Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "Guaranteed machining accuracy requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

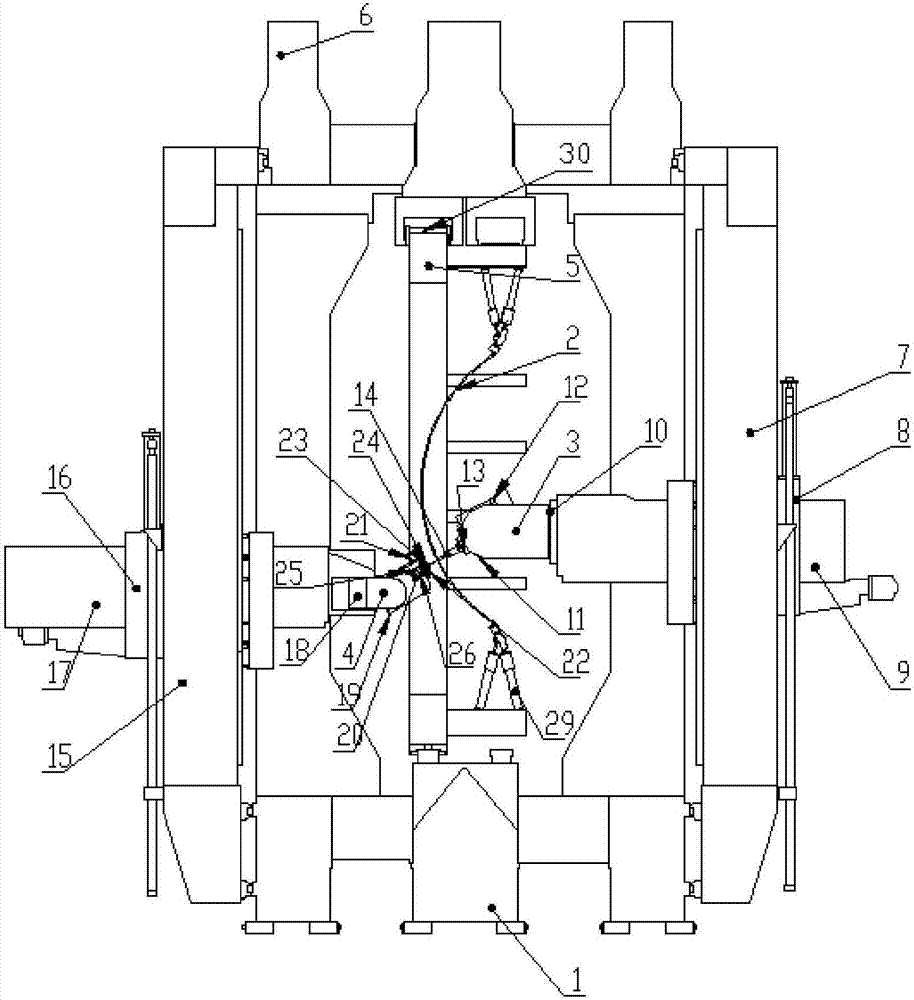

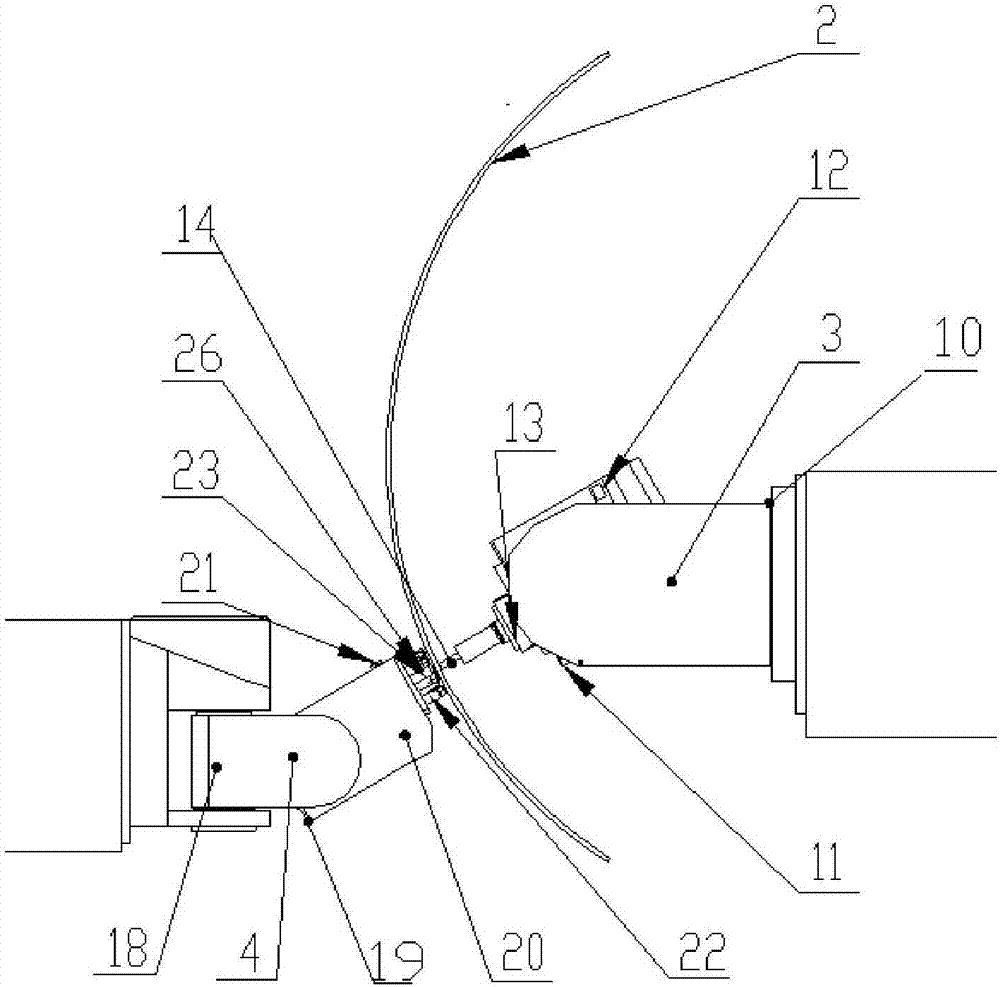

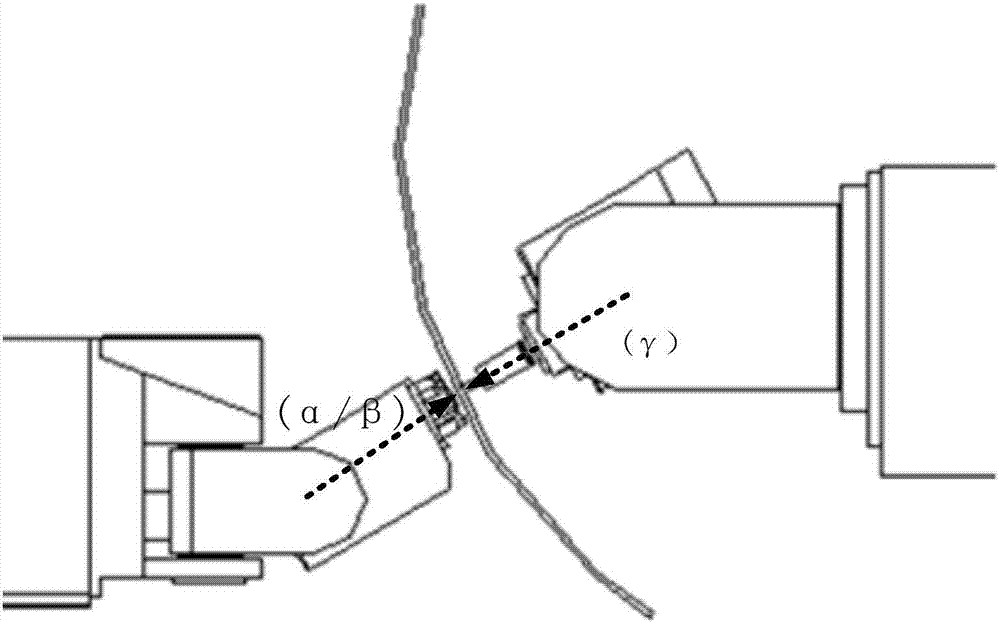

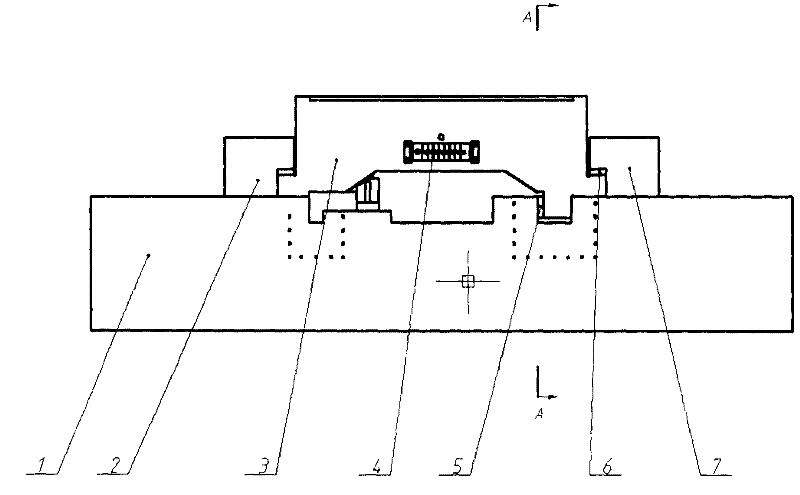

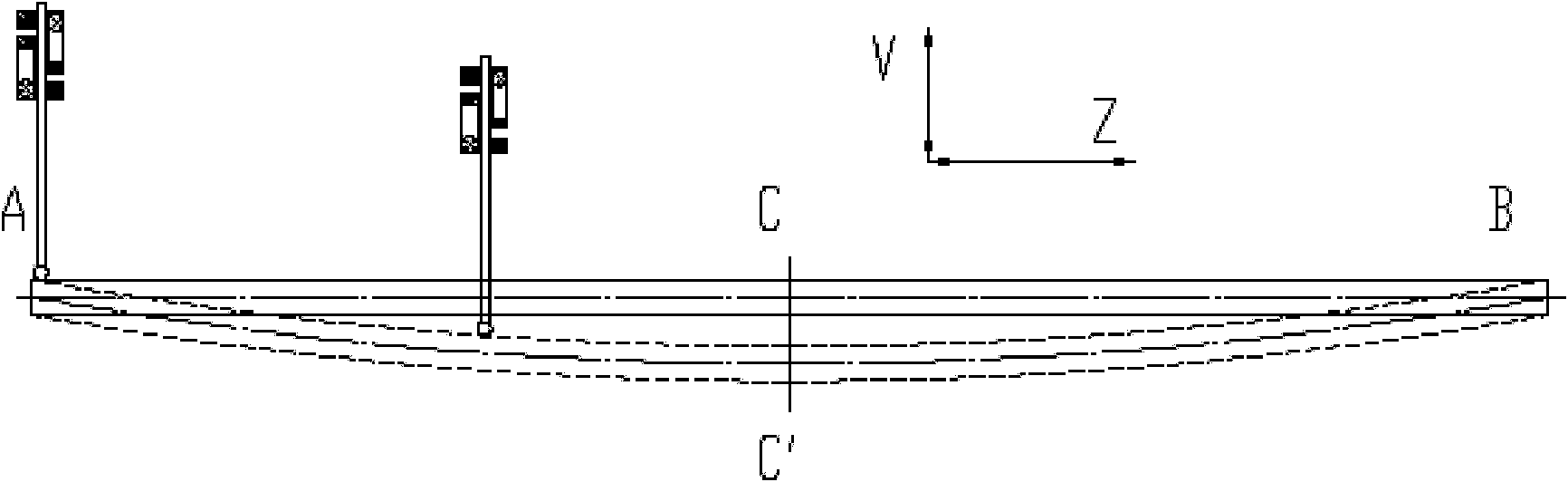

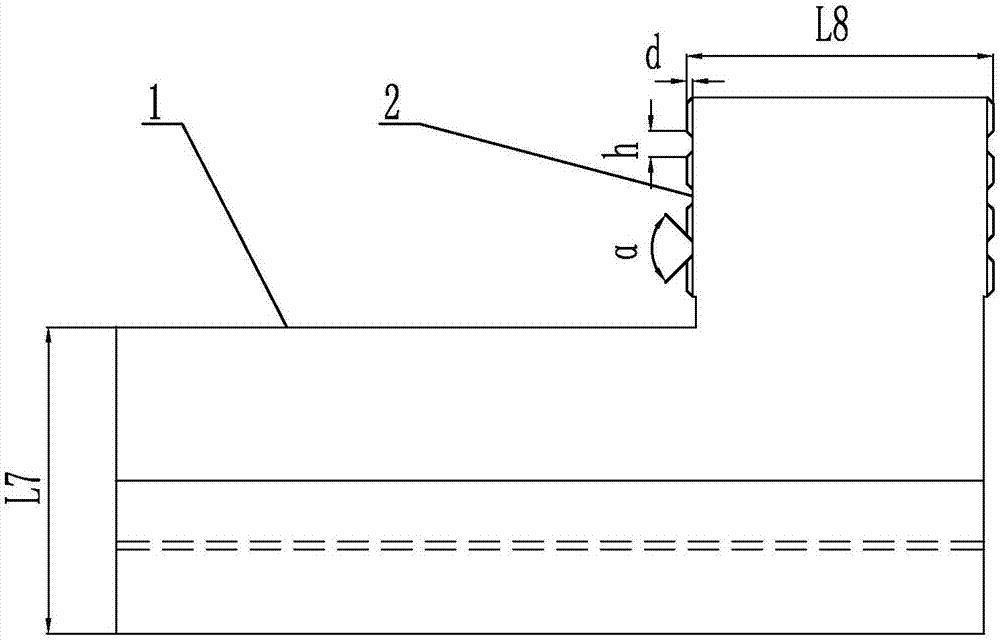

Mirror image milling method and system for skin machining

ActiveCN107344251AGuaranteed machining accuracy requirementsEmission reductionAutomatic control devicesMeasurement/indication equipmentsSelf adaptiveLaser scanning

The invention provides a mirror image milling method and system for skin machining. A machining tool is arranged on a machining surface. A set of floating supporting devices, a skin appearance laser scanning device and a set of skin wall thickness real-time measuring devices are arranged in a symmetric area of the machining surface of the skin. Before skin machining, the skin appearance laser scanning device is used for obtaining the actual skin molded surface, and the machining path is adjusted in a self-adaptation manner according to the actual skin molded surface. Then, in the skin machining process, the machining tool collaboratively moves with the floating supporting devices and the skin wall thickness real-time measuring devices in the symmetric area on the machining surface; and in the machining process, flexible supporting of the machining area of the skin workpiece is provided through floating supporting, the skin wall thickness real-time measuring devices obtain the thickness of the machining area, the machining tool adjusts the cutting depth in a self-adaptation manner according to the measured actual workpiece thickness, and wall thickness control over the skin is achieved.

