Atmospheric plasma jet processing tool setting method

A plasma and jet technology, used in plasma welding equipment, metal processing, metal processing equipment, etc., to achieve the effects of low cost, commercialization, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

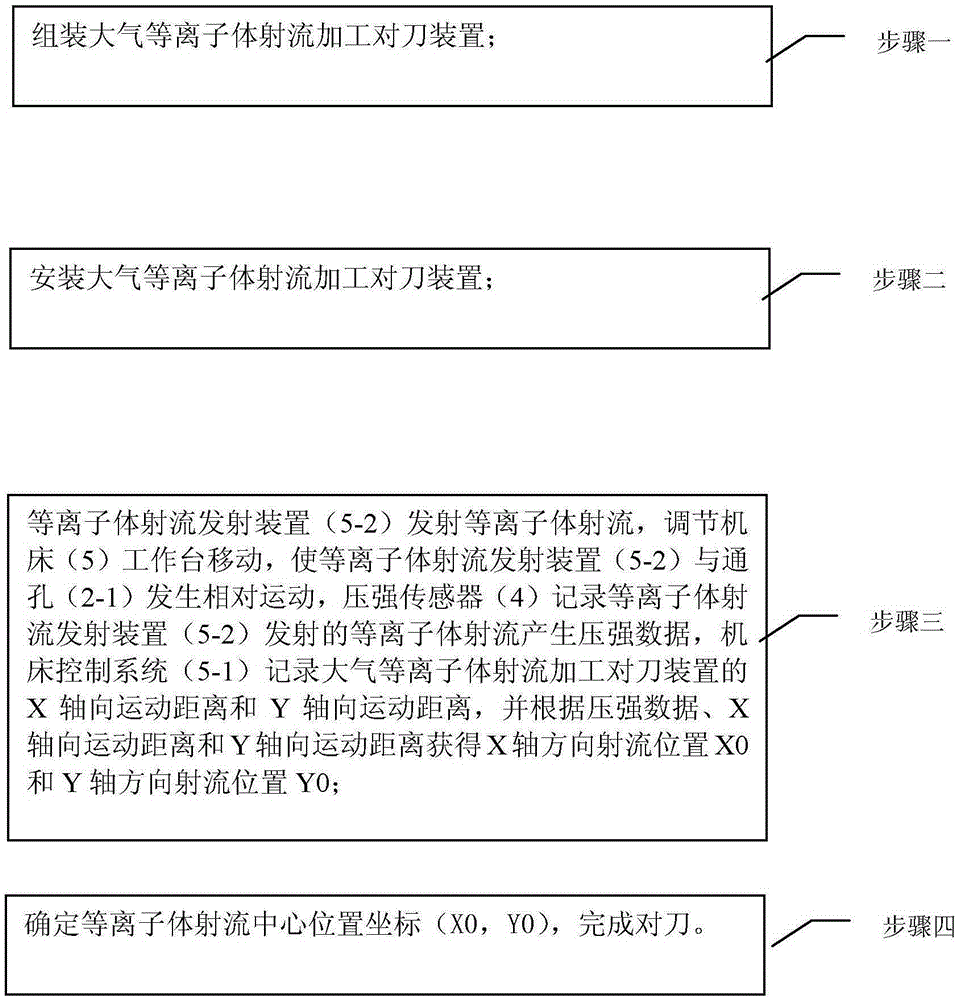

[0037] Specific implementation mode 1, refer to Figure 1 to Figure 7 Describe this embodiment in detail, a kind of atmospheric plasma jet machining tool setting method described in this embodiment, this method is realized based on machine tool 5, machine tool 5 comprises machine tool control system 5-1 and plasma jet emission device 5-2 The machine tool control system 5-1 is used to record the moving distance of the workbench of the machine tool 5; the plasma jet emission device 5-2 is located above the workbench of the machine tool 5;

[0038] The method comprises the steps of:

[0039] Step 1. Assembling the tool setting device for atmospheric plasma jet processing;

[0040] Step 2. Install the tool setting device for atmospheric plasma jet processing;

[0041] Step 3: The plasma jet emission device 5-2 emits the plasma jet, adjusts the movement of the workbench of the machine tool 5, so that the plasma jet emission device 5-2 moves relative to the through hole 2-1, and the...

