Special machine tool for roller boring

A special machine tool and roller technology, applied in the field of machine tools, can solve the problems of inability to guarantee the accuracy of boring holes, not meeting the requirements of low cost, and low machining accuracy, and achieve the effects of obvious industrial application value, low noise and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

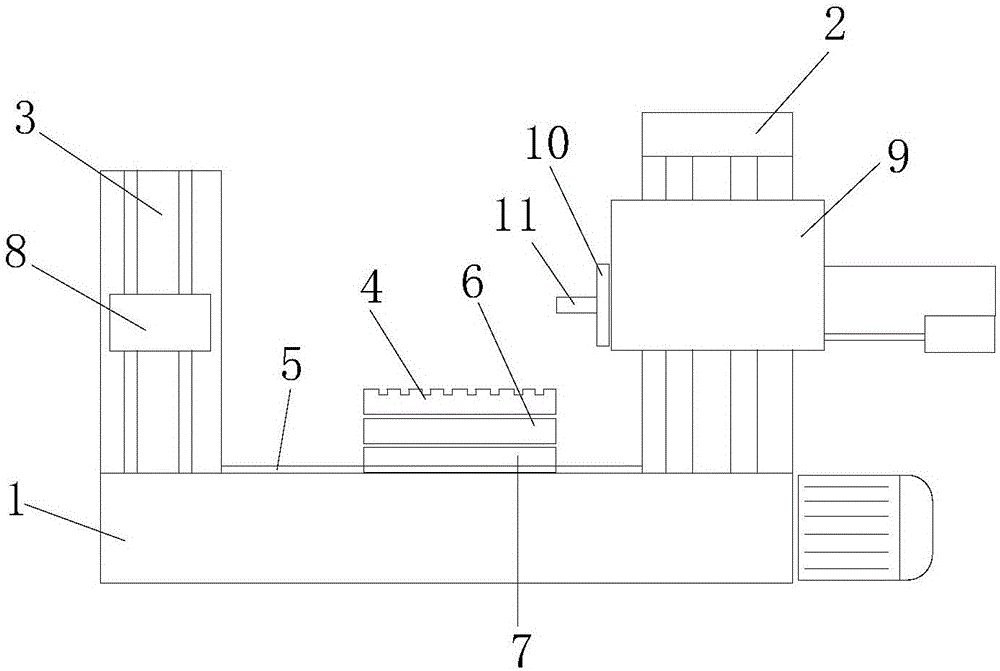

[0018] like figure 1 As shown: a special machine tool for boring roller holes provided by the present invention is an improved horizontal boring machine, including a bed 1, and the bed 1 is provided with a front column 2, a rear column 3 and a workbench 4, The workbench 4 is located between the front column 2 and the rear column 3, and the bed 1 is provided with an axial slideway 5 at a position connected to the rear column and the worktable surface. An upper slide seat 6 and a lower slide seat 7 are provided in sequence, the workbench 4 is arranged on the axial slideway 5 of the bed 1, and the workbench 4 and the bed 1 form a moving pair, and the rear column 3 is set On the axial slideway 5 and form a moving pair with the bed 1, a vertical slide rail is arranged on the rear column 3, and a rear support frame 8 is installed on the vertical slide rail of the rear column. There is a vertical slide rail, and a headstock 9 is installed on the vertical slide rail of the front colu...

Embodiment approach

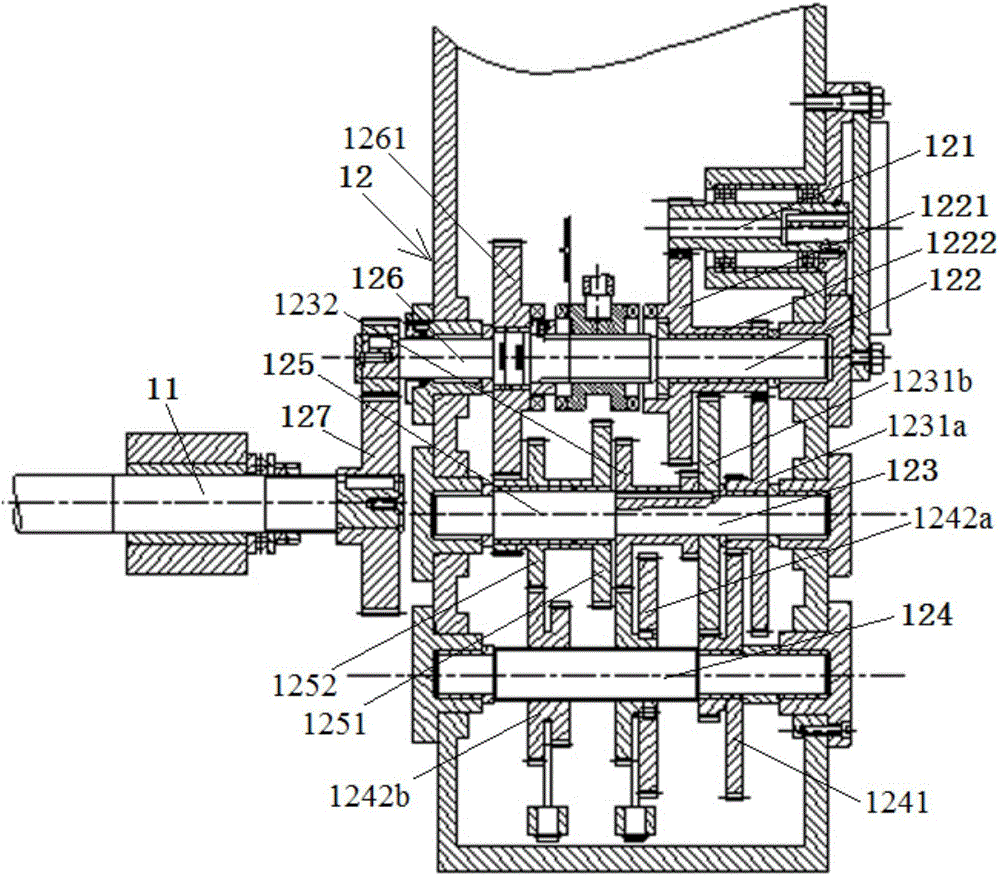

[0020] One embodiment, the input transmission shaft 122 is provided with a large transmission gear 1221 and a transmission pinion 1222, and the primary transmission shaft 123 is provided with two sets of transmission gear sets 1231a, 1231b and a transmission gear 1232, A transmission gear set 1241 and two sets of sliding gear sets 1242a, 1242b are provided on the two-stage transmission shaft 124, a transmission gear 1251 and a transmission gear set 1252 are set on the output transmission shaft 125, and the output shaft 126 The upper sleeve is provided with a transmission gear 1261; and, the transmission bull gear 1221 on the input transmission shaft 122 is meshed with the input shaft 121 to form two sets of transmission gear sets 1231a, 1231b on the primary transmission shaft 123. The bull gears are all connected to the input The small gears on the transmission shaft 122 are meshed and connected, and the large gears forming the transmission gear set 1241 on the secondary speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com