Owner:SHANGHAI TOPNC NUMERICAL CONTROL TECH CO LTD +1

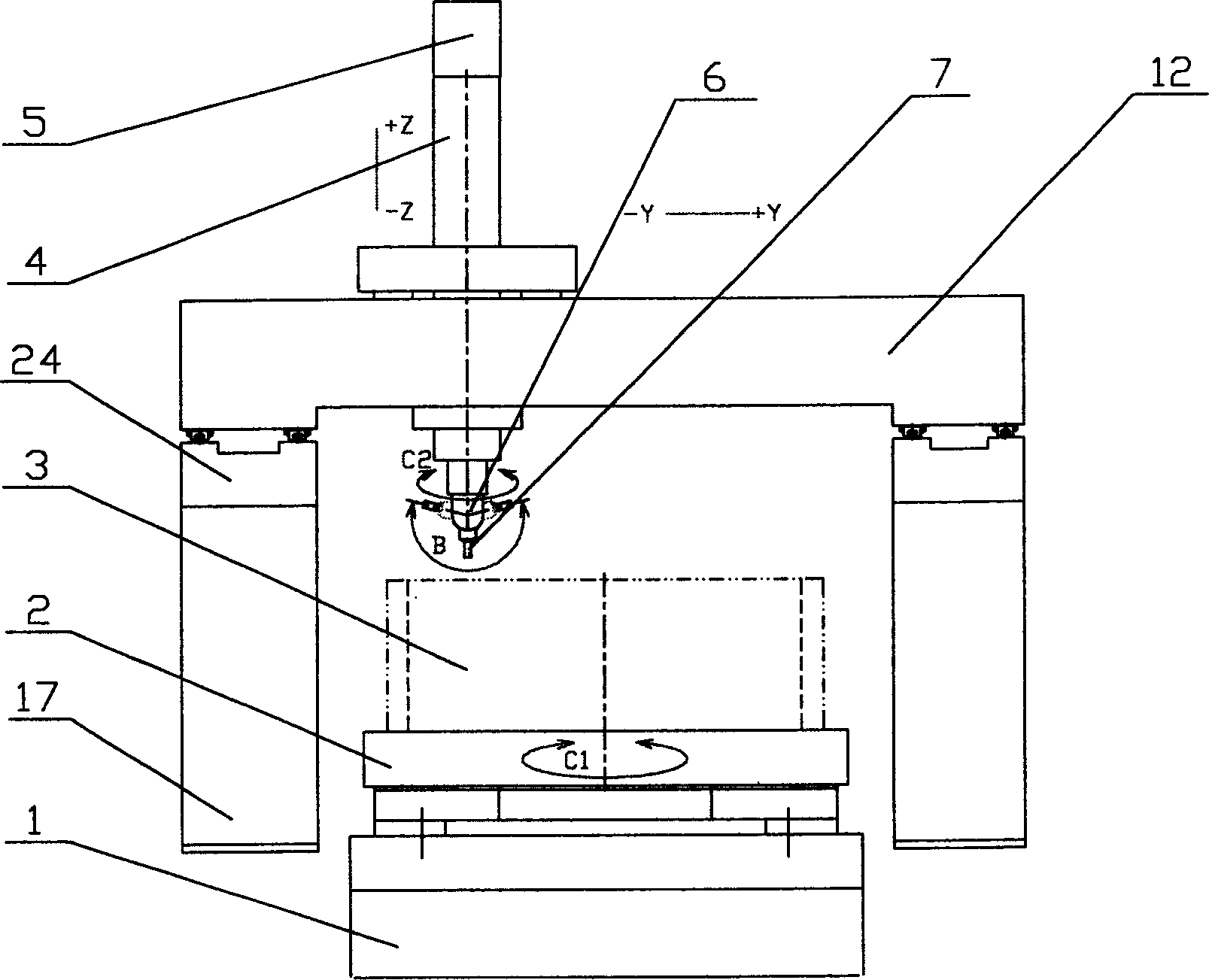

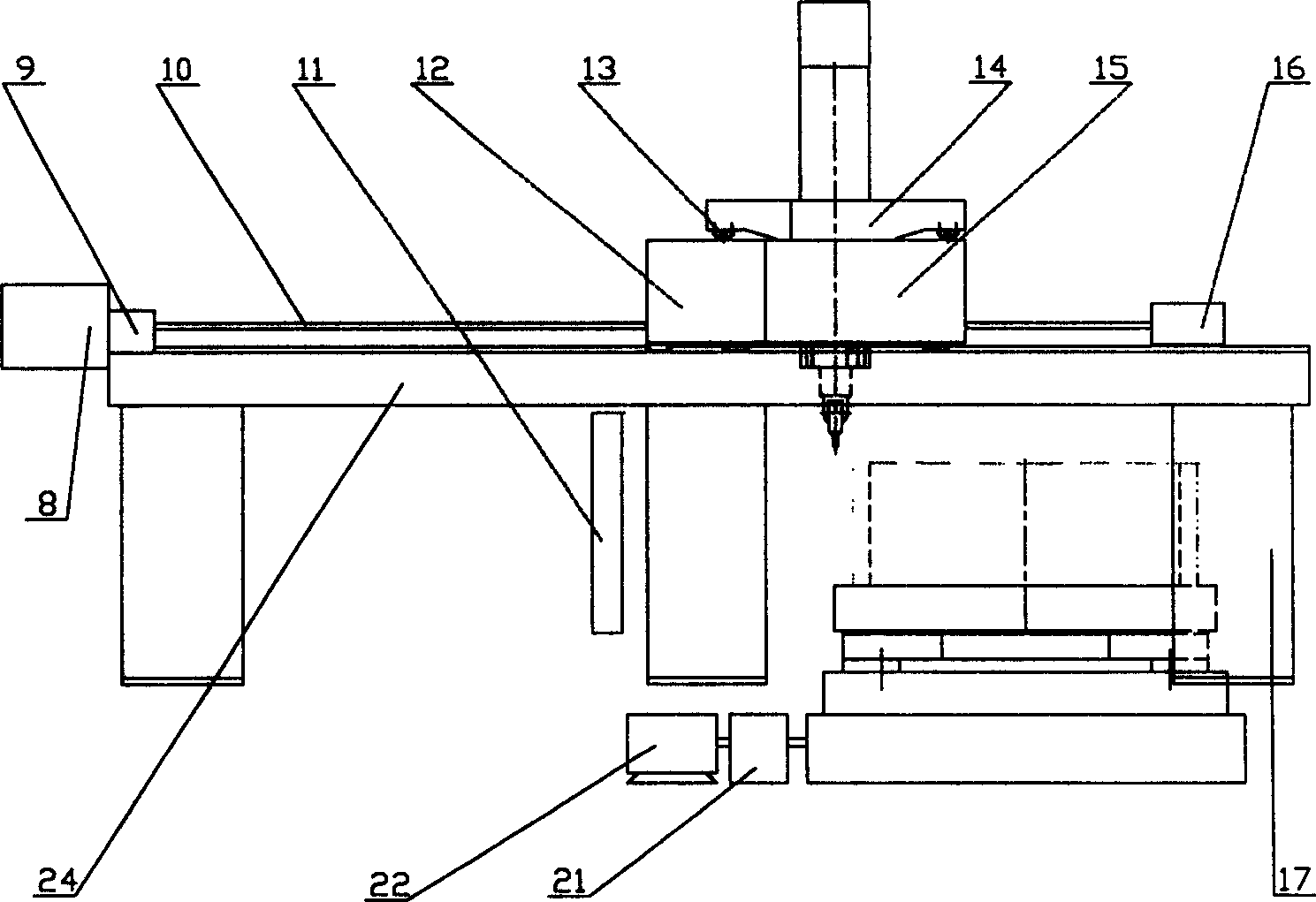

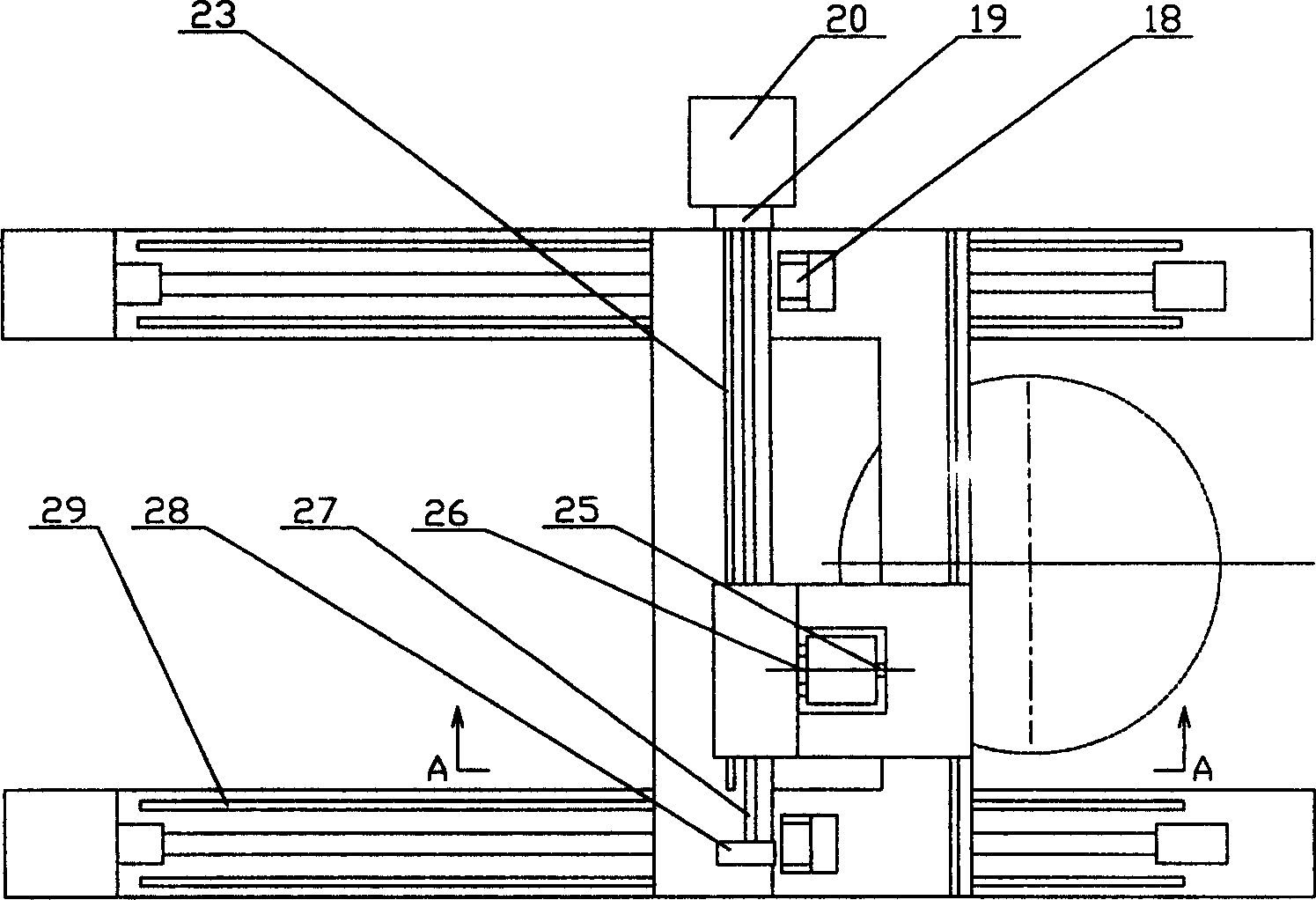

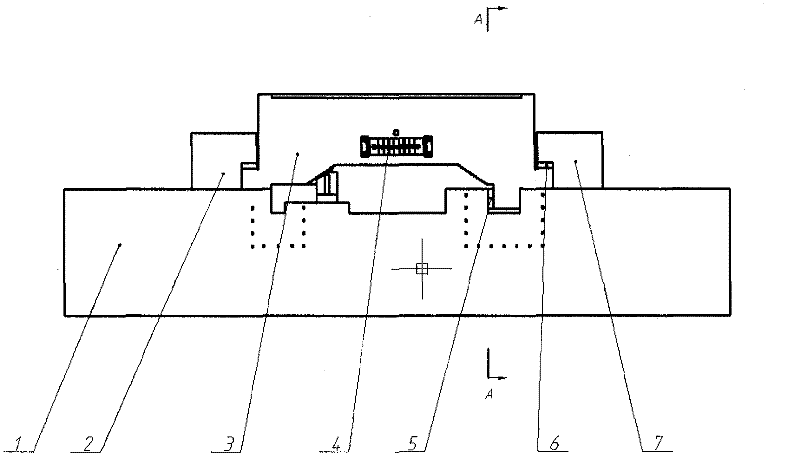

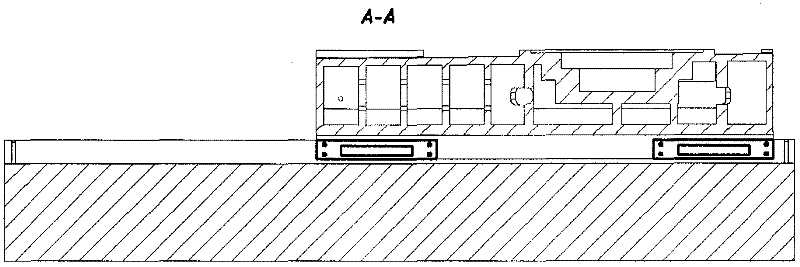

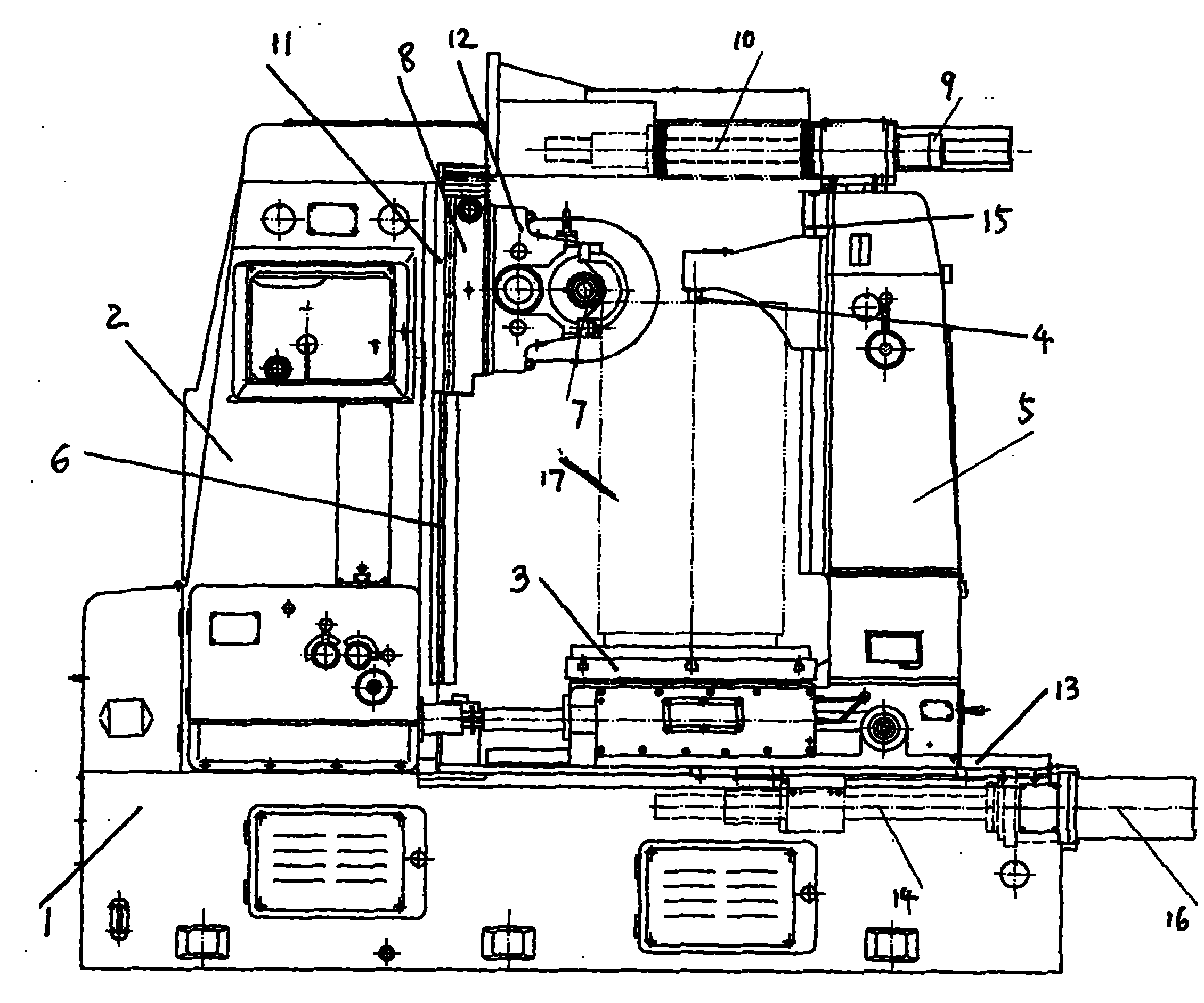

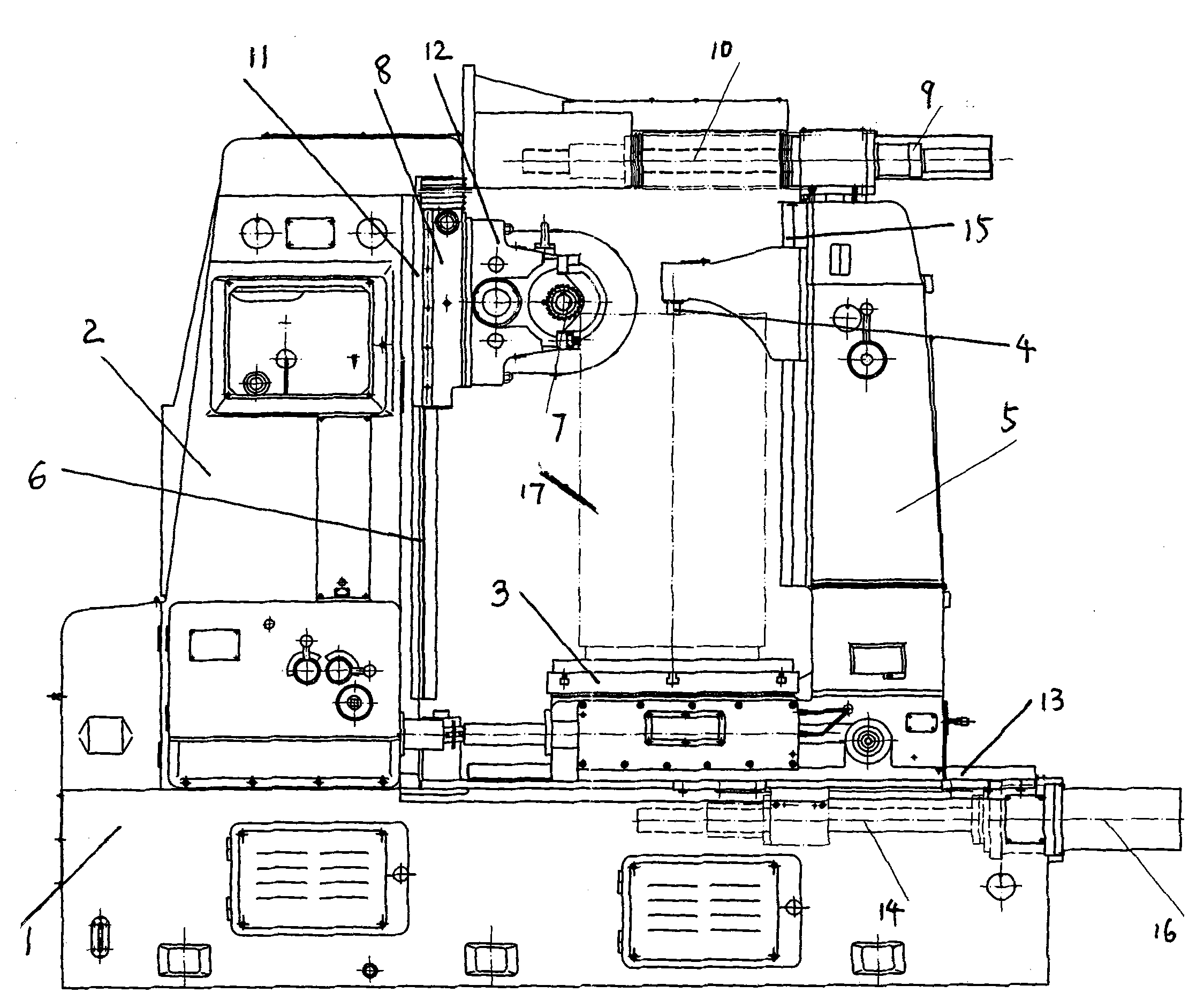

Elevated platform type automatic processing center of lathe and milling machine of five shafts

InactiveCN1562557ASolve the problem of high-speed turning and millingSimple structureOther manufacturing equipments/toolsMilling equipment detailsGear wheelEngineering

An automatic machining center with high frame and 5 shafts for turning and milling is composed of a high frame consisting of left and right vertical columns and dual horizontal beams, rotary bench and its base, speed-regultable DC motor, gear box, the rolling guide tracks X, Y and Z, rotating axles C1 and C2, the main shaft for turning and milling and tool library.

Owner:沈阳工业学院

T-shaped hydrostatic guide rail for precision finishing machine tool

InactiveCN102189410ARealize pure liquid friction stateGuaranteed pure liquid friction stateLarge fixed membersMachine toolAdvanced manufacturing

The invention discloses a T-shaped hydrostatic guide rail for a precision finishing machine tool, which belongs to the field of advanced manufacturing and is a structural improvement on the traditional hydrostatic guide rail. In respect of materials, the machine tool body is made of granite, and a slide carriage is made of cast iron; in respect of the structural form, a specific T-shaped guide rail form is adopted, i.e. the machine tool body is provided with a T-shaped guide rail groove matched with a moving guide rail; in respect of hydrostatic control, a flow controller group conveys lubricating oil to each static pressure cavity on the guide rail; static pressure blocks are mounted in the horizontal direction and vertical direction respectively; and the adjustment of the oil film thickness between guide rails is realized by adjusting the static pressure blocks. The hydrostatic guide rail adopting the T-shaped structure has high rigidity, high guide ratio and high precision.

Owner:XI AN JIAOTONG UNIV

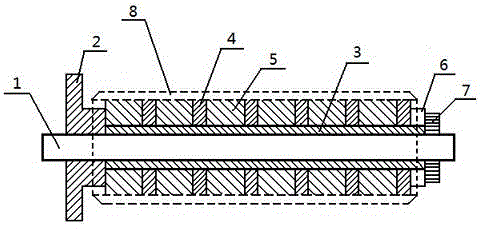

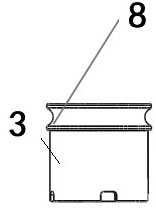

Novel clamp for machining thin-wall cylinder part

The invention discloses a novel clamp for machining a thin-wall cylinder part. The novel clamp comprises a mandrel, a positioning plate, connecting pipes, spacer bushes, expansion components and a pressing plate. The positioning plate is fixed to one end of the mandrel. The connecting pipes are fixed to the mandrel and tightly attached to the positioning plate. The spacer bushes, the expansion components and the pressing plate are installed on the connecting pipes. The novel clamp for machining the thin-wall cylinder part is easy to manufacture, operation is convenient, multiple supporting points exist on the clamp, the area is large, the good expansion performance is achieved, the part can be prevented from deforming and vibrating in the machining process, the machining precision of the part is effectively ensured, and the use requirement of the part is effectively met.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

