Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Guaranteed operating conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

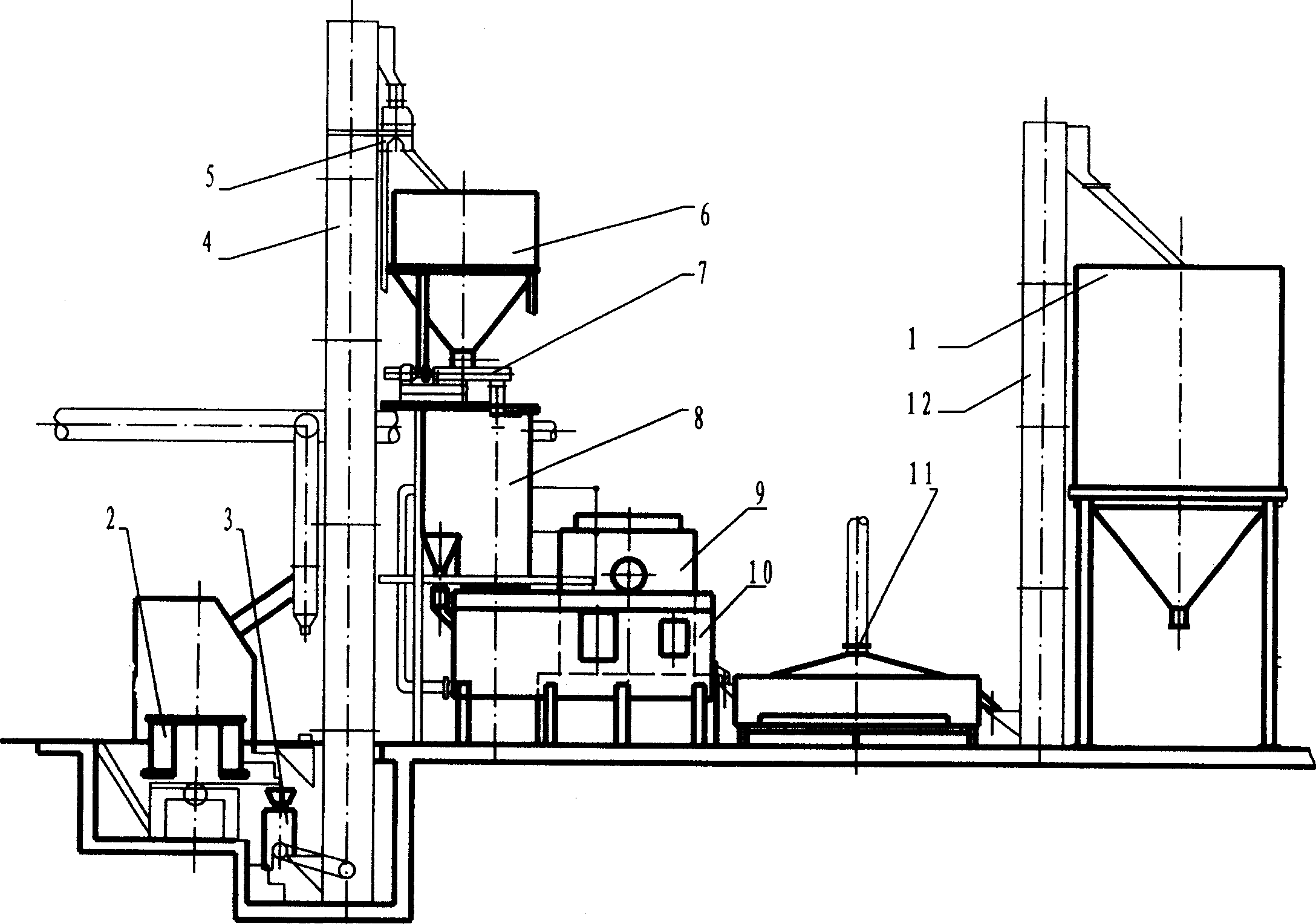

Biomass graded temperature-control slow pyrolysis process and its system

ActiveCN1935941AMeet the requirements of gasification reactionGuaranteed operating conditionsBiofuelsEnergy inputSyngasTemperature control

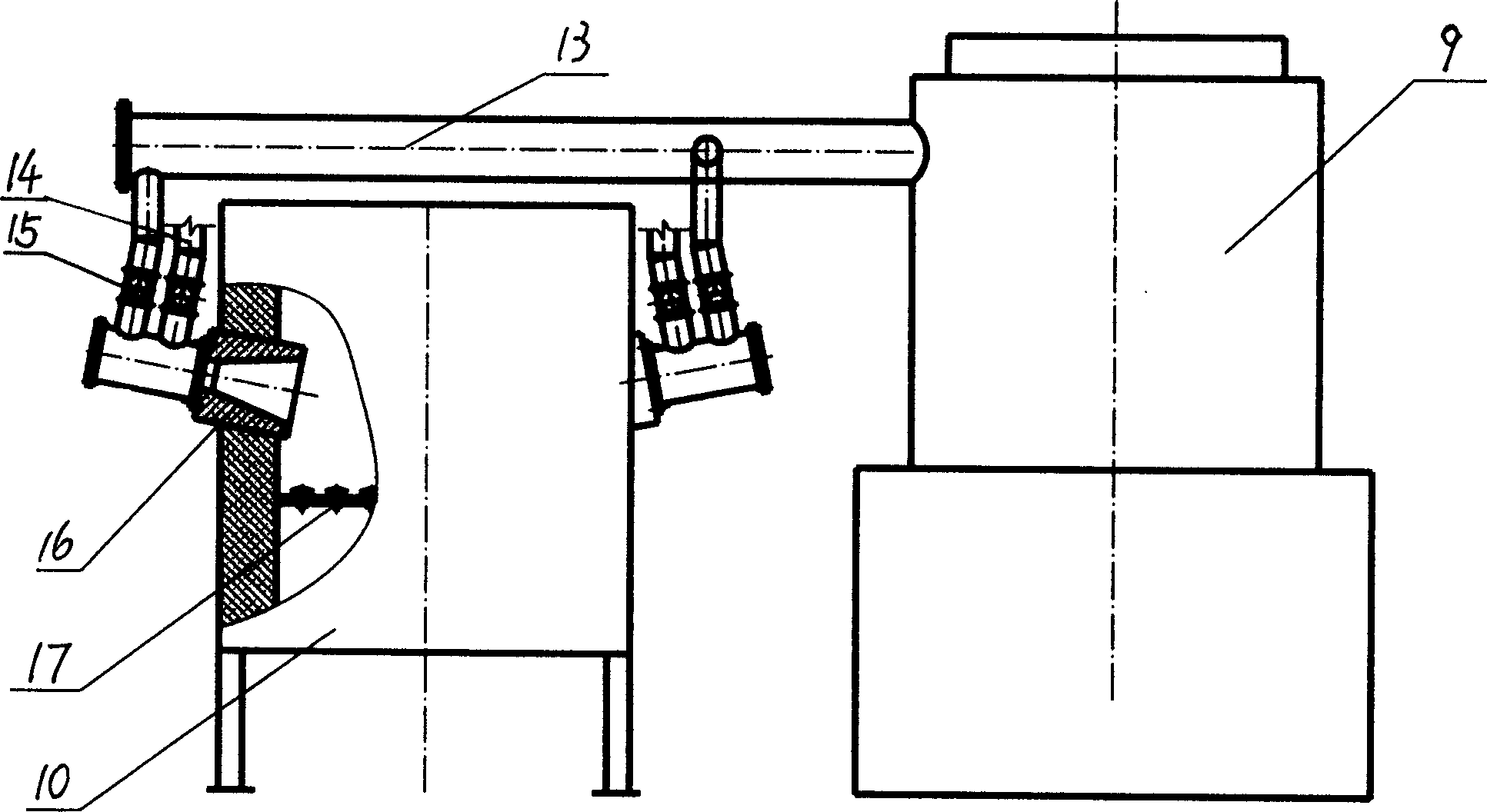

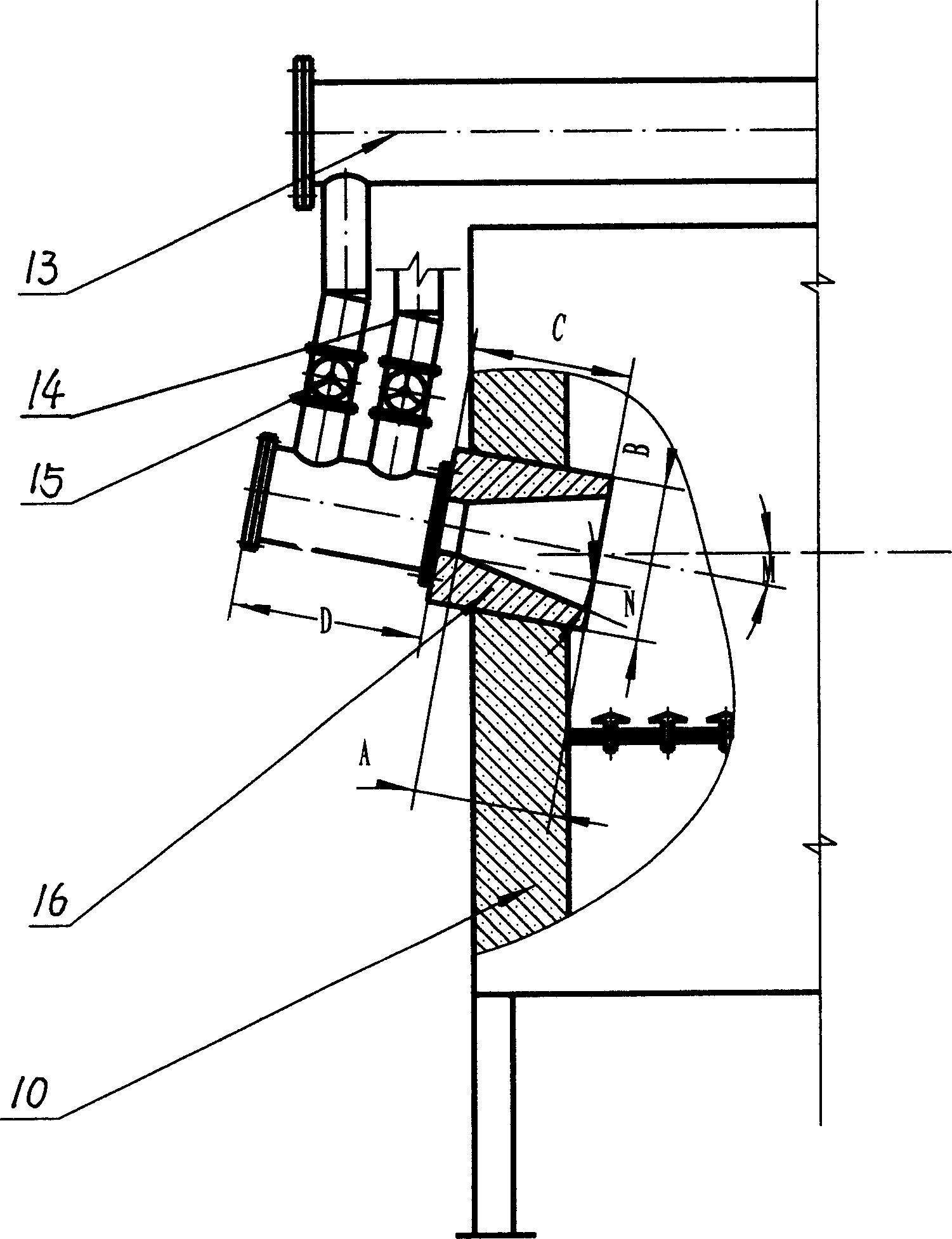

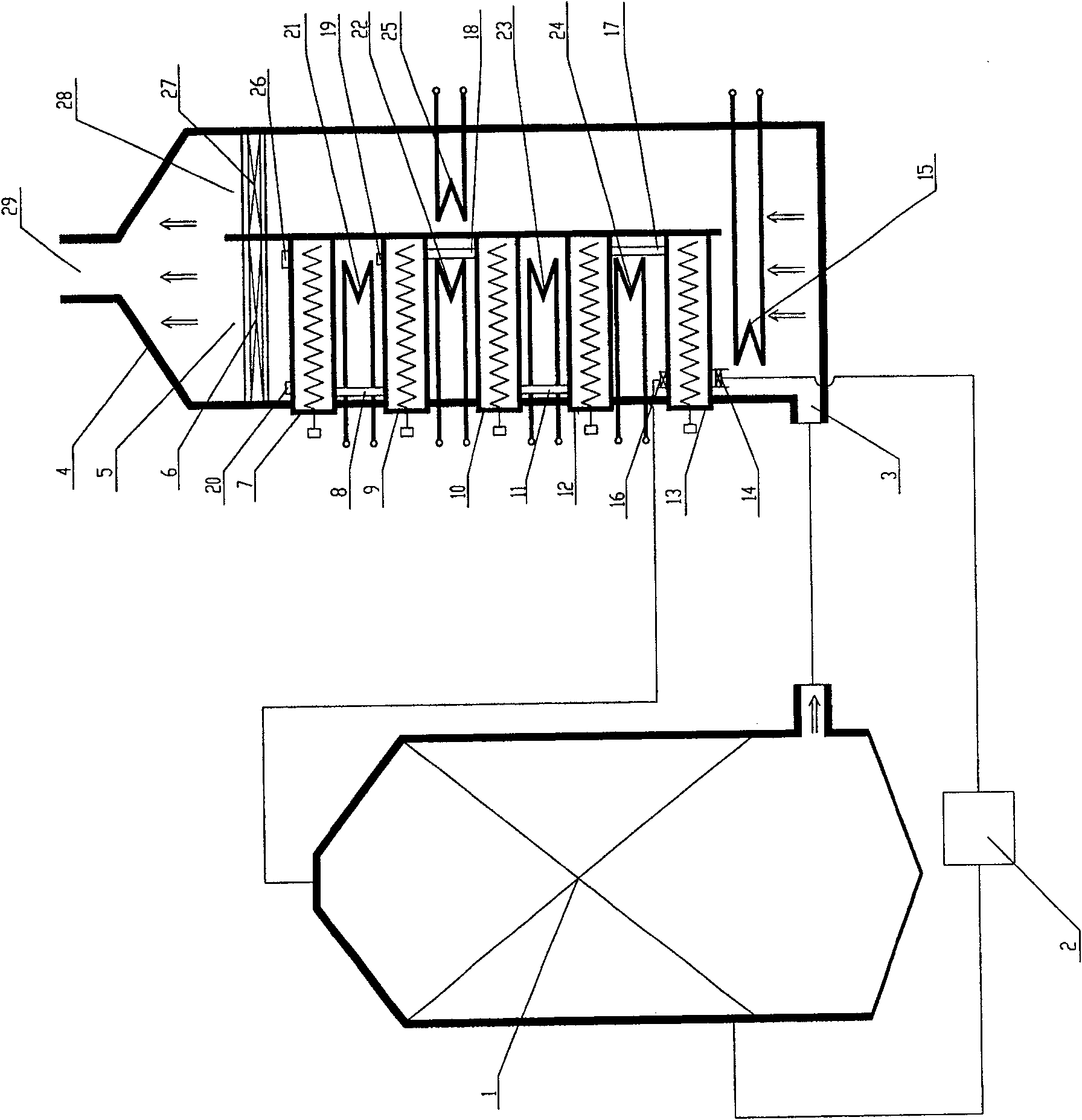

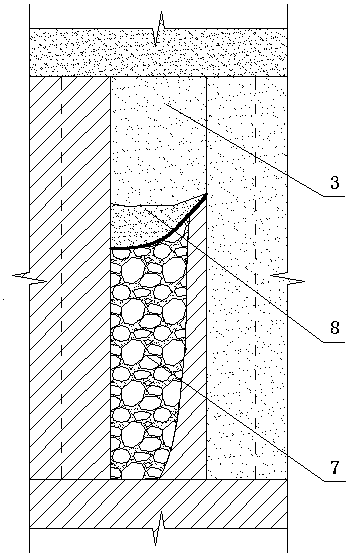

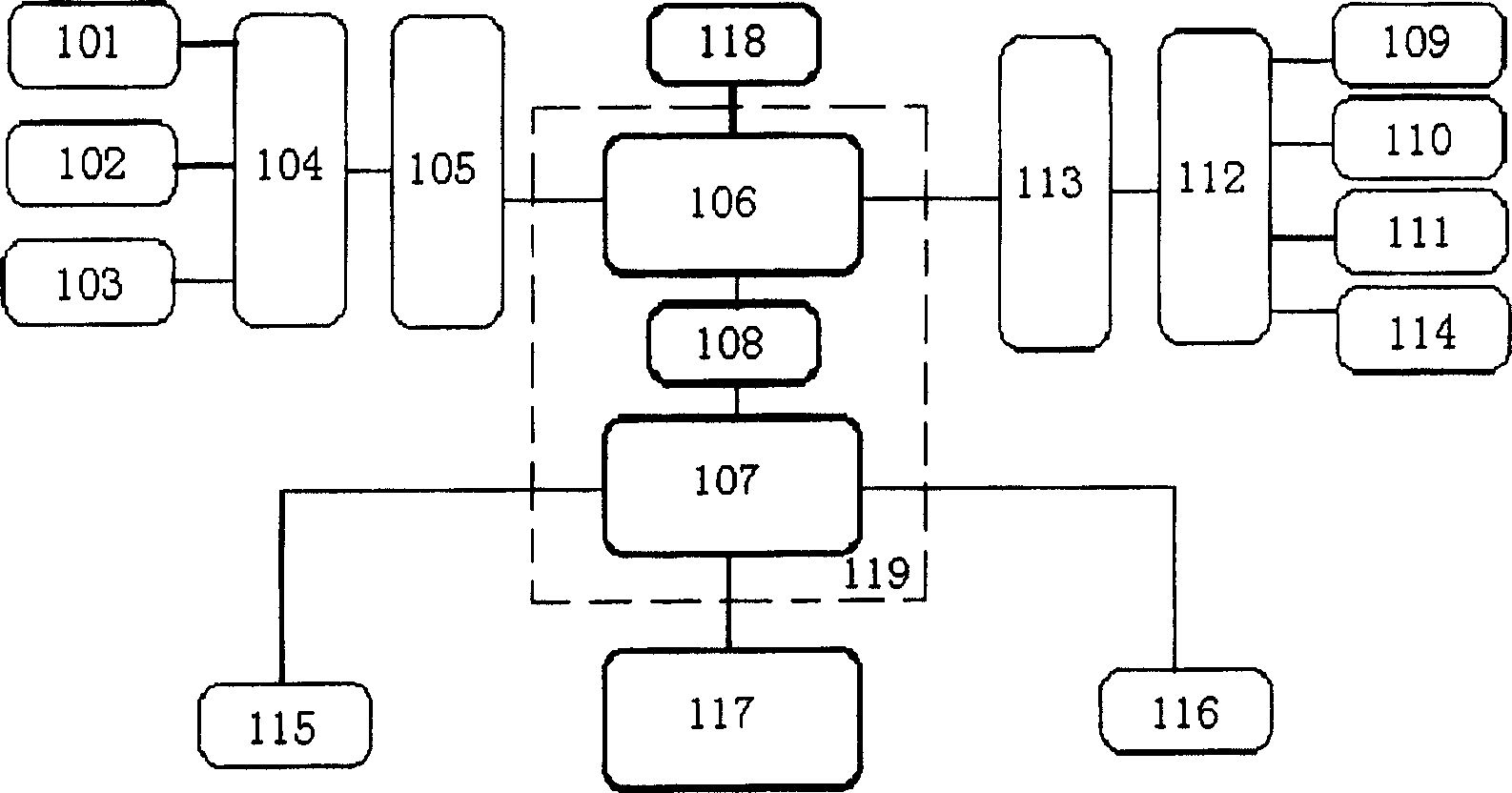

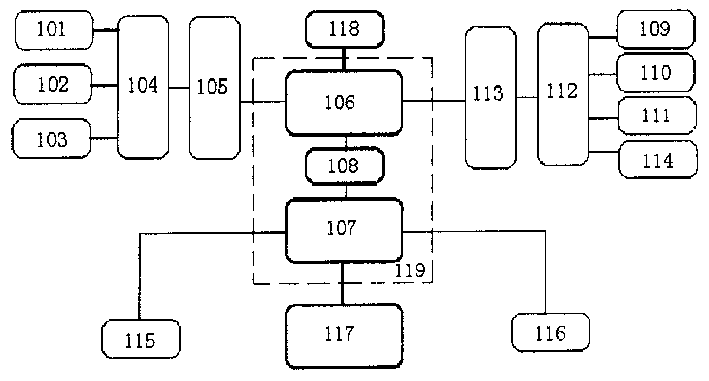

The invention relates to biomass grading temperature controlling slow speed pyrolysis technology and its system. The technology includes the following steps: dividing the pyrolysis into many independent stages with temperature increasing; processing countercurrent flow for external heat source and biomass; heating the biomass grade by grade to make it pyrolyse; pre-drying and deep drying the material to make sure its water content is 5-10%; pre-charring and charring to gain charcoal, pyrolysis gas, little gas state biological crude oil; processing the secondary decompose for the crude oil at roasting stage to gain the pyrolysis product. The system is made up of external hot gas source and its bypass route, main heat exchanger, multiple-stage pyrolyzer, and multiple-stage heat exchanger. The invention has the advantages of wide material accommodation limit, easy adjustable pyrolysis process, easy controllable pyrolysis product, utilizing waste heat to increase gasification efficiency.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

