Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

202results about How to "High clamping precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Connector product test device

ActiveCN103018608ANot easy to damageReduce manufacturing costElectrical testingMeasurement instrument housingTest efficiencyElectricity

The invention discloses a test device, in particular to a connector product test device which is high in test accuracy, reduces test cost and improves test efficiency. According to the connector product test device, a test pin is adopted to replace the test connector in the prior art for product testing, is arranged on a movable carrier and is electrically connected with a test terminal. During testing, the carrier moves by aid of manual operation or through a power device and drives the test pin to move in the direction of a connector to be tested, and finally the tail end of the test pin is contacted with a metal sheet of the connector to be tested to achieve testing. The connector product test device is widely applied to the connector test field.

Owner:珠海市运泰利自动化设备有限公司

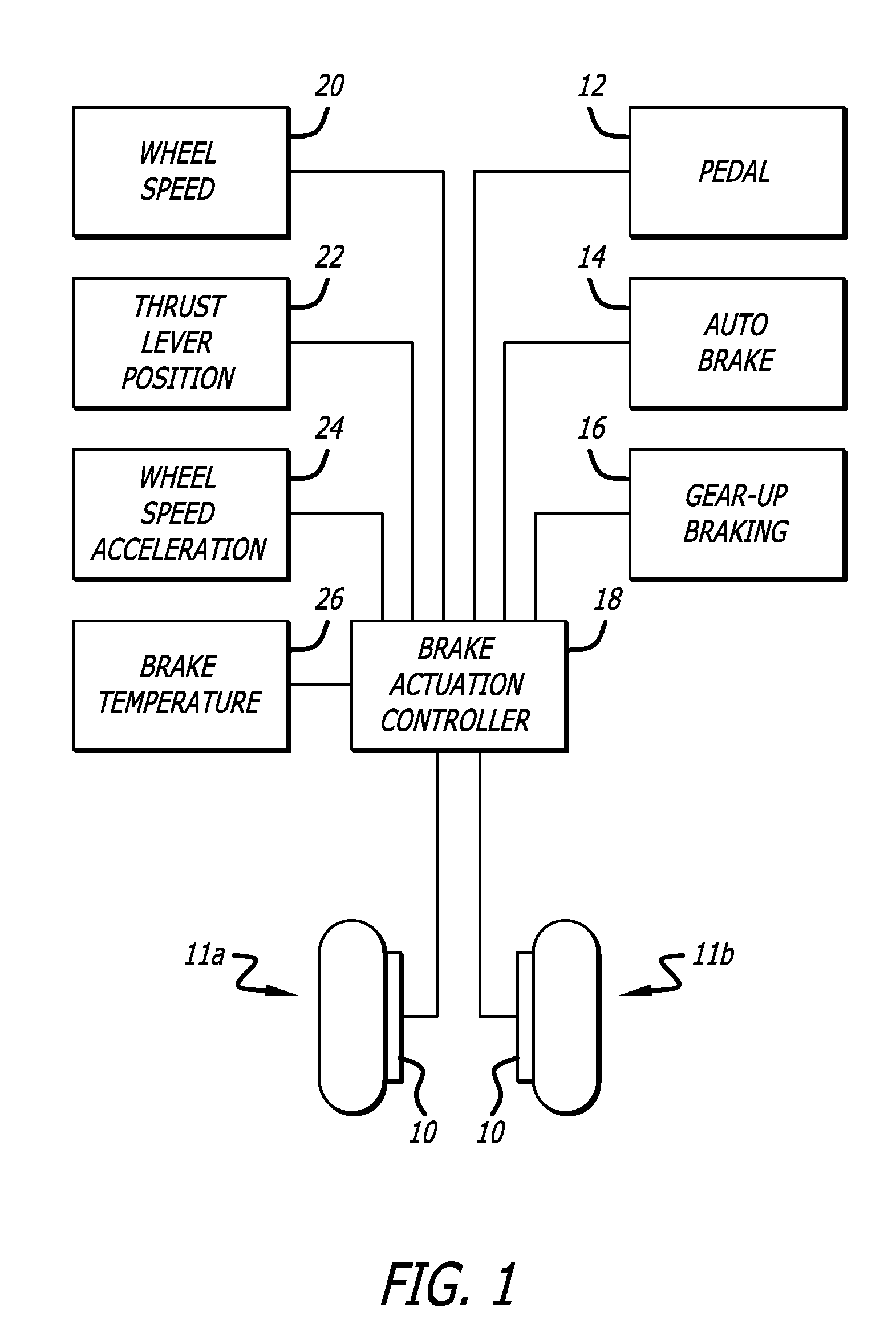

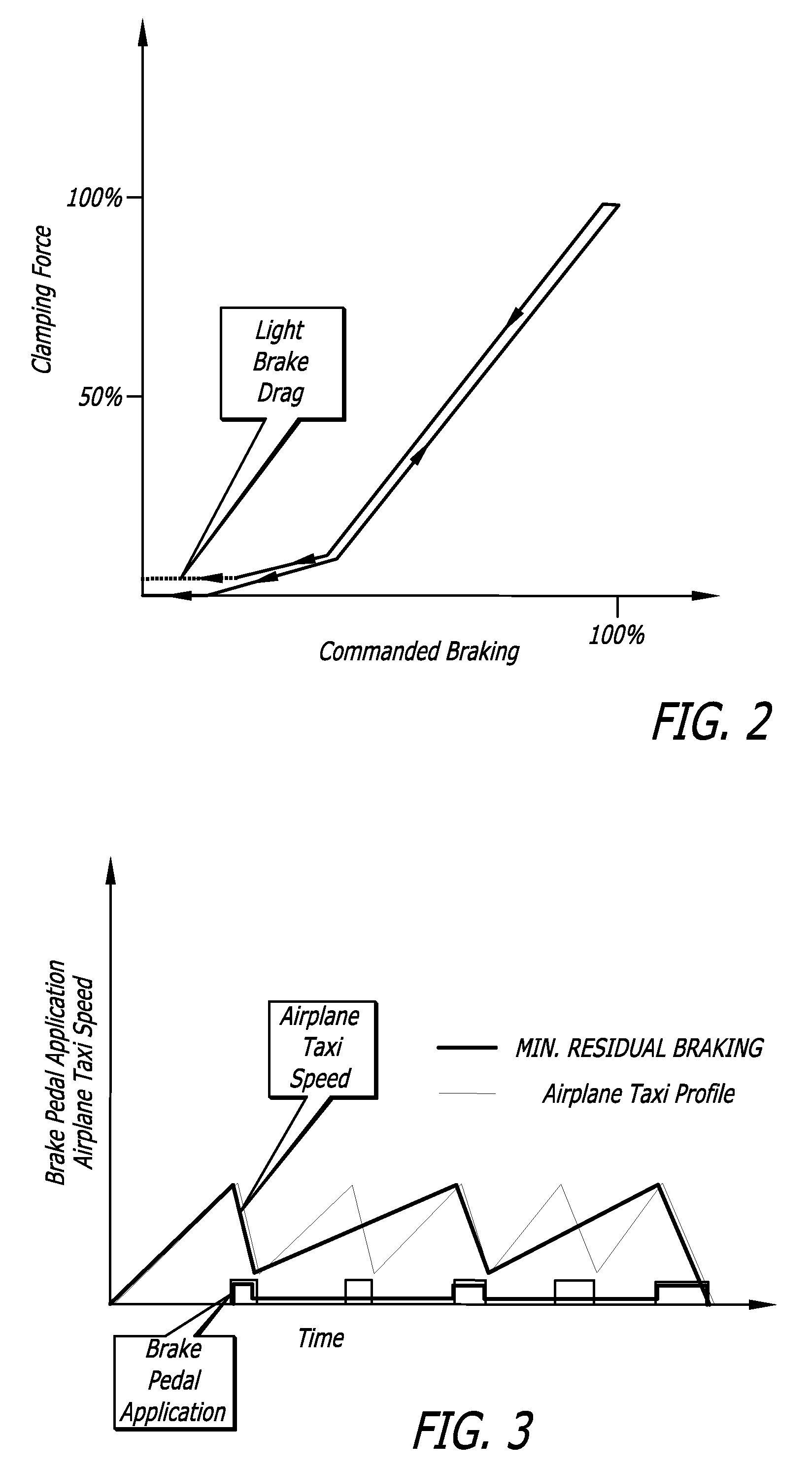

Method and system to increase electric brake clamping force accuracy

ActiveUS7410224B2High clamping precisionGreat accuracy and sensitivity to brake commandBraking action transmissionElectrodynamic brake systemsElectric aircraftActuator