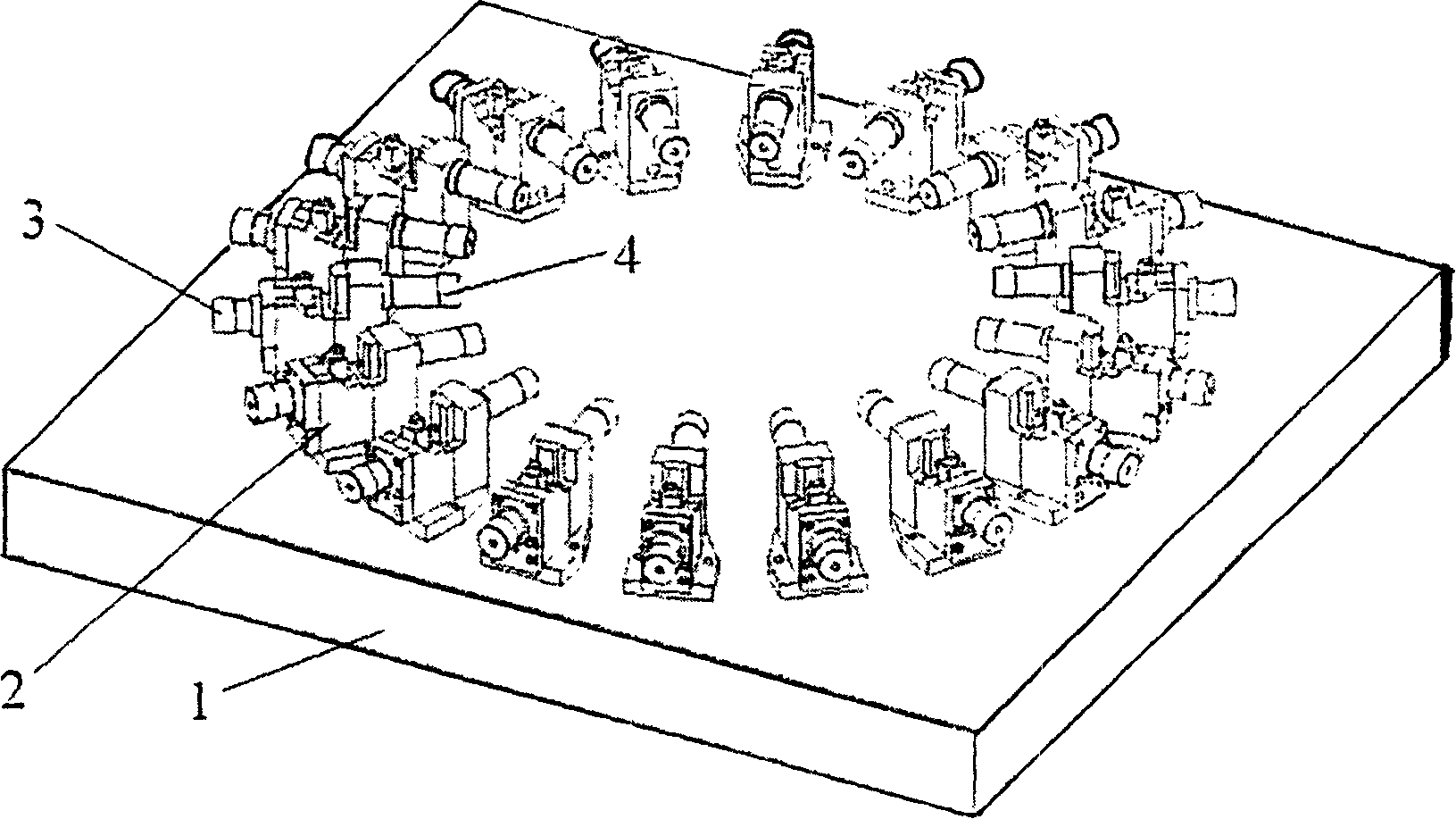

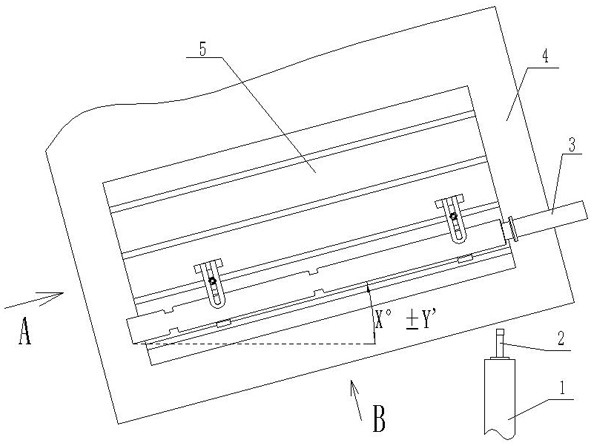

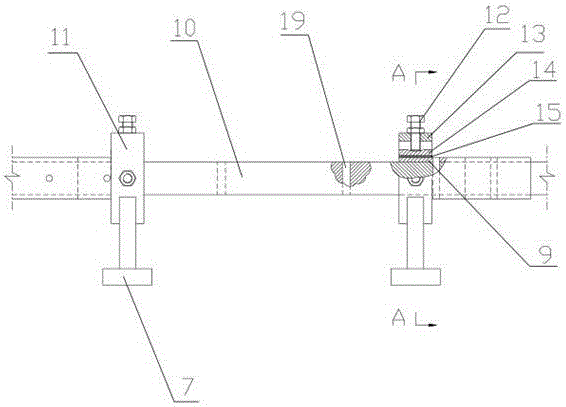

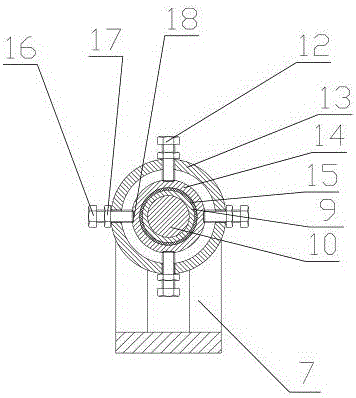

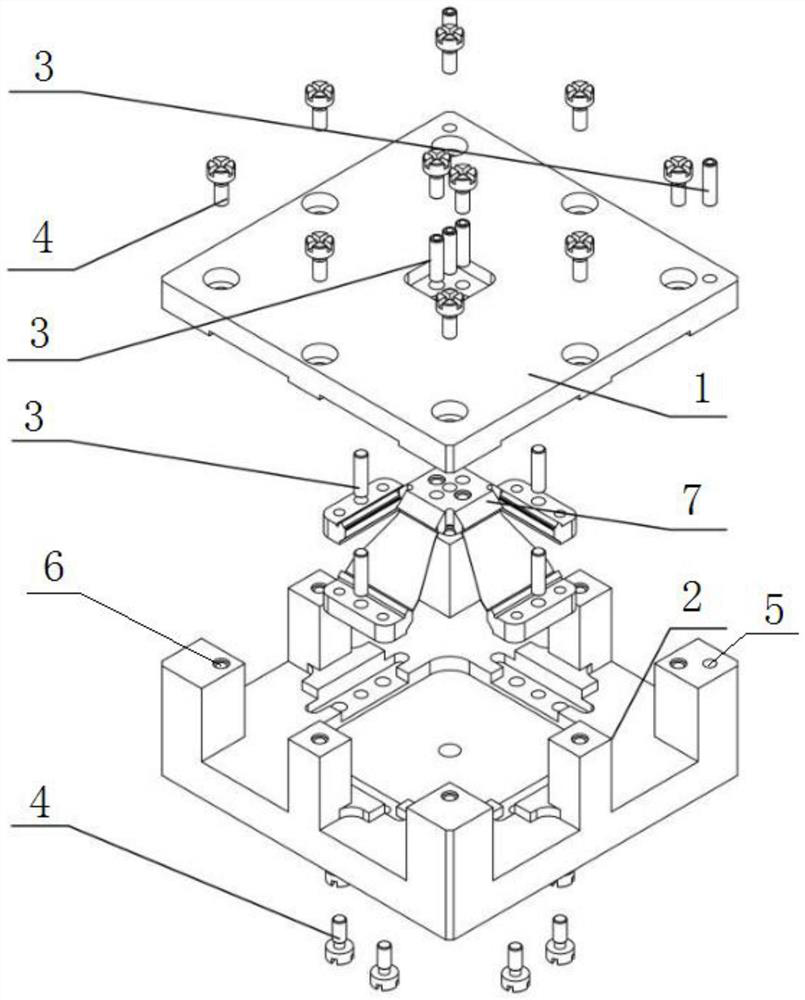

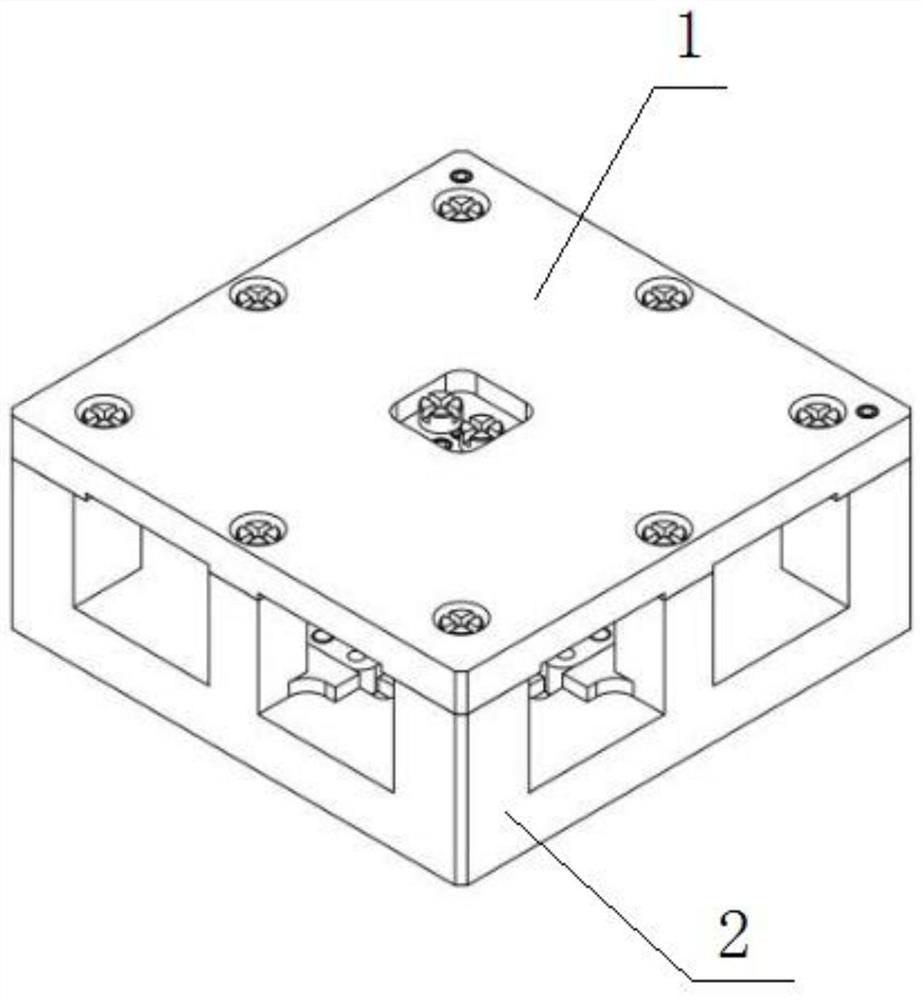

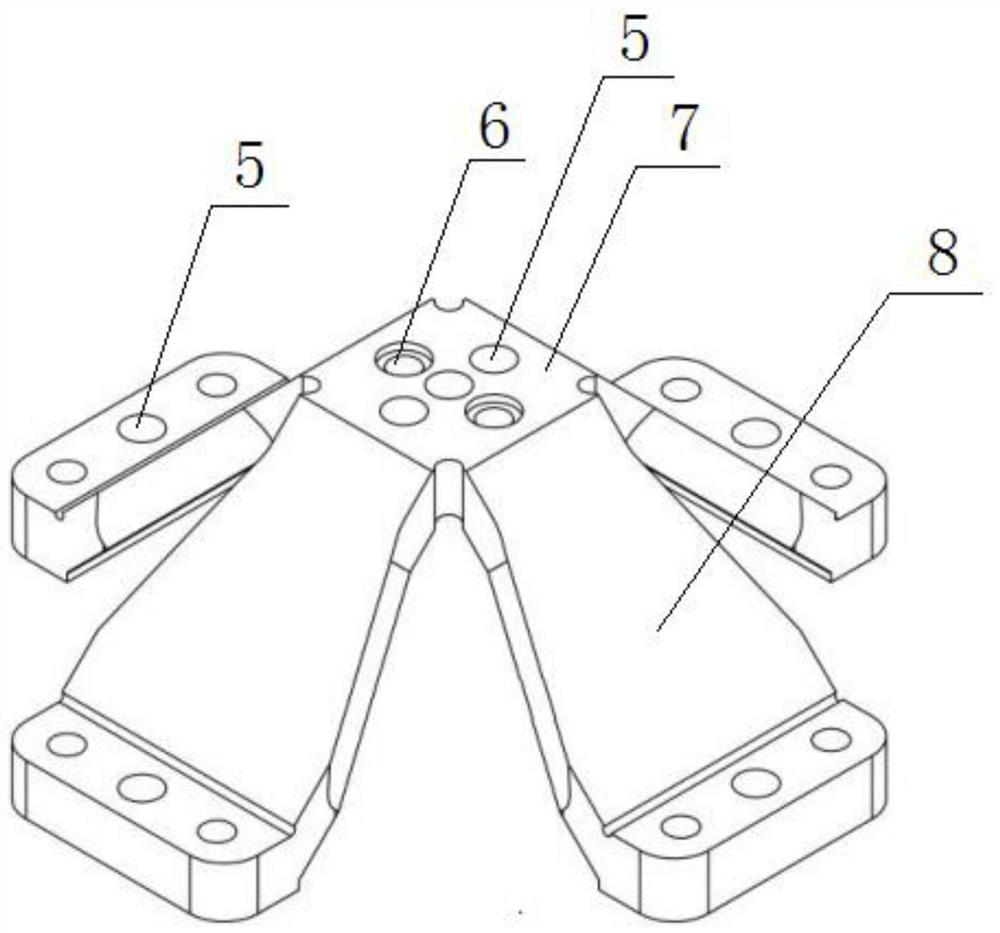

Adjustable hydraulic frock

ActiveCN101200037AAvoid deformationHigh clamping precisionWork holdersPositioning apparatusEngineeringHydraulic equipment

Disclosed is an adjustable hydraulic fixture, which is structured by an installation platform and 18 supporting devices. The supporting devices are arranged on the installation platform along the circumference by equal circumference divisions; the supporting device is structured by each free end bearing seat which is equipped with an elevating seat; the elevating seat is equipped with a lifting poker; both sides of the elevating seat are equipped with an stretching oil cylinder and a pressure-keep cylinder, etc. The piston rod of the stretching oil cylinder is equipped with a pressure spring. The front end of the piston rod of the stretching oil cylinder is equipped with a stretching claw; the pressure-keep oil cylinder is connected with an hydraulic oil-channel connector through a pipeline. Eighteen hydraulic equipments are arranged in the fixture structure as the supporting points in the invention, and the clamping force at each point can be regulated to equal by hydraulic system; meanwhile, a pressure spring is arranged in hydraulic equipment for workpiece pre-fixing, and the parts deformation is avoided. The invention has the advantages of convenient installation and regulation, and can improve the clamping precision and reliability of the workpiece.

Owner:SHANGHAI PEITONG MACHINERY

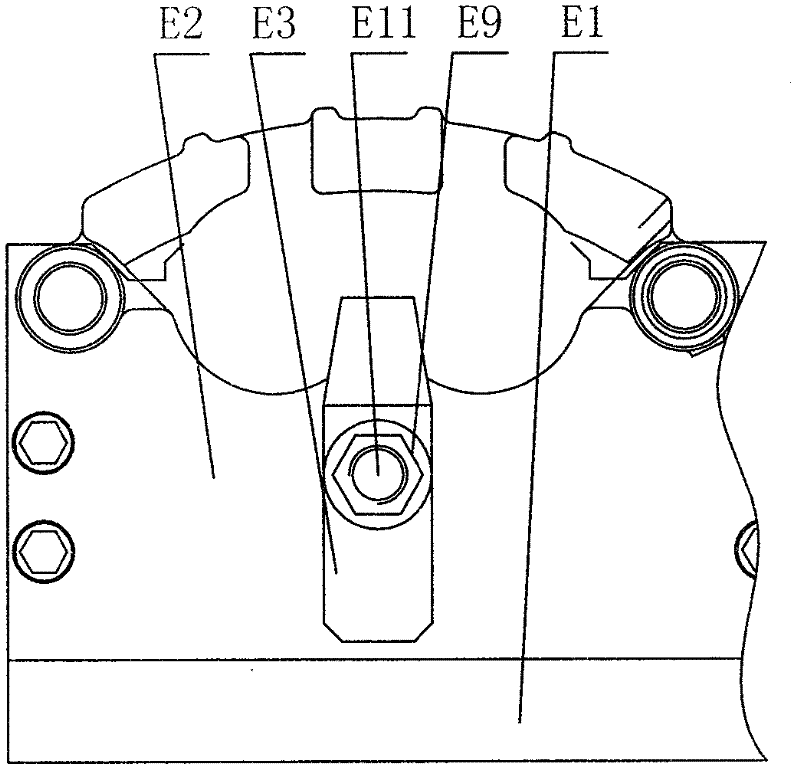

A precision production method for a light passenger car front brake caliper body

A precision production method of a front brake callipers body of a light bus comprises the following steps: A. a circular arc of a working surface of a callipers body cylinder is milled; B. a front support lug hole of a support lug of the callipers body is processed; C. a reverse support lug hole of the support lug of the callipers body is processed; D. a cylinder hole of the callipers body is processed; E. an oil inlet hole and a vent hole of the callipers body are processed. The invention has the characteristics of low equipment investment, high working efficiency, stable product quality and short parts production period. After being clamped by a corresponding fixture, the brake callipers body can be completely processed by a correspondingly cheaper vertical machining centre, thus the investment is greatly reduced, and the cost is reduced by 1 / 2, meanwhile, accurate position of related hole distances guarantees each processing precision requirement of the parts. The processed brake callipers body can smoothly realize an automatic assembly on a full-automatic assembly line, and the product quality is not worse than that of the same parts imported from Europe, and the purchasing cycle is shortened to be 20 days from the original 90 days.