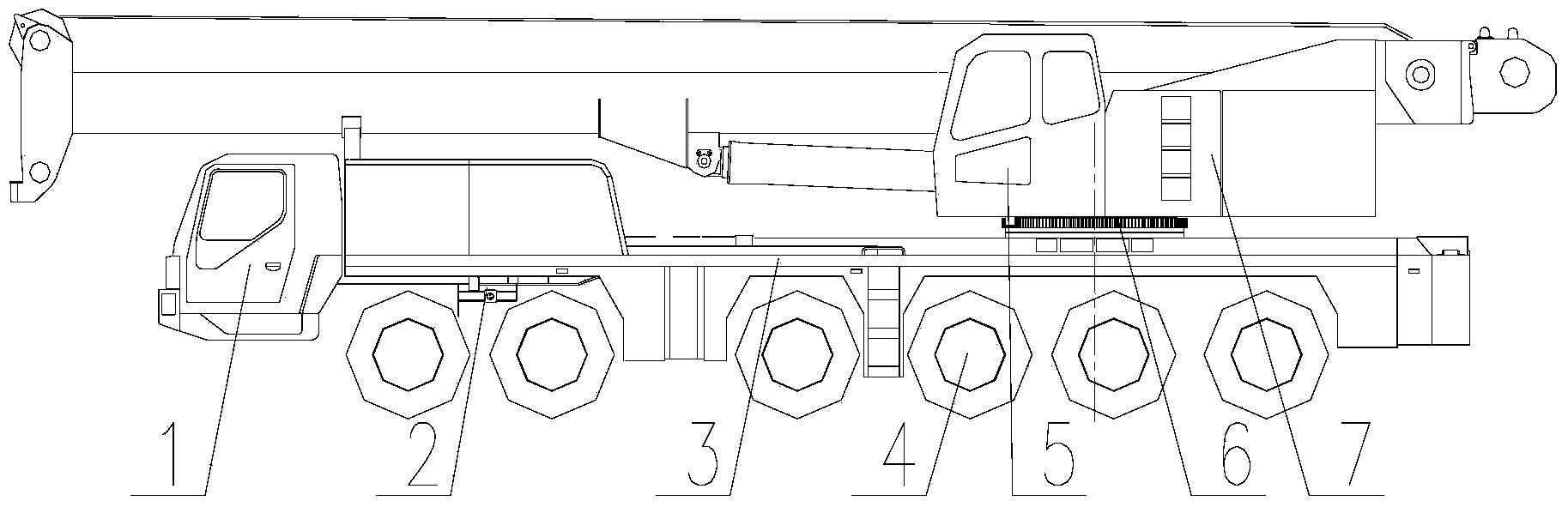

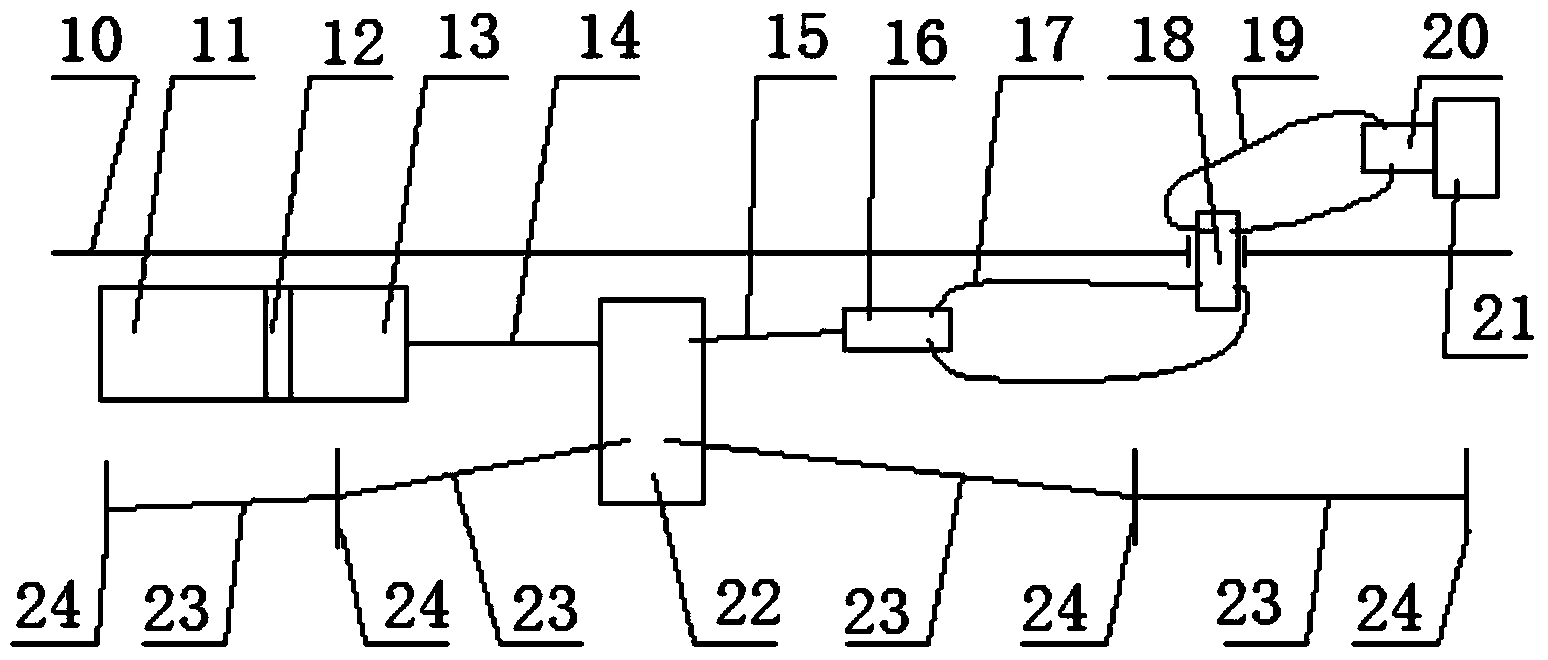

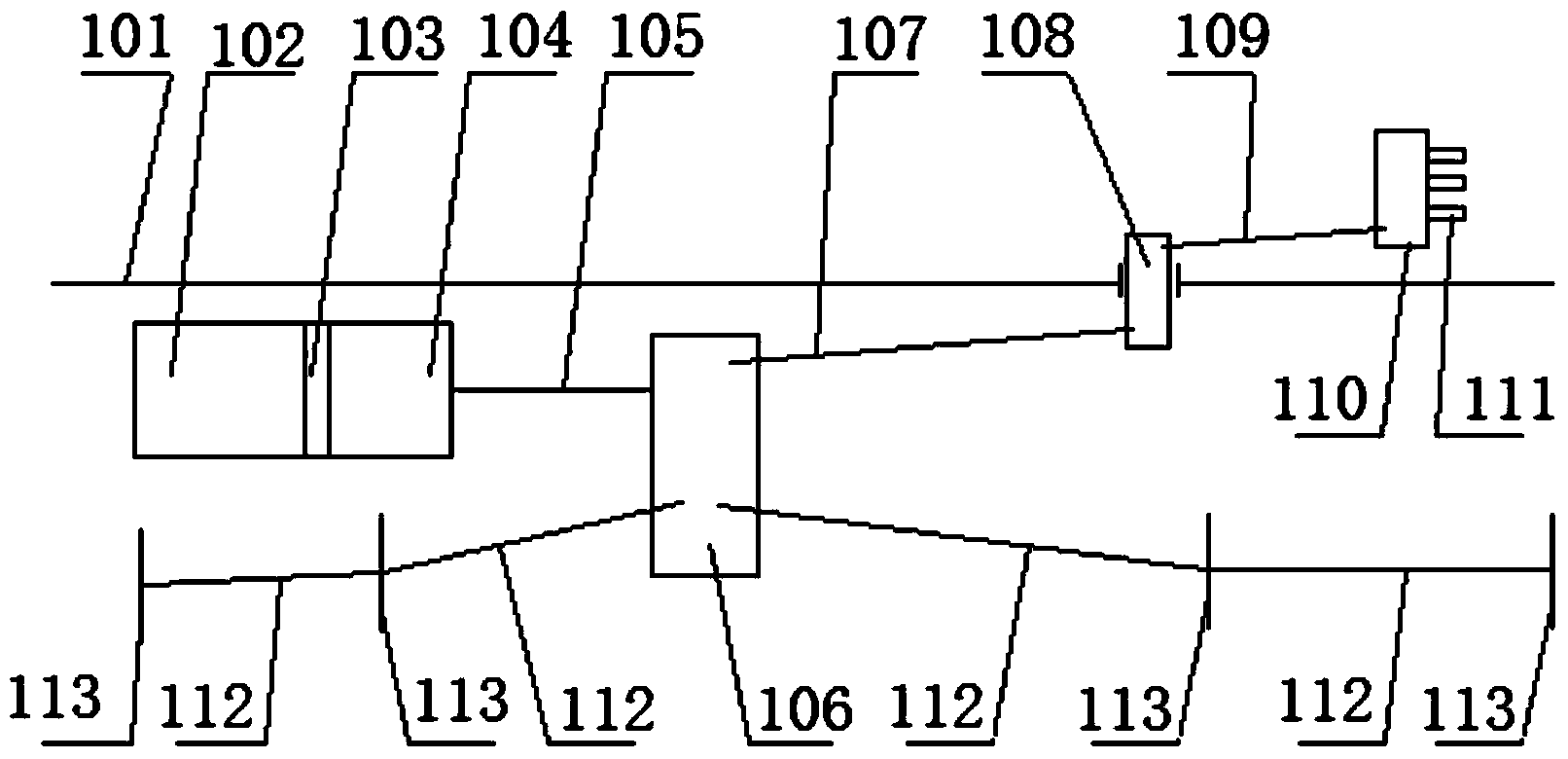

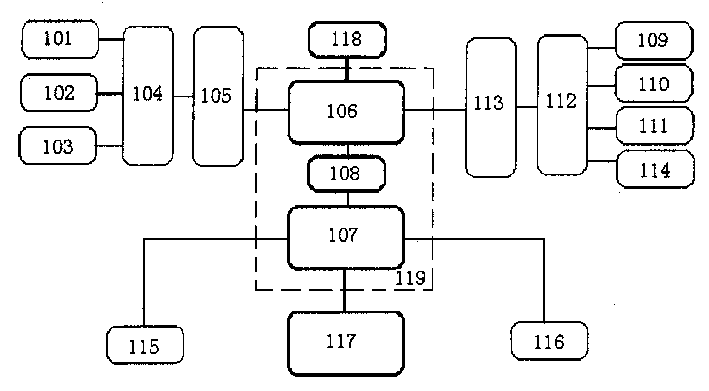

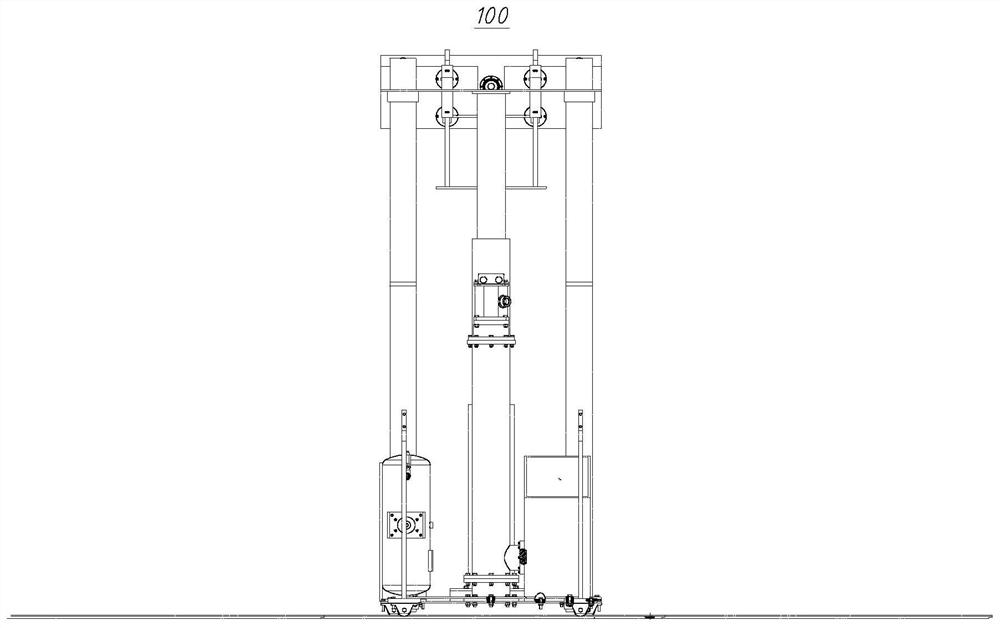

Single-engine power driving device and method and crane

The invention relates to a single-engine power driving device and method and a crane. The single-engine power driving device comprises an lower crane engine, a speed changing box and a lower crane transfer case, and further comprises a central rotation transfer case, an upper crane transfer case and an upper crane hydraulic pump, the central rotation transfer case is connected with the lower crane engine or the speed changing box or the lower crane transfer case through a first transmission shaft, the central rotation transfer case is connected with the upper crane transfer case through a second transmission shaft, the power provided by the lower crane engine is changed in direction by the central rotation transfer case to penetrate through a vehicle rotation seat ring, and then is changed in direction again to be transmitted to the upper crane transfer case, and the upper crane transfer case is in driving connection with the upper crane hydraulic pump. According to the single-engine power driving device, the power transmission mode is a pure mechanical mode, the power is transmitted through the transmission shafts and the central rotation transfer case from a lower crane engine power system, working efficiency is high, energy losses are low, and the operation of upper crane hoisting in various working conditions can be ensured.

Owner:XUZHOU HEAVY MASCH CO LTD

Hot process regenerative apparatus for tectorial sand using for casting

InactiveCN1481951AEasy to control and transportGuaranteed gas volumeMould handling/dressing devicesFluidised-bed furnacesEngineeringFuel supply

The coated sand heating regeneration apparatus includes crushing mechanism, feeding mechanism, preheating mechanism, fuel supplying mechanism, fluidizing roast furnace, cooling discharge mechanism and sand storing bin. The fuel supplying mechanism includes one low pressure hot gas generating furnace and one secondary blast blower; and the fluidizing roast furnace has on its wall two multiple-flow gas-burning nozzles connected to the gas generating furnace and the blast blower via pipeline. With low pressure gas as heat source, the present invention has convenient gas control and conveyance, stable burning, obvious environment protecting and energy saving effect and low cost.

Owner:NINGGUO CITY WEAR RESISTANCE MATERIAL GENERAL FACTORY ANHUI PROV

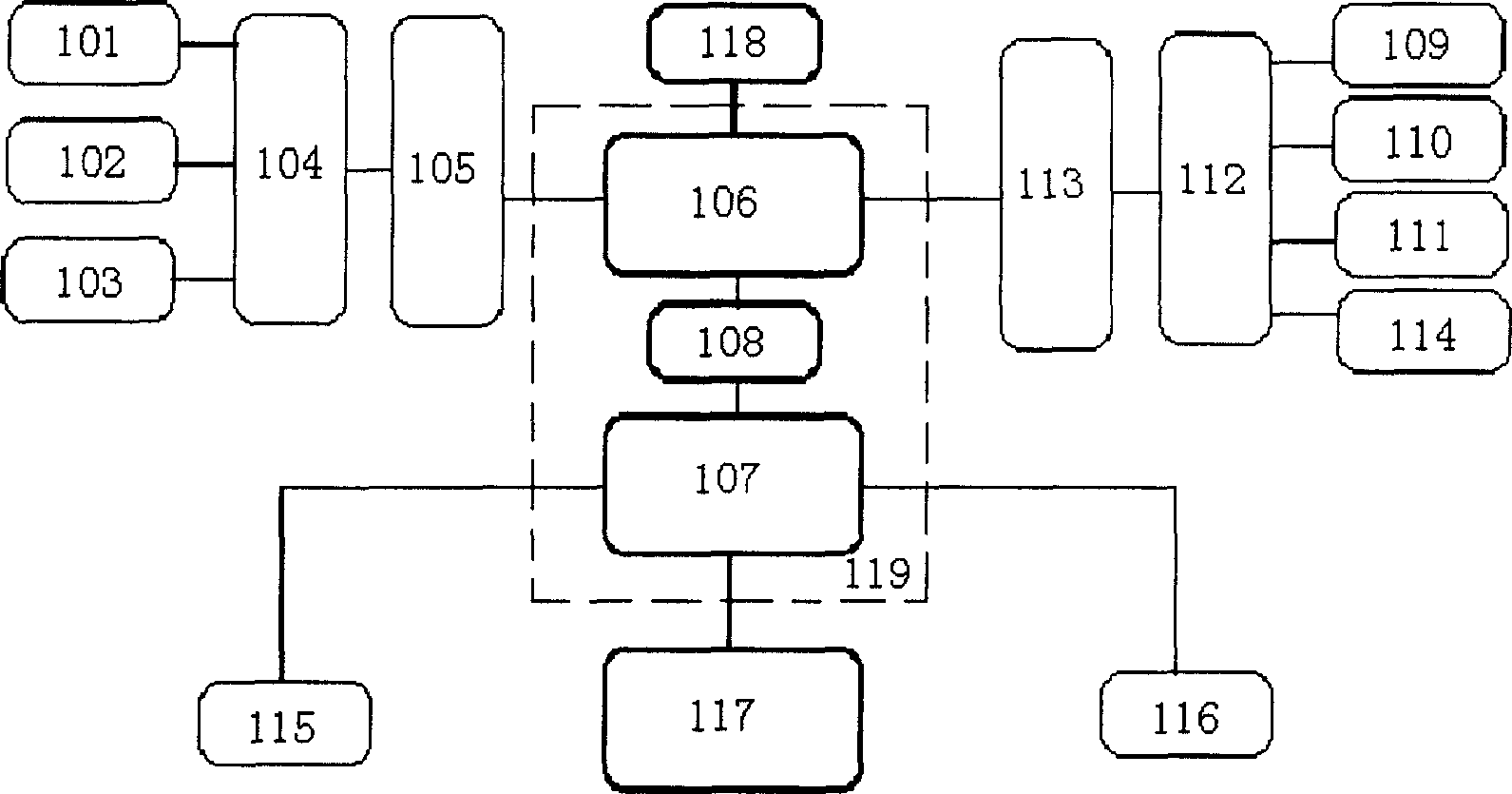

Automatic control system and method of parking device

InactiveCN1438146ARealize safety anti-slipHigh degree of automationTrain hauling devicesTrack brakesEmbedded systemAutomatic control

The present invention discloses a control system which utilizes the collected hump head and hump tail working information to control the controllable the scotch to make hump loose shunting or prevent vehicle from loosing and its control method. Said control system includes: control machine main machine, hump head information collecting and transmission device, pathway lighting protection device, hump tail information collecting device, signal processing device, scotch device and power supply device, and said control method includes the following steps: static and dynamic analogic defining scotch arrangement poiston and scotch arrangement number; collecting hump head and hump tail working informations, controlling scotch state to implement safe loose shunting and raise its automatic extent.