Owner:HYDRO AIRE AEROSPACE CORP

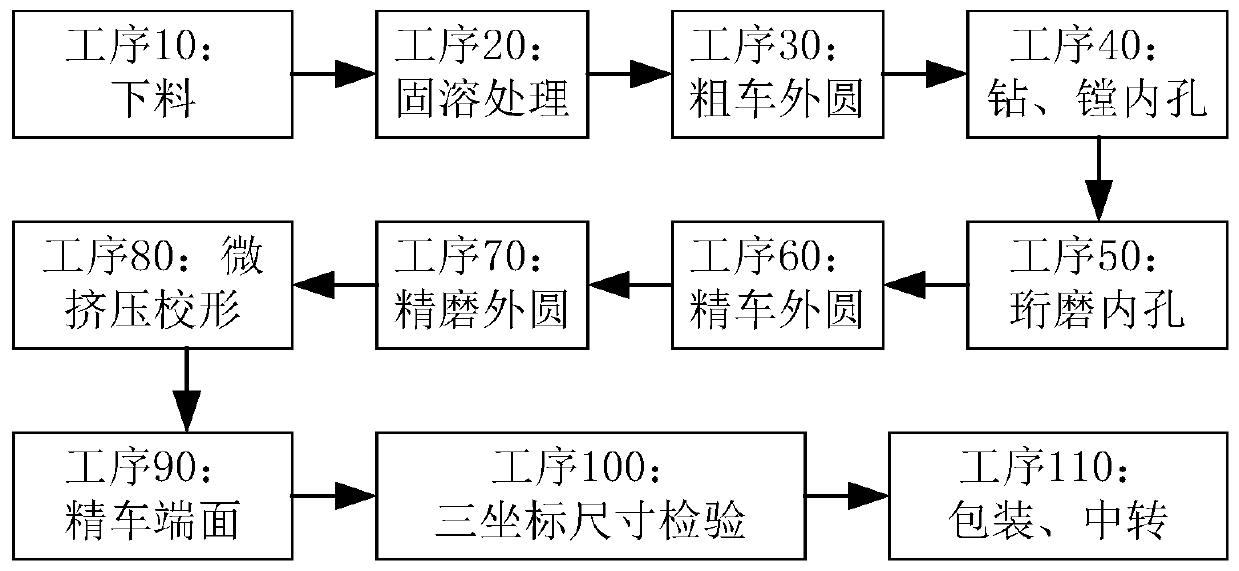

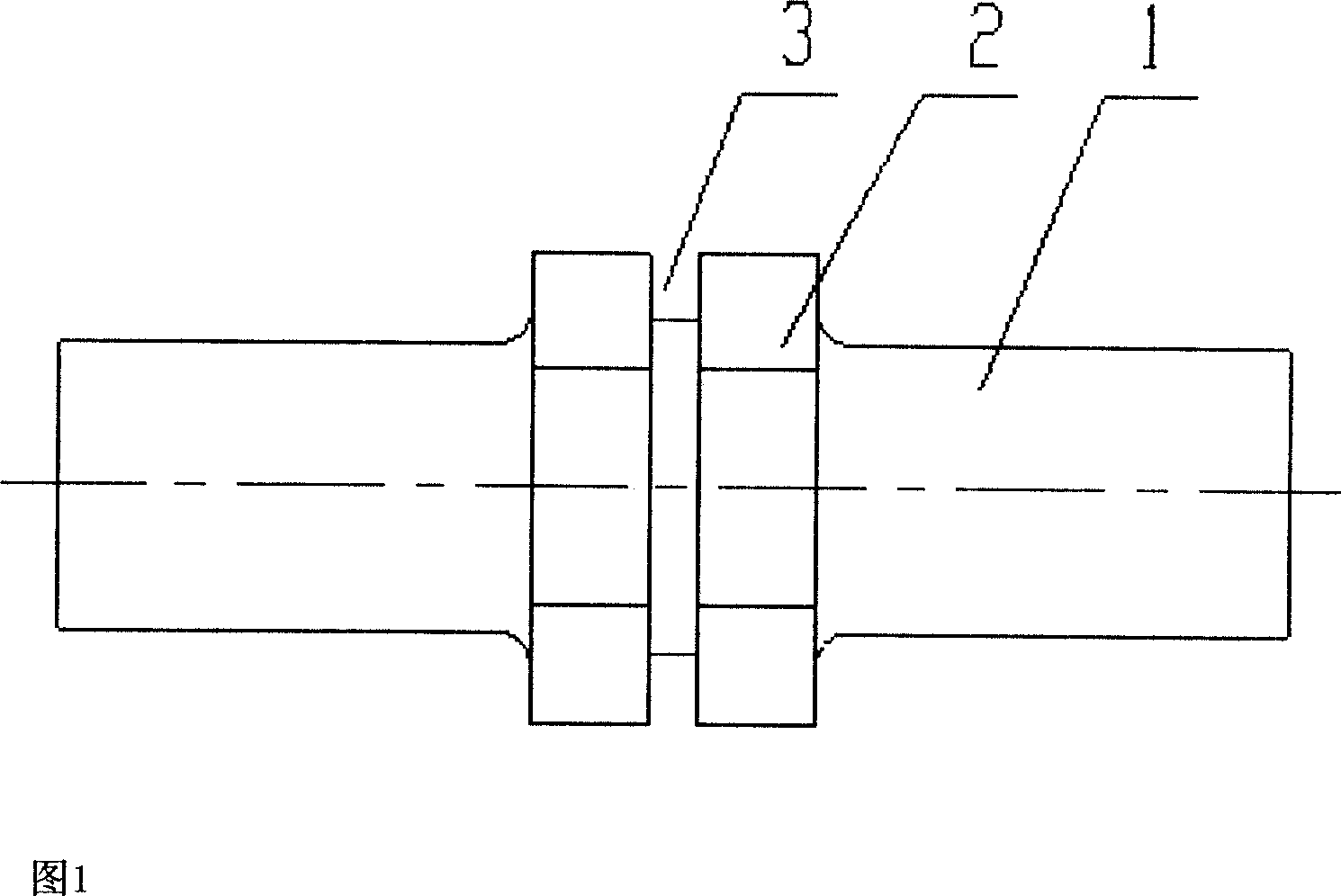

Thin-walled elongated pipe member whole precision processing method

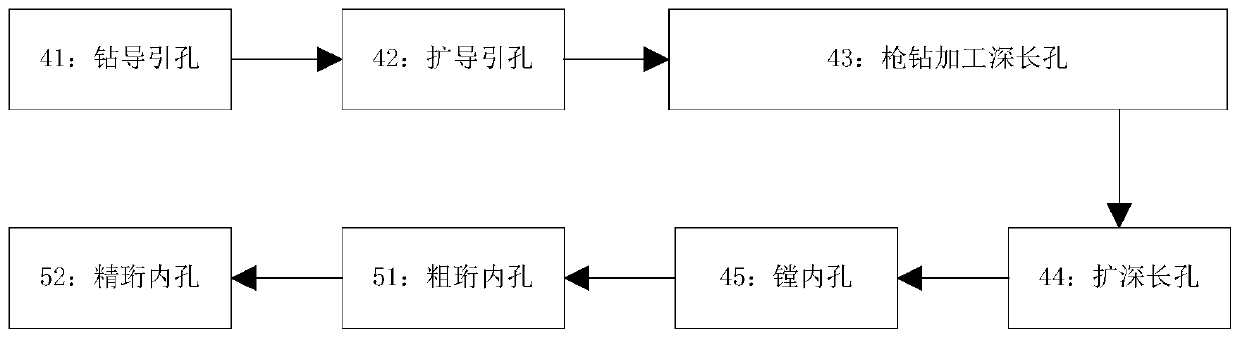

The invention provides a thin-walled elongated pipe member whole precision processing method. The thin-walled elongated pipe member whole precision processing method comprises the following steps of S1, blanking; S2, hot working; S3, rough turning of the end face and the outer circle; S4, drilling and boring of an inner hole; S5, honing of the inner hole; S6, semi-finish turning and finish turningof the outer circle; S7, fine grinding of the outer circle; S8, micro-extrusion correction; S9, finish turning of the end face; and S10, inspection and packaging. By means of the method, the whole precision machining of thin-walled elongated pipe members which are made of austenitic stainless steel materials, have the maximum length being 575 mm, have the minimum pipe diameter being 24 mm, have the maximum draw ratio being 24 and have the thinnest wall thickness being 0.3 mm can be achieved, and the inner hole and outer circle precision reaches the IT5 stage, the coaxiality reaches 0.025 mm,the straightness reaches 0.025mm, the surface roughness reaches Ra0.8, and the method is a high-efficiency, precise and low-cost thin-walled elongated pipe member processing method.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST +1

