High-precision flexible zero point positioning system

A zero-point positioning and high-precision technology, which is applied in the field of positioning systems, achieves the effects of reducing the time for tooling replacement, high positioning accuracy, and avoiding the decline in accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

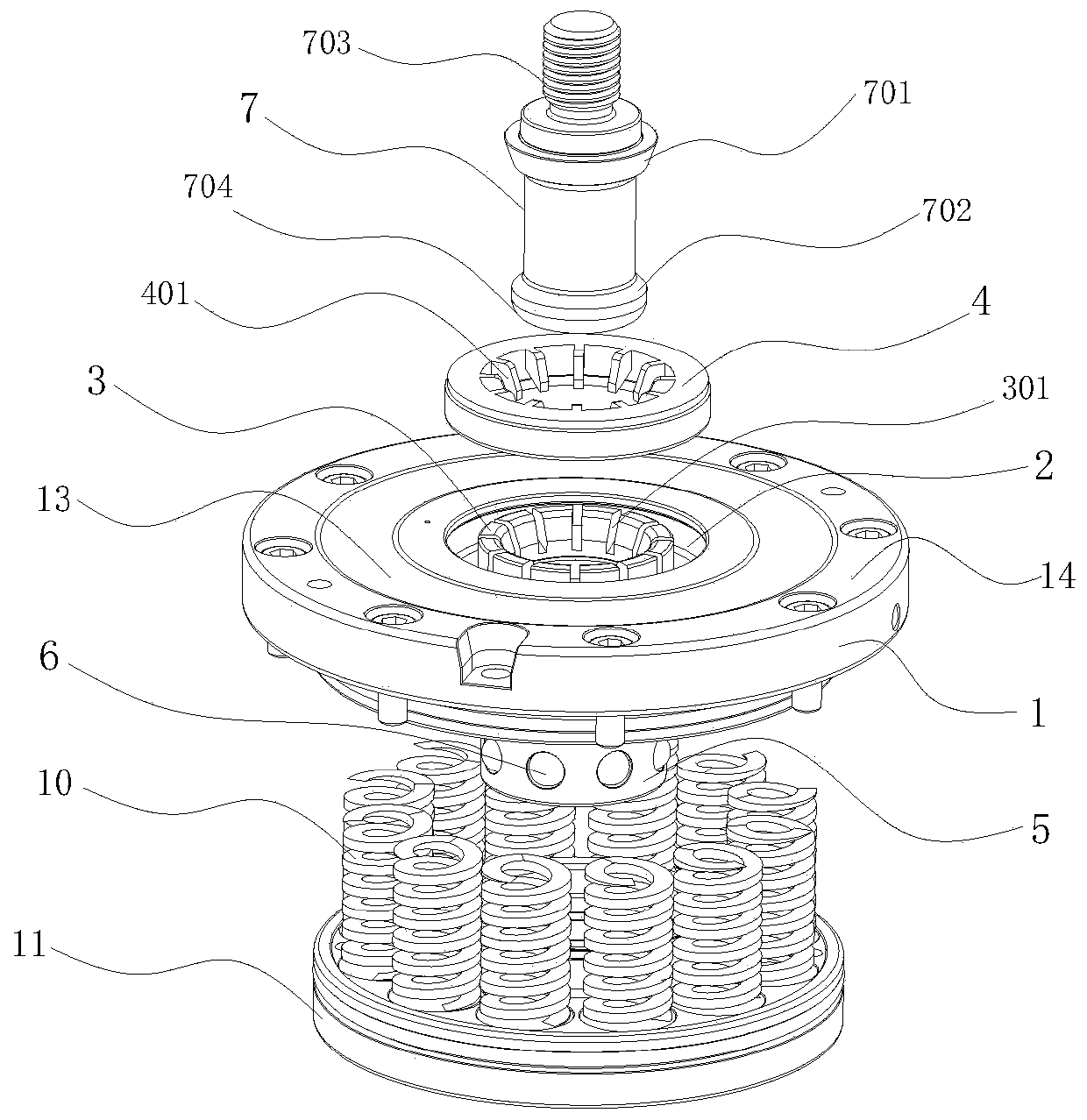

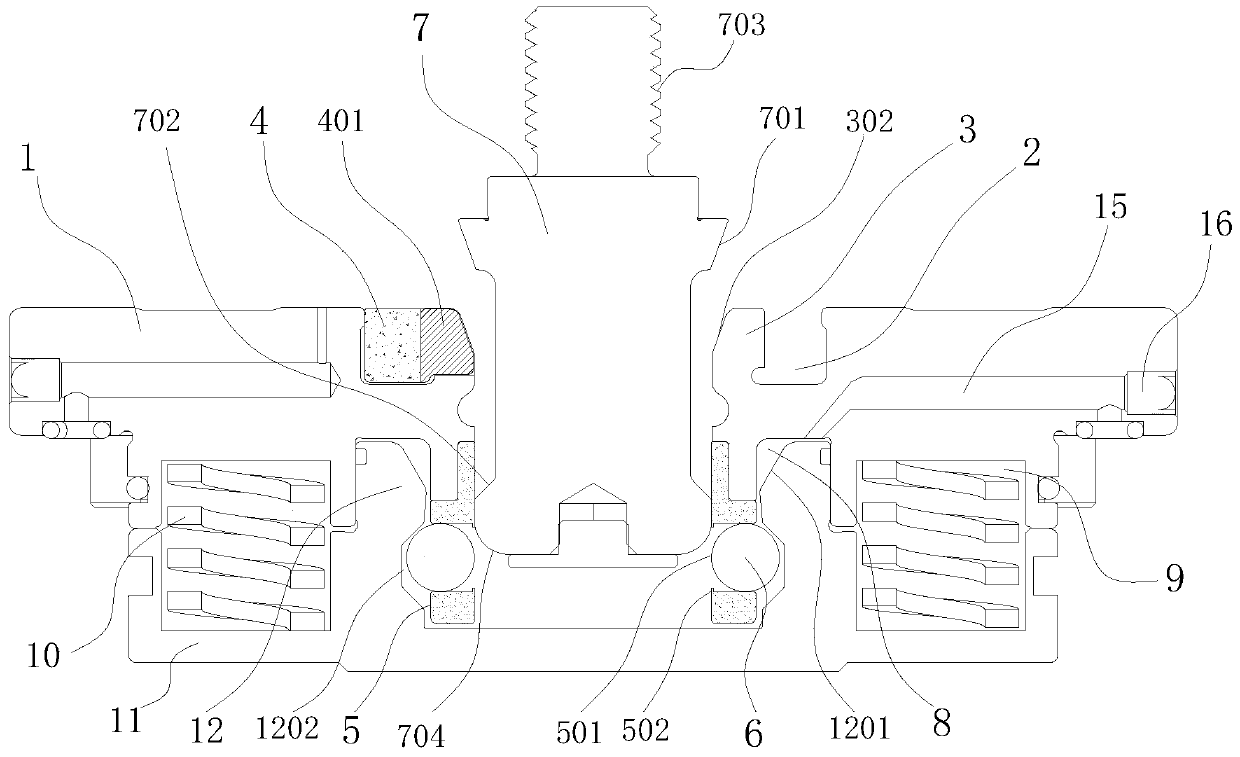

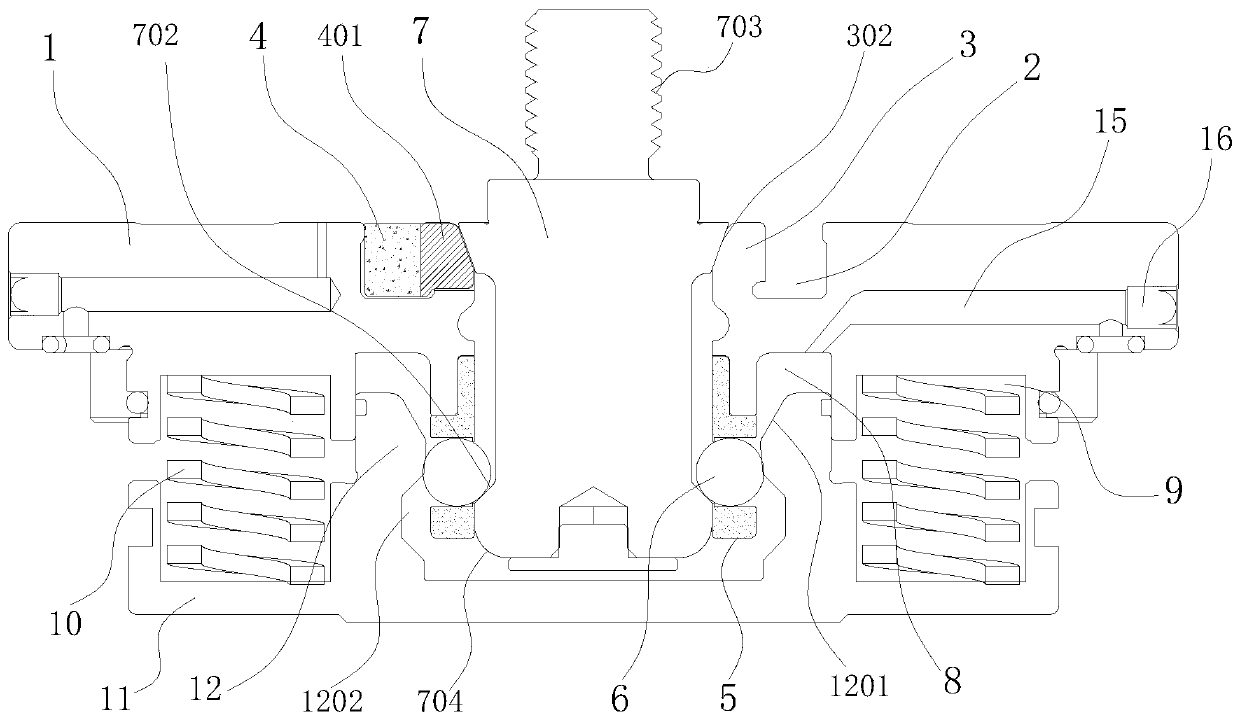

[0027] see Figure 1-3 , the present invention provides the following technical solutions: a high-precision flexible zero point positioning system includes a clamping disc 1, a short cone expansion tube 3, a protective nest 4 and a short cone pull stud 7, and the center of the top surface of the clamping disc 1 is provided with a center The positioning hole 2, the inner hole of the central positioning hole 2 is fitted with a short cone expansion tube 3, the top surface of the short cone expansion tube 3 is flush with the top surface of the clamping disc 1, and the top of the short cone expansion tube 3 is provided with ten A deformation groove 301, the top of the short cone expansion tube 3 inner hole is provided with a top cone positioning surface 302, the center positioning hole 2 is fitted with a protective nest 4, and the inner ring of the protective nest 4 is provided with ten annular comb teeth 401 , ten annular comb teeth 401 are correspondingly embedded in ten deformat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com