Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Improve clamping quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

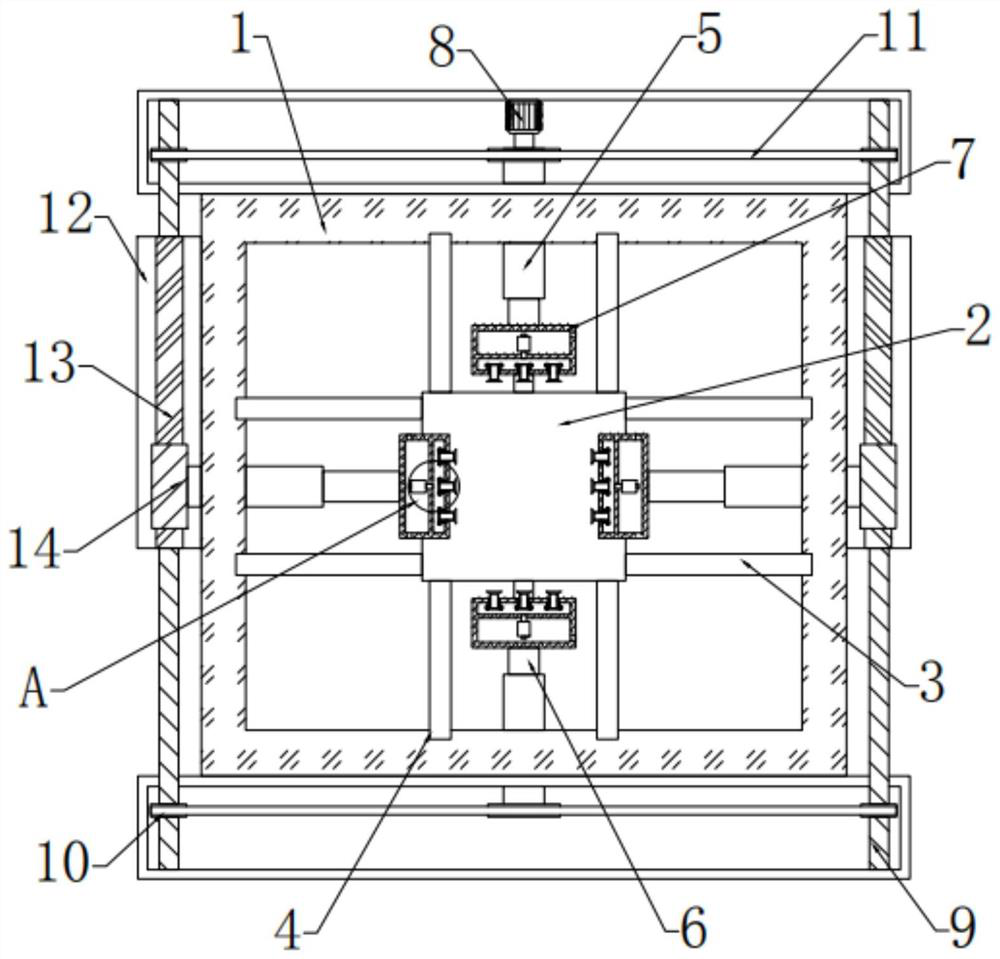

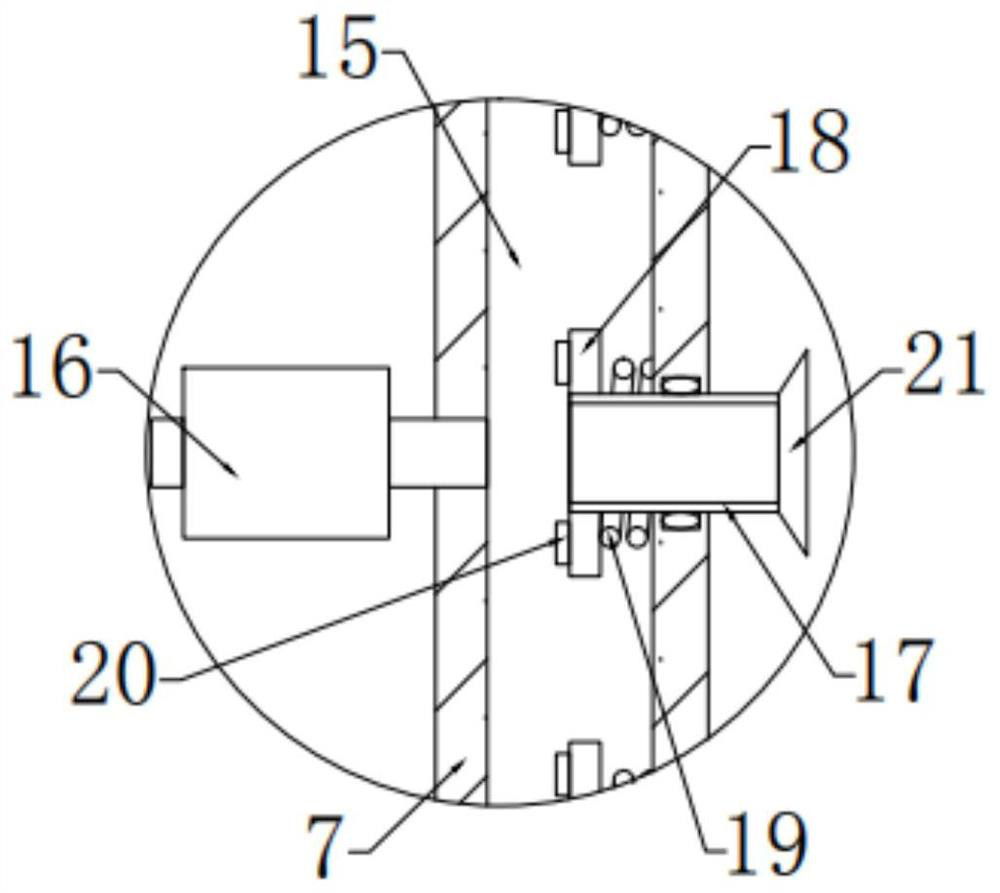

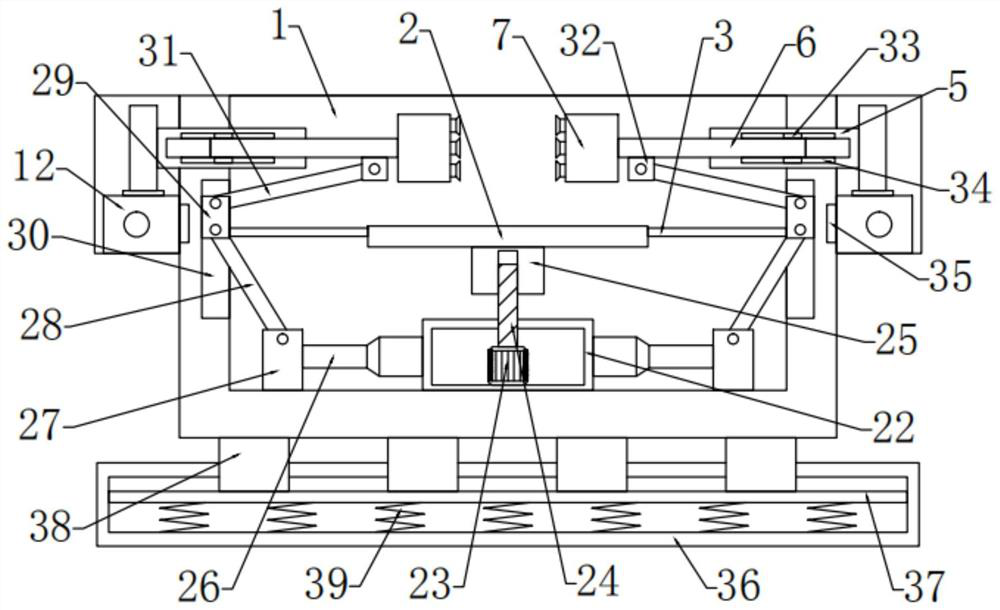

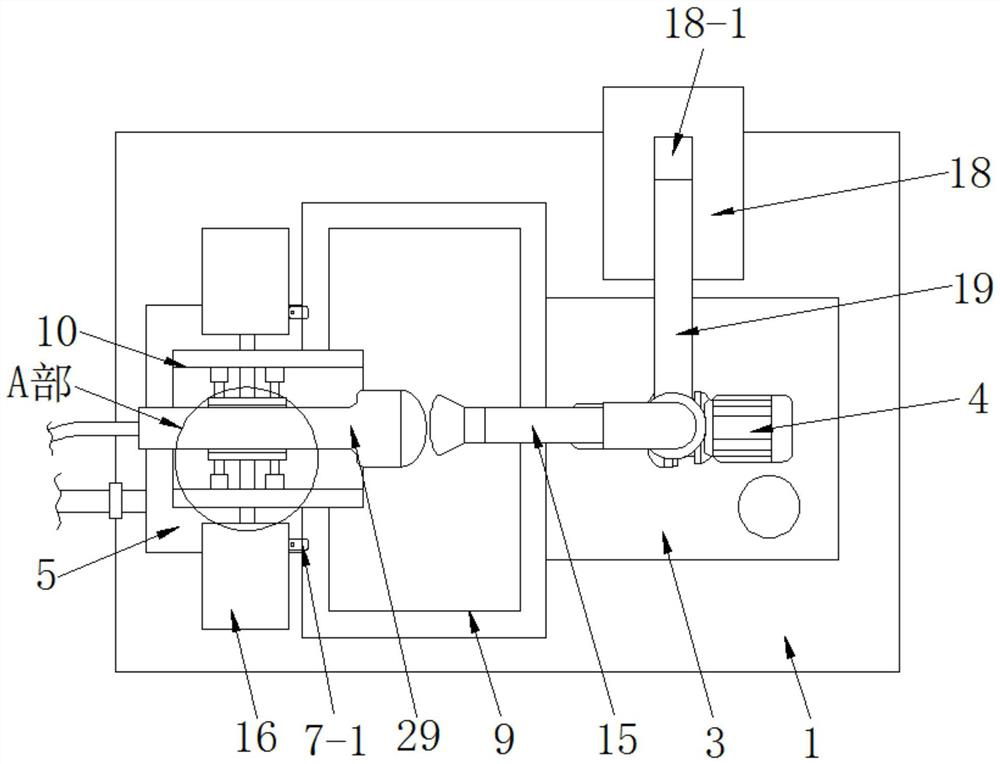

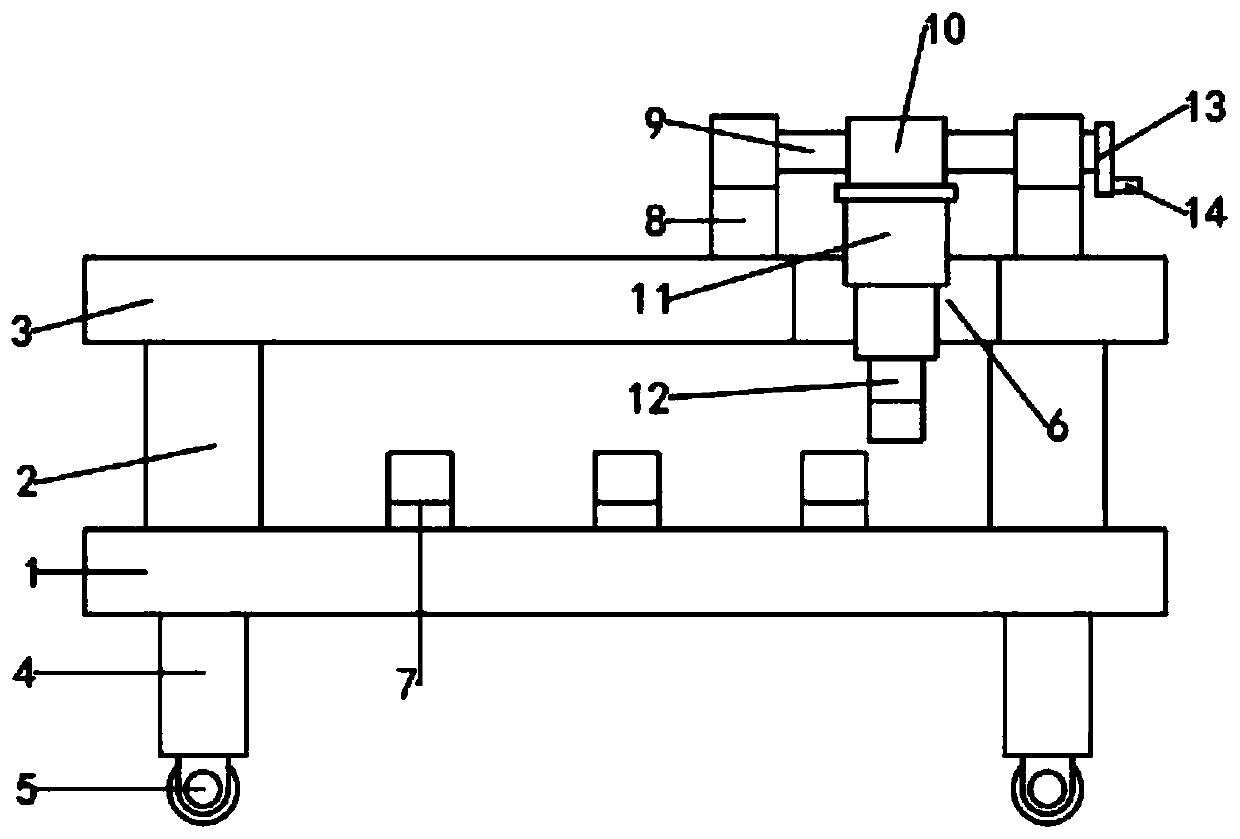

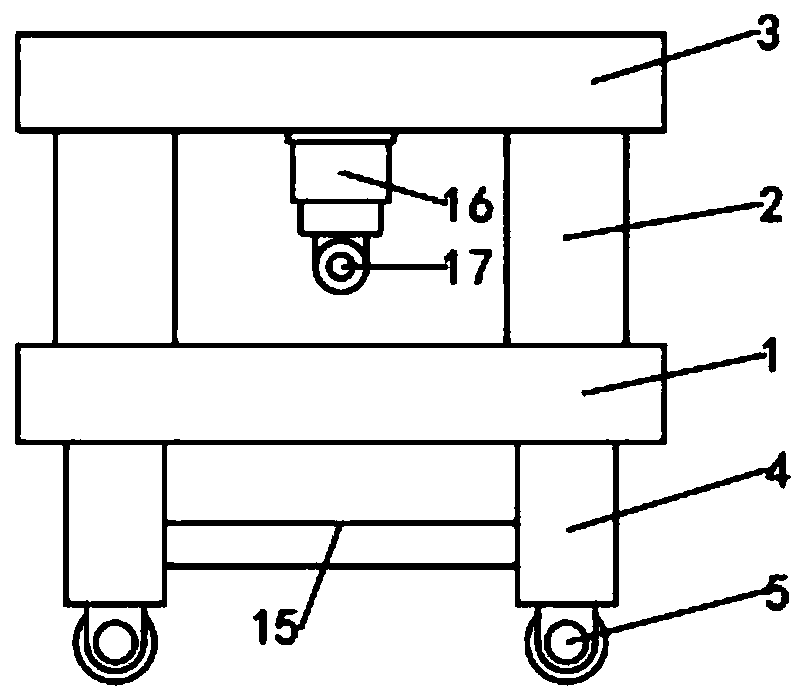

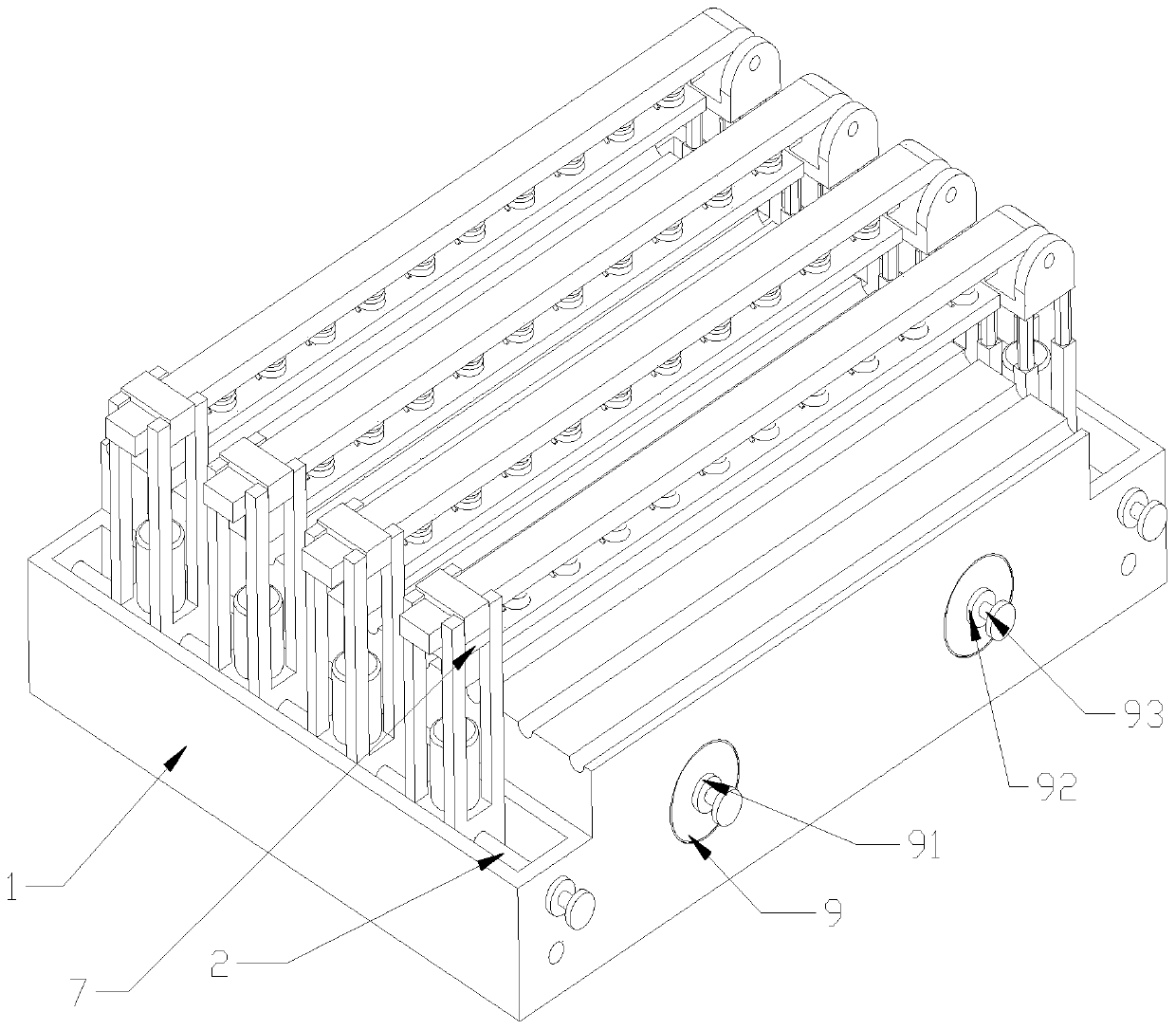

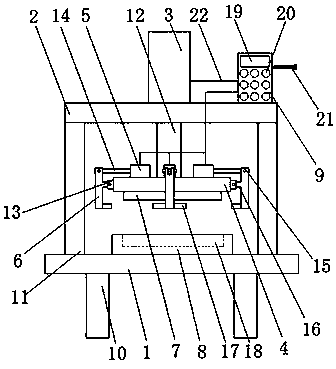

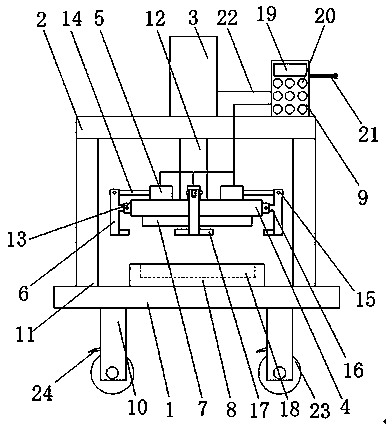

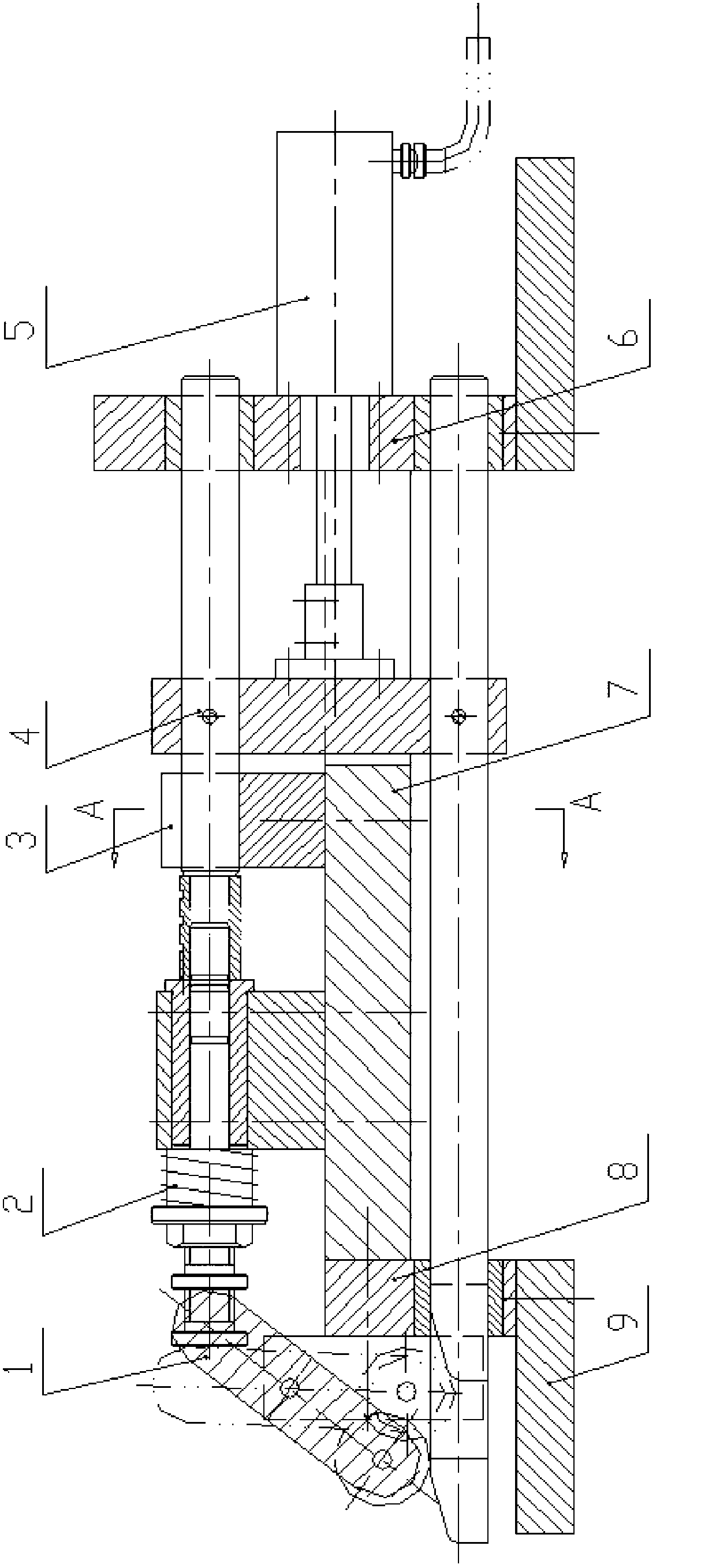