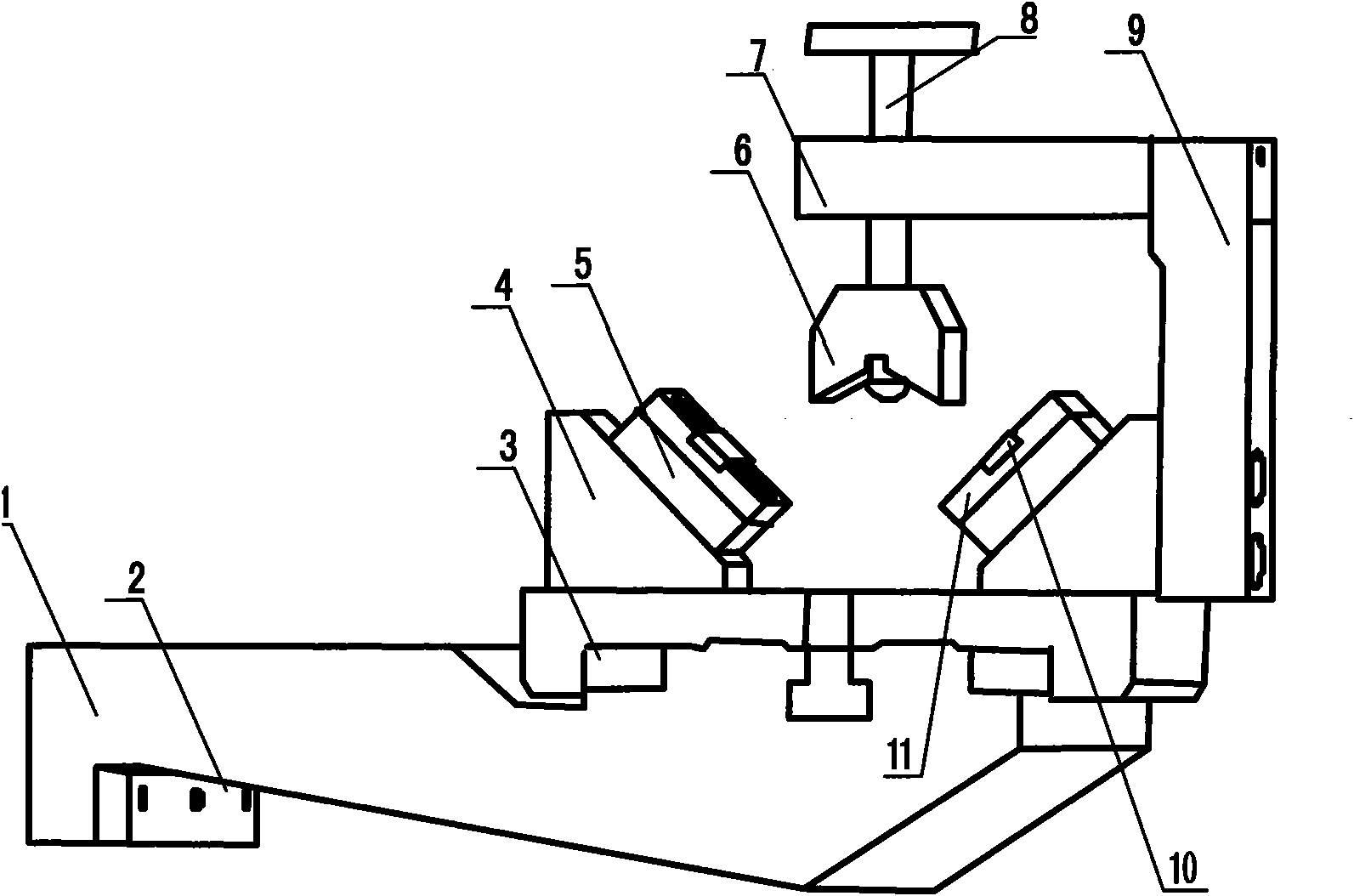

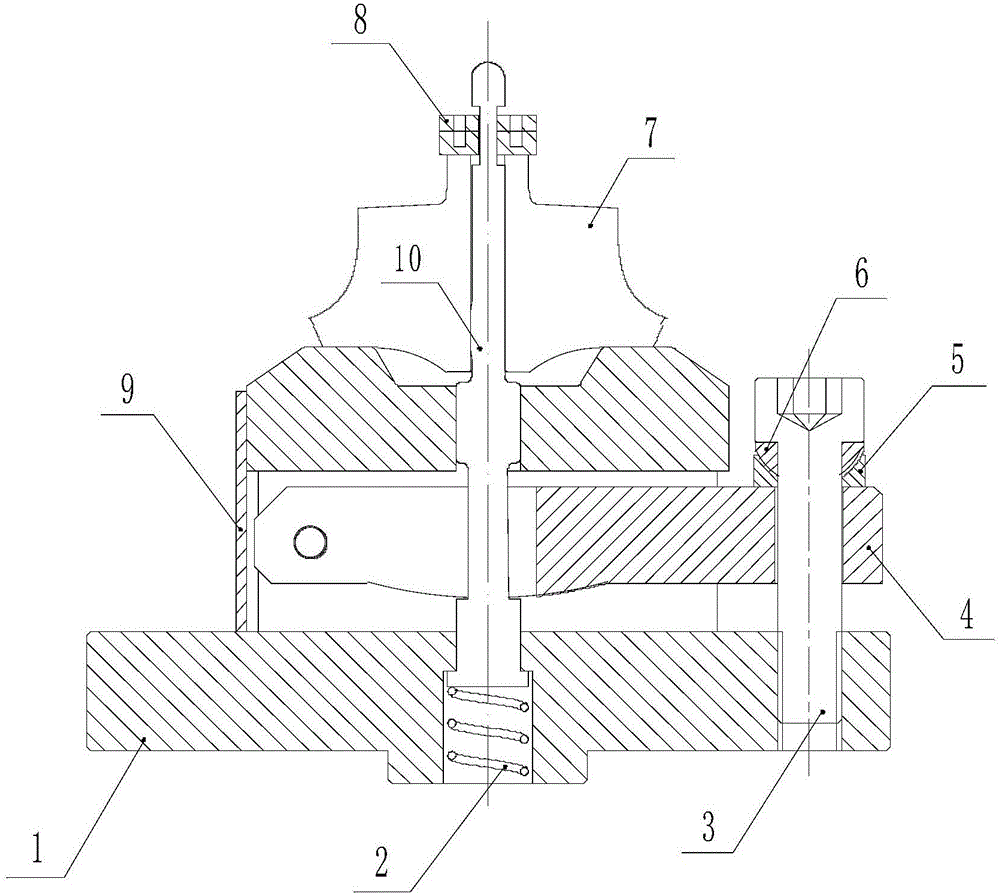

Clamp

InactiveCN102528494AReduce vibrationHigh clamping precisionPositioning apparatusMetal-working holdersEngineeringShock resistance

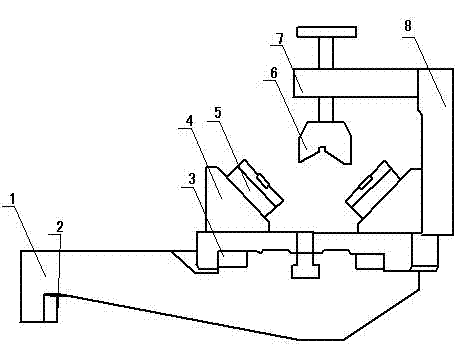

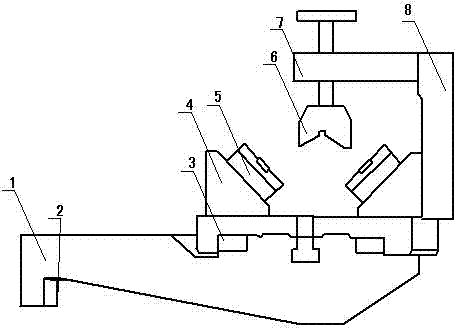

The invention belongs to the technical field of processing. In the prior art, different clamps are used, special clamps are needed for changing different parts, the complex and high-cost clamps have low shock resistance, and after installation, the clamp has low positioning precision and low working efficiency. The invention provides a clamp. According to the clamp, cushion blocks are movably hinged below a clamp holder; the lower plane of the clamp holder has two inclined planes arranged in a V shape; a big clamp block is arranged on the clamp holder by left and right cushion blocks; small cushion blocks are arranged on the two V-shaped faces of the big clamp block; the big clamp block and the small clamp block both have a V-shaped opening and are symmetrically distributed; a supporting block is arranged on the side face of the big clamp block; a fixed block is arranged on the supporting block; and the small clamp block is connected to the fixed block by threads. When used, the clamp can reduce vibration and increase clamping precision; and the clamp can be used for clamping different workpieces and therefore increases working efficiency considerably, and the clamp has the characteristics of low cost, wide application range and the like.

