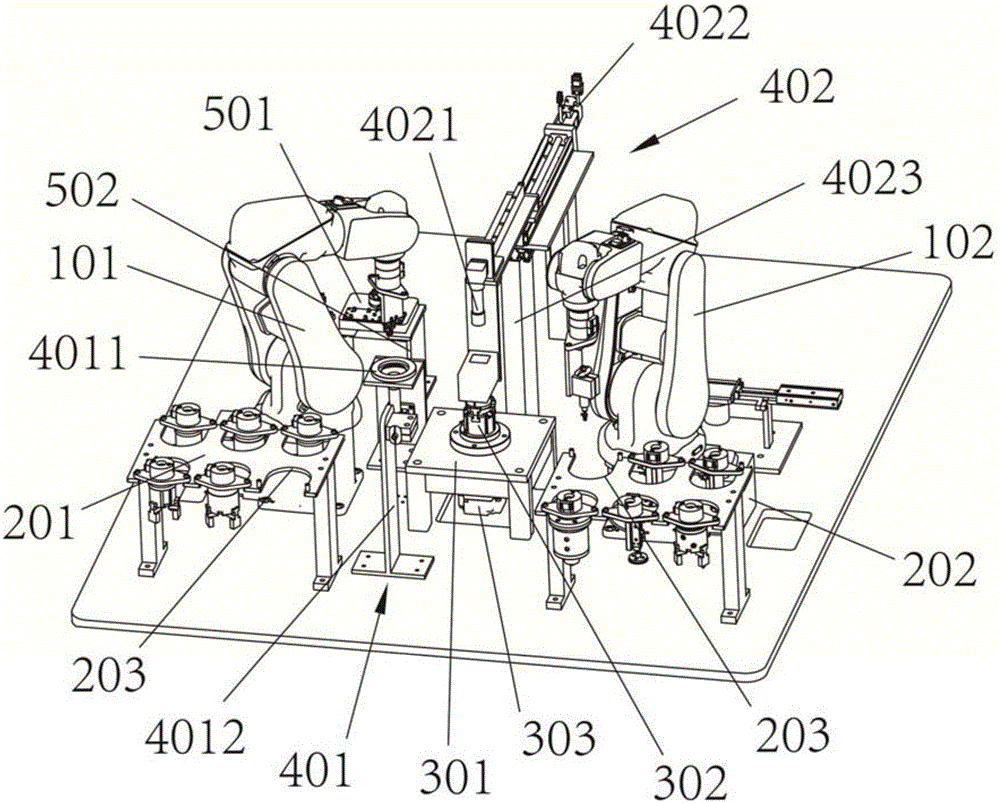

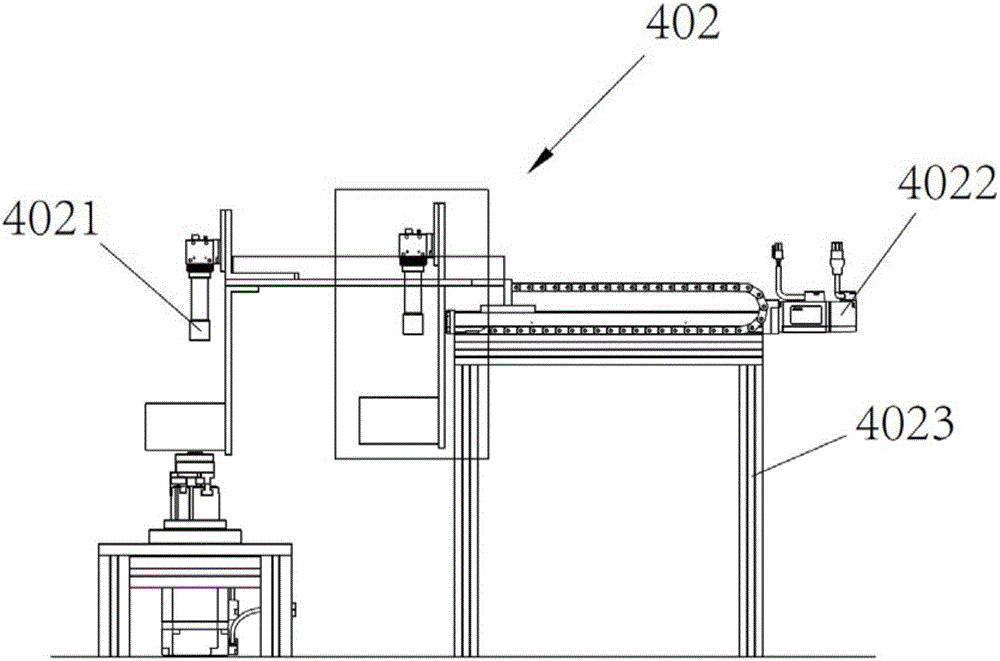

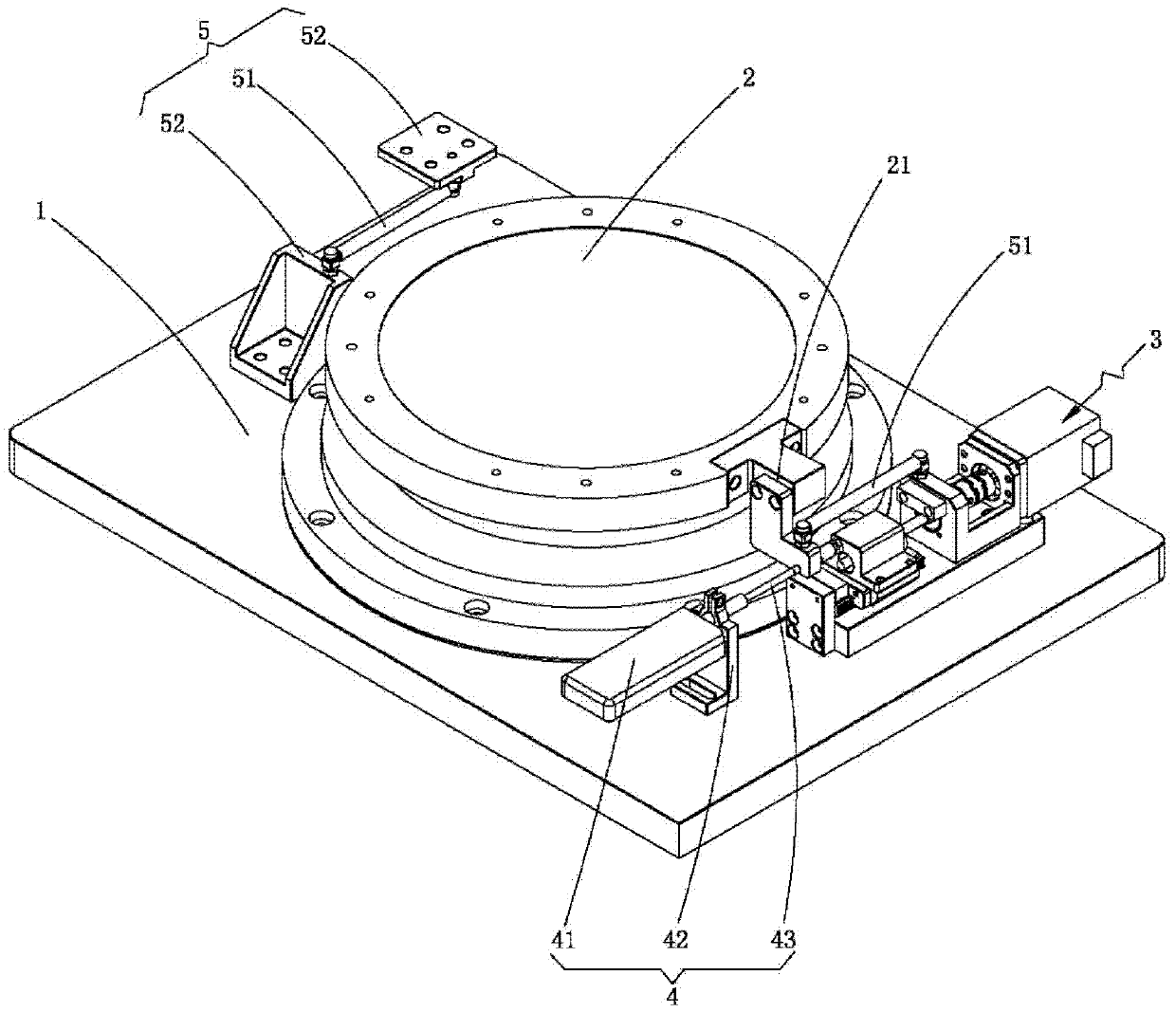

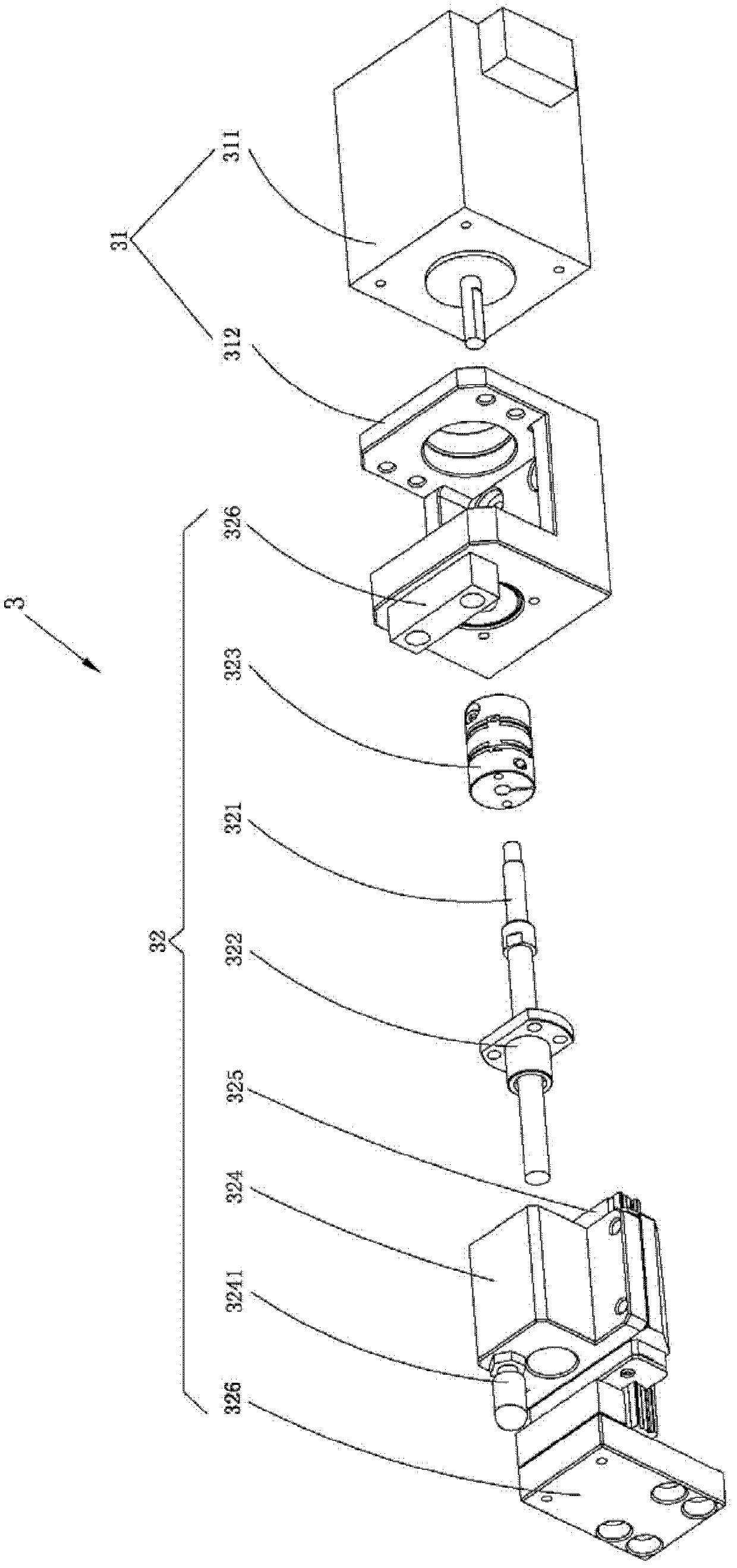

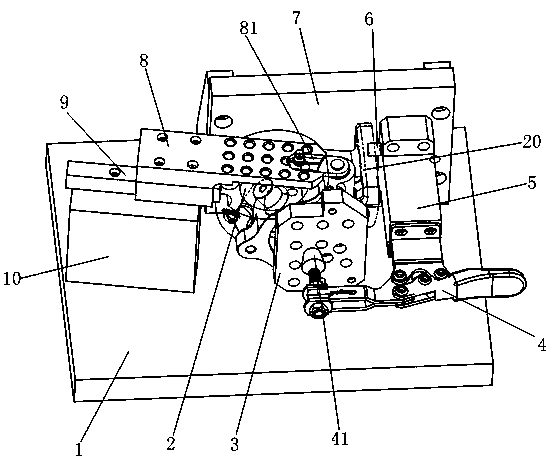

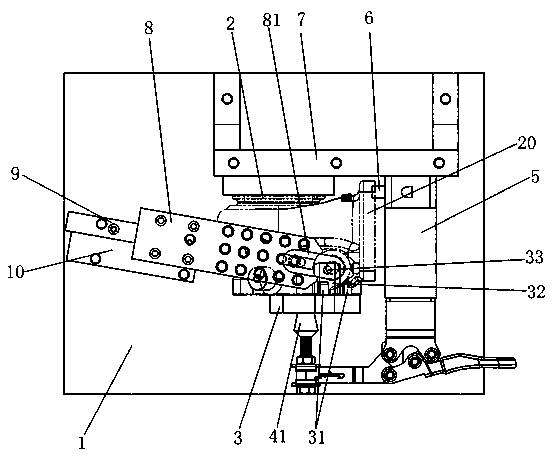

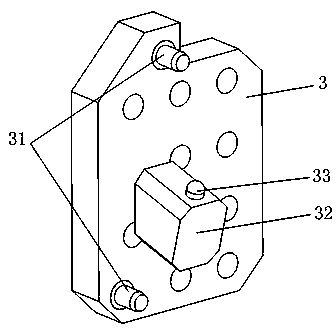

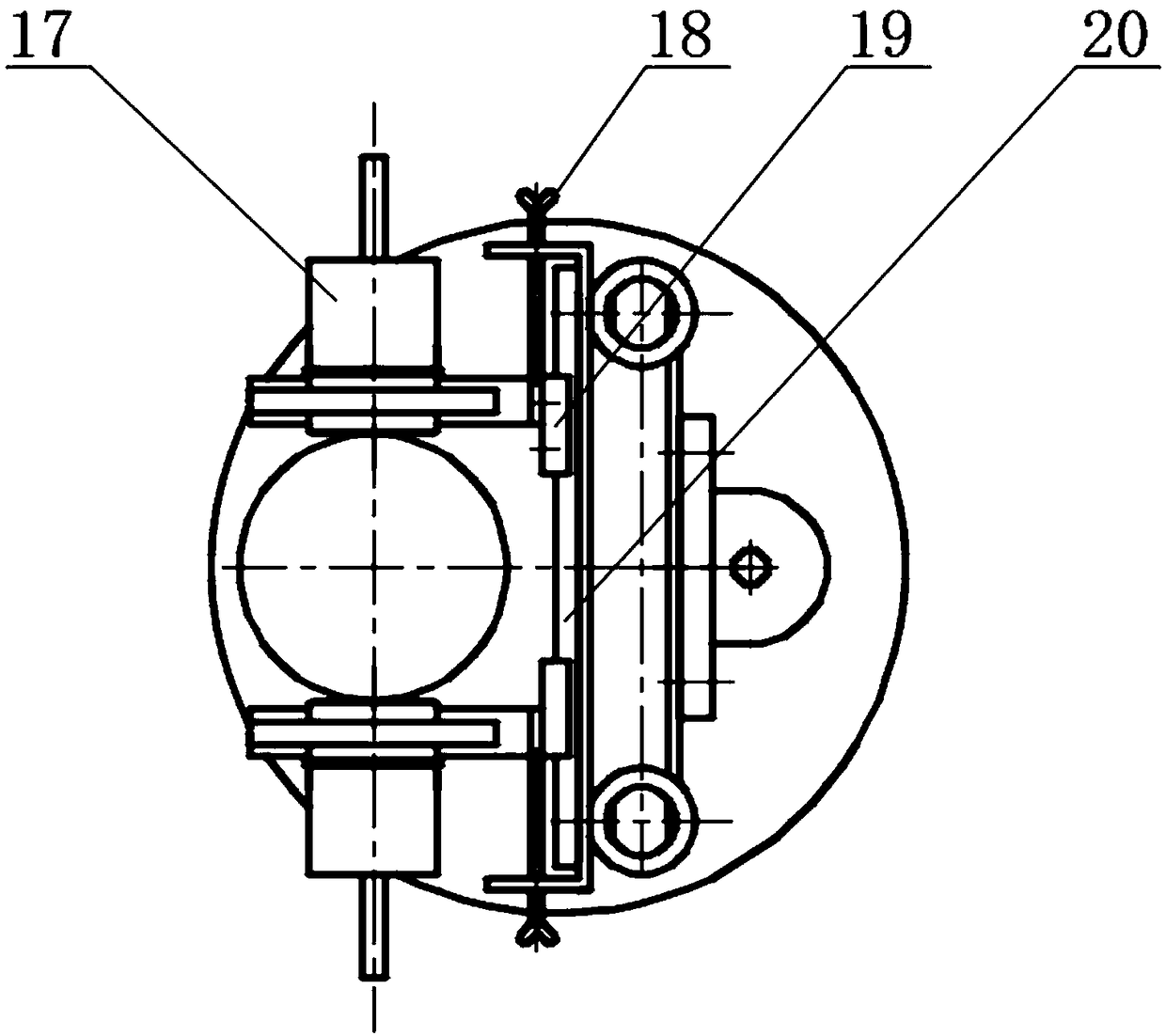

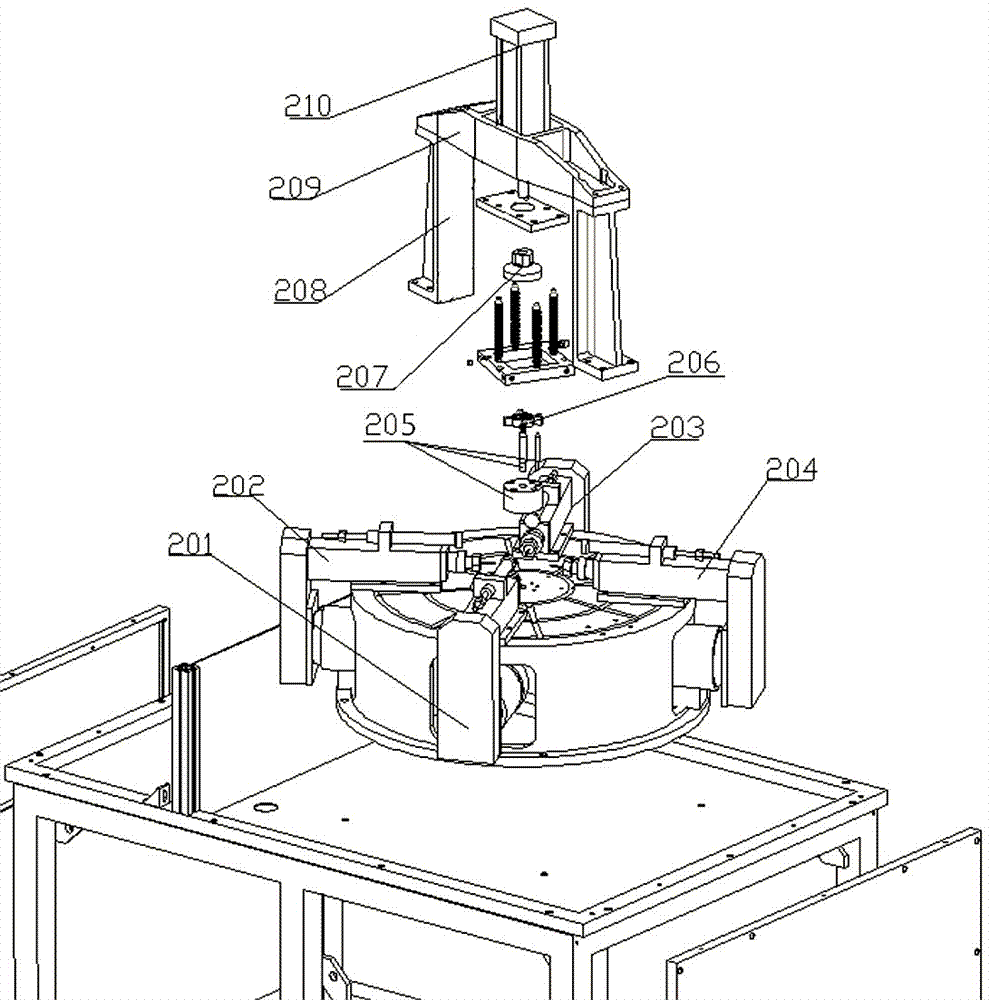

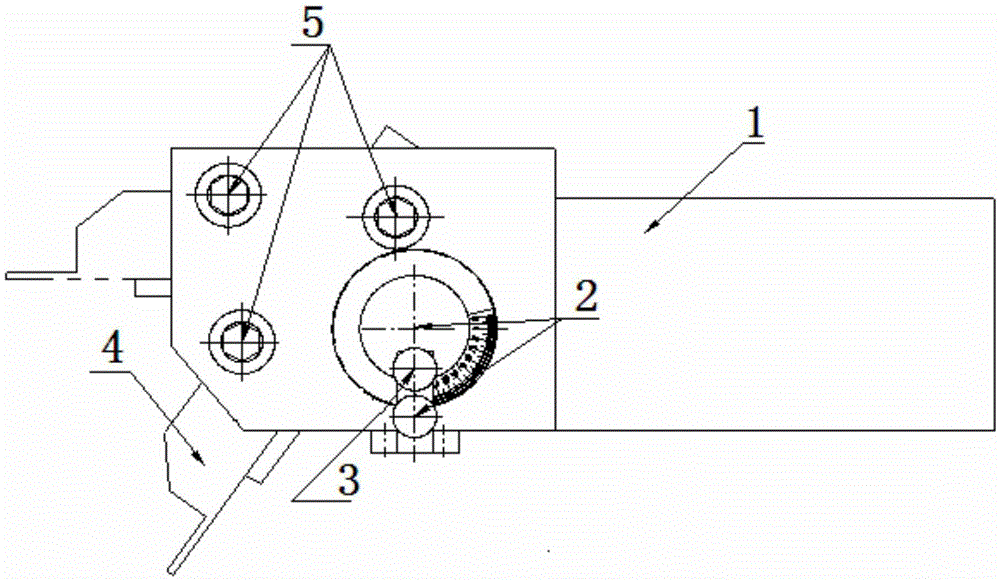

Magnetic steel assembling equipment and magnetic steel assembling method therefor

ActiveCN106374696AEffect of position errorQuick changeManufacturing stator/rotor bodiesExecution unitEngineering

The invention relates to magnetic steel assembling equipment. The magnetic steel assembling equipment comprises an execution unit, a tool unit, an assembling unit and a detecting-positioning unit, wherein the detecting-positioning unit comprises a magnetic steel detecting-positioning mechanism for detecting position information of the magnetic steel and an iron core detecting-positioning mechanism for detecting position information of an iron core. By adoption of the equipment, quick and high-precision assembling of the magnetic steel can be realized; and in addition, detecting-positioning is performed in assembling of the magnetic steel in each time, so that positioning accuracy is ensured.

Owner:NINGBO SUNNY INTELLIGENT TECH CO LTD

Blade profile electric spark shaping machining method for integral closed blade ring and clamp thereof as well as electrode

PendingCN108994402AImprove processing efficiencyImprove machining accuracyElectrical-based auxillary apparatusMolding machineEngineering

The invention belongs to the technical field of special machining, in particular to a blade profile electric spark shaping machining method for an integral closed blade ring and a clamp thereof as well as an electrode. The method depends on an electrode profile to guarantee blades and an airflow channel profile, and the method is not limited by the complexity degree of the blade profile; by usinga molding electrode, the multi-axis linkage electric spark shaping machining can be realized on an electric spark shaping machine by cooperating with an electrode clamp; the method comprises the following steps that the to-be-machined blade ring is clamped on a workbench of the electric spark shaping machine, and tight compressing and aligning are carried