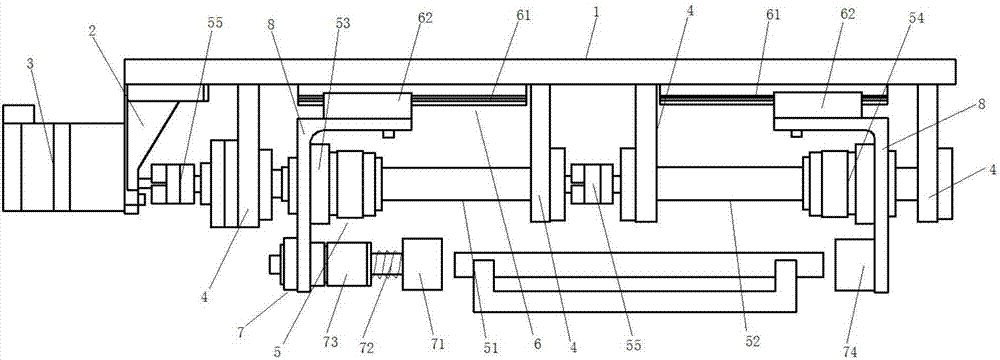

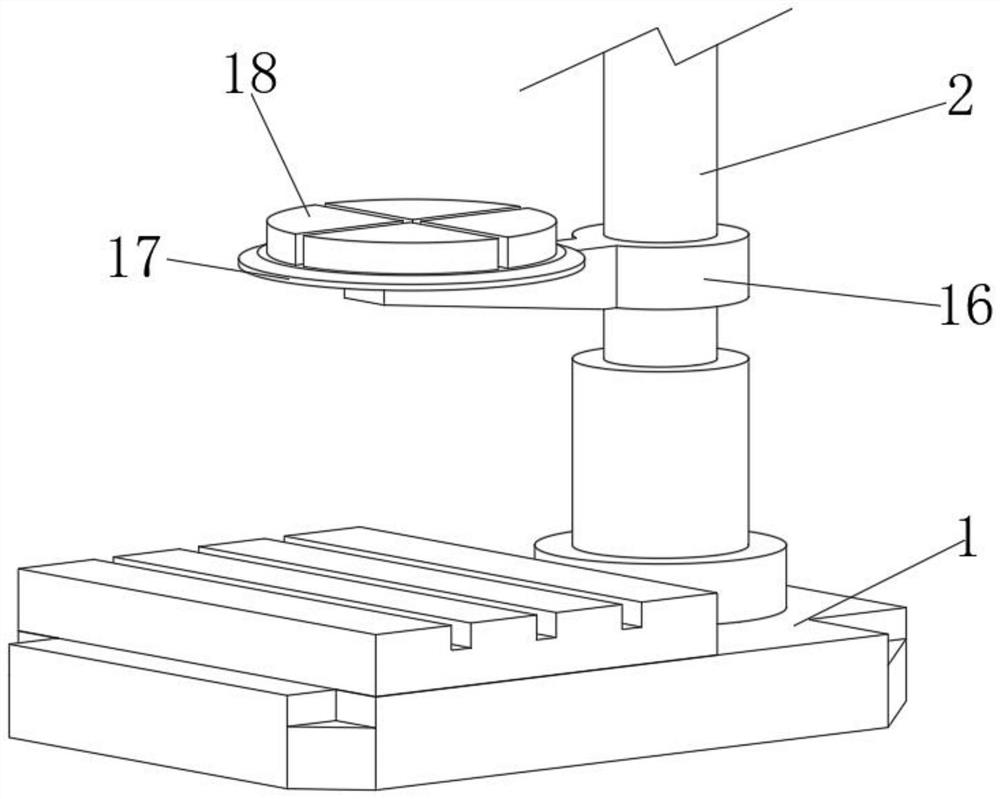

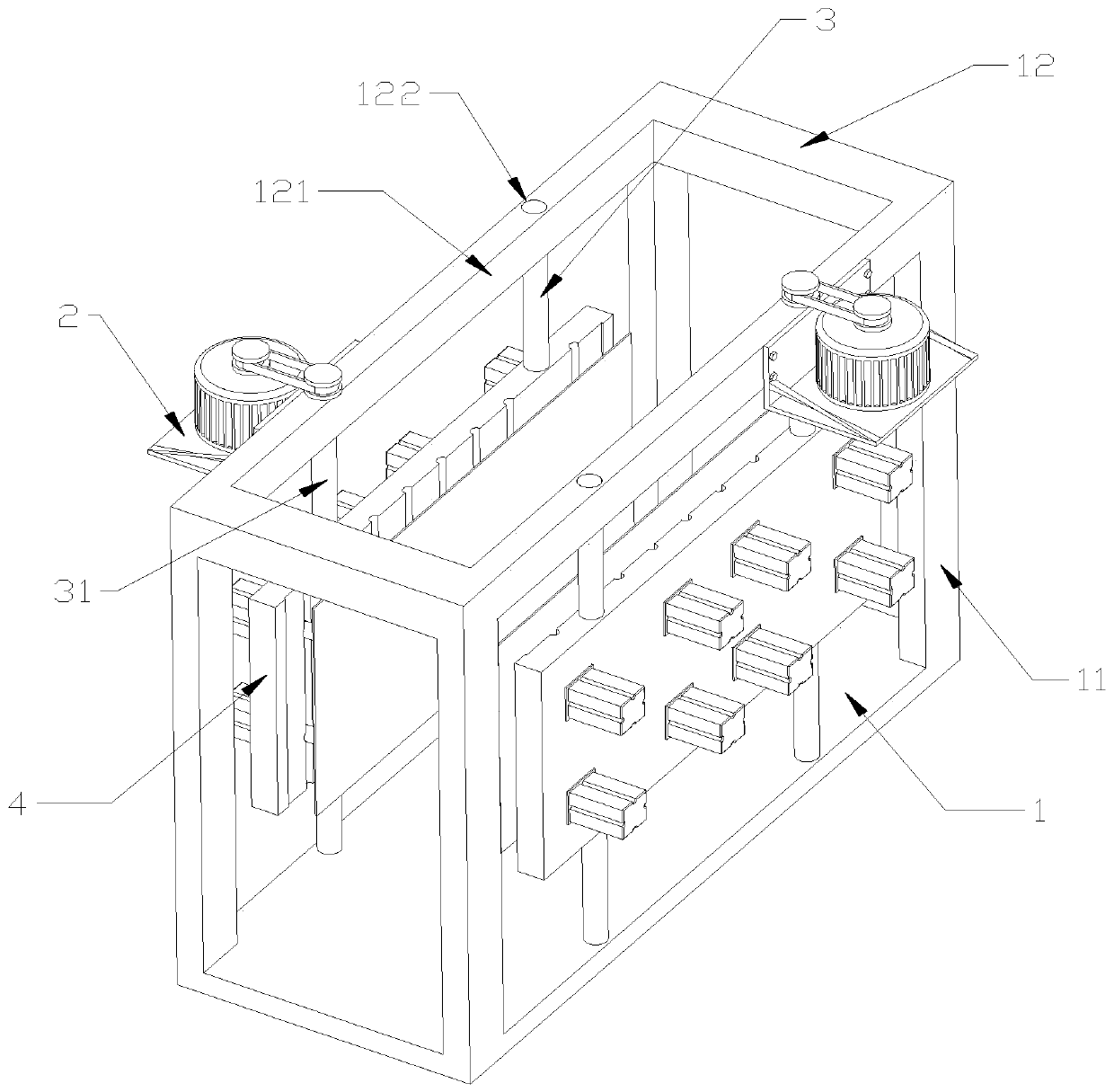

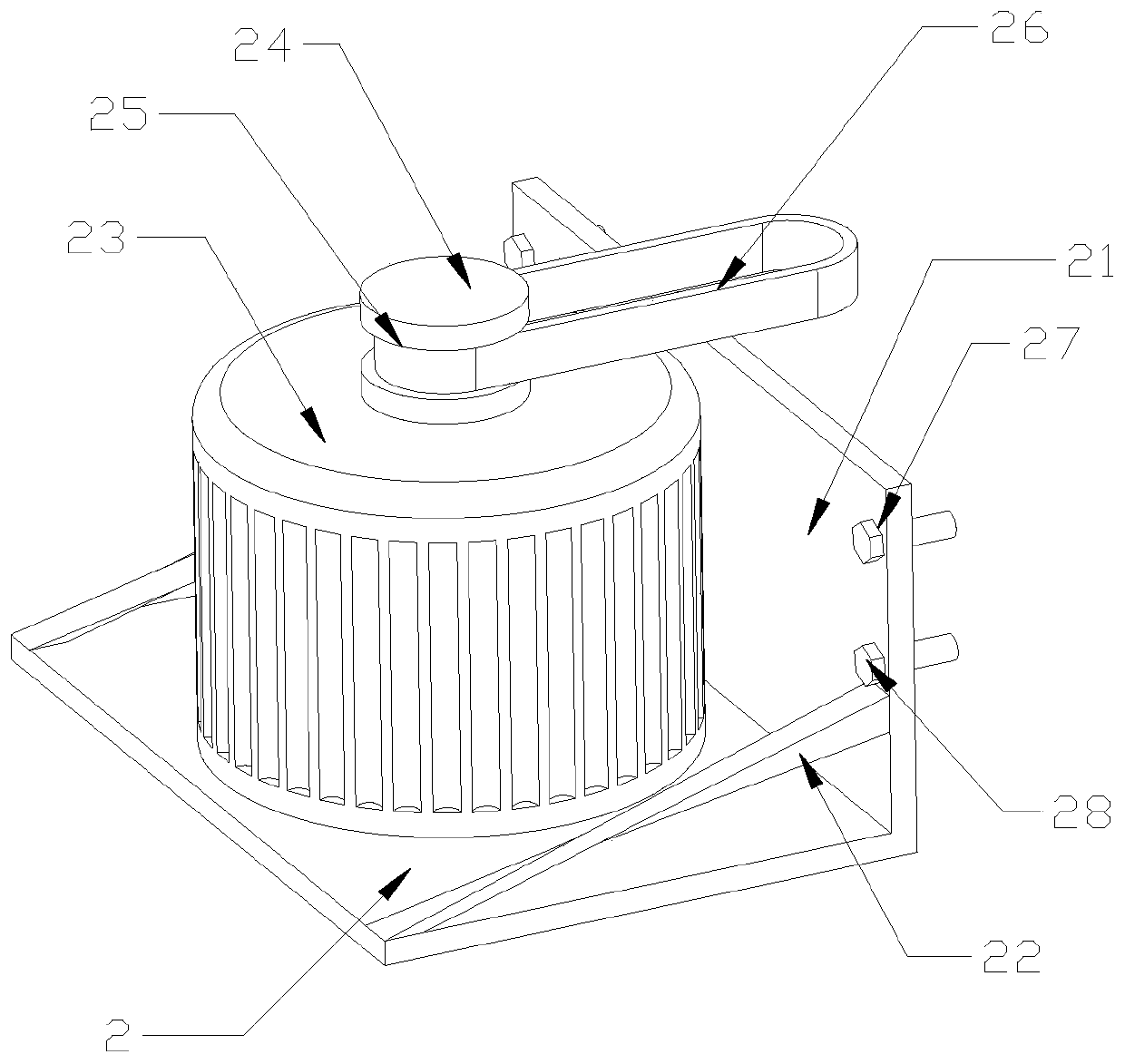

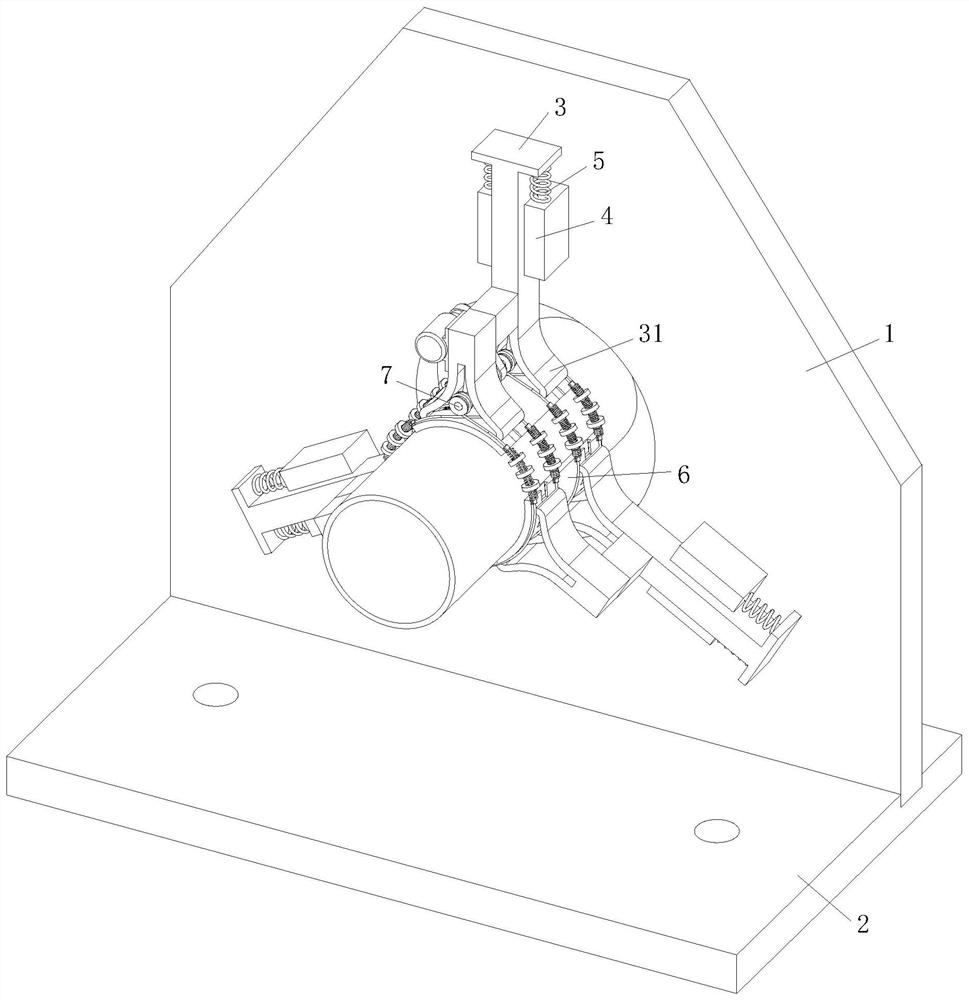

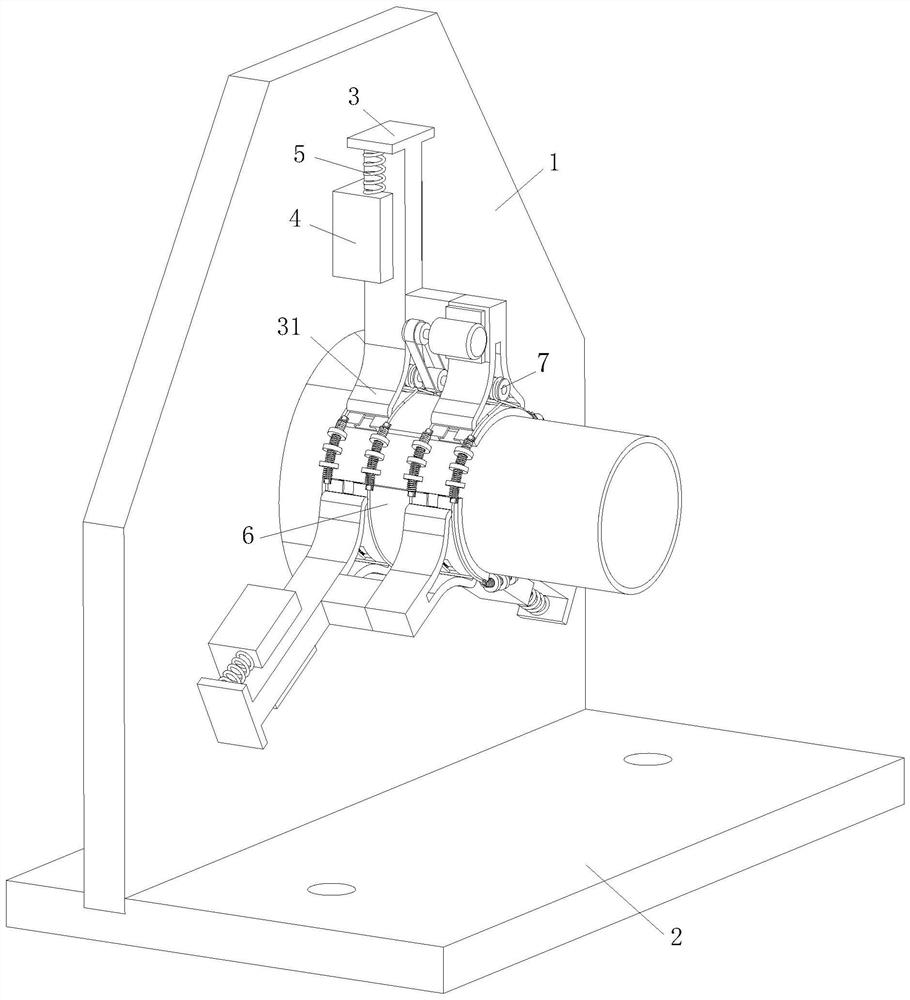

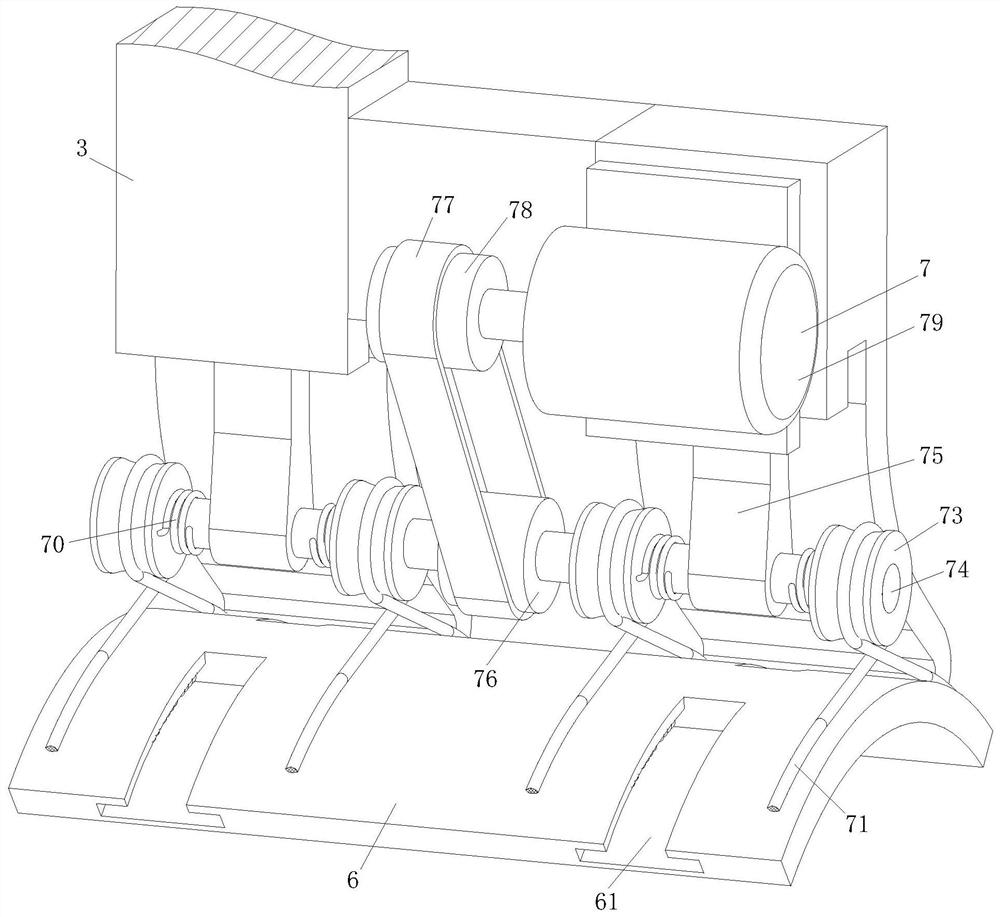

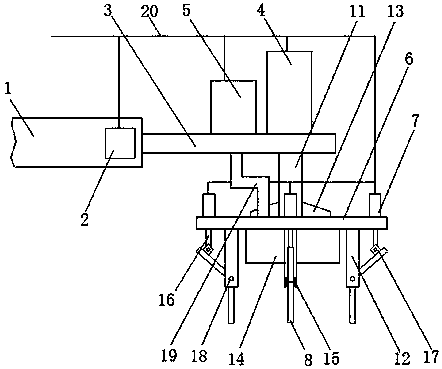

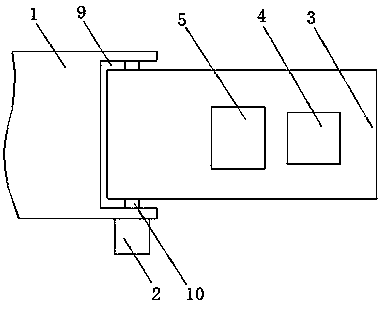

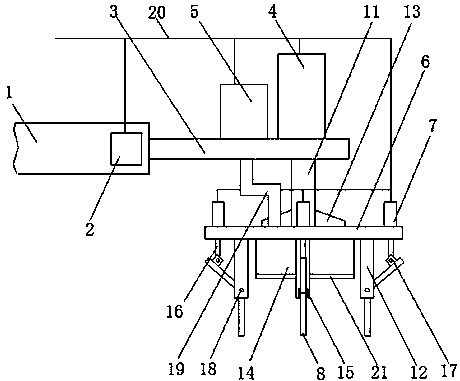

Clamp for sewing machine shell machining

ActiveCN112496800AEasy accessEasy to processPositioning apparatusMetal working apparatusAir pumpEngineering

