Graphite film rolling equipment deviation rectifier

A technology of graphite film and deviation corrector, which is applied in winding strips, thin material processing, transportation and packaging, etc., can solve the problems of large manual adjustment errors, deviation, and affect the demand for mass production, and meet the requirements of guaranteed processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

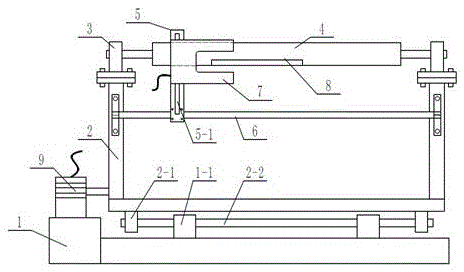

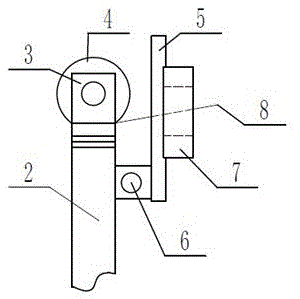

[0011] Depend on figure 1 , figure 2 It is known that a graphite film calendering equipment correction device of the present invention is composed of a base 1, a main support 2, a bearing seat 3, a conveying roller 4, a sensor support 5, a sensor crosspiece 6, a distance sensor 7, a graphite film 8, and a hydraulic cylinder 9. , the main bracket 2 is connected and fixed with the base 1, the two bearing housings 3 are symmetrically fixed on the top of the main bracket 2, the conveying roller 4 is installed and fixed on the two bearing housings 3, the sensor bracket 5 and the sensor crosspiece 6 are fixed together , the sensor crosspiece 6 is installed and fixed on the middle position of the main bracket 2, the distance sensor 7 is installed and fixed on the sensor bracket 5, the graphite film 8 passes through the distance sensor 7 through the conveying roller 4, the hydraulic cylinder 9 is fixed on the top of the base 1, and the hydraulic cylinder 9. The front end is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com