out; the rough machining electrode is clamped on the electrode clamp; then is integrally clamped on a main shaft head of the electric spark shaping machine, rough machining of the airflow channel is carried out on the blade ring according toa drawing; and then the rough machining electrode on the electrode clamp is detached, a finish machining electrode substitutes for the rough machining electrode to carried out finish machining on theairflow channel, and the machining of the integral closed blade ring is completed; and the machined blade ring is taken down from the workbench of the electric spark shaping machine. According to themethod, the electrode clamp and the electrode with a special structure are adopted to complete.

Owner:西安西航集团莱特航空制造技术有限公司

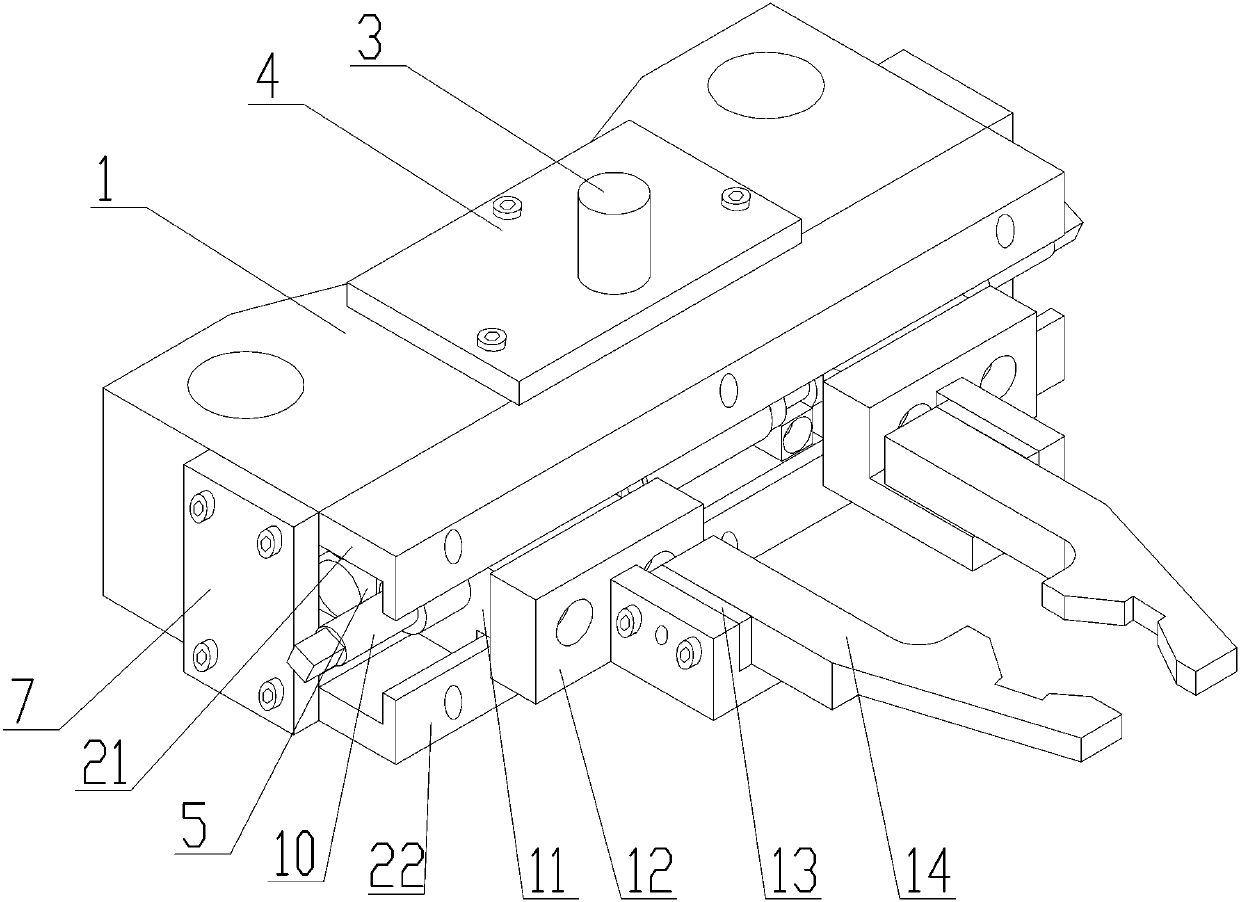

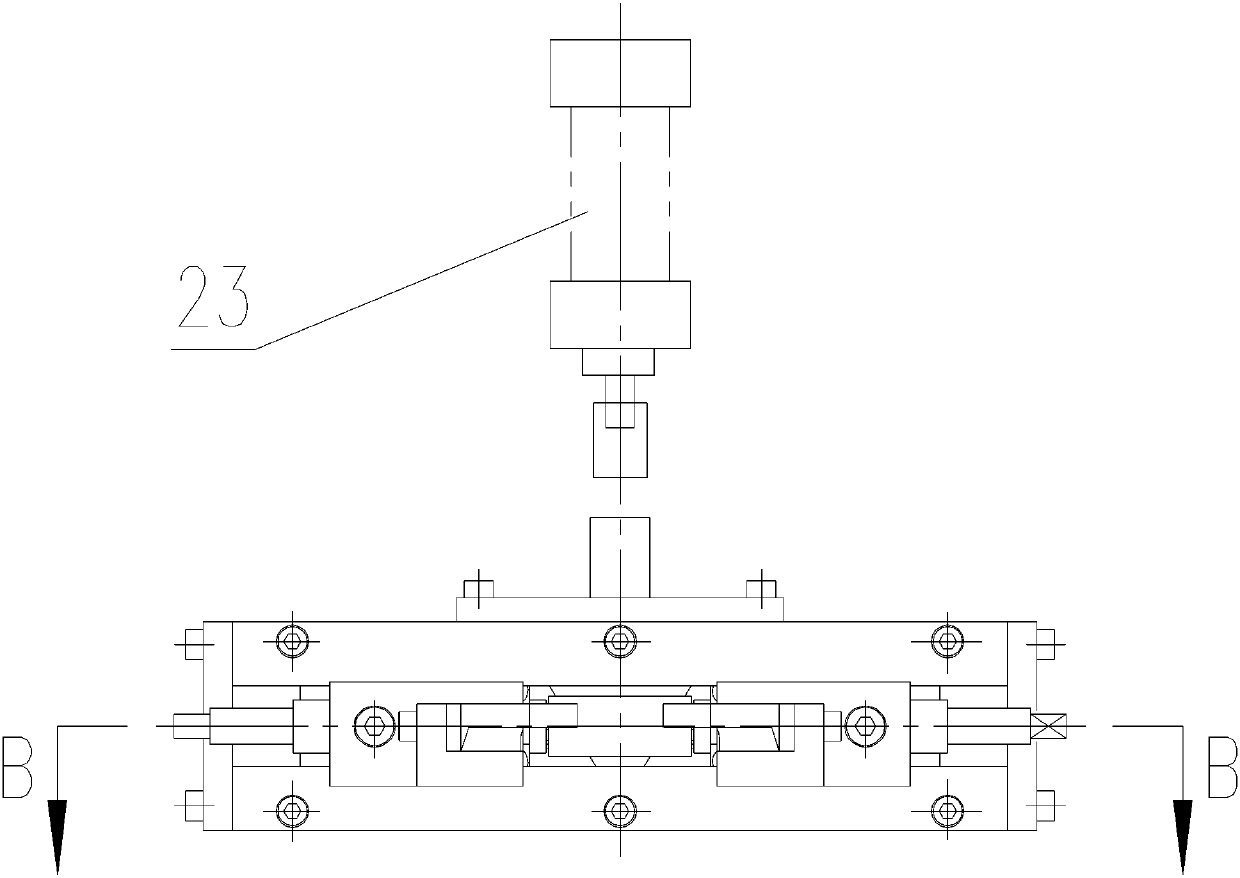

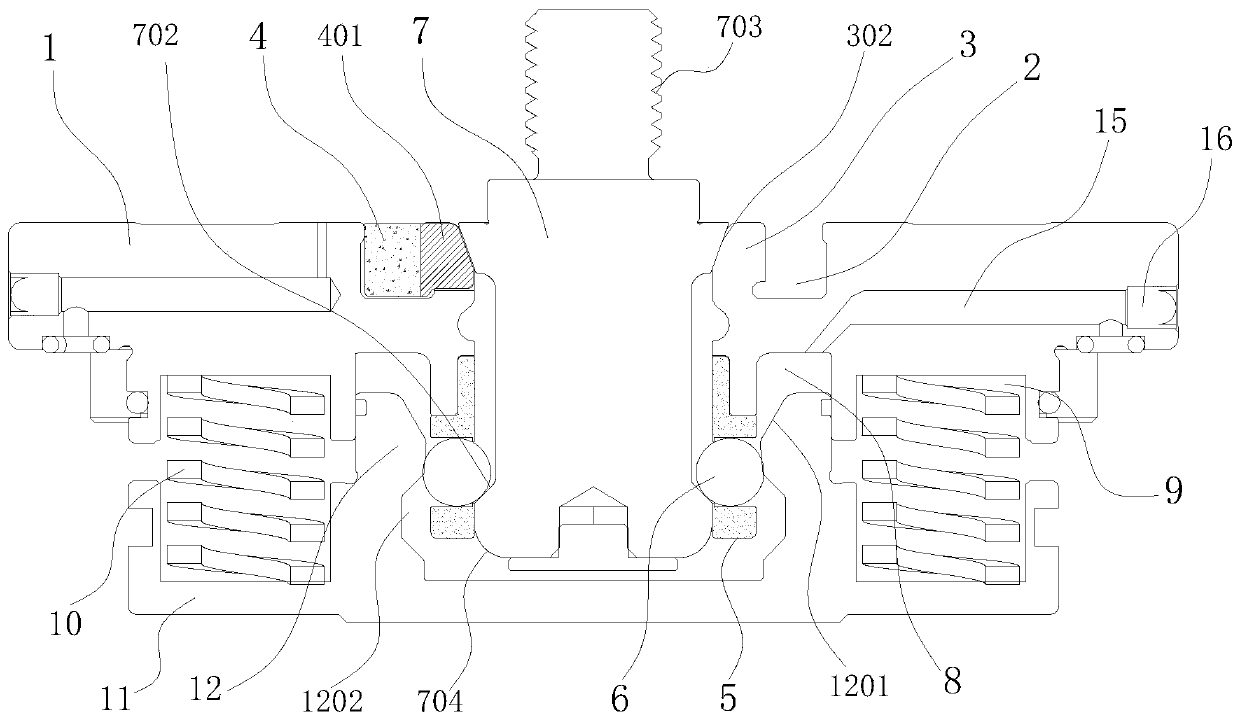

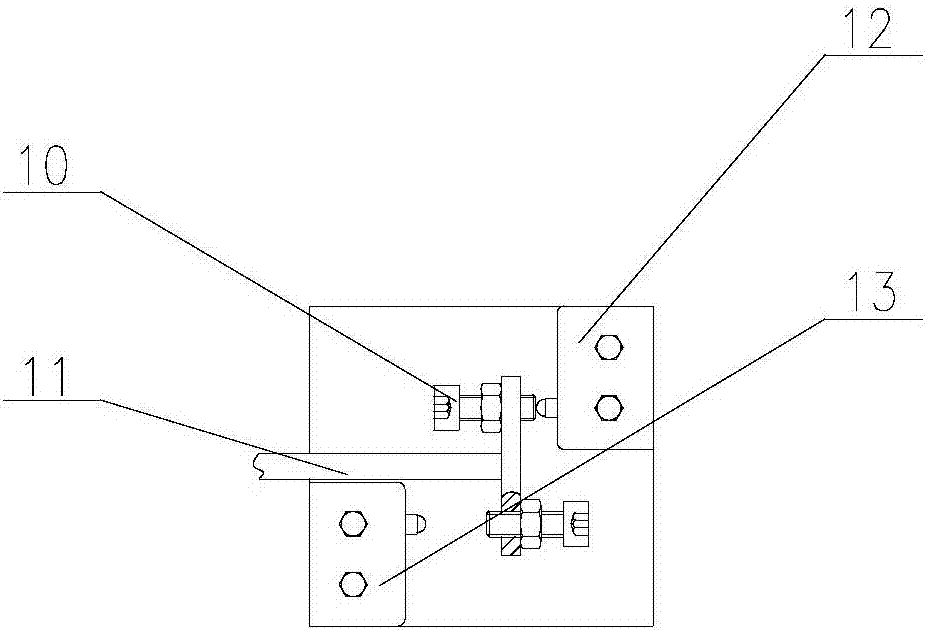

Grabbing mechanism capable of quickly adjusting positions of clamping jaws and using method thereof

The invention relates to a grabbing mechanism capable of quickly adjusting the positions of clamping jaws and a using method thereof. A chute penetrates through a base body; a first sliding inclined block and a second sliding inclined block are symmetrically and reversely arranged and are arranged on the chute in a sliding fit mode; the end face of the first sliding inclined block is in fit connection with a first adjusting screw; the end face of the second sliding inclined block is in fit connection with a second adjusting screw; a first sliding block is arranged on the first adjusting screwin a transmission fit mode through a right-hand thread; a second sliding block is arranged on the second adjusting screw in a transmission fit mode through a left-hand thread; a first clamping jaw isfixedly arranged on the first sliding block through a first clamping jaw mounting seat; a second clamping jaw is fixedly arranged on the second sliding block through a second clamping jaw mounting seat; and the first adjusting screw rod and the second adjusting screw rod match and are connected through an internal spline sleeve. According to the grabbing mechanism, the manipulator claws are rapidly adjustable clamping claws, so that the shape changing efficiency of the claws is greatly improved, and the repeated positioning precision is guaranteed.