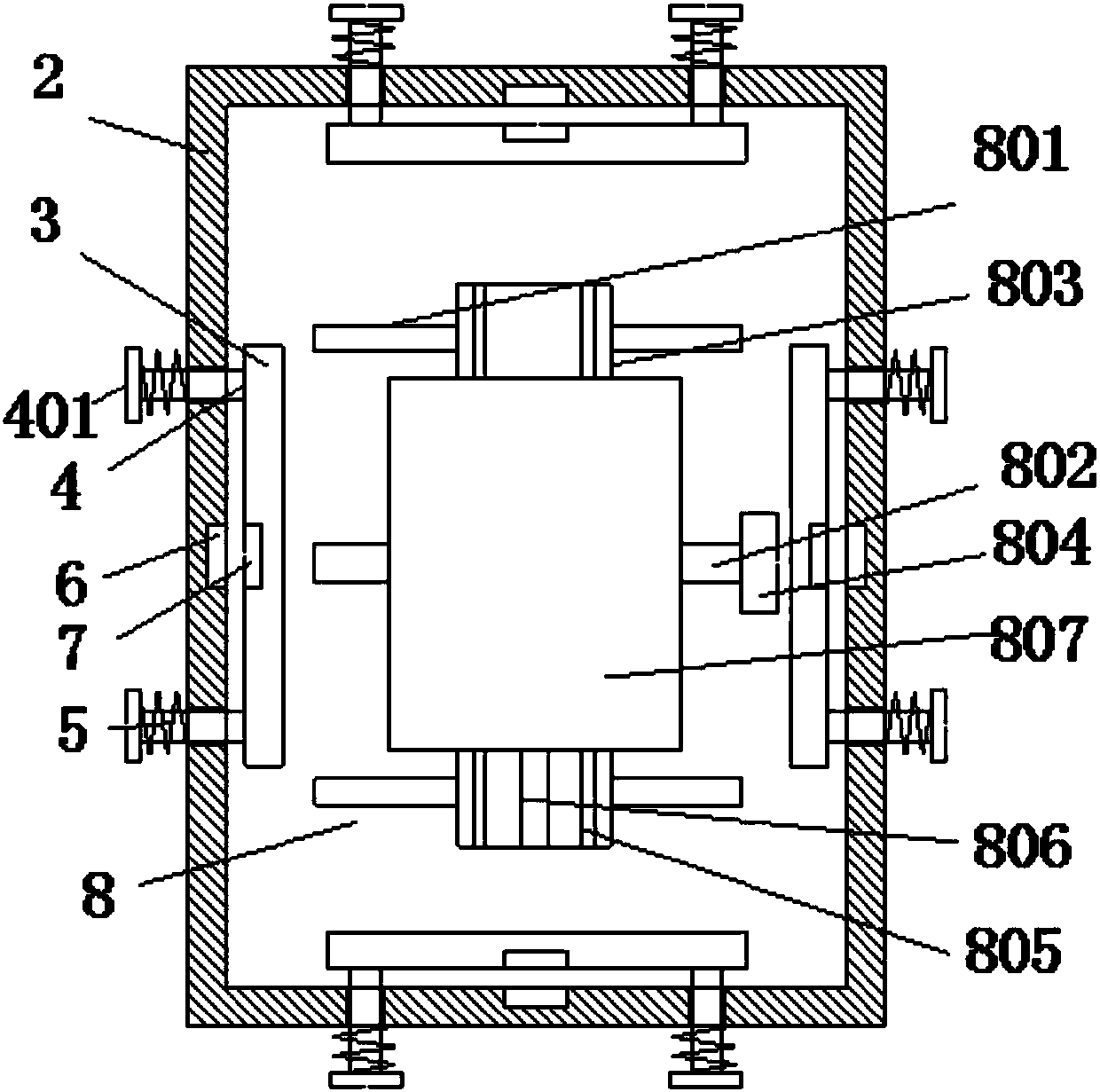

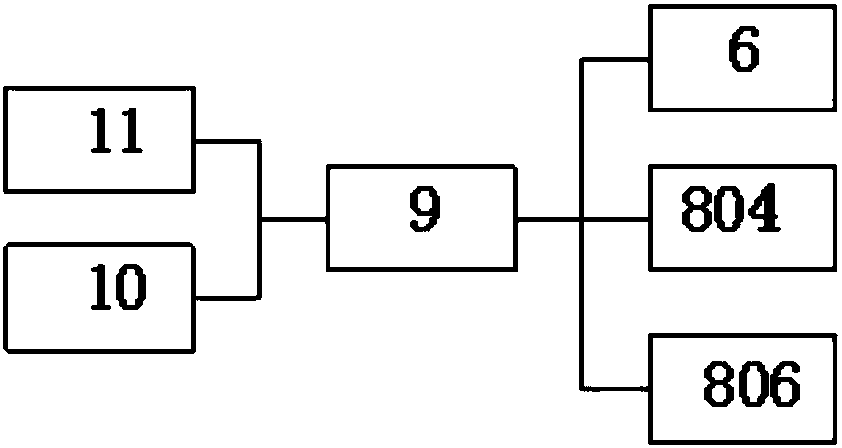

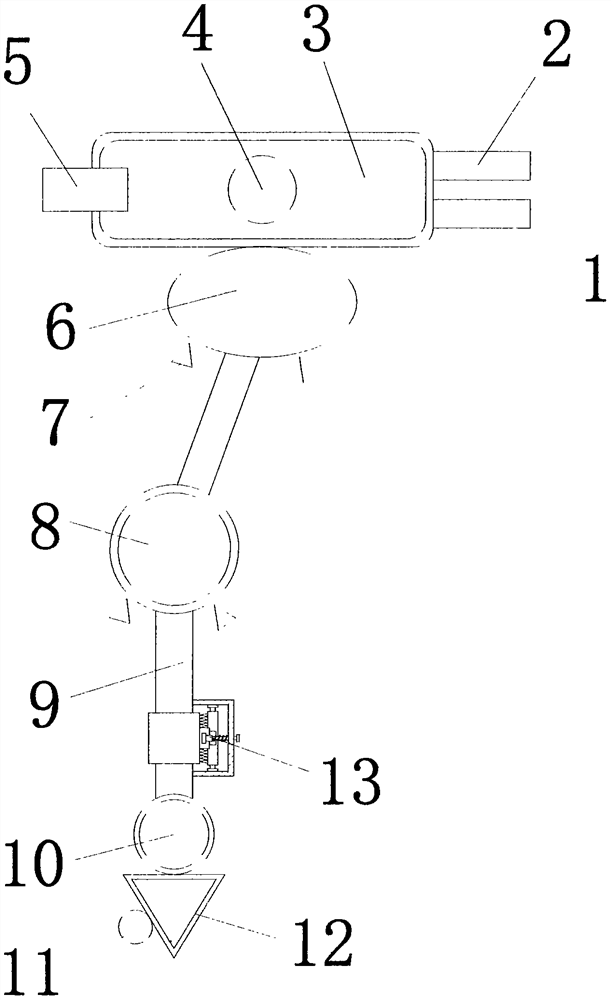

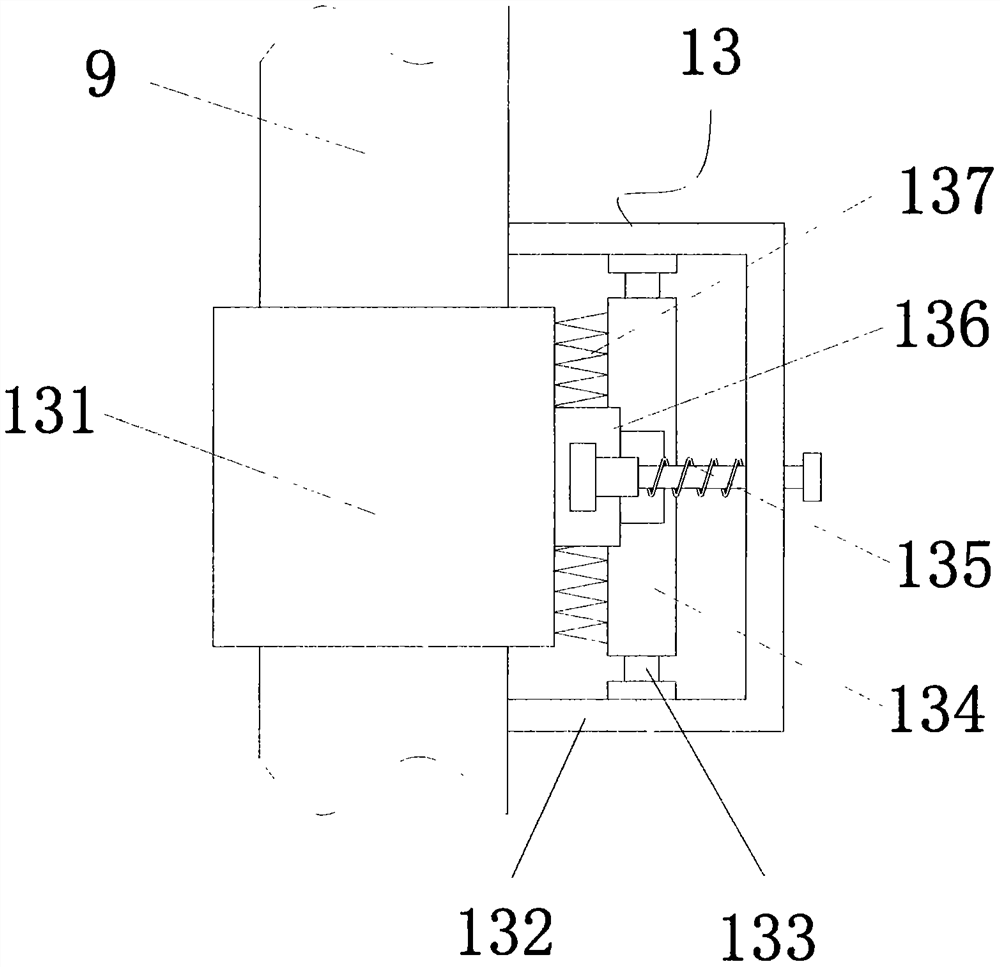

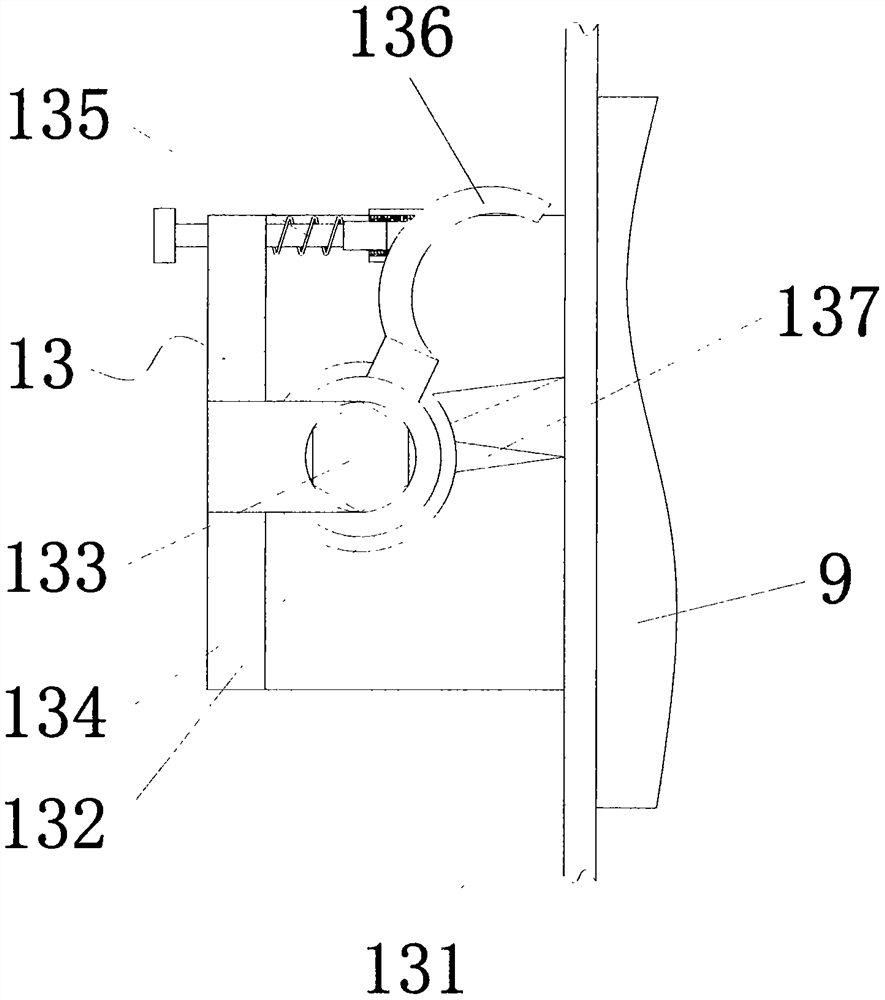

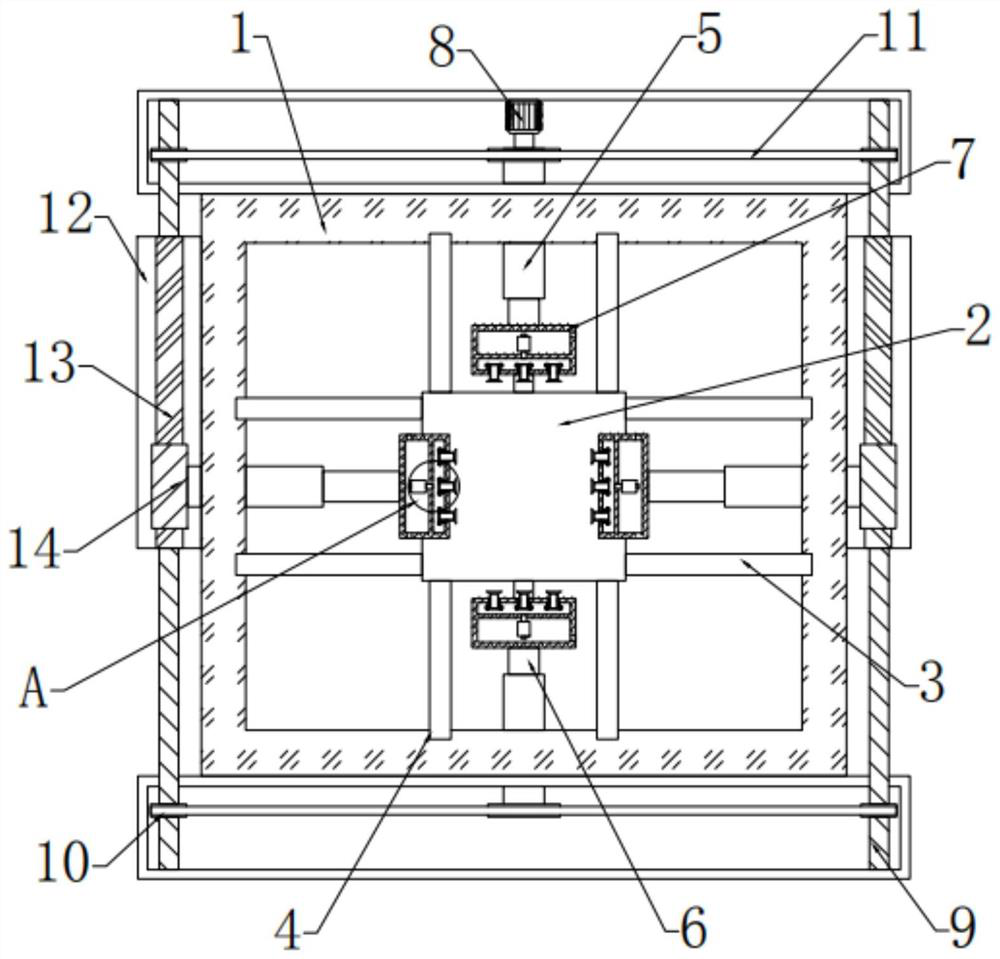

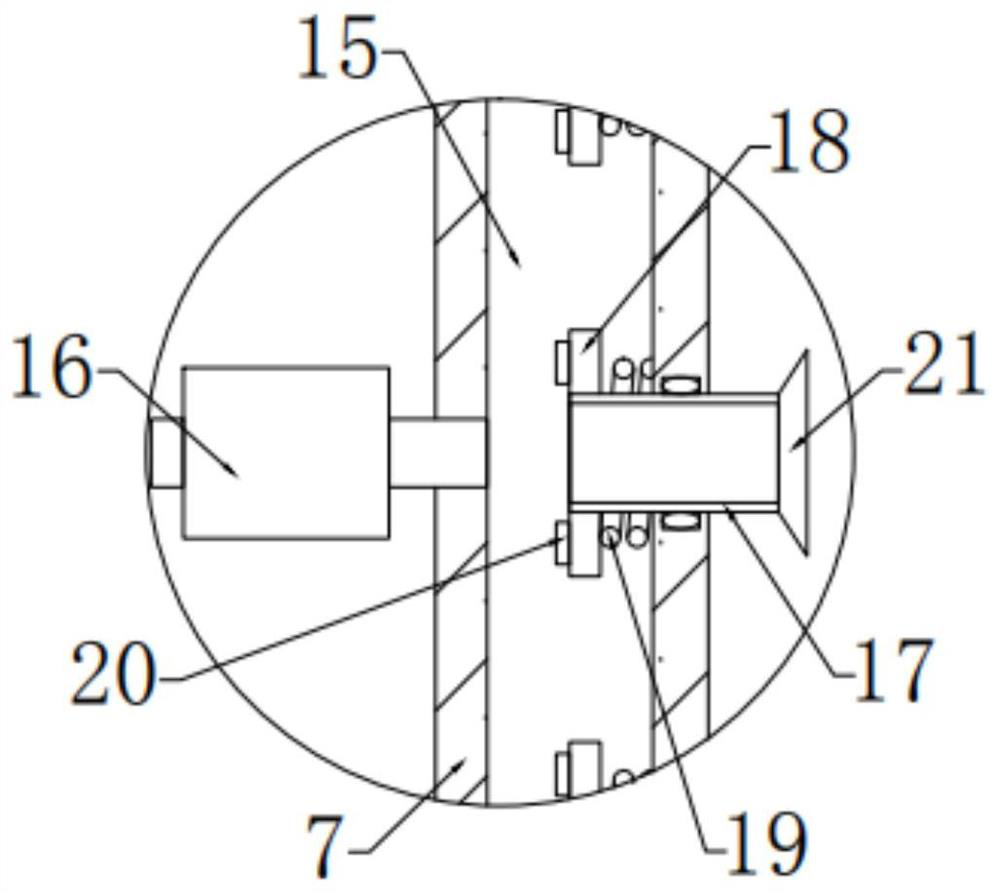

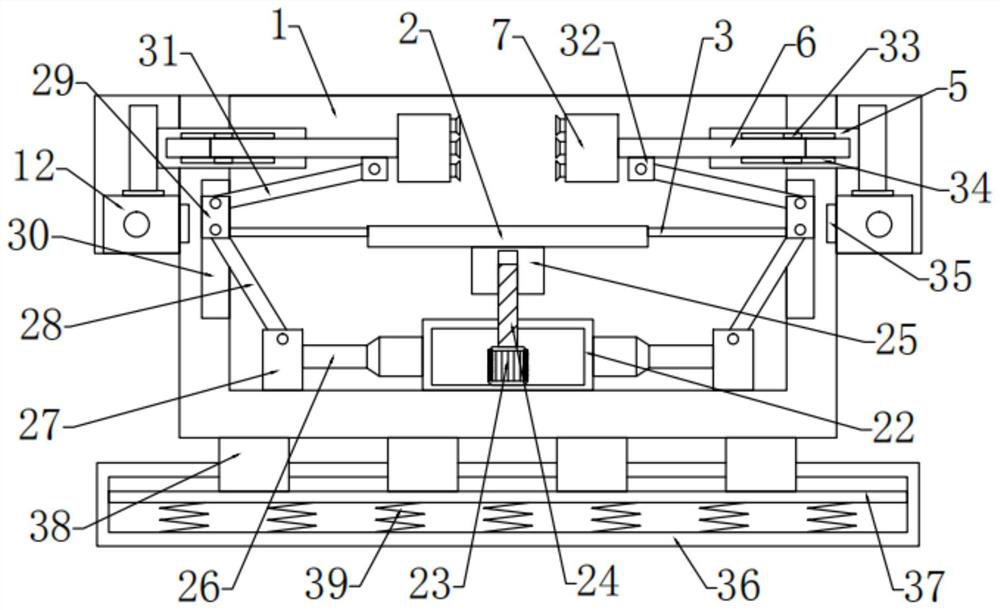

The invention relates to the field of sewing machine accessory machining, in particular to a clamp for sewing machine shell machining. The clamp comprises a machining table, a supporting mechanism used for containing a shell is arranged on the inner side of the machining table, a clamping mechanism used for fixing the shell is arranged on the upper side of the supporting mechanism, and the clamping mechanism is connected with a driving mechanism arranged on the outer side of the machining table. According to the clamp, By arranging the clamping mechanism, telescopic rods are utilized for pushing a connecting block to move, the connecting block drives a sliding block to move through a first connecting rod, and the sliding block drives clamping block to move through a second connecting rod to complete fixing the shell. By arranging the multiple telescopic rods, the device can complete fixing the shell from the left side and the right side, the shell can also be fixed from the front sideand the rear side, and then people can machine different faces of the shell conveniently. By arranging an adsorbing pipe and a sucker, under the effect of an air pump, the device can provide further fixing to the shell, and thus firmness of device fixing can be enhanced.

Owner:SUZHOU KAICHENG SEWING EQUIP

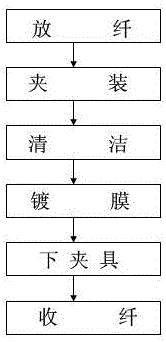

Optical vacuum coating process

InactiveCN105154828AImprove clamping qualityImprove installation efficiencyVacuum evaporation coatingSputtering coatingOptical fiber cableVacuum coating

The invention discloses an optical vacuum coating process which comprises the following six steps: unreeling optical fiber heads, clamping the optical fiber heads, cleaning the optical fiber heads, coating the optical fiber heads, discharging the optical fiber heads from a clamp and reeling the optical fiber heads. By adopting the optical vacuum coating process disclosed by the invention, on one hand, the clamping quality and clamping efficiency of the optical fiber heads are effectively improved, and the defects that the positioning is unstable and optical fibers are easy to pinch off because lines are easy to get out by using a clamp for fixing the optical fiber heads in the prior art are effectively overcome; and on the other hand, the cleaning working efficiency and cleaning quality of the optical fiber heads are effectively improved and a good foundation is laid for improvement on optical fiber coating quality.