Owner:CRSC RESEARCH & DESIGN INSTITUTE GROUP CO LTD

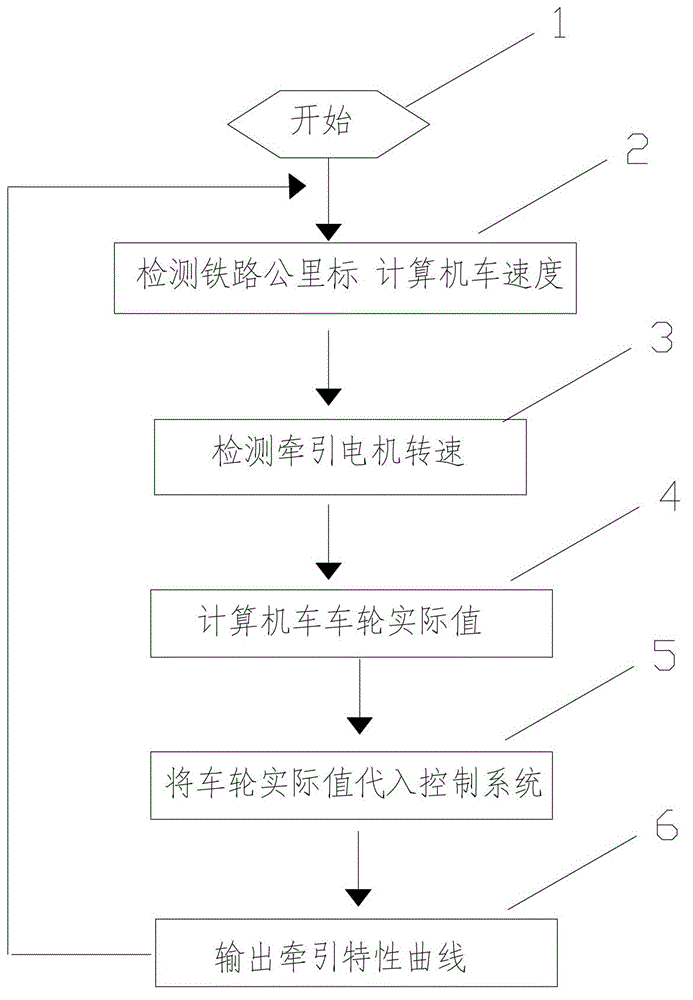

Automatic correction method of railway locomotive tractive characteristic curve

InactiveCN103057549AGuaranteed operating conditionsImprove reliabilityElectric locomotivesControl systemLife time

Disclosed is an automatic correction method of railway locomotive tractive characteristic curve. The method includes that a locomotive running velocity V is obtained by detecting railway kilometer posts and traction motor rotation speed n at the same time, a locomotive practical wheel diameter value D is obtained by calculating the locomotive velocity V and traction motor rotation speed and a control system provides a locomotive tractive characteristic curve according to the locomotive practical wheel diameter value. The automatic correction method judges the locomotive practical wheel diameter value by using the corresponding relationship of the traction motor rotation speed and a practical velocity of locomotive, and then revises automatically the characteristic curve to ensure normal working condition of devices such as the tractive motor and a traction converter, thereby the system reliability is enhanced and service life is prolonged.

Owner:CRRC DALIAN CO LTD

Overload protection control method and apparatus for heat pump type clothes dryer and clothes dryer equipped with the apparatus

InactiveCN101435150AGuaranteed operating conditionsControl loadHeat pumpsTextiles and paperDevice breakageMoisture sensor

The invention provides an overload protection control device of a heat pump type dry wardrobe, a control method of the device, and a dry wardrobe with the device, wherein, the control device comprises a temperature sensor used for measuring the temperature of circulated air in the dry wardrobe, a humidity sensor used for measuring the humidity of the circulated air in the dry wardrobe, a calculating device connected with the temperature sensor and the humidity sensor, and external forced draft ventilation equipment connected with and controlled by the calculating device. When the temperature-humidity of the circulated air in the wardrobe exceeds or is close to a safety range, the external forced draft ventilation equipment is started to reduce temperature, therefore, the damage to the equipment caused by the overload of a heat pump system can be avoided without stopping the operation of the heat pump system, the structure is simple and the drying efficiency is higher.

Owner:北京科力康技贸有限公司

Chromalizing device and process for small hole of driving device for control rod of nuclear reactor

InactiveCN103103591AGuaranteed operating conditionsOvercome the difficulty of uniform growth and the lack of easy initiation of cracksCellsElectrodesCrazingNuclear reactor

The invention provides a chromalizing device for a small hole of a driving device for a control rod of a nuclear reactor. The chromalizing device comprises an anode and auxiliary cathodes, wherein the auxiliary cathodes are shaped like sheets and arranged by covering the two ends of the small hole; the anode is of a cylindrical body arranged along the axial direction of the small hole and penetrates through the end surfaces of the auxiliary cathodes, and radial gaps are arranged between the anode and the auxiliary cathodes; and anode insulation sleeves are sheathed at the parts at the two ends of the anode, which are exposed on the outer side of the small hole. A preparation process sequentially comprises the following steps of: (1) performing alkaline cleaning to remove oil and cleaning with B-grade pure water; (2) assembling the chromalizing device; and (3) using an electroplating solution which only comprises CrO3, concentrated H2SO4 and Cr<3+> components to chromalize the small hole. The thickness of a plated layer prepared by adopting the method is at least not less than 45mu m; the deviation of the axle center of the plated layer after plating does not exceed 10mu m; and the plated layer has no micro-cracks and can meet the using requirements of working conditions and ensure the effective operation of the driving device for the nuclear control rod.

Owner:DONGFANG TURBINE CO LTD

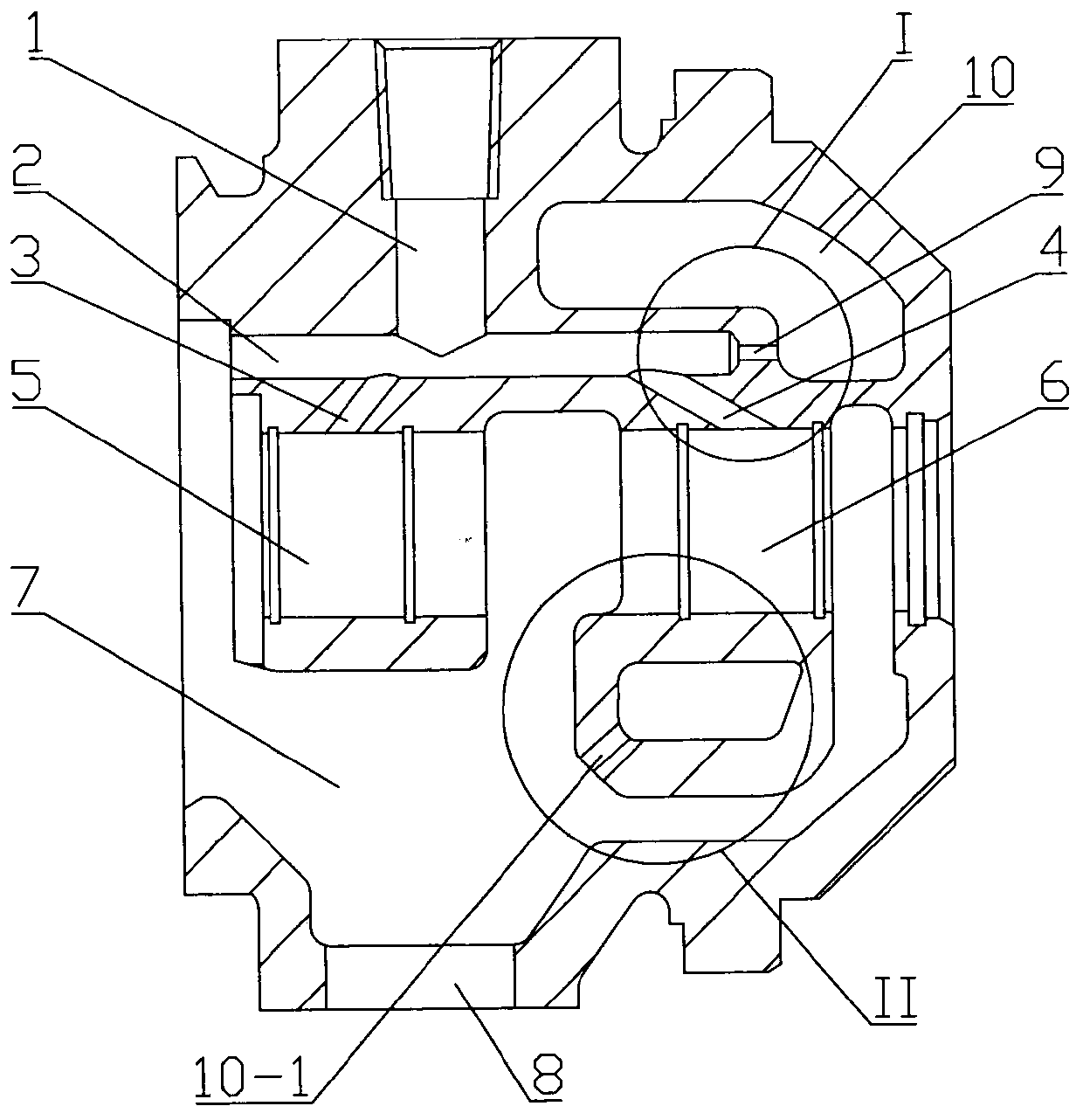

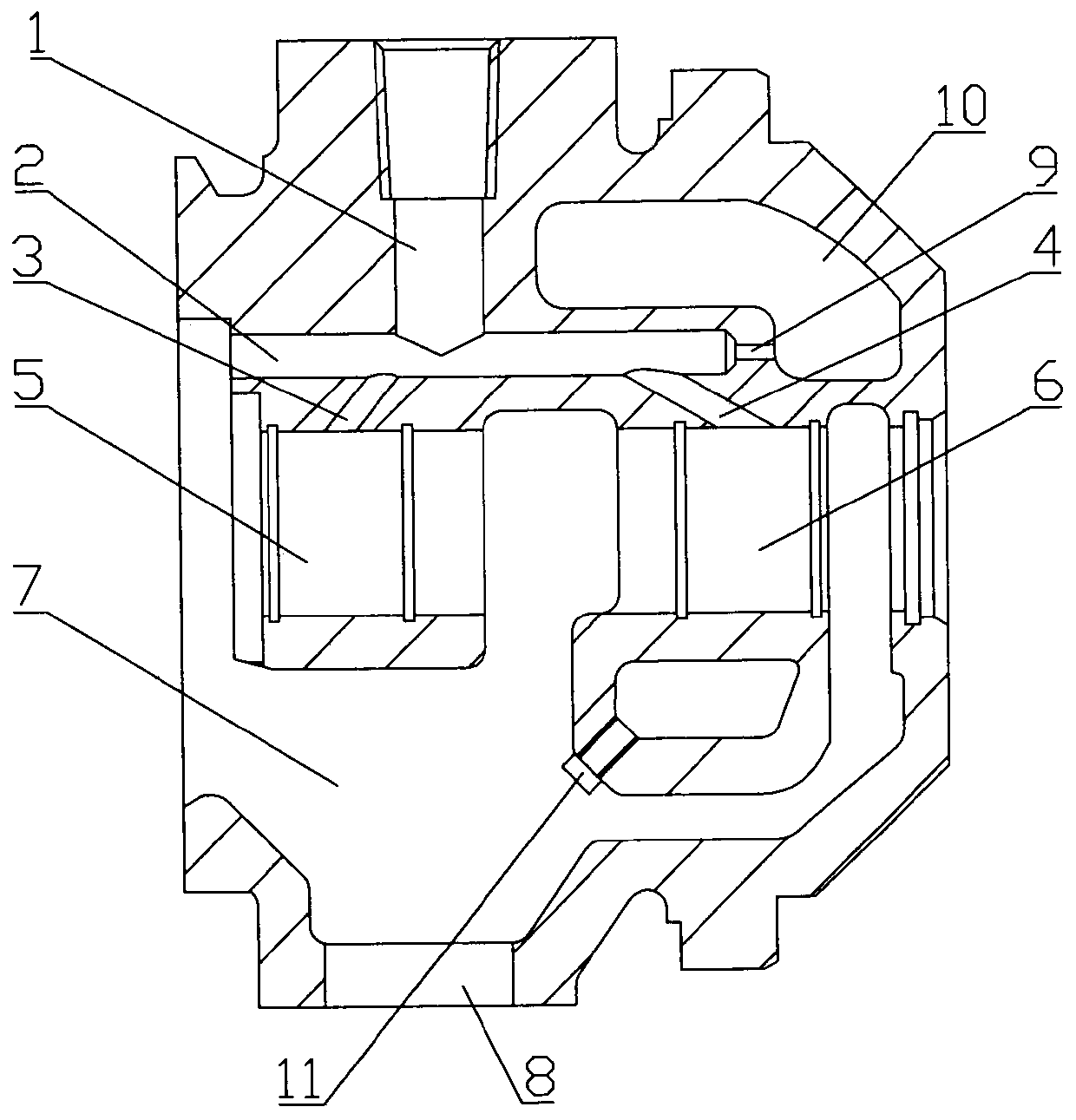

Turbocharger bearing body assembly

PendingCN107869364AReduce the temperatureGuaranteed operating conditionsMachines/enginesEngine componentsTurbochargerOil cooling

The invention relates to a turbocharger bearing body assembly. A bearing body is provided with an oil inlet hole, a main oil guide hole, an air-pressure-end oil guide inclined hole, a turbine-end oilguide inclined hole, an air-pressure-end floating bearing hole, a turbine-end floating bearing hole, a main oil chamber and an oil outlet hole. An independent cooling oil cavity is arranged at the turbine end of the bearing body, and penetrates through the upper and lower structures of the turbine end of the bearing body. An oil injection hole is arranged at the turbine end of the main oil guide hole, and communicates with the independent cooling oil cavity. A lubricating oil pressure relief hole is arranged at the bottom, near the oil outlet hole, of the independent cooling oil cavity, and communicates with the main oil chamber to facilitate the timely discharge of lubricating oil in the cooling oil cavity to the main oil chamber.

Owner:HUNAN TYEN MACHINERY

Spraying environment-friendly energy-saving anti-explosion fan based on shaft sump water source

ActiveCN103362832AAvoid security issuesSave money on energy consumptionDust removalFire preventionWater wheelWater source

A spraying environment-friendly energy-saving anti-explosion fan based on a shaft sump water source comprises a water tank substrate; a water wheel device is arranged on the water tank substrate and is connected with a wind wheel device by a belt; a high-pressure water spraying device is connected with the water wheel device and the wind wheel device; the technical scheme of taking the shaft sump water source as a power source and combining the functions of wind feeding and spraying of a high-pressure water spraying device, the water wheel device and the wind wheel device is adopted; the defects of high frequency of gas and coal dust explosion caused by electric sparks of a motor, high investment cost, complete demand on the system auxiliary project, large machine noise, poor radiating performance, short service life, low production efficiency, severe production labor environment, easily caused occupational diseases of operation staff and severe coal source waste of the existing coal-mining equipment used for the high-gas shaft are overcome; and the spraying environment-friendly energy-saving anti-explosion fan based on the shaft sump water source is suitable for various ventilation equipment for mine excavation, particularly the ventilation equipment for excavation of the high-gas protruded shaft coal layer.