Owner:宜昌长机科技有限责任公司

Prestretching mounting structure for screw rod

ActiveCN106078176AAdjustable pre-stretchGuaranteed repeat positioning accuracyFeeding apparatusMetal working apparatusMachine toolFlange

The invention discloses a prestretching mounting structure for a screw rod. One end of the screw rod is fixed, and the other end of the screw rod is free; bearings are separately arranged at the fixed end and the free end; the bearing at the fixed end is arranged in a bearing block fixed with a machine tool main body structure; a bearing bush is arranged outside the bearing at the free end of the screw rod; a motor base connecting flange is arranged outside the bearing bush and is fixedly connected with a motor base; a through hole is formed in the motor base connecting flange; a longitudinal sliding chute is formed in a position, corresponding to the through hole, of the bearing bush; a thread section is arranged at the outer side of the bearing bush; a thread section part is located at the lower side of the motor base connecting flange; part of the thread section part extends from the outer side of the motor base connecting flange; and a bearing bush adjusting nut is screwed in the thread section. The bearing bush adjusting nut can screw in the thread section of the bearing bush by a certain distance, so that the prestretching amount of the screw rod can be controlled, further the control over the prestretching amount of the screw rod is conveniently realized, and the simplicity in operation is realized.

Owner:广州市高品机床有限公司

Rotary working table

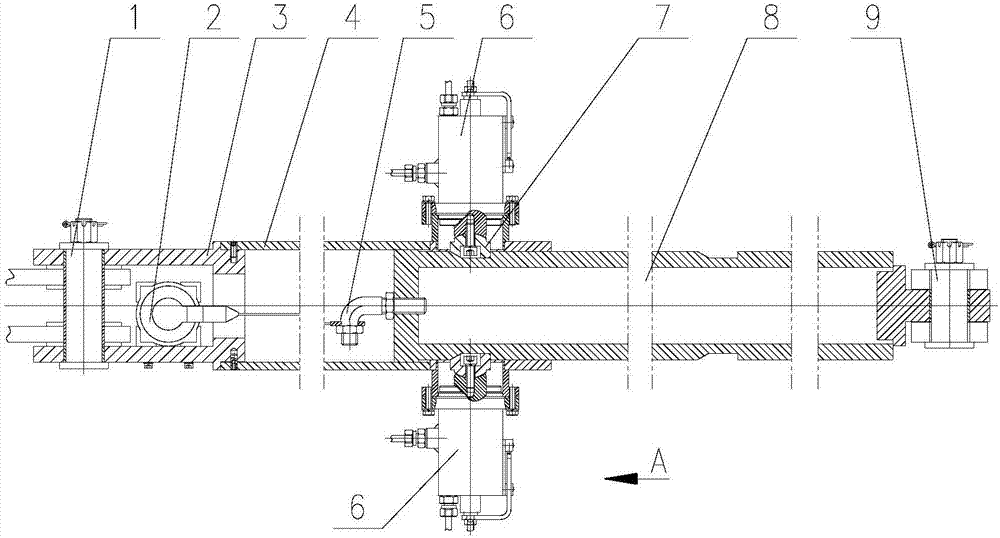

ActiveCN101450446AEliminate windingGuaranteed repeat positioning accuracyLarge fixed membersGas pipelineEngineering

The invention provides a rotary working-table, which adopts a hydraulic power lift and lock mechanism for lifting and locking of a working-table, so that the rotary working-table can support vertical heavy-load acting force of a side edge. A multiple oil way variable-position integration mechanism is integrated inside the working-table to be communicated with an oil gas pipeline of an additional device and the like on the working-table, so as to eliminate a winding problem of a hydraulic pneumatic pipeline. A 90-degree variable-position drive mechanism and a high-accuracy end-toothed disc ensure the scale division of every 90 degrees and the resetting accuracy.

Owner:ZHEJIANG CHR INTELLIGENT EQUIP

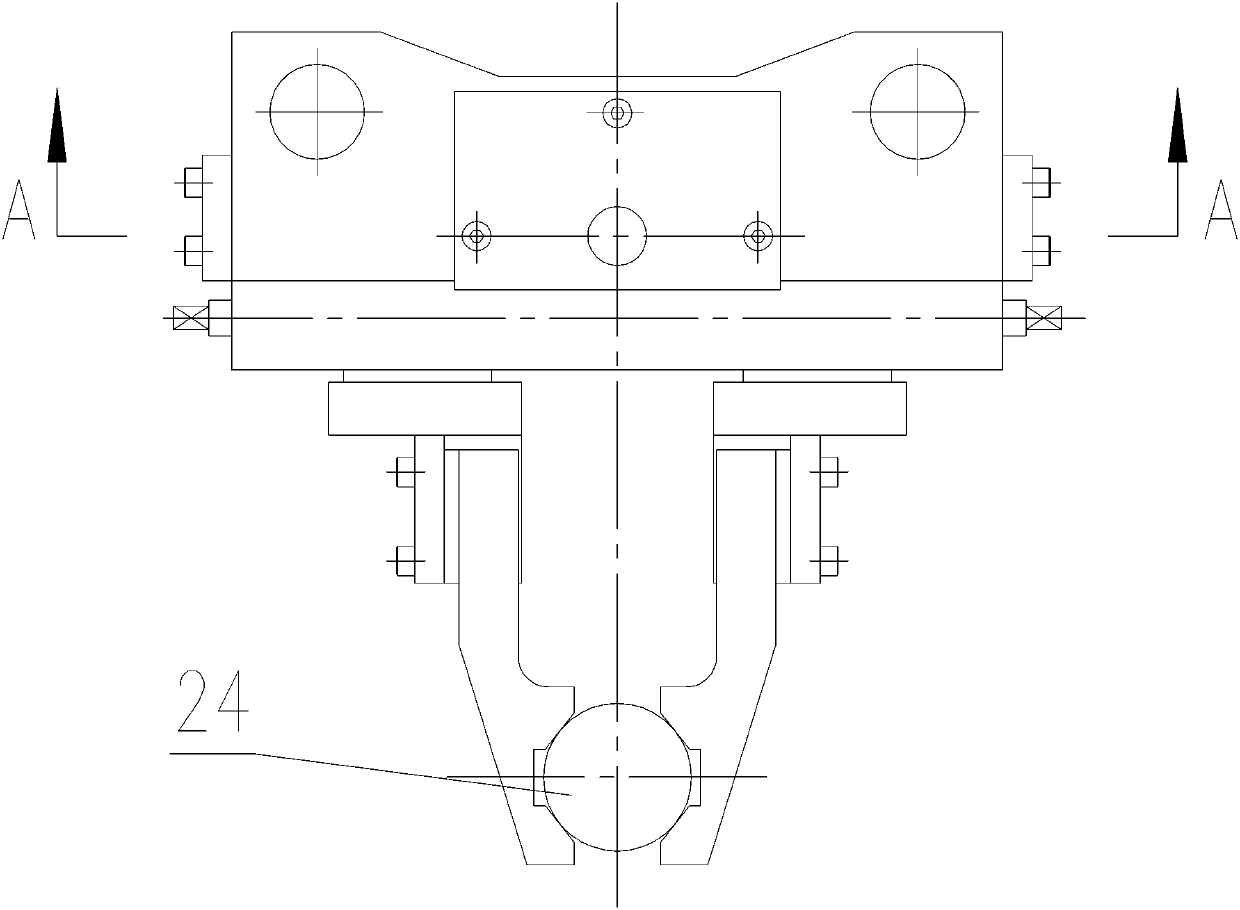

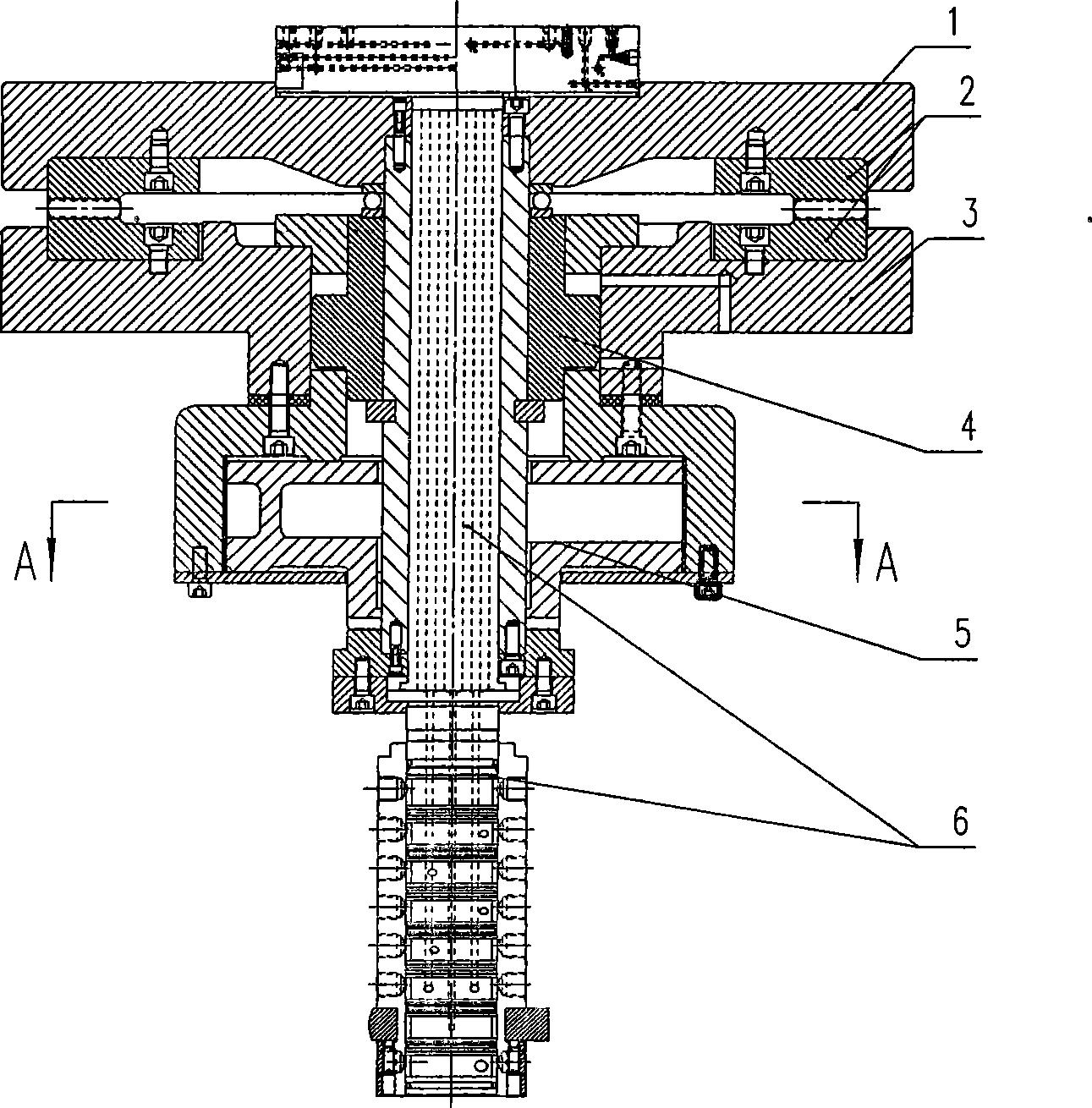

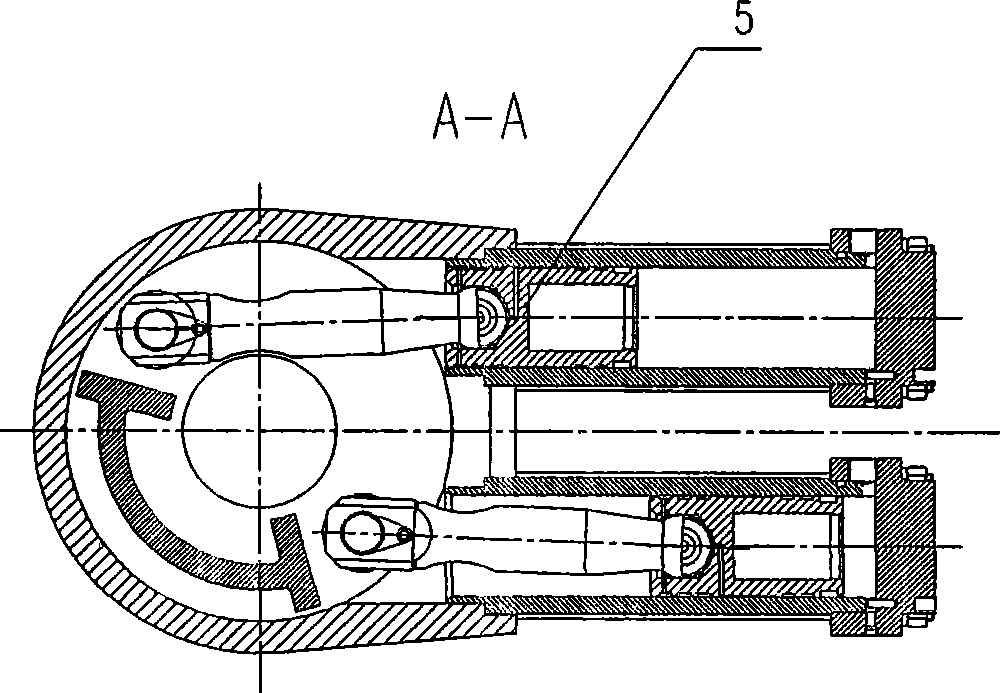

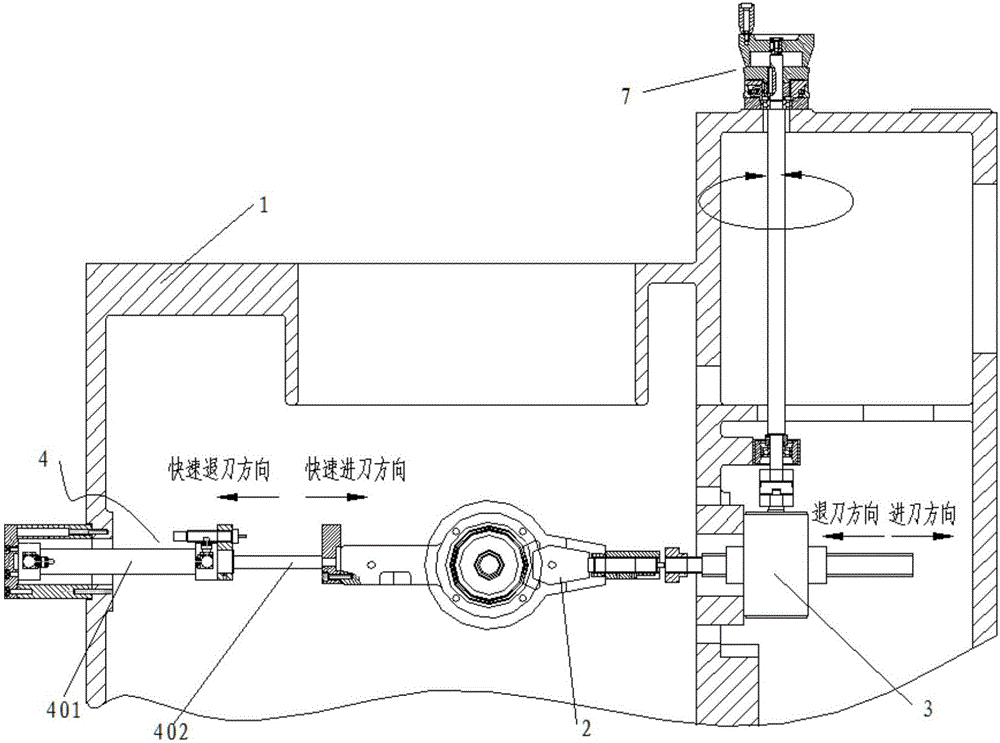

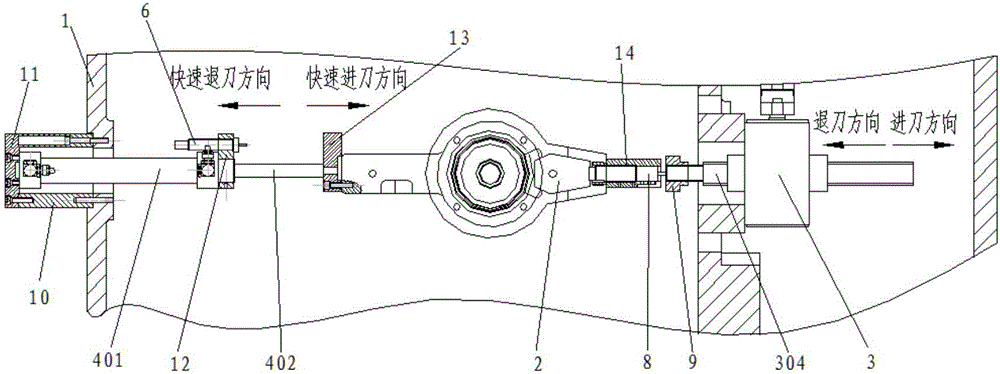

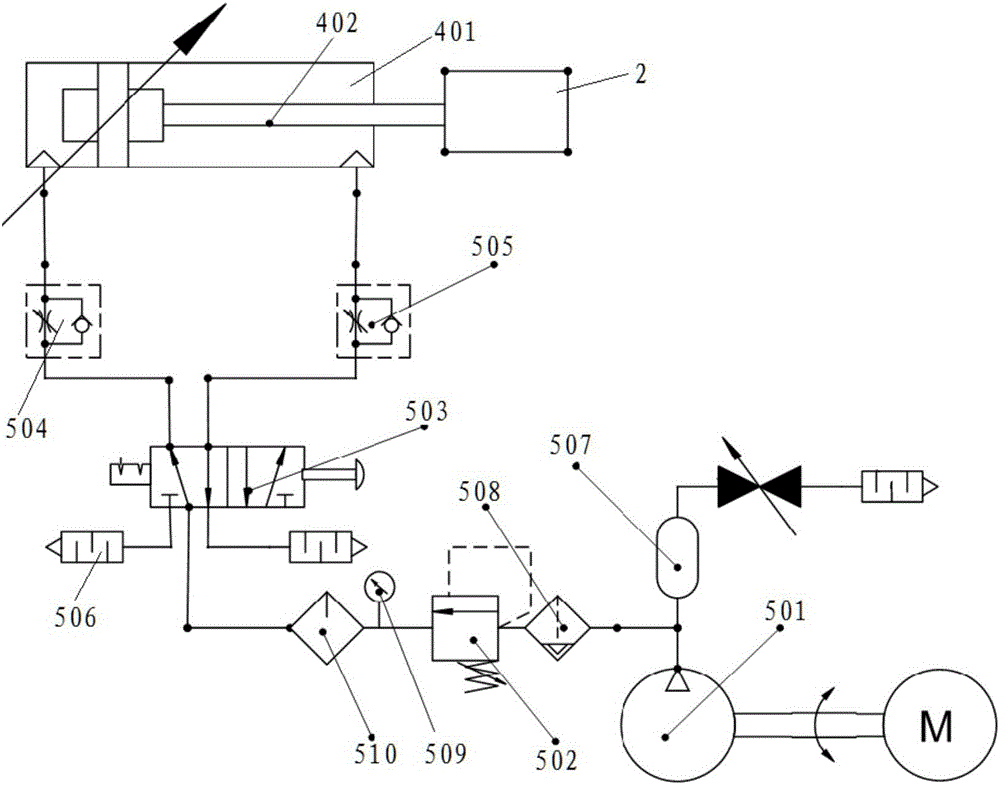

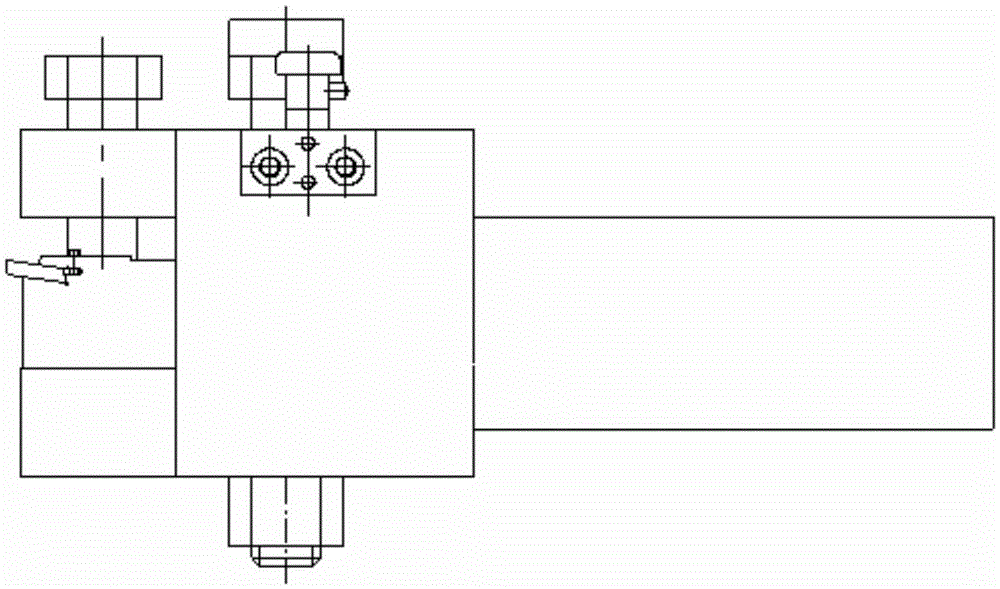

Quick cutter feeding/retreating and constant-pressure feeding mechanism

ActiveCN106625241ARapid advance and retreatRealization of constant pressure feedGrinding carriagesGrinding drivesPressure transmissionControl system