Owner:SINY OPTIC COM CO

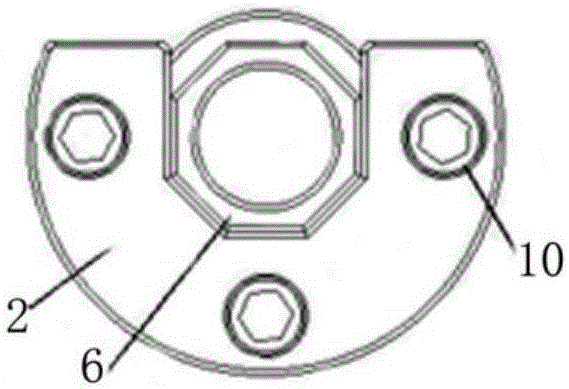

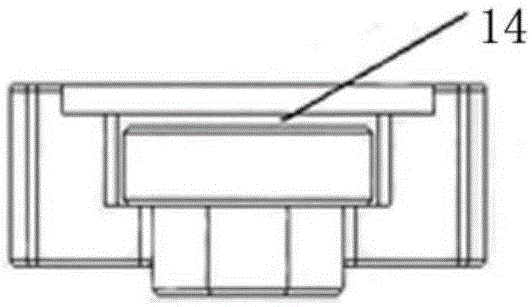

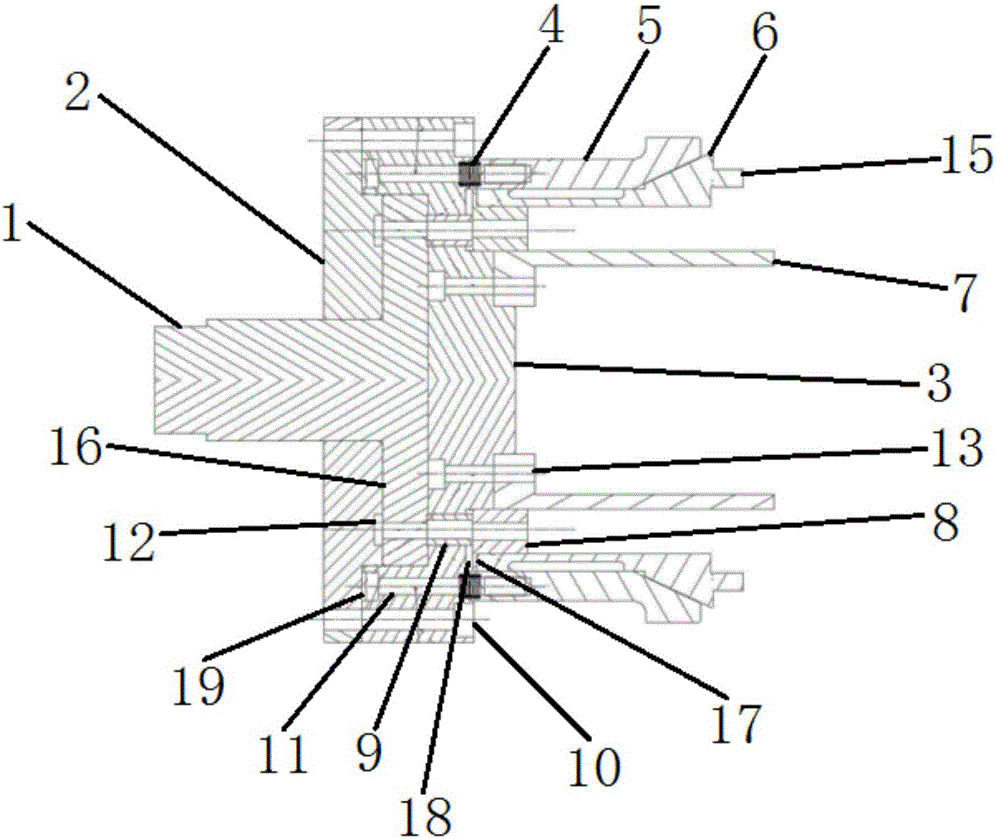

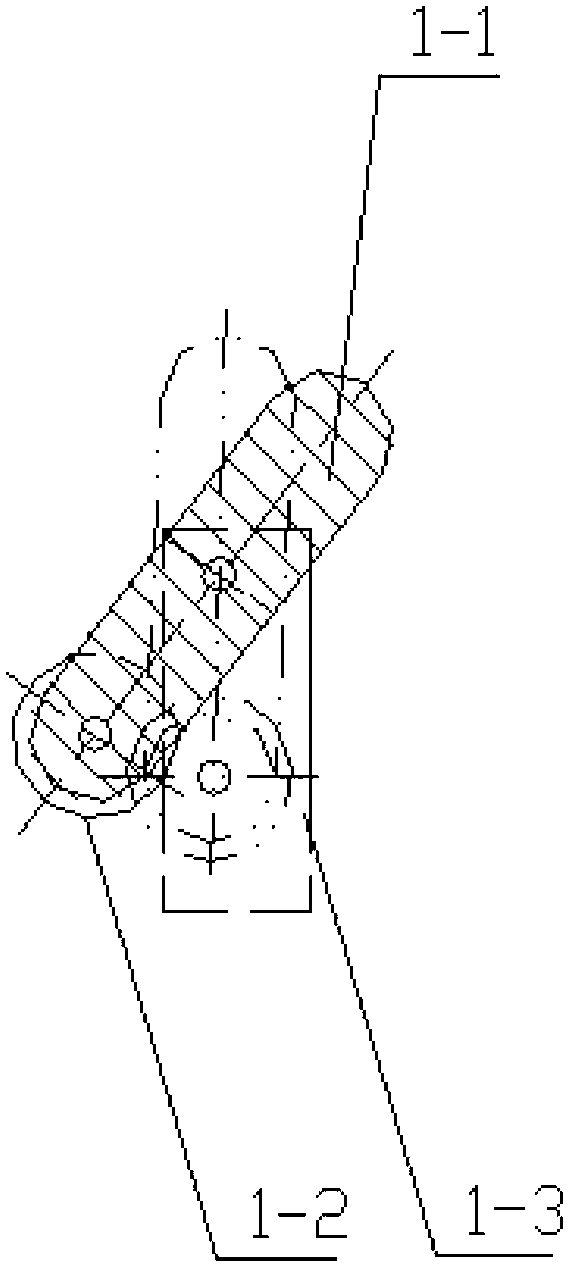

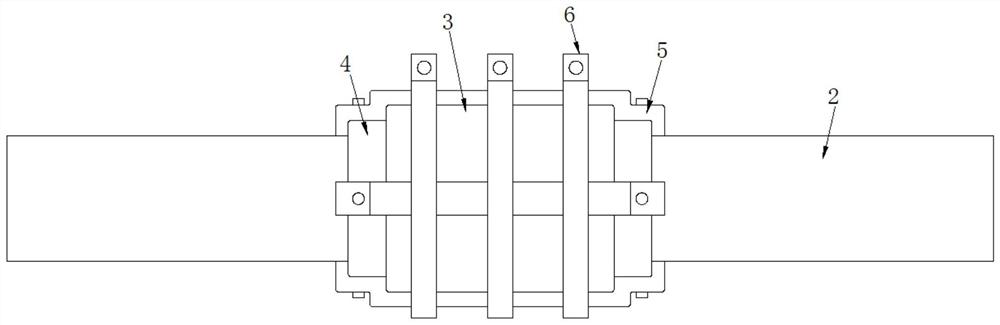

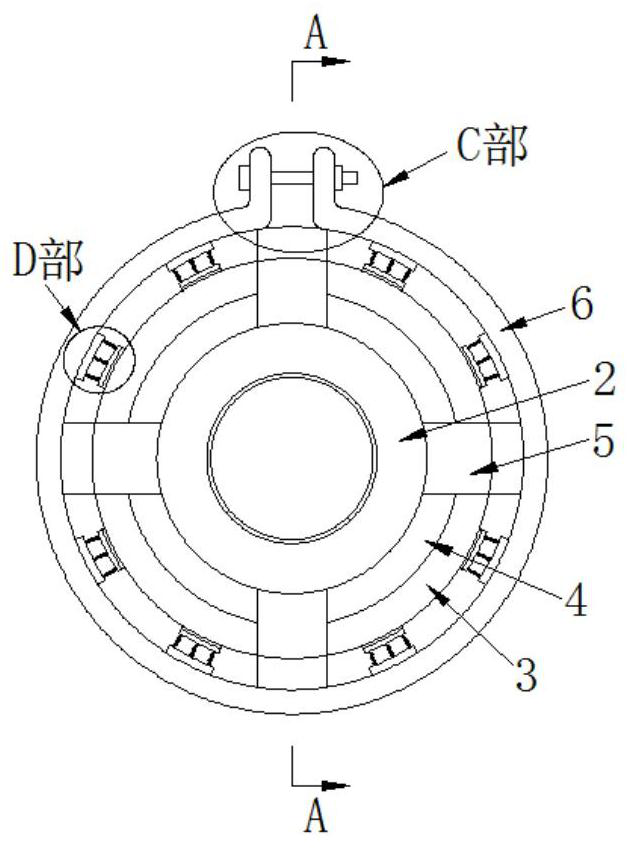

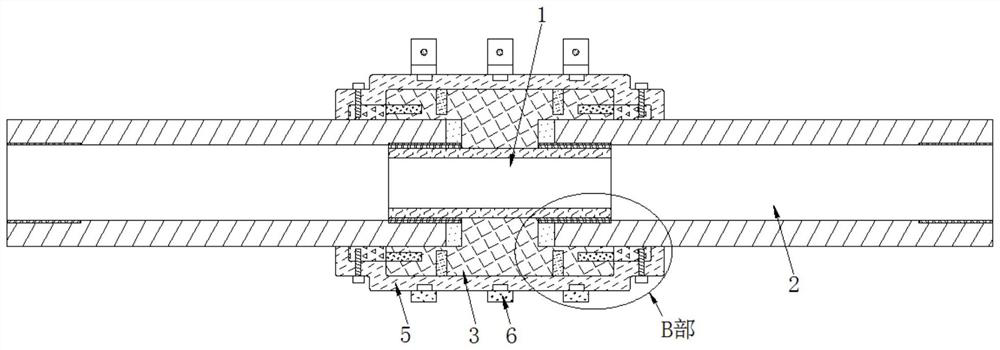

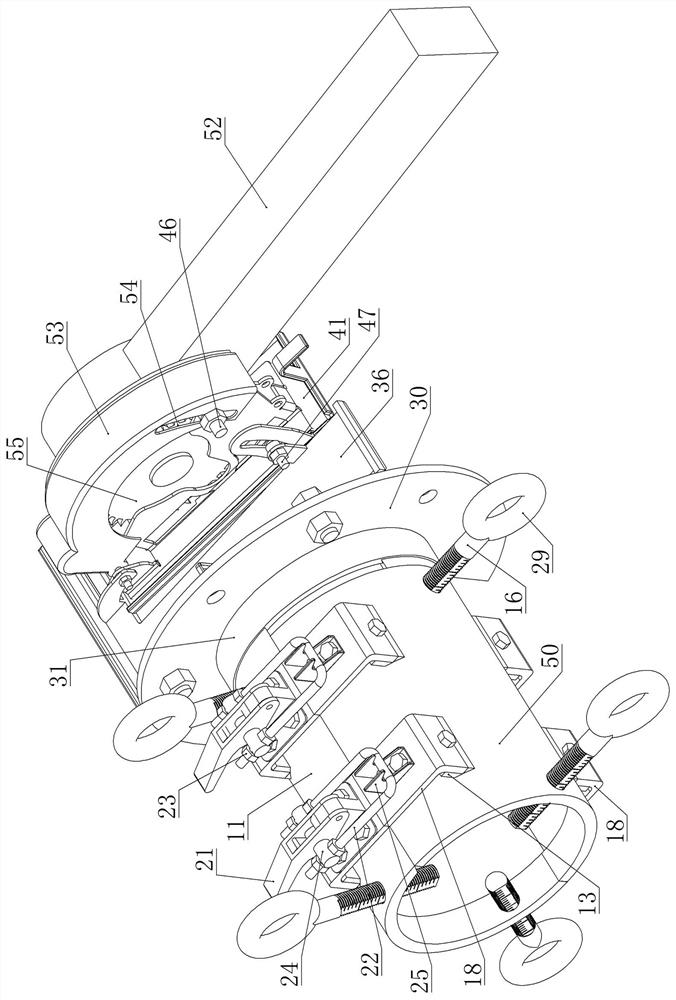

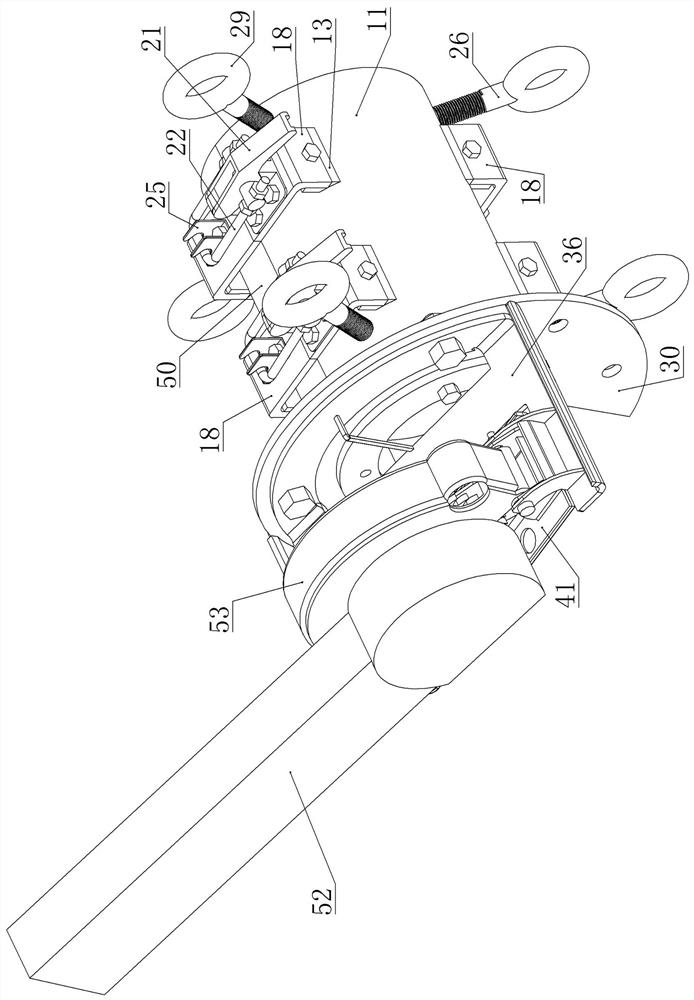

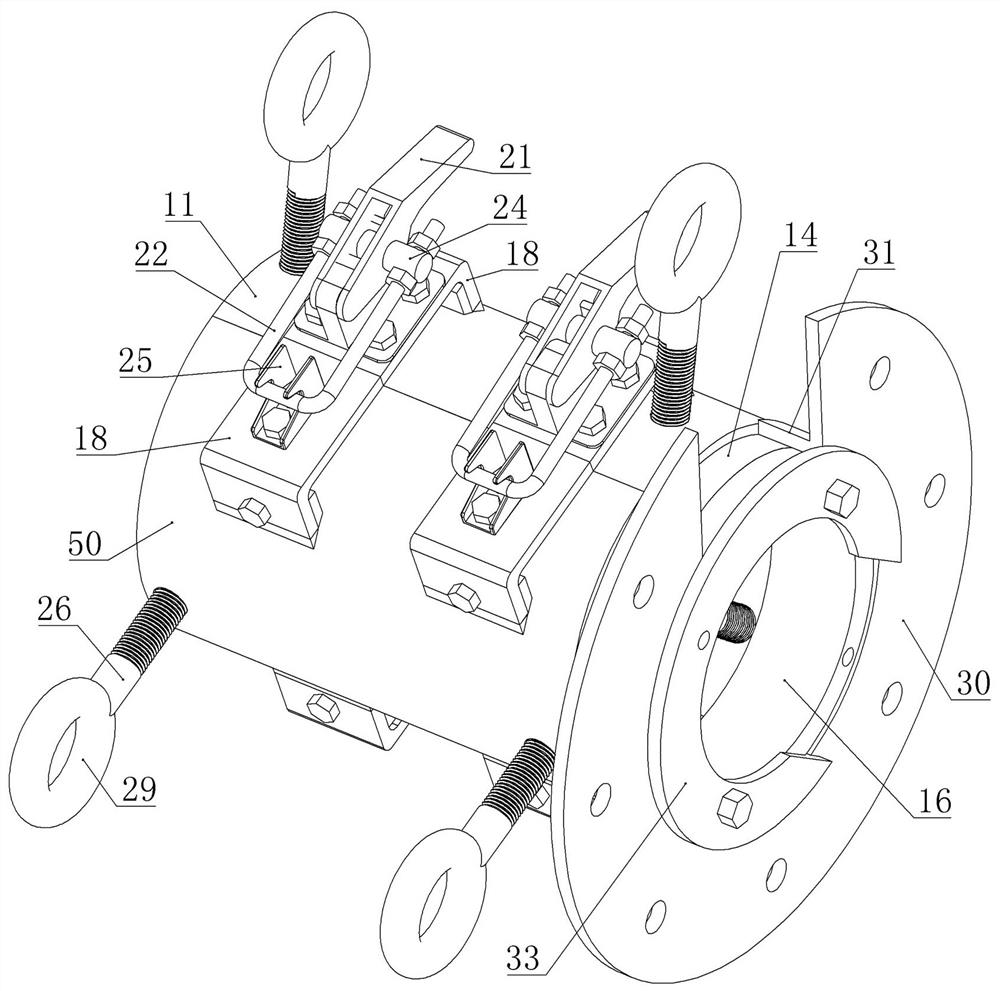

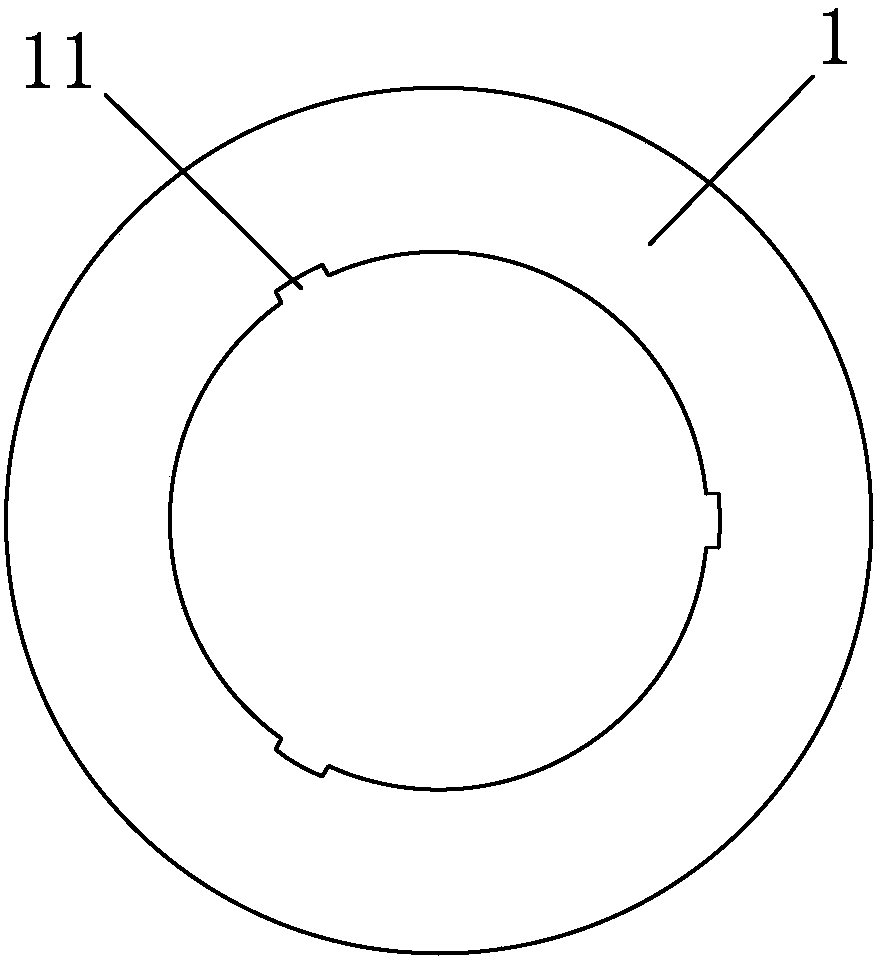

Movable connector rapid positioning and clamping tool used for pipelines

InactiveCN105108685AReduce labor intensityImprove assembly efficiencyWork holdersCentre of rotationEngineering

The invention relates to the field of positioning and clamping tools, in particular to a movable connector rapid positioning and clamping tool used for pipelines. The movable connector rapid positioning and clamping tool comprises an opening chuck used for clamping a movable connector. The movable connector rapid positioning and clamping tool is characterized by further comprising a clamping body used for positioning the movable connector; the clamping body comprises a movable piston assembly and a movable positioning and clamping head connected with the piston assembly; the positioning and clamping head can extend into a positioning hole of the movable connector so that the rotation central line of the movable connector and the rotation central line of the positioning and clamping head can coincide. The movable connector rapid positioning and clamping tool has the advantages that the labor intensity is lowered during the clamping work of movable connector assembling, the assembling efficiency is improved, the clamping quality of the movable connector is improved, the clamping deformation of the movable connector can be eliminated so that the assembling quality can be improved, the positioning accuracy of the movable connector is improved, and the automatic connection of the movable connector and the pipelines can be achieved through the mechanical device.

Owner:NANJING RUIFA MACHINERY EQUIP

Sand box fixing device of molding sand pressing equipment

InactiveCN107626900AImprove clamping qualityImprove the compaction effectMoulding flasksEngineeringElectromagnet

The invention discloses a sand box fixing device of molding sand pressing equipment. The sand box fixing device comprises a rack, wherein a fixed die of a quadrilateral structure is arranged above therack, fixed pressing plates are respectively arranged on four inner side walls of the fixed die, guide posts are arranged between the fixed pressing plates and the inner side walls of the fixed die,and compression springs sleeve the guide posts; electromagnets are respectively arranged on the inner side walls of the fixed die, and iron blocks which correspond to the electromagnets are arranged on the inner side walls of the fixed pressing plates; rubber layers are arranged on the outer side surfaces of the fixed pressing plates, and friction grains are formed on the surfaces of the rubber layers; and a sand box moving mechanism is arranged at the bottom in the fixed die. The sand box fixing device has the characteristics that the sand box clamping quality can be effectively increased, the compaction effect can be improved, and the molding sand compaction efficiency can be improved.

Owner:湖州市下昂多联铸造有限公司

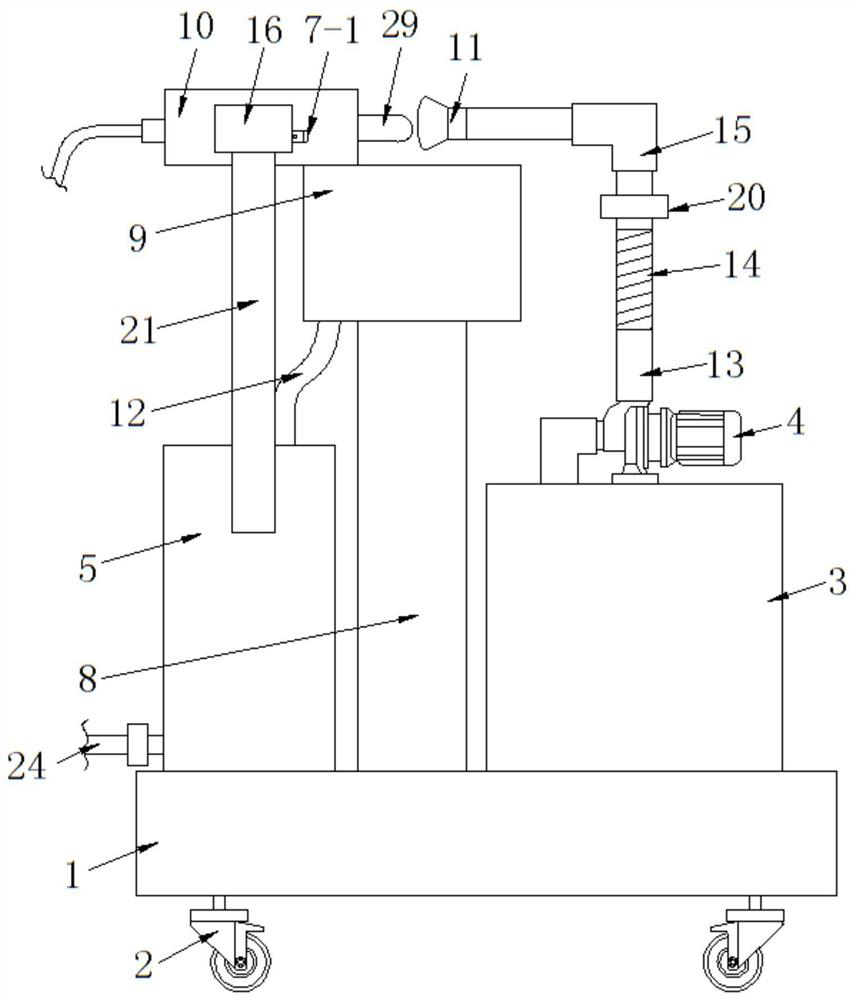

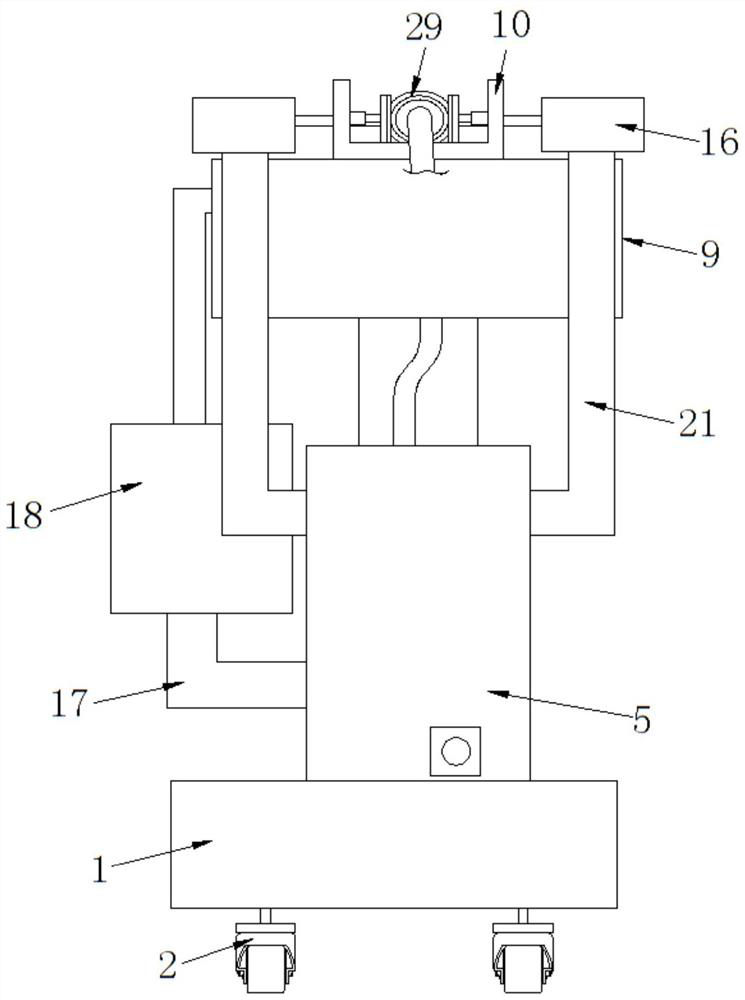

Disinfection sprayer for traditional Chinese medicine gynecological examination

PendingCN113082259AImprove rinse qualityPrevent splashLavatory sanitoryCleaning using liquidsNebulizerGynecologic examination

The invention discloses a disinfection sprayer for traditional Chinese medicine gynecological examination, and relates to the technical field of medical instruments. A water accumulation tank, a support and a water tank are sequentially fixed to a base from left to right, a cleaning tank is fixed to the support, a clamping seat is fixed to the upper end of the left side of the cleaning tank, the cleaning tank is in through connection with the water accumulation tank through a drain pipe, a water pump is fixed to the water tank, and a water inlet end of the water pump is in through connection with the water tank through a water pipe, and a drainage pipe is fixed to a water outlet end of the water pump. A telescopic hose is fixed to a drainage end of the drainage pipe, an extension pipe is fixed to the drainage end of the telescopic hose, a spray head is arranged at the horizontal end of the extension pipe and arranged in the cleaning box, a supporting frame is fixed to the rear side of the water tank, a supporting seat is fixed to the vertical end in the supporting frame, and a reciprocating adjusting mechanism is arranged in the supporting seat. According to the B-ultrasonic probe spraying device, a B-ultrasonic probe can be limited and clamped, the spray head is driven to perform movable spraying, and the B-ultrasonic probe is subjected to spraying disinfection operation, so that the cleanliness of the B-ultrasonic probe is improved, cross infection is avoided, and the inspection quality is improved.

Owner:胡彦平

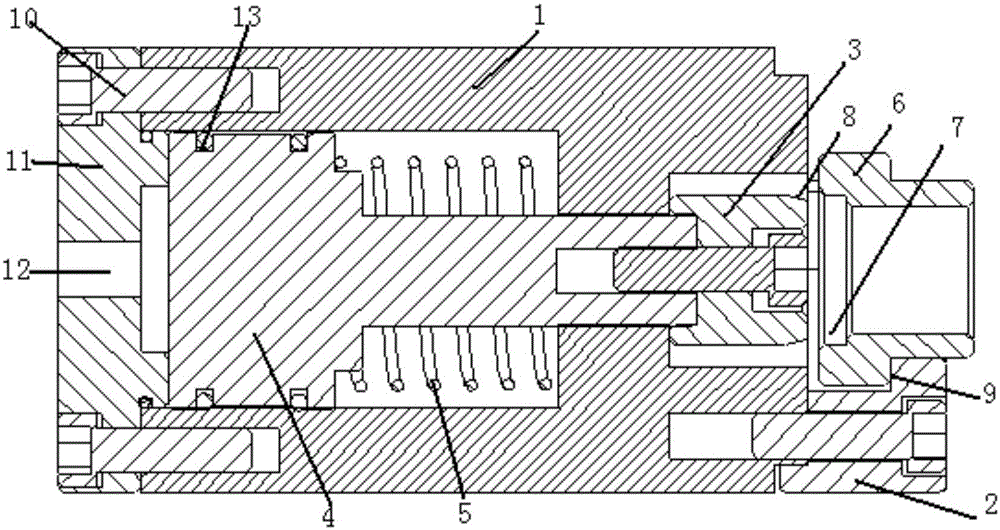

Turning fixture for clutch hub in automatic transmission of automobile

ActiveCN106141233AHigh positioning accuracyImprove processing stabilityChucksAutomatic transmissionEngineering

The invention relates to a turning fixture for a clutch hub in an automatic transmission of an automobile. The fixture comprises a fixture supporting body, a positioning body arranged at one end of the fixture supporting body and an elastic clamping mechanism arranged outside the positioning body, wherein the elastic clamping mechanism comprises a spring chuck arranged outside the positioning body as well as a casing which sleeves the outside of the spring chuck and is fit with the spring chuck, a first elastic assembly is arranged between the spring chuck and the fixture supporting body, a second elastic assembly is arranged between the casing and the fixture supporting body, the clutch hub is arranged on the inner side of the spring chuck, the positioning body axially positions the clutch hub, the casing presses the spring chuck inwards, and the clutch hub is fixed on the fixture. Compared with the prior art, the clutch hub is firmly fixed on the fixture by the aid of the elasticity of a compression spring, the self-locking effect of the spring chuck and the axial positioning of the positioning body, the positioning accuracy is high, clamping and dismounting are convenient and labor-saving, and the clamping efficiency of the clutch hub is greatly improved.

Owner:SHANGHAI UNIV OF ENG SCI

Fast mounting and demounting device for aviation plug

ActiveCN110744494AUnhindered and convenientImprove disassembly efficiencyMetal-working hand toolsAviationTorsion spring

The invention discloses a fast mounting and demounting device for an aviation plug. The fast mounting and demounting device comprises a locking block and an inserting block. The locking block and theinserting block are rotationally connected through a torsion spring. An inserting groove is formed in the side wall of the locking block, and an inserting rod is welded to the side wall of the inserting block. The inserting rod abuts against the inner wall of the inserting groove. A locking mechanism used for limiting moving of the inserting rod is arranged in the inserting groove. Clamping grooves are formed in the side walls of the locking block and the inserting block correspondingly in a penetrating manner, and a set of clamping springs are welded on each of the inner walls of the sides, away from each other, of the two clamping grooves. The fast mounting and demounting device has the beneficial effects that the locking block and the inserting block are designed so that a cable connected with the plug can penetrate the locking block and the inserting block in the process that the locking block and the inserting block are combined, blockage and interference cannot be caused in the subsequent plug screwing process, the whole demounting and mounting process is not hindered, convenience and rapidness are achieved, and the whole demounting and mounting efficiency is greatly improved.