Owner:盛汉昌

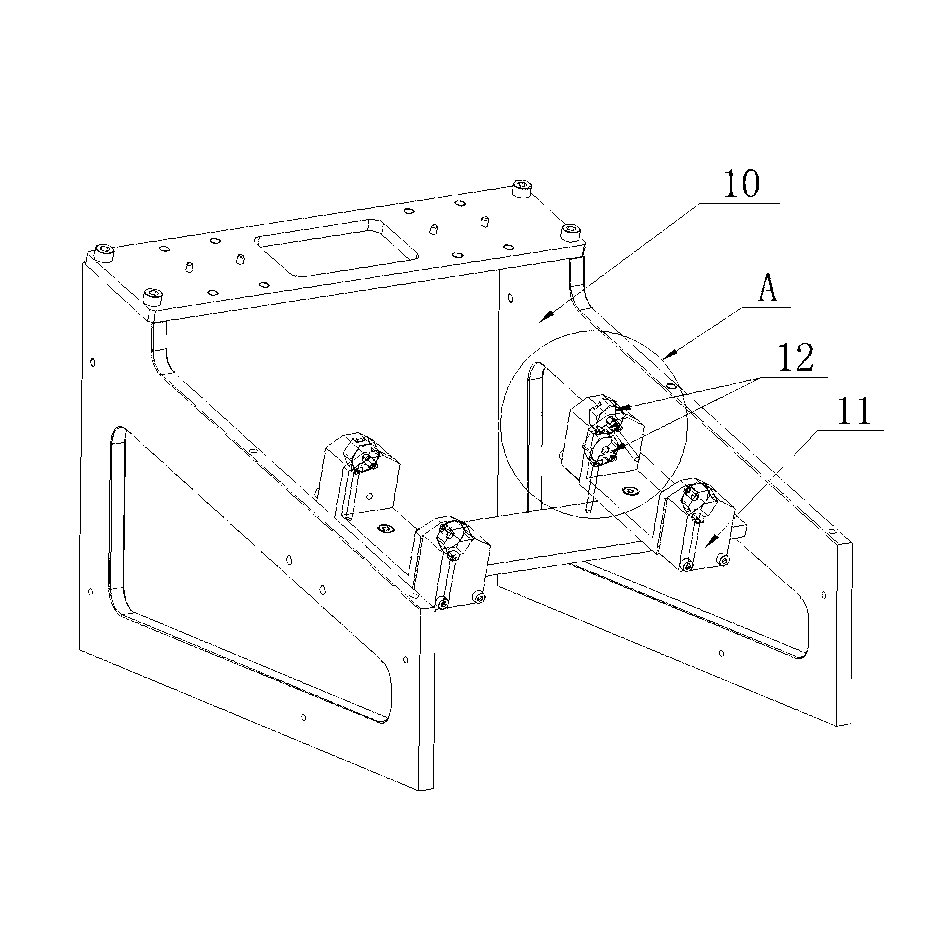

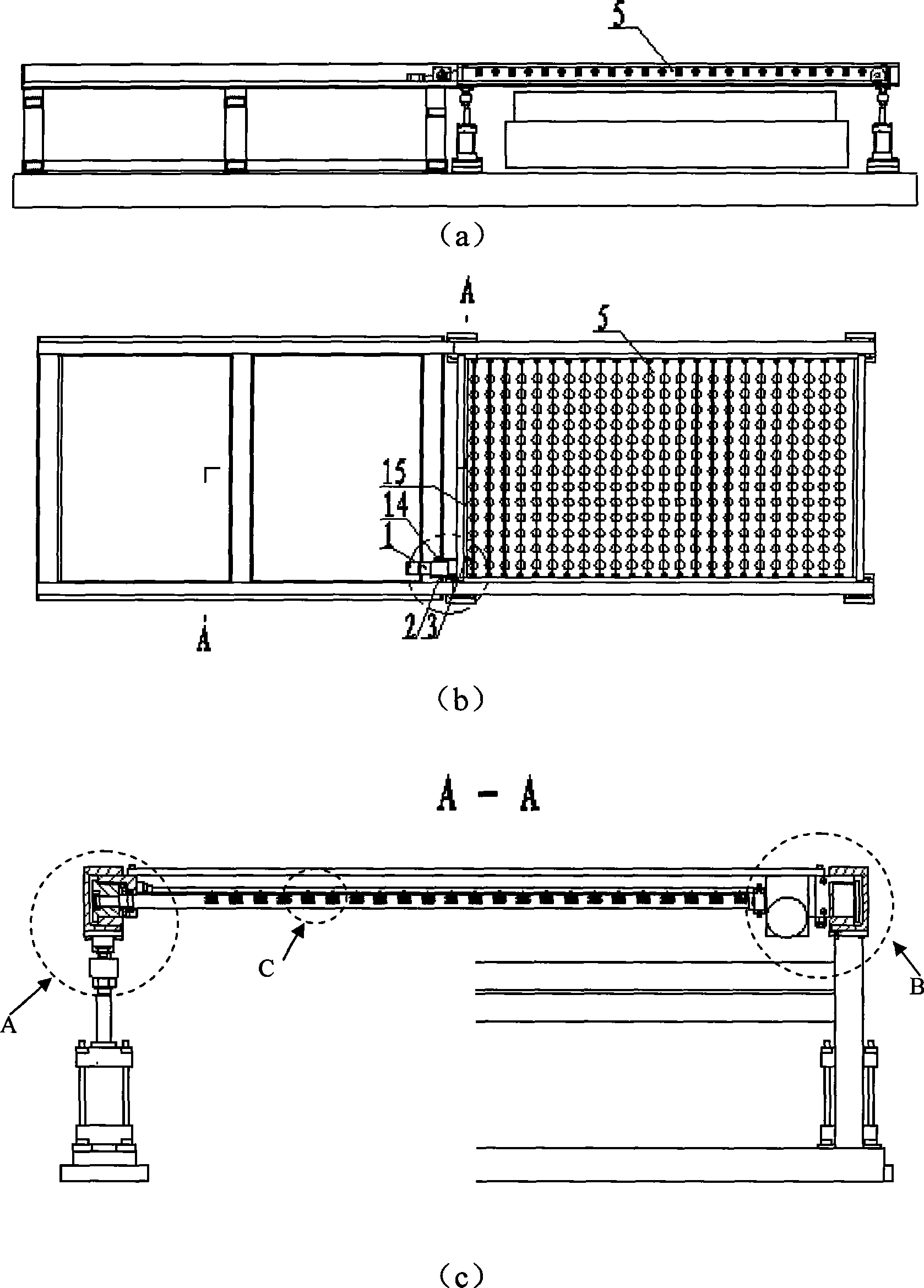

Pre-compressing device for processing and fixing the honeycomb flexible material

InactiveCN101362297AEvenly filledHigh clamping precisionPositioning apparatusMetal-working holdersIron powderReduction drive

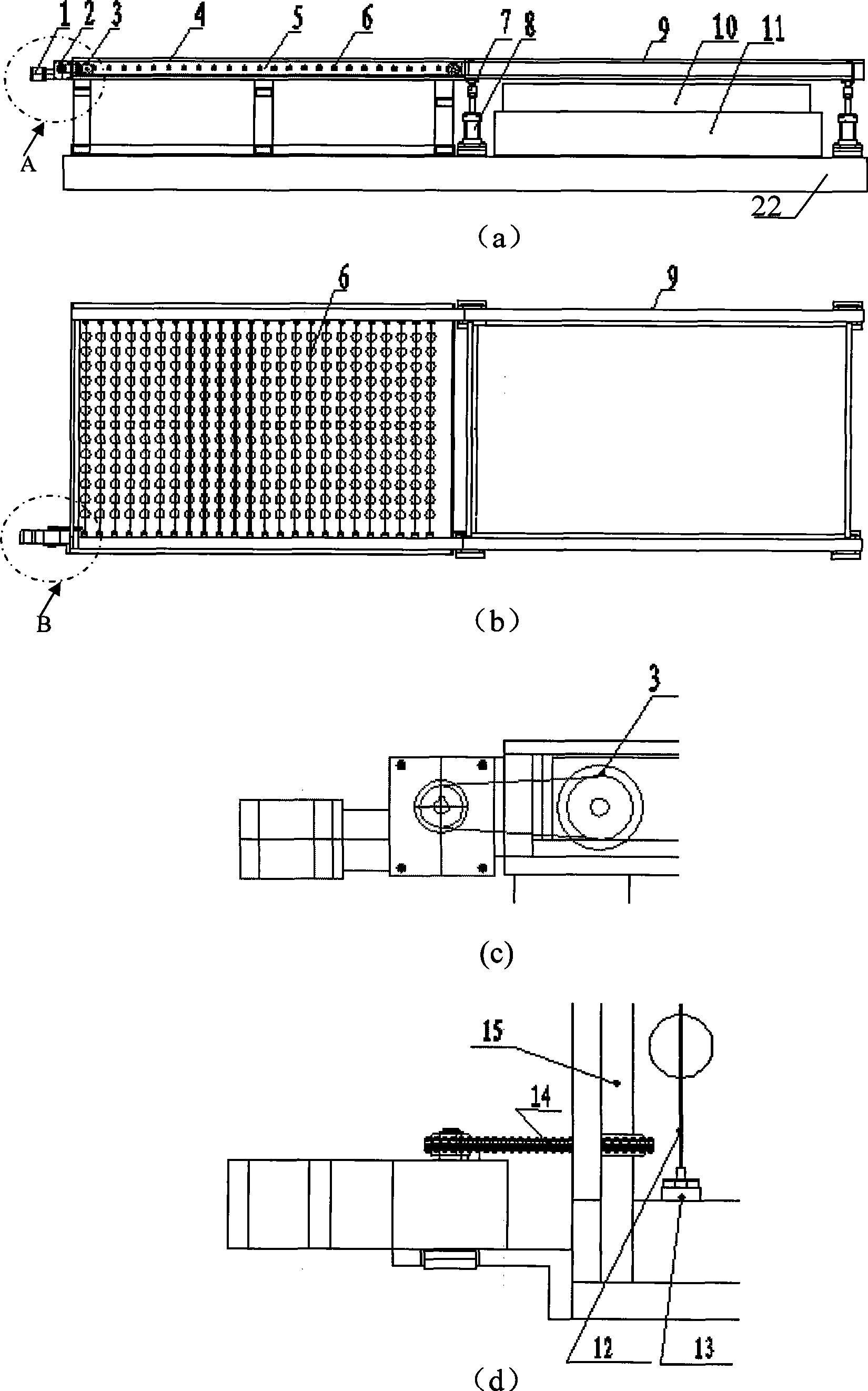

The invention discloses a prepressing device for honeycomb flexible material processing and fixing. The device consists essentially of a fixing support, a lifting support, a movable clamping frame, four air cylinders, a chain wheel drive mechanism, a stepper motor and a worm gear reducer, wherein, the movable clamping frame is consisted essentially of a drive shaft, a guide rail and springs in the quantity of m multiplied by n. The device can automatically clamp the honeycomb flexible material before the honeycomb flexible material is filled with iron power, the clearance between the flexible material and a magnetic fixing platform is eliminated, the honeycomb flexible material and the magnetic fixing platform are tightly contacted, the honeycomb pore of the honeycomb flexible material can be uniformly filled with the iron powder, and the clamping precision of the honeycomb flexible material is improved. After the magnetic circuit is connected and the honeycomb flexible material is fixed, the movable clamping frame can be moved from the lifting support to the fixing support, and the interference between the movable clamping frame and the cutting process can be avoided.

Owner:ZHEJIANG UNIV +1

Integral processing method for truck frame of high-speed motor train unit

ActiveCN101342663AControl stressGuaranteed accuracyAutomatic control devicesFeeding apparatusBogieNumerical control

The invention discloses an integrated processing technology of a high speed motor train unit bogie frame, comprising a magnetic dial indicator which is used to quantize and control clamping deformation and clamping force, an integrated accompanying chemical device which is used for the integrated processing of the frame, a numerical control core milling processing center which is used for the integrated processing of the frame. By using the magnetic dial indicator to quantize and control clamping deformation and clamping force, the integrated processing technology effectively controls the stress produced by clamping frocks, and furthermore guarantees the precision of the size of the frame after finishing processing and loosening the clamp. By using the method for determining the relationship between the workpiece and the machine tool coordinate system through two positioning, the integrated processing technology improves the utilization rate of the machine tool, and ensures that the improvement of the clamping precision of the frame becomes possible on the other hand. By using the numerical control core milling processing center, the integrated processing technology fully utilizes all kinds of functions of the machine tool to process the frame with a pentahedron analogously type, with the result that the precision loss which may be produced by multiple step processing can be effectively avoided, and the processing precision and quality of the frame can be greatly improved.

Owner:CHINA RAILWAYS CORPORATION +2

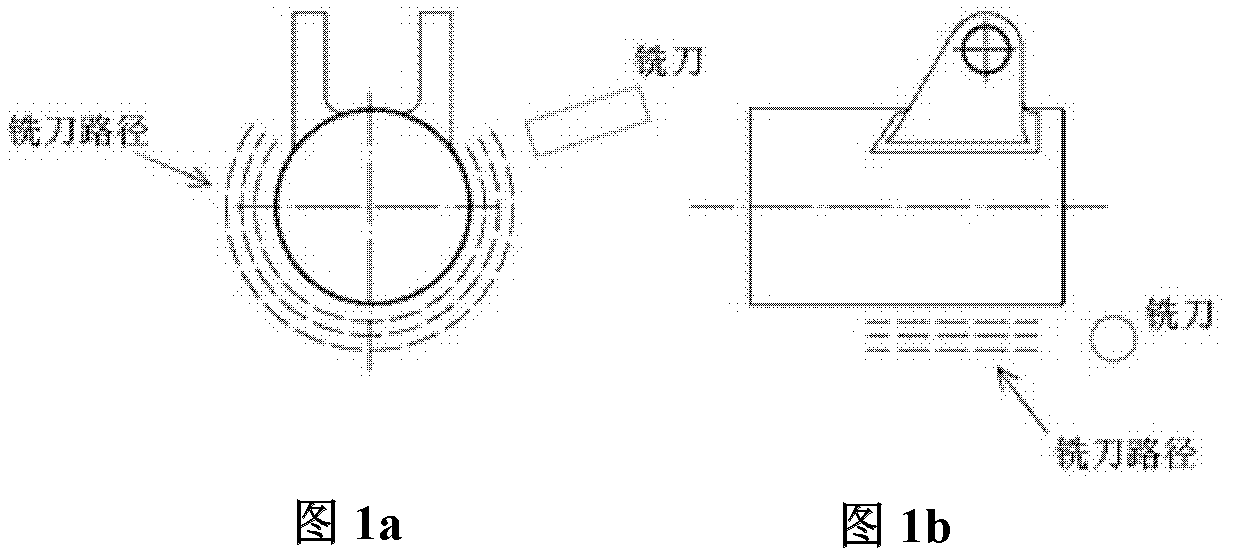

Method for turning and milling to realize typical characteristics of aircraft landing gear

InactiveCN102581620AShorten the time for clamping and positioningHigh clamping precisionOther manufacturing equipments/toolsMilling equipment detailsAircraft landingMachining process

A method for turning and milling to realize typical characteristics of an aircraft landing gear includes the steps: firstly, orthogonal turn-milling for rough machining; secondly, milling to remove intermediate allowance of a lug; thirdly, fine trimming of the bottom of the lug; fourthly, milling of the periphery of the lug; fifthly, fine trimming of the top of the lug; sixthly, semi-finish machining of the inner wall of the lug; seventhly, semi-finish machining and finish machining of the outer wall of the lug; eighthly, finish machining of the inner wall of the lug; and ninthly, finish machining of an outer cylindrical surface. The method mainly aims to realize the common lug characteristics of parts of the landing gear to solve problems in machining the parts. The technological method has the advantages that machining efficiency and the quality of surfaces of workpieces can be effectively improved, and simultaneously, machining is lowered. In addition, the method has an actual reference value in the field of machining process.

Owner:BEIHANG UNIV +1

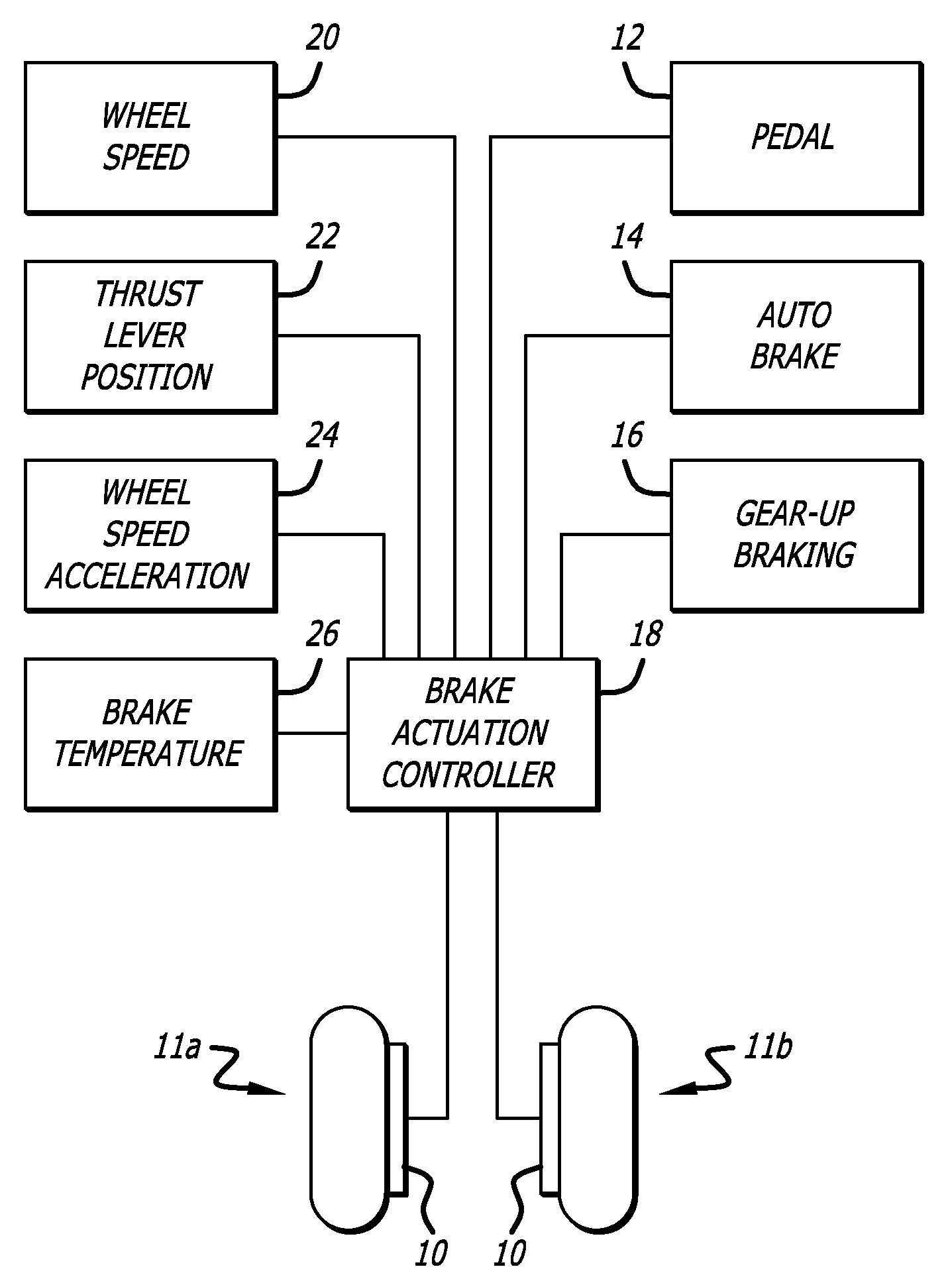