The invention relates to the technical field of machining, in particular to a quick cutter feeding / retreating and constant-pressure feeding mechanism. The mechanism comprises a slideable feeding carriage, a screw speed reducer, a feeding hand wheel mechanism, a buffer device and an air-pressure transmission system; one end of the feeding carriage is connected with the air-pressure transmission system, and the other end of the feeding carriage is connected with a second buffer; the second buffer tightly presses a screw of the screw speed reducer when a cutter enters a machining station; the air-pressure transmission system includes a cylinder and an air-pressure transmission control system; a first buffer is arranged at the head part of a cylinder body of the cylinder; the outer end of a piston rod is rigidly connected with the feeding carriage; the air-pressure transmission control system includes an air compressor, a pressure relief valve, a two-position five-way valve and a one-way throttling valve module connected in sequence; and an input shaft of the screw speed reducer is connected with the feeding hand wheel mechanism. The quick cutter feeding / retreating and constant-pressure feeding mechanism adopts a mode of combining mechanical feeding with the air-pressure transmission system to realize quick cutter feeding and retreating, guarantees repeated positioning precision of quick movement of the feeding carriage, and meanwhile, realizes constant-pressure feeding in cutter machining.

Owner:北京市电加工研究所有限公司

Solar cell chip bonding machine

InactiveCN101372064AAvoid rushing to the bottomReduce shockWelding/soldering/cutting articlesMetal working apparatusEngineeringSolar cell

The invention discloses a solar battery welding machine, comprising a frame, a large cylinder, a small cylinder, a large cylinder pushing plate, a floating plate, a welding head guiding shaft, a guideway and a welding head; the large cylinder is fixed on the frame; the lower end of the large cylinder is connected with the large cylinder pushing plate; the end of the large cylinder pushing plate and the end of a welding head supporting crossbeam are fixedly connected with a guideway sliding block; the small cylinder is fixed on the welding head supporting crossbeam; the small cylinder pushing plate is fixed on the small cylinder; two ends of the small cylinder pushing plate are fixedly connected with a welding head guiding shaft which is connected with the floating plate by a conical surface matching pair; the welding process of the welding machine is completed by two strokes, thus avoiding the impact on the welding part caused by that the large cylinder is punched to the bottom; the welding head guiding shaft and the conical surface matching pair floating mechanism of the floating plate of the welding machine lead the welding head to be always attached to the welding parts of different feeding precisions reliably and closely, thus reducing the requirement on the welding part and the feeding mechanism precision and ensuring the welding quality.

Owner:MIASOLE SOLAR ENERGY TECH SHANGHAI

Aiming device and aiming method of X-ray optical system for plasma diagnosis

InactiveCN103514966AImprove reliabilityGuaranteed repeat positioning accuracyNuclear energy generationHandling using diffraction/refraction/reflectionEpoxyObject point

The invention relates to an aiming device and an aiming method of an X-ray optical system for plasma diagnosis. The device comprises an analog positioning assembly and an adjustment mechanism thereof. The analog positioning assembly comprises a positioning rod, an analog positioning member, a slider, a bracket, a linear guide rail and an objective lens group, wherein one end of the positioning rod is connected with the analog positioning member and the other end of the positioning rod is connected with the slider, the lower side of the bracket is provided with the linear guide rail and the upper side of the bracket is provided with the objective lens group, the slider is slidingly connected with the linear guide rail, and the bracket is connected with the adjustment mechanism. The method comprises the following steps: first, coincidence of the analog positioning member and a marking hole of a square-hole mesh is finished under surveillance of a tool microscope; then, an optimal object point of the system and an optimal field of view of the square-hole mesh are enabled to coincide with each other through an X-ray grid imaging experiment; and finally, the objective lens group and the bracket are solidified together by epoxy resin. Compared with the prior art, the collimation device and the collimation method have the advantages of high system reliability, high theoretical and practical aiming accuracy, simple structure, low cost and the like.

Owner:TONGJI UNIV

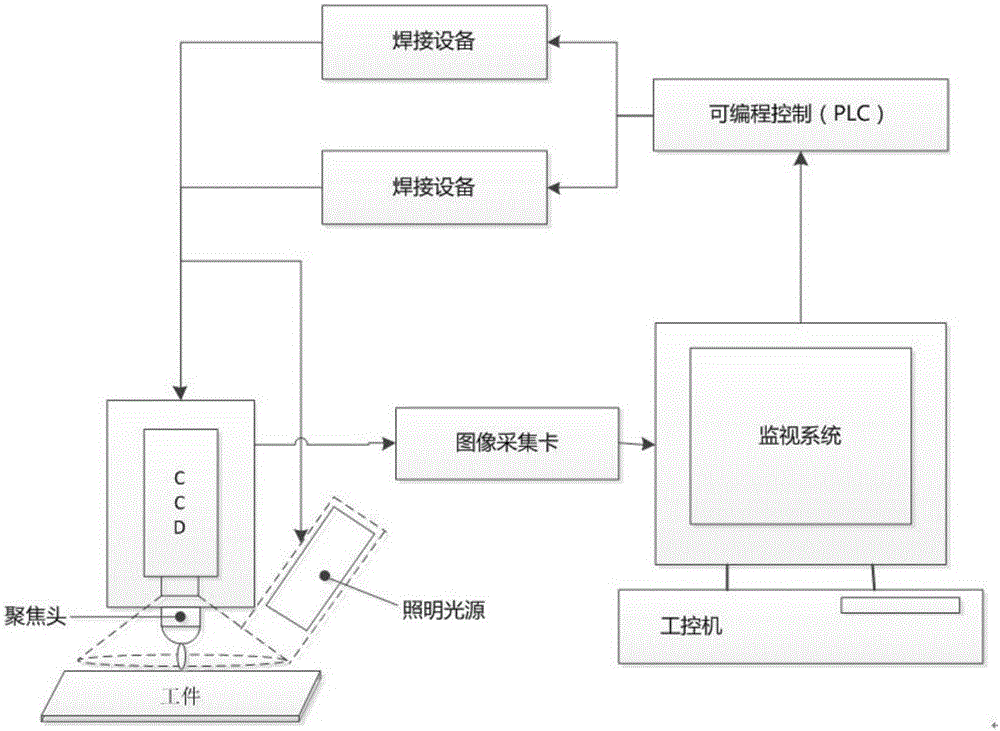

Method for laser welding of vibration motor clip and mass block

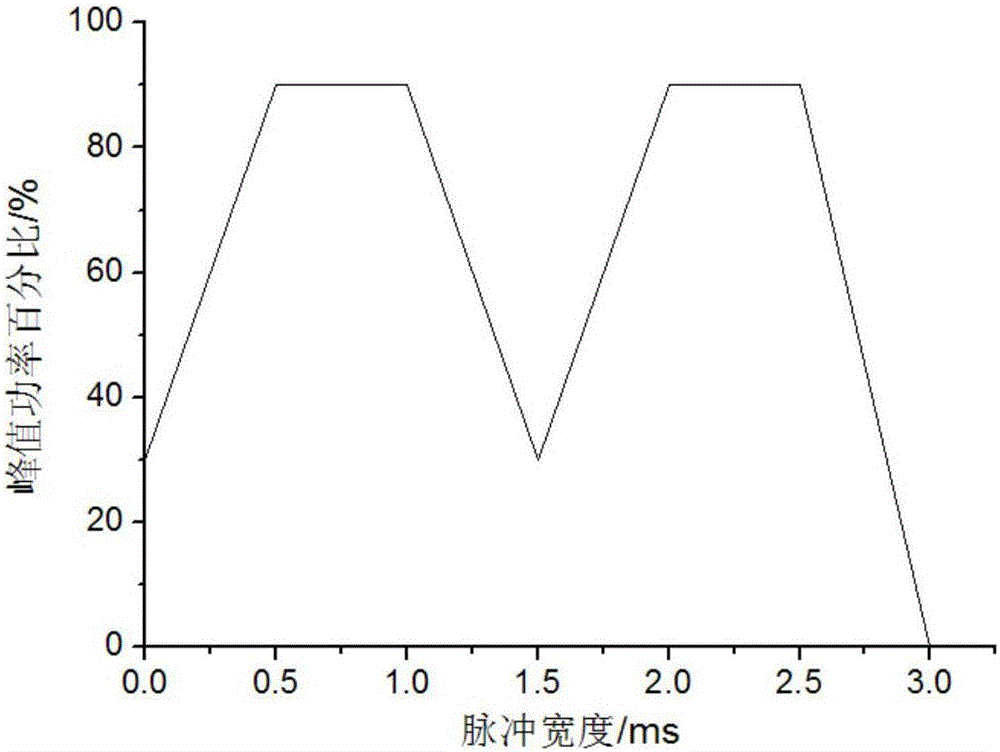

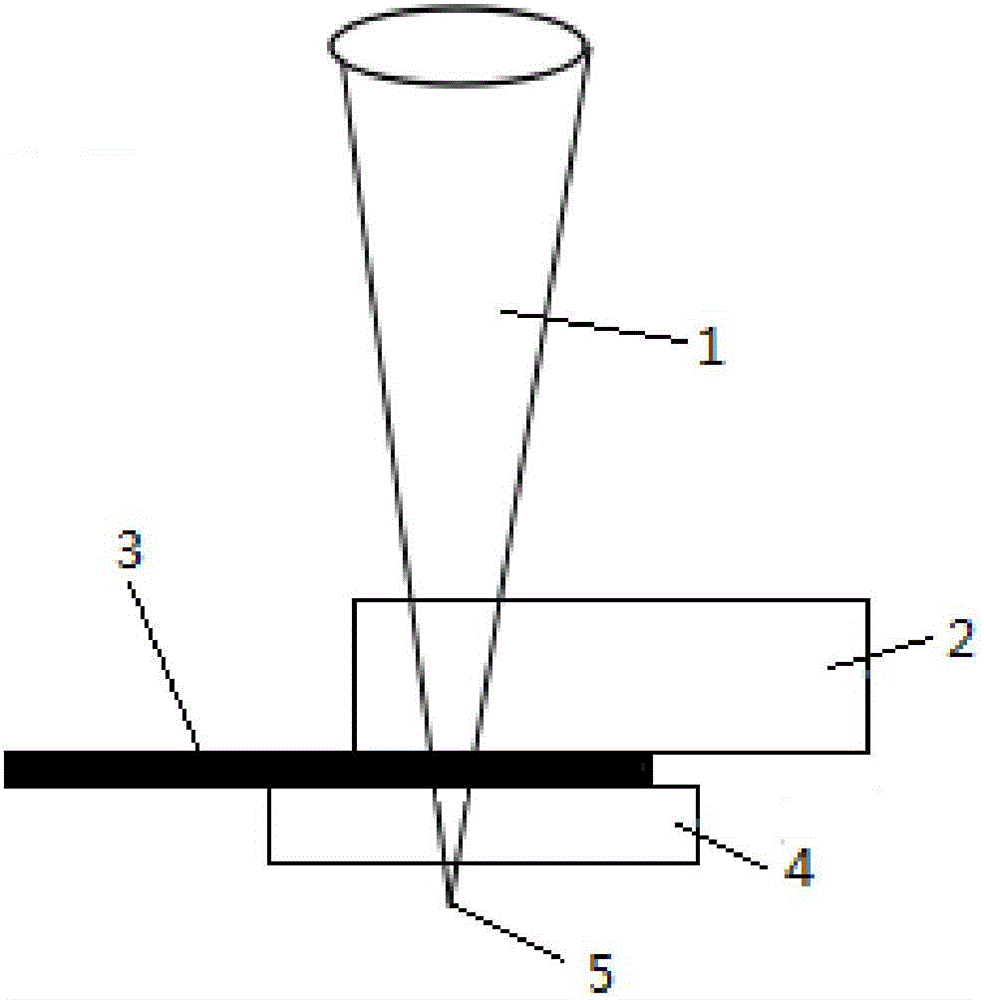

ActiveCN106271073AGuaranteed positioning accuracyGuaranteed repeat positioning accuracyLaser beam welding apparatusLaser lightFocal position

The invention discloses a method for laser welding of a vibration motor clip and a mass block. The method comprises the steps of 1, conducting precise positioning on a welding position by means of CCD vision; 2, setting an M-shaped welding waveform, wherein energy is increased slowly and lasts for a while, then energy is reduced and increased again and lasts for a while, and finally energy is reduced to zero; 3, finding out the focal position of a focus lens and the distance between the focus lens and a workpiece; 4, adjusting the focal point of the focus lens to a position below the surface of the workpiece, and conducting step-by-step adjustment of the focal position of laser light multiple times to enable the focal point to move downwards and get away from the surface of the workpiece till spatter does not occur during welding and welding strength meets the requirement. By the adoption of CCD vision positioning, the position accuracy of a welding spot reaches 0.03mm, and repeated positioning precision of the welding spot during production is guaranteed; by the adoption of the M-shaped waveform and the negative defocus welding method, the strength of a single welding spot can reach 3 kg, and the welding spot is smooth and flat.

Owner:WUHAN HGLASER ENG CO LTD

High-precision rotary device

ActiveCN103298264ASimple structureFew partsConductive material chemical/electrolytical removalGratingDirect imaging

The invention provides a high-precision rotary device which comprises an installing base plate and a rotary panel. The high-precision rotary device is characterized by further comprising an air floatation rotary bearing arranged between the installing base plate and the rotary panel, a driving device used for driving the air floatation rotary bearing to rotate, and a length gauge used for measuring the linear displacement of the driving device, and the air floatation rotary bearing is provided with a connecting piece. The locating precision of the high-precision rotary device is less than or equal to 5'', the repeated locating precision of the high-precision rotary device is less than or equal to 2.5'', and the rotating angle of the high-precision rotary device is + / -5 degrees. The high-precision rotary device is applied to the field of laser direct imaging processing, and is simple in structure, small in number of parts and convenient to install. Due to the fact that a low-power stepping motor and the length gauge, instead of a high-precision circular-arc optical grating ruler, are adopted to carry out repeated measurement, to carry out feedback and to determine the repeated locating precision, the high-precision rotary device is low in cost and applicable to practical application, and has wide industrial use value.

Owner:HANS CNC SCI & TECH

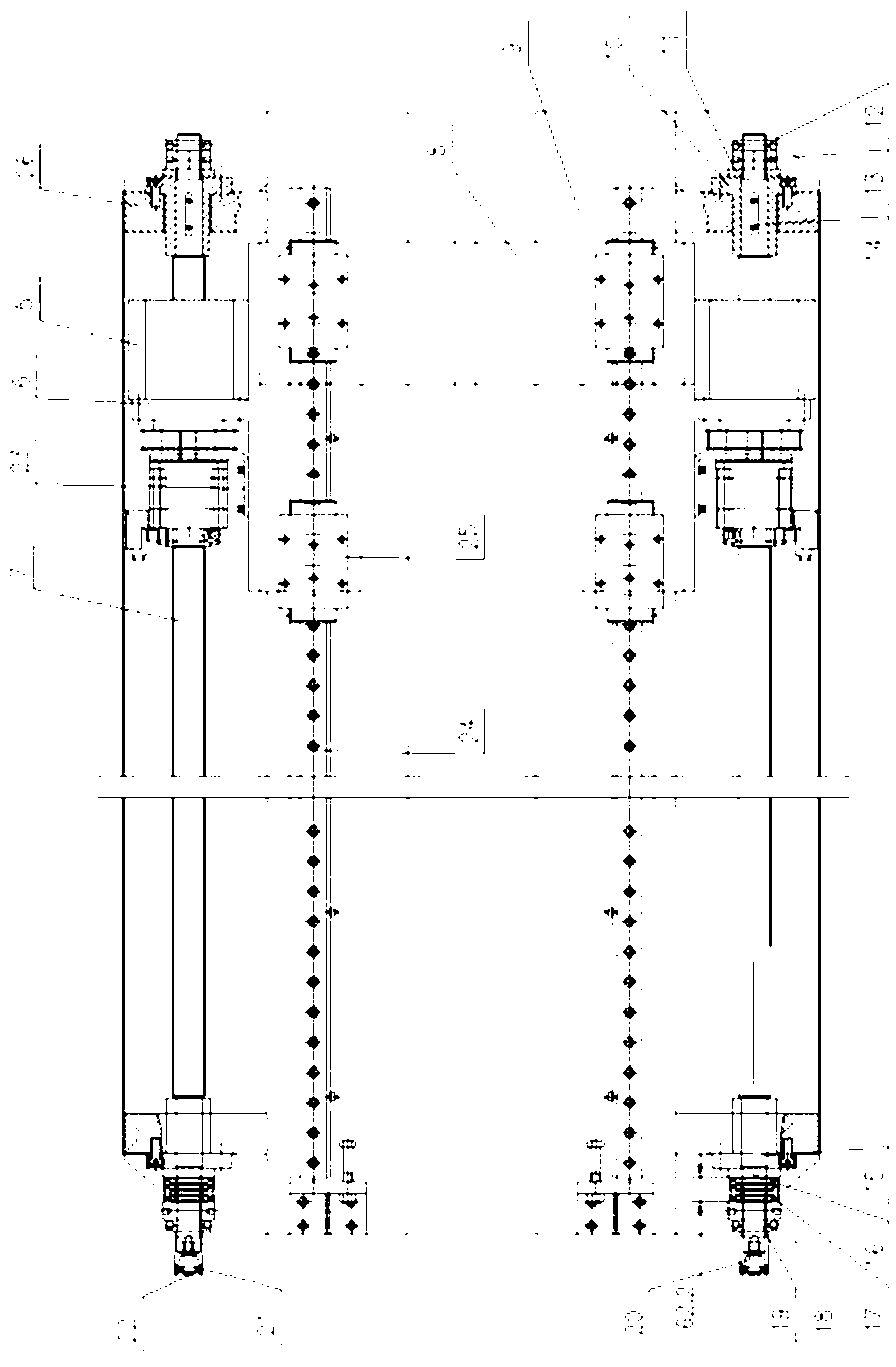

Nut rotating ball screw pair transmission unit

InactiveCN103008773ACompact structureInnovative design ideasGearingShearing machine accessoriesBall screwEngineering

The invention discloses a nut rotating ball screw pair transmission unit which comprises fixed brackets, a servo motor, ball screw pairs, linear guide rails and a feeding beam, wherein the fixed brackets are symmetrically arranged on two ends of the feeding beam, the linear guide rails are arranged on the upper part of the fixed brackets, roller type slide blocks are arranged on the linear guide rails, the feeding beam is arranged on the roller type slide blocks, lead screw seat plates are arranged on the upper parts of the fixed brackets, ball lead screws are arranged on the lead screw seat plates through fixing devices, ball lead screw pair nuts are sleeved on the ball lead screws and are connected with nut seats, the nut seats are connected with the feeding beam, two ends of the feeding beam are connected with a servo motor bracket, and the servo motor is arranged on the servo motor bracket. The nut rotating ball screw pair transmission unit provided by the invention has a simple and compact structure, and is novel and special in design thought. A ball lead screw transmission system is used for replacing a gear-rack transmission mode in an overlong stroke feeding process, and the difficulty of poor feeding precision caused by axial and radial runout in an overlong distance conveying process is solved. High-speed feeding and returning of a plate are realized, and locating precision and repeated locating precision are ensured.