Owner:NANJING CHENXI AERODYNAMIC TECH

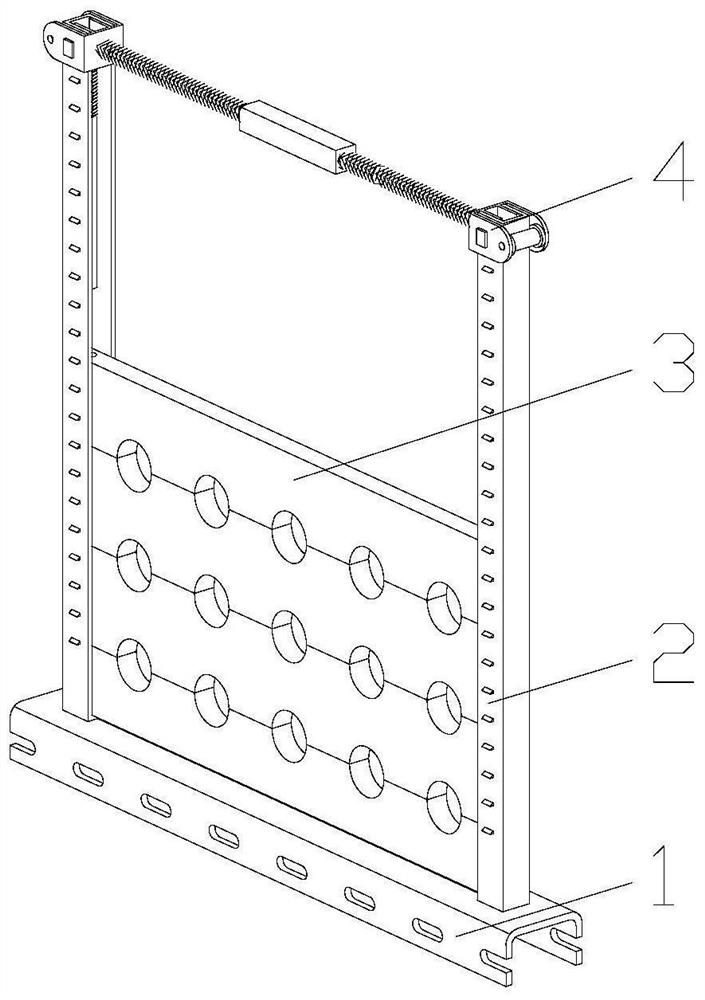

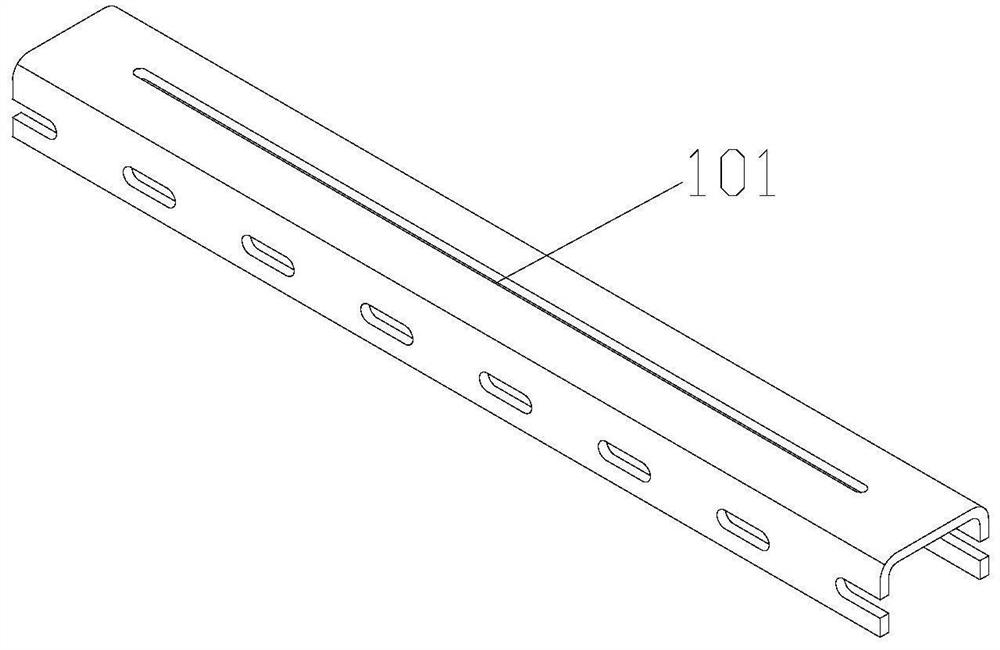

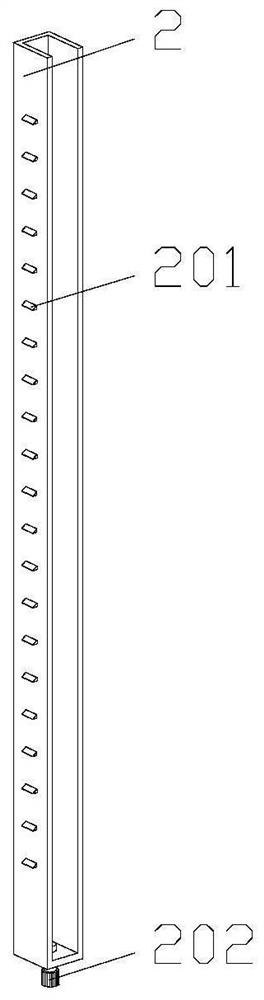

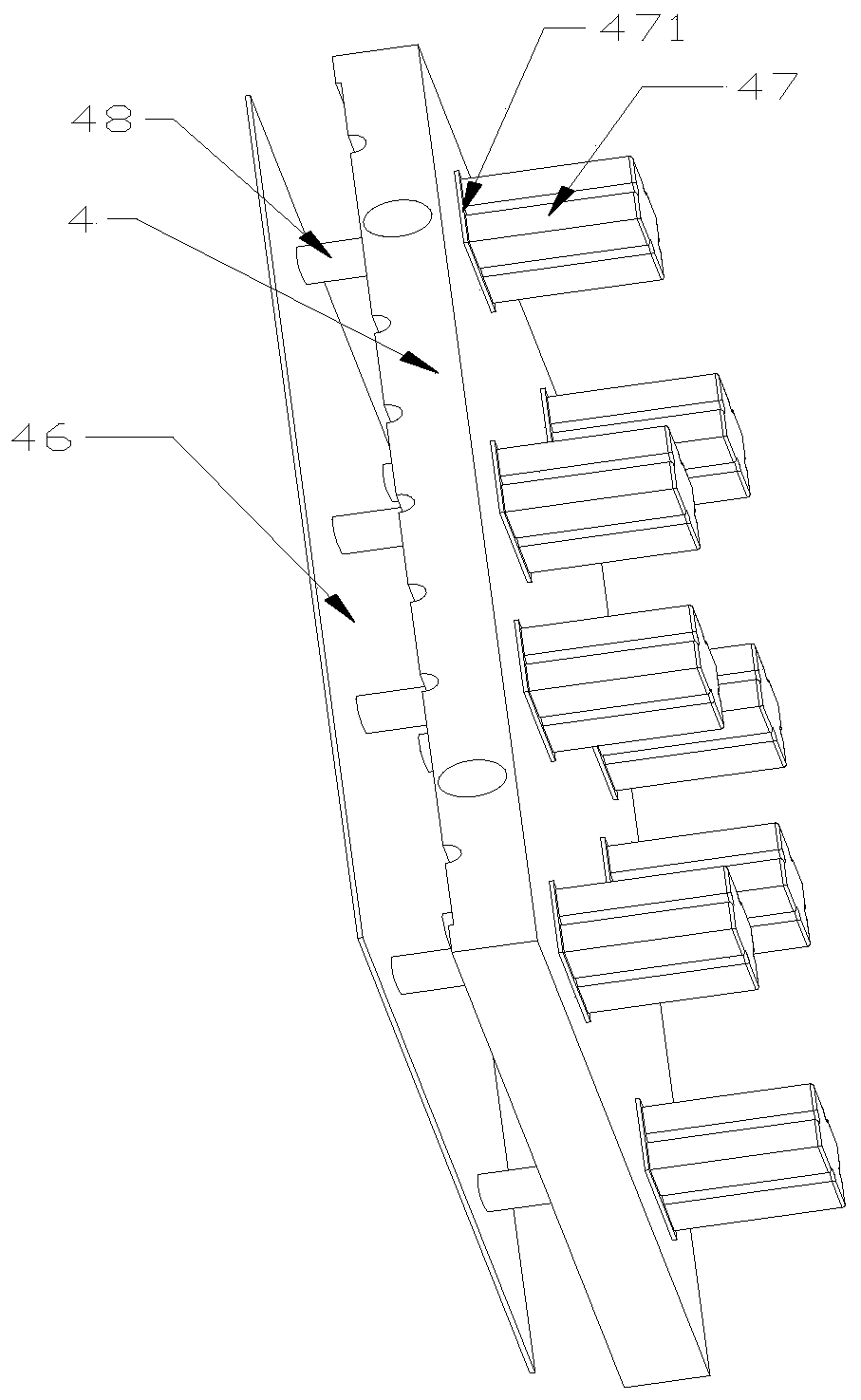

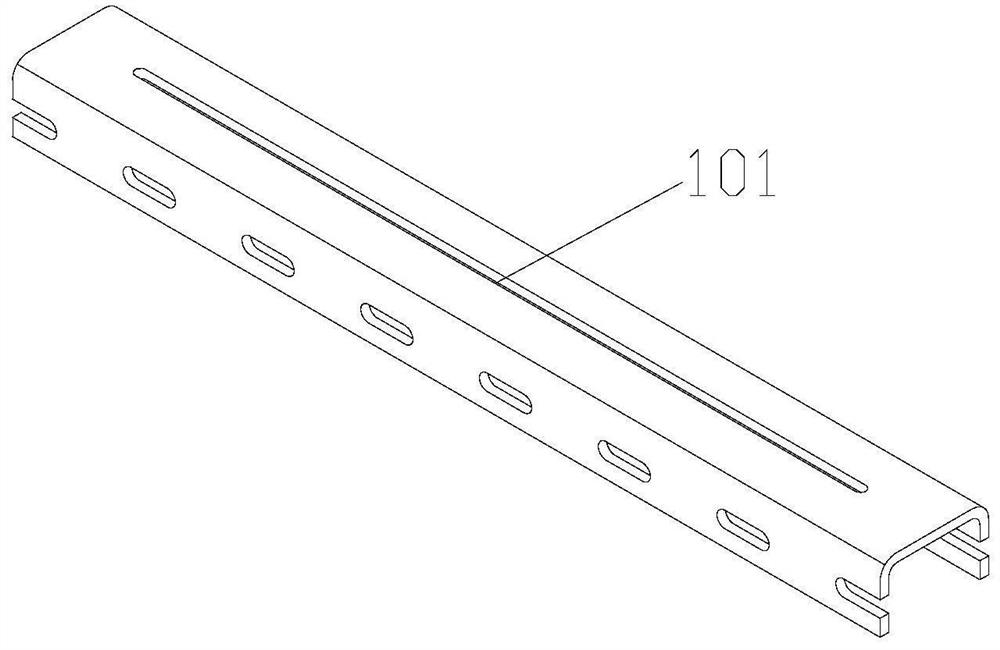

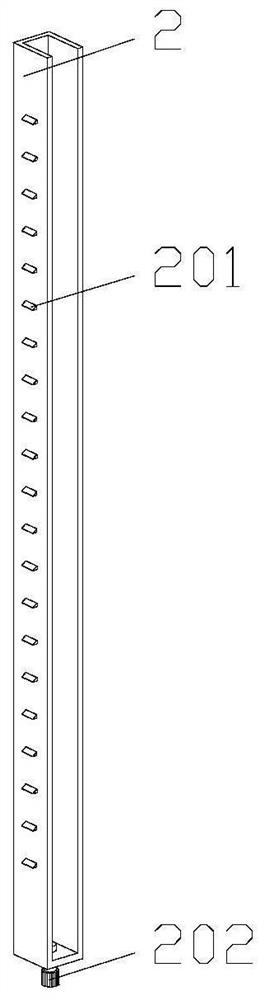

Secondary cable laying support

ActiveCN113315049AImprove laying efficiencyImprove fixation efficiencyElectrical apparatusStructural engineeringElectric cables

Owner:PINGYIN POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

Pipe cutting device for water conservancy project

InactiveCN111515452AImprove clamping qualityImprove protectionGripping headsWork clamping meansPipeScrew thread

The invention discloses a pipe cutting device for a water conservancy project. The pipe cutting device comprises a workbench. Multiple limiting seats are distributed on the workbench at equal distance. A feeding mechanism is distributed above the workbench and comprises assembly seats. A sliding lead screw is assembled between the two assembly seats, a sliding seat in transmission fit with the sliding lead screw is assembled on the sliding lead screw, and a vertical lifting table is fixedly connected to the lower end of the sliding seat. According to the pipe cutting device for the water conservancy project, a rocking handle can feed pipes by a proper length by controlling the clamping action of clamping rods; the work segments of limiting blocks and limiting grooves are arranged concentrically, the limiting blocks and limiting air cylinders are mounted and connected through cooperation threads, and therefore the limiting blocks of different specifications can be selected to assemble pipes of different sizes conveniently; and in addition, protection layers are distributed on the contact faces of the limiting blocks and the clamping rods with pipes, pipes can be protected conveniently, and the cutting quality of pipes is ensured.

Owner:高彩真

Automatic clamping device for EPP foam plate cutting

ActiveCN110370359AEasy to operateImprove cutting efficiencyMetal working apparatusMechanical engineeringThreaded rod

The invention discloses an automatic clamping device for EPP foam plate cutting. The automatic clamping device comprises a cutting plate table, wherein connecting boxes which are in mirror distribution are arranged on the two sides of the cutting plate table, a sliding groove is formed in each connecting box, a first bearing hole penetrating through one side connecting box is formed in each sliding groove, and a first positioning hole is formed below the corresponding first bearing hole;a fixed table top is arranged on the cutting plate table, anti-skid grooves distributed in an array are formed in the fixed table top, servo motor fixing grooves which are distributed in an array are formed in one side of the cutting plate table, a threaded rod is arranged in each first bearing hole, and asliding rod is arranged in each first positioning hole; a first sliding block is arranged in the connecting box on one side, and a second sliding block is arranged in the connecting box on the other side; and a connecting block is arranged on the second sliding block, a clamping rod is arranged on the connecting block, a locking block is arranged on the first sliding block, and a servo motor is arranged in each servo motor fixing groove. The automatic clamping device has the advantages that the structure is simple, the cutting operation of operators is facilitated, positioning and clamping canbe adjusted according to EPP foam plates with different thicknesses, and the clamping quality of the EPP foam plates is improved.

Owner:安徽艾普塑料科技有限公司

Workpiece stamping device with clamping function

InactiveCN107597992AImprove clamping qualityImprove stabilityMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

Disclosed is a workpiece stamping device with a clamping function. The workpiece stamping device with the clamping function comprises a base plate, a top plate, a first air cylinder, a connecting plate, second air cylinders, adjusting blocks, stamping blocks, a lower cushion block and a controller. The workpiece stamping device with the clamping function is characterized in that the base plate isarranged on a support, the top plate is arranged on stand columns, and the first air cylinder is arranged on the top plate; and the connecting plate is arranged on a first piston rod, the second air cylinders are arranged on the connecting plate, one end of each adjusting block is connected with a second piston rod through a hinge pin, and the stamping blocks are arranged on the connecting plate.According to the workpiece stamping device with the clamping function, the second air cylinders and a plurality of connecting blocks are arranged on the connecting plate, the connecting blocks are connected with limiting rods on the adjusting blocks through the hinge pins, the adjusting blocks are connected with the second piston rods through the hinge pins, after stamping of a workpiece is accomplished, the second air cylinders and the second piston rods push the adjusting blocks to enable clamping rods on the adjusting blocks to clamp the workpiece, and therefore the clamping quality of theworkpiece is improved, the stability of the workpiece in the clamping process is enhanced, and then the working efficiency is improved.