Owner:永州市亿达自动化机械有限公司

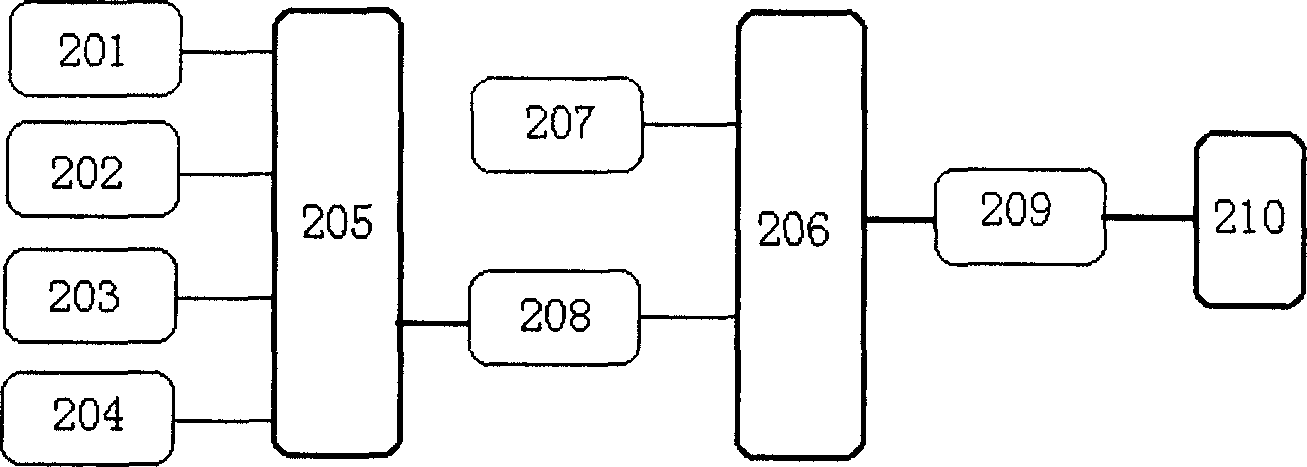

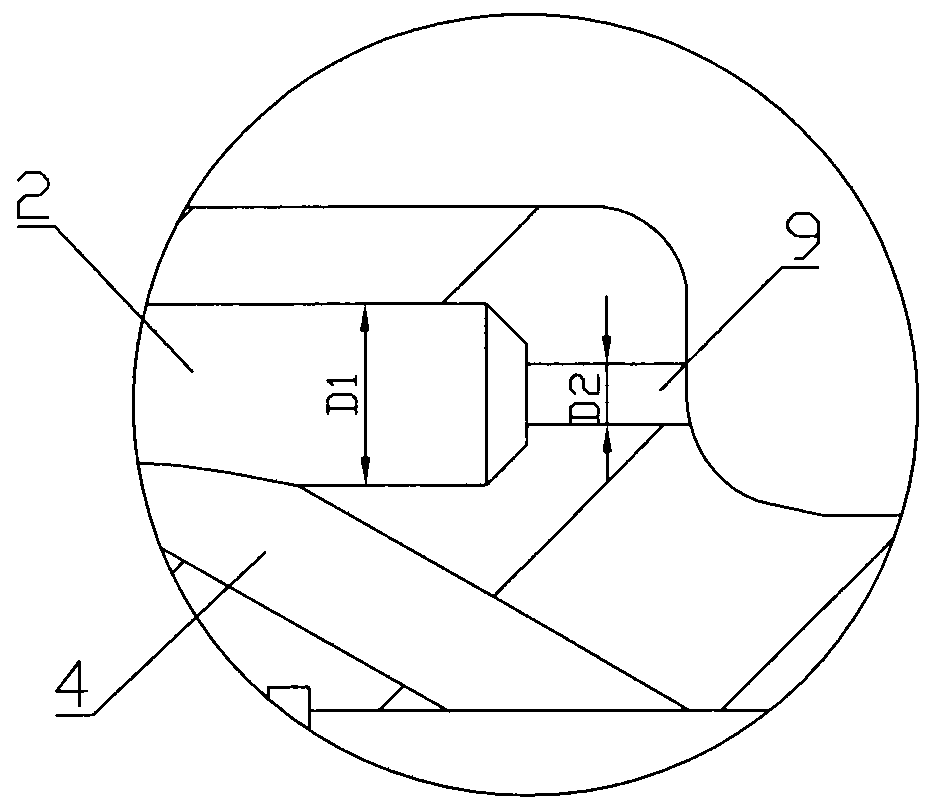

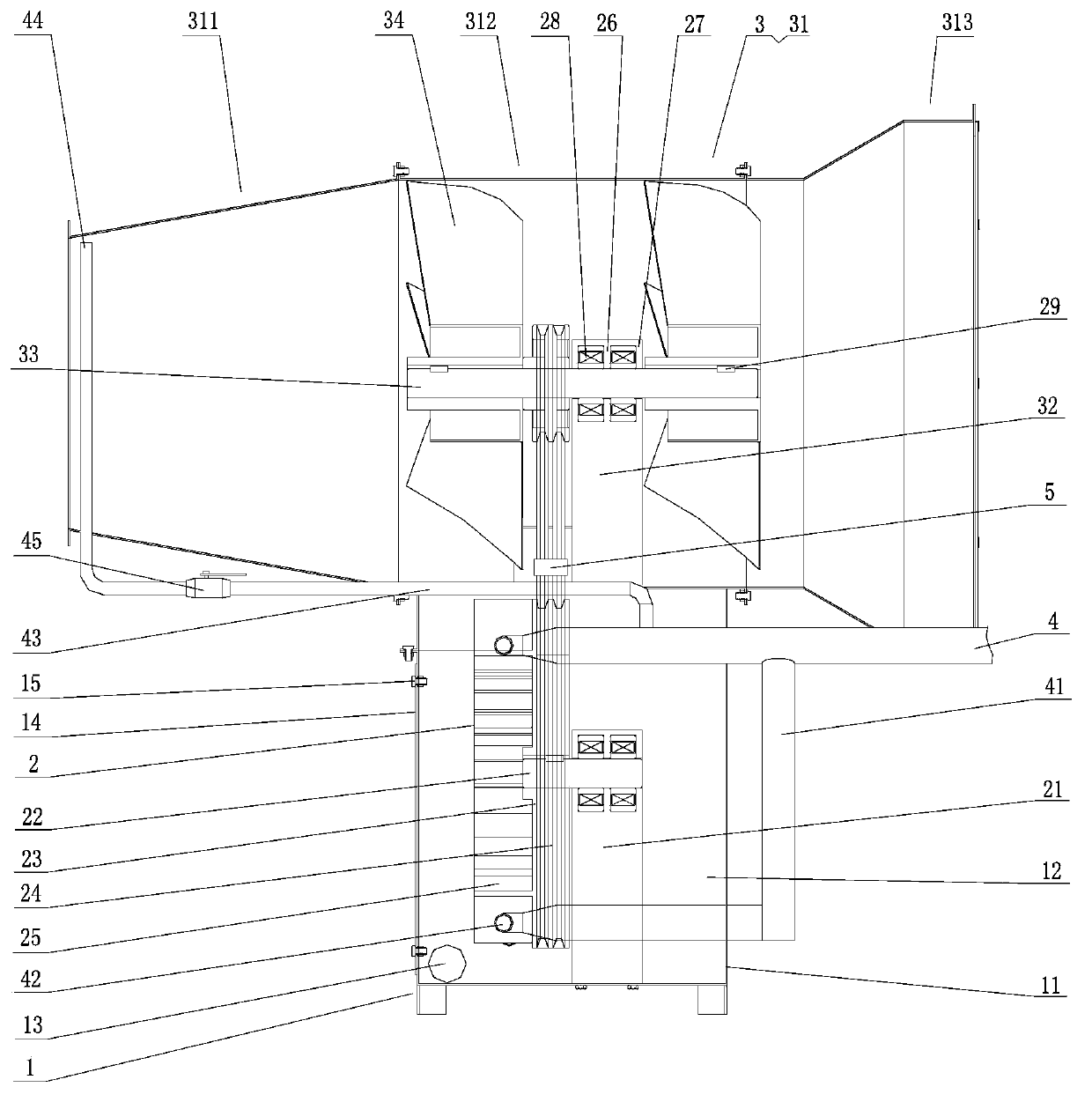

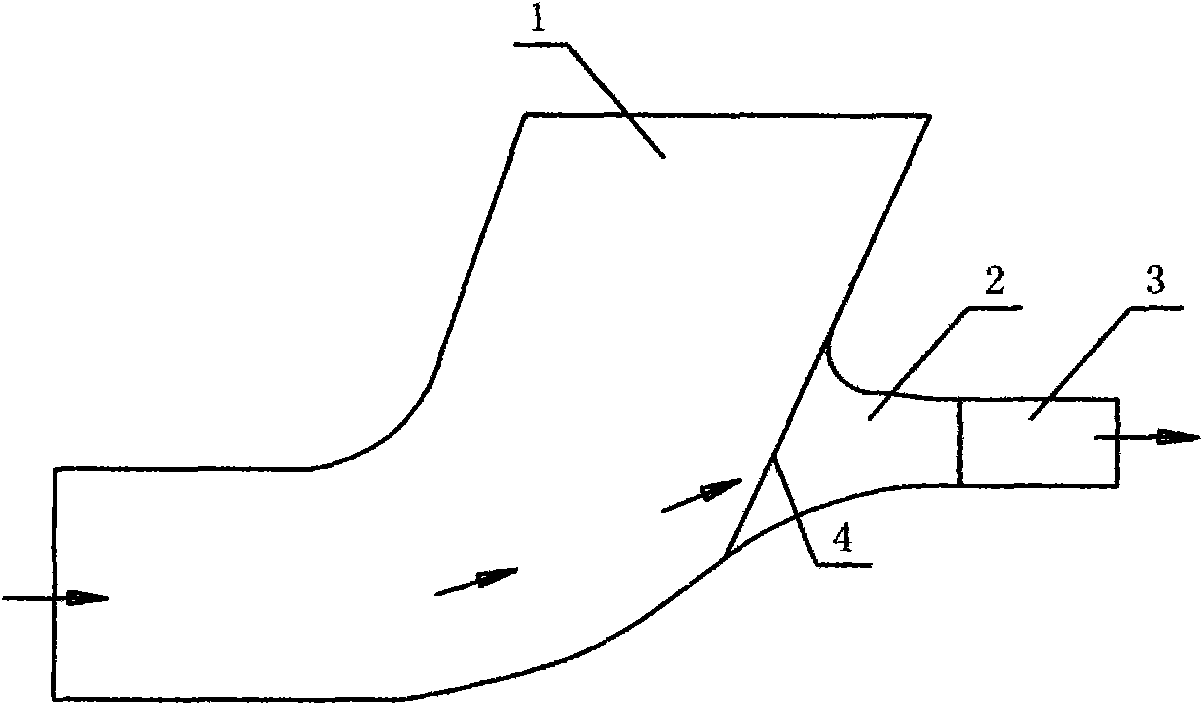

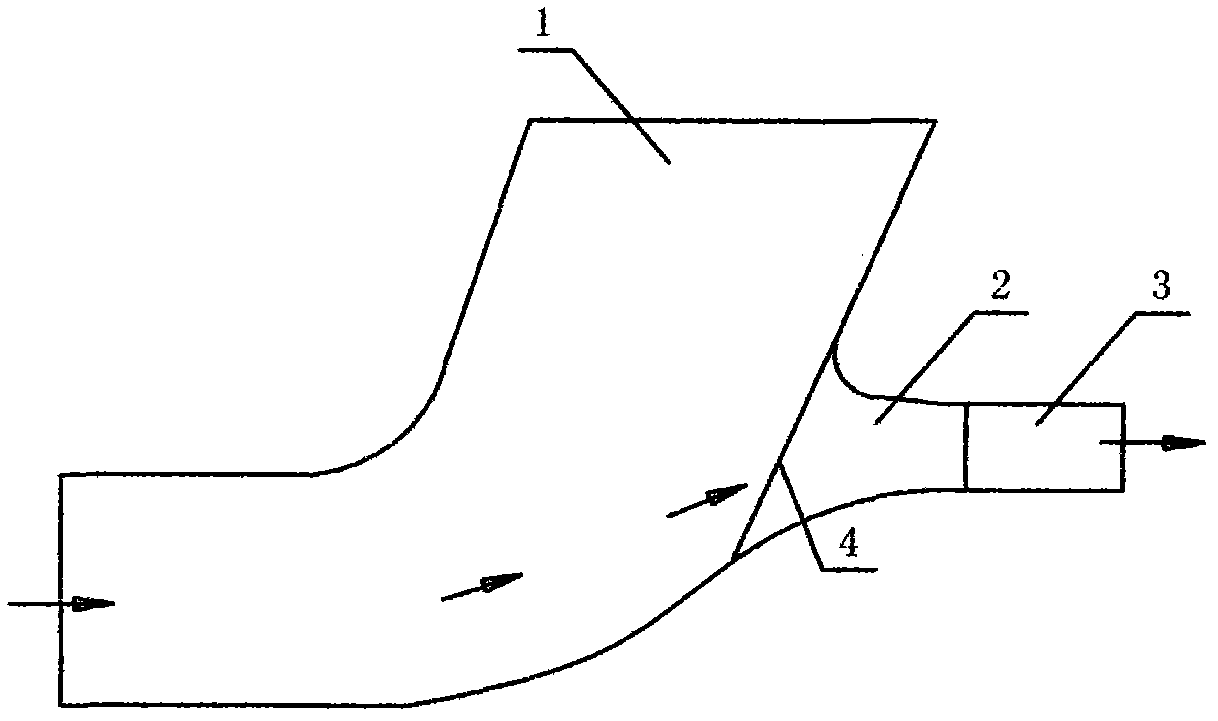

A method and device for collecting exhaust air gas in a coal mine

The invention discloses a collection method and a collection device for coal mine ventilation air methane. The collection device comprises a transitional pipeline and an air collection pipeline, wherein the transitional pipeline is a reducer pipe of which the diameter is reduced gradually; the large end of the transitional pipeline is connected to an air collection opening which is adjacent to the streamline ending position of an outlet on the outer side of a diffuser of a main ventilator of a mine; and the air collection pipeline is connected to an outlet at the small end of the transitional pipeline. In the collection device, the air collection pipeline collects ventilation air methane by utilizing the loss of the kinetic energy of the ventilation air methane under the guiding action of the transitional pipeline, so the normal work condition of the coal mine main ventilator is not influenced, new energy consumption is also not formed, the utilization rate of coal mine methane is improved, and a greenhouse gas effect is avoided. The collection device has a simple structure, is convenient to use, low in collection cost and high in recovery benefit, and can be widely suitable for collecting the ventilation air methane discharged from the diffuser of the coal mine main ventilator.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

