Method and device for treating landfill leachate

A landfill leachate and treatment method technology, which is applied in the field of landfill leachate back-spraying method and its device, can solve the problems of frequent replacement and maintenance, large investment amount, etc., and achieve increased convective heat transfer effect, improved heat transfer effect, and evaporation capacity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

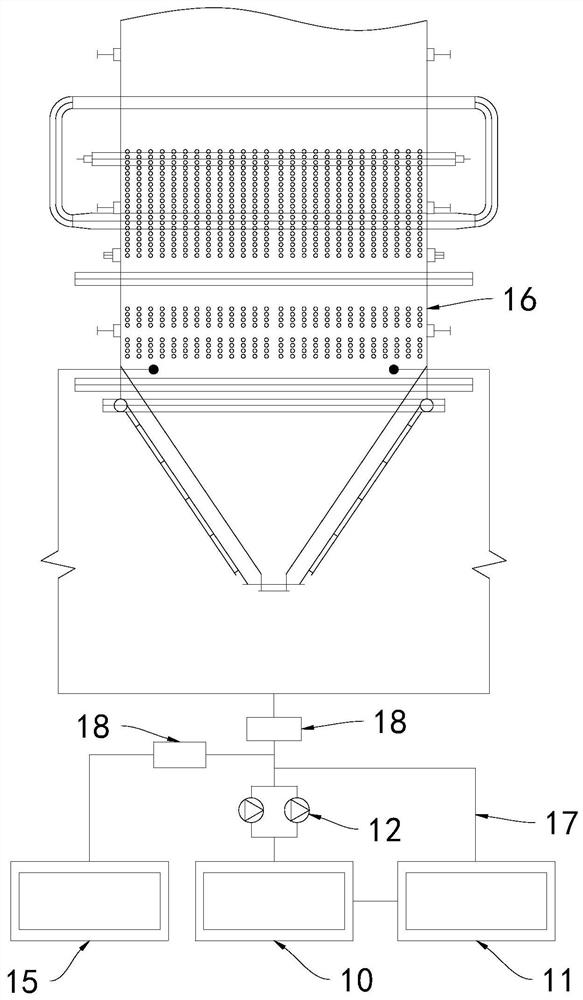

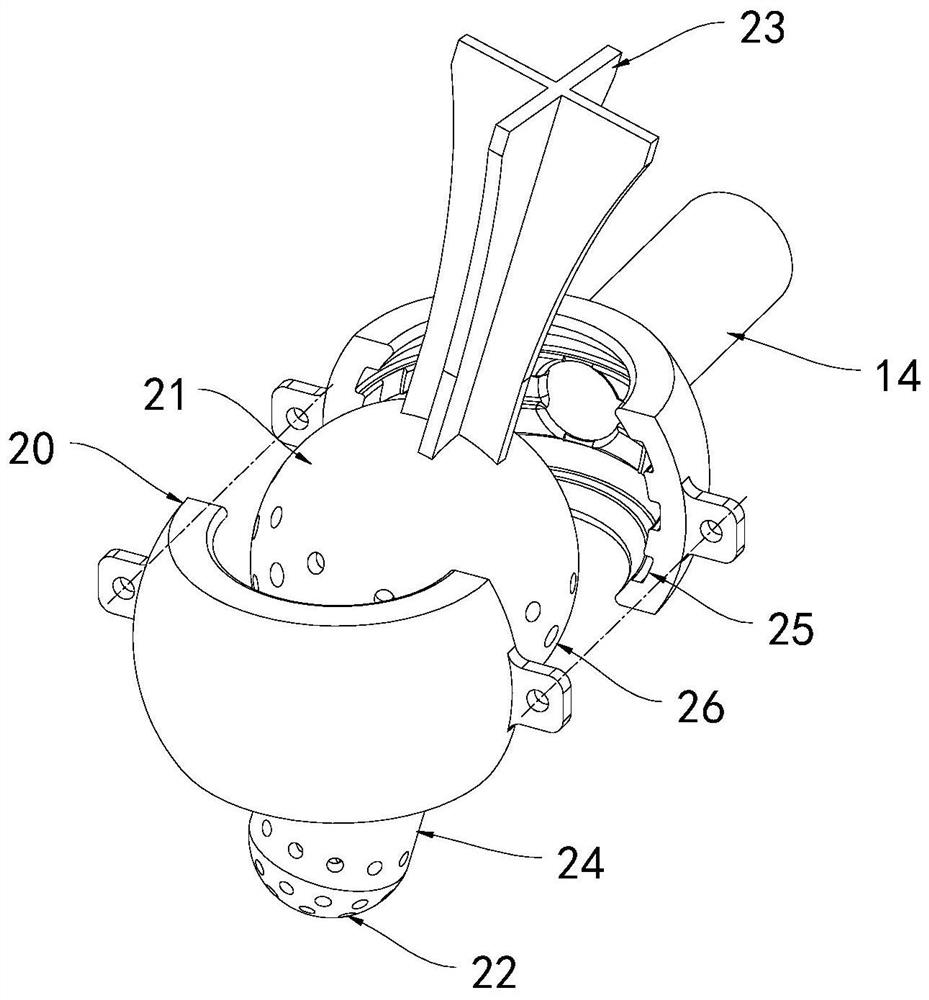

[0030] Embodiment: A method for treating landfill leachate, fermenting the landfill leachate in an environment with a pH value of 7.0-7.6 and a temperature of 20-40°C. Since landfill leachate is acidic, sodium carbonate can be used to adjust the pH value. Sodium carbonate is less corrosive to the human body, less risk during transportation and use, and the neutralization reaction will not produce precipitation, and the generated carbon dioxide gas helps to ensure the low oxygen of the environment and improve the fermentation effect. Considering that the incinerator 16 takes heat conveniently, a medium-temperature fermenting flora of 20-40° C. is adopted to adapt to the situation that the amount of leachate is large and the temperature is high in summer. The fermentation time depends on the amount of landfill leachate, and generally changes seasonally. In summer, there is a lot of rain, a large amount of leachate, high temperature, and short fermentation time. On the one hand,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com