Clamping tool

A technology for clamping tooling and clamping parts, which is applied in the field of clamping tooling, can solve problems such as low work efficiency, and achieve the effect of improving efficiency, saving time for tooling replacement, and better clamping workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

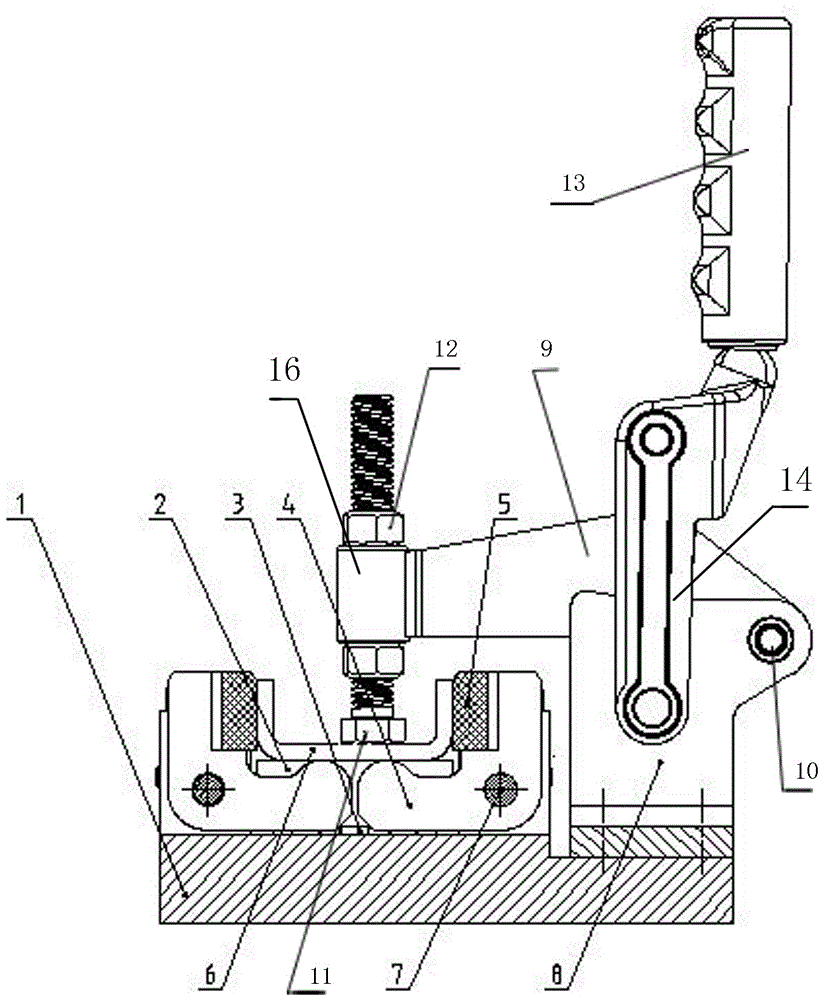

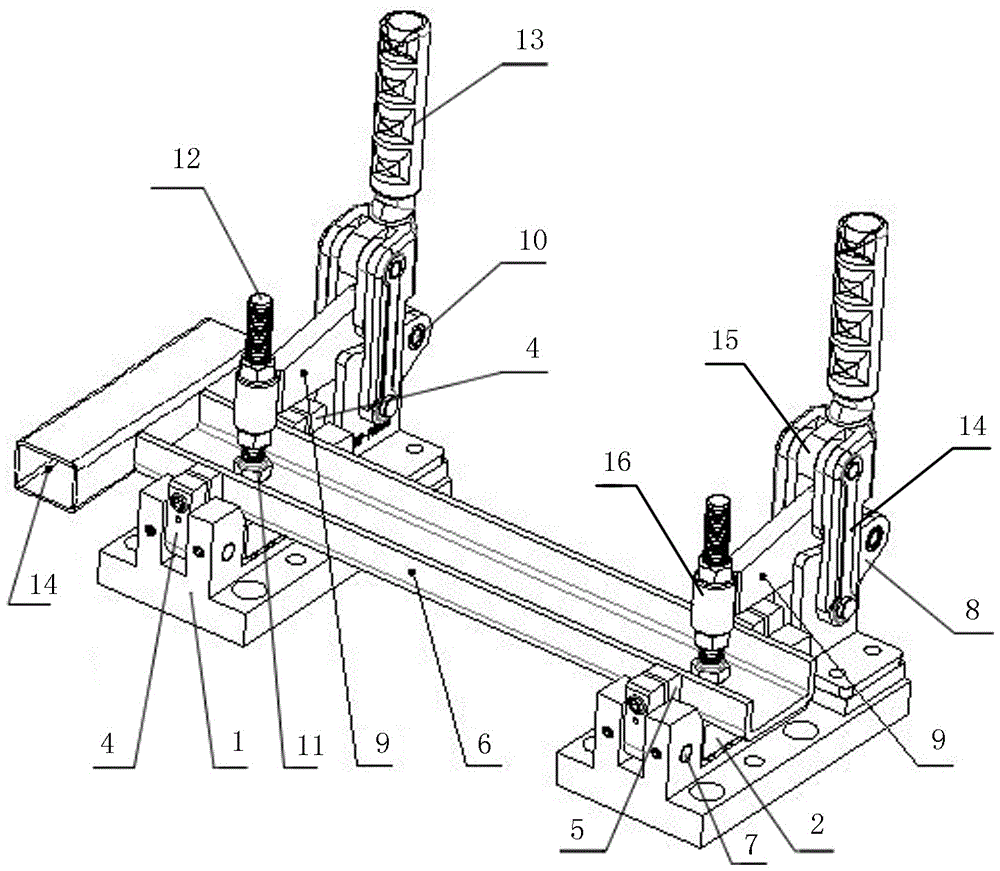

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

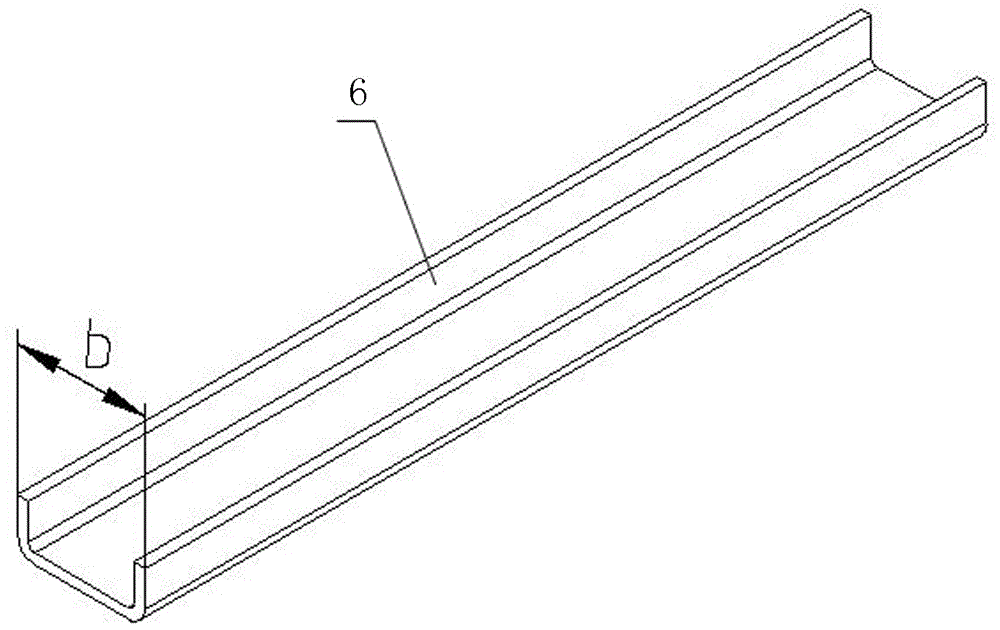

[0023] A specific embodiment of a clamping device of the present invention, such as Figure 2 to Figure 3 As shown, including the base 1, a pair of L-shaped crank arms 4 are arranged on the left side of the base 1, and the two L-shaped crank arms 4 are symmetrically distributed, and are hingedly connected to the base 1 through the first pin shaft 7 respectively, and the L-shaped crank arms 4 The supporting edge above is a clamping part that contacts and cooperates with the side of the workpiece 6, and the supporting edge below the L-shaped crank arm 4 is a supporting part that supports and cooperates with the bottom surface of the workpiece 6. The clamping parts on the two L-shaped crank arms 4 Elastic pads 5 made of polyurethane material are respectively provided on the top, and the ends of the support parts on the two L-shaped crank arms 4 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com