Owner:XIANTAO XIANGTAI AUTO PARTS

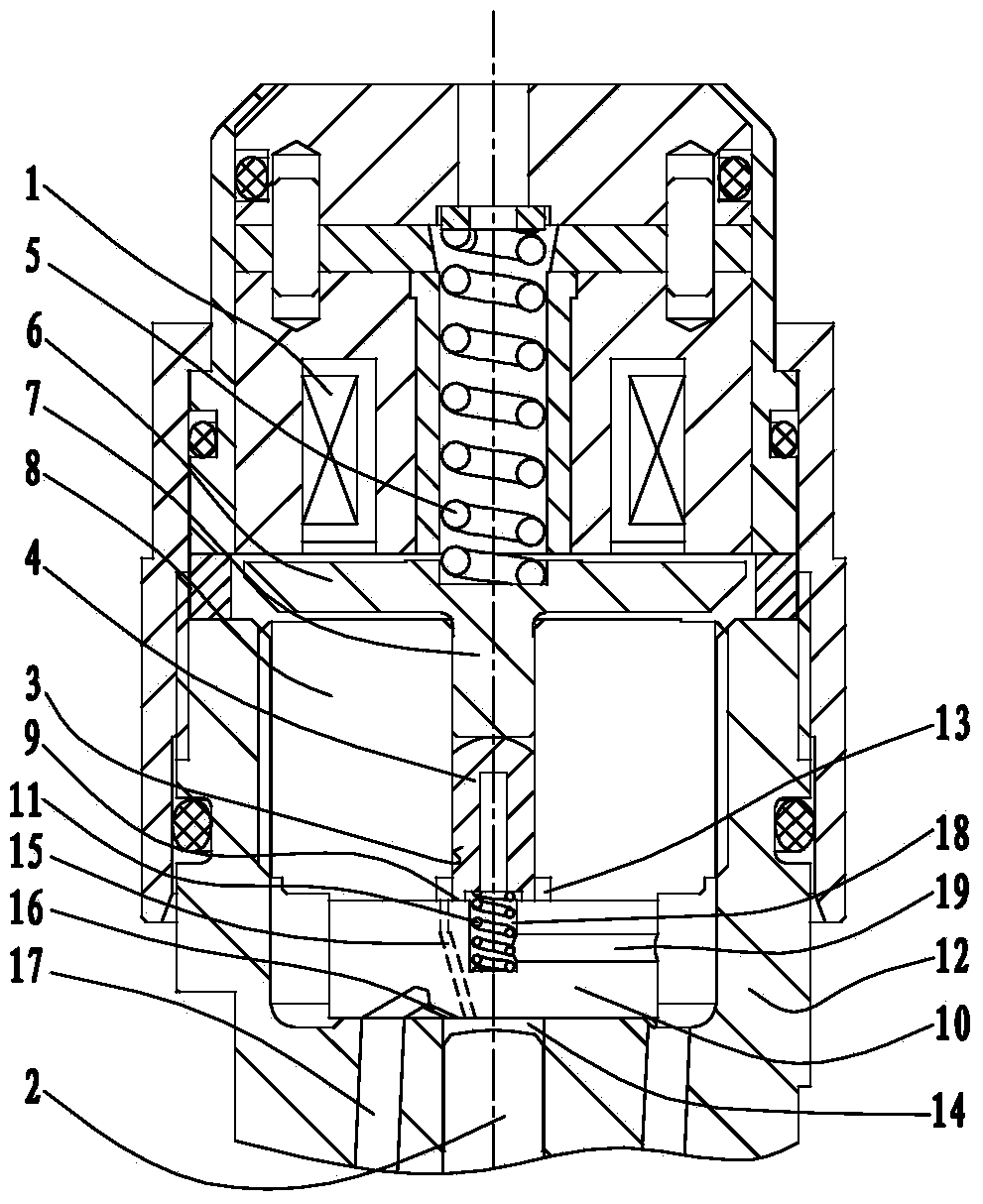

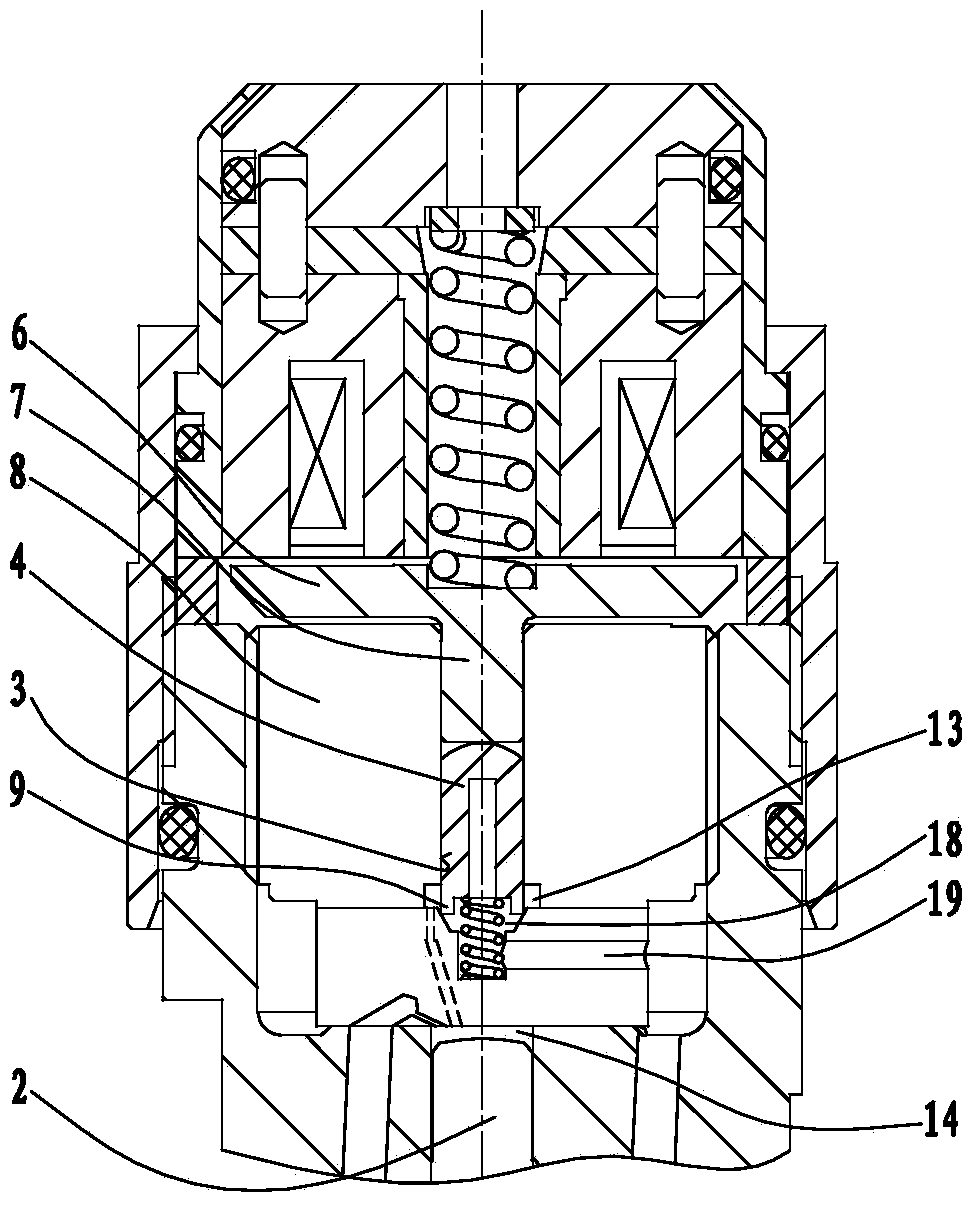

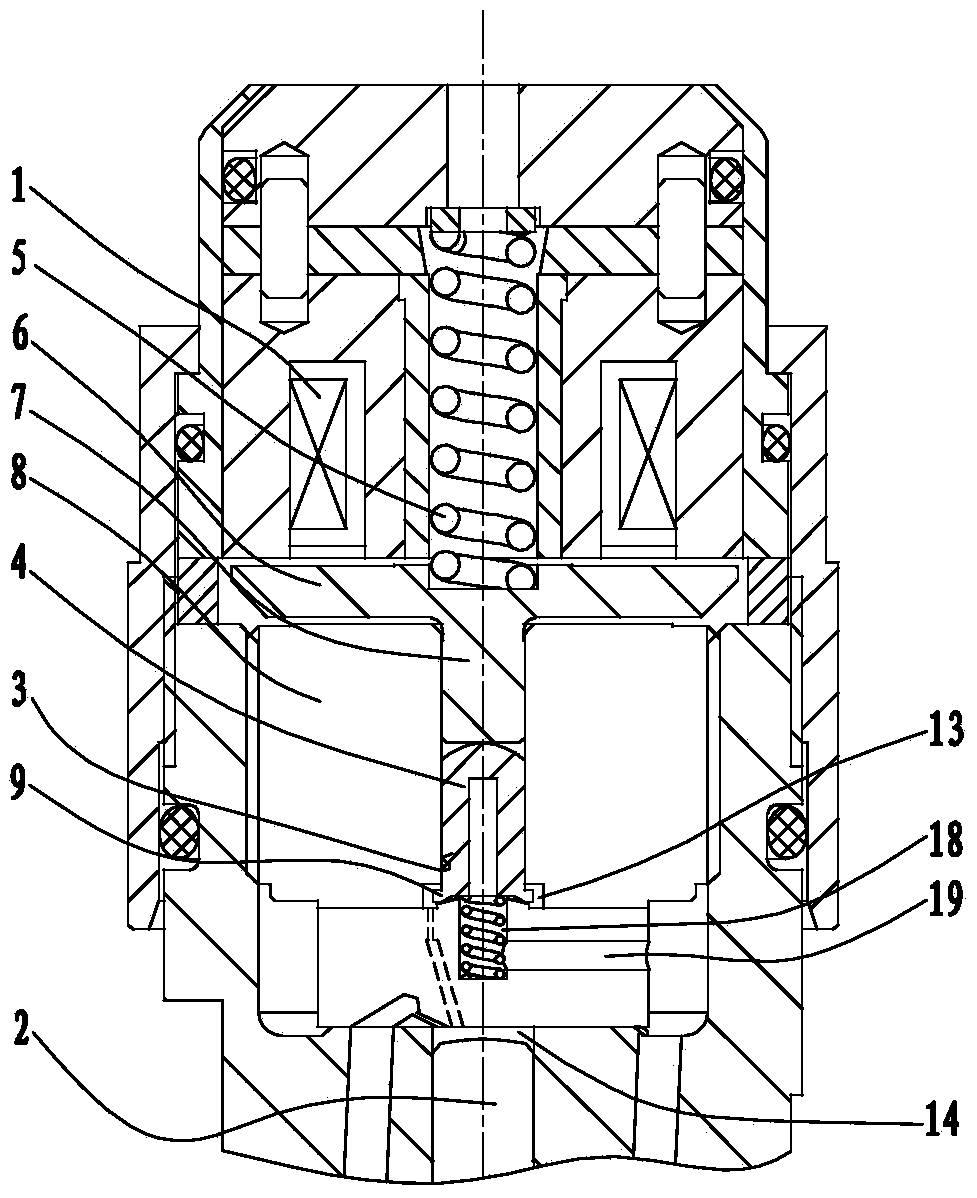

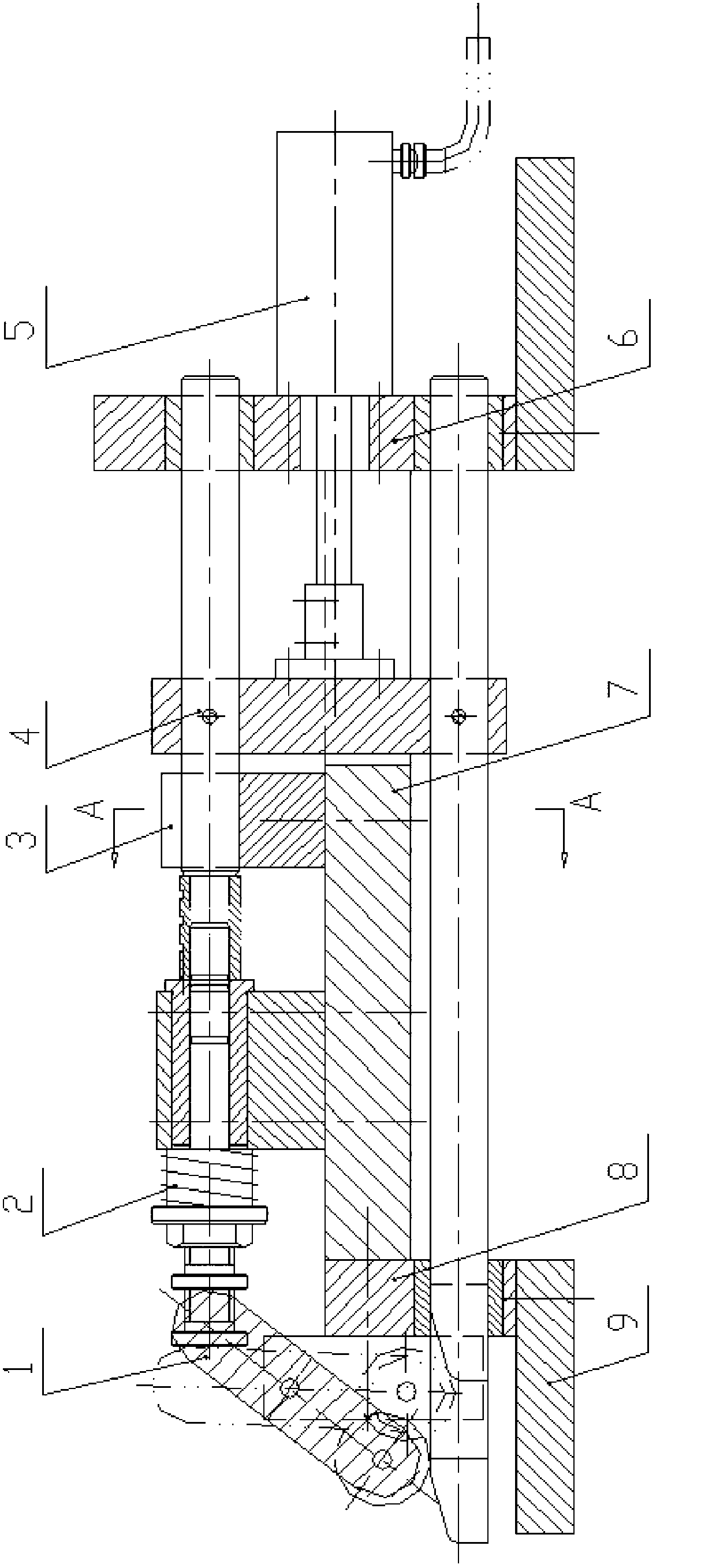

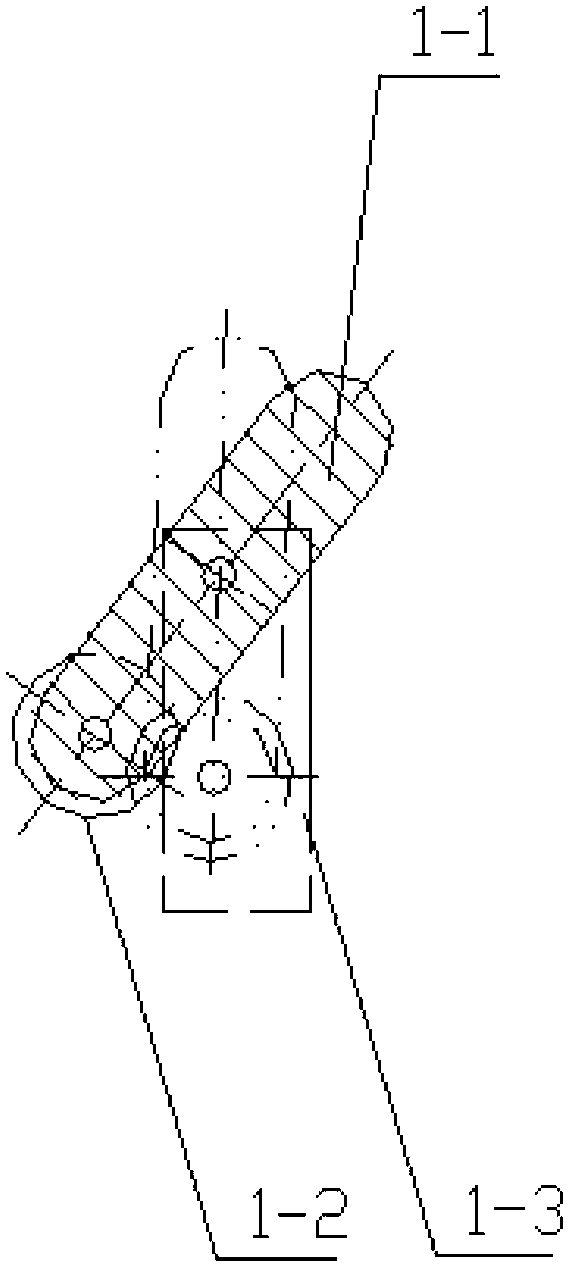

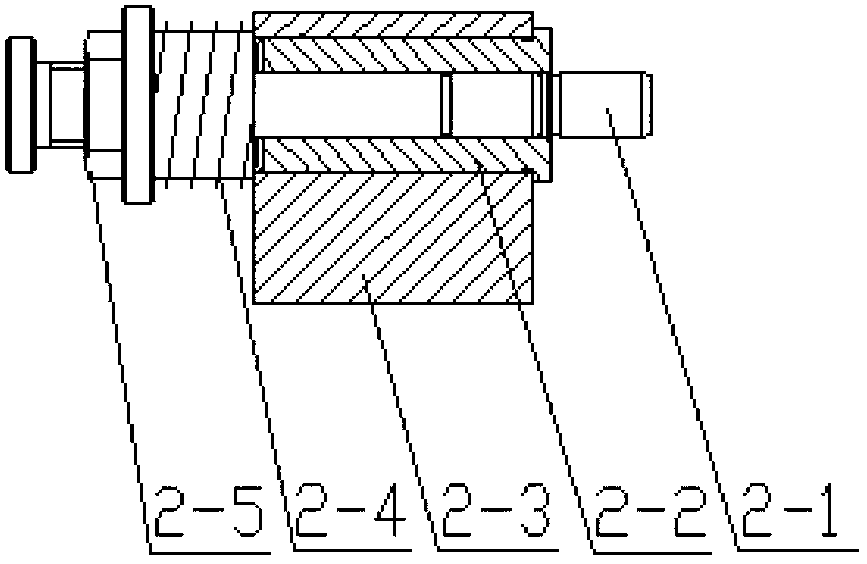

Control valve for oil atomizer

ActiveCN104265532AOpen quicklyQuick closeFuel injection apparatusMachines/enginesEngineeringControl room

The invention relates to a control valve for an oil atomizer. The control valve comprises electromagnets, a sealing bolt pin, electromagnet springs, an armature, an armature guide rod, control valve bases, a restriction orifice and an oil atomizer body. The control valve is characterized in that the sealing bolt pin is arranged in inner holes of the control valve bases; a high-pressure sealing face is formed by the outer circle surface of the sealing bolt pin and the inner holes of the control valve bases; a valve chamber is defined by the sealing bolt pin, the control valve base and the restriction orifice and is communicated with a control chamber through an oil outlet path; the sealing bolt pin is in rigid connection with the armature guide rod and is pressed on a supporting face at the upper end of the restriction orifice under downward elastic force of the electromagnet springs; a closed portion is arranged on the lower end face of the sealing bolt pin; a high-pressure sealing face is formed by the supporting face of the lower end of the closed portion and the supporting face of the upper end of the restriction orifice; a blind hole is formed in the center of the restriction orifice; an oil returning cavity is formed between the blind hole and the lower end face of the sealing bolt pin and is communicated with an oil returning channel. The control valve can be closed only through small spring pre-tightening force.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

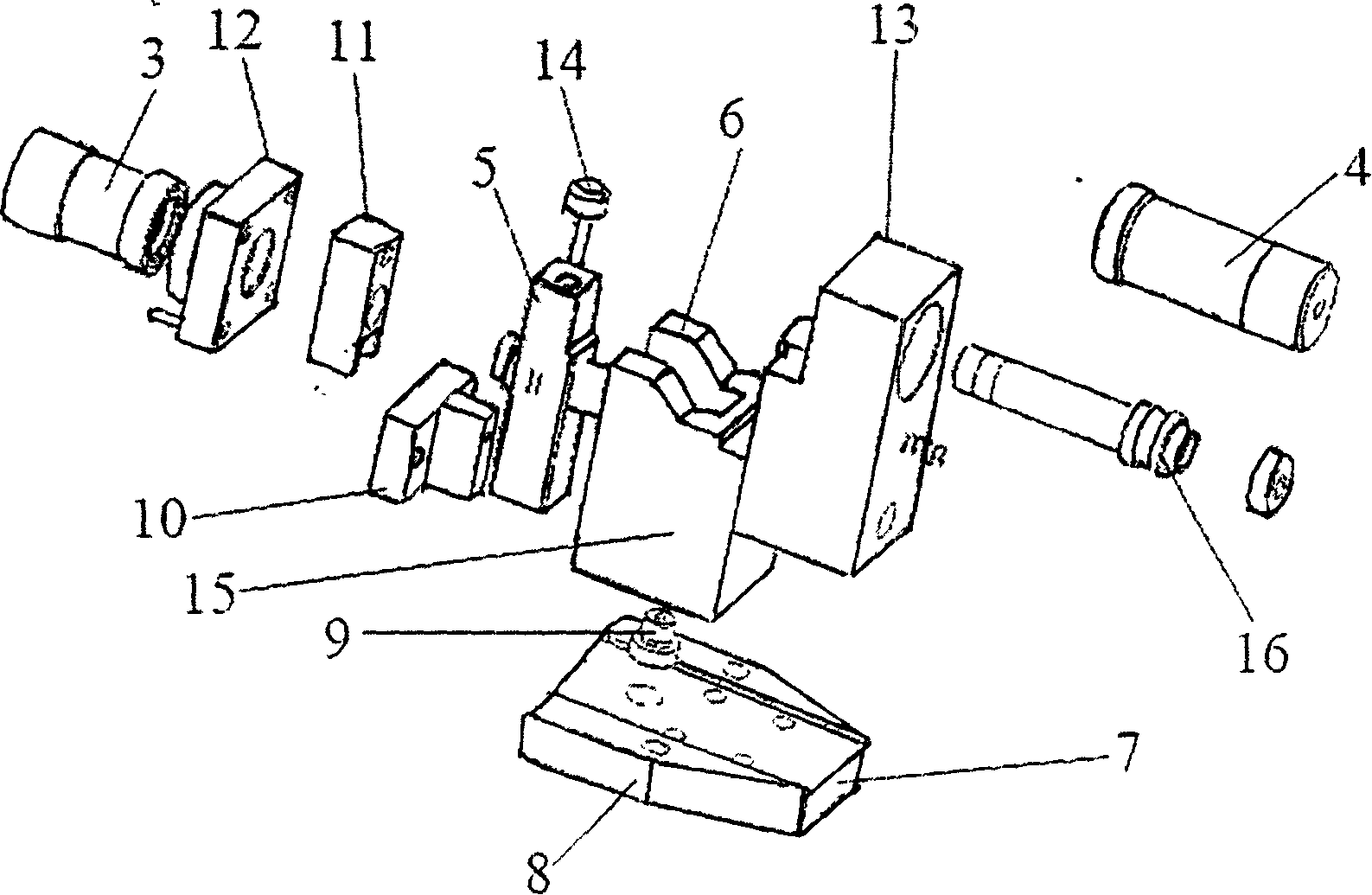

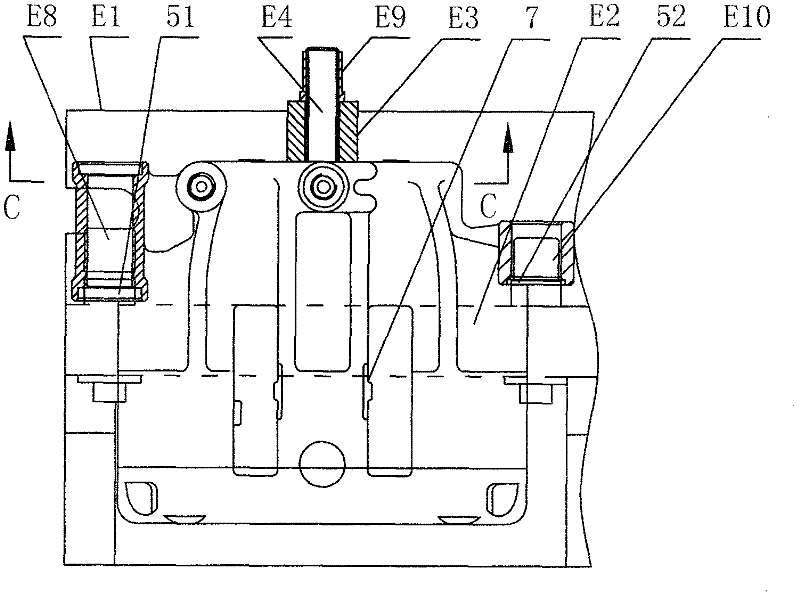

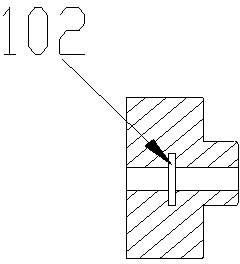

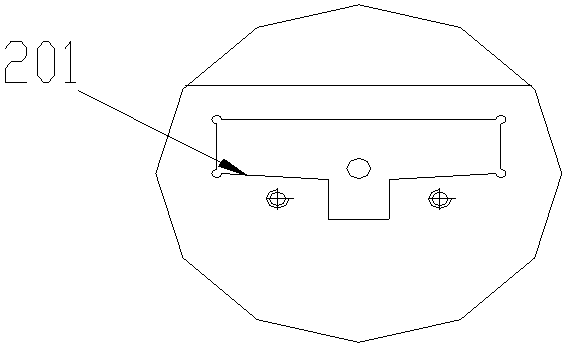

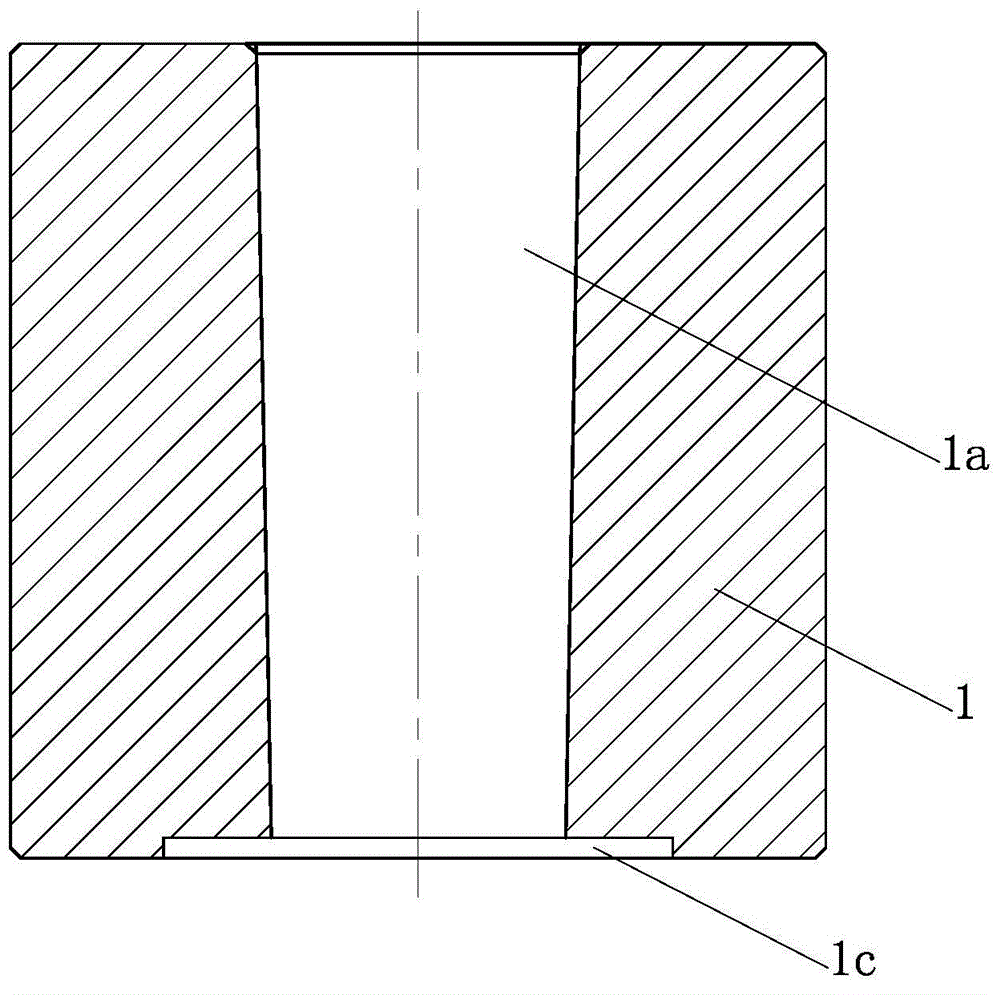

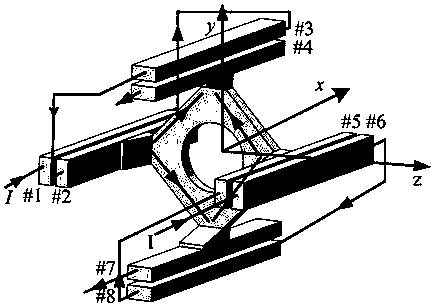

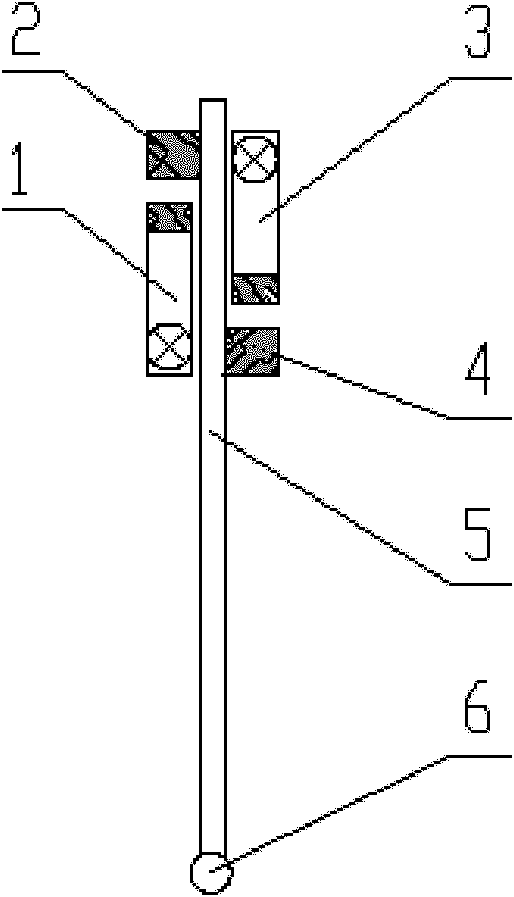

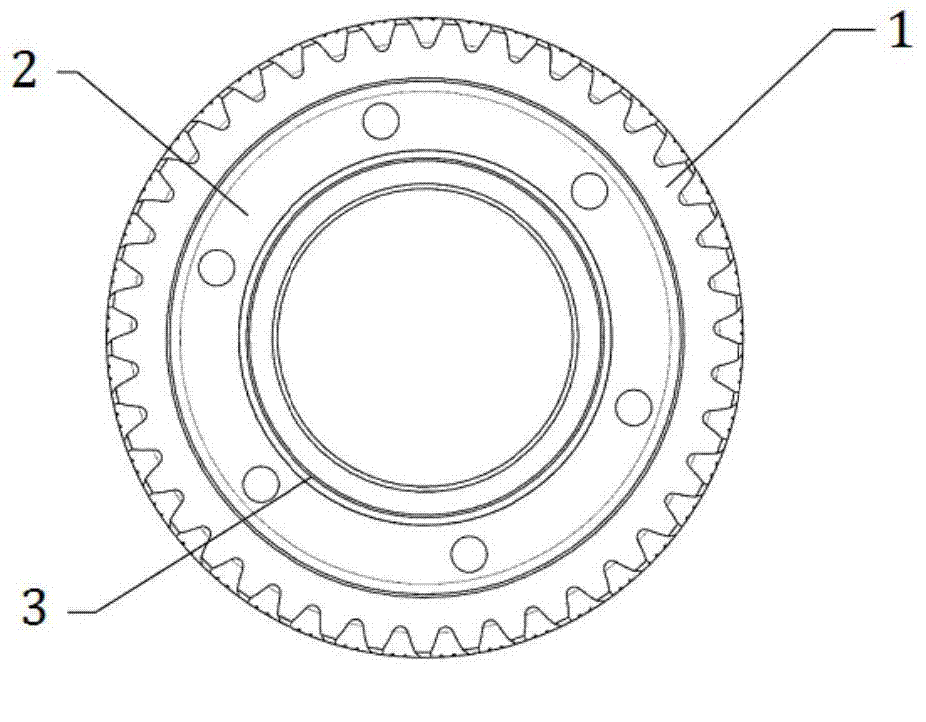

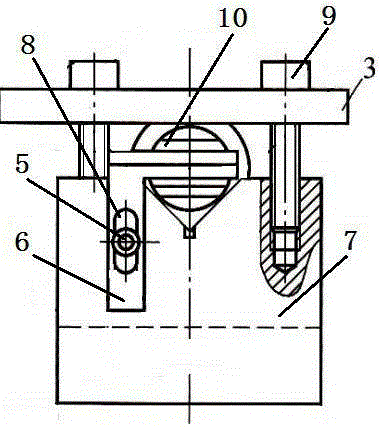

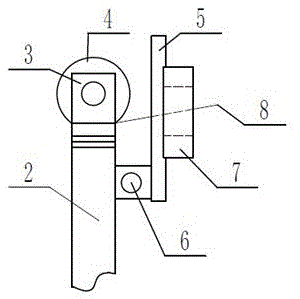

Turning clamp for plate part hole and inner annular groove machining

InactiveCN104959863AGuaranteed machining accuracy requirementsImprove clamping efficiencyPositioning apparatusMetal-working holdersProduction rateEngineering

The invention discloses a turning clamp for plate part hole and inner annular groove machining. The turning clamp comprises a clamp body. A clamp installation groove is formed in the clamp body. The clamp installation groove comprises an X-axis positioning reference plane, a Y-axis positioning reference plane and a Z-axis positioning reference plane. The four corners of the X-axis positioning reference plane are provided with interference receding grooves. The two sides of the upper portion of the X-axis positioning reference plane are each provided with a pressing block body and provided with compressing bolts. A pressing block boss is arranged at the tail end of each pressing block body. A lateral abutting bolt hole is formed in the side face of the clamp body. A lathe installation shaft is arranged on the back face of the clamp body. Due to the fact that the special clamp is adopted for machining holes and inner annular grooves of plate parts, the clamping efficiency of parts to be machined is improved, the productivity is increased by about 50%, strict positioning precision control is achieved, the part machining precision requirement is ensured, the yield of the machined parts reaches 100%, and the clamp material and manufacturing costs are saved by about 70%.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Structure-stable ceiling joist and adjustable fastening piece therefor

The invention relates to a ceiling joist with stable structure and relative adjusting fixer, especially providing a ceiling joist mounted with transcendental hidden inserted ceiling. Wherein, it comprises a main joist, a T-shape joist under the main joist and crossed with said main joist, a suspension member connecting the T-shape joist and the main joist, and an adjusting fixer between the connected parts of main joist and T-shape joist; the adjusting fixer is formed by a clamper mounted on the top bar at the top of T-shape joist and the fixing element for fixing the clamper and the top bar; the upper surface of clamper is plane compacted contacted with the lower surface of main joist; said clamper is in gate structure. The invention can solve the problem that the connection between main joist and T-shape joist is instable, and the ceiling will fall.

Owner:BEIJING NEW BUILDING MATERIALS PLC

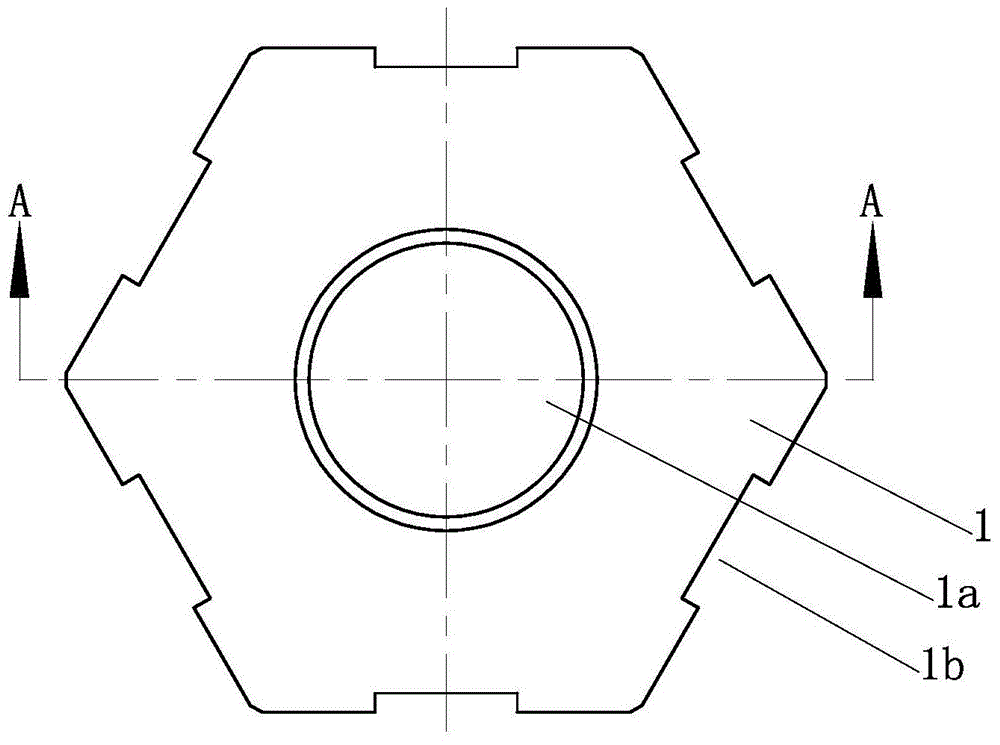

Hexagonal center grinding method

ActiveCN104476357AGuaranteed to be equal in sizeGuaranteed machining accuracy requirementsGrinding machinesGrinding work supportsEngineeringGrinding wheel

The invention discloses a hexagonal center grinding method. The hexagonal center grinding method is characterized by comprising the following steps: step a, an auxiliary tool of a corresponding size is selected, wherein the auxiliary tool is of a regular hexagonal prism structure and the six surfaces of the auxiliary tool are taken as working faces; step b, one external surface of the auxiliary tool is fitted and fixed with the upper surface of a sine disk, the lower end of the sine disk is directly supported on a base, and the middle of the sine disk is supported on the base by use of a block gauge; step c, the hexagonal center is mounted in the central hole of the auxiliary tool and in tight fit with the central hole of the auxiliary tool, and the first small plane of the hexagonal center is ground by use of a grinding wheel; step d, after one small plane of the hexagonal center is ground, the auxiliary tool is rotated so that the corresponding plane of the auxiliary tool can be fitted and fixed with the upper surface of the sine disk, and then the other small planes of the hexagonal center are ground by use of the grinding wheel. As the auxiliary tool adopted in the hexagonal center grinding method is of the regular hexagonal prism structure, the six small planes of the hexagonal center are well kept equal in size and uniform in inclination angle in the peripheral direction.

