Aiming device and aiming method of X-ray optical system for plasma diagnosis

An optical system and plasma technology, applied in the application of diffraction/refraction/reflection for processing, reducing greenhouse gases, nuclear reactors, etc., can solve the problems of complex system structure, limited aiming accuracy, high manufacturing cost, etc., and achieve high system reliability, The effect of high aiming accuracy and low purchase cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Taking the system assembly and aiming of an 8keV energy point KB type X-ray imaging system as an example to further illustrate the content of the present invention.

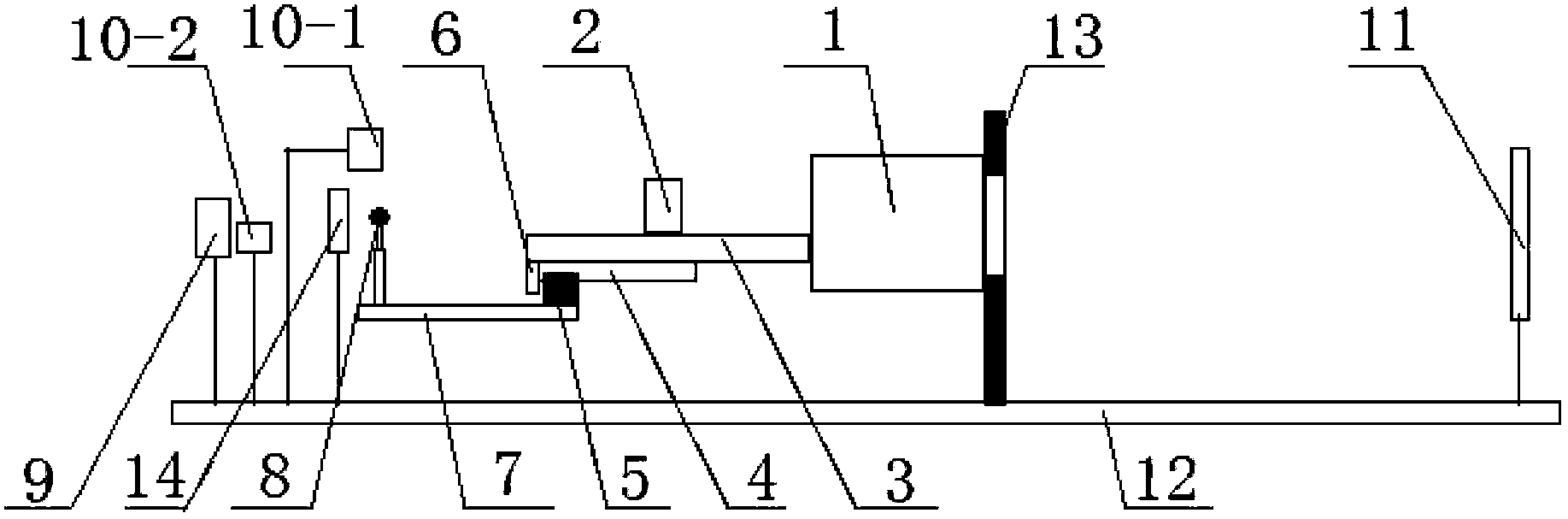

[0039] The aiming method of the KB type X-ray imaging system in the present embodiment is to carry out according to the following steps, as figure 1 As shown, all steps are completed on the optical bench 12. The flange 13 is fixed on the optical platform 12, and is used to simulate the actual working target port of the KB microscope on the strong laser device, and the dimensions are exactly the same. The adjustment mechanism 1 adopts a three-dimensional manual translation platform produced by Beijing Optical Instrument Factory, and is fixed on the flange 13 . Objective lens group 2 adopts W / B working at 8keV energy point 4C multilayer film KB objective lens group. Linear guide rail 4 and slide block 5 are MGN15C linear guide rail and slide block produced by HIWIN Company. The simulated positioning part...

Embodiment 2

[0053] An aiming device of an X-ray optical system for plasma diagnosis, the structure of which is as follows figure 1 As shown, the device includes an analog positioning assembly and its adjustment mechanism 1. The analog positioning assembly includes a positioning rod 7, an analog positioning member 8, a slider 5, a bracket 3, a linear guide rail 4 and an objective lens group 2, and one end of the positioning rod 7 is connected to the analog The positioning part 8 is connected to the slider 5 at the other end, the linear guide rail 4 is provided on the lower side of the bracket 3, and the objective lens group 2 is provided on the upper side, the slider 5 is slidingly connected to the linear guide rail 4, and the bracket 3 is connected to the adjustment mechanism 1. The adjustment mechanism 1 completes the aiming and pointing operations of the X-ray imaging system by adjusting the posture of the X-ray imaging system itself. In addition, according to specific physical experime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com