Owner:ANHUI HAITUO ZHIYONG INTELLIGENT EQUIP CO LTD

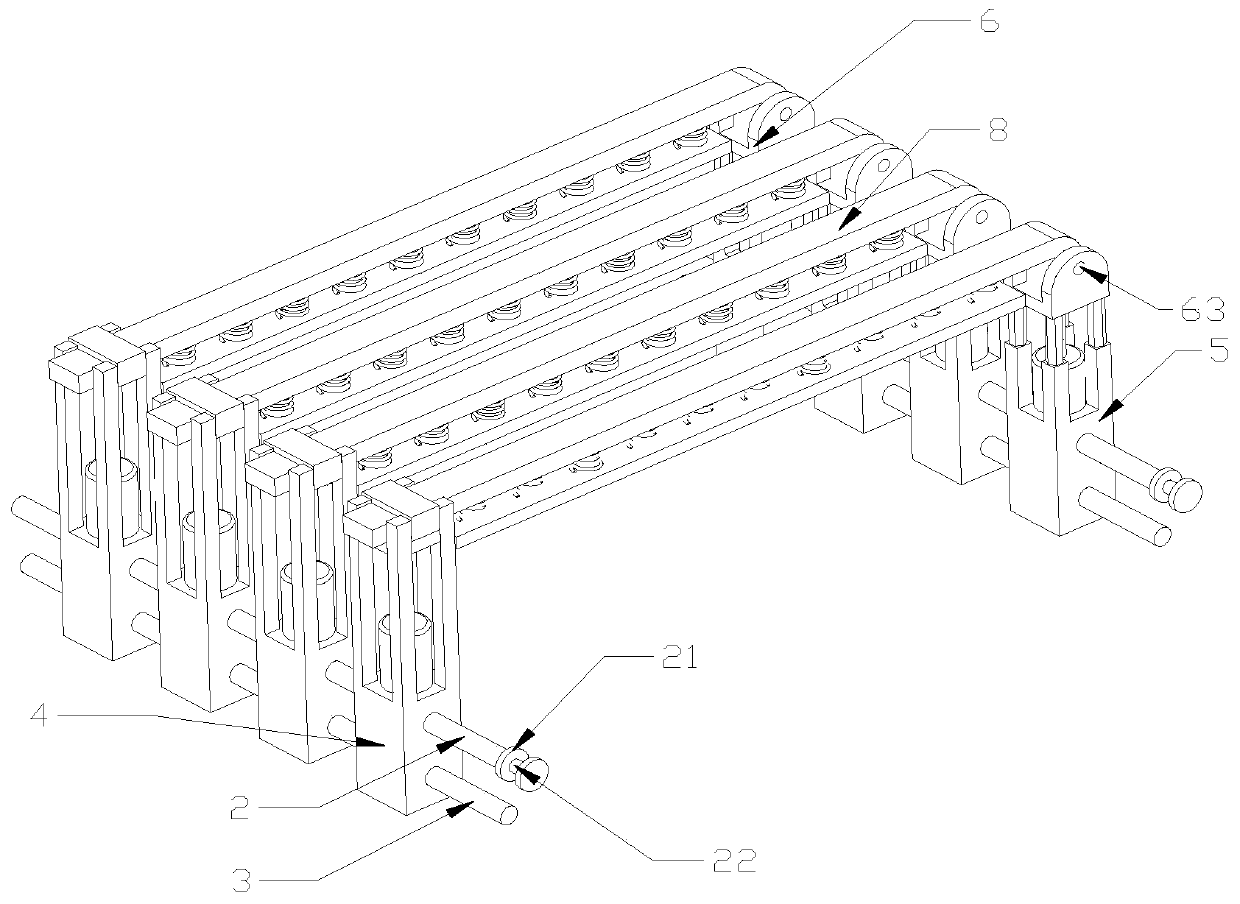

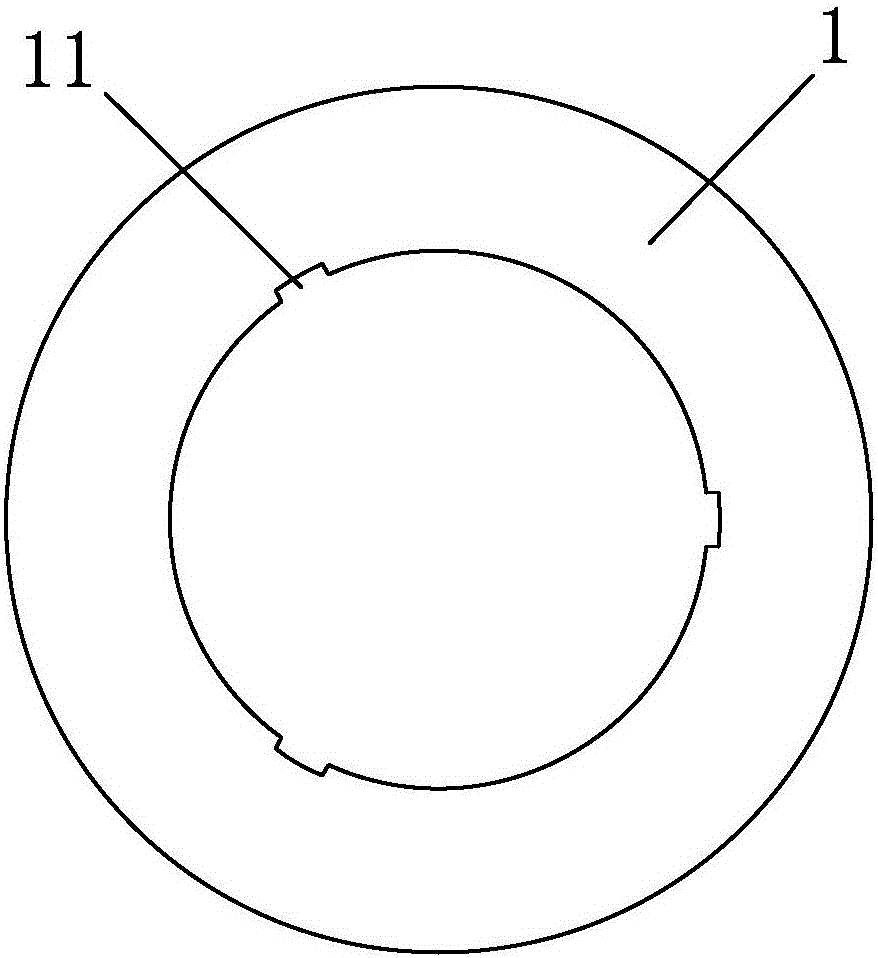

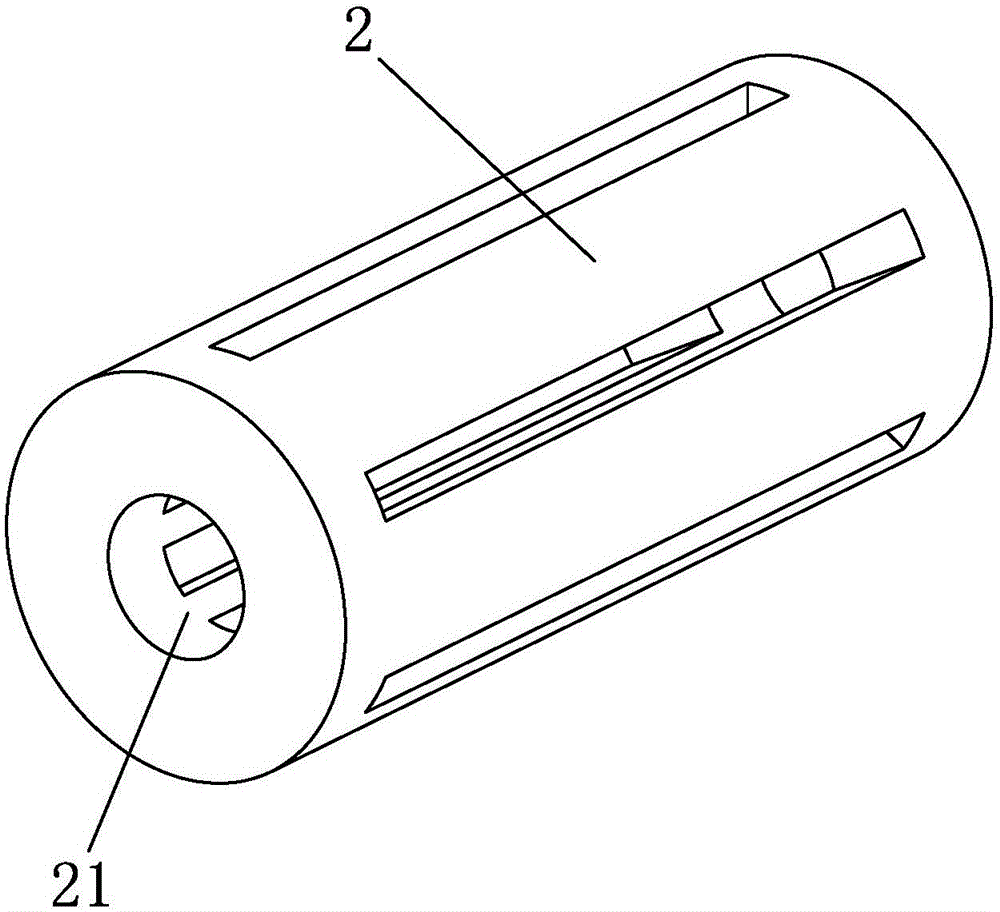

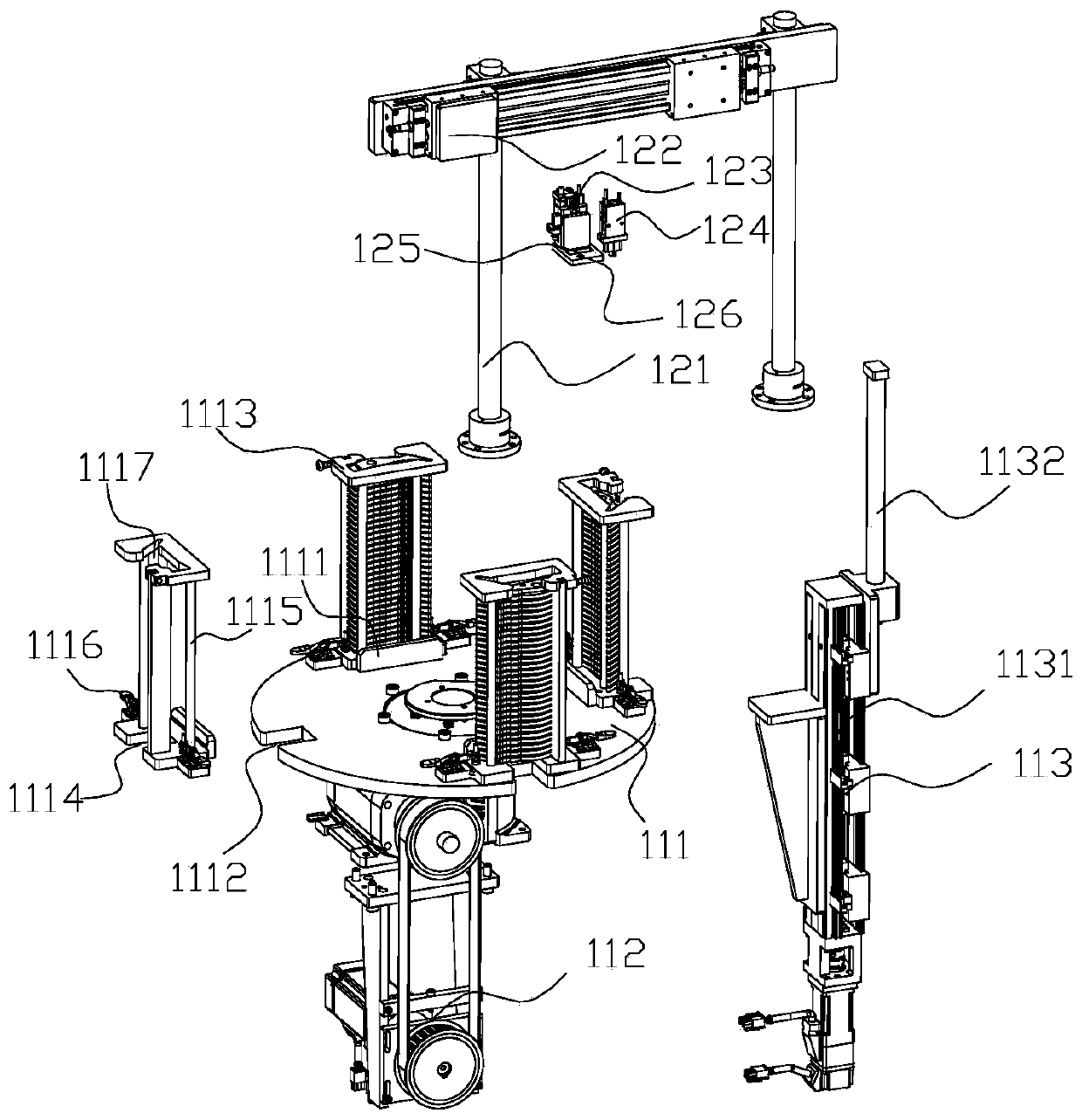

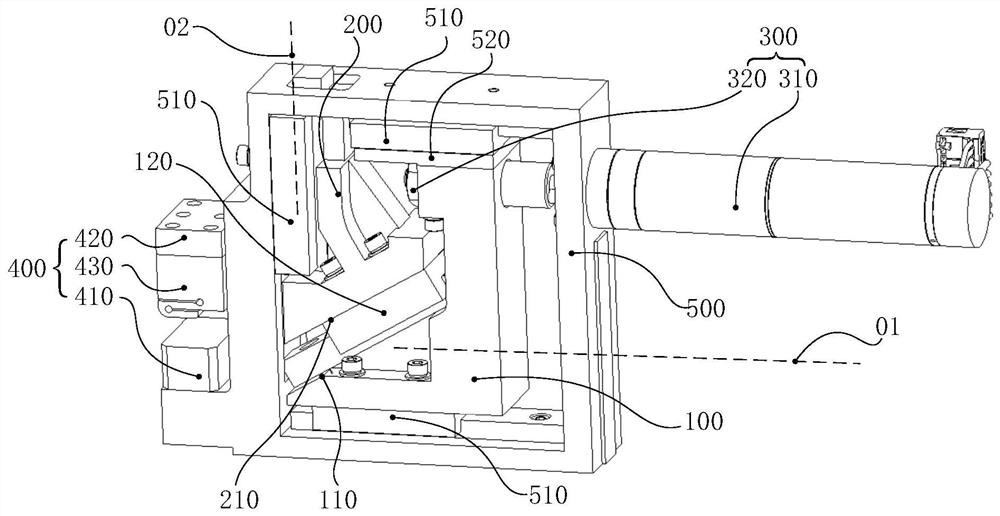

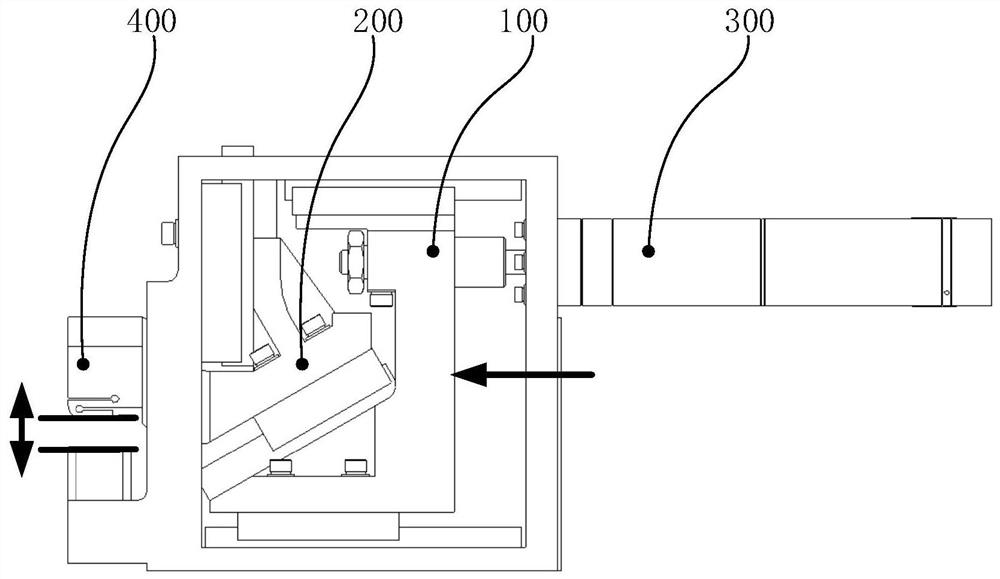

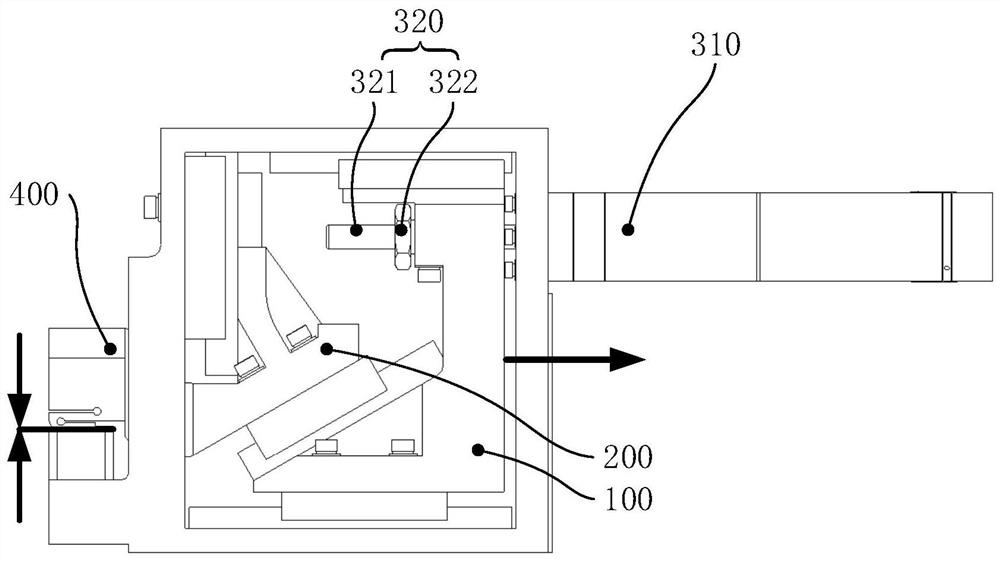

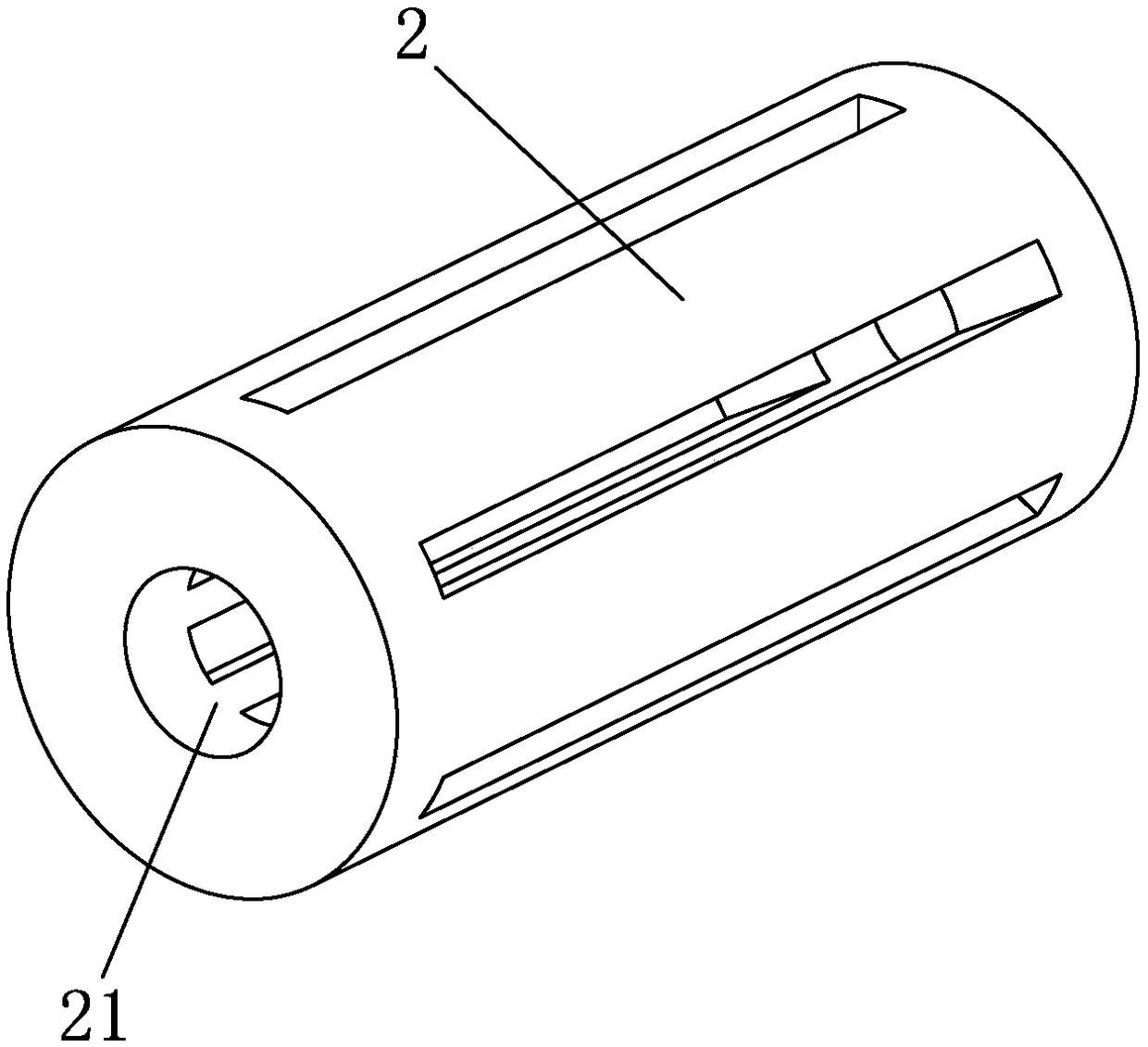

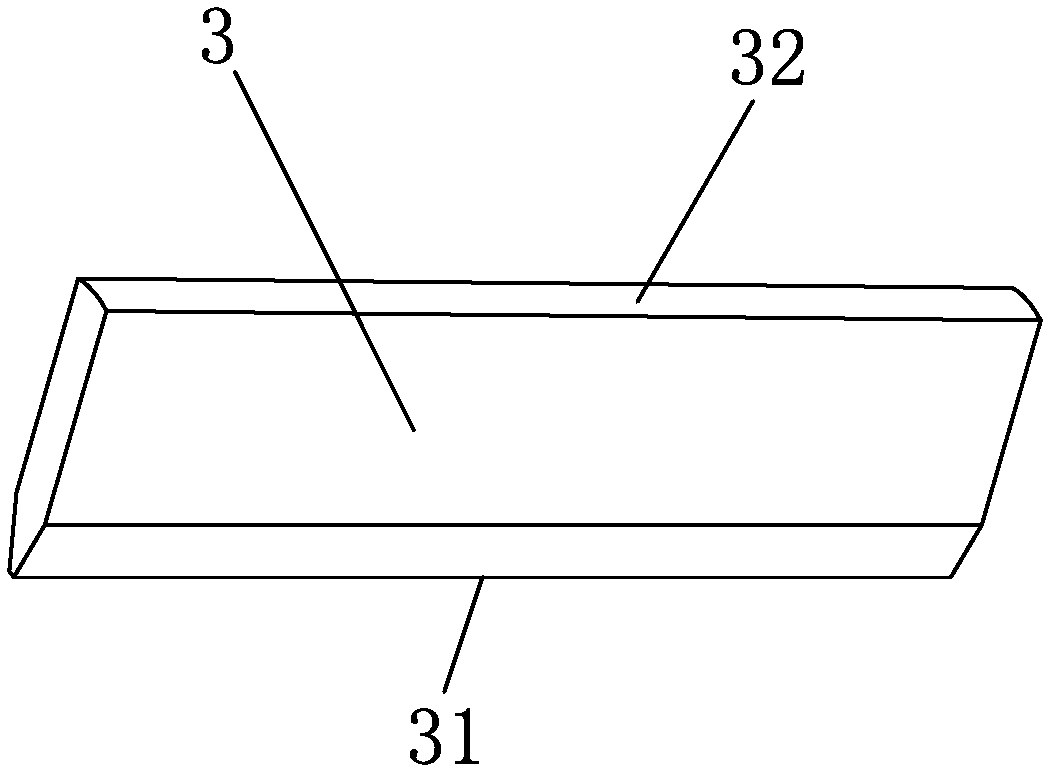

Assembly mold and assembly method for composite tube shell spiral line slow-wave structure

ActiveCN106783470AClamping volume controllableSolve the impossible clamping problem of composite shellVessels or leading-in conductors manufactureWave structureMechanical engineering

The invention discloses an assembly mold and an assembly method for a composite tube shell spiral line slow-wave structure. The assembly mold comprises a grasp module, a support component and an installation component. The grasp module comprises a tube body and a clamp. The clamp comprises a grip-body and a support rod. An internal end face of the support rod is utilized for supporting and pressing on an external wall face of the spiral line and an external end face of the support rod is utilized for supporting and pressing on an internal wall face of the tube body. The support component comprises a support shaft lever and a support shaft chuck. The support shaft chuck is disposed between two adjacent support rods which make the spiral line have elastic deformation. The installation component comprises a first member bar and a second member bar. According to the deformability of the spiral, through the cooperation among assembly molds and spiral lines, the assembly of the composite tube shell spiral line slow-wave structure is achieved.

Owner:北京真空电子技术研究所

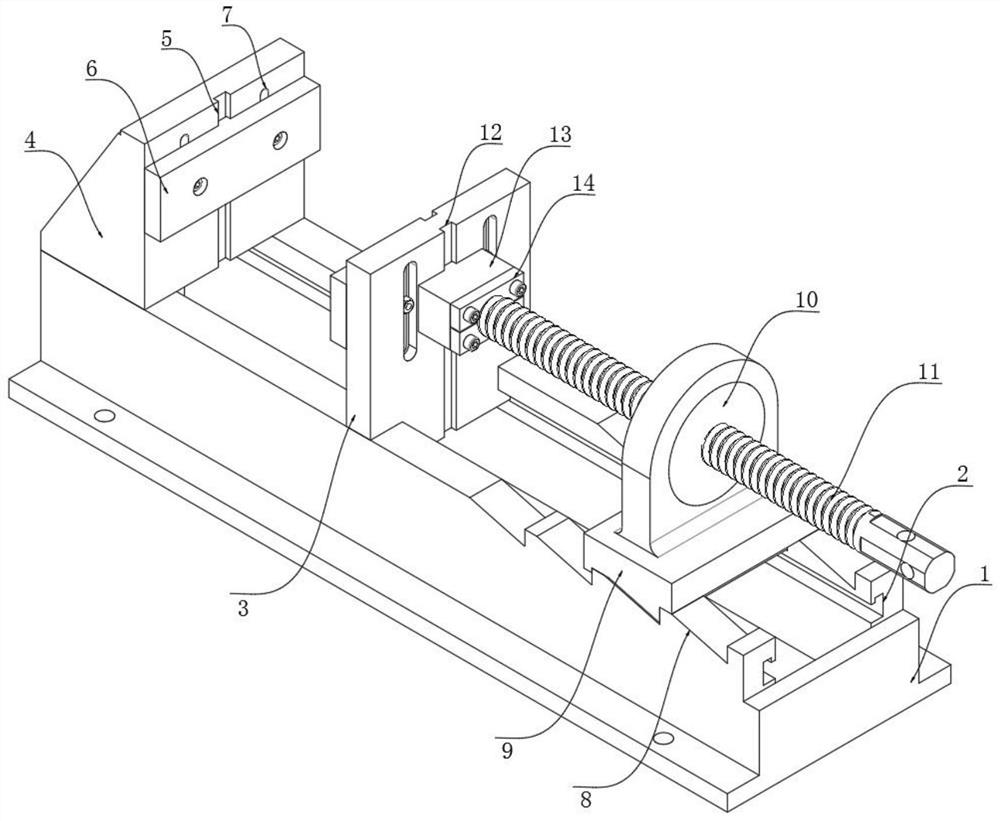

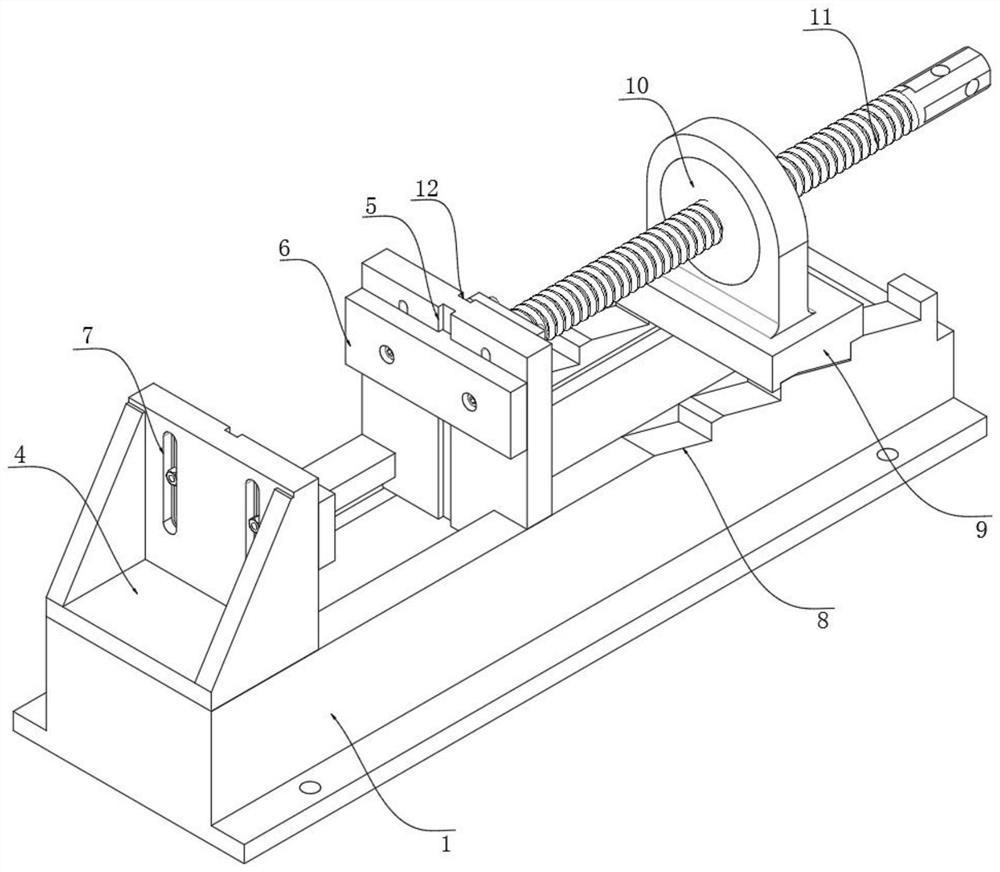

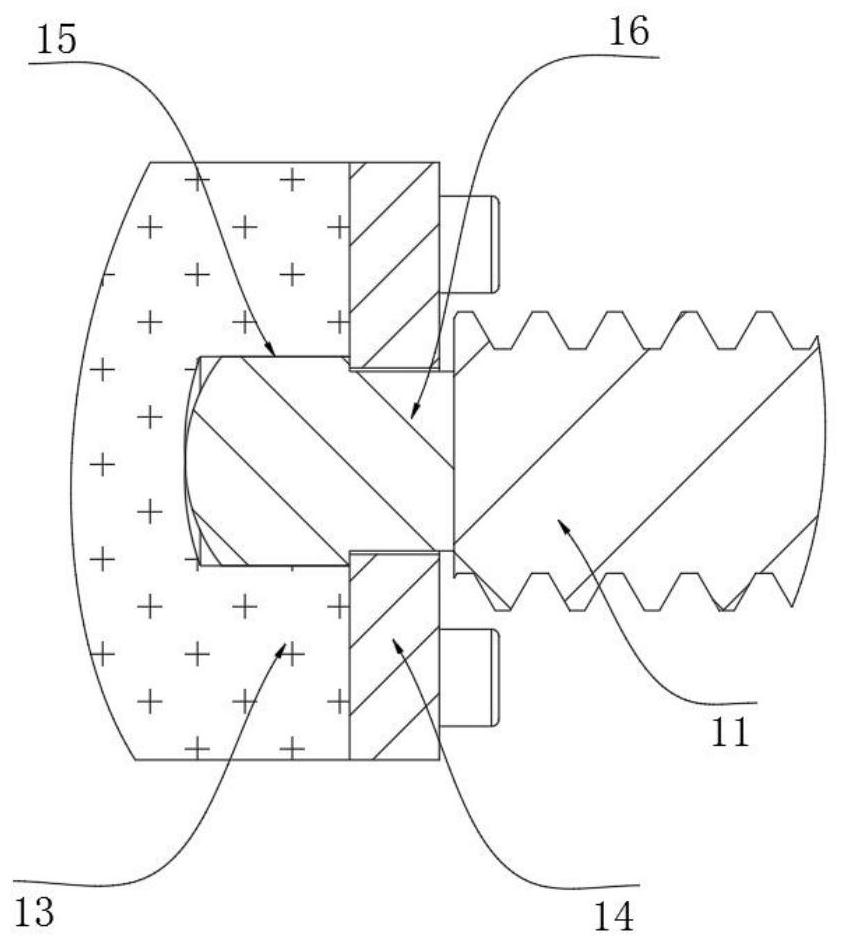

Simple adjustable bench clamp

PendingCN113319752AAchieve lockingAdjustable height direction force pointVicesStress pointClassical mechanics

The invention discloses a simple adjustable bench clamp. The simple adjustable bench clamp comprises a base, wherein a sliding groove is formed in the side wall of the base, a movable backup plate is slidably connected to the inner wall of the sliding groove, a fixed backup plate is fixed to the upper end of the base, positioning clamping mechanisms are arranged on the side wall of the movable backup plate and the side wall of the fixed backup plate, and tooth grooves are formed in the upper end of the base; and the upper ends of the tooth grooves abut against a supporting tooth block, an adjusting support is fixed to the upper end of the supporting tooth block, the side wall of the adjusting support is connected with a propelling screw in a penetrating and threaded manner, and the end of the propelling screw is connected with a propelling combination mechanism. The simple adjustable bench clamp has the advantages that clamping plates are locked through mounting bolts of the clamping plates, and the bolts for mounting the clamping plates penetrate through positioning kidney-shaped holes, so that the clamping plates can adapt to any position of the clamping plates in the range of the positioning kidney-shaped holes, mounting and position adjustment of the clamping plates cannot conflict, and meanwhile, a stress point in the height direction of a workpiece can be adjusted, and the workpiece can be clamped more stably.

