Special automatic production line for drilling of oil pump rotor type workpieces

An automatic production line and workpiece technology, applied in the direction of boring/drilling, drilling/drilling equipment, metal processing, etc., can solve the problems of high labor cost, low processing efficiency, high cost, etc., to ensure repeat positioning accuracy, improve The level of automation, the effect of increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further clarify the technical solution of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

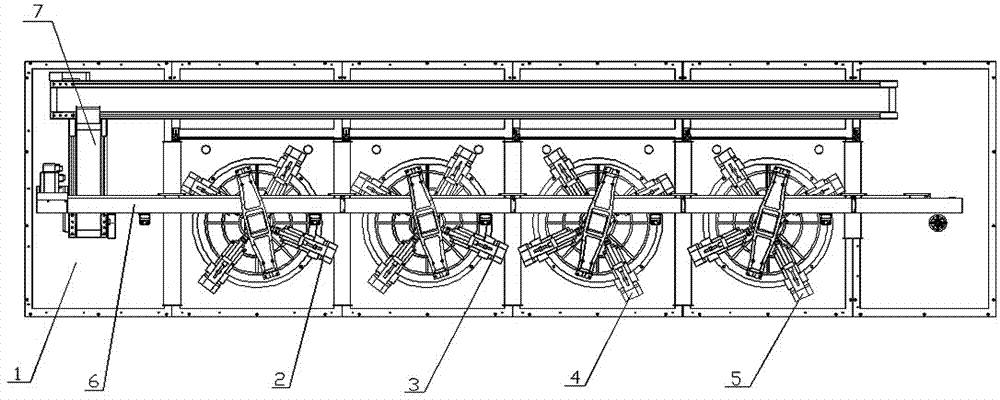

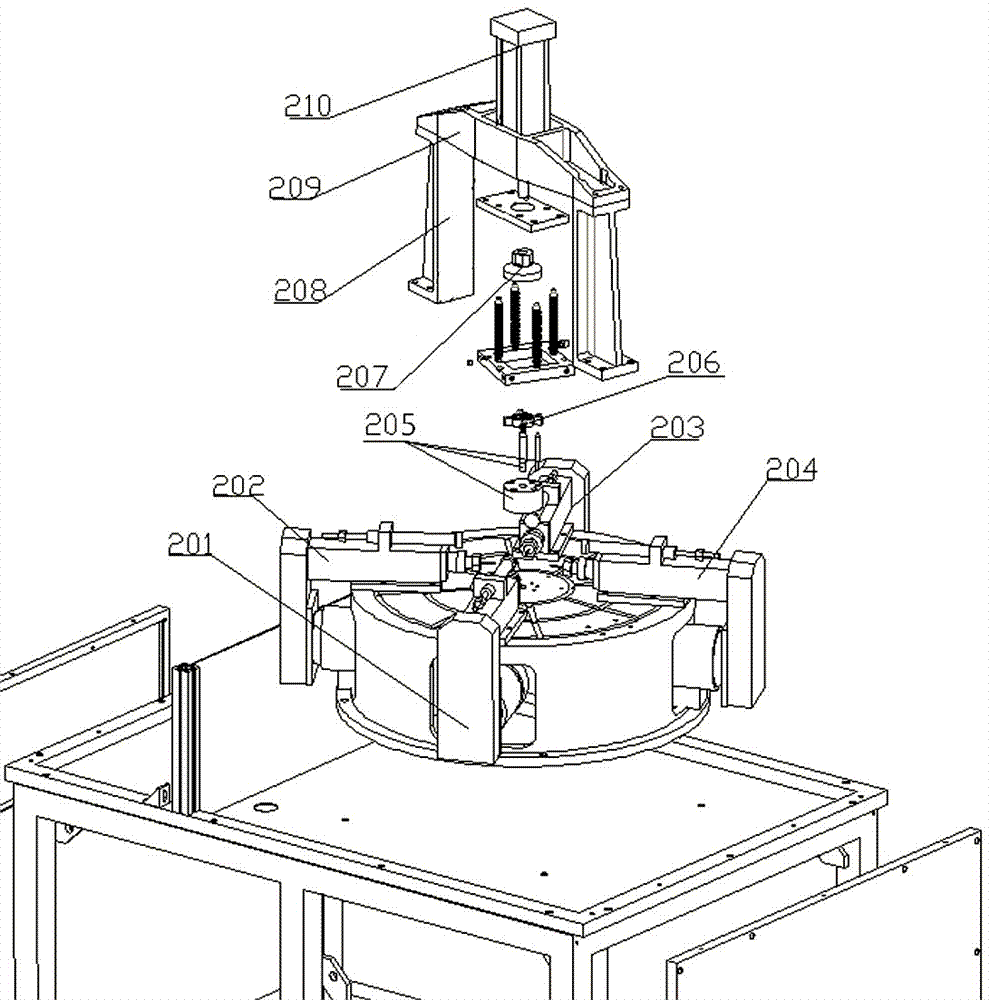

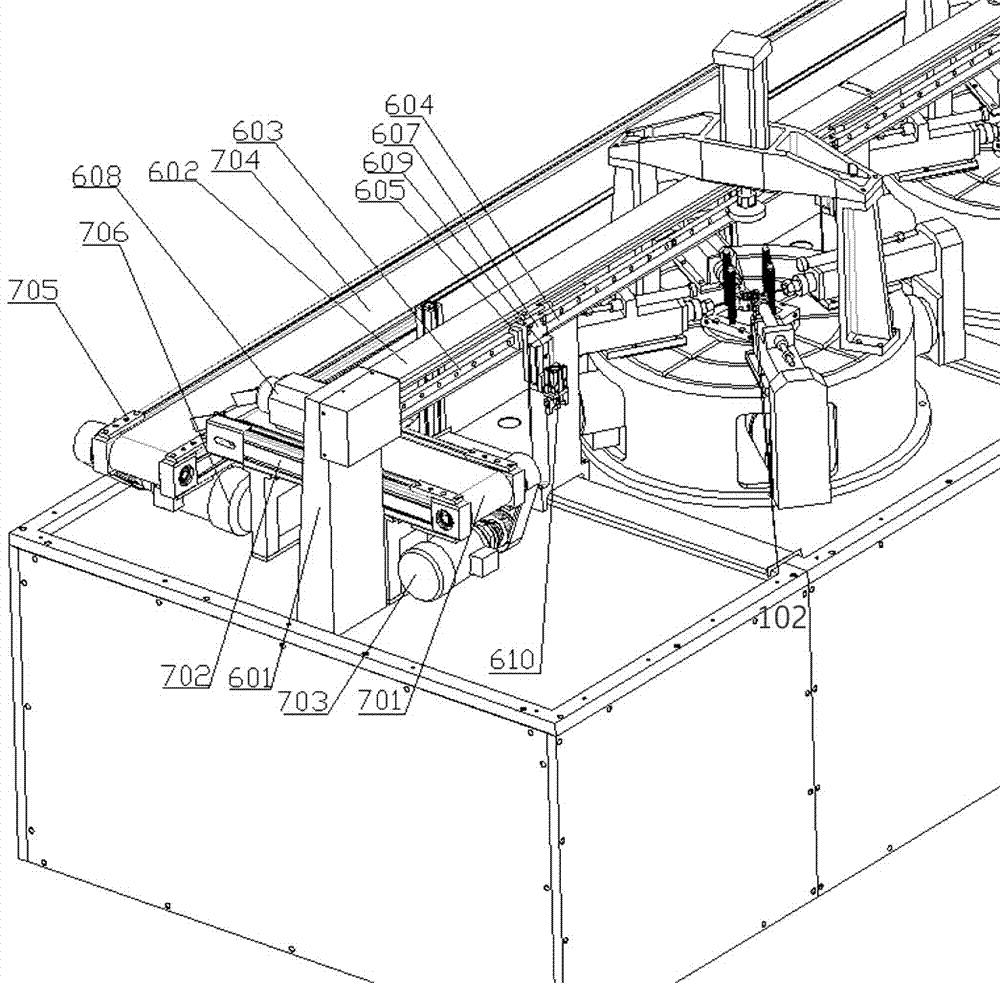

[0024] like Figure 1 to Figure 5 As shown, an automatic production line dedicated to drilling oil pump rotor workpieces, including a bed 1, a drilling module group, a truss manipulator 6, a gantry-type pneumatic pressing device, and a workpiece receiving and conveying mechanism 7 and other components. In this embodiment, the workpiece 206, as shown in 6, includes a cylindrical base and protruding teeth protruding from the periphery of the base. The workpiece 206 is provided with two groups of holes A and B along the circumference, not at the same height, distributed On both sides of the protruding teeth, the holes in group A and group B are composed of four uniformly distributed unit holes.

[0025] The base 101 of the bed 1 is provided with four workbenches arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com