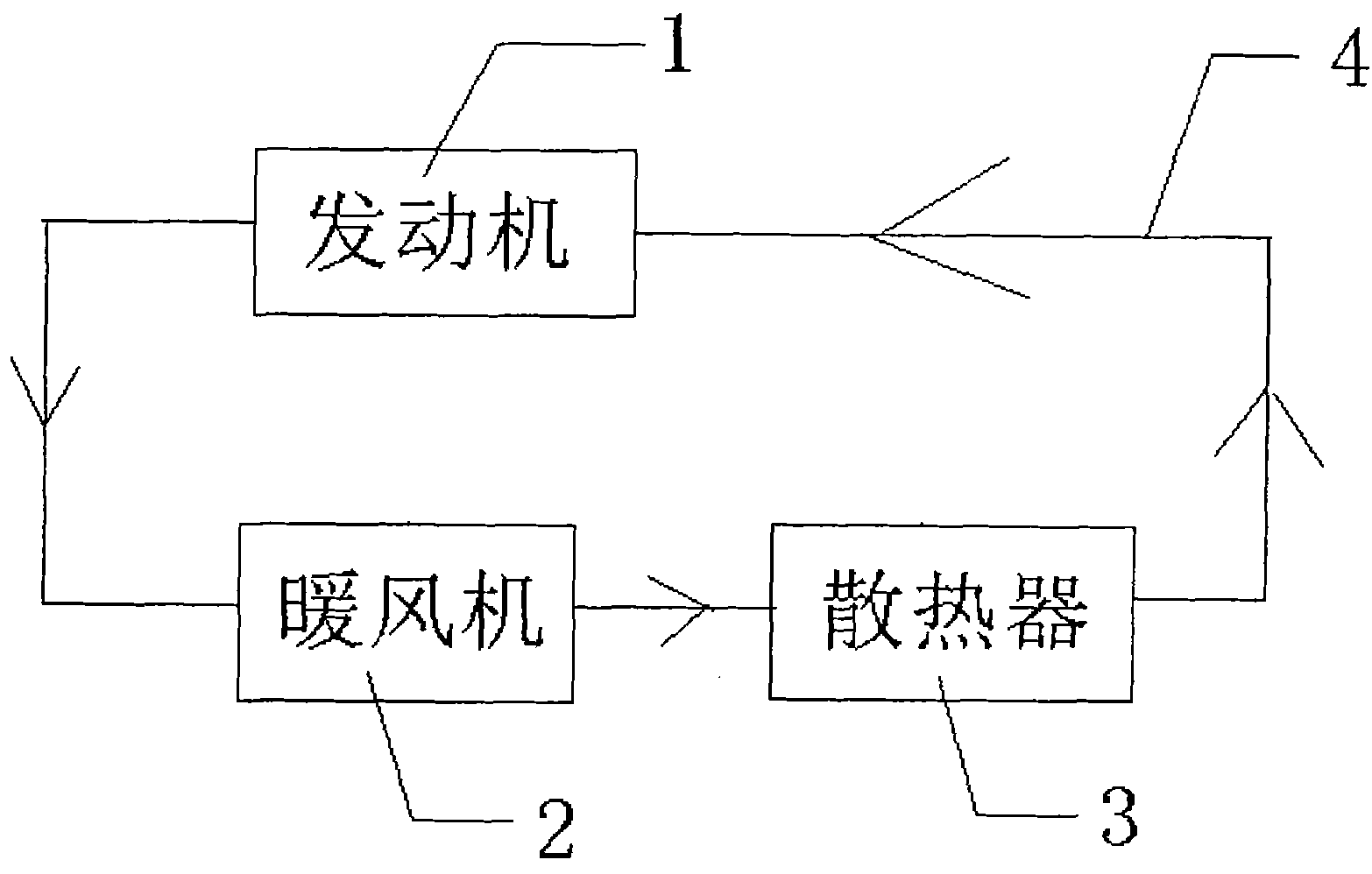

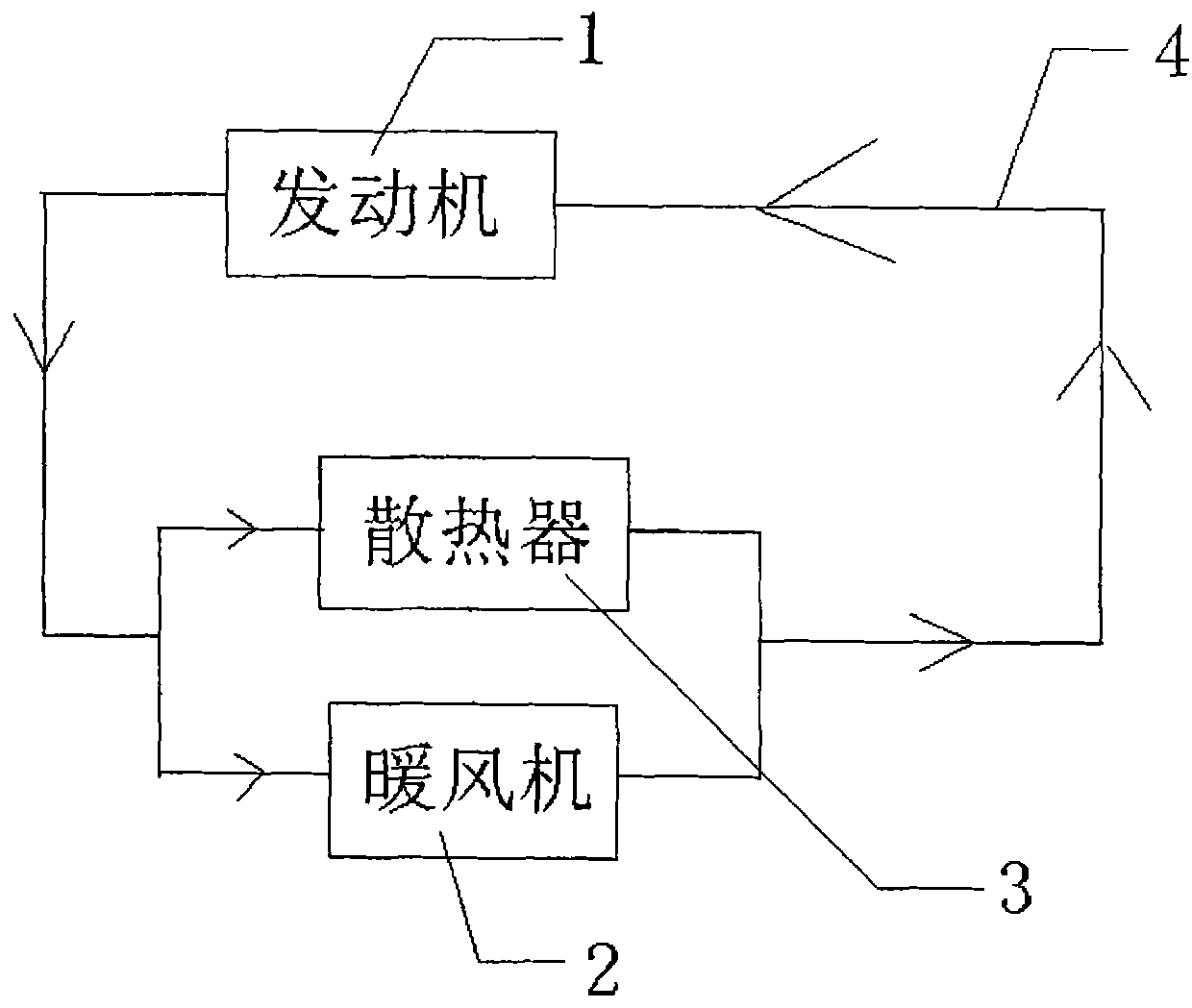

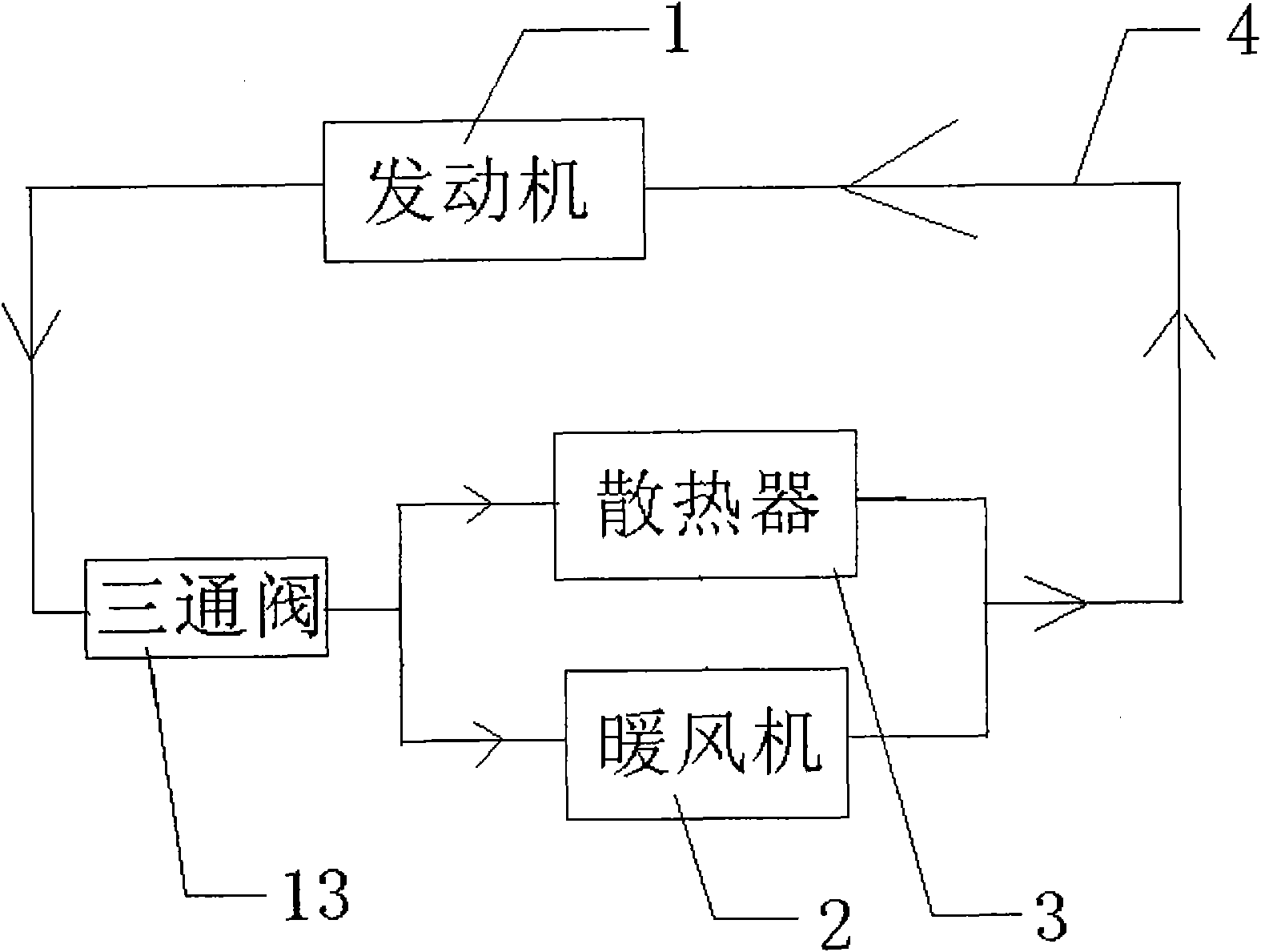

Warm air adjusting system for small motor vehicle

InactiveCN102092262AGuaranteed operating conditionsEfficient use ofAir-treating devicesVehicle heating/cooling devicesHeating effectEngineering

The invention relates to a warm air adjusting system for a small motor vehicle, which comprises an engine, a fan heater and a radiator which are connected through a conduit, and is characterized in that: a three-way valve is connected between the engine and the fan heater and the radiator, and is connected with the engine, the fan heater and the radiator respectively through a conduit; and the engine is connected with the fan heater and the radiator through the three-way valve. Due to the technical scheme, the invention has the advantages that: the three-way valve is arranged between the engine and the fan heater and the radiator, so the heat conducted from the engine can be adjusted, the heat of the engine is fully and effectively utilized, the system cannot repeatedly do work so as to avoid energy waste, and works stably, the working condition of the engine is ensured and the heating effect is ensured.

Owner:陈伟国

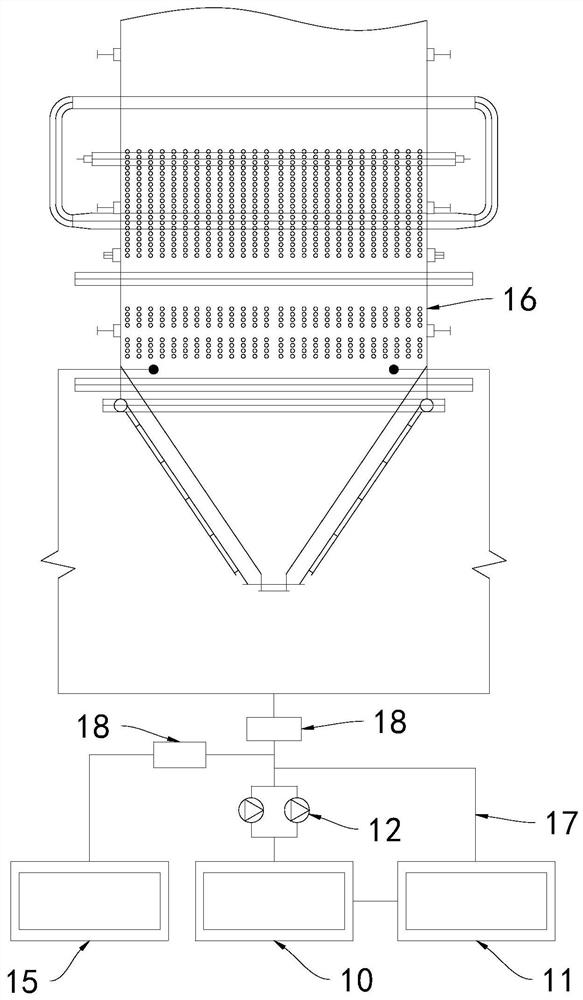

Biomass gasifying coupled coal-fired boiler full-load SCR denitration system and technique

PendingCN109966915AGuaranteed operating conditionsAchieve the effect of heatingCombination devicesGas treatmentFlue gasCoal fired

The invention provides a biomass gasifying coupled coal-fired boiler full-load SCR denitration system and technique. The system comprises a biomass gasifying system and a coal-fired boiler SCR denitration system. The biomass gasifying system comprises a biomass gasifying furnace and a heat exchanger. The biomass gasifying furnace is connected to the heat exchanger. The heat exchanger is connectedto the coal-fired boiler SCR denitration system. The coal-fired boiler SCR denitration system comprises a coal-fired boiler and a coal saver. The flue gas outlet of the coal saver is sequentially connected to ammonia spraying grating, a SCR denitration reactor, an air preheater, an electrostatic dust collector, a desulfurization device, and a chimney. The provided denitration system and techniquecan increase the temperature of flue gas in the denitration inlet, the feeding / transporting requirements of a low-load denitration device of a boiler can be satisfied, at the same time, a large amountof biomass is consumed, and the using of clean energy is increased.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

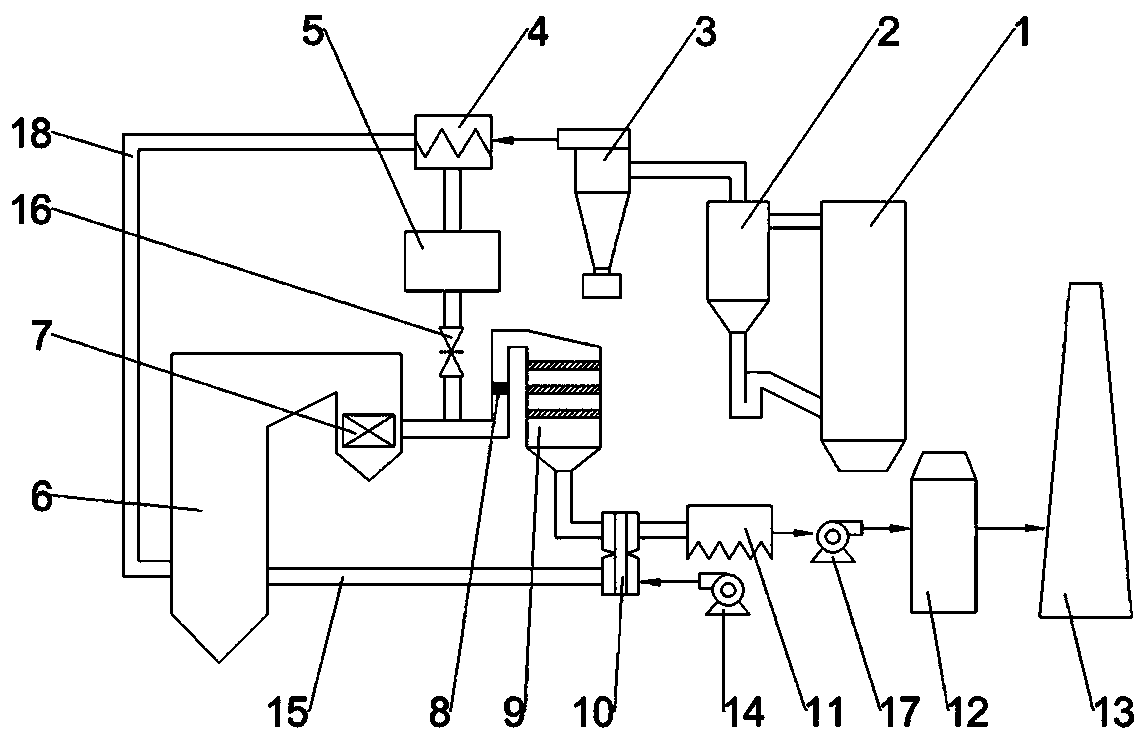

Biomass graded temperature-control slow pyrolysis process and its system

ActiveCN100549131CMeet the requirements of gasification reactionGuaranteed operating conditionsBiofuelsEnergy inputTemperature controlSyngas

The invention relates to biomass grading temperature controlling slow speed pyrolysis technology and its system. The technology includes the following steps: dividing the pyrolysis into many independent stages with temperature increasing; processing countercurrent flow for external heat source and biomass; heating the biomass grade by grade to make it pyrolyse; pre-drying and deep drying the material to make sure its water content is 5-10%; pre-charring and charring to gain charcoal, pyrolysis gas, little gas state biological crude oil; processing the secondary decompose for the crude oil at roasting stage to gain the pyrolysis product. The system is made up of external hot gas source and its bypass route, main heat exchanger, multiple-stage pyrolyzer, and multiple-stage heat exchanger. The invention has the advantages of wide material accommodation limit, easy adjustable pyrolysis process, easy controllable pyrolysis product, utilizing waste heat to increase gasification efficiency.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Method for producing silicate clinker by using coal gangue instead of tailings and silicon-aluminum raw materials

InactiveCN111718136ARegardless of sulfur contentSolve pollutionCement productionClinker (cement)Calcination

The invention relates to a method for producing silicate clinker by using coal gangue instead of tailings and silicon-aluminum raw materials. The method comprises the following steps: (1) preparationof double-component powder; (2) preheating, mixing and decomposing; and (3) oxidizing calcination. According to the invention, the problems of influence on clinker production quality, energy consumption and the like due to crusting and sticking caused by the characteristics of raw coal gangue can be solved; and a large amount of raw coal gangue is consumed, and meanwhile, a part of tailings and silicon-aluminum raw materials used in dry cement produced are replaced, so the coal consumption of cement production and the consumption of clay (shale) type silicon-aluminum raw materials are reduced,and the problem of environmental pollution caused by coal gangue accumulation is solved.

Owner:长沙紫宸科技开发有限公司

Method for recycling high-grade ore bodies in deep collapse area

ActiveCN107559009AAccurate basic dataMaster Spatial Data AccuratelyUnderground miningSurface miningRecovery methodStructure of the Earth

The invention discloses a recovery method of a high-grade ore body in a deep collapse area, which is characterized in that: a three-dimensional laser void area detection system is used to detect the upper void area of the collapse area, and a high-strength grouting material is used to grout the ore body in the collapse area , the upper empty area is filled and maintained with low-strength and high-strength filling materials, and the mining and cutting work is arranged outside the collapsed area. The flat bottom structure is adopted. During the mining work, combined with the detection data, the fan-shaped medium-deep holes are accurately arranged, and remote control is used. The scraper goes out of the mine and fills the empty area after mining. The invention is especially suitable for the recovery of deep high-grade collapsed ore bodies, and has the characteristics of high mining efficiency, safe operation, high recovery rate of high-grade collapsed ore bodies, and the like.