Owner:霍山嘉远智能制造有限公司

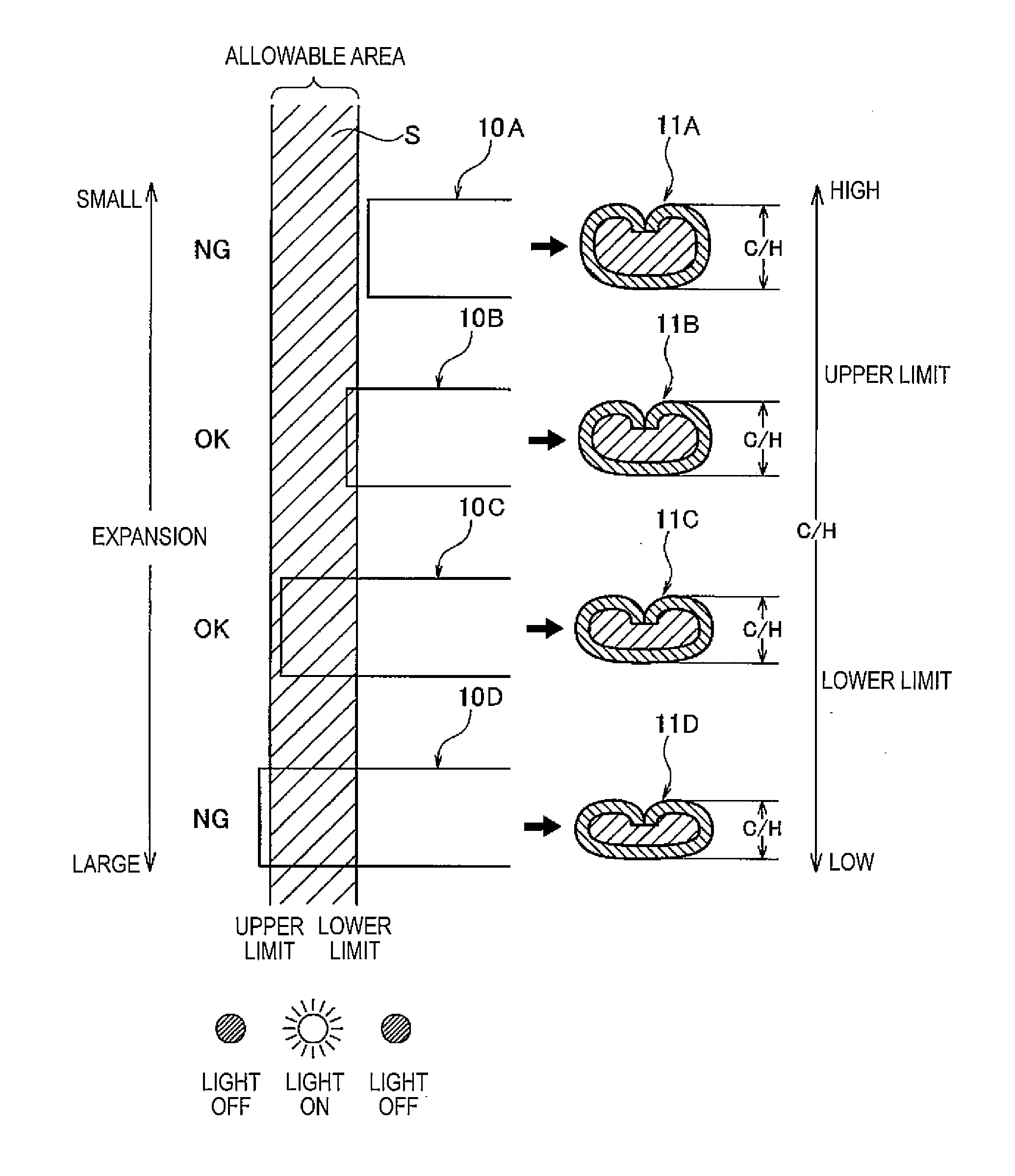

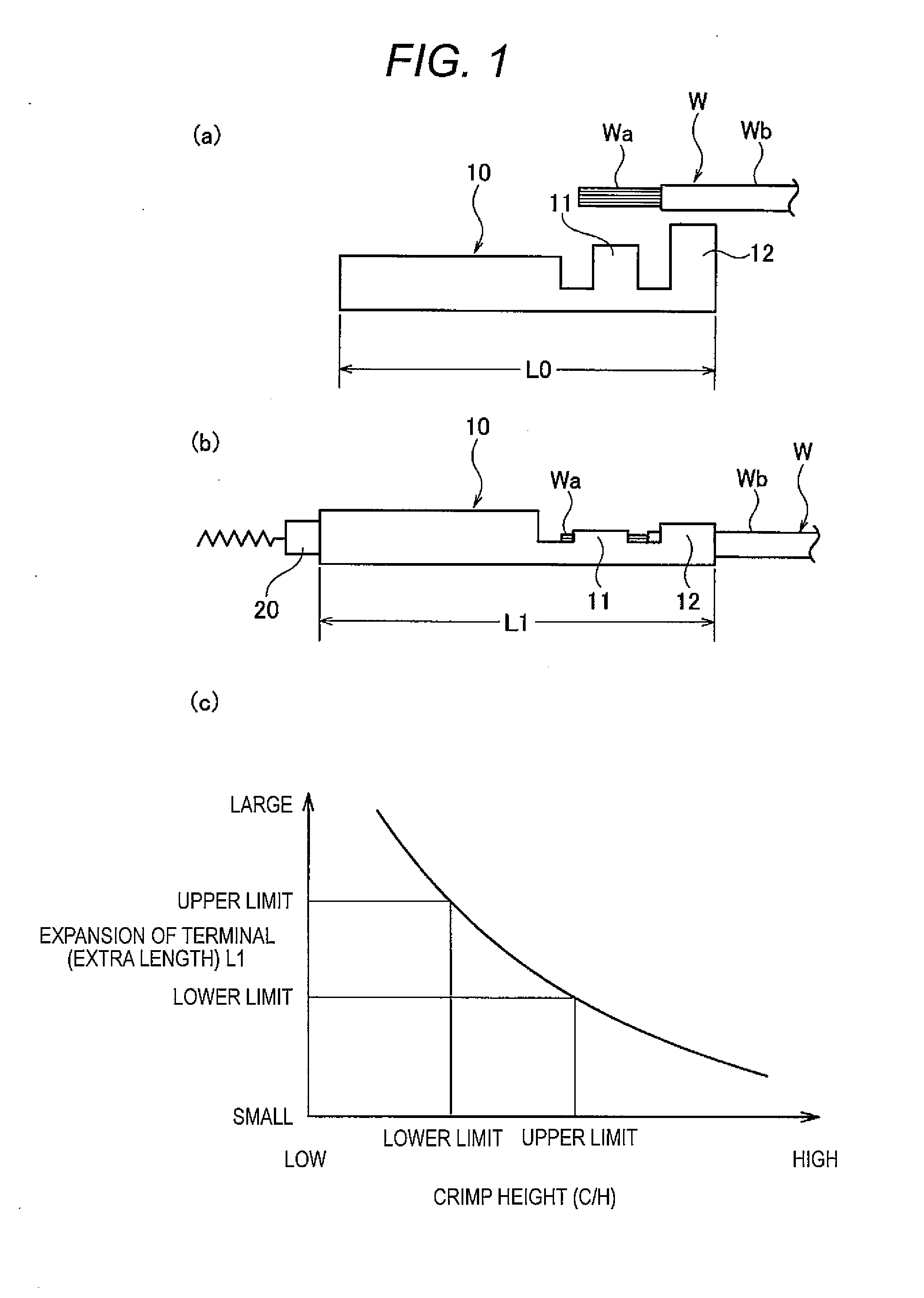

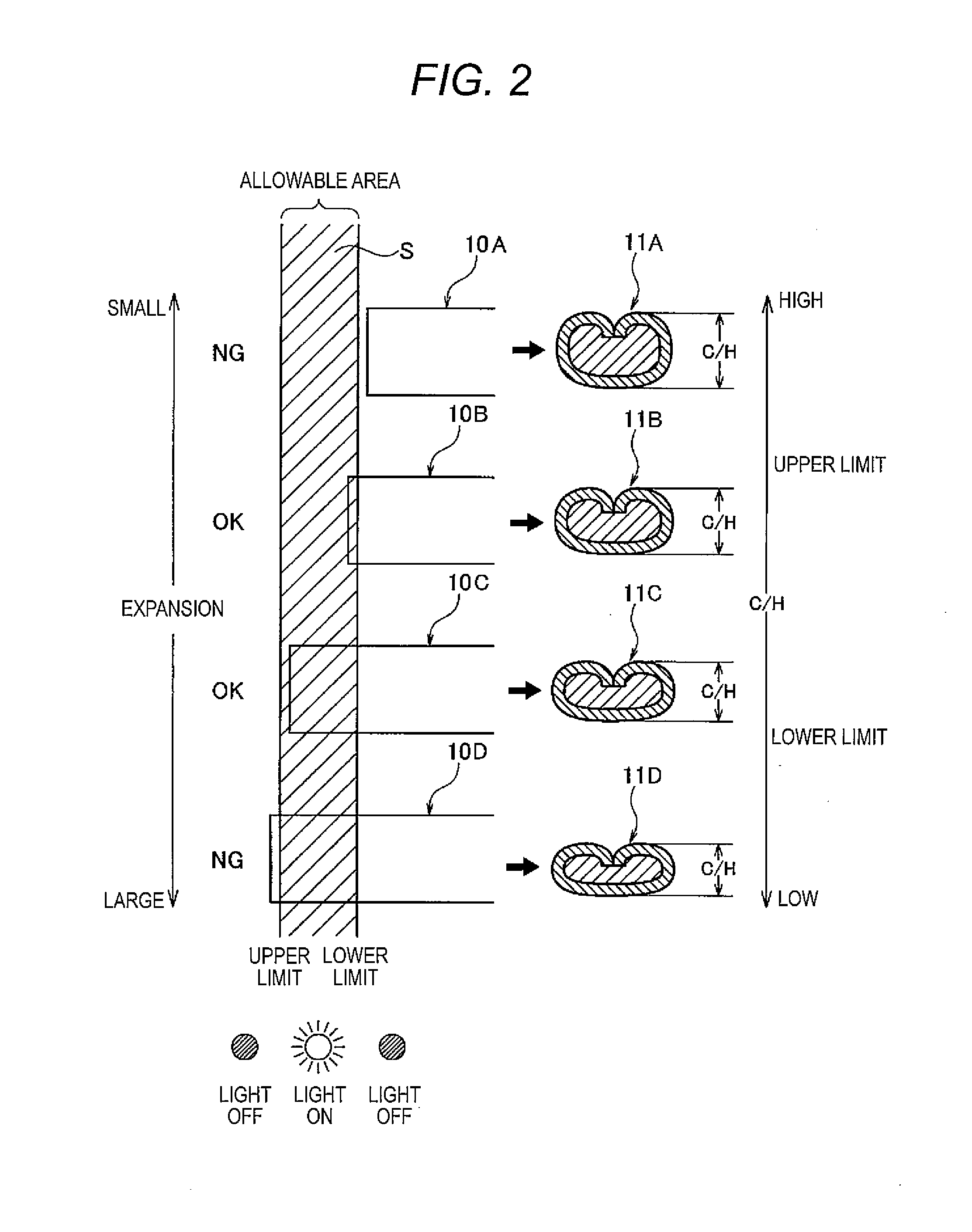

Method of evaluating a clamping portion of an electric wire and a terminal, and device for evaluating the clamping portion

ActiveUS20120146659A1Easy assessment processImprove clamping qualityLine/current collector detailsElectrical testingLower limitIndustrial engineering

There is provided a method of evaluating a clamping portion of an electric wire and a terminal, which can determine whether a clamping quality is good, or not, through simple test, and can easily test all of the clamping portions. The method of evaluating the clamping portion of an electric wire (W) and a terminal (10) includes measuring a length (L1) of the terminal (10) after clamping to detect an expansion of the terminal (10) after clamping to a length (L0) of the terminal (10) before clamping, determining that the clamping quality is “good” when the expansion falls within an allowable range between a given lower limit and a given upper limit, and determining that the clamping quality is “no good” when the expansion falls outside the allowable range.

Owner:YAZAKI CORP

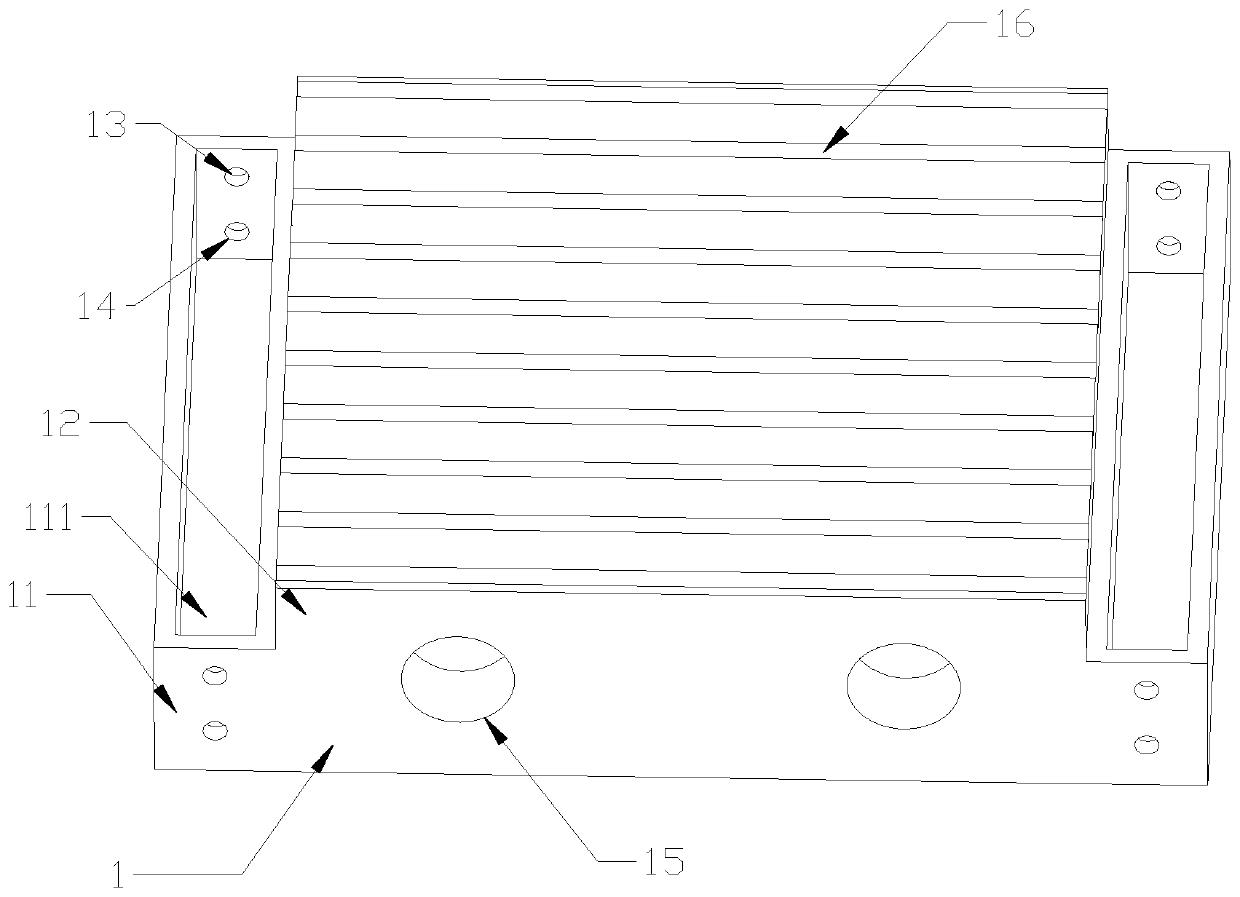

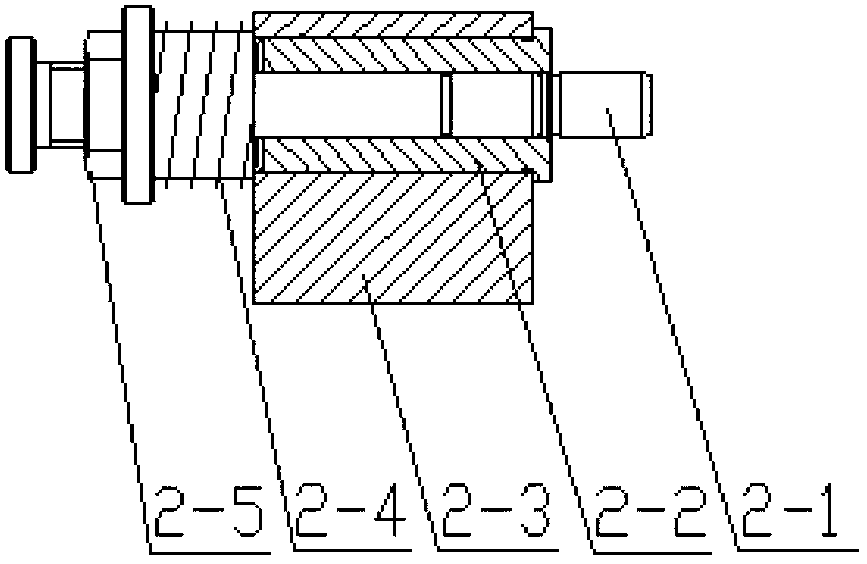

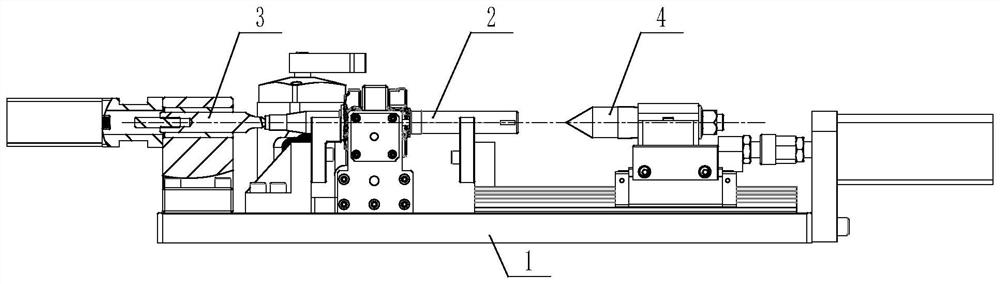

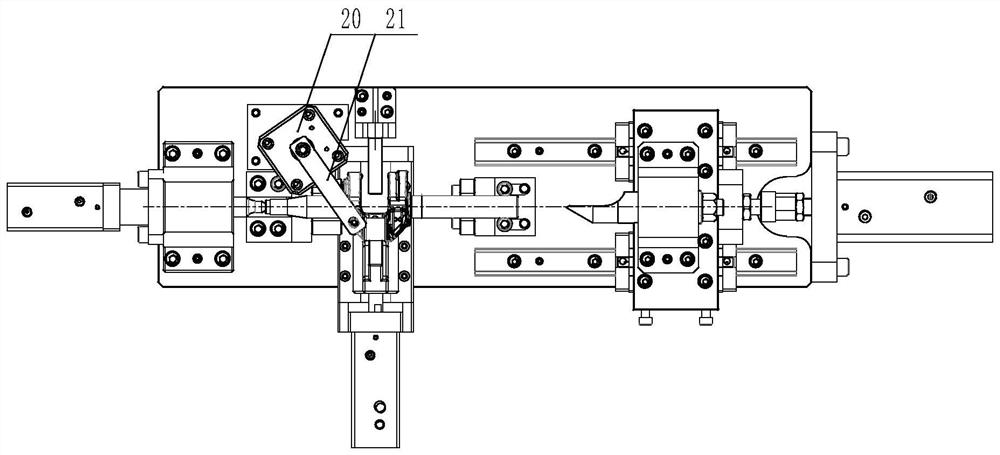

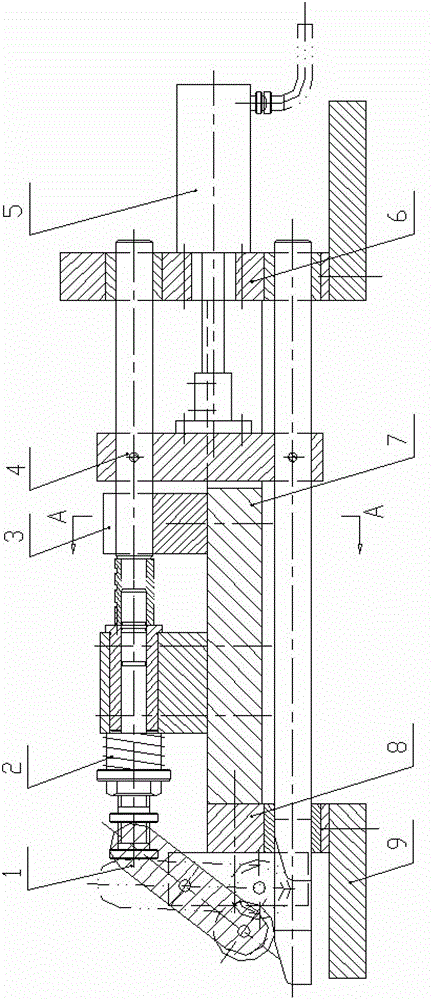

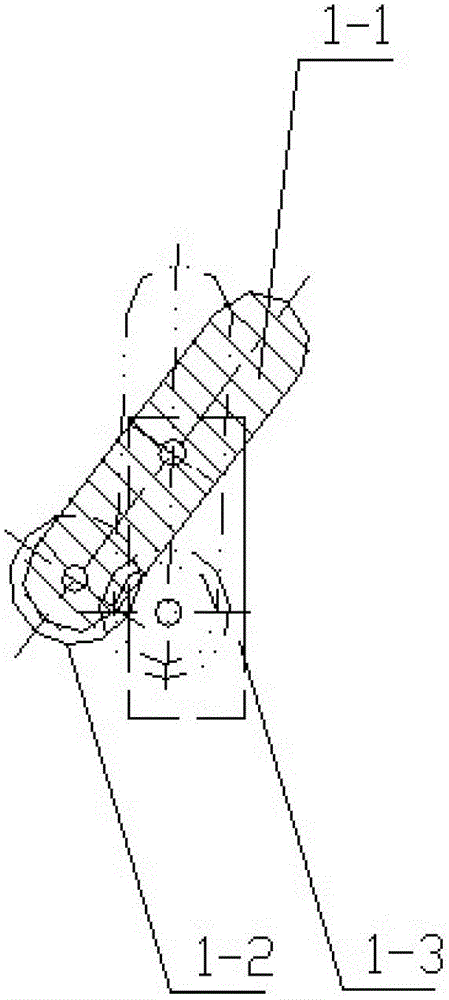

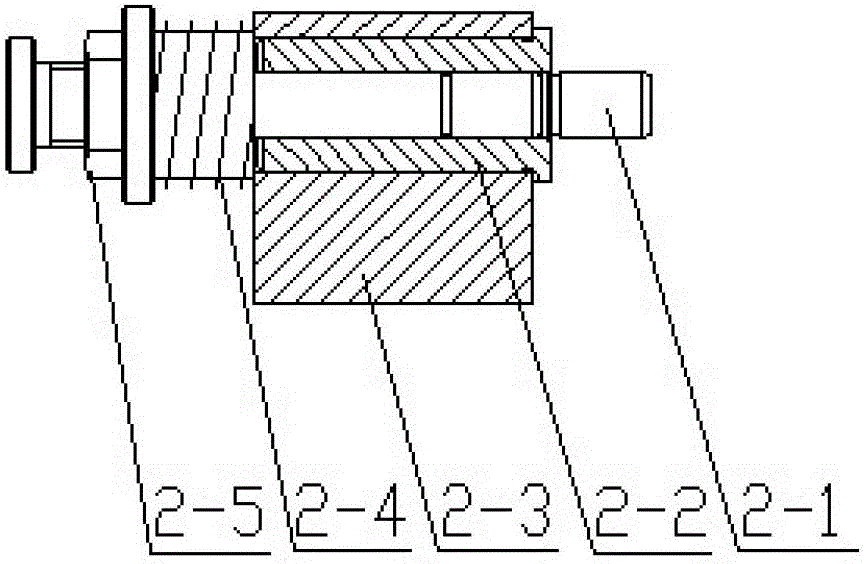

Milling groove clamping device of sleeve-class part

ActiveCN103121177AStable clamping forceImprove clamping qualityMetal working apparatusPistonClip device

The invention relates to a milling fixture, in particular to a milling groove clamping device of a sleeve-class part. The milling groove clamping device of the sleeve-class part comprises a fixed base, a left vertical plate and a right vertical plate, wherein the left vertical plate and the right vertical plate are fixedly connected on the fixed base, a horizontal supporting plate fixedly connected between the left vertical plate and the right vertical plate, an air cylinder fixedly connected on the right vertical plate, a double-pushrod mechanism connected on a piston of the air cylinder, a power transmission mechanism hinged on the left vertical plate, a positioning mechanism fixedly connected on the horizontal supporting plate and an automatic feeding and discharging mechanism arranged on the right side of the positioning mechanism. By adopting the technical scheme, the machining accuracy requirement of the part can be guaranteed, clamping force is stable, clamping quality is high, the speediness and automation of the clamping of the part are achieved, production efficiency is improved greatly and working intensity of workers is relieved greatly.

Owner:佛山市顺德区上锐机械有限公司

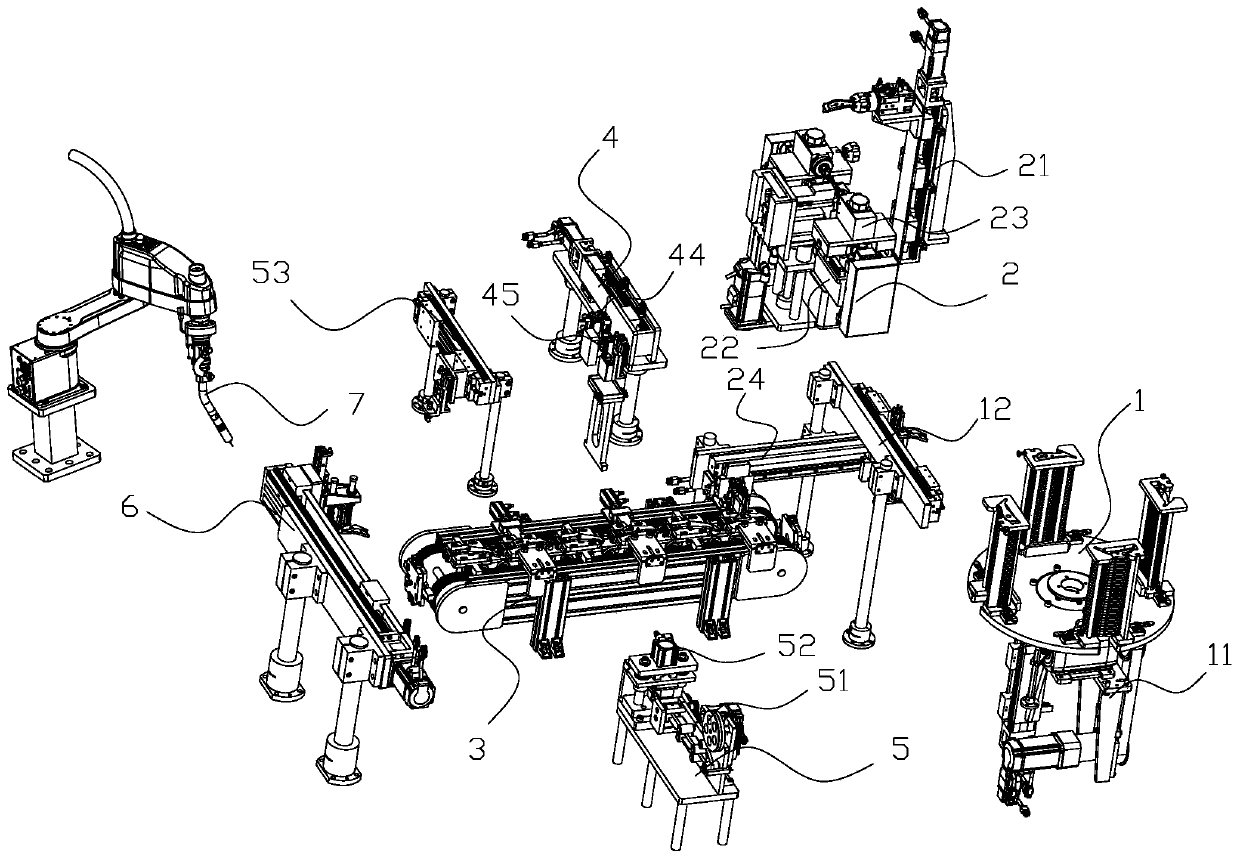

Circuit breaker, and contact and copper sheet automatic assembling method and device thereof

InactiveCN111430189AEasy transferPrevent fallingEmergency protective device manufactureCopperMaterials science

The invention relates to the technical field of circuit breaker production, and discloses a contact and copper sheet automatic assembling device of a circuit breaker. The automatic assembling device comprises a rack, and a contact conveying and transferring device, a contact deburring device, a contact synchronous belt conveying device, a contact cleaning and coating device, a copper sheet assembling device, a discharging device and a welding device which are arranged on the rack. The device has the advantages that the contact clamping quality is improved, the synchronous belt conveying efficiency is improved, and the copper sheet and contact assembling quality is improved.