specific Embodiment approach 2

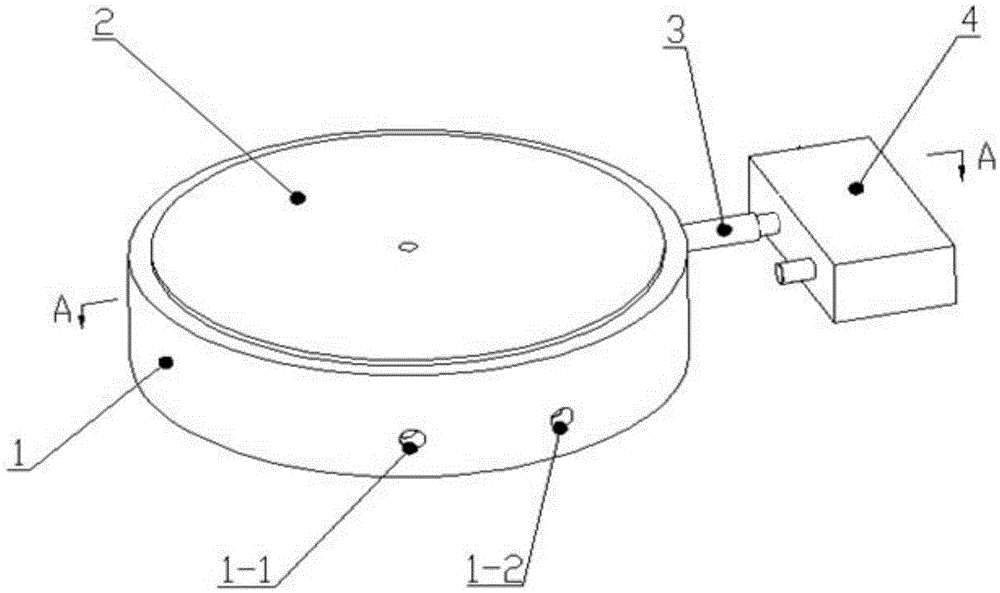

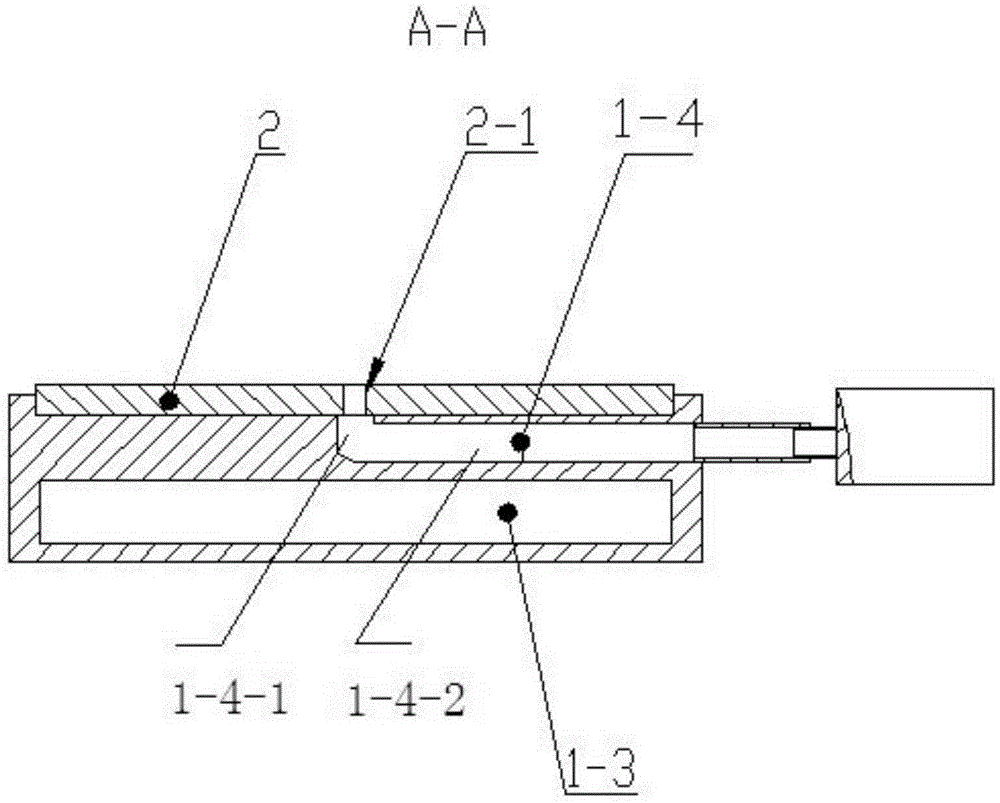

[0043] Specific implementation mode two, refer to Figure 2 to Figure 4 Describe this embodiment in detail. This embodiment is a further description of the tool setting method for atmospheric plasma jet processing described in Embodiment 1. In this embodiment, the tool setting device for atmospheric plasma jet processing includes a base 1 , fused silica sheet 2, connecting pipe 3 and pressure sensor 4;

[0044] The upper surface of the base 1 is provided with a groove, the fused silica sheet 2 is fixedly arranged in the groove of the base 1, and the center of the fused silica sheet 2 is provided with a through hole 2-1;

[0045] The upper surface of the base 1 is provided with a channel 1-4, and the channel 1-4 includes a vertical channel 1-4-1 and a horizontal channel 1-4-2; a vertical channel 1-4-1 and a horizontal channel 1-4-2 Forming an L shape, one end of the vertical channel 1-4-1 communicates with the through hole 2-1, and one end of the horizontal channel 1-4-2 passe...

specific Embodiment approach 3

[0046] Specific Embodiment 3. This embodiment is a further description of the tool setting method for atmospheric plasma jet processing described in Embodiment 2. In this embodiment, an atmospheric plasma jet processing tool setting device is installed in step 2. The specific The installation method is:

[0047] The base 1 of the tool setting device for atmospheric plasma jet processing is fixed on the workbench of the machine tool 5, and the plasma jet emission device 5-2 is arranged above the through hole 2-1 of the fused silica sheet 2, and is located at Within the range of a circle with a diameter of 10 mm centered on the center of the through hole 2-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com