Owner:CHONGQING LANDAI POWER TRANSMISSION MACHINERY

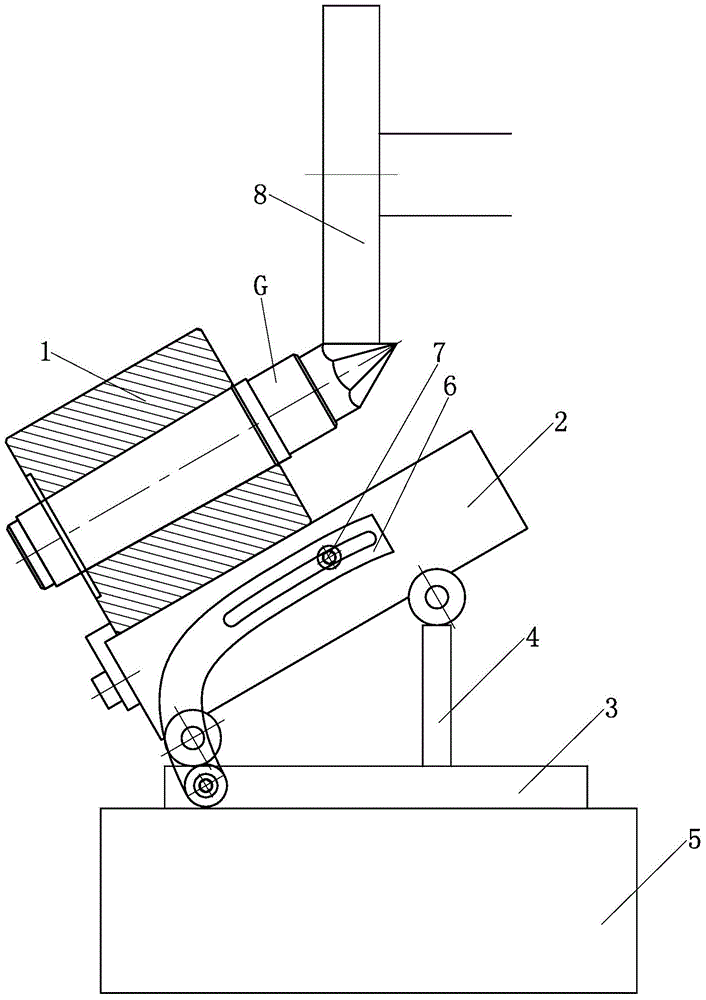

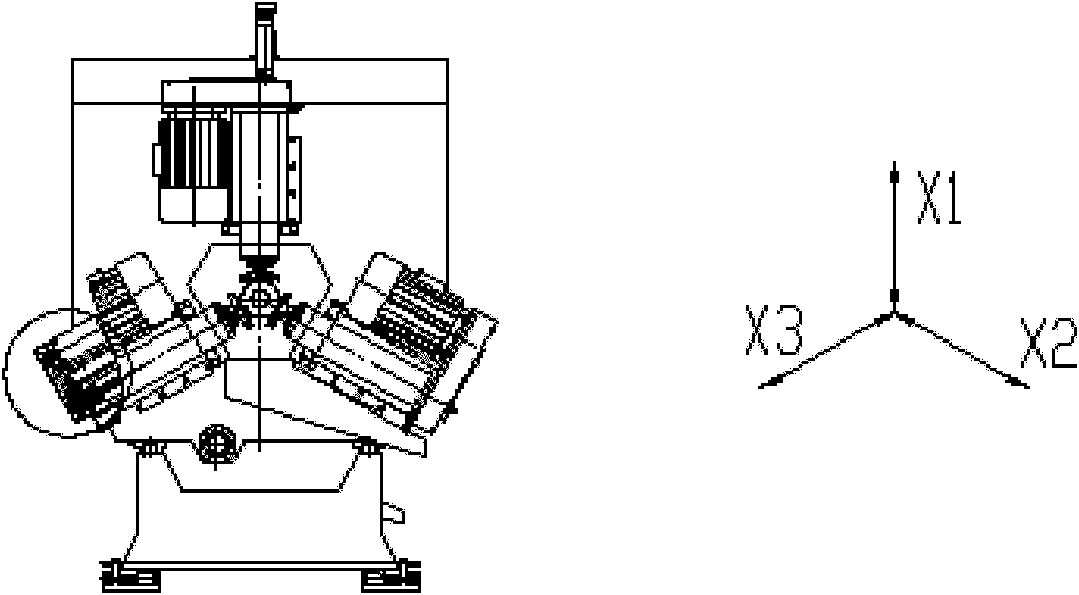

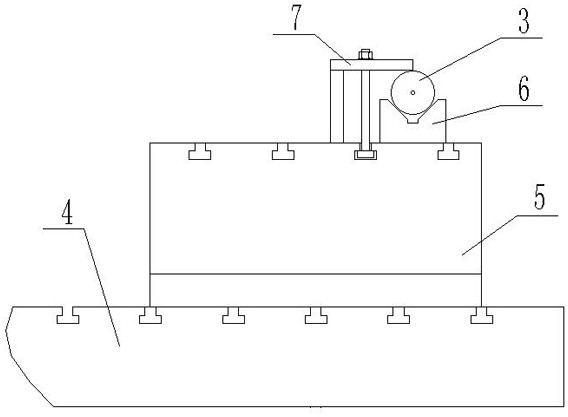

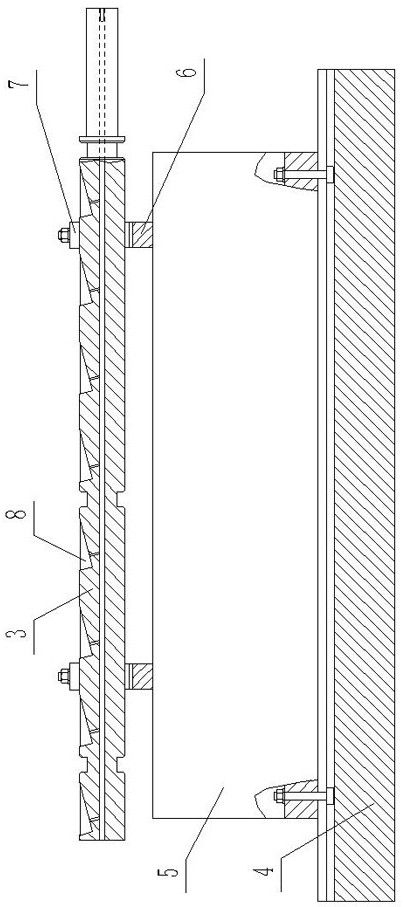

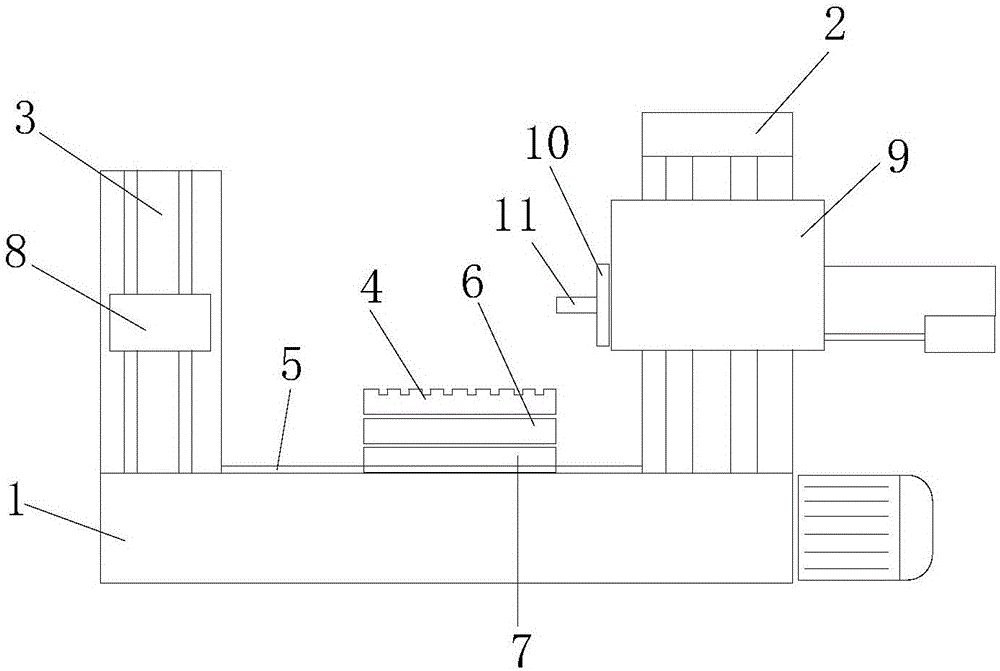

Equipment for processing tooth surface of gear

ActiveCN102151914AGuaranteed machining accuracy requirementsSimple structureGear-cutting machinesGear teethMilling cutterSlide plate

The invention provides equipment for processing a tooth surface of a gear. The equipment mainly comprises a machine base, a large stand column arranged on the machine base, a working turntable for clamping a workpiece, a small stand column which is connected with the working turntable and provided with a tip, and a sliding plate frame which is arranged on the large stand column, capable of movingup and down along a guide rail of the large stand column and used for installing a milling cutter; a screw rod mechanism capable of adjusting a position between the large stand column and the small stand column is transversely arranged between the upper end of the large stand column and the upper end of the small stand column; the large stand column is fixed on the machine base; the sliding plateframe consists of a sliding plate capable of sliding up and down on the large guide rail, and a milling cutter frame fixed on the sliding plate; the working turntable is arranged on a transverse guide rail on the machine base in the north and capable of moving left and right; the lower part of the working turntable is connected with a lower screw rod with a servo motor; and the tip capable of moving up and down on a vertical small guide rail of the small stand column is arranged on the small stand column connected with the working turntable. The equipment for processing the tooth surface of the gear has the characteristics of meeting the requirement of the processing precision of the tooth surface of the gear by test and control adjustment, along with simple structure and convenience for use and installation.

Owner:绍兴骏马机械制造有限公司

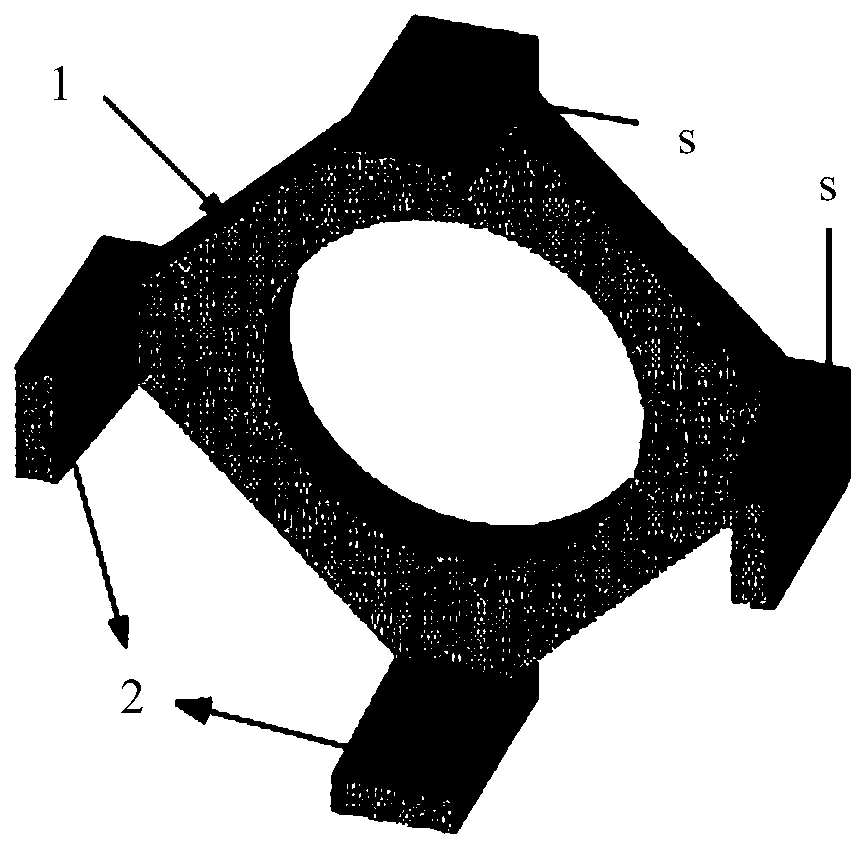

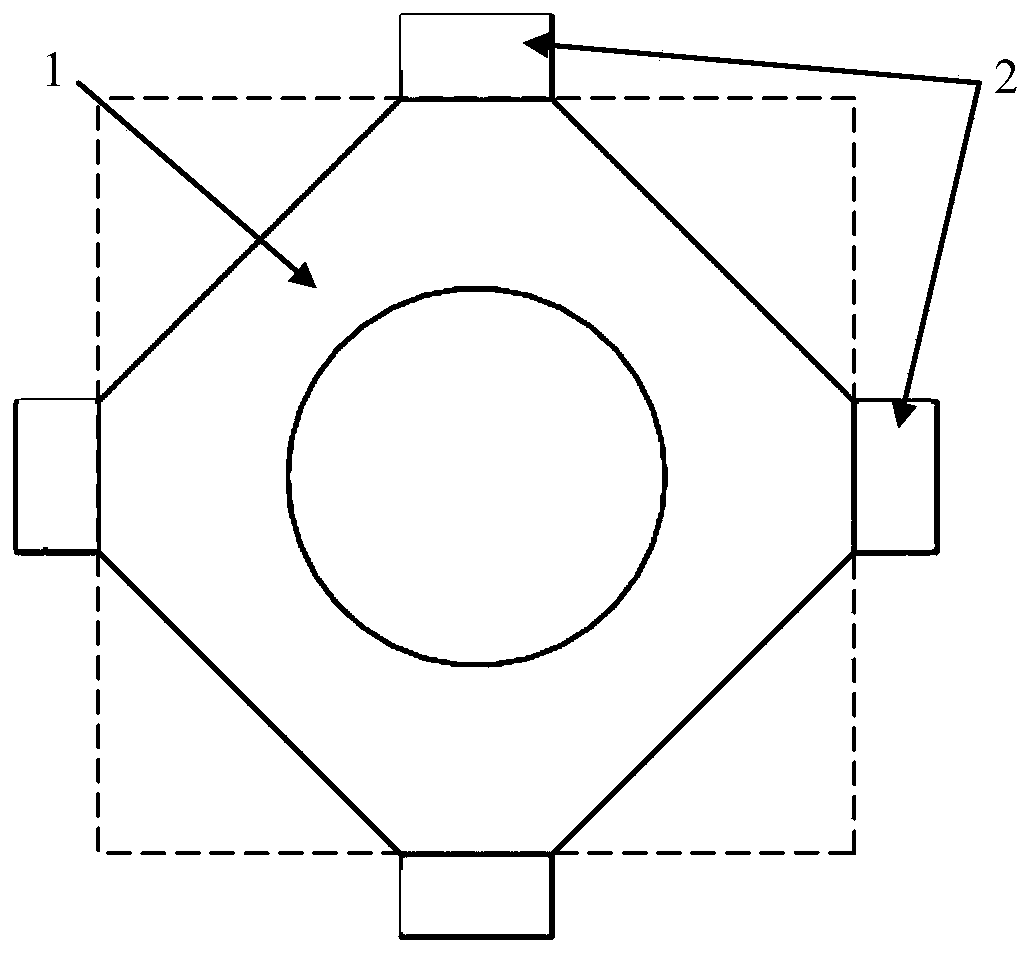

Four-pole armature

InactiveCN109827469AGuaranteed stabilityGuaranteed machining accuracy requirementsElectromagnetic launchersElectromagnetic launchInterference fit

The invention relates to a four-pole armature. The four-pole armature comprises an armature body and armature cantilevers. The armature body is a block body of which the cross section is shaped like acentrally symmetrical octagon. The armature cantilevers are connected with the armature body and are connected to four opposite lateral sides of the armature body, wherein two of the four lateral sides are opposite to the other two lateral sides correspondingly. The length of the lateral sides is the same as the width of the armature cantilevers. The armature cantilevers are flexible arms and extend backwards in the direction parallel to the armature moving direction from the armature body. The tail portions of the armature cantilevers are closer to the axis of the armature body than the headportions of the armature cantilevers. The armature cantilevers are in interference fit with a track in an electromagnetic emitter. The armature cantilevers extending outwards from the armature body are arranged, and the flexible armature cantilevers are in interference fit with the track, so that sufficient contact area and contact pressure between the armature and the track can be obtained whenthe armature is installed, the problems that the armature and the track are separated due to phenomena like abrasion and ablation of the contact surface between the armature and the track in the electromagnetic emission process are solved, and the stability of electromagnetic emission is ensured.

Owner:AIR FORCE UNIV PLA

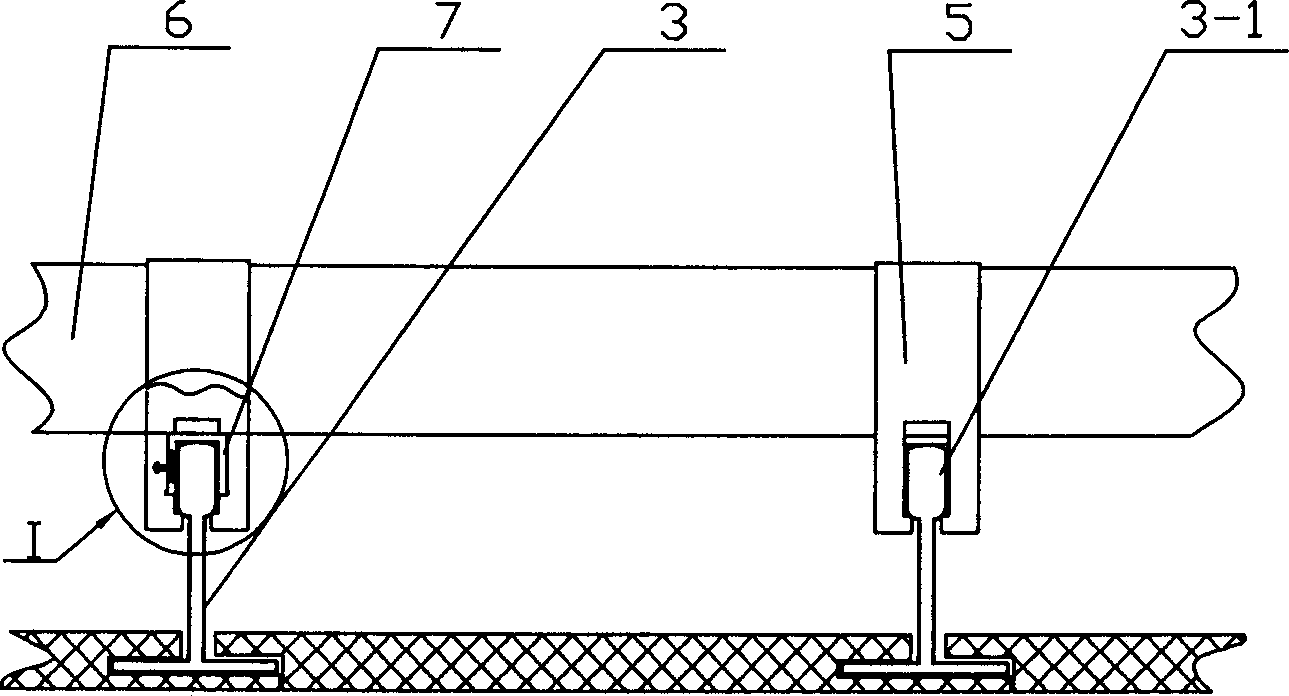

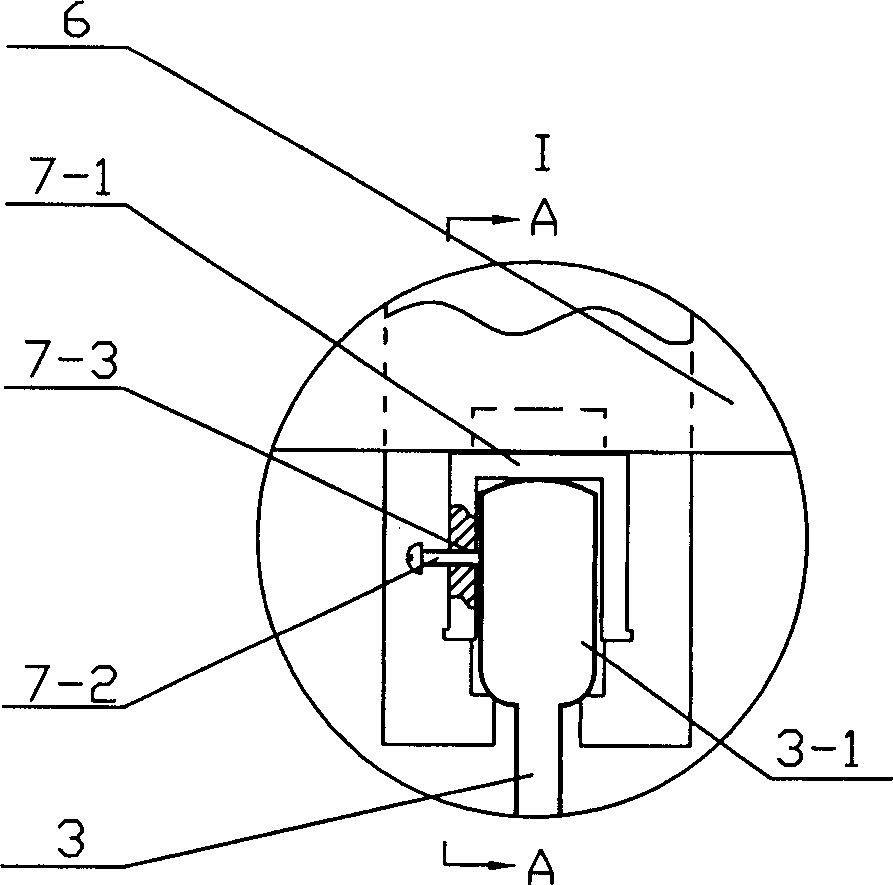

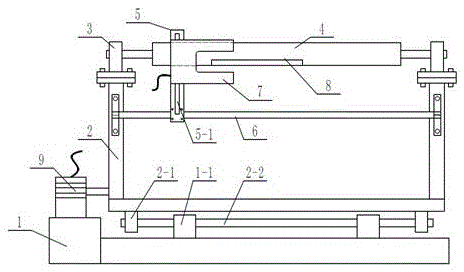

Automatic follow machining method of numerically controlled machine tool

ActiveCN102081375AGuaranteed machining accuracy requirementsNumerical controlNumerical controlLong axis

The invention discloses an automatic follow machining method of a numerically controlled machine tool. In the method, deformation displacement of a workpiece to be machined in the vertical direction is detected in real time by using a measuring device; an interruption subroutine is called according to the displacement; and a position of a cutter in the vertical direction is adjusted to guarantee the machining accuracy. By the automatic follow machining method of the numerically controlled machine tool provided by the invention, a follow workpiece supporting mechanism can be saved when long-axis parts are machined, so that the problem caused by supporting variation of the follow workpiece supporting mechanism is solved, and the machining accuracy requirement can be met.