Owner:XINJIANG UNIVERSITY

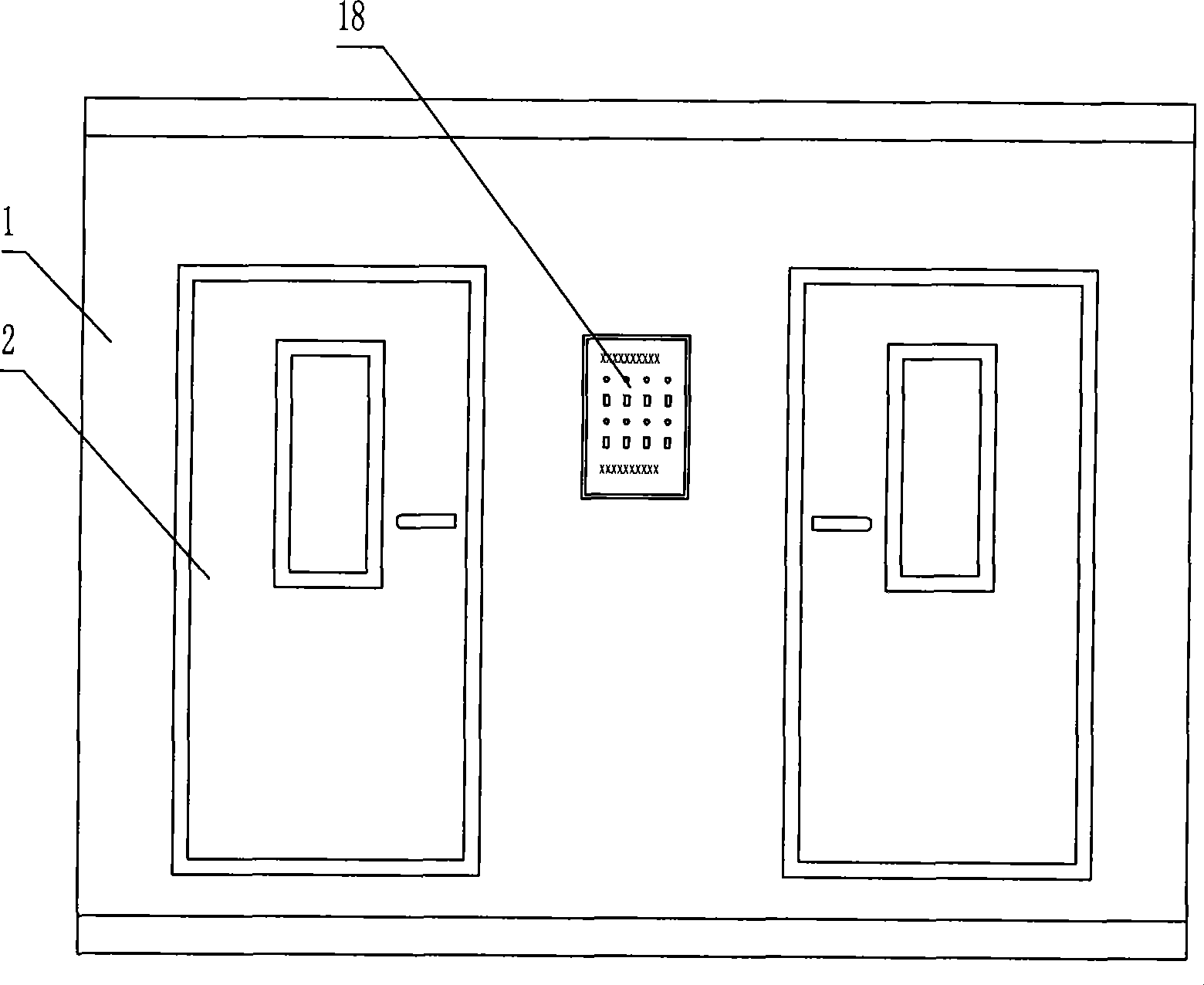

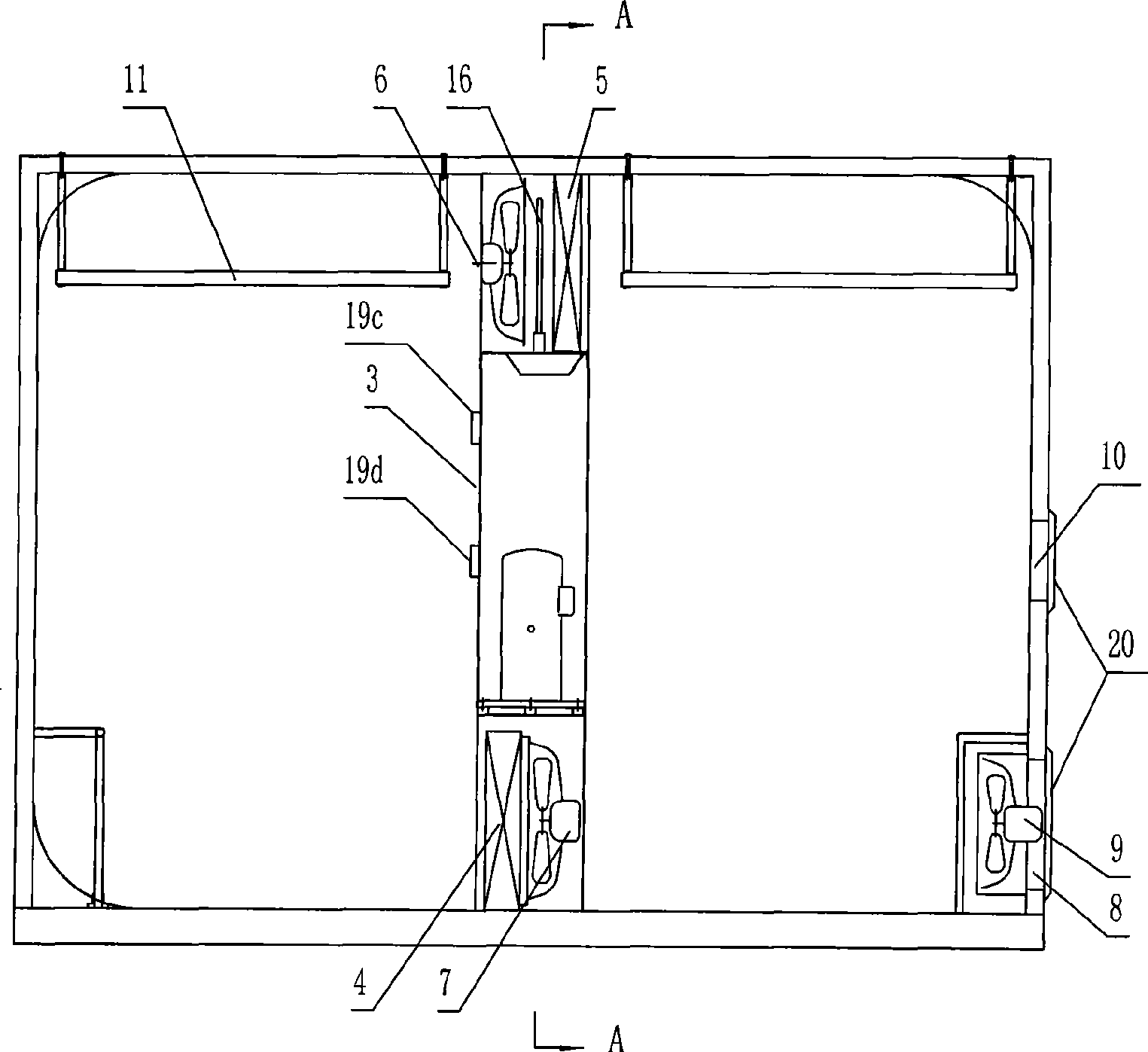

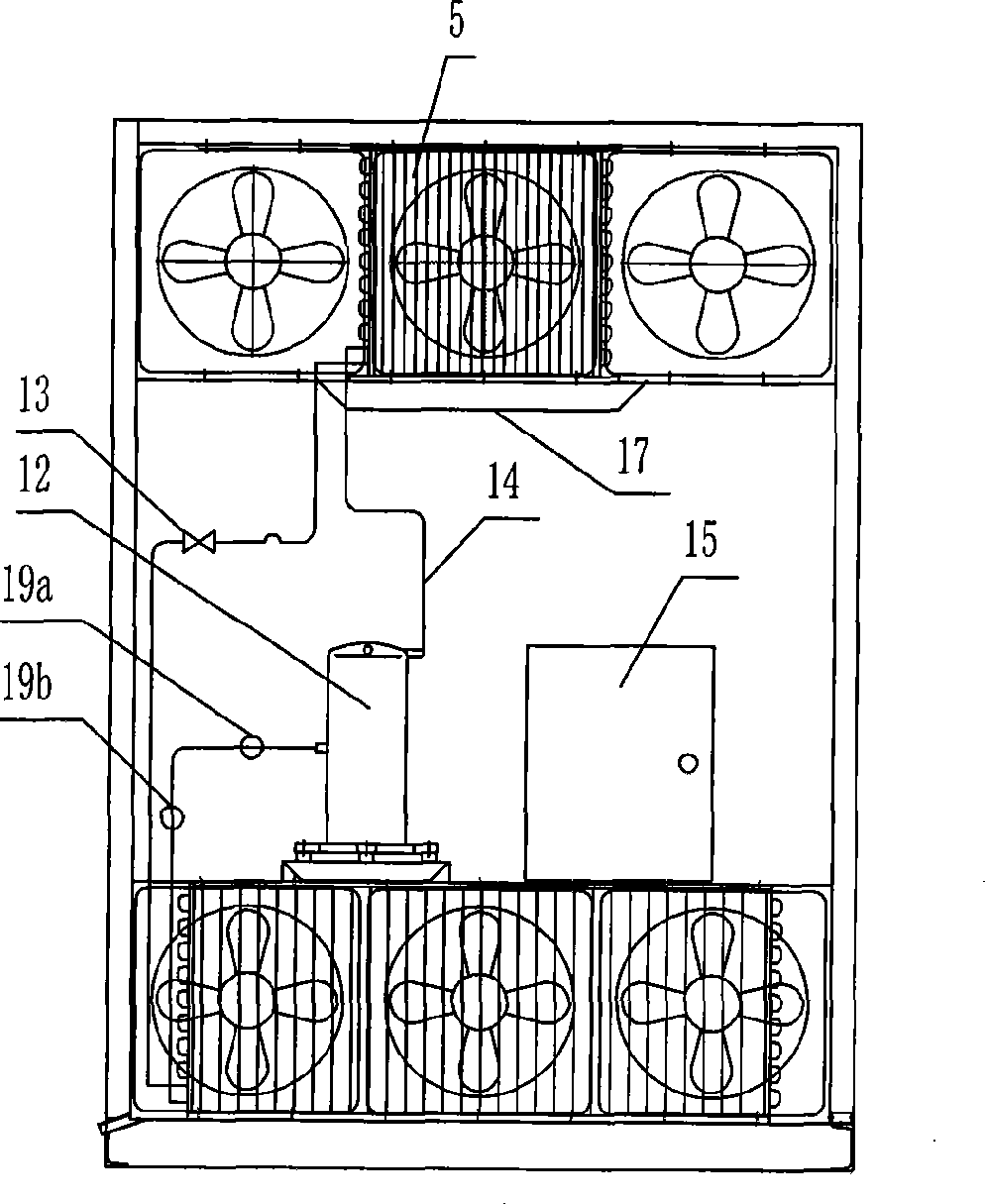

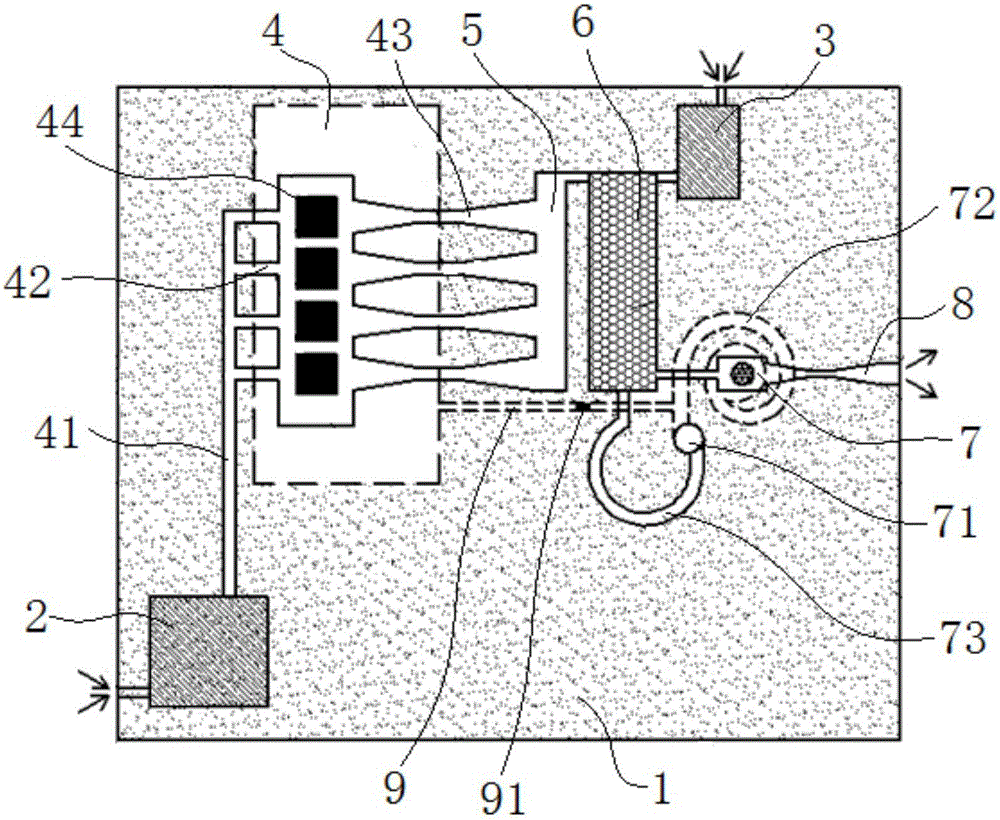

Ternary evaporator non-frost cold storage

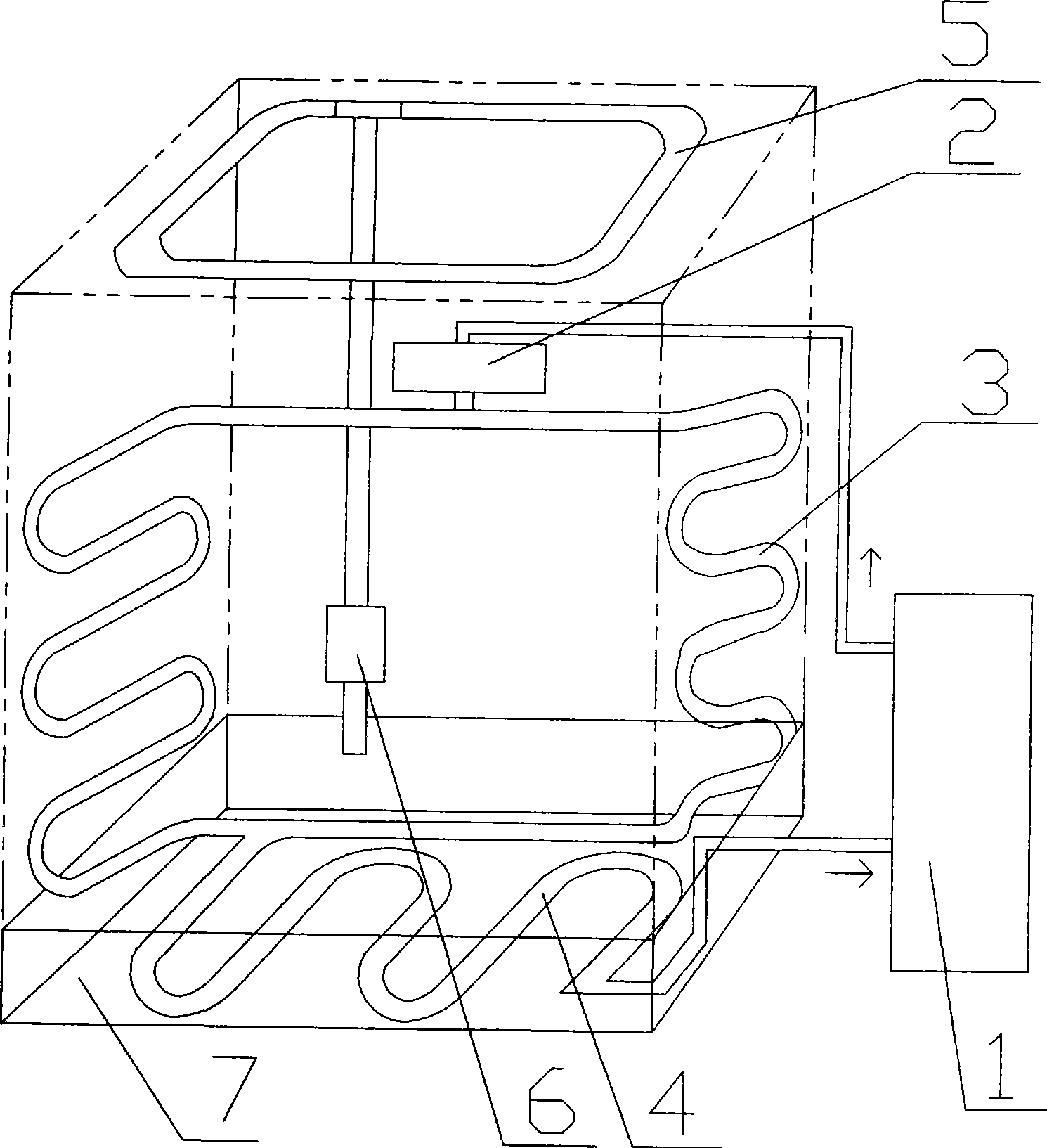

InactiveCN101419009AGuaranteed operating conditionsImprove cooling efficiencyLighting and heating apparatusStationary refrigeration devicesHigh humidityEvaporation

The invention relates to a frostless refrigerated storage of a ternary evaporator for preservation of agricultural products, which comprises a compressive condensing refrigerating unit (1) outside the storage and an air cooler (2) inside the storage, a wall evaporation exhaust tube (3) on the storage wall, a terrace shallow pool (7), an evaporation exhaust tube (4) in the terrace shallow pool (7), and the like. A refrigerating medium is placed in the terrace shallow pool (7); and the compressive condensing refrigerating unit (1), the air cooler (2), the wall evaporation exhaust tube (3), the evaporation exhaust tube (4) and the compressive condensing refrigerating unit (1) are communicated in turn to form a refrigeration and heat exchange cycle. The wall evaporation exhaust tube (3) can arranged on any one wall or multiple walls except the wall provided with the air cooler (2). The frostless refrigerated storage can also be provided with a spray device consisting of a spray pipe (5), a pump (6), and the like. The frostless refrigerated storage has the characteristics of reducing frosting of the air cooler, reducing defrosting operation, and reducing energy consumption, keeping high humidity and comparatively constant temperature of the refrigerated storage, and improving preservation effect of the agricultural products greatly.

Owner:SHANDONG INST OF POMOLOGY

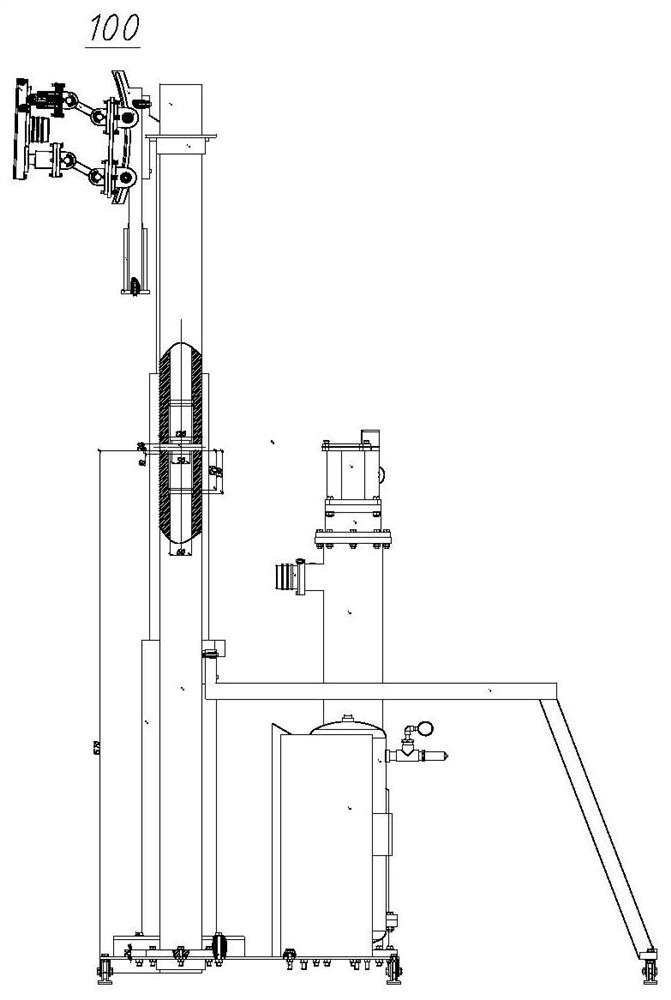

Adjustable automatic plastering device

PendingCN112252683AAvoid cumbersomeShorten the timeBuilding constructionsReciprocating motionStructural engineering

The invention provides an adjustable automatic plastering device. The device comprises a movable base, a plastering executing mechanism, a feeding mechanism and a lifting mechanism, wherein the feeding mechanism and the lifting mechanism are arranged on the movable base, the plastering executing mechanism is arranged on the lifting mechanism, the feeding mechanism is connected with the plasteringexecuting mechanism, the movable base is used for bearing the plastering executing mechanism, the feeding mechanism and the lifting mechanism which are arranged on the movable base, and the movable base does reciprocating motion in the first direction; the lifting mechanism can reciprocate in the second direction; the plastering executing mechanism comprises a plastering plate and a plastering adjusting part, and the plastering plate is provided with a discharging port; and the feeding mechanism comprises a material box, a conveying pump and a conveying pipeline, the material box is used for loading plastering mortar, the conveying pipeline is connected with the plastering plate, and the conveying pump is used for conveying the mortar in the material box to the plastering plate through theconveying pipeline and conveying the mortar out through the discharging port in the plastering plate, so that the plastering plate evenly plasters the mortar conveyed out through the discharging port.