Owner:TIANSHUI METALFORMING MACHINE TOOL GROUP

X-shaft ball screw nut transmission mechanism of numerical control floor type boring and milling machine

InactiveCN101850435AHigh precisionGuaranteed accuracyMetal working apparatusBoring/drilling componentsNumerical controlBall screw

The invention discloses an X-shaft ball screw nut transmission mechanism of a numerical control floor type boring and milling machine. The transmission mechanism comprises a ball screw nut transmission pair, an anti-backlash gear pair and a power source, wherein the anti-backlash gear pair comprises a pinion gear and a double-tooth anti-backlash gear which are linked with a power source output shaft; the ball screw nut transmission pair is a ball screw nut component and comprises a ball screw and a nut; a nut sleeve is arranged outside the nut; the double-tooth anti-backlash gear is arranged on the nut sleeve; and one end of the ball screw is fixed, while the other end is born. The transmission mechanism has the advantages of simple structure, low cost, high degree of standardization, short production cycle and high transmission precision.

Owner:德阳嘉龙机械制造有限公司

Valve rocker arm assembly welding tool of turbine shell

PendingCN109590652ACompact structureReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftTurbine

The invention relates to a valve rocker arm assembly welding tool of a turbine shell. The welding tool is characterized by comprising a substrate, wherein a positioning support plate is connected withthe substrate, a positioning disc is fixedly connected with the positioning support plate, one side of the positioning disc is provided with a linear guide rail, a rocker arm positioning plate is connected with the linear guide rail, a positioning groove for positioning the rocker arm assembly is arranged in the front end of the rocker arm positioning plate, and a connecting block is arranged onthe other side of the positioning plate, a quick clamp and an angular positioning pin are fixedly connected with the connecting block; two positioning pins are arranged on the positioning plate, a topblock is obliquely arranged and is fixedly connected with the positioning plate, and an ejector rod hole is arranged in the front part of the top block, an ejector rod is connected in the ejector rodhole in a sliding mode, and during welding, the positioning plate is positioned by two positioning pins and covers an air outlet of the turbine shell, the ejector rod abuts against the lower portionof a valve transmission shaft assembly, and the positioning plate is tightly clamped by the clamp head of the quick clamp. The device has advantages of being simple and compact in structure, low in manufacturing cost, convenient and rapid in operation, ensured in repeated positioning precision, the working efficiency is improved, the labor intensity of operators is relieved, and the processing cost is reduced.

Owner:WUXI ZEMIN PRECISION MACHINERY MFG

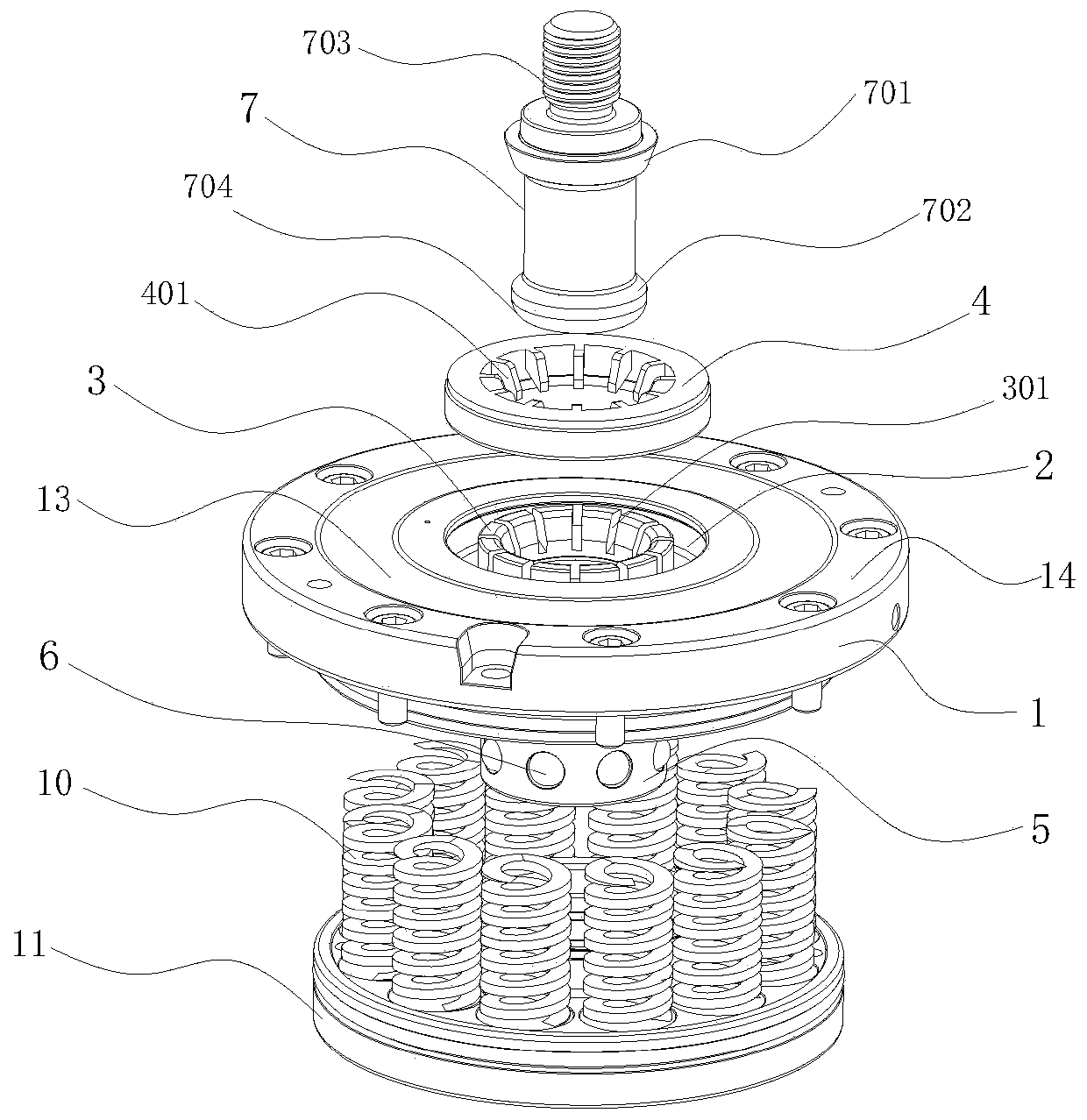

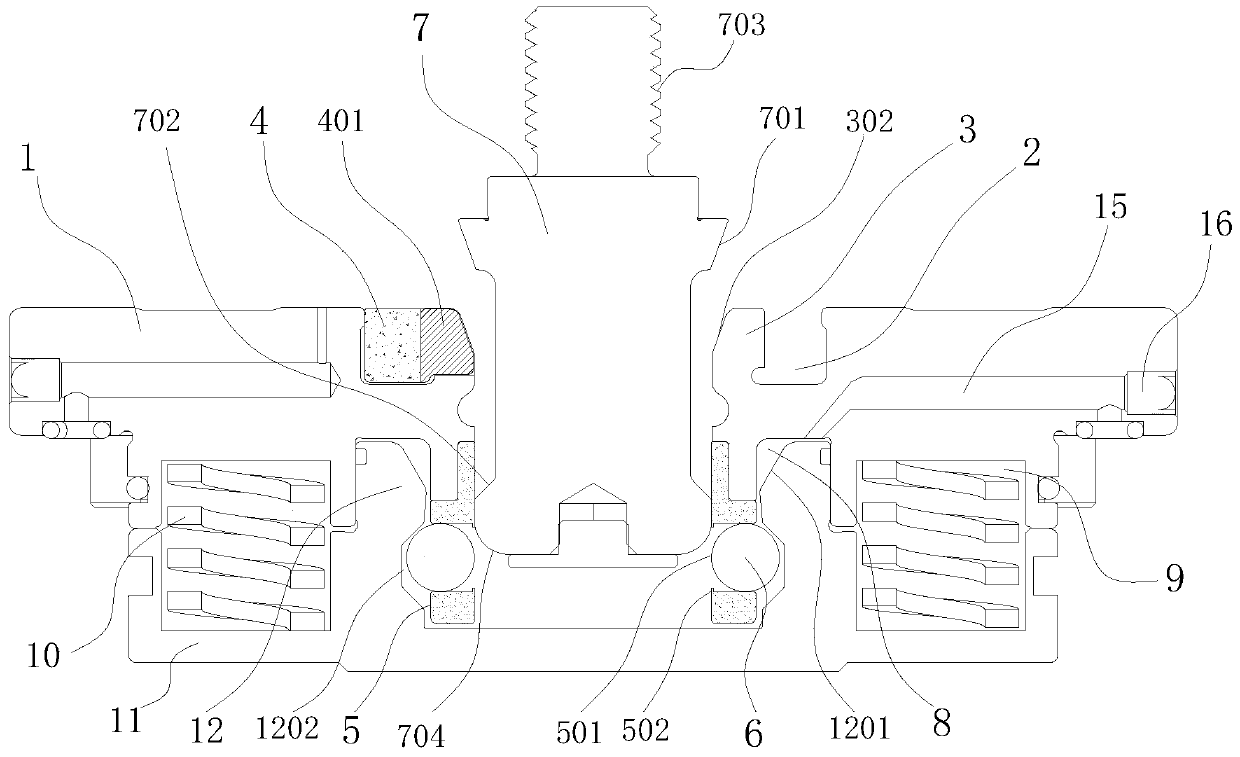

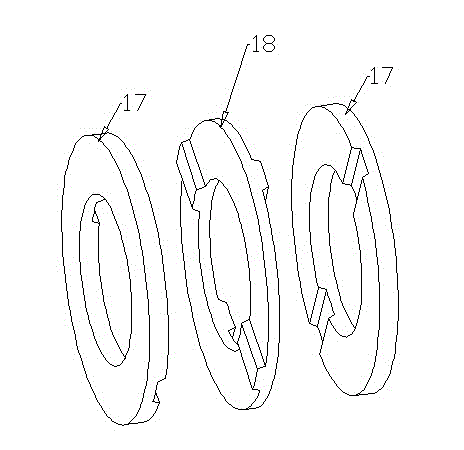

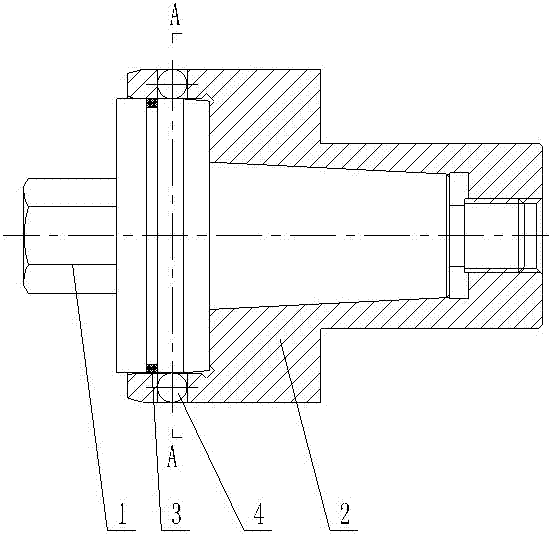

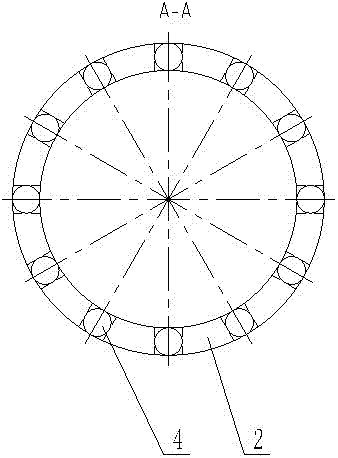

High-precision flexible zero point positioning system

PendingCN110421395AReduce time to change toolingHigh positioning accuracyPositioning apparatusMetal-working holdersSingle useEngineering

The invention belongs to the technical field of positioning systems, and particularly discloses a high-precision flexible zero point positioning system. The system comprises a clamping disk, a short cone expansion pipe, a protection nest and a short cone pop rivet; a central positioning hole is formed in the center of the top surface of the clamping disk; the short cone expansion pipe is embeddedin the inner hole of the central positioning hole; the top surface of the short cone expansion tube is level with the top surface of the clamping disk; ten deformation grooves are formed in the top end of the short cone expansion pipe; a top cone positioning surface is arranged at the top end of the inner hole of the short cone expansion pipe; the protection nest is embedded in the central positioning hole; and ten ring-shaped comb teeth are arranged at the inner ring of the protection nest. According to the system provided by the invention, the tooling change time is greatly shortened, mechanical locking is carried out through spring force and the pressure source can be cut off at any time in a locking state; the system is particularly applied to the machine tools of rotary tables with four shafts and five shafts to prevent the problem of air pipe and hydraulic pipe winding, is high in positioning precision and is capable of ensuring the repeated positioning precision when adopting single use or combined use.

Owner:苏州速易德工业装备系统有限公司

Automatic gluing equipment for shoemaking

ActiveCN110916295AGuaranteed stabilityGuaranteed repeat positioning accuracyShoe gluingRobot handLaser scanning

The invention provides automatic gluing equipment for shoemaking. The invention belongs to the field of shoemaking equipment, the equipment comprises a tray bottom plate, and a six-axis manipulator, agluing assembly, a dispensing assembly and a laser scanning assembly which are arranged on the tray bottom plate, the six-axis manipulator clamps the shoe tree to move through the clamping assembly;wherein the gluing assembly comprises a gluing machine and a gluing spray head which are integrally arranged, the dispensing assembly comprises an automatic dispensing machine and a bottom plate assembly, the bottom plate assembly is arranged on a station of the automatic dispensing machine, the number of the laser scanning assemblies is two, one laser scanning assembly is directly arranged on thetray bottom plate, and the other laser scanning assembly is arranged at the end, close to the bottom plate assembly side, of the automatic dispensing machine. According to the invention, the dispensing and gluing requirements of different positions of the vamp are met, and the gluing quality is improved.