Owner:NANJING CNC MACHINE TOOL

Sectional machining structure of large stamping die set

InactiveCN104339185AGuaranteed hole position accuracyGuaranteed machining accuracy requirementsShaping toolsPositioning apparatusEngineeringMachining

The invention discloses a sectional machining structure of a large stamping die set. The sectional machining structure comprises a plurality of sub die plates for machining the large stamping die set, wherein every two adjacent sub die plates are detachably and fixedly connected into a female die plate, and at least one common locating reference is arranged on each of the opposite end faces at intervals when every two adjacent sub die plates are connected. The structure meets machining precision requirements, can effectively reduce the machining cost and the machining difficulty, improve the machining safety at the same time, is convenient to carry, is applicable to general machining centers, and is not limited to an ultra large machining center.

Owner:JIANGSU BOJUN IND TECH

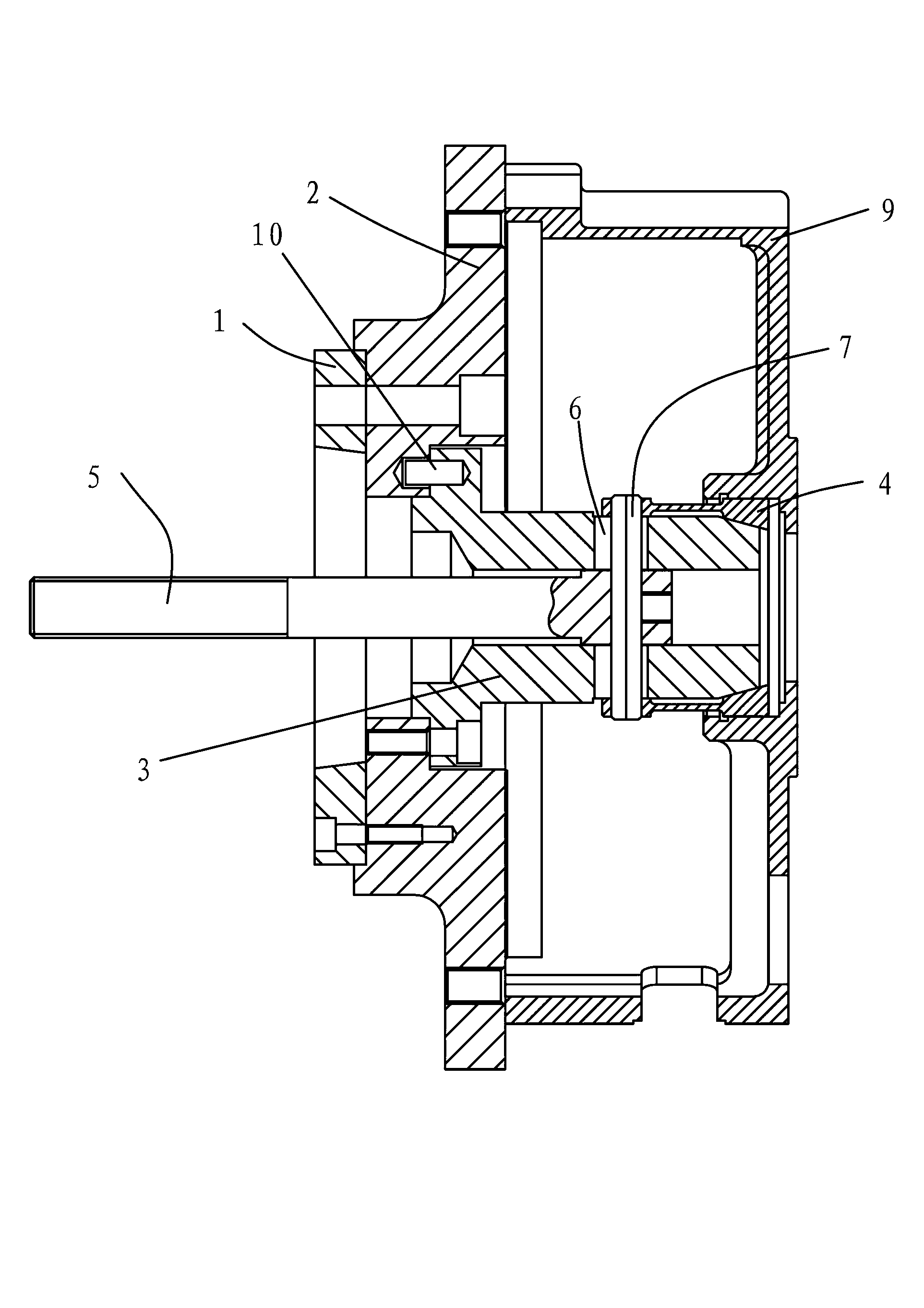

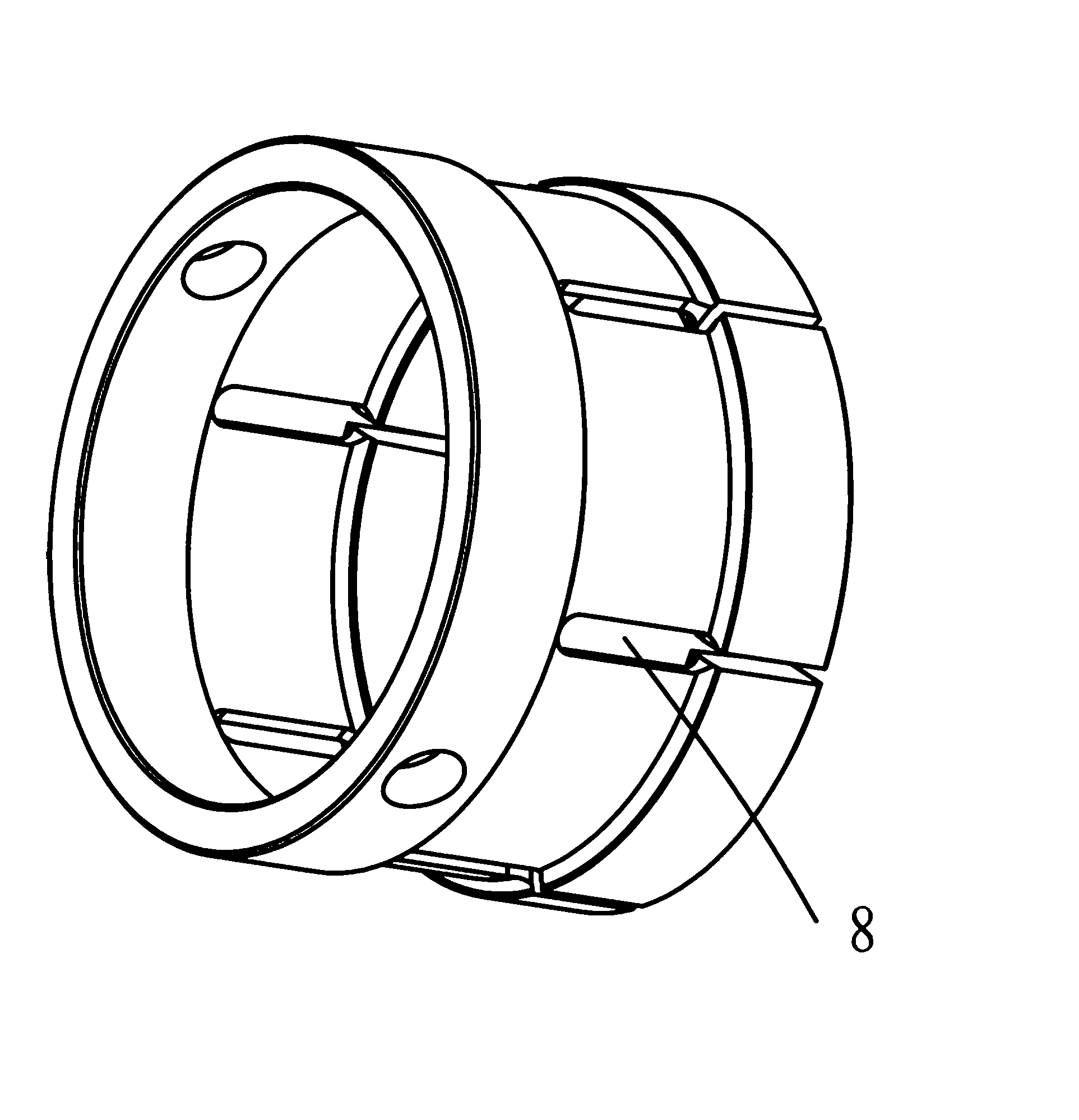

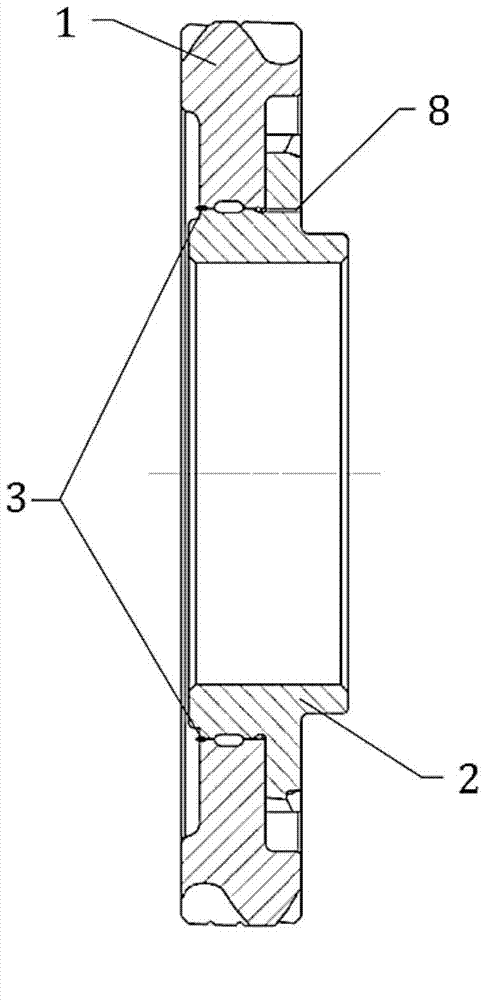

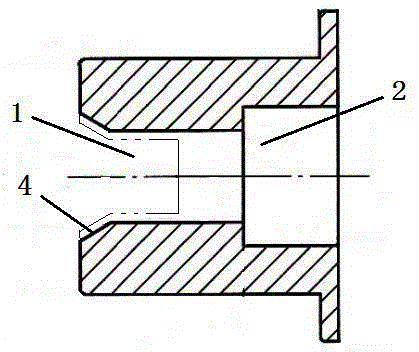

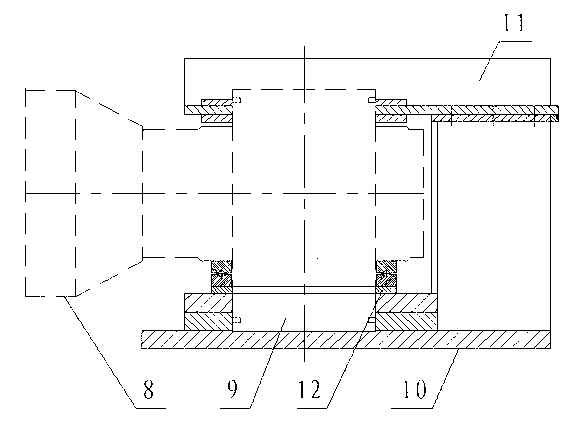

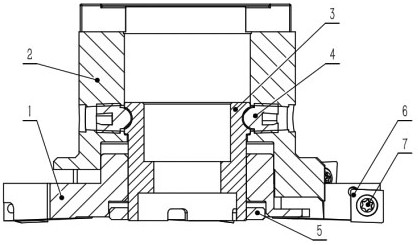

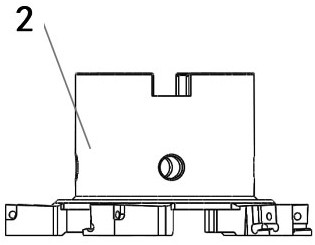

Clamp for machining motor end cover

InactiveCN103009128AGuaranteed machining accuracy requirementsReasonable designPositioning apparatusMetal-working holdersElectric machineryEngineering

The invention relates to a clamp for machining a motor end cover. The clamp comprises an end plate, a spindle, a jacket and a pull rod, wherein the end plate is axially hollow; the spindle is axially hollow; the inner end of the spindle is arranged on the end plate; the spindle and the end plate are guaranteed to be on the same axis; the spindle is radially provided with a through groove; a pin is arranged in the through groove; the width of the through groove in the axial direction of the spindle is greater than the diameter of the pin; the outer end head of the spindle is sleeved in the jacket; and two end heads of the pin, extending out of the through groove, are connected with the end head in the jacket. The clamp is rational in design; one clamp can be used for producing motor end covers of different types; the frequency and the time for replacing the clamp are saved; the production efficiency is increased; and the machining accuracy requirement of the end cover can also be guaranteed excellently. The time for mounting the end cover on the clamp and disassembling the end cover from the clamp is also greatly shortened, and the clamp is extremely convenient.

Owner:KINETEK DE SHENG SHUNDE MOTOR CO LTD

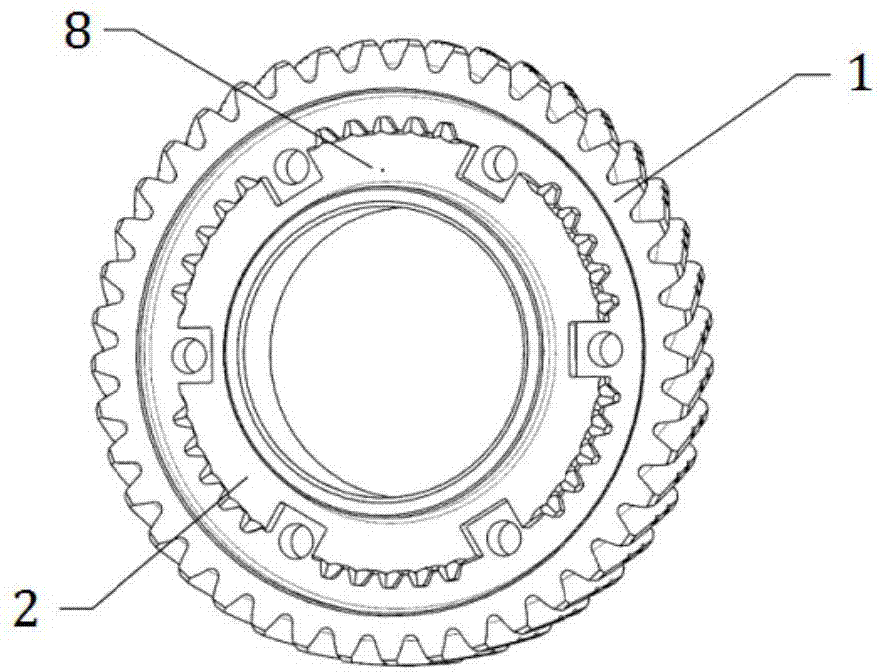

Optimization welding method and structure for gear and conjunction gear

ActiveCN104722940AAvoid fusesEven by forceWorkpiece edge portionsWelding apparatusEngineeringWelding process

The invention provides an optimization welding method for a gear and a conjunction gear, and belongs to the field of transmission manufacturing. The inner side of the to-be-welded position of the matched surface of the shifting gear and the conjunction gear is sequentially provided with a first cavity for reducing the grinding area of the matched surface and a second cavity communicated with the first cavity. The second cavity is communicated with the opposite side of the to-be-welded position of the matched surface, and then exhausting in the welding process is achieved. The requirements for assembly accuracy of a part are met, machining cost is reduced, finally the effects that the welding position is evenly stressed and welding stability is high after welding is finished are achieved, a formed welding joint is located on the outer side of the end face of the part, and welding work and the quality inspection of the welding position are facilitated.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

Method for machining multiple rows of inclined grooves in shaft parts

ActiveCN113828835AGuaranteed Depth DimensionsGuaranteed Angular DimensionsMeasurement/indication equipmentsMilling equipment detailsNumerical controlStructural engineering

According to the machining method for the multiple rows of inclined grooves in shaft parts. A numerical control boring and milling machine with a rotating table is adopted, the depth size and the angle size of the inclined grooves are guaranteed through auxiliary measurement of a measuring block, a strip-shaped gauge block and a coordinate system of the numerical control boring and milling machine are controlled to rotate synchronously, so that the rotation angles of the shaft parts are corrected through the alignment plane of the strip-shaped gauge block, and the angle size between two adjacent rows of inclined grooves in the circumferential direction of the shaft parts is ensured. According to the method, tools such as the measuring block and the strip-shaped gauge block match with a numerical control boring and milling machine for use, so that various sizes, which are difficult to control, of the multiple rows of inclined grooves on the shaft parts can be measured and corrected, and finally, the machining precision requirement of the multiple rows of inclined grooves on the shaft parts is ensured, the defect that the machining precision of multiple rows of inclined grooves in the shaft parts is difficult to guarantee by a traditional machining method is overcome, and the machining method is integrally simple, reliable, easy to operate, free of special tools, free of pollution, energy-saving, environment-friendly and convenient to apply and popularize.

Owner:CITIC HEAVY INDUSTRIES CO LTD

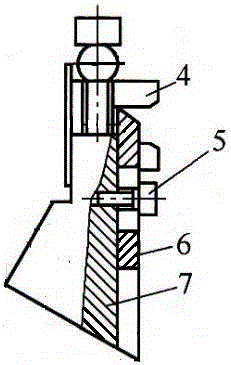

Chamfer grinding device

InactiveCN105234766AIncrease contactPrecise positioningEdge grinding machinesGrinding carriagesEngineeringMachining

The invention discloses a chamfer grinding device. The chamfer grinding device comprises an L-shaped knife edge block, a fixing screw, a pressing rod, a pressing screw and a base. A kidney-shaped groove is formed in one end of the knife edge block, and a knife edge is arranged at the other end of the knife edge block. A V-shaped groove is formed in the clamping end face of the base, and a 60-degree angle is formed between the bottom end face of the base and the machining plane. The pressing rod presses a workpiece into the V-shaped groove of the base through the two pressing screws on the two sides, the knife edge end of the knife edge block is tightly attached to the groove face of the upper end of the workpiece, and the other end of the knife edge block is fixed to the base through the kidney-shaped groove and the fixing screw. A 90-degree V-shaped groove is formed in the clamping end face of the base. The 60-degree knife edge is arranged at the knife edge end of the knife edge block. The fixing screw is a hexagon socket head screw M5*12. The pressing screws are hexagon socket head screws M8*40. The chamfer grinding device is simple in structure and quick to install; machining accuracy requirements are guaranteed, machining procedures are simplified, and meanwhile the machining period is shortened; and production efficiency is greatly improved.

Owner:孙双彪

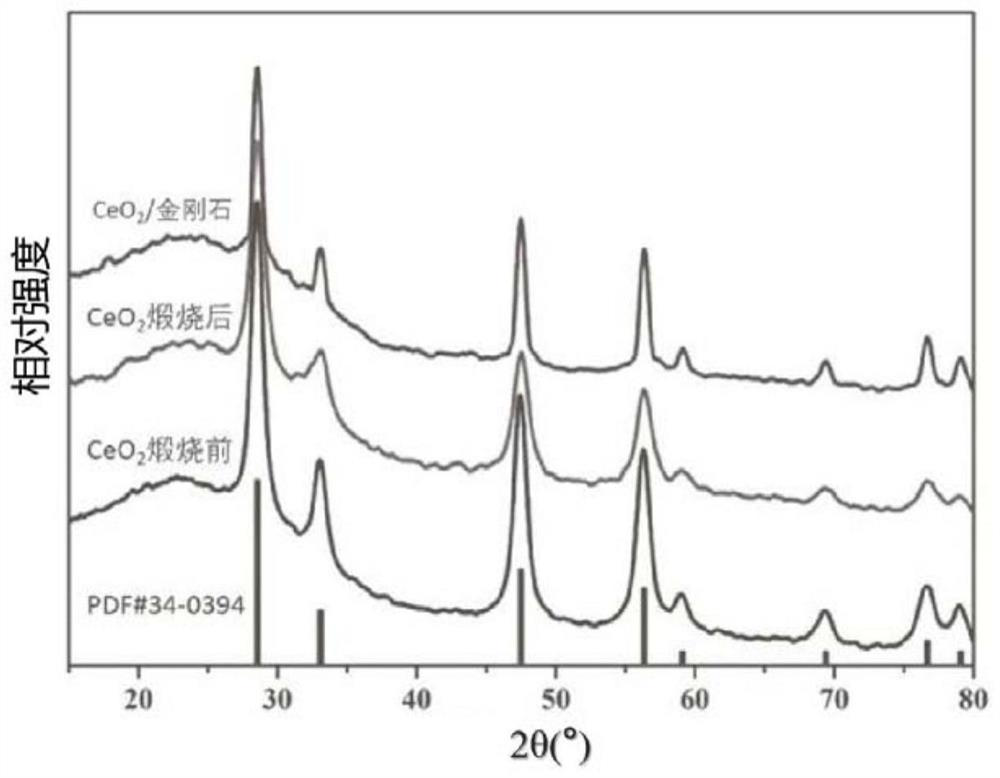

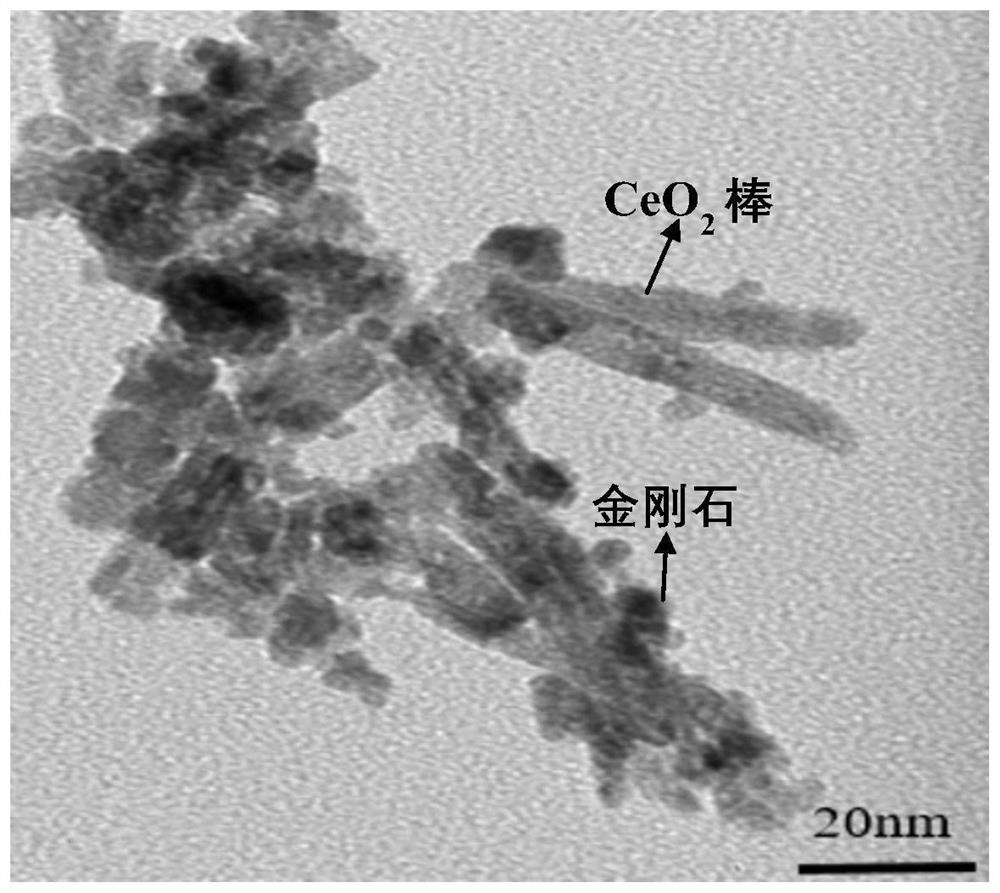

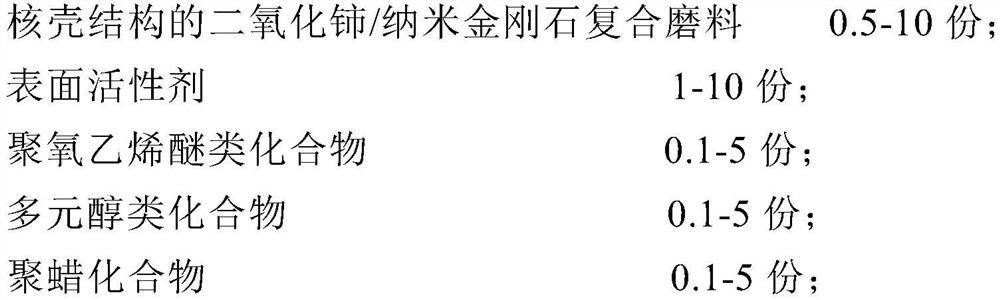

Core-shell-structured cerium dioxide/nano-diamond composite abrasive material, preparation method thereof, and polishing solution for ultra-precision polishing of sapphire

ActiveCN113563843AEasy to scratchAvoid scratchesOther chemical processesPolishing compositions with abrasivesSurface roughnessSapphire

The invention provides a cerium dioxide / nano-diamond composite abrasive with a core-shell structure, a preparation method thereof, and a polishing solution for ultra-precision polishing of sapphire. The cerium dioxide / nano-diamond composite abrasive material with the core-shell structure is a cerium dioxide nano-rod on which nano-diamond particles grow, and the novel composite abrasive material not only can prevent diamond from scratching sapphire and remarkably reduce the surface roughness of the sapphire, but also can effectively improve the polishing efficiency. The invention also discloses the polishing solution for ultra-precision polishing of sapphire. The cerium dioxide / nano-diamond abrasive in the polishing solution is uniformly dispersed, is not easy to agglomerate, is easier to form a stable turbid liquid system, and is uniformly dispersed and not layered for a long time.

