Kitchen waste oil removing method

A kitchen waste and kitchen technology, which is applied in the field of solid waste treatment, can solve the problems of long operation time, high degree of wear and unreasonable methods of the decanter centrifuge, and achieves improved oil removal effect, high oil separation purity, prolonged The effect of equipment life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

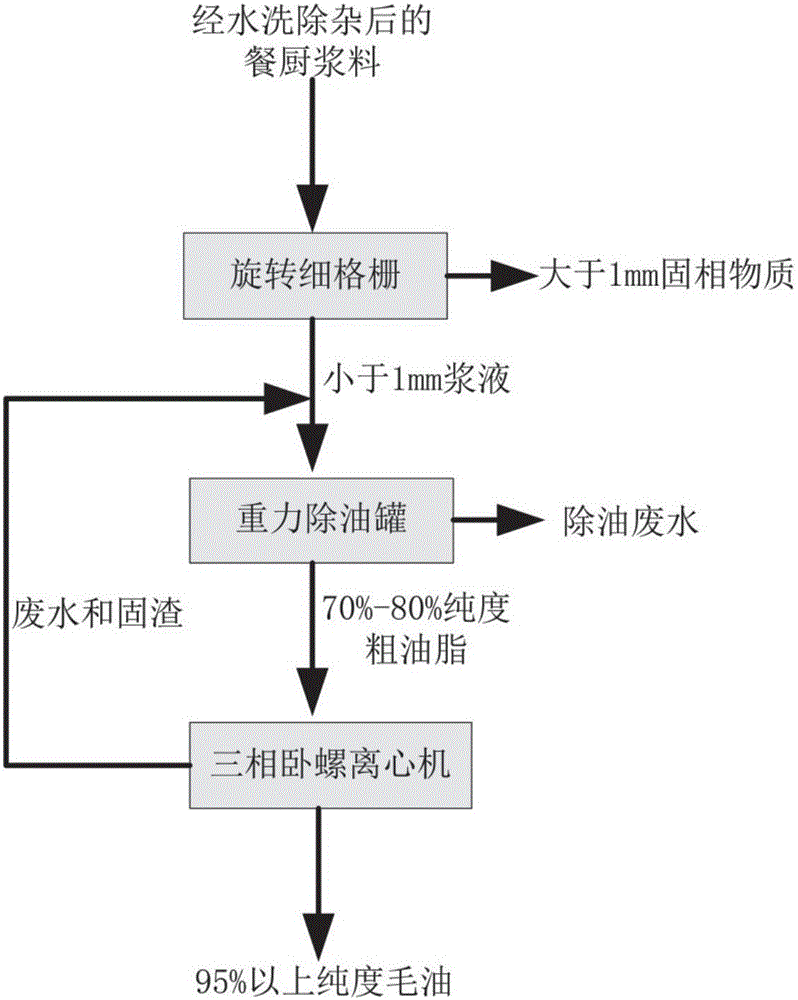

[0040] see figure 1 , the kitchen waste degreasing method of the present invention comprises the following steps:

[0041] (1) The kitchen waste is evenly conveyed to the drum sieve by a shaftless screw, and sieved and washed with circulating water at 45-50°C to obtain a kitchen slurry that removes large impurities. The drum sieve here is an invention The drum sieve disclosed in the patent application CN105381871A;

[0042] (2) The kitchen slurry is separated into a solid phase substance larger than 1mm and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com