Nuclear boiler water indoor surface television set automatic checking device

A steam generator and automatic inspection technology, applied in nuclear power generation, nuclear reactor monitoring, nuclear engineering, etc., can solve problems such as difficulty in inspecting the inner surface, and achieve the effect of improving the use ability and utilization value, saving money, and ensuring the repeatability of positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

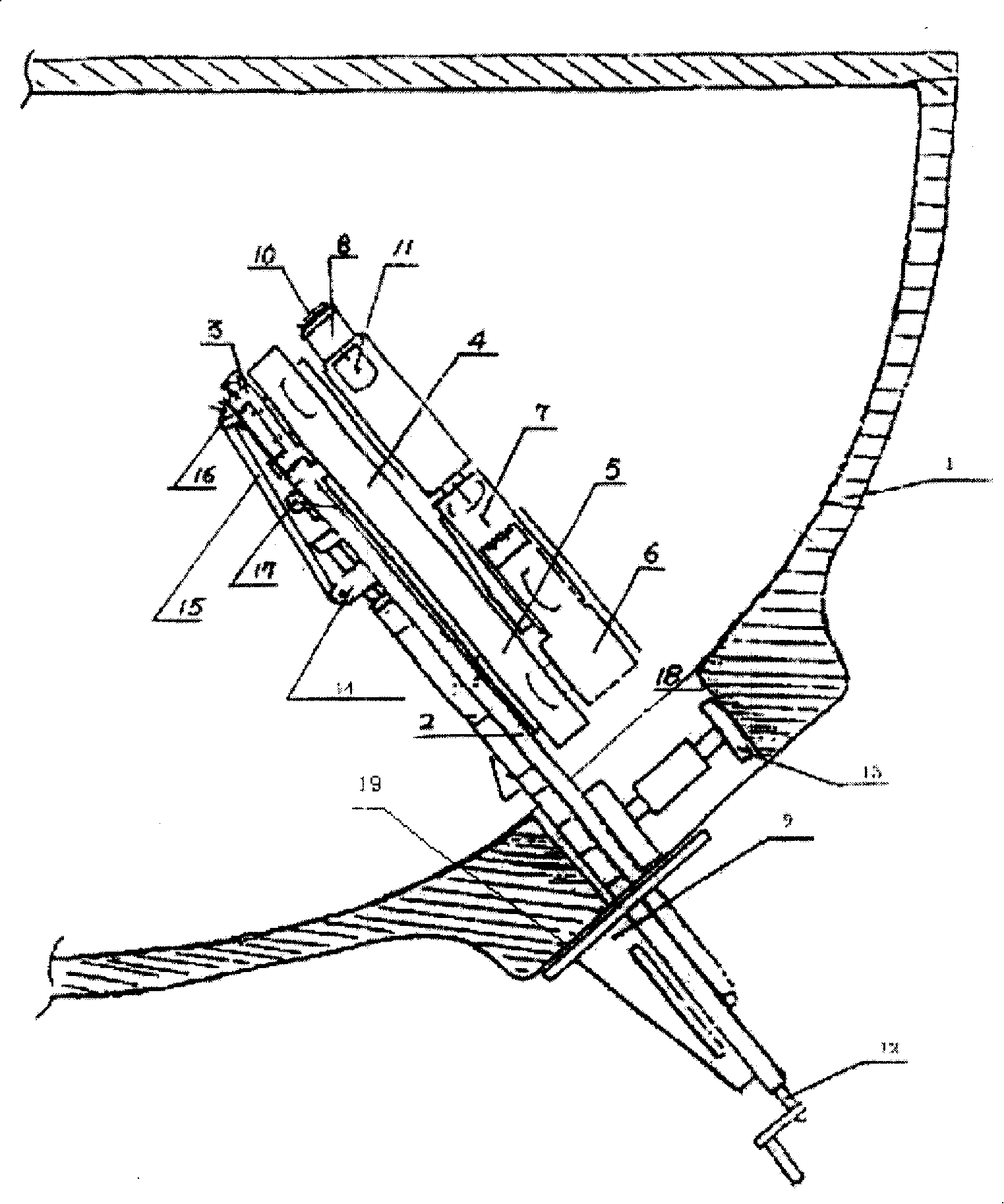

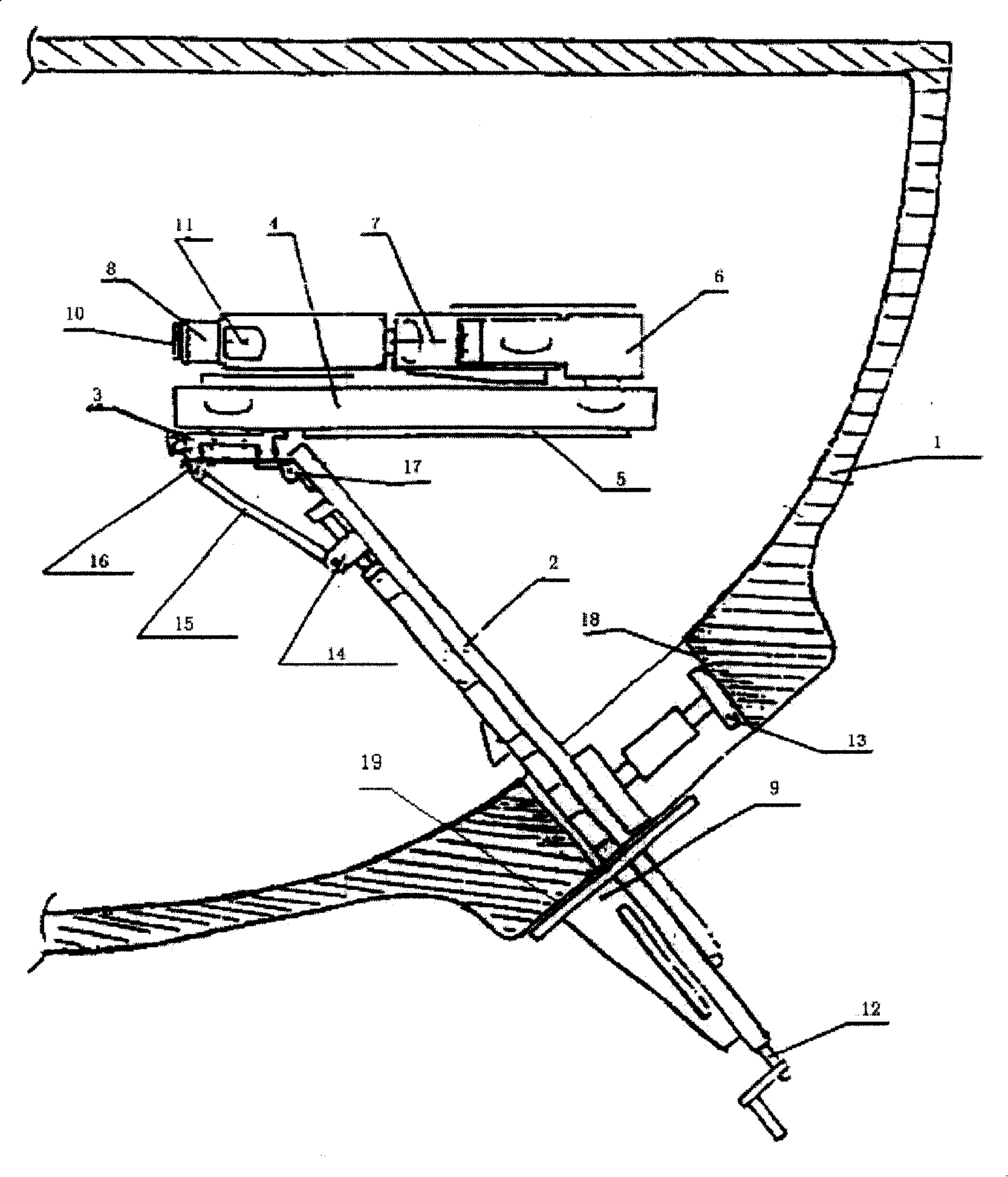