Owner:ZHEJIANG AUFIRST MATERIAL TECH CO LTD

Machining method for trapezoidal threaded hole chuck claw

ActiveCN107538184ASolve the problem of machining accuracyGuaranteed machining accuracy requirementsChucksMachining processEngineering

The invention discloses a machining method for a trapezoidal threaded hole chuck claw and relates to machining methods. Through the machining method, the problem that through an existing machining process, the machining precision of a trapezoidal threaded hole chuck claw cannot be ensured is solved. The machining method comprises the following steps of rough milling, rough drilling, rough boring,heat treatment, grinding of an end face D, finish milling, finish hole turning, cutting, finish boring, planing of antiskid teeth, heat treatment of the antiskid teeth, chamfering of all edges and printing of a figure number. The machining method is used for machining of the trapezoidal threaded hole chuck claw.

Owner:HARBIN TURBINE +1

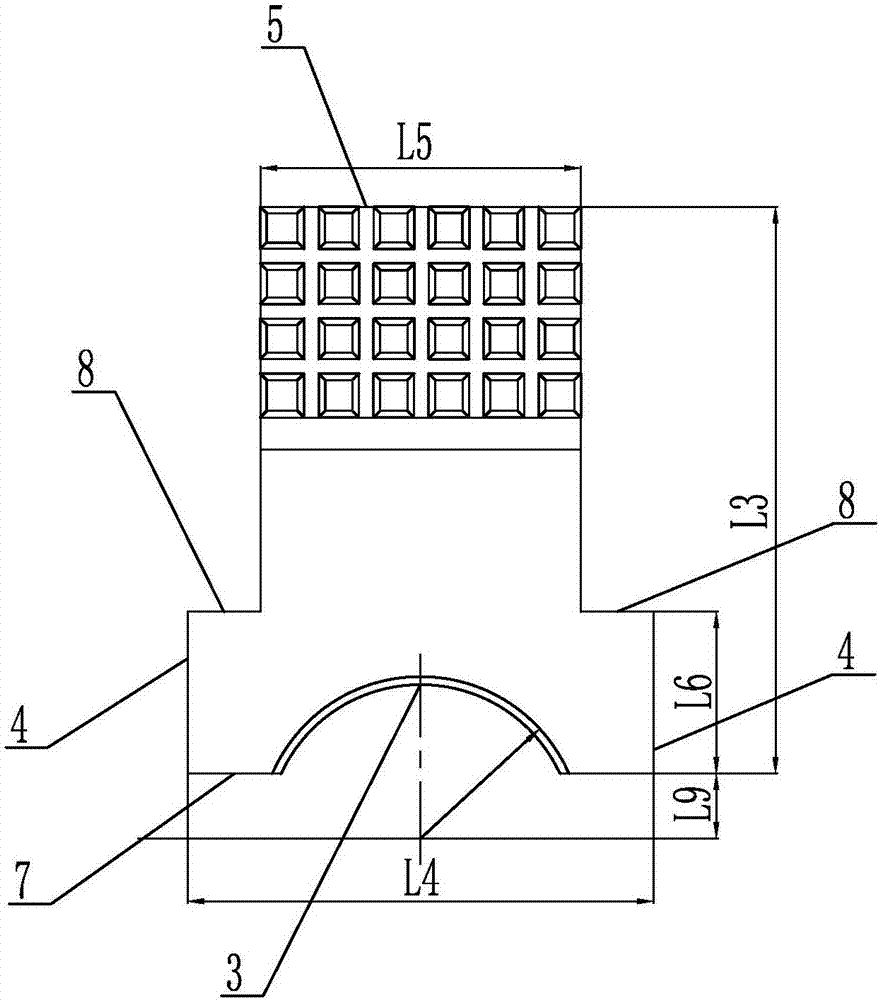

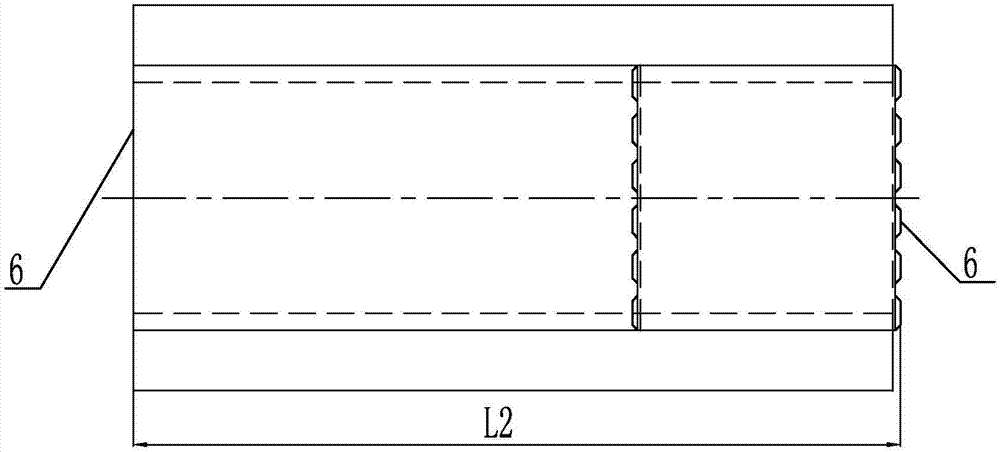

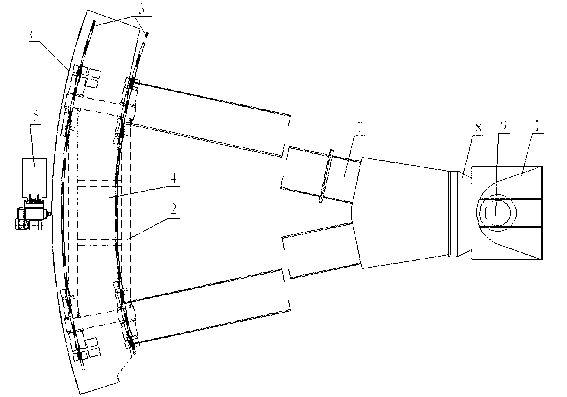

Processing device of lateral arc forming machine for large arc gate panel

InactiveCN103317173AControllable running forward speedEasy to controlGeometric arrangementsFeeding apparatusNumerical controlEngineering

The invention discloses a processing device of a lateral arc forming machine for a large arc gate panel, belonging to the technical field of arc gate body processing. The processing device comprises an arc track and a tool hinged seat, wherein a travelling trolley capable of placing an arc gate body is arranged on the arc track; a movable plane miller is arranged on the outer side of an outer arc of the arc track; a milling head cutter of the movable plane miller is vertical to the arc gate body; an arc gate supporting arm capable of being connected with the arc gate body is arranged on the inner side of an inner arc of the arc track; the arc gate supporting arm is hinged on the tool hinged seat; a hydraulic control system for driving the travelling trolley to run is arranged in the travelling trolley; the arc gate body can run along the arc track by taking the tool hinged seat as a center on the travelling trolley. According to the processing device, the technical problem that the large arc gate panel is processed in the absence of a numerical control boring and milling machine is solved and the safety risk of high-altitude operation of a vertical tool and the high input of the numerical control boring and milling machine can be avoided.

Owner:CHINA GEZHOUBA GRP MECHANICAL & ELECTRICAL CONSTR

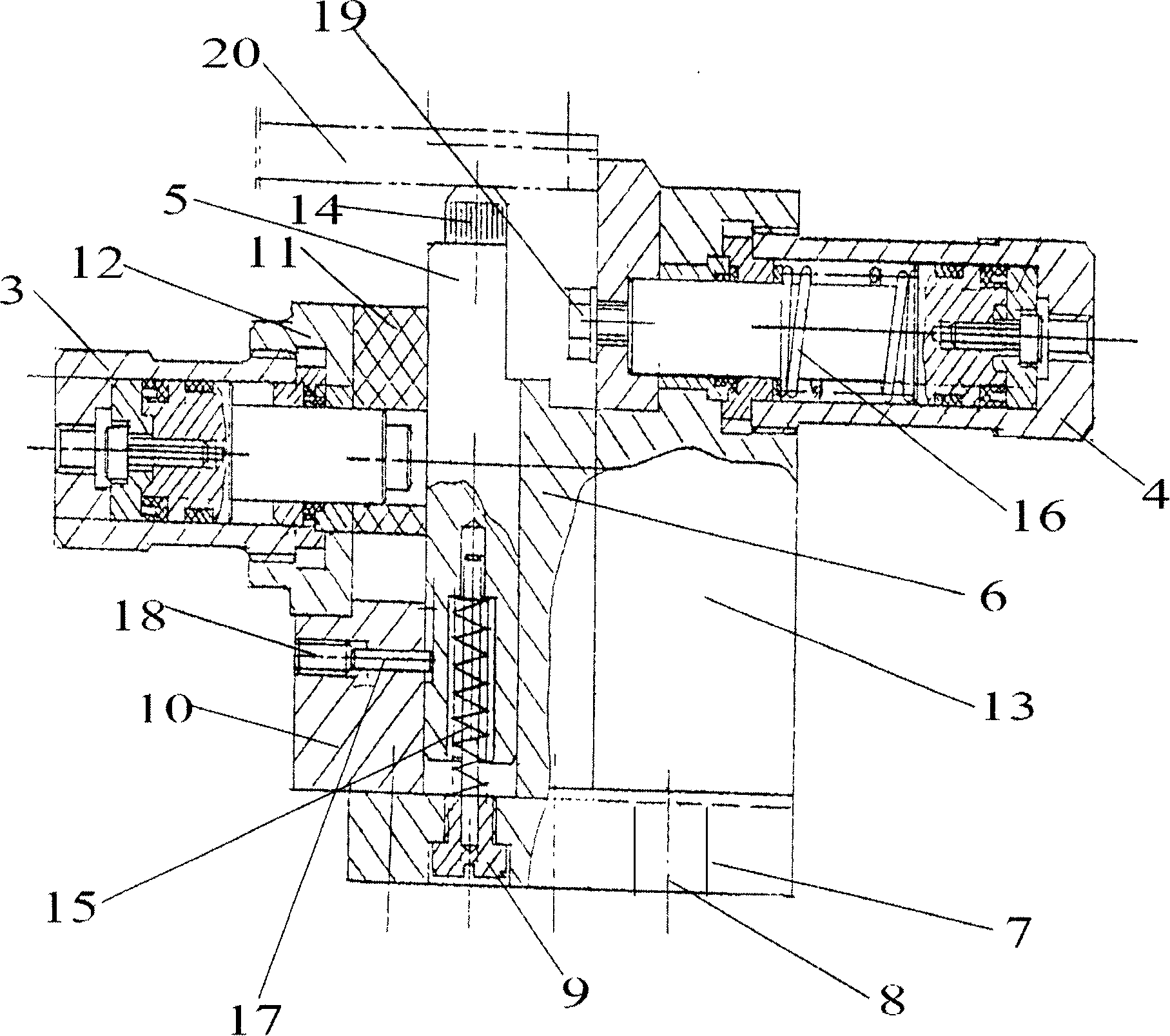

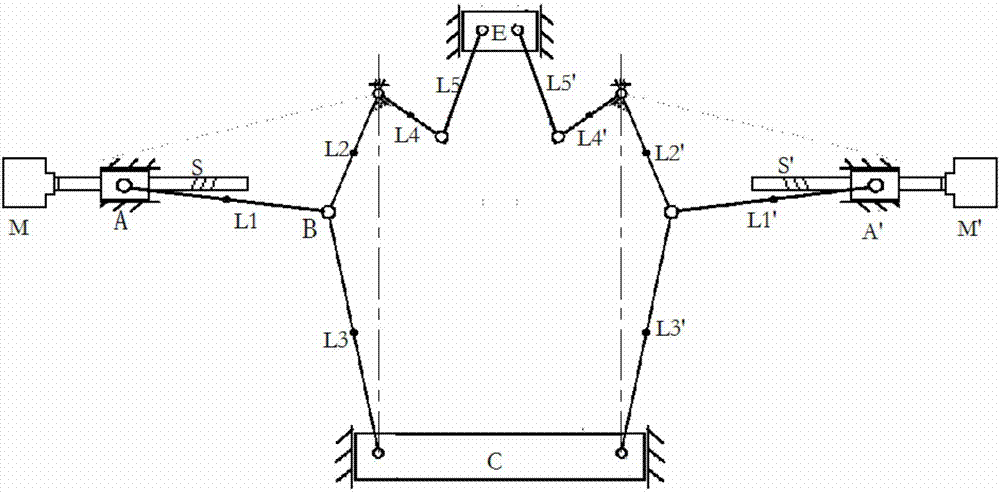

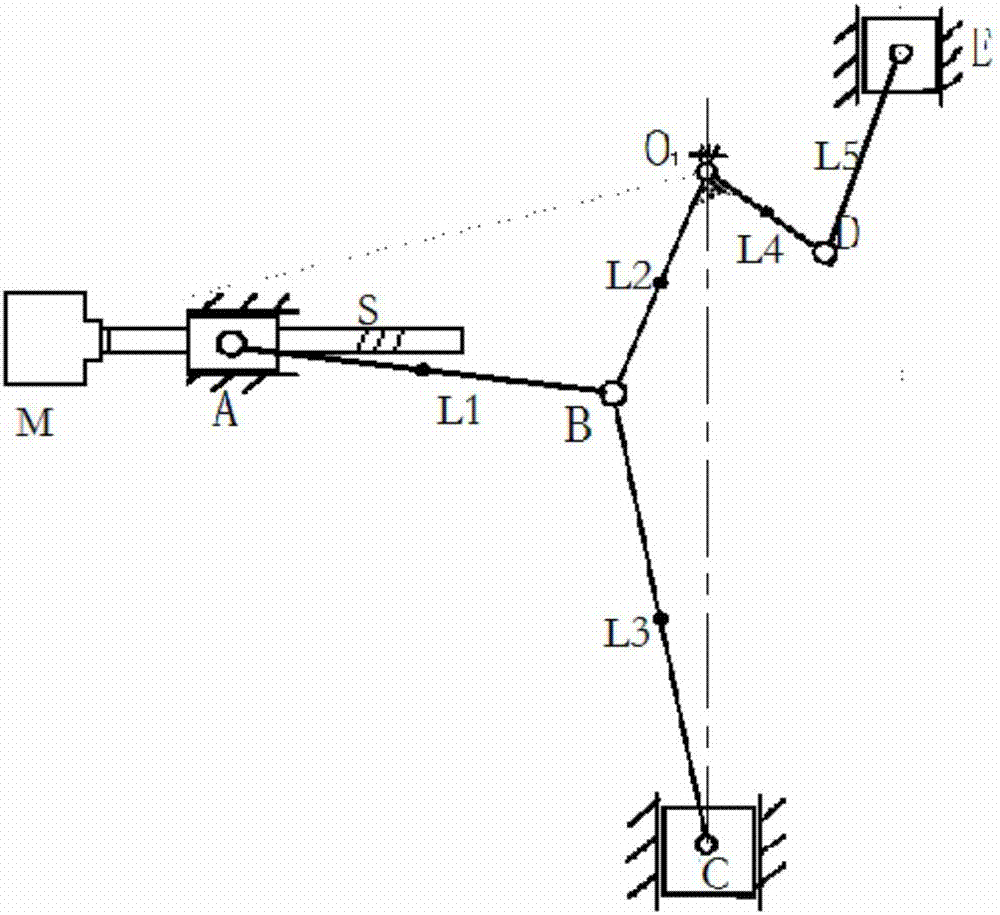

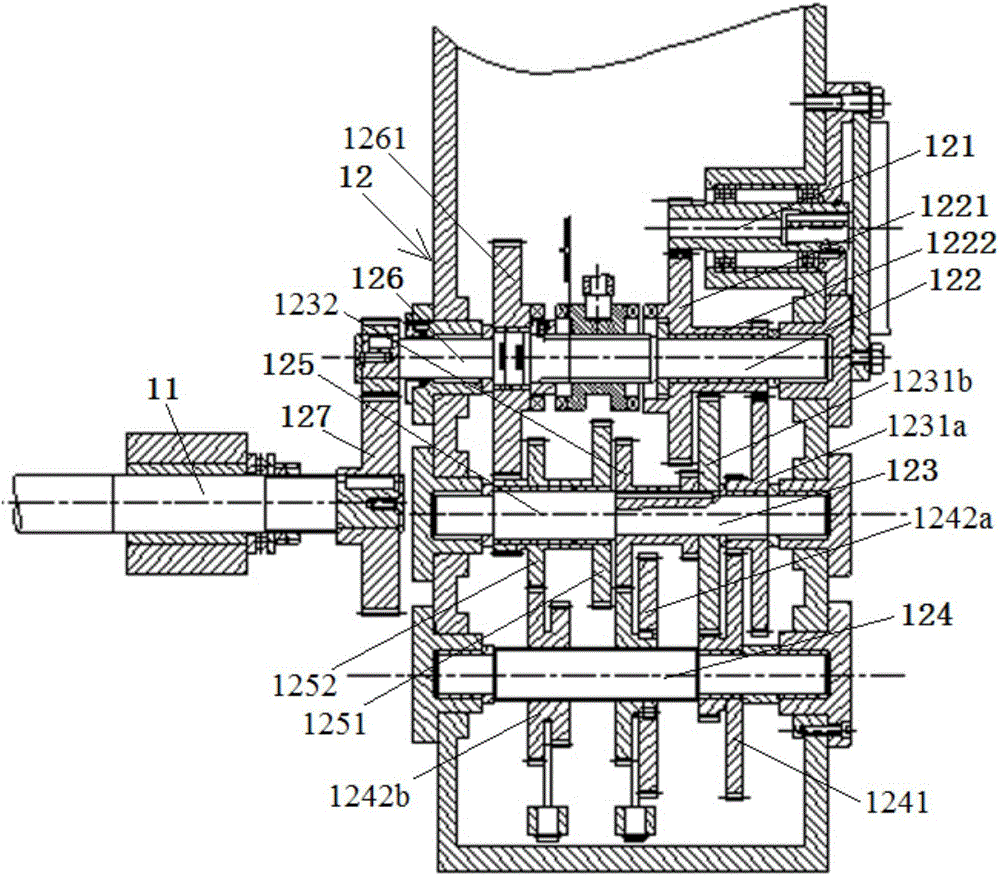

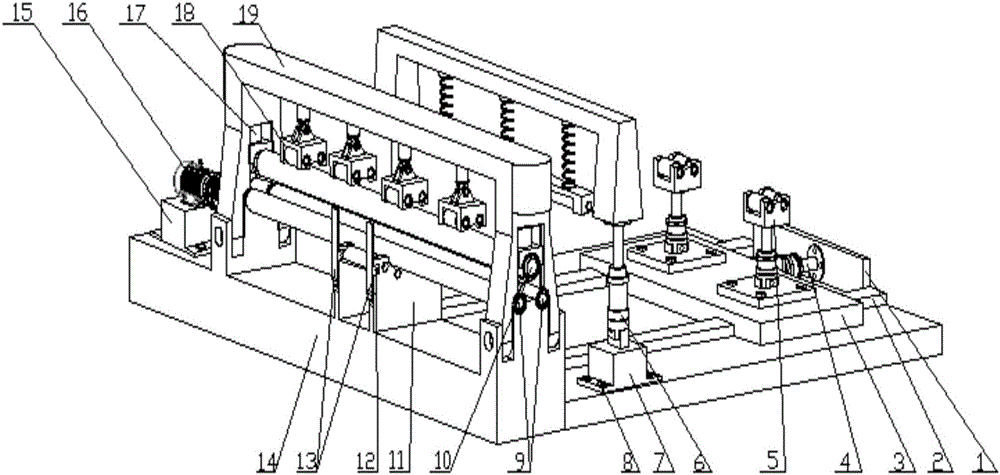

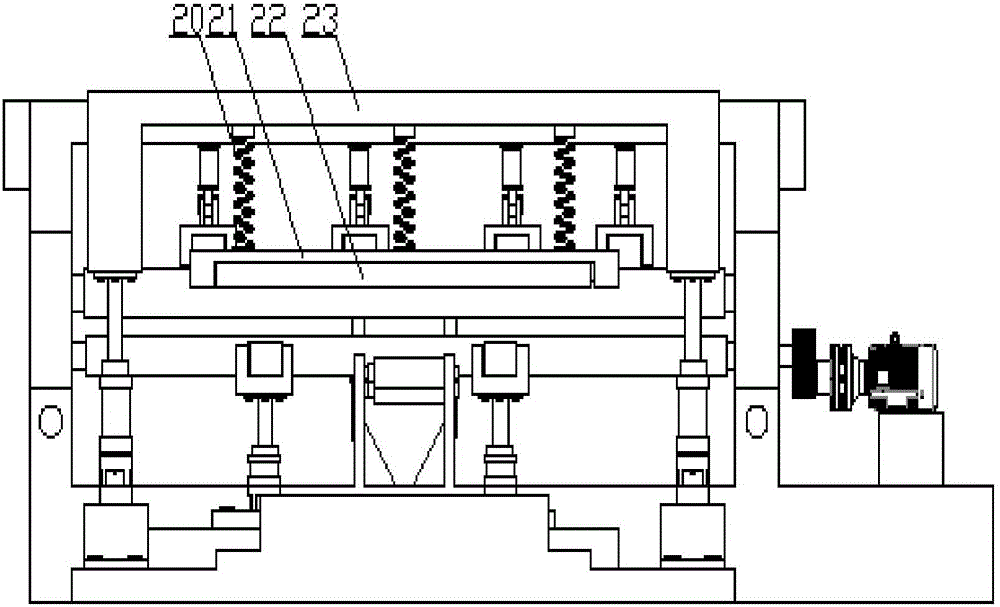

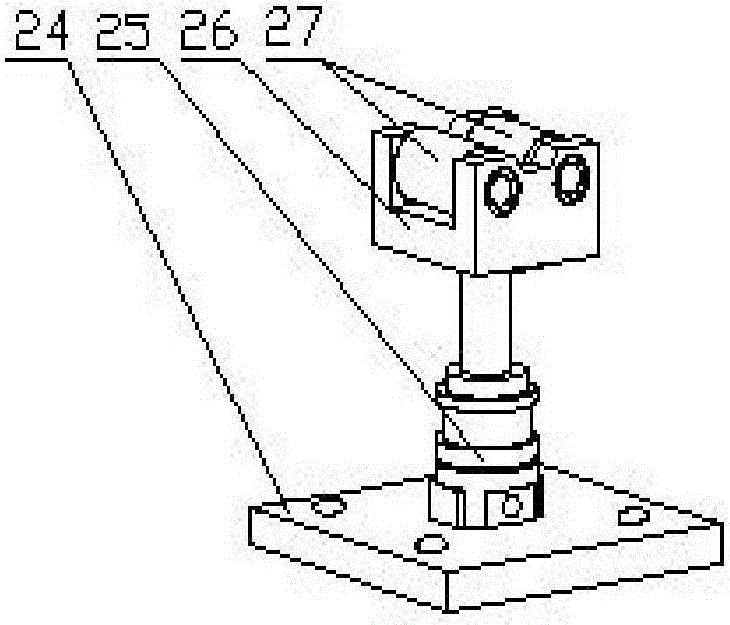

Mechanical servo main transmission device of large-tonnage high-speed fine blanking machine

The invention relates to a mechanical servo main transmission device of a large-tonnage high-speed fine blanking machine. The mechanical servo main transmission device comprises a main slide block, an auxiliary slide block and a drive mechanism, wherein the main slide block and the auxiliary slide block can only linearly move, and the drive mechanism can drive the main slide block and the auxiliary slide block to move at the same time. The drive mechanism comprises a servo motor, a lead screw connected with an output shaft of the servo motor, a slide block arranged on the lead screw in a sleeving manner and can only linearly move, a connection rod L1, a connection rod L2, a connection rod L3, a connection rod L4 and a connection rod L5. One end of the connection rod L1, one end of the connection rod L2 and one end of the connection rod L3 are hinged to the same point. The other end of the connection rod L1 and the other end of the connection rod L3 are hinged to the slide block and the main slide block correspondingly. The other end of the connection rod L2 is a fixed hinge point. One end of the connection rod L4 and the connection rod L2 are fixed into a whole, and the other end of the connection rod L4 is hinged to one end of the connection rod L5, and the other end of the connection rod L5 is hinged to the auxiliary slide block. The movement directions of the main slide block and the auxiliary slide block are opposite all the time. The device is good in dynamic characteristic, reasonable in arrangement, small in vibration, high in machining precision and capable of balancing inertia force.