Owner:广东海洋大学寸金学院

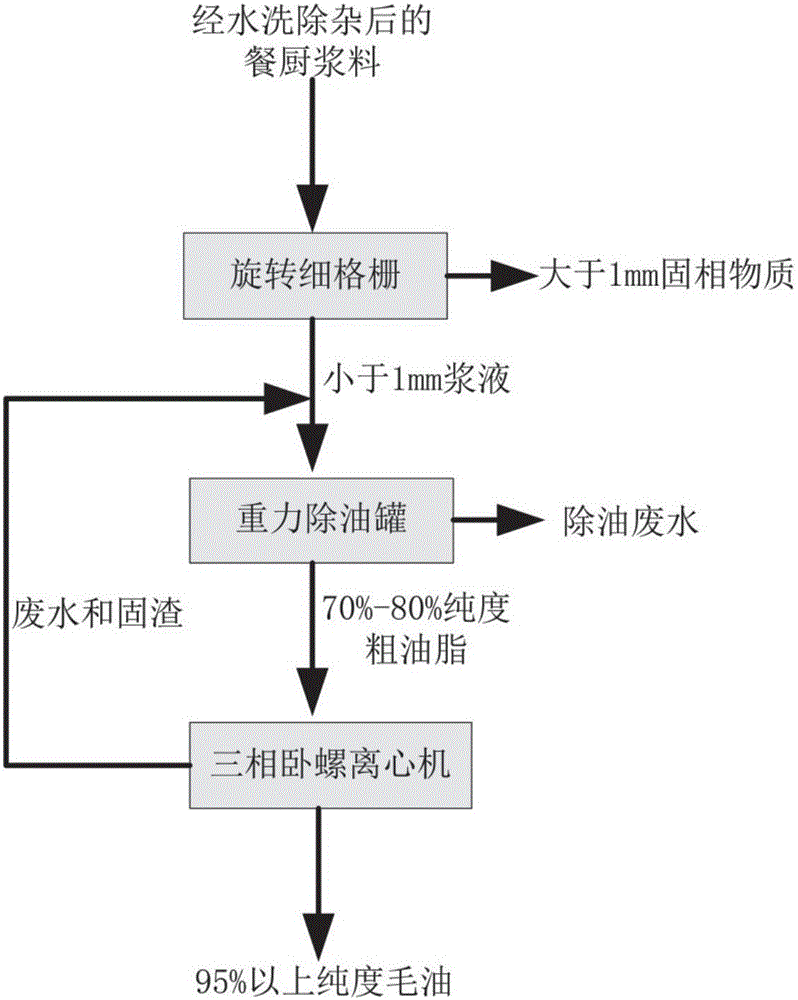

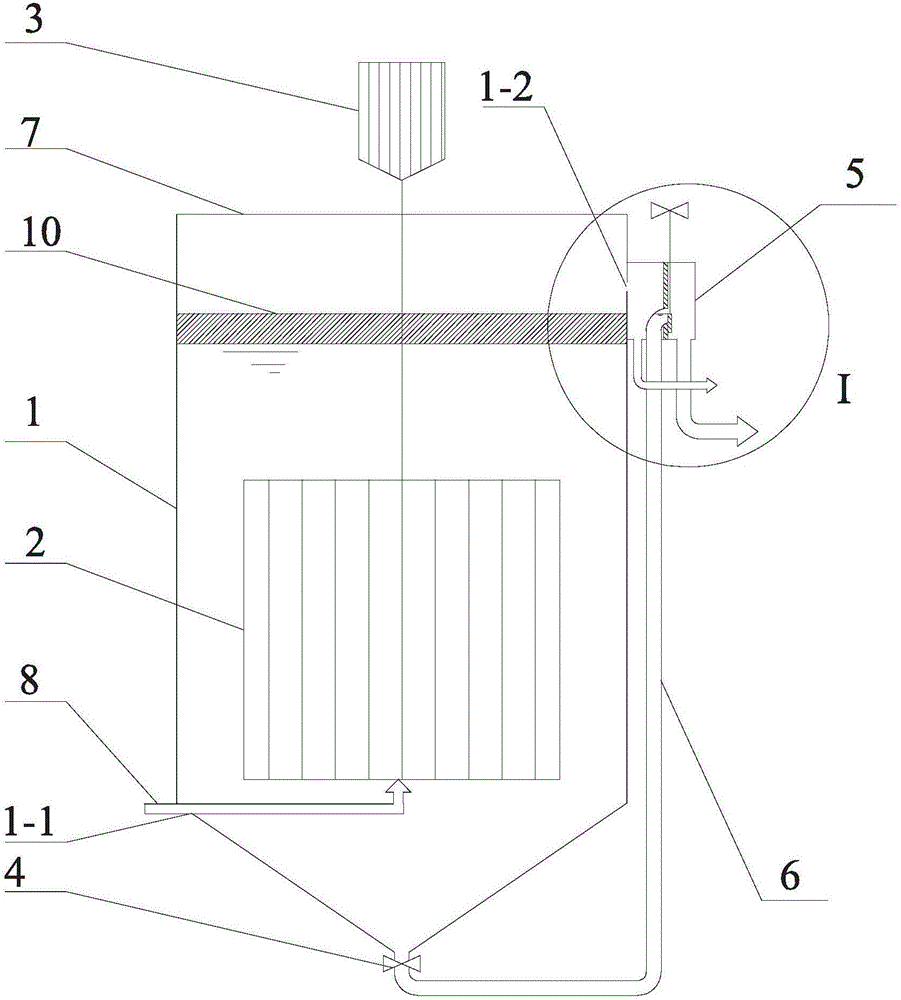

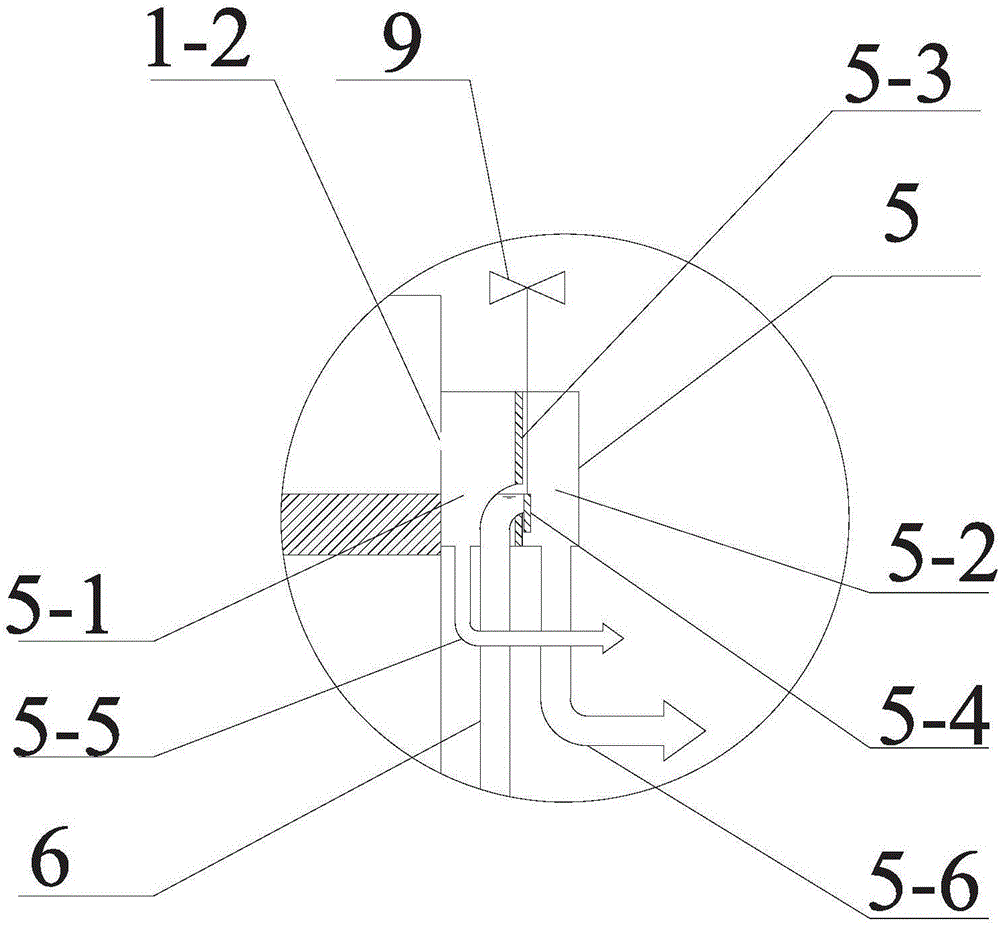

Kitchen waste oil removing method

InactiveCN105936555AReduce solid contentReduce steamFatty/oily/floating substances removal devicesTreatment involving filtrationOil and greaseSlurry

The invention discloses a kitchen waste oil removing method. The kitchen waste oil removing method comprises the following steps that 1, kitchen waste is uniformly delivered to a rotary drum screen through a shaft-free helix and is washed with circulating water of 45-50 DEG C to obtain kitchen slurry without large impurities; 2, the kitchen slurry is subjected solid-liquid separation through a rotary fine grille and then is separated into solid-phase substance greater than 1 mm and kitchen slurry oil-water mixed liquid smaller than 1 mm; 3, the kitchen slurry oil-water mixed liquid is fed into a gravitational oil removing tank through an oil-water mixture inlet to separate crude oil; 4, the crude oil separated from the gravitational oil removing tank is fed into a three-phase horizontal screw decanter centrifuge through a pump for further purification and separation, and separated solid residues and waste water flow back to the gravitational oil removing tank. The kitchen waste oil removing method can achieve oil separation and recovery of kitchen waste.

Owner:SUZHOU CLEAR IND CO LTD

System for increasing inlet temperature of SCR denitration reactor by utilizing flue gas recirculation

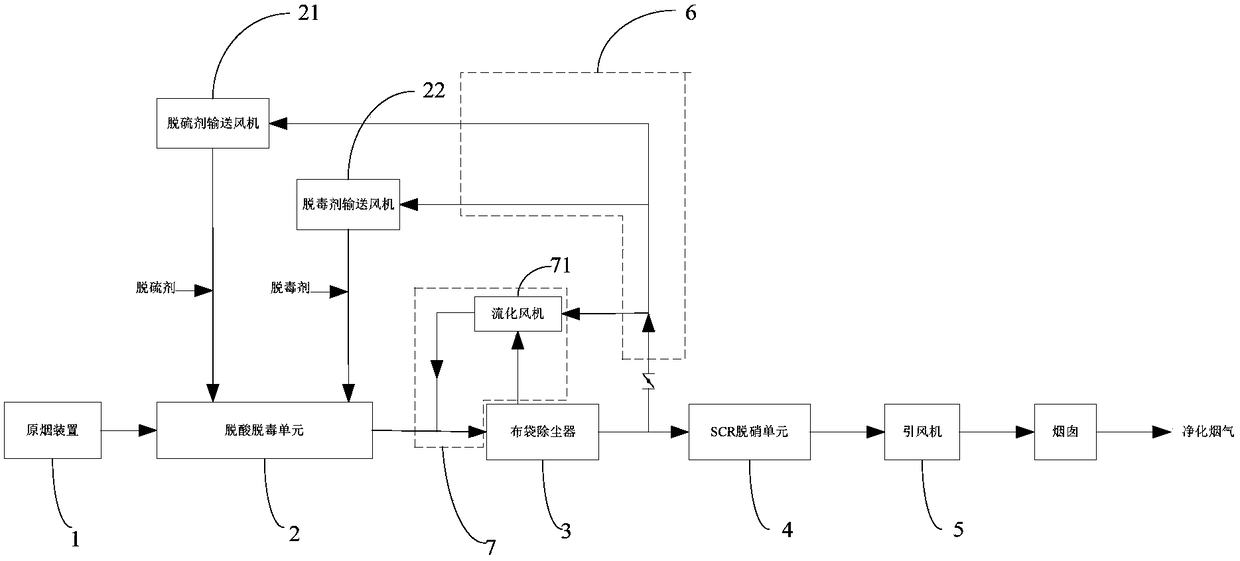

PendingCN108339386ARaise the inlet temperatureGuaranteed operating conditionsGas treatmentDispersed particle filtrationBaghouseProcess engineering

The invention discloses a system for increasing the inlet temperature of an SCR denitration reactor by utilizing flue gas recirculation. The system comprises an original smoke device, a flue gas deacidifying and detoxifying unit, a bag dust collector, an SCR denitration unit, an induced draft fan and a flue gas recirculating pipeline which are sequentially connected by flues, wherein the flue gasrecirculating pipeline is provided with a smoke inlet end and a smoke outlet end; the smoke inlet end is connected to an outlet flue of the induced draft fan, or is connected to an outlet flue of thebag dust collector; the smoke outlet end is connected with an upstream flue of the bag dust collector. According to the system disclosed by the invention, by arranging the flue gas recirculating pipeline, waste heat flue gas from the outlet flue of the bag dust collector or the outlet flue of the induced draft fan is brought back to the upstream of the bag dust collector and the waste heat flue gas in the system is fully utilized, so that the inlet temperature of the SCR denitration unit is increased, heating energy of input flue gas of the SCR denitration unit is reduced, and operating conditions of the SCR denitration unit are ensured; in addition, the smoke exhausting amount of a chimney is overall reduced, and the whole system achieves the effect of economical and environment-friendlyoperation.

Owner:武汉致衡环境安全工程技术有限公司

Automatic control system and method of parking device

InactiveCN1201956CRealize safety anti-slipHigh degree of automationTrain hauling devicesTrack brakesInformation controlAutomatic control

The invention discloses a control system and method for controlling a controllable parking device to prevent the vehicle from slipping and releasing the hump by collecting operation information of the head of the hump and the tail of the hump. device, channel lightning protection device, hump tail operation information collection device, signal processing device, parking device and power supply device. The method includes static and dynamic simulation to determine the arrangement position and quantity of the parking devices, collecting the operation information of the head of the hump and the tail of the hump, etc., and according to the collected information, the system automatically controls the parking devices of each lane to be in the braking or releasing state, Realize the safety and anti-slipping of vehicles on the shunting line. The system has significant effects in improving the automation of rear shunting operations, improving operating conditions, ensuring operating safety and reducing labor intensity of workers.

Owner:CRSC RESEARCH & DESIGN INSTITUTE GROUP CO LTD

Starch syrup specially used for concrete, and preparation method of starch syrup

ActiveCN107601951AModerate viscositySignificant water reducing and retarding effectFermentationGluconic acidD-Glucose

The invention relates to starch syrup specially used for concrete, and a preparation method of the starch syrup. Taking syrup as dry basis, the starch syrup is prepared from the following components by mass percent: 40-55% of maltose, 10-18% of maltotriose, 22-28% of polysaccharide of maltotetraose or higher, 4-8% of sodium gluconate and 0-9.5% of glucose. The starch syrup specially used for the concrete is prepared by innovatively taking the maltose as a main body, taking macromolecular malt polysaccharides of the maltotriose or higer as support and adding a right amount of the sodium gluconate; a syrup product which is moderate in viscosity and remarkable in water reducing and retarding effect is developed; a new way is developed for the production of the starch syrup specially used forthe concrete.

Owner:SHANDONG LUZHOU FOOD GROUP +1

Water purification method suitable for low-temperature low-turbidity period

PendingCN112225346AImprove precipitation effectGood flocculation effectTreatment involving filtrationMultistage water/sewage treatmentFlocculationPurification methods

The invention discloses a water purification method suitable for a low-temperature and low-turbidity period, which adopts a water purification device suitable for the low-temperature and low-turbidityperiod to perform water purification treatment, and the device comprises a dosing well, a flocculation tank, a sedimentation tank and a filter tank; the dosing well is connected with the flocculationtank connected with the sedimentation tank, and the sedimentation tank is connected with the filter tank; the sedimentation tank is provided with a muddy water suction pump, and the muddy water suction pump is connected with the dosing well through a sedimentation tank muddy water return pipe; and the dosing well is connected with a dosing mechanism, and a water treatment agent is fed into the dosing well by the dosing mechanism. According to the scheme, muddy water in the sedimentation tank is controlled to flow back to the water inlet end of the flocculation tank and is mixed with conventional chemicals to enter a flocculation system, so that the defects that the conventional flocculation sedimentation tank is relatively high in effluent turbidity when coping with low-temperature and low-turbidity source water, the load of the filter tank is increased and the filter tank needs to be frequently washed are avoided, and the operation condition of the filter tank is well guaranteed; andwater quality of a water purification plant is guaranteed to reach the standard safely and stably, water consumption is low, medicine consumption is low, and the method is suitable for water purification-to-water process treatment.

Owner:HUALAN DESIGN GRP CO LTD

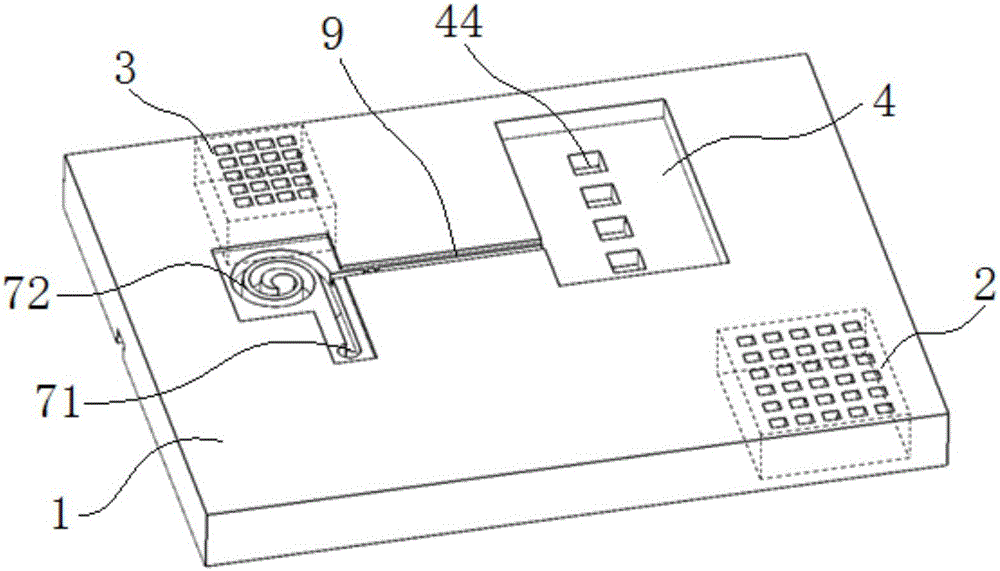

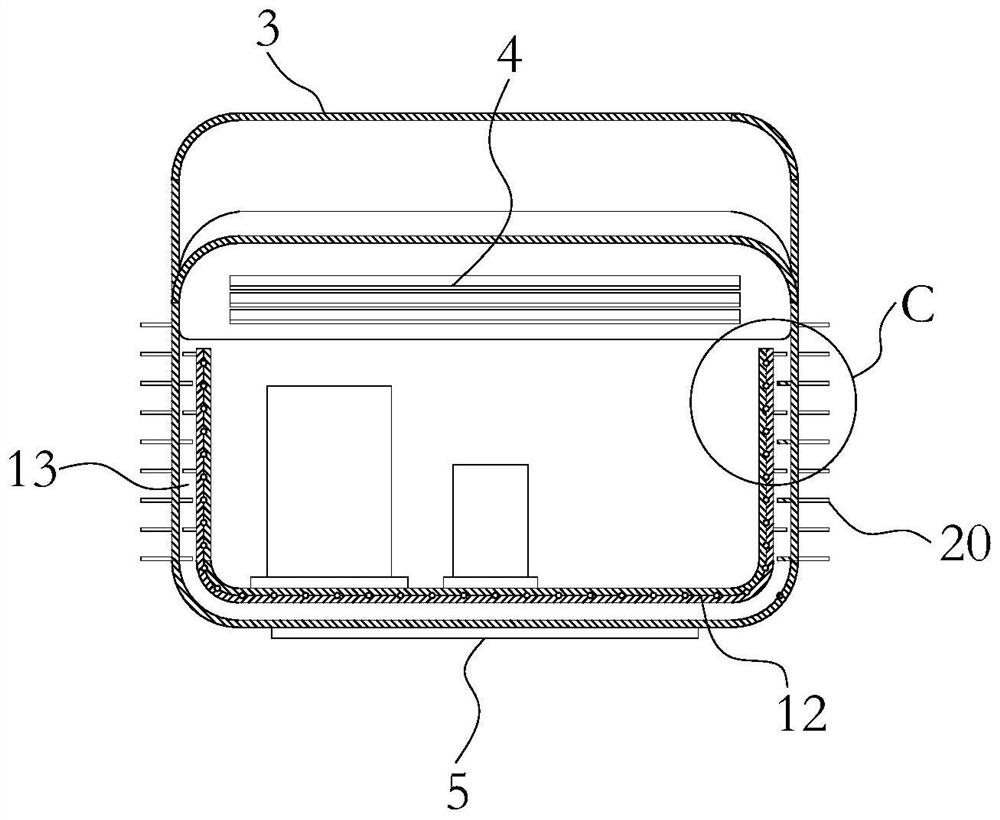

Mobile phone chip active heat dissipation device

ActiveCN106304775ARealize integrationSimple and precise structureCooling/ventilation/heating modificationsHeat flowReturn channel

The invention discloses a mobile phone chip active heat dissipation device which comprises two multi-stage Knudsen compressors one of which is a main multi-stage Knudsen compressor and the other one of which is a auxiliary multi-stage Knudsen compressor; an evaporation chamber in which a refrigerant is stored and the air inlet of which is connected with the main multi-stage Knudsen compressor; a converging chamber connected with the air outlet of the evaporation chamber; a condensing chamber including a heat flow chamber connected to the converging chamber and a cold flow chamber connected with the auxiliary multi-stage Knudsen compressor; a descending channel connected to the heat flow chamber; a spiral channel connected with the descending channel; a gas-liquid separation chamber connected to the spiral channel and the upper end of which is covered with a hydrophobic flat film; an exhaust passage connected to the outlet of the cold flow chamber and the upper end of the gas-liquid separation chamber; and a liquid return channel via which the lower end of the spiral channel is connected with the liquid inlet of the evaporation chamber. The mobile phone chip active heat dissipation device realizes the integration of the heat dissipation device and the chip, and can realize the active heat dissipation, and has a good heat dissipation effect and a self-regulating ability.