Owner:FUDAN UNIV

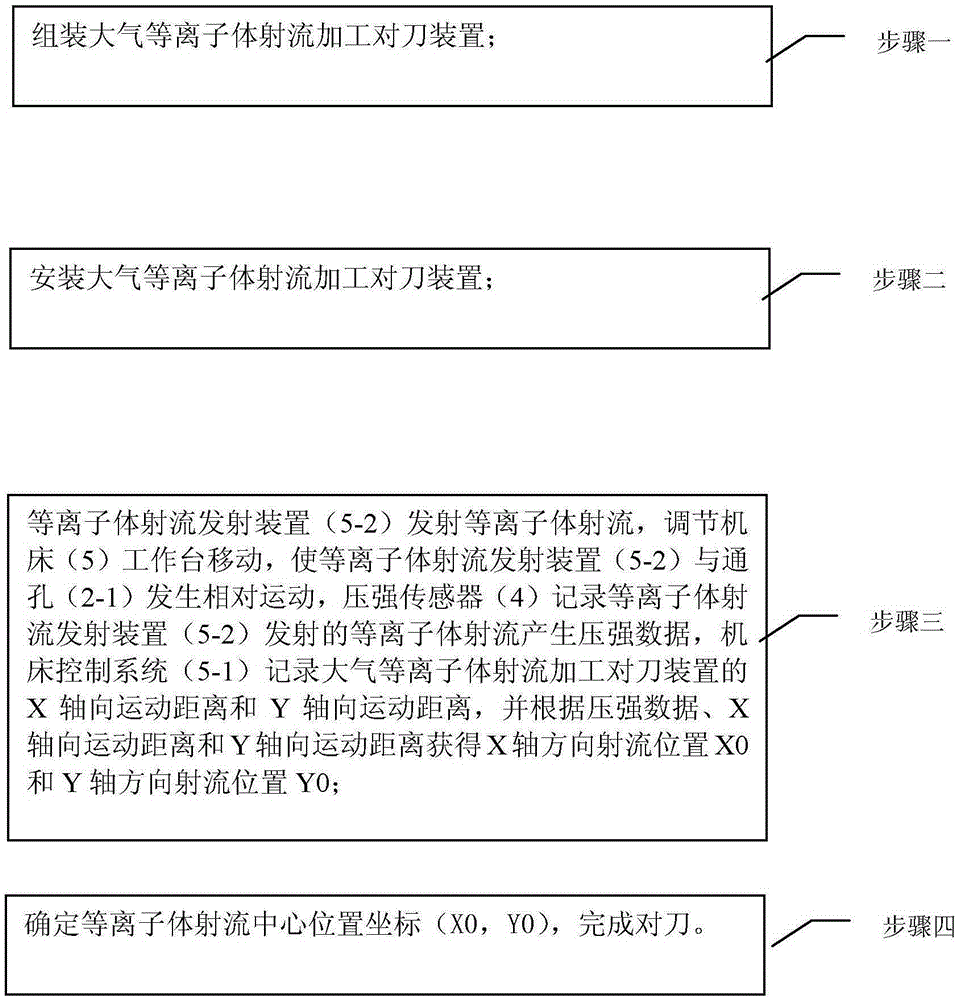

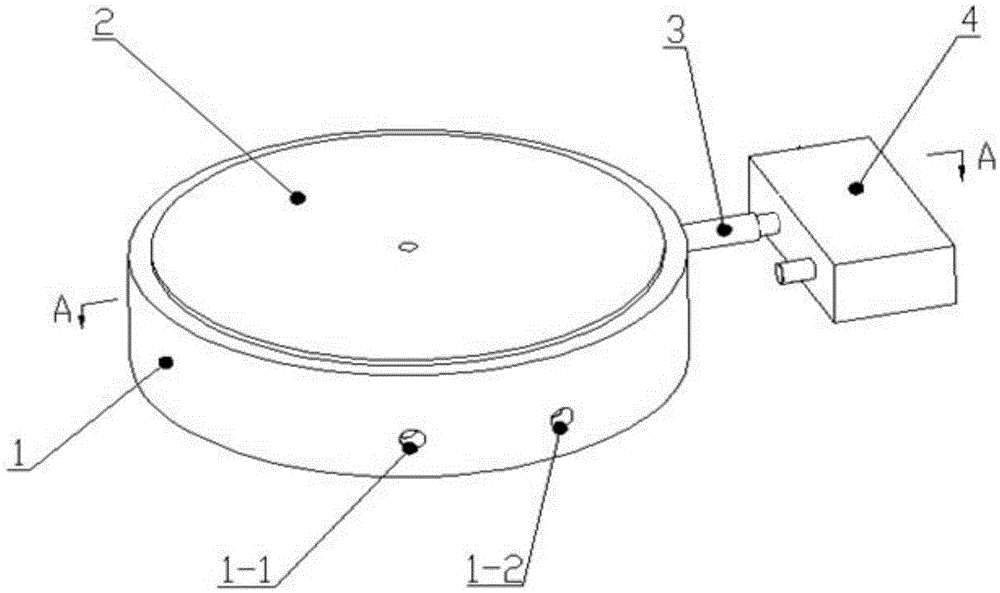

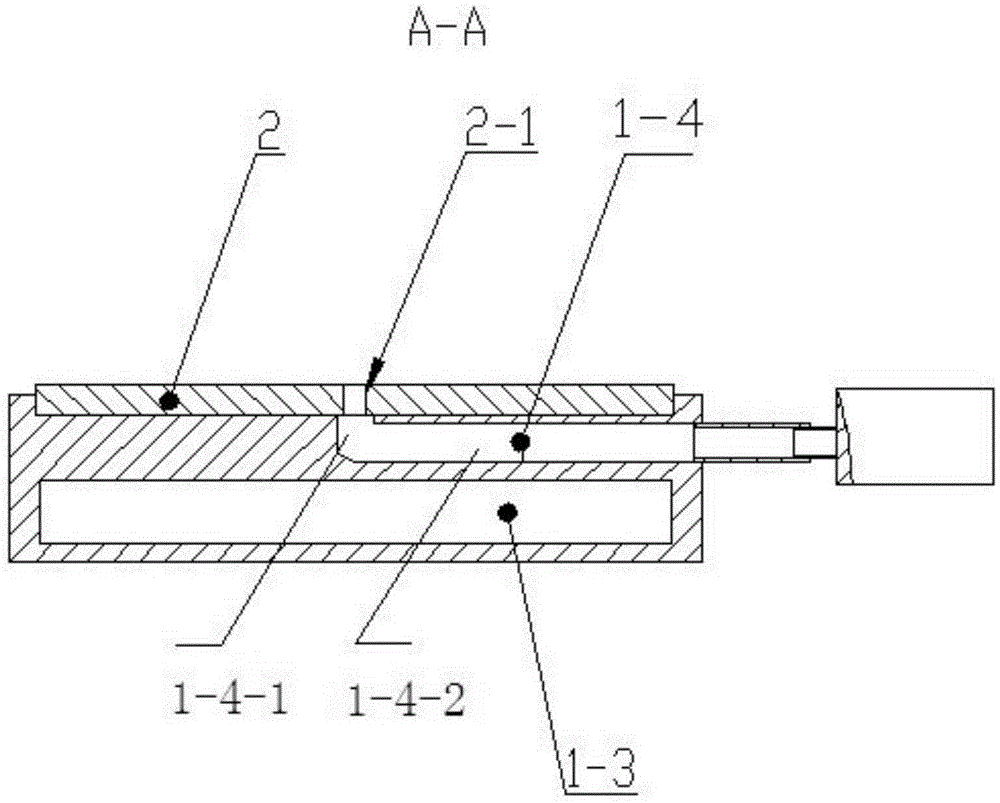

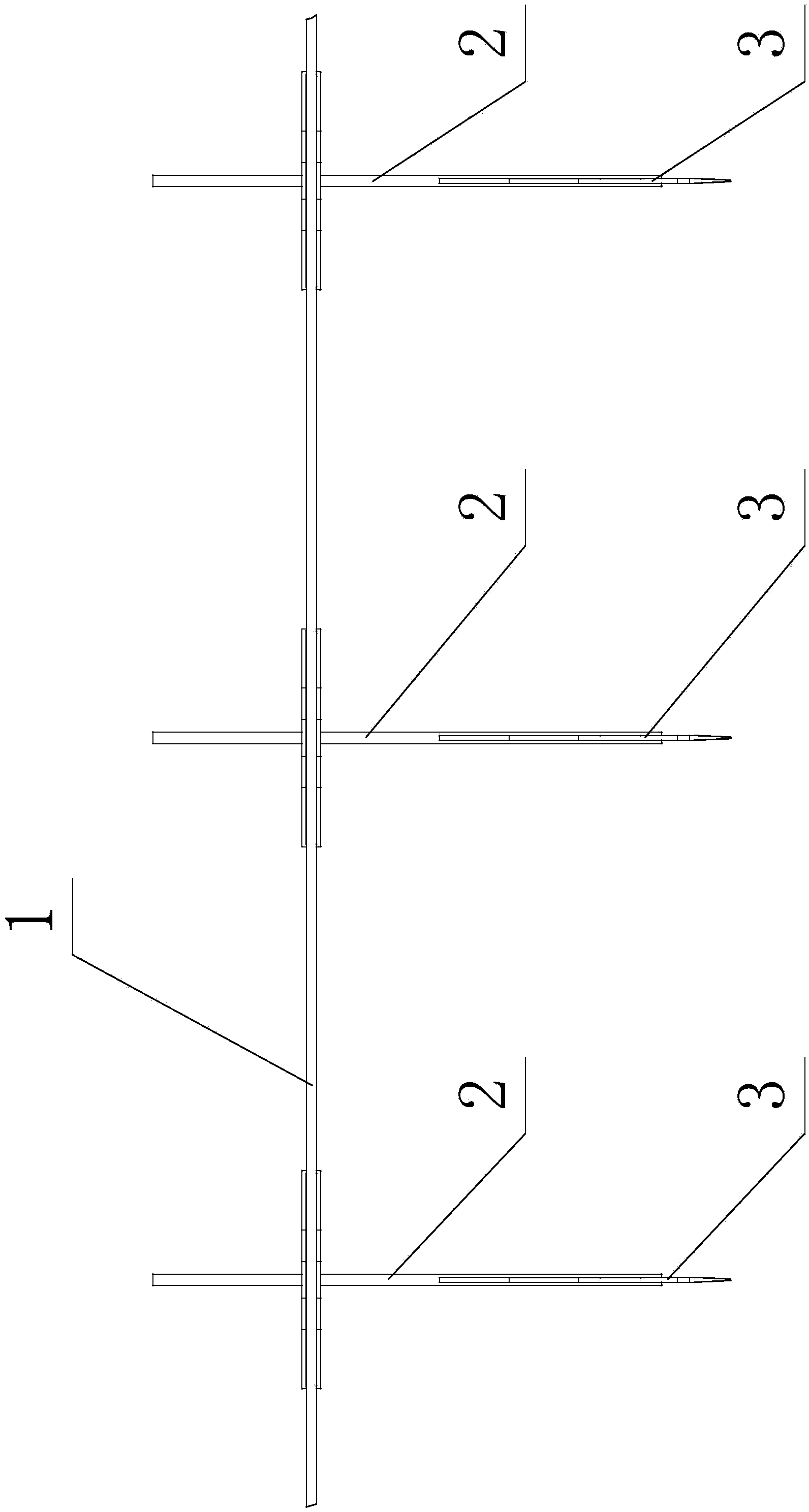

Atmospheric plasma jet processing tool setting method

ActiveCN105328318AGuaranteed repeat positioning accuracyGood repeatabilityAutomatic control devicesMeasurement/indication equipmentsPlasma jetControl system

The invention discloses an atmospheric plasma jet processing tool setting method, relates to the field of precise optical processing, and solves the atmospheric plasma jet tool setting problem. The method comprises the following steps: 1) an atmospheric plasma jet processing tool setting device is assembled; 2) the atmospheric plasma jet processing tool setting device is installed; 3) a plasma jet emitting device emits plasma jets; a machine tool is adjusted to enable the plasma jet emitting device and a through hole to generate a relative motion; a pressure sensor records plasma jet generation pressure data; a machine tool control system records an X-axle moving distance and a Y-axle moving distance of the atmospheric plasma jet processing tool setting device; and an X-axle direction jet position X0 and a Y-axle direction jet position Y0 are obtained according to the pressure data, the X-axle moving distance and the Y-axle moving distance; and 4) the center position coordinate of the plasma jets is determined to finish the tool setting. The method is suitable for other places needing the tool setting.

Owner:HARBIN INST OF TECH

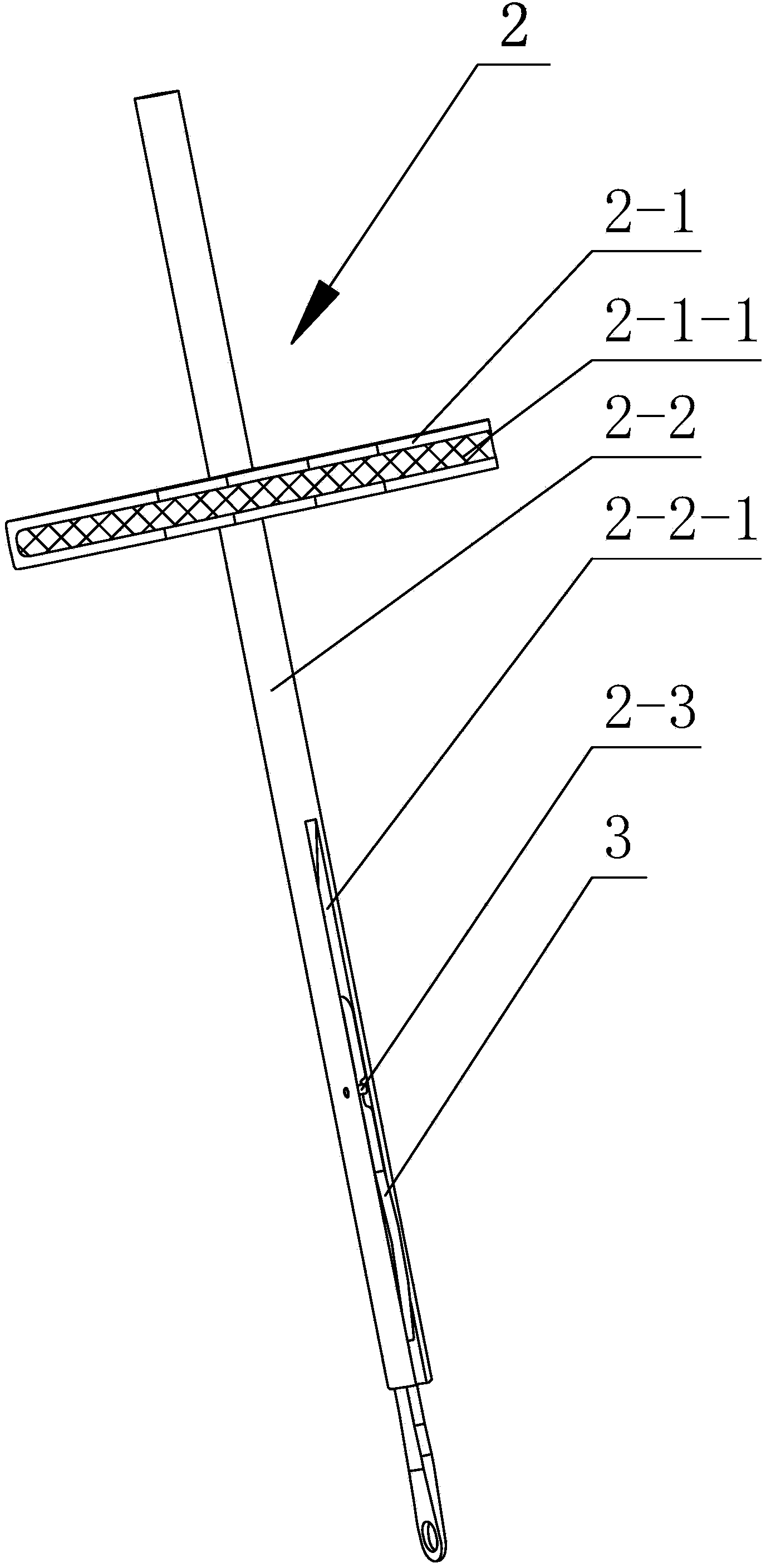

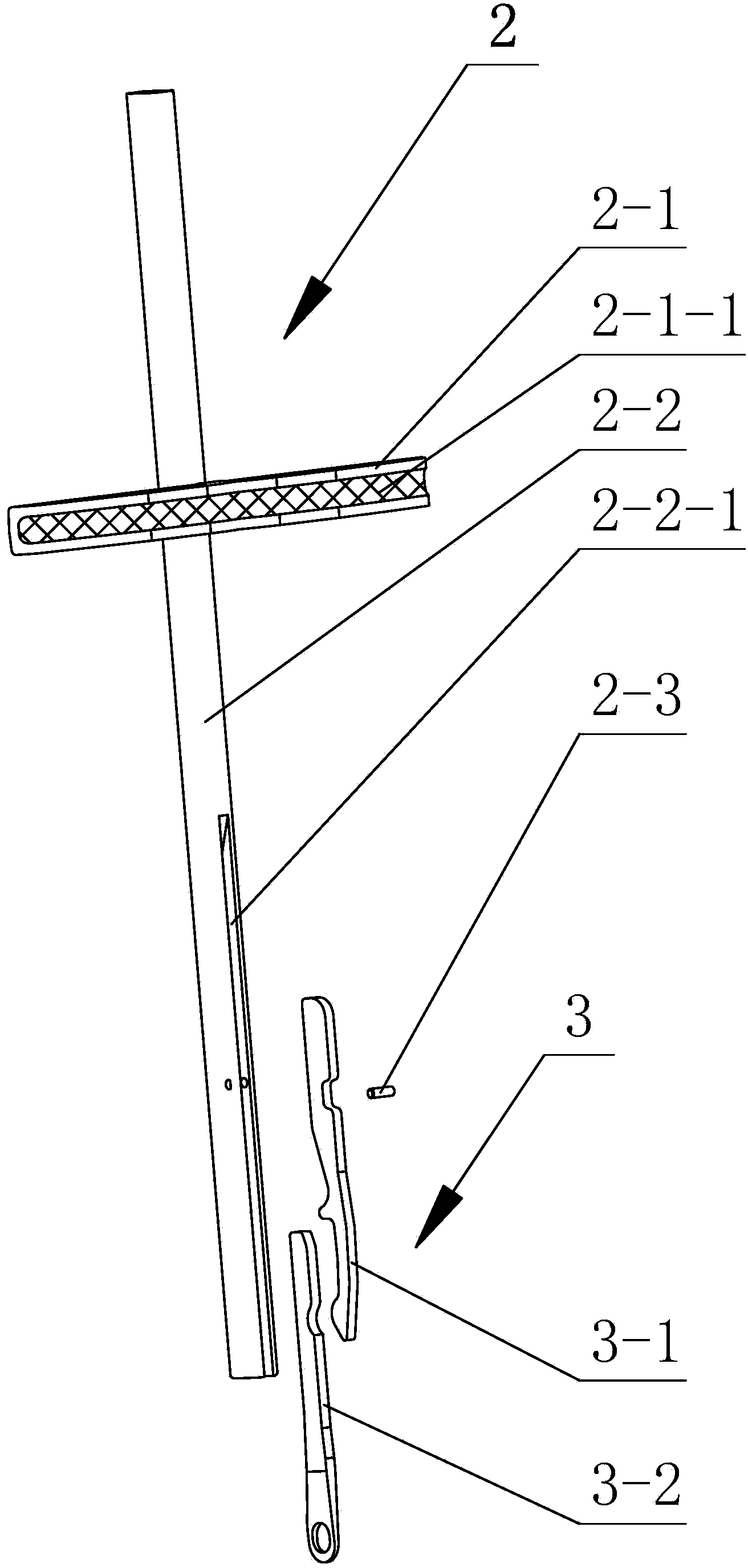

Steel wire guide bar jacquard needle device, and assembling tool and method thereof

ActiveCN104358021AEasy to fixMeet needsWarp knittingMetal working apparatusStructural engineeringMechanical engineering

The invention relates to a steel wire guide bar jacquard needle device, and an assembling tool and an assembling method thereof. The device comprises a steel wire, jacquard needle mounting frames and jacquard needle assemblies, wherein each jacquard needle mounting frame comprises a transverse needle rod and a vertical needle rod; each jacquard needle assembly is mounted on the corresponding vertical needle rod; a groove is formed in each transverse needle rod; the groove wall distance at an opening of each groove is smaller than the diameter of the steel wire, and the groove wall distance from the opening of each groove to the groove bottom direction is gradually increased, is in accordance with the diameter of the steel wire and then is gradually decreased. The steel wire guide bar jacquard needle device is easy to manufacture, short in production period and stable in product quality; the jacquard needle assemblies can move with any needle pitch to meet requirements on various different patterns; the assembling tool and the assembling method for the steel wire guide bar jacquard needle device are high in assembling efficiency and low in labor intensity, positioning of all the jacquard needle assemblies in the same plane can be effectively guaranteed, personal errors are small, and the distance accuracy between every two jacquard needle assemblies is effectively guaranteed.