Owner:WUHAN UNIV OF TECH

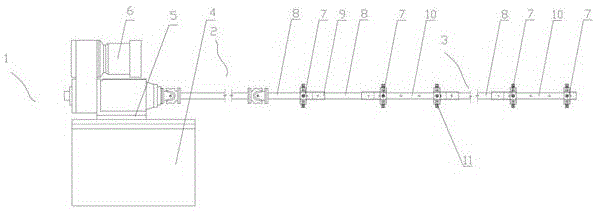

A method for boring a rotary hinge water seal seat using a rotary hinge water seal seat boring device

ActiveCN104325168BFulfill process requirementsGuaranteed machining accuracy requirementsBoring/drilling machinesTransfer systemMechanical engineering

The invention discloses a rotating hinge water seal seat boring device. The rotating hinge water seal seat boring device comprises a power system, a force transfer system and a boring system; the power system comprises a sliding table seat, a sliding table and a boring head, wherein the boring head is connected with the sliding table and slides along the sliding table seat, the boring head is connected with the force transfer system, and the force transfer system is connected with the boring system; the boring system comprises a plurality of support seats, connecting rods, a connecting sleeve and a boring rod, wherein a radial adjusting mechanism is arranged on each support seat, the boring rod corresponds to an axial hole to be bored, and the two ends of the boring rod are respectively, coaxially and rotatably connected with the radial adjusting mechanism on each support seat; every two adjacent support seats are respectively and rotatably connected through the connecting rod. The invention also discloses a method for boring a rotating hinge water seal seat by using the boring device. The boring device and the boring method are simple in structure and convenient to use, the coaxiality of each hinge axle hole of the rotating hinge water seal seat is ensured by means of the coaxiality of the support seats, and the machining precision requirement can be met.

Owner:SINOHYDRO BUREAU 12 CO LTD

Adjustable face-and-side cutter head and adjusting method

PendingCN113145912AMeet milling requirementsGuaranteed machining accuracy requirementsMilling cuttersPositioning apparatusGroove widthMilling cutter

The invention relates to the field of machining, in particular to an adjustable face-and-side cutter head and an adjusting method. The adjustable face-and-side cutter head can implement one-time machining of grooves with different widths under the condition of the same diameter, the machining time can be saved to the maximum extent by adjusting the groove widths, and the production efficiency is improved. In actual trial cut for machining, an adjustable three-sided blade can achieve the same milling effect as a traditional fixed-width three-sided blade, and the milling requirements for various groove widths can be met. Meanwhile, due to the fact that the width is adjustable, the economic effect that one cutter can be used instead of various face and side cutter heads is achieved. As the groove width can be adjusted, the efficiency can be maximized according to the design requirement of the actual groove width of the part. The adjustable three-sided blade changes the knowledge on milling with a traditional fixed three-sided blade, deep-groove milling is more easier and direct to carry out. The groove width can be adjusted at will, and meanwhile the machining precision and efficiency requirements of parts can be effectively met.

Owner:西安海纳精密机械有限公司

Milling groove clamping device of sleeve-class part

ActiveCN103121177AStable clamping forceImprove clamping qualityMetal working apparatusPistonClip device

The invention relates to a milling fixture, in particular to a milling groove clamping device of a sleeve-class part. The milling groove clamping device of the sleeve-class part comprises a fixed base, a left vertical plate and a right vertical plate, wherein the left vertical plate and the right vertical plate are fixedly connected on the fixed base, a horizontal supporting plate fixedly connected between the left vertical plate and the right vertical plate, an air cylinder fixedly connected on the right vertical plate, a double-pushrod mechanism connected on a piston of the air cylinder, a power transmission mechanism hinged on the left vertical plate, a positioning mechanism fixedly connected on the horizontal supporting plate and an automatic feeding and discharging mechanism arranged on the right side of the positioning mechanism. By adopting the technical scheme, the machining accuracy requirement of the part can be guaranteed, clamping force is stable, clamping quality is high, the speediness and automation of the clamping of the part are achieved, production efficiency is improved greatly and working intensity of workers is relieved greatly.

Owner:佛山市顺德区上锐机械有限公司

Precise linear cutting clamping device for titanium alloy weak-rigidity piece and working method of precise linear cutting clamping device

ActiveCN112276267AHigh precisionImprove surface roughnessElectrical-based auxillary apparatusWire cuttingSurface roughness

The invention relates to a precise linear cutting clamping device for a titanium alloy weak-rigidity piece and a working method of the precise linear cutting clamping device, and belongs to the technical field of precise electric machining. The clamping device comprises an upper cover, an E-shaped lower cover, a positioning pin and a fixing screw. The invention provides a machining method of a modern process, which can effectively meet the requirements of the size precision, the surface roughness and the parallelism of the weak-rigidity titanium alloy thin-wall piece, and designs a precise clamping device which can be applied to slow-feeding wire cutting machining and can ensure the machining precision and the size requirement. The main content of the invention includes that the thin-wallpiece with the linear cutting allowance after a milling process is installed in the designed clamping device for a slow-feeding wire cutting process, and the technological process of thinning a wing plate of the thin-wall piece to 0.2 mm is completed. The machining precision and the surface roughness of the thin-wall piece are improved by the precise linear cutting clamping device for the titaniumalloy weak-rigidity piece; and the device is suitable for machining the special-shaped curved surface thin-wall piece which cannot be completed by a traditional process.

Owner:CHANGCHUN UNIV OF SCI & TECH

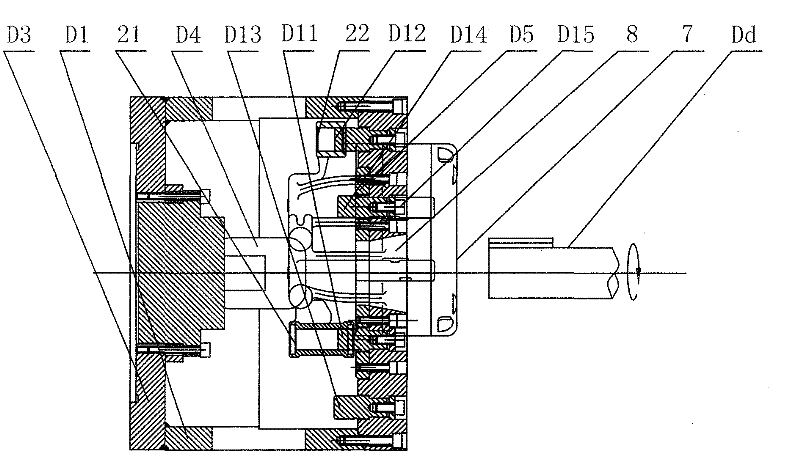

Special machine tool for roller boring

InactiveCN106513764AGuaranteed machining accuracy requirementsCompact designDriving apparatusBoring/drilling componentsDrive shaftEngineering

The invention discloses a special machine tool for roller boring, and the special machine tool is an improved horizontal boring mill. The special machine tool comprises a lathe bed. The lathe bed is provided with a front stand column, a rear stand column and a workbench. An upper sliding base and a lower sliding base are sequentially arranged below the workbench. A main shaft box is arranged on the front stand column. A rear supporting frame is arranged on the rear stand column. A facing head is arranged on the end face of the main shaft box. The main shaft box is internally provided with a speed change transmission structure used for driving the movement of a main shaft. An output shaft of the speed change transmission structure is in transmission connection with the main shaft. The speed change transmission structure comprises an input shaft, an input transmission shaft, a first-level speed change shaft, a second-level speed change shaft, an output transmission shaft and the output shaft. The input shaft is in transmission connection with an outside power output shaft, the input transmission shaft is in transmission connection with the input shaft, the first-level speed change shaft is in transmission connection with the input transmission shaft, the second-level speed change shaft is in transmission connection with the first-level speed change shaft and the output transmission shaft, and the output transmission shaft is in transmission connection with the output shaft. The special machine tool can guarantee boring machining precision and also has the beneficial effects of being simple in structure, low in noise and the like.

Owner:SHANGHAI UNIV OF ENG SCI

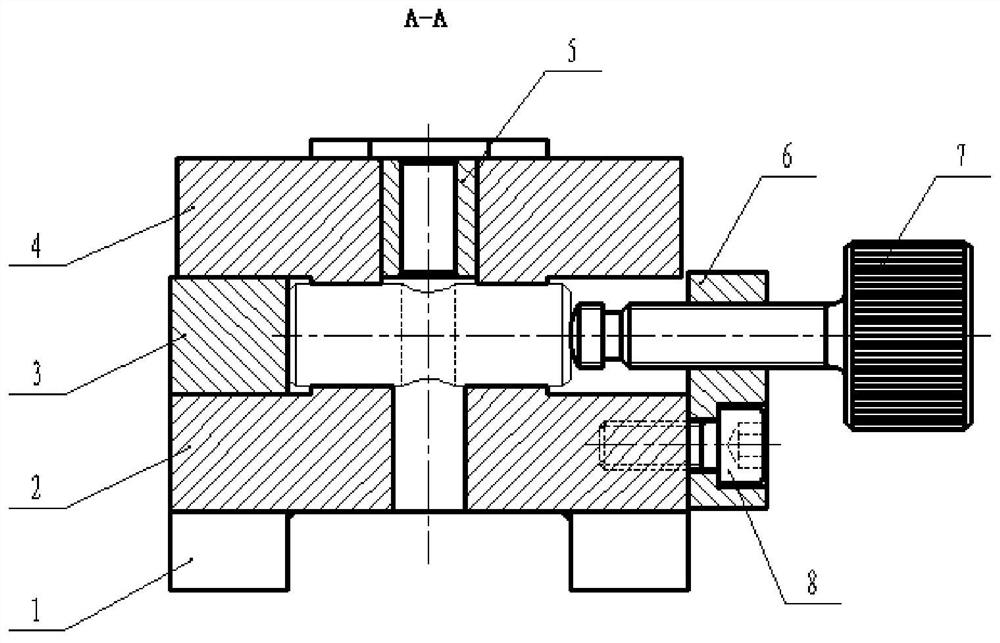

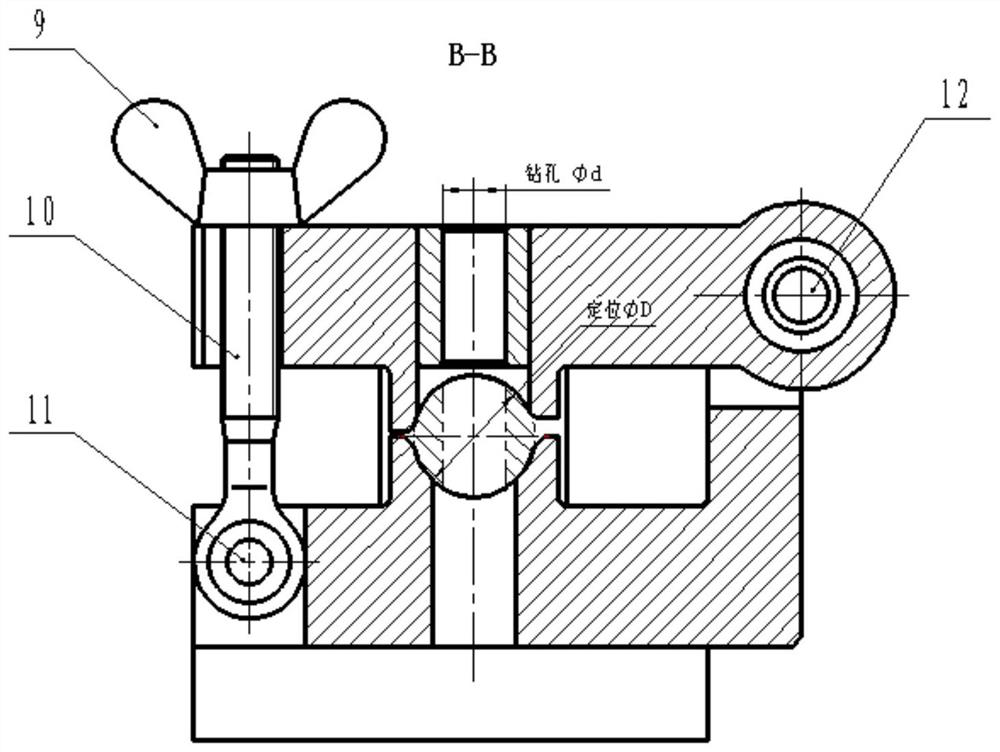

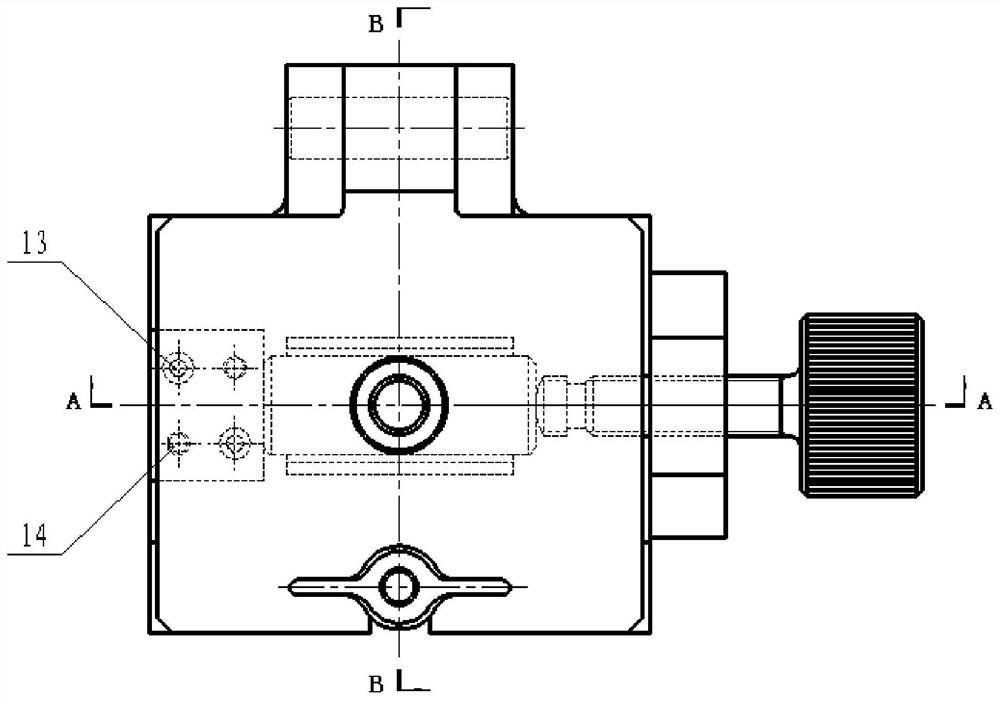

Special clamp for drilling cambered surface of shaft part and use method

The invention relates to the field of machining, in particular to a special clamp for drilling a cambered surface of a shaft part. The special clamp for drilling the cambered surface of the shaft partcomprises a base (2) and a drill plate (4); a baffle (3) with a semi-cylindrical cavity, a positioning block A and a supporting plate (6) are sequentially arranged on the base (2); centers of the baffle (3), the positioning block A and the supporting plate (6) remain on the same plane; a positioning block B with a semi-cylindrical cavity is arranged on the drill plate (4), and the positioning block B and the positioning block A are concentric when closed; the drill plate (4) is connected with the base (2) through a cylindrical pin (12) to form a hinged mechanism, so that the purpose of simplyand fast assembling and disassembling the part is achieved; a swing bolt (10) is arranged on the edge of an open end of the formed hinged mechanism; and a drill sleeve (5) is arranged on the drill plate (4). The special clamp has the characters that the structure is simple, operation is convenient, the cost is saved, and the working efficiency is improved.

Owner:GUIZHOU FENGLEI AVIATION ORDNANCE CO LTD

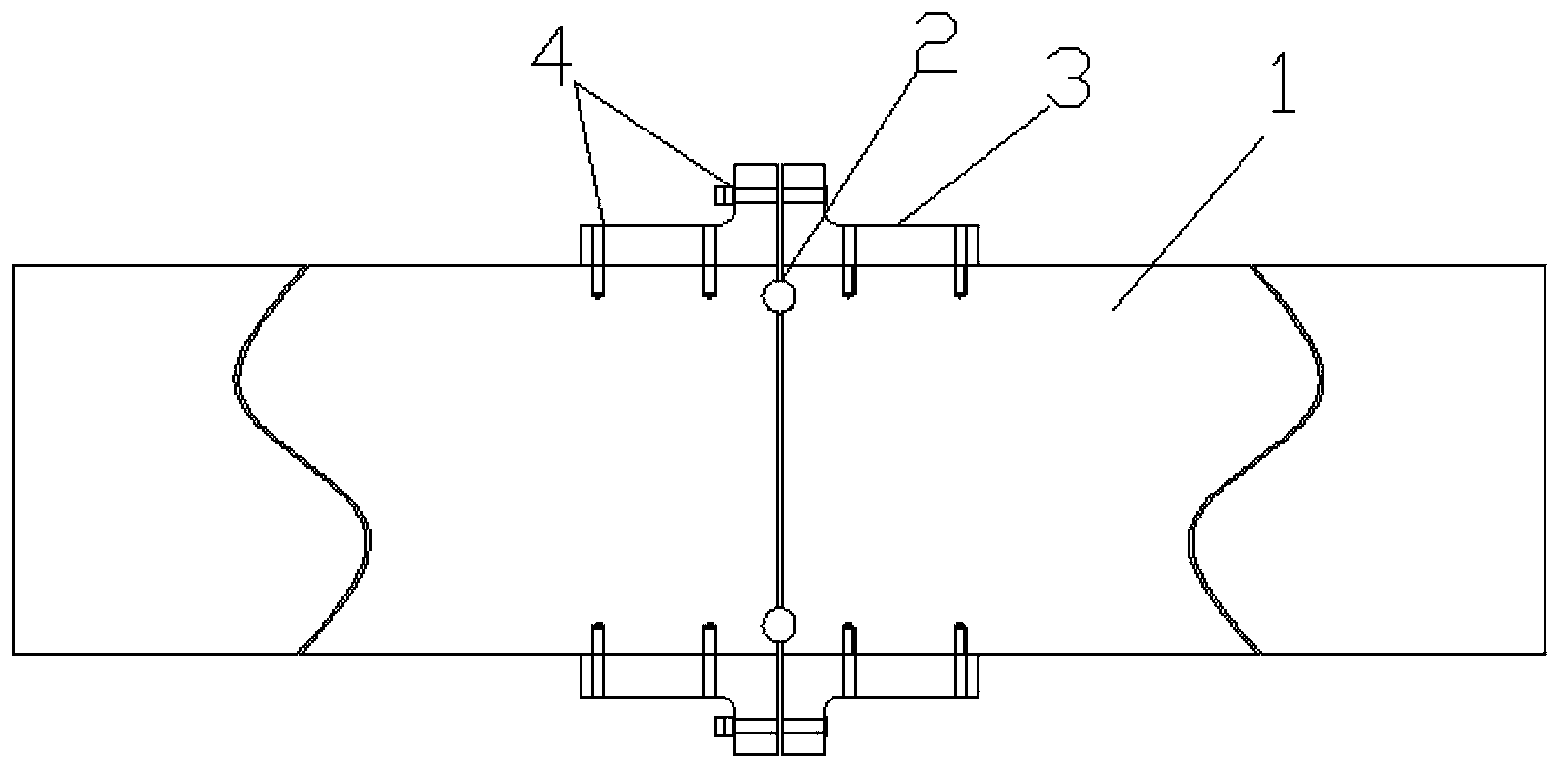

Three-roll plate rolling machine for large ships

InactiveCN105537334BSimple structureLow costMetal-working feeding devicesPositioning devicesHydraulic cylinderPulp and paper industry

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

Graphite film rolling equipment deviation rectifier

InactiveCN105599200AMove preciselyGuaranteed machining accuracy requirementsWebs handlingHydraulic cylinderEngineering

The invention discloses a graphite film rolling equipment deviation rectifier. The graphite film rolling equipment deviation rectifier comprises a base (1), a main support (2), bearing pedestals (3), a conveying roller (4), a sensor support (5), a sensor transome (6), a distance sensor (7), a graphite film (8) and a hydraulic cylinder (9), wherein the two bearing pedestals (3) are symmetrically fixed to the top of the main support (2), the conveying roller (4) is fixedly arranged on the two bearing pedestals (3), the sensor support (5) and the sensor transome (6) are fixed together, the distance sensor (7) is fixedly arranged on the sensor support (5), the hydraulic cylinder (9) is fixed above the base (1), and the front end of the hydraulic cylinder (9) is connected with the lower side of the main support (2). According to the invention, via precise pushing of the hydraulic cylinder, the whole main support can move left and right precisely, the position of the graphite film on the conveying roller can be regulated precisely, and thus the requirement on processing precision of the graphite film can be met.

Owner:ZHENJIANG BROWAH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com