Owner:GUANGXI UNIV

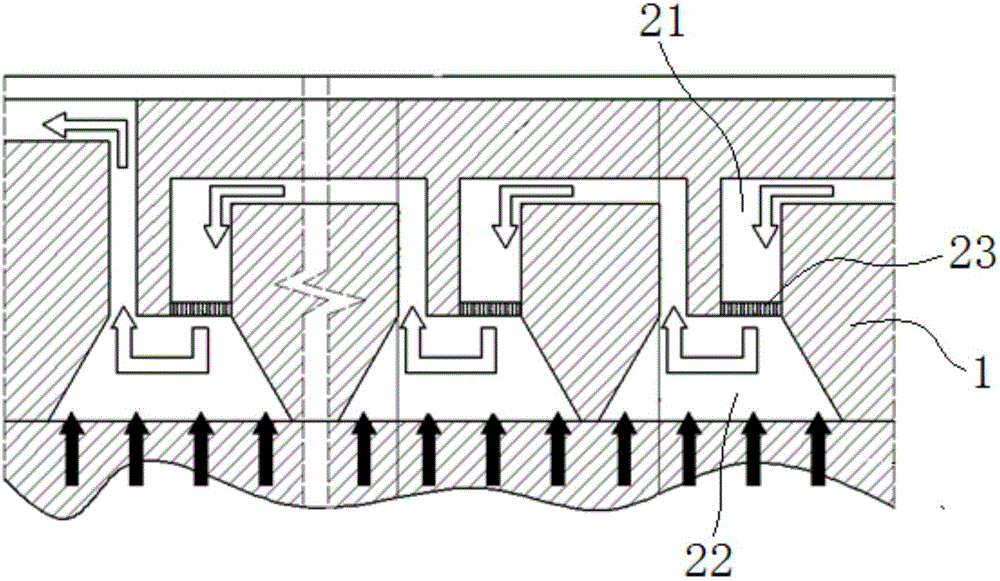

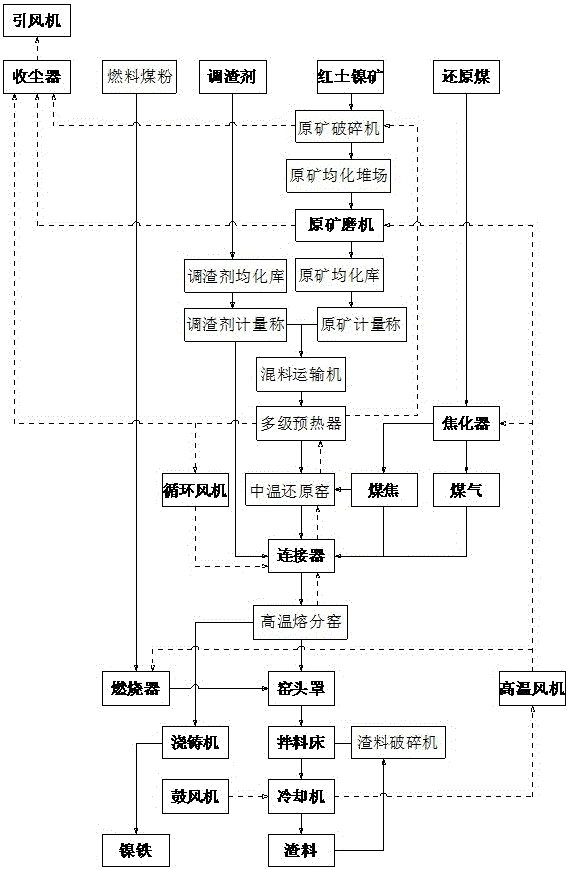

Facility and method for ferronickel production through coal-based powder state reduction of red soil nickel ores

The invention discloses a facility and method for ferronickel production through coal-based powder state reduction of red soil nickel ores and belongs to facilities and methods for ferronickel production through red soil nickel ores. The method comprises the following steps that (1) powder materials are prepared and homogenized, and drying, powder grinding and homogenizing of raw ores and slag-modifiers are completed; (2) upgrading and preparing of reducing agents are conducted, coking of reduction coals is completed, and meanwhile, reducing gas is supplied; (3) the powder materials are subjected to pre-heating and pre-reduction, and ore powder and the slag-modifiers are mixed in a preheater and then subjected to drying, temperature rising and pre-reduction to prepare mixed ore materials; (4) reduction of the mixed ore materials is conducted, specifically, the mixed ore materials are restored into reduction ore materials with coal chars and reducing gas in a medium-temperature reduction kiln; (5) fusing reduction separation is conducted, specifically, slag and iron separation is achieved while the reduction ore materials complete residual reduction in a high-temperature smelting separating kiln; (6) discharging is conducted, specifically, molten ferronickel and molten slag are discharged from different passageways, and finished ferronickel products are formed; and (7) the slag is subjected to treatment, specifically, the high-temperature molten slag is cooled and circularly stirred and blended, and high-temperature waste heat is provided for preorder techniques. The method for ferronickel production through the coal-based powder state reduction of red soil nickel ores is large in productivity scale, low in cost, stable in kiln ores and high in heat utilization ratio.

Owner:XUZHOU CUMT BACKFILL TECH

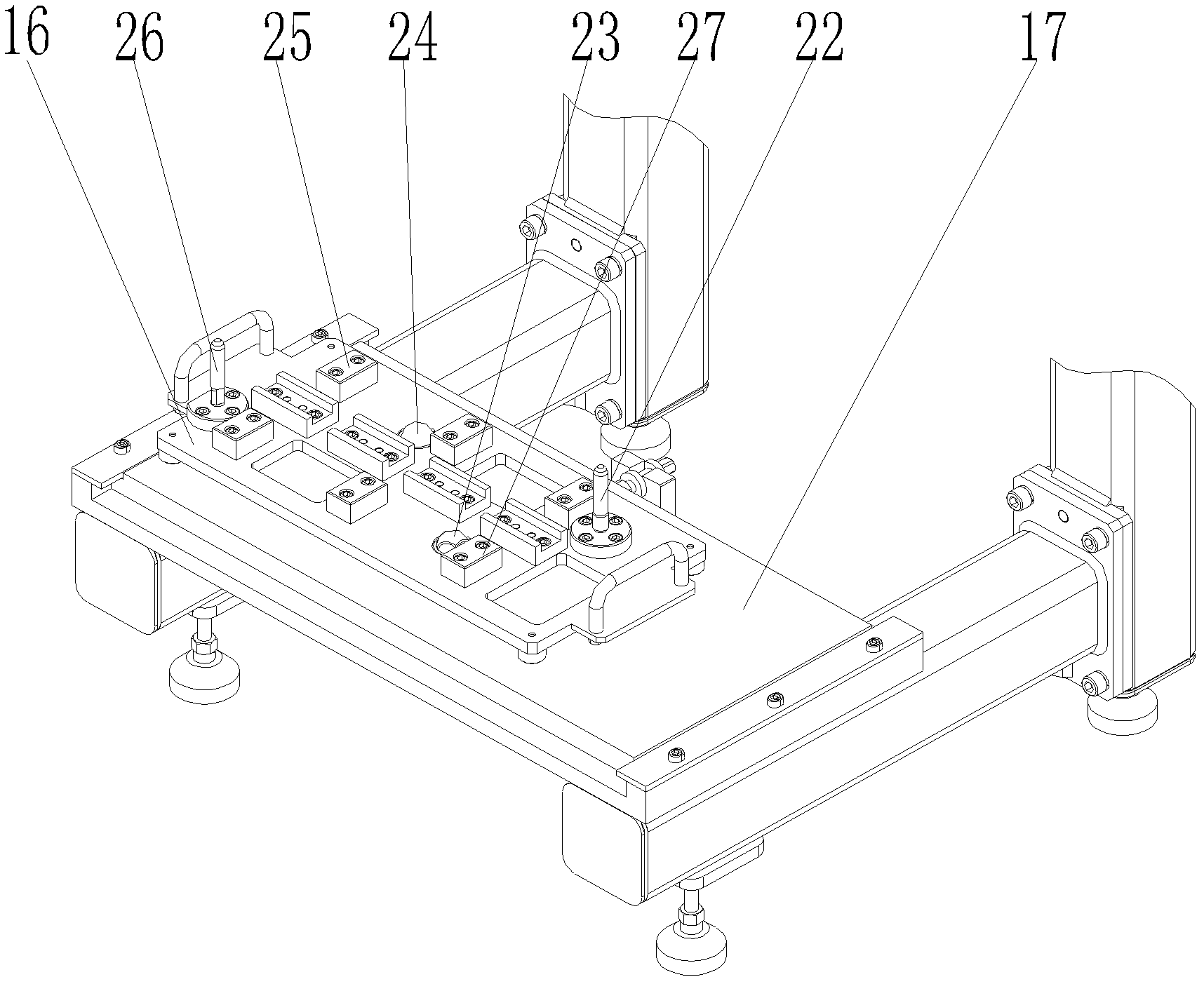

Mechanical wear testing device

ActiveCN104777052AGuaranteed operating conditionsNo changeInvestigating abrasion/wear resistanceAbrasive blastingMechanical wear

The invention discloses a mechanical wear testing device. The mechanical wear testing device comprises a cabinet body, a bracket, a spray gun, a laser pen, and a sand and water mixing and stirring device, wherein the bracket is driven to be arranged in the cabinet body in a vertical moving mode and is used for bearing a sample; the spray gun is vertically arranged in the upper part of the internal space of the cabinet body and is driven to move left and right in a reciprocating mode for the mechanical wear testing for a plastic lens; the laser pen is horizontally arranged at one side of the cabinet body and is used for assisting in the flush arrangement of a sample; the sand and water mixing and stirring device is arranged at one side outside the cabinet body and is used for providing mixed sand and water for the spray gun. The mechanical wear device is used for sand spray wearing, and meanwhile is used for adjusting the height of the liquid level of the sand and water mixing and stirring device, so that the working condition of the spray gun can be ensured effectively, and the testing effect is improved when the sand spray condition is not changed in the testing process; moreover, the laser pen is arranged so as to improve the sample and the integral horizontal alignment effect; the testing conditions of samples are the same, and the detection effect is improved.

Owner:TIANJIN JINGPU TECH

Assembly tooling for diesel engine valve collet

ActiveCN102601613BGuaranteed coaxialityGuaranteed operating conditionsAssembly machinesMulti-valveSpring force

The invention discloses an assembly tooling for a diesel engine valve collet, which comprises a forked pressure head, wherein an opening of the forked pressure head is smaller than a horizontal size of a valve spring upper base and used for pressing down the valve spring upper base, and the opening of the forked pressure head is at least larger than a stem outer diameter of a valve stem for installing the valve collet. In use, a pressure towards the valve spring upper base is applied to the forked pressure head, the spring is compressed and three ring slots are exposed, three annular bulges on two flaps of the valve collet are embedded in three rings and the valve collet is formed as one piece, the forked pressure head releases the valve spring upper base, and the valve spring upper base is externally sleeved on the valve collet outer circle under the spring action. With the assembly tooling, positioning and assembling can be rapidly carried out; the coaxiality of the valve collet, the valve spring upper base and the valve stem can be ensured; the direction of the spring force can be made to meet the stem movement requirement; the assembled valve system can be ensured to accord with the operating condition of the diesel engine; the working efficiency in assembly can be increased; and the assembly tooling is especially suitable for the assembling requirement of batch production of multi-valve diesel engines.

Owner:重庆小康动力有限公司

Adjustable rotation auxiliary roller device for cold bend forming machine

The invention discloses an adjustable rotation auxiliary roller device for a cold bend forming machine. An axial key groove is formed in an upper shaft. A fixing sleeve is fixed to the upper shaft through a flat key matched with the key groove. A rotating seat is arranged on the fixing sleeve in a sleeving mode and is further limited through a stopping step arranged on one side of the fixing sleeve, and the other side of the rotating seat is flush with the axial end of the fixing sleeve and is further positioned through a compressing sleeve. The fixing sleeve is positioned and locked through alocating pin which penetrates through the stopping step and a rotating seat pin hole in the axial direction. A plurality of sets of unsymmetrical auxiliary roller arms are fixed to the outer side ofthe rotating seat in the circumferential direction through screws. Auxiliary rollers are fixed to the tail ends of the auxiliary roller arms through arc-shaped roller shafts. The positions, located onthe outer side of the fixing sleeve and the outer side of the compressing sleeve, of the upper shaft are sleeved with shaft sleeves used for adjusting the left and right position of the auxiliary roller device correspondingly. The outer side axial ends of the shaft sleeves are locked through gland nuts respectively. According to the adjustable rotation auxiliary roller device for the cold bend forming machine, the specification replacement time is short, operation is convenient, and the adjustable rotation auxiliary roller device can be suitable for quickly switching the auxiliary rollers ofdifferent bottom widths and different thickness specifications; and moreover, the structure rigidity is good and formation is stable and reliable.

Owner:XINXIANG TIANFENG MACHINERY MFG

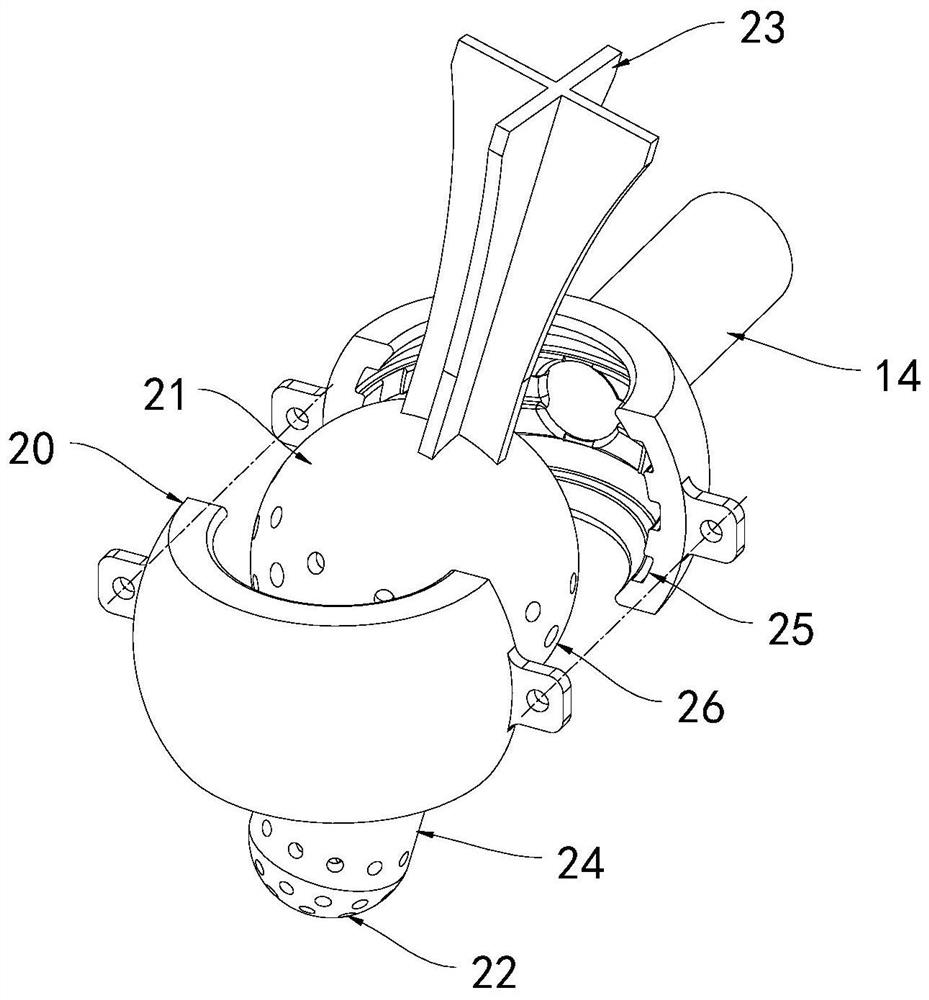

Method and device for treating landfill leachate

ActiveCN110240355BTake advantage ofAccelerate evaporationTreatment involving filtrationTreatment with aerobic and anaerobic processesEconomic benefitsEnvironmental engineering

The invention discloses a method and device for treating landfill leachate. The landfill leachate is fermented, filtered, and finally sprayed into the high-temperature area of an incinerator in a hemispherical shape from both sides of the air inlet direction. The invention not only solves the leachate treatment problem, but also produces good economic benefits in practice. After the leachate is sprayed back, the load of the boiler increases obviously. Therefore, the present invention has the characteristics of environmental protection, good treatment effect and high economic benefit.

Owner:浙江欣源企业管理有限公司

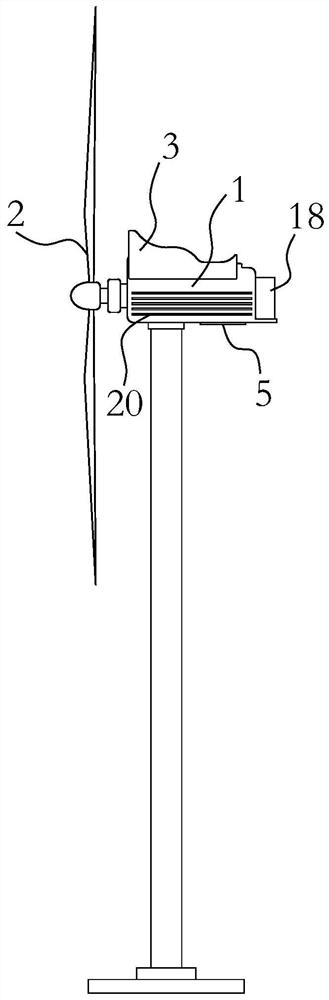

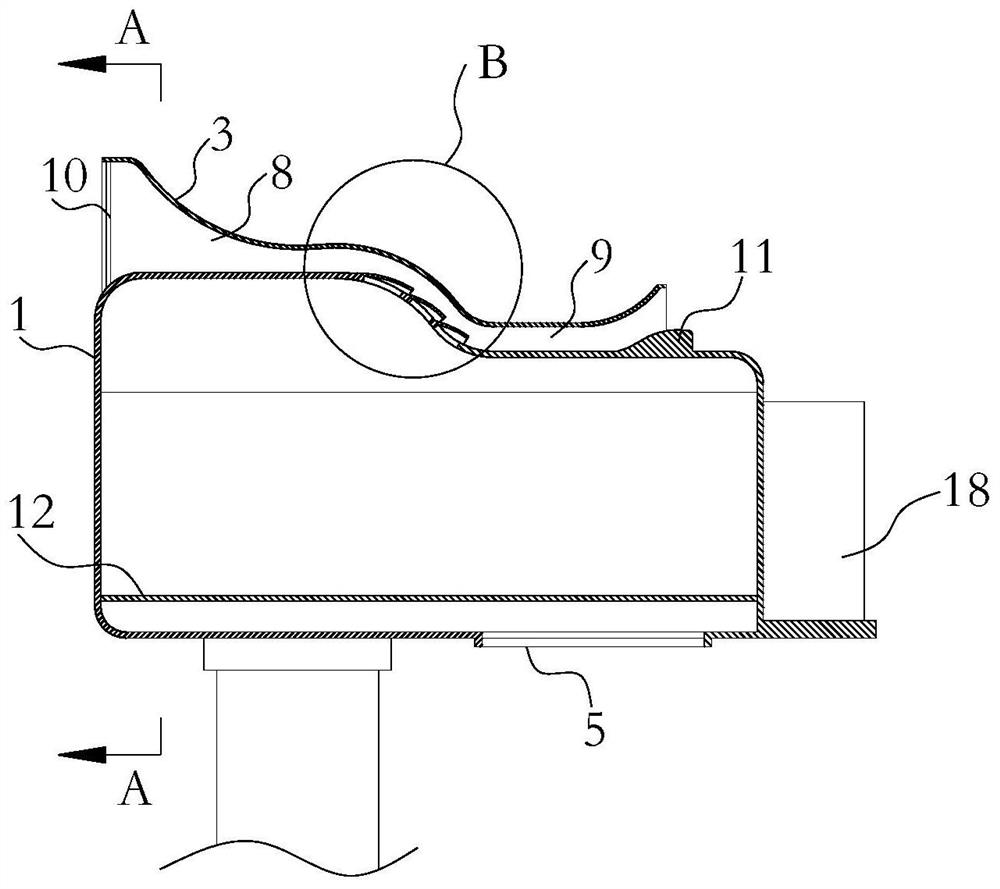

Circulating cooling device for wind power generation

ActiveCN113048028AImprove reliabilityGuaranteed operating conditionsMachines/enginesWind energy generationHeat depositionEngineering

The invention relates to the technical field of wind power generation. The invention aims to provide a circulating cooling device for wind power generation. The circulating cooling device for wind power generation comprises an engine room installed on an iron tower, a wind wheel is arranged at the front end of the engine room, a wind gathering cover is fixedly arranged on the upper portion of the engine room, and an injection channel is defined between the wind gathering cover and the top face of the engine room; and a heat dissipation opening communicating with the injection channel is further formed in the top of the engine room, and a cold air inlet is formed in the bottom of the engine room. According to the circulating cooling device for wind power generation, high-altitude high-speed air flow can be fully utilized to dissipate heat inside the engine room, hot air inside the engine room is ejected and exhausted, heat deposition in the engine room is prevented, the heat dissipation reliability of the engine room is improved, the working condition stability of functional equipment inside the engine room is guaranteed, and the service life of the functional equipment is prolonged.

Owner:中顺元通新能源集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com