Owner:CHANGLE WANDA TEXTILE MACHINERY

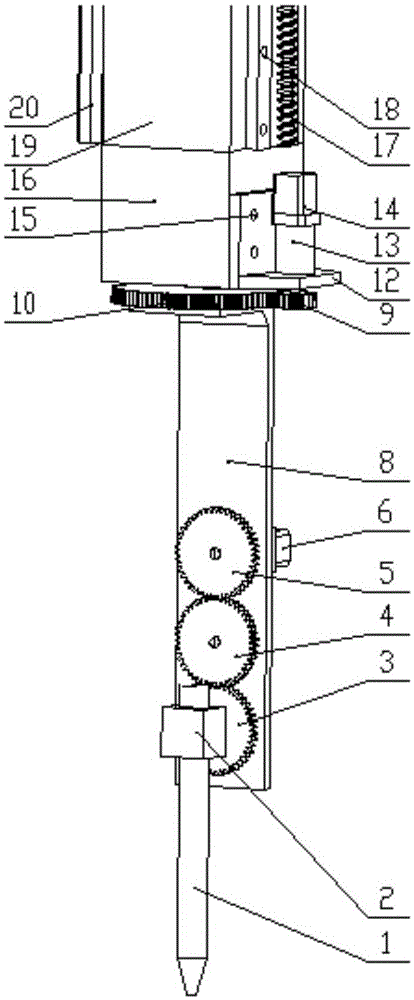

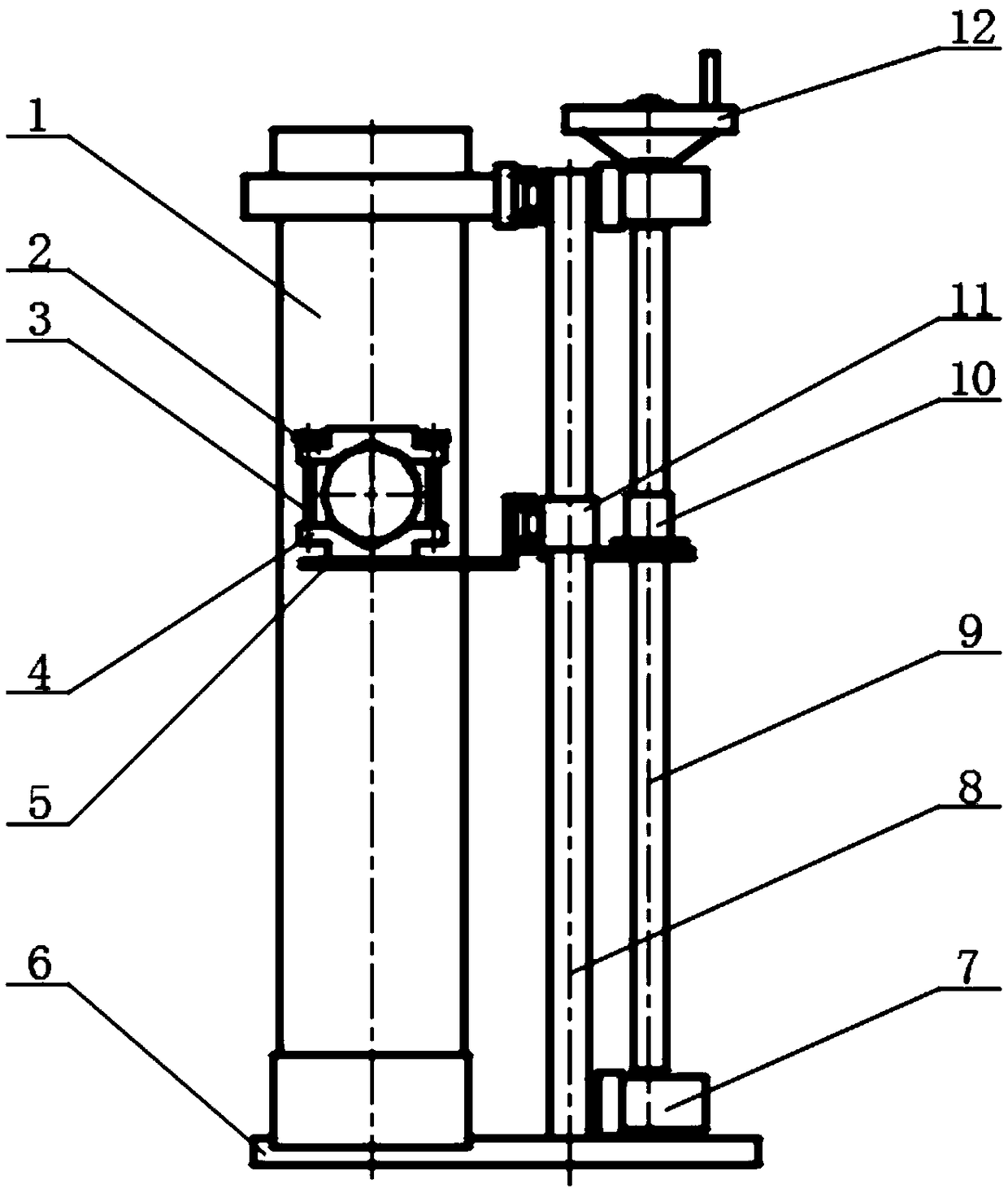

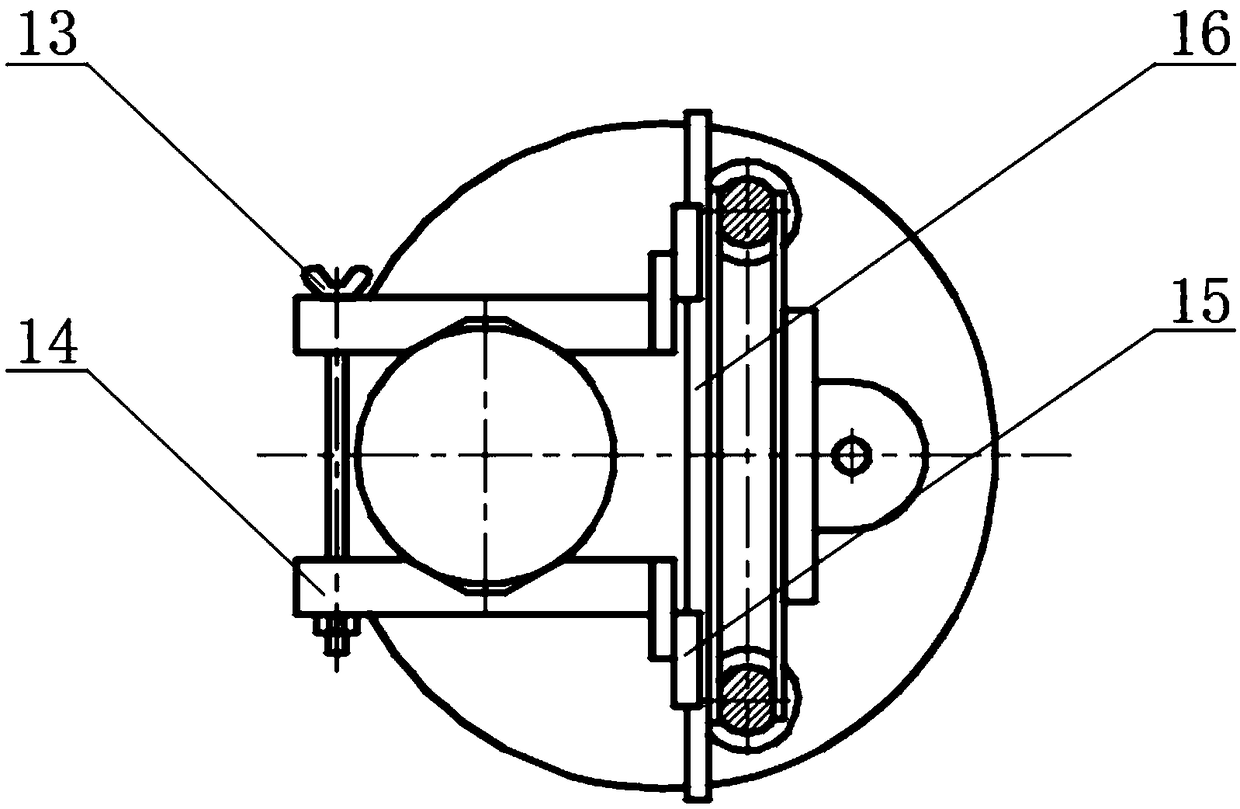

Acoustic profile measuring device and method for seafloor sediment

PendingCN108760888ARealize measurementAvoid runningAnalysing solids using sonic/ultrasonic/infrasonic wavesAcoustic profileOcean bottom

The invention provides an acoustic profile measuring device and method for seafloor sediment. The acoustic profile measuring device comprises a core tube, a transducer clamping mechanism, a lifting mechanism, the fixed connection and attitude adjustment between the core tube and a lifting guide rail are carried out by a core tube locating device, the fixed connection and attitude adjustment between the transducer clamping mechanism and the lifting guide rail are carried out by a transducer locating mechanism, the transducer locating device is connected with the lifting guide rail through a lifting guide sleeve, the transducer locating device can go up and down along the guide rail, a lifting handwheel is arranged on the upper end of a lifting screw to realize the lifting of the transducerclamping mechanism by shaking the lifting handwheel. The transducer group is mounted on the lifting guide rail by a clamping mechanism, the transducer group can be driven up and down by rotating lifting handwheel which can be used to measure the arbitrary cross-section of the core tube, and the core pipe is placed vertically, and the sediment fills the sample tube, which avoids the flowing of flowing plastic, soft plastic or water-saturated seabed surface sediment, and greatly improves the measurement accuracy.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