Owner:丁水珍

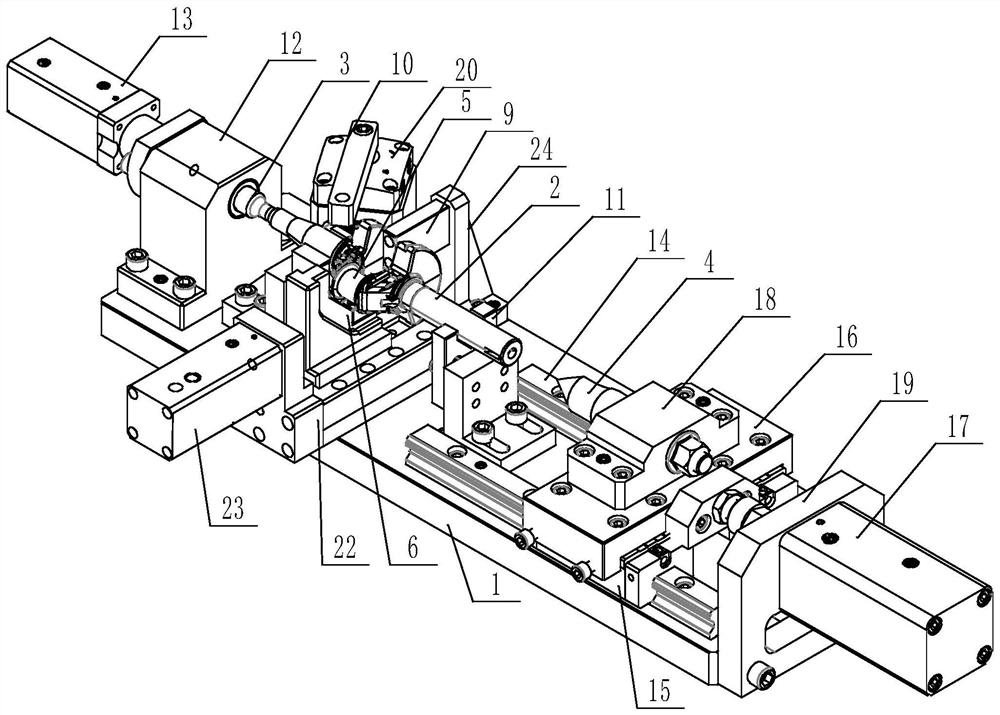

Clamping fixture for milling key grooves in two ends of crankshaft

PendingCN113579807AHigh precisionSimple structureWork clamping meansPositioning apparatusCrankClassical mechanics

The invention discloses a clamping fixture for milling key grooves in two ends of a crankshaft. The clamping fixture comprises a horizontal bottom plate, wherein a supporting structure is arranged on the bottom plate, the supporting structure is provided with two V-shaped supporting faces which are spaced apart in the longitudinal direction of the bottom plate, and the two ends of the crankshaft to be machined can be placed on the two V-shaped supporting faces in a lap joint mode respectively; the outer sides of the two ends of the crankshaft to be detected on the bottom plate are provided with a positioning tip device and an abutting tip device respectively; the positioning tip device comprises a horizontal positioning tip, and the tip end of the positioning tip can abut against the interior of a center hole in one end of the crankshaft so as to limit the axial position of the crankshaft; the abutting tip device comprises an abutting tip, and a longitudinal movement control structure is arranged between the abutting tip and the bottom plate so that the abutting tip can move towards the end face of the crankshaft and the tip end of the abutting tip can abut against the interior of a center hole in the end face of the crankshaft; and a push plate is arranged on the bottom plate and corresponds to the crank throw of the crankshaft. The clamping fixture has the advantages that the structure is simple, clamping can be completed more conveniently, the clamping quality is high, and the position precision of the key groove can be improved.

Owner:CHONGQING MEIXIN YINGSHEN MACHINERY CO LTD

Clamp tool used for clamping long workpiece

InactiveCN107471132AAchieve clampingGood consistency in processing and installationWork holdersEngineeringMachining

A fixture tooling for clamping long workpieces is provided. An installation base is fixed on the bottom surface of the left end of the installation platform and a geared motor is fixed on the installation base. The bottom surface of the installation platform is provided with four installation plates and a transmission device connected to the geared motor It is located on the mounting plate, so two sets of traversing devices are provided on the bottom surface of the mounting platform and each set of traversing devices is located between the corresponding mounting plates. A clamping device is provided under the transmission device and the clamping device passes through the L-shaped connecting plate After being connected with the transmission device and the traversing device, the geared motor drives the transmission device to work, and then drives the clamping device to move in the opposite direction or in the opposite direction along the traversing device, and then clamps or loosens the workpiece between the clamping devices. The invention ensures that the fixture tooling is always clamped with the middle part of the workpiece as the reference during the clamping process, and the processing and installation of the workpiece are consistent after clamping, providing conditions for high precision of the subsequent processing of the workpiece, simple structure, convenient operation, and high efficiency. use value.

Owner:宝鸡市泰得电子信息有限公司

Mask clamping module, mask stretching device and net stretching machine

ActiveCN113584428AImprove clamping qualityHigh precisionSolid-state devicesVacuum evaporation coatingPhysicsEngineering

The invention provides a mask clamping module, a mask stretching device and a net stretching machine. The mask clamping module comprises a driving assembly, a first movable block, a second movable block and a clamping assembly, wherein the first moving block is driven by the driving assembly to move horizontally in the first direction; the first movable block comprises a first contact surface, the second movable block comprises a second contact surface arranged opposite to the first contact surface, the first movable block and the second movable block are connected through the first contact surface and the second contact surface, and the first contact surface and the second contact surface are limited at the moving freedom degree in the direction perpendicular to the first contact surface and the second contact surface; the second moving block is driven by the translational motion of the first moving block to do a translational motion along a second direction; and the clamping assembly is connected with the second movable block, moves along with the second movable block and is used for clamping the mask. According to the configuration, the transmission mechanism is simple in structure, stable and reliable in transmission and high in movement precision, clamping force transmission errors are reduced, and the clamping quality of the mask is improved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

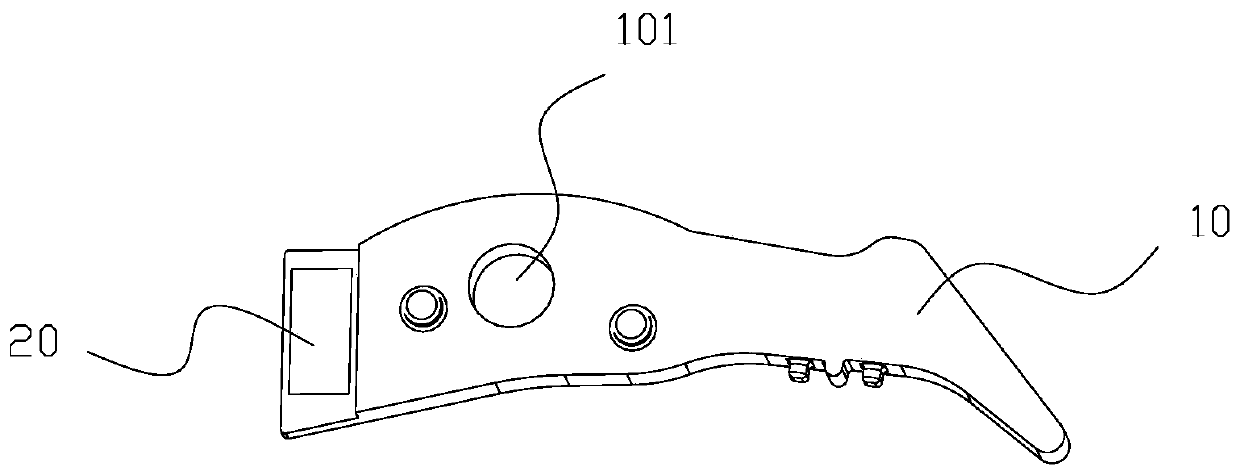

Intelligent lower limb functional compensation and gait orthosis

PendingCN112674993AReal-time access to force statusEasy to correctWalking aidsDiagnostic recording/measuringMuscle groupKnee Joint

The invention discloses an intelligent lower limb functional compensation and gait orthosis, and belongs to the technical field of biomedical engineering. The intelligent lower limb functional compensation and gait orthosis comprises a waist muscle group, hip joints, knee joints, ankle joints and feet, wherein a flexible force sensor is arranged on one side of the waist muscle group, a total processor is arranged at the upper end of the flexible force sensor, a gyroscope is arranged on the surface of the waist muscle group, a charging port is formed in the side, away from the flexible force sensor, of the waist muscle group, braking devices are symmetrically arranged on the two sides of the hip joints and the knee joints, sole analyzers are arranged at the bottom ends of the ankle joints and the feet, and exoskeleton connecting frames are arranged between the hip joints and the knee joints and arranged between the knee joints and the ankle joints. By arranging a convenient binding assembly, the convenience in mounting of the exoskeleton connecting frames is guaranteed, the attaching effect is improved, the use comfort degree is guaranteed, the use quality is improved, the clamping quality of binding bands is ensured, and the clamping stability of the binding bands is improved.

Owner:新乡医学院三全学院

A jig for sewing machine shell processing

ActiveCN112496800BEasy accessEasy to processPositioning apparatusMetal working apparatusAir pumpEngineering

The invention relates to the field of sewing machine accessories processing, in particular to a fixture for sewing machine shell processing, including a processing table, a supporting mechanism for placing the shell is arranged on the inner side of the processing table, and a clamping mechanism for fixing the shell is arranged on the upper side of the supporting mechanism. The clamping mechanism is connected with the driving mechanism arranged outside the processing table. In the present invention, by setting the clamping mechanism, the telescopic rod is used to push the connecting block to move, the connecting block drives the slider to move through the first connecting rod, and the slider moves through the second connecting rod. Drive the clamp block to move to complete the fixing of the shell. By setting multiple telescopic rods, the device can not only fix the shell from the left and right sides, but also fix the shell from the front and back sides, which is convenient for people to process different sides of the shell. , by setting the adsorption tube and suction cup, the device can provide further fixation to the shell under the action of the air pump, thereby enhancing the firmness of the device fixation.

Owner:SUZHOU KAICHENG SEWING EQUIP

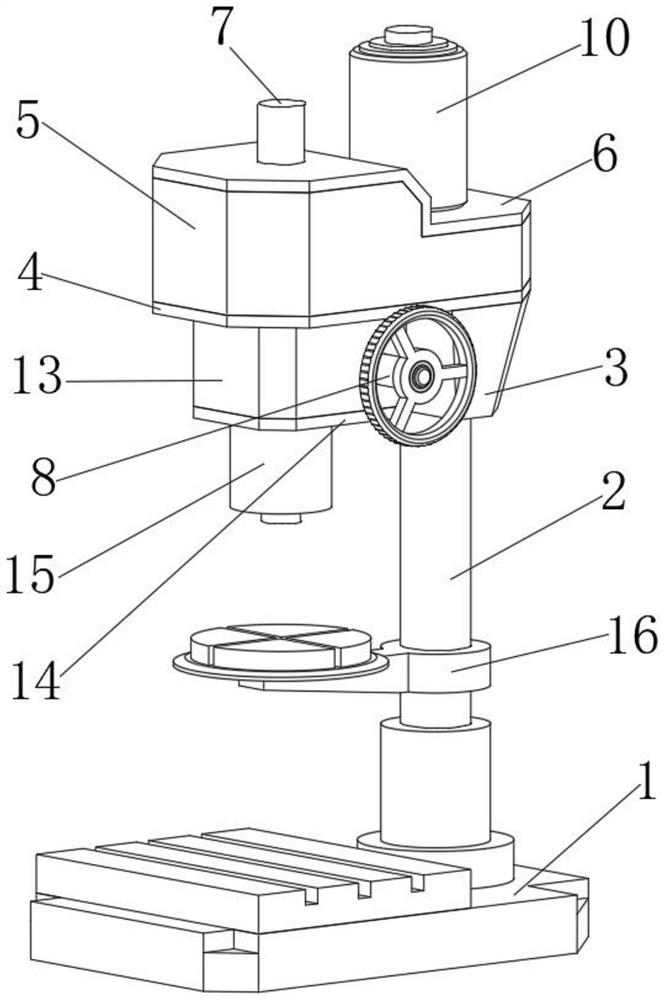

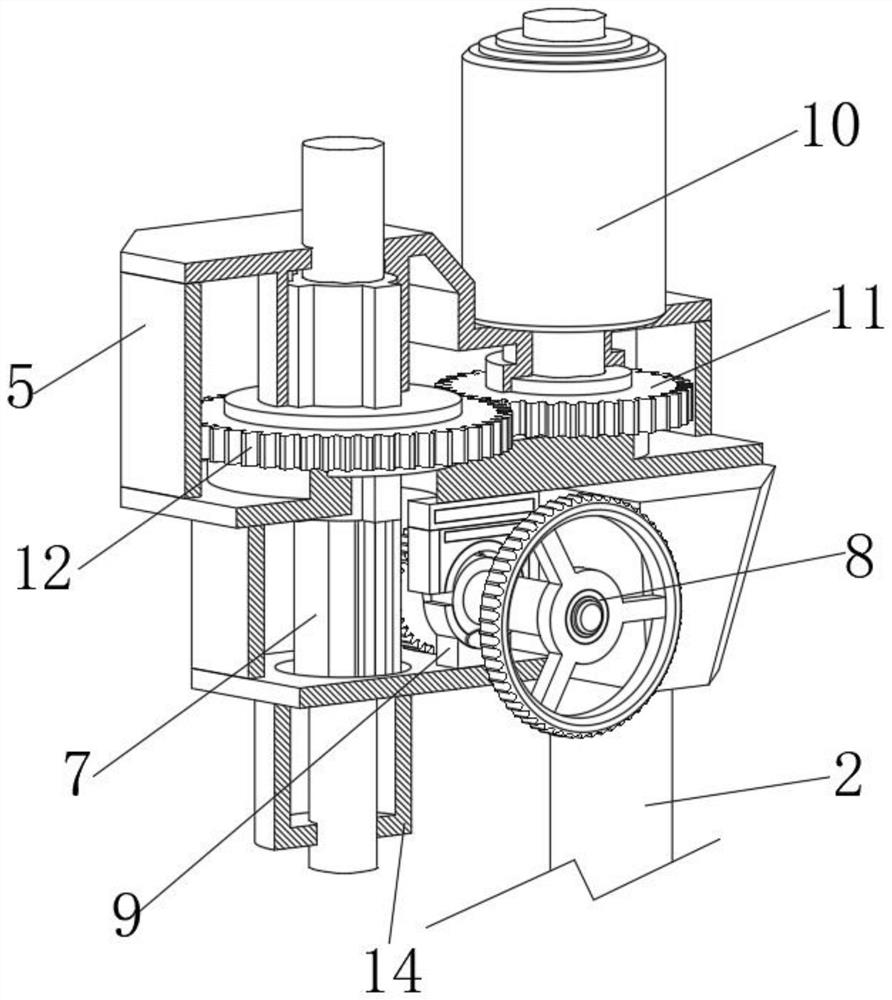

A Benchtop Drilling Machine Easy to Operate

ActiveCN112222481BAvoid damageAvoid machining errorsDrilling/boring measurement devicesDriving apparatusGear wheelElectric machinery

Owner:山东新景机械有限公司

Anti-falling sealing structure for joint of ductile cast iron pipe

The invention discloses an anti-falling sealing structure for a joint of a ductile cast iron pipe, and relates to the technical field of pipe sealing. A limiting table is fixedly arranged on a connecting pipe in a sleeved mode and arranged between a left pipe body and a right pipe body, annular grooves are formed in the inner walls of the left side and the right side of the limiting table, the pipe bodies are rotatably inserted into the annular grooves, the number of limiting rings is two, the two limiting rings are respectively arranged and fixed to the corresponding pipe bodies in a sleeved mode, the limiting rings are arranged at the outer sides of the limiting table, the number of limiting frames is four, the left inner clamping corner and the right inner clamping corner of each limiting frame are respectively arranged at the outer sides of the corresponding limiting rings in a clamped mode, a left limiting clamping block and a right limiting clamping block of each limiting frame are respectively arranged at the outer sides of the corresponding limiting rings in a clamped mode, a plurality of limiting insertion blocks are fixed to the inner ring walls of the limiting frames in a bilateral symmetry mode, and the limiting insertion blocks are inserted into limiting grooves formed in the outer ring wall of the limiting table. The ductile cast iron pipe can be tightly connected, the sealing performance is guaranteed, operation and installation are easy, and the work efficiency is improved.

Owner:宿迁雄振科技有限公司

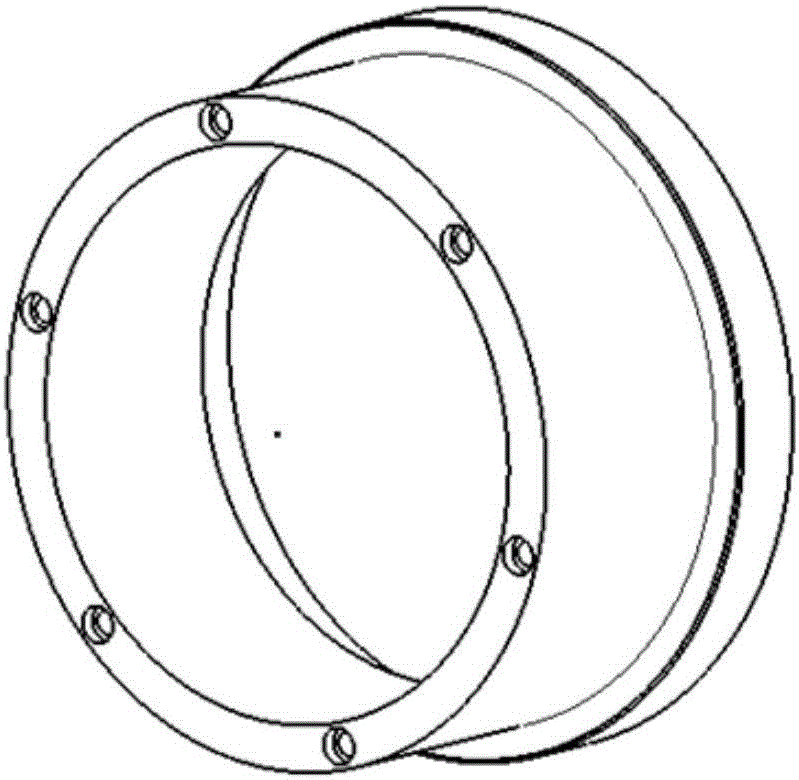

Full Diameter Composite Core Conductor Rotary Cutting Fixture

ActiveCN112886490BEasy loadingEasy to clamp concentricallyLine/current collector detailsApparatus for removing/armouring cablesScrew threadIndustrial engineering

The invention relates to a full-diameter composite core wire rotary cutting fixture, which includes a wire clamping assembly and a cutting machine mounting bracket, and the wire clamping assembly includes a first barrel body, a second barrel body and a clamping screw The column, the first cylinder unit and the second cylinder unit are combined to form a complete, cylindrical support cylinder, and the two butt joints of the first cylinder unit and the second cylinder unit are respectively connected by hinges and buckles A movable opening and closing structure is formed. At least two groups of clamping studs are arranged on the supporting cylinder. The clamping studs are arranged along the radial direction of the supporting cylinder and connected by threads. The cutting machine mounting bracket includes a rotating fixed body, Positioning ring, main frame body and sub-frame body; the invention can realize the cutting of the cored wire in the full diameter range, and the cutting machine is manually rotated to cut the wire, and the precise and non-damaging cutting of the cored wire is realized. The invention can be used in ground and high-altitude operations, and can greatly improve construction efficiency and construction accuracy.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +1

Assembly mold and assembly method for composite shell helical slow wave structure

ActiveCN106783470BClamping volume controllableSolve the impossible clamping problem of composite shellVessels or leading-in conductors manufactureWave structureMechanical engineering

The invention discloses an assembly mold and an assembly method for a composite tube shell spiral line slow-wave structure. The assembly mold comprises a grasp module, a support component and an installation component. The grasp module comprises a tube body and a clamp. The clamp comprises a grip-body and a support rod. An internal end face of the support rod is utilized for supporting and pressing on an external wall face of the spiral line and an external end face of the support rod is utilized for supporting and pressing on an internal wall face of the tube body. The support component comprises a support shaft lever and a support shaft chuck. The support shaft chuck is disposed between two adjacent support rods which make the spiral line have elastic deformation. The installation component comprises a first member bar and a second member bar. According to the deformability of the spiral, through the cooperation among assembly molds and spiral lines, the assembly of the composite tube shell spiral line slow-wave structure is achieved.

Owner:北京真空电子技术研究所

EPS board vertical slitting prestress positioning device

InactiveCN110370357AEasy to cut verticallyImprove vertical cutting efficiencyMetal working apparatusEngineeringThreaded rod

the invention discloses an EPS board vertical slitting prestress positioning device which comprises a bottom plate, supporting columns distributed in an array are arranged on the bottom plate, a frameis arranged at the upper ends of the supporting columns, and the two sides of the frame are respectively provided with a servo motor table, a vertical cutting groove is formed in the frame, and a first positioning hole and a bearing hole which penetrate through the bottom plate are further formed in the frame, a sliding rod is arranged in the first positioning hole, a threaded rod is arranged inthe bearing hole, and a positioning plate is arranged on the sliding rod and the threaded rod, second positioning holes are formed in the two sides of the frame, a fixed plate is arranged on one sideof the servo motor table, and an array-distributed pull rod is arranged between the servo motor table and the fixed plate, a servo motor is arranged on a servo motor table between the pull rods, and adriving shaft is arranged on the servo motor. According to the invention, the structure is simple, the vertical cutting operation of operators is facilitated, and the vertical cutting efficiency of the EPS board is improved., the EPS board can be adjusted and clamped according to different specifications of EPS boards, the clamping quality of the EPS board is improved, and the cutting quality ofthe EPS board is further improved.

Owner:安徽艾普塑料科技有限公司

A milling and clamping device for sleeve parts

ActiveCN103121177BGuaranteed machining accuracy requirementsStable clamping forceMetal working apparatusStructural engineeringPiston

The invention relates to a milling fixture, in particular to a milling groove clamping device of a sleeve-class part. The milling groove clamping device of the sleeve-class part comprises a fixed base, a left vertical plate and a right vertical plate, wherein the left vertical plate and the right vertical plate are fixedly connected on the fixed base, a horizontal supporting plate fixedly connected between the left vertical plate and the right vertical plate, an air cylinder fixedly connected on the right vertical plate, a double-pushrod mechanism connected on a piston of the air cylinder, a power transmission mechanism hinged on the left vertical plate, a positioning mechanism fixedly connected on the horizontal supporting plate and an automatic feeding and discharging mechanism arranged on the right side of the positioning mechanism. By adopting the technical scheme, the machining accuracy requirement of the part can be guaranteed, clamping force is stable, clamping quality is high, the speediness and automation of the clamping of the part are achieved, production efficiency is improved greatly and working intensity of workers is relieved greatly.

Owner:佛山市顺德区上锐机械有限公司

A self-centering clamping device for stainless steel thin-walled pipe fittings

The invention belongs to the technical field of clamping devices, specifically a self-centering clamping device for stainless steel thin-walled pipes, including a support plate, a bottom plate, a limit rod, a guide seat, a No. 1 spring, an elastic wrapping plate and a binding part; The binding parts include binding rope, limit buckle, reel, transmission shaft, fixed support plate, No. 1 pulley, timing belt, No. 2 pulley and brake motor; in the present invention, all reels are driven by the transmission shaft Rotate, and then the winding wheel pushes all the elastic wrapping plates radially towards the center through the binding rope, so that the elastic wrapping plates are attached to the cylindrical surface of the thin-walled pipe, and then the thin-walled pipe is realized through the elastic wrapping plate Encircling and clamping, the elastic wrapping board drives the limit rod to slide along the chute of the guide seat in the process of moving closer to the center, so that the stop rod can only slide along the direction of the chute, and then all the elastic wrapping boards gather toward the center and converge One point, and then achieve the function of self-centering clamping of thin-walled pipe fittings.

Owner:重庆晟如新科技发展有限公司

A bracket for secondary cable laying

ActiveCN113315049BImprove laying efficiencyImprove fixation efficiencyElectrical apparatusStructural engineeringElectric cables

Owner:PINGYIN POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

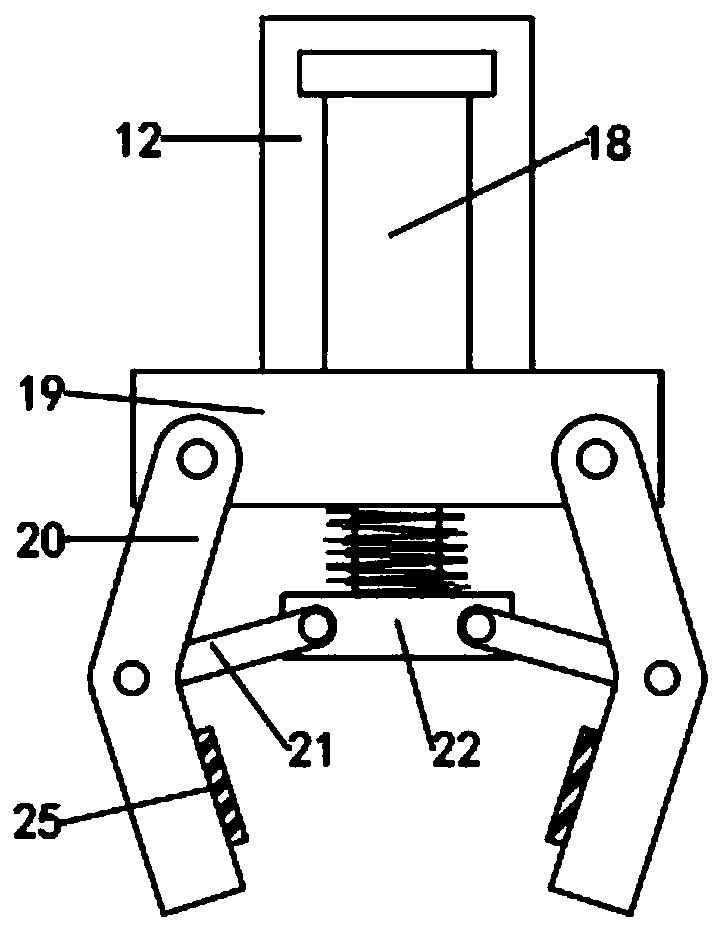

Clamping structure of industrial robot

InactiveCN108789467AImprove clamping qualityImprove stabilityGripping headsPiston rodIndustrial engineering

The invention provides a clamping structure of an industrial robot. The clamping structure comprises a positioning plate, a motor, a bearing plate, an air cylinder I, a vacuumizing pump, a fixing plate, an air cylinder II and a clamping rod. The clamping structure is characterized in that a limiting groove is formed in the positioning plate, the motor is arranged on the positioning plate, one endof the bearing plate is connected with a rotating shaft, the air cylinder I is arranged on the bearing plate, the vacuumizing pump is arranged on the bearing plate, the fixing plate is arranged on a piston rod I, the air cylinder II is arranged on the fixing plate, moreover, a piston rod II is arranged on the air cylinder II, the middle part of the clamping rod is arranged in a connecting groove through a connecting shaft, and a connecting plate is arranged at one end of the clamping rod. According to the clamping structure of the industrial robot, the bearing plate is arranged to be of a structure capable of rotating along with the rotating shaft, and the position of the bearing plate on the positioning plate is rotated, and therefore, a workpiece can be clamped from different angles, andthe working efficiency is improved.

Owner:WUHU DEJIA INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com