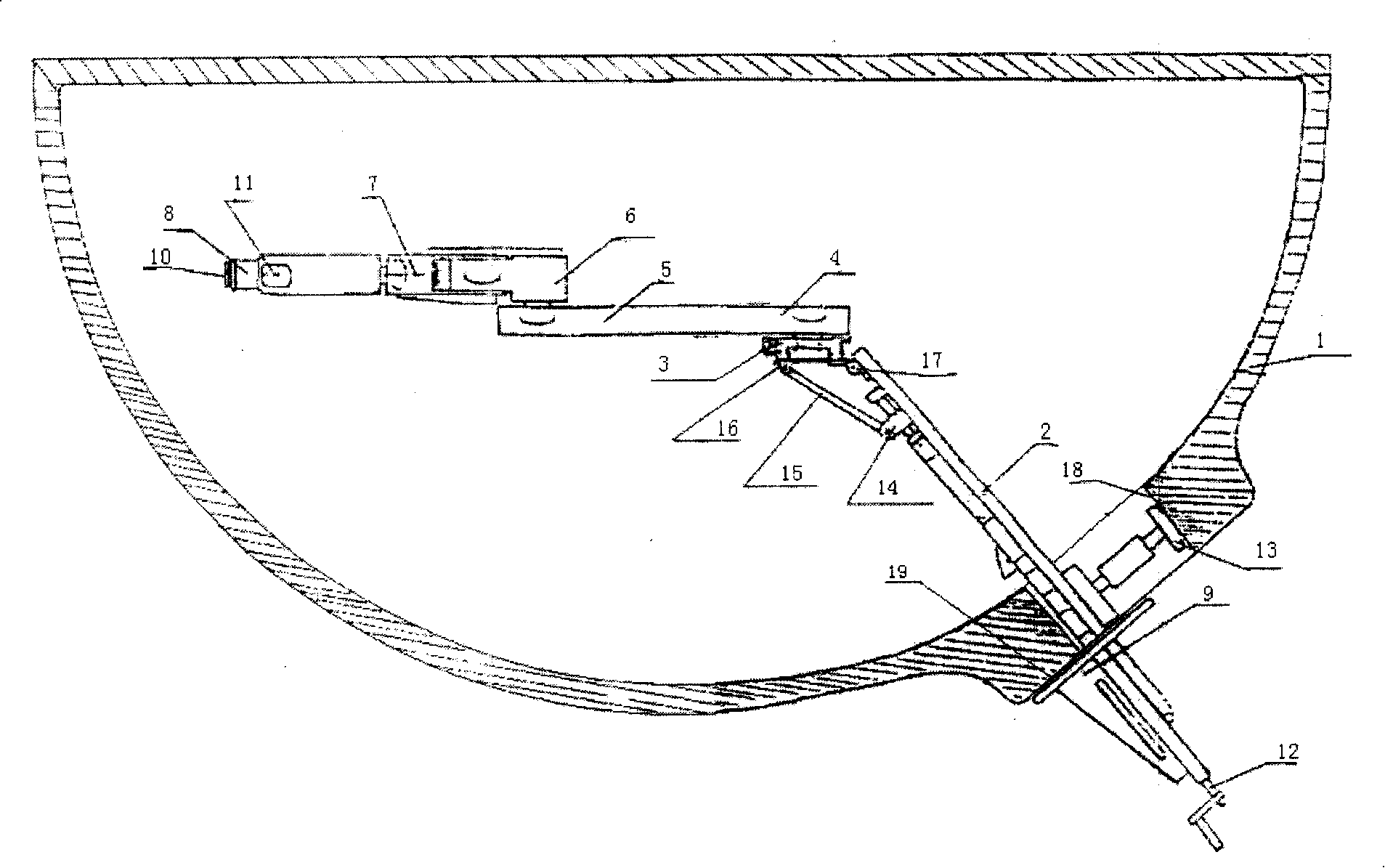

[0010] Such as figure 1 , 2 As shown, a nuclear steam generator water chamber surface automatic inspection device for television, including guide rail 2, supporting platform 3, big arm 4, telescopic arm 5, small arm 6, rotating arm 7, pitching arm 8, rib plate 9, camera 10. Lamp 11, hand wheel 12, support 13, steel plate 15; hand wheel 12 is connected to the lead screw, and fixed on one end of the guide rail 2 by bolts; the support 13 is connected by bolts so that its two ends are respectively pressed against the surface of the guide rail 2 and the steam The inner surface of the manhole 18 on the generator water chamber 1; the guide rail 2 and the flange 19 outside the manhole 18 are fixedly connected by bolts, and one end of the guide rail 2 is fixedly installed on the rib 9, and the rib 9 is a right-angled trapezoid whose length The bottom edge is fixedly installed on the end face of the flange 19 by bolts, and one end of the guide rail 2 is fixedly installed on the right-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com