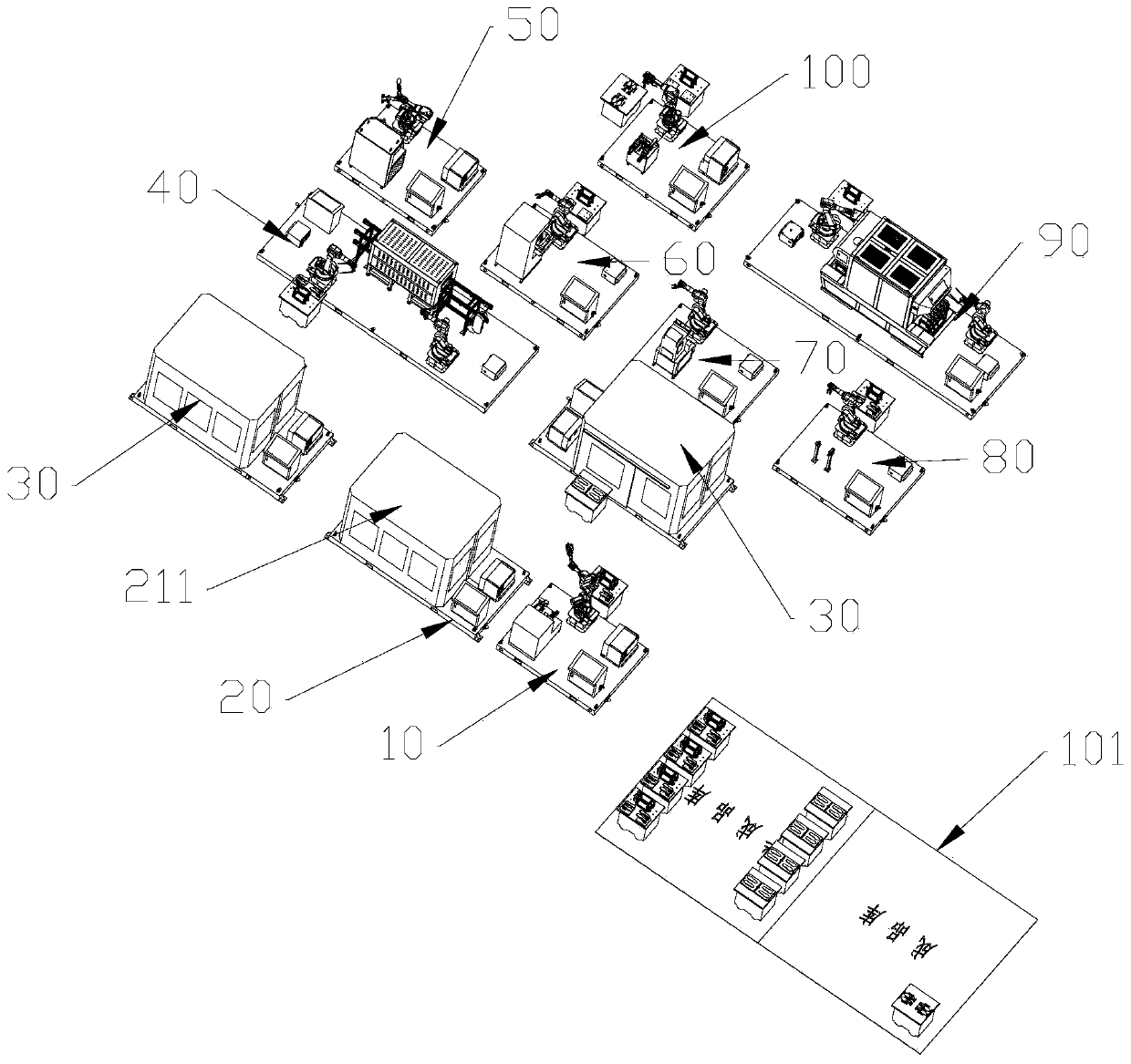

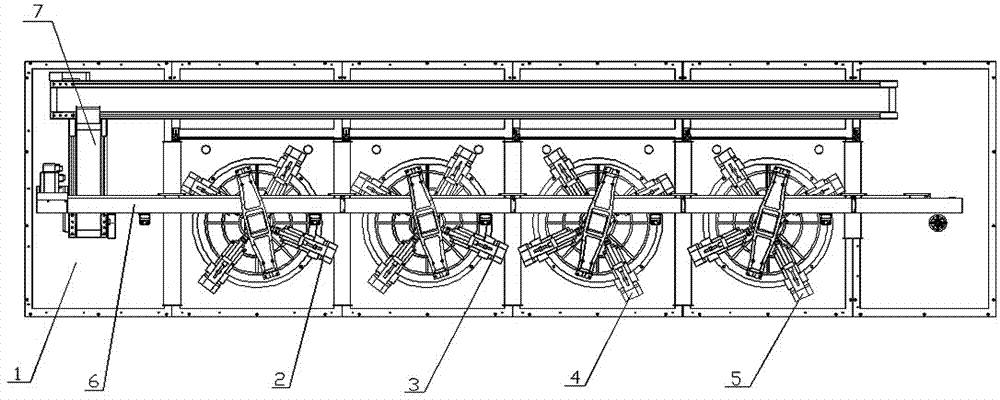

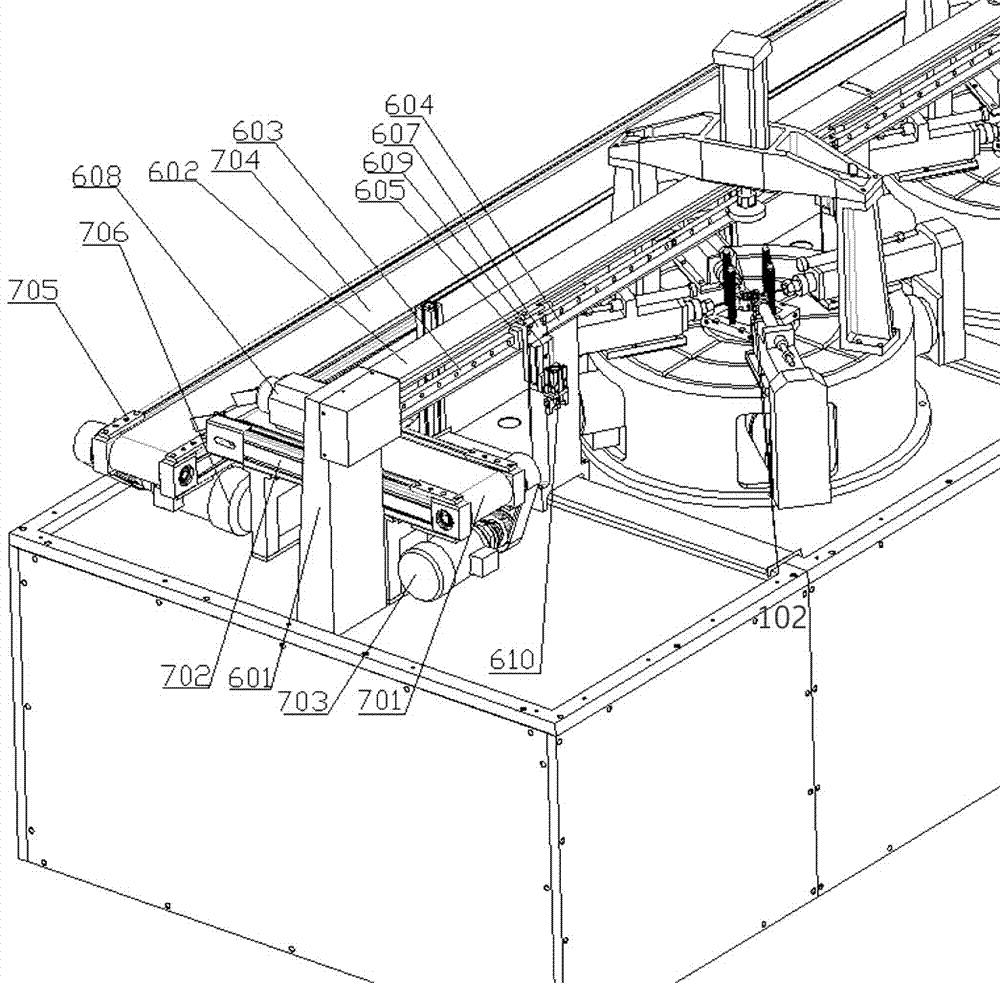

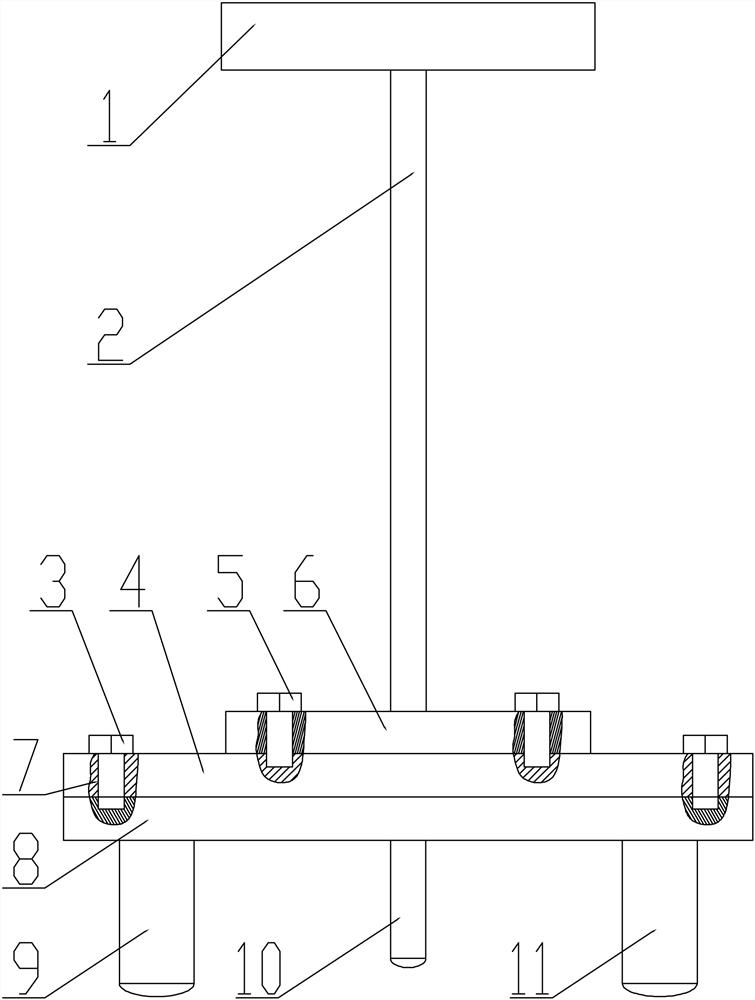

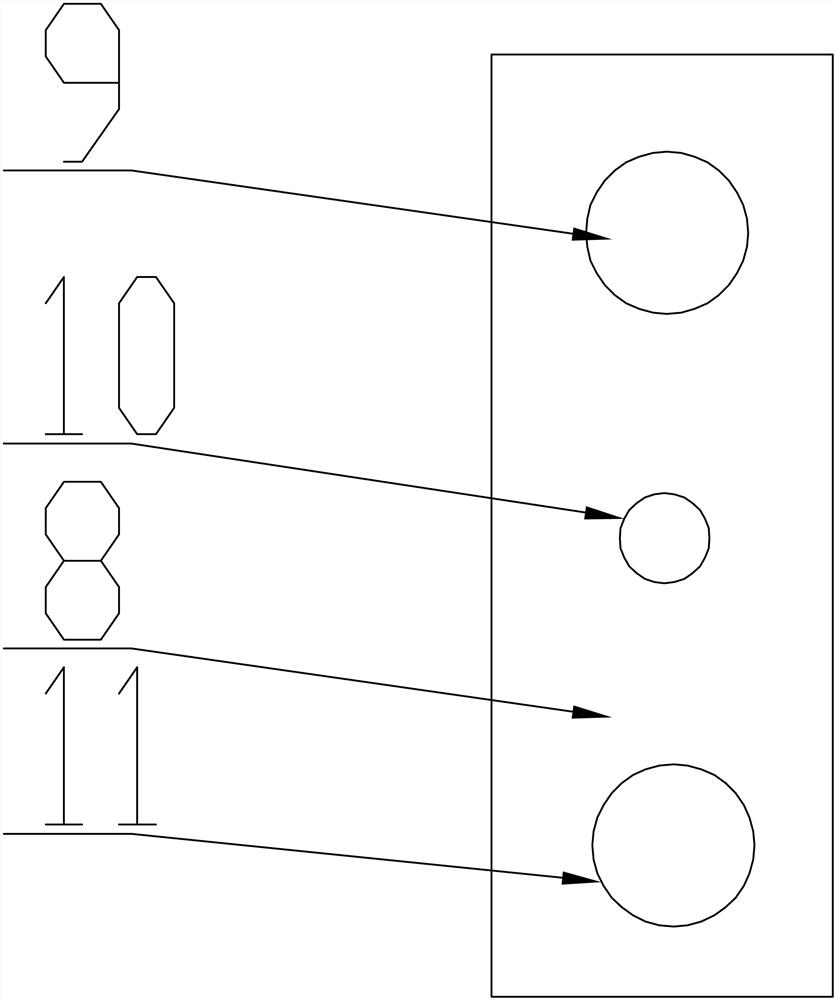

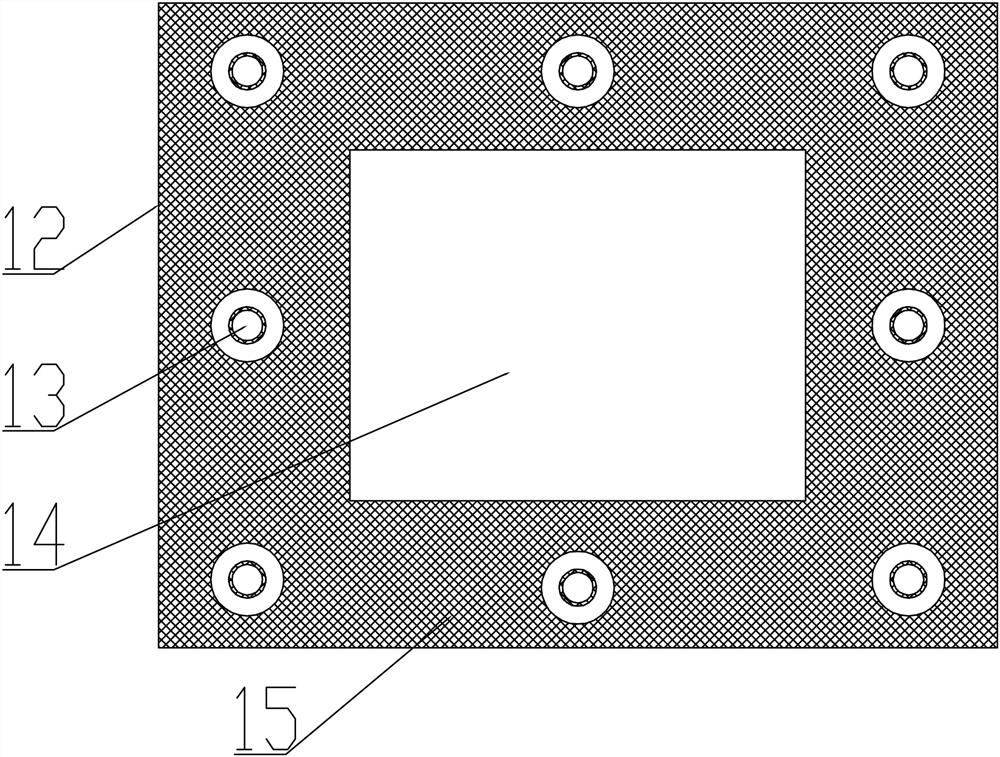

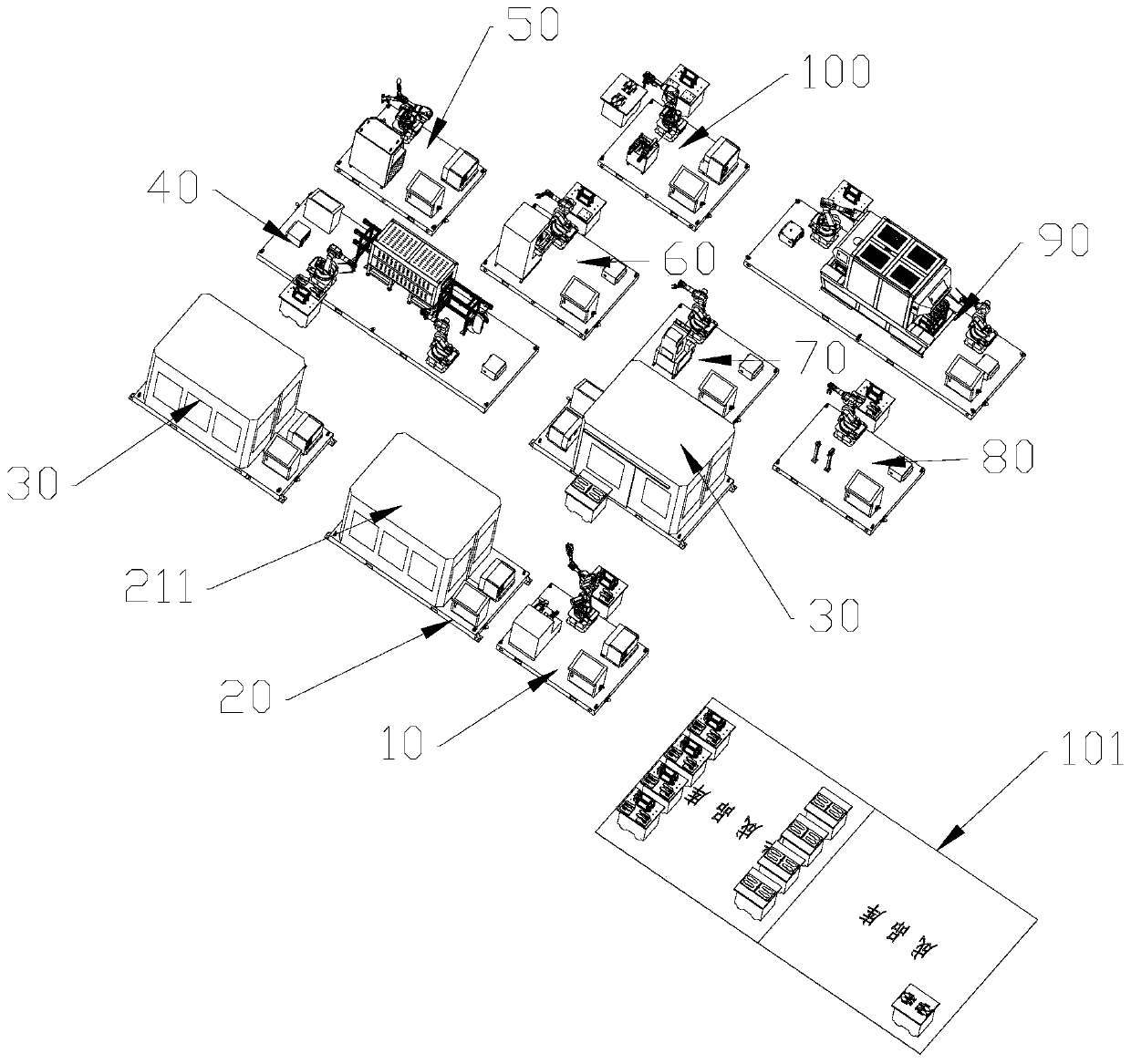

Special automatic production line for drilling of oil pump rotor type workpieces

ActiveCN107081446ARealize linear continuous processingGuaranteed stabilityMetal working apparatusBoring/drilling machinesProduction lineEngineering

The invention discloses a special automatic production line for drilling of oil pump rotor type workpieces. Component parts comprising a boring machine body, a drilling module set, a truss manipulator, a gantry air clamper, a workpiece material collecting and conveying mechanism and the like are arranged. According to the special automatic production line disclosed by the invention, the workpieces are transferred between service positions through the synchronous manipulator, so that the linear continuous processing of the workpieces is realized, and the automation level of integral production is increased; drilling and chamfering are all synchronously performed on each processing service position by a plurality of drilling main shafts, so that the stability of the location degree of a hole in each workpiece is guaranteed; the special automatic production line adopts a positioning manner of a plane and two pits and the gantry air clamper for the workpieces, so that the repeated positioning accuracy of the workpieces can be guaranteed, and the stability of the locating degree of the workpieces is further guaranteed; and through the workpiece material collecting and conveying mechanism, the processed workpieces are transported to a material collecting service position to be processed in a centralized manner, so that the automation degree of production of the workpieces is increased.

Owner:YANGZHOU UNIV

Fixed-point self-locking mechanism

ActiveCN107448449AAvoid hard-to-extract problemsEasy to controlSecuring devicesFastening meansConstant forceInductor

The invention provides a fixed-point self-locking mechanism. The fixed-point self-locking mechanism comprises an outer drum flange, an outer drum, a locking oil cylinder, a universal locking block and an inner drum. The outer drum flange and the end part of the outer drum are connected and fixed. The inner drum is arranged in the outer drum in a sleeved mode. The outer drum is fixedly provided with the locking oil cylinder. The inner end part of the locking oil cylinder is connected with the universal locking block. The locking oil cylinder is provided with a trigger and an inductor, and starting and stopping of the locking oil cylinder is controlled by the trigger and the inductor. An annular clamping groove is formed in the inner drum. The shape of the annular clamping groove is matched with the shape of the universal locking block. According to the fixed-point self-locking mechanism, locking is achieved by using a mode of the annular clamping groove, the problem that an inserted pin is hard to be pulled out due to long-time stress of a traditional inserted pin mode is avoided, an in-place state of load is detected by using a constant force opening instrument, control is easy, and working is reliable.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

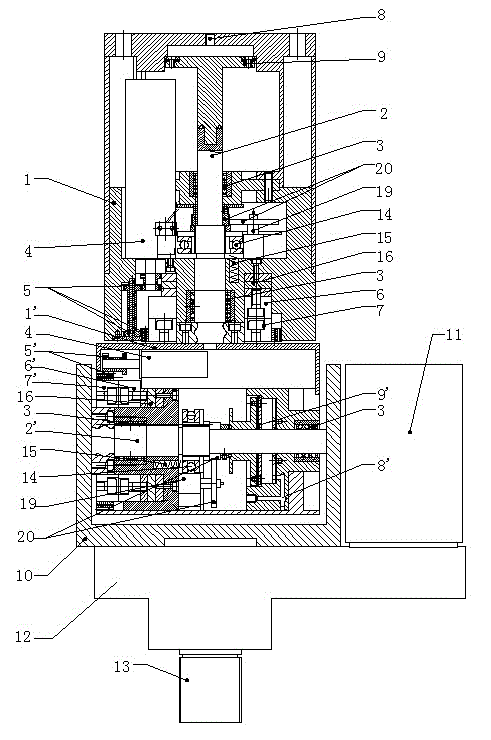

Numerical-control dual-rotation milling head for three-coordinate measuring machine

ActiveCN102873389ALow costFast processingAttachable milling devicesMeasurement/indication equipmentsControl engineeringProcess engineering

The invention belongs to the technical field of application of three-coordinate measuring machines, and particularly relates to a numerical-control dual-rotation milling head for a three-coordinate measuring machine. The numerical-control dual-rotation milling head aims to realize that a model can be quickly and precisely machined on the three-coordinate measuring machine. In order to achieve the purpose, the technical scheme includes that the numerical-control dual-rotation milling head for the three-coordinate measuring machine comprises a shaft component B, a shaft component A and a milling system, wherein the shaft component B and the shaft component A are perpendicular to each other, and the shaft component A is connected with the milling system by a mounting plate. By the numerical-control dual-rotation milling head, the model can be quickly formed and machined on the three-coordinate measuring machine, utilization rate of equipment is increased, and cost is lowered for an enterprise.

Owner:XIAN HIGH TECH AEH INDAL METROLOGY

Handheld concrete roughness three-dimensional detection device and method

The invention provides a handheld concrete roughness three-dimensional detection device and method, and the device comprises a camera installation plate, and the bottom end surface of the camera installation plate is symmetrically and fixedly provided with a first camera assembly and a second camera assembly. A laser used for positioning is fixed between the first camera assembly and the second camera assembly, and the camera installation plate is connected with a handheld structure through a connecting plate; and a calibration plate used for positioning a scanning position is further included, is matched with the first camera assembly, the second camera assembly and the laser, and is used for realizing three-dimensional scanning of the concrete surface in a set area. According to the detection device, the concrete roughness condition is scanned and digitized through three-dimensional laser, then three-dimensional point cloud data of the concrete surface are obtained, the concrete surface roughness is obtained through calculation, and the purpose of accurately measuring the concrete surface roughness is achieved.

Owner:CHINA THREE GORGES PROJECTS DEV CO LTD +1

Vamp polishing device for shoemaking production line

ActiveCN111011995AGuaranteed stabilityGuaranteed repeat positioning accuracyShoemaking devicesBelt grinding machinesPolishingLaser scanning

The invention provides a vamp polishing device for a shoemaking production line, and belongs to the field of shoemaking equipment. The device includes a tray bottom plate, and includes a six-axis manipulator, a hand reversing table support, a shoe side face polishing assembly, a shoe sole polishing assembly, a shoe heel polishing assembly and a laser scanning assembly, which are arranged on the tray bottom plate. The hand reversing table support is used for being matched with the six-axis manipulator to adjust the direction and the position of the shoe tree; the shoe side face polishing assembly comprises a first polishing wheel used for polishing the side face of a shoe; the shoe sole polishing assembly comprises a second polishing wheel used for polishing the bottom of the shoe; the shoeheel polishing assembly comprises a tensioning wheel, a dull polish belt is arranged on the outer side of the tensioning wheel, and the dull polish belt swings up and down under the action of a grinding shell to grind shoe heels. The vamp polishing device achieves polishing of different positions of vamps, the automation degree is high, the cost is reduced, and the labor efficiency is improved.

Owner:FUDAN UNIV

Precision centralized positioning tool

ActiveCN103707080AFlexible activitiesFlexible rotationPositioning apparatusMetal-working holdersEngineeringSteel ball

The invention discloses a precision centralized positioning tool comprising a positioning mandrel and a taper sleeve mandrel. The positioning mandrel is coaxially embedded in the taper sleeve mandrel and is positioned in a matched manner. A plurality of positioning steel balls are arranged between the taper sleeve mandrel and the positioning mandrel on same cross section with same angles, and are in gap-free fit with the taper sleeve shaft. The precision centralized positioning tool has the advantages that the positioning steel balls and the taper sleeve mandrel are in gap-free fit so that the positioning steel balls are guaranteed moving flexibly; the taper sleeve mandrel and the positioning mandrel are positioned in the matched manner of taper positioning and end face positioning, and repeated positioning precision of the tooling is guaranteed; an O-shaped ring can prevent scrap iron from entering, and the positioning steel balls are guaranteed rotating flexibly.

Owner:JIANGSU OSCEN HYDRAULIC TECH

Angle-adjustable inner circle helical tooth and chute machining device

InactiveCN105397120AGuaranteed compression positionGuaranteed stabilityCutting insertsTurning toolsNumerical controlSkill level

The invention relates to an angle-adjustable inner circle helical tooth and chute machining device. Structurally, a chute is formed in the end of a cutter rod, three screw holes are formed in a cutter rod clamping groove cutter, and the cutter rod is provided with an angle adjusting unit and an adjusting locking unit; and after the angle is adjusted, a locking screw of the adjusting locking unit is screwed and presses and fixes the angle adjusting unit, the groove cutter is closely attached to the positioning plane of a positioning plate of the angle adjusting unit for positioning, the groove cutter is pressed through two pressing screws close to the cutter rod clamping groove cutter, and the positioning plate of the angle adjusting unit is fixed to the cutter rod by screwing three pressing screws. Installing and using are convenient and fast, positioning is stable, the angle correction is adjusted within the angle adjusting range allowed by the device through a meshing gear pair of the angle adjusting unit, and reliable, convenient and efficient machining of the inner circle chute and helical teeth can be effectively guaranteed due to high precision of numerical control equipment. The device is easy and convenient to install and operate, and the requirement for the skill level of operators is low. The labor intensity of the operators is low during online machining.

Owner:CHINA CHANGJIANG ENERGY CORP GROUP

High-efficiency high-pressure alloy steel pipe welding groove processing equipment

PendingCN110802241AGuaranteed Dimensional ConsistencyEnsure consistencyTailstocks/centresAuxillary equipmentProcess equipmentPipe fitting

The invention discloses high-efficiency high-pressure alloy steel pipe welding groove processing equipment, and relates to the field of steel rolling. The high-efficiency high-pressure alloy steel pipe welding groove processing equipment comprises a lathe body and a steel pipe, wherein a screw rod mechanism is transversely arranged at the center of the lathe body, wired rail mechanisms are arranged on two sides of the screw rod mechanism, and a steel pipe tensioning mechanism is arranged at the right end of the lathe body. The high-efficiency high-pressure alloy steel pipe welding groove processing equipment has the beneficial effects that a main shaft is clamped by adopting hydraulic tensioning and end face positioning, so that the dimensional consistency of the groove turning of a workpiece is guaranteed, the efficiency is increased by rapidly clamping the workpiece aiming at the groove machining of a pipe fitting with variable length, the coaxiality of an inner circle and an outer circle is guaranteed by high positioning precision of a turning head, a positioning structure is additionally arranged on a pipe opening, repeated tool setting is avoided, and the consistency of the length of a groove is guaranteed; and the stable and repeated positioning accuracy of a tailstock is guaranteed by adding wired rails and wired rail pairs to fixing the tailstock, a torque limiter is additionally arranged on a speed reducer, the lead screw transmission force is controlled, and the jacking force of the tailstock is guaranteed.

Owner:JIANGSU DONGFANG WHOLE SET EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com