X-shaft ball screw nut transmission mechanism of numerical control floor type boring and milling machine

A ball screw, transmission mechanism technology, applied in the components of the boring machine/drilling machine, boring/drilling, drilling/drilling equipment, etc., can solve the problems of low standardization, long production cycle, complex structure, etc. The effect of high degree of specialization, short production cycle and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

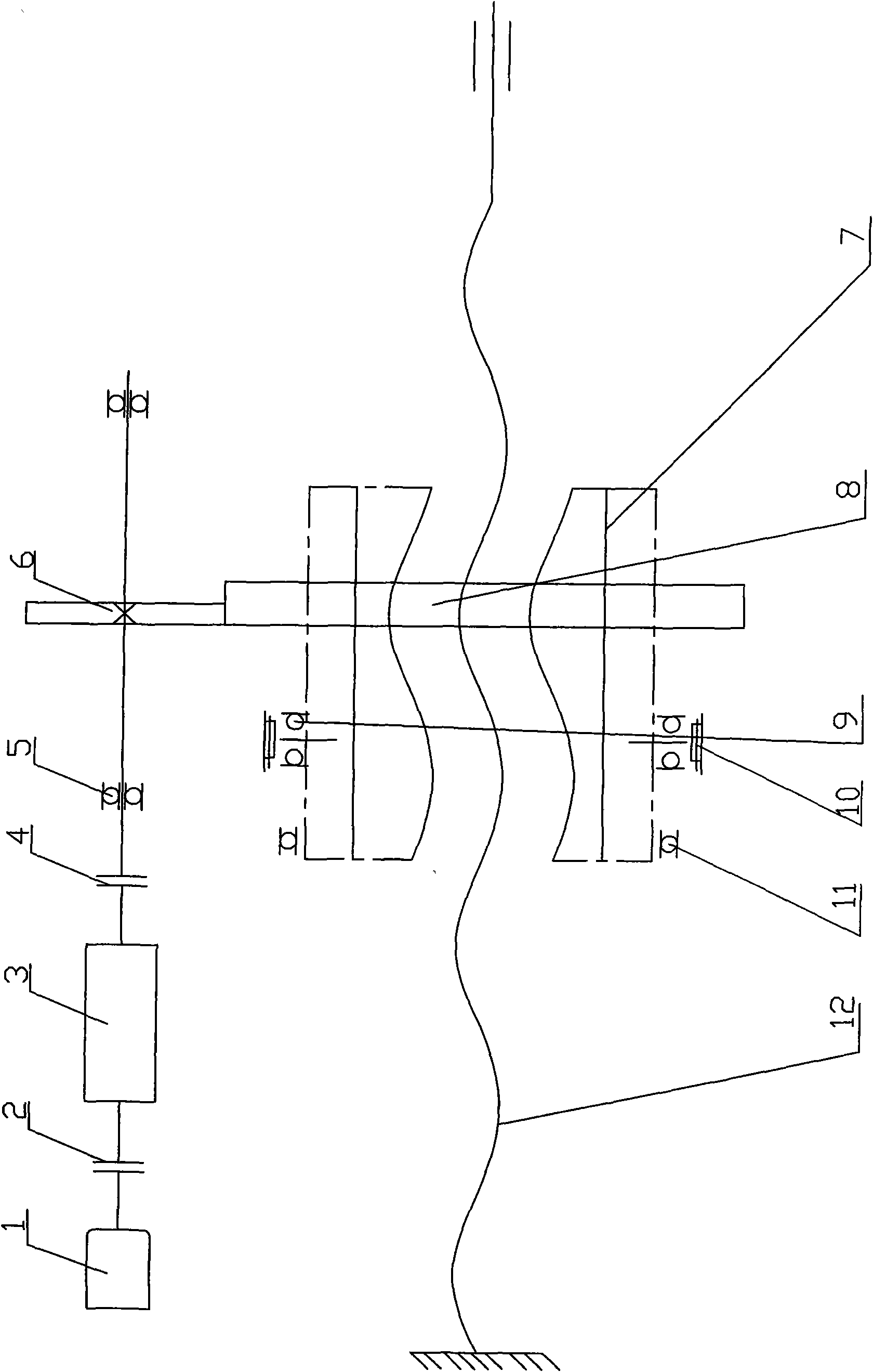

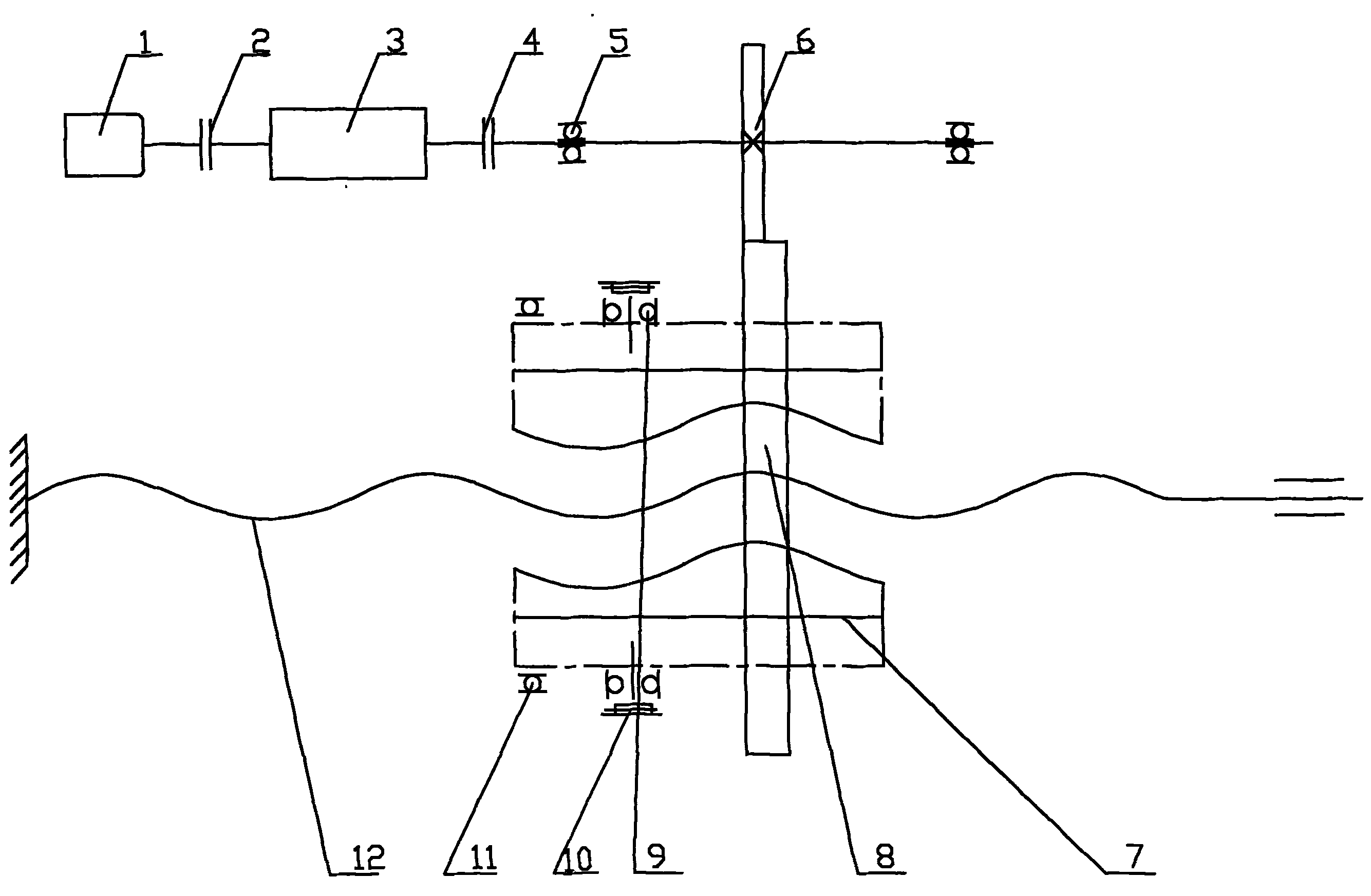

[0018] With reference to the drawings in the description, the present invention discloses an X-axis ball screw nut transmission mechanism for a CNC floor boring and milling machine, which includes a ball screw nut transmission pair, an anti-backlash gear pair and a power source. The pinion 6 and the double-teeth anti-backlash gear 8 connected to the output shaft, the ball screw nut transmission pair is a ball screw nut assembly 12, including a ball screw and a nut, and a nut sleeve 7 is arranged outside the nut, and the double-teeth anti-backlash Gear 8 is installed on the nut sleeve 7, one end of the ball screw is fixed on the machine tool, and the other end is supported on the slide seat of the machine tool. The power source is a servo motor 1, and the servo motor 1 is connected with the pinion 6 through a reduction box 3. Between the servo motor 1 and the reduction box 3 , between the reduction box 3 and the pinion 6 are respectively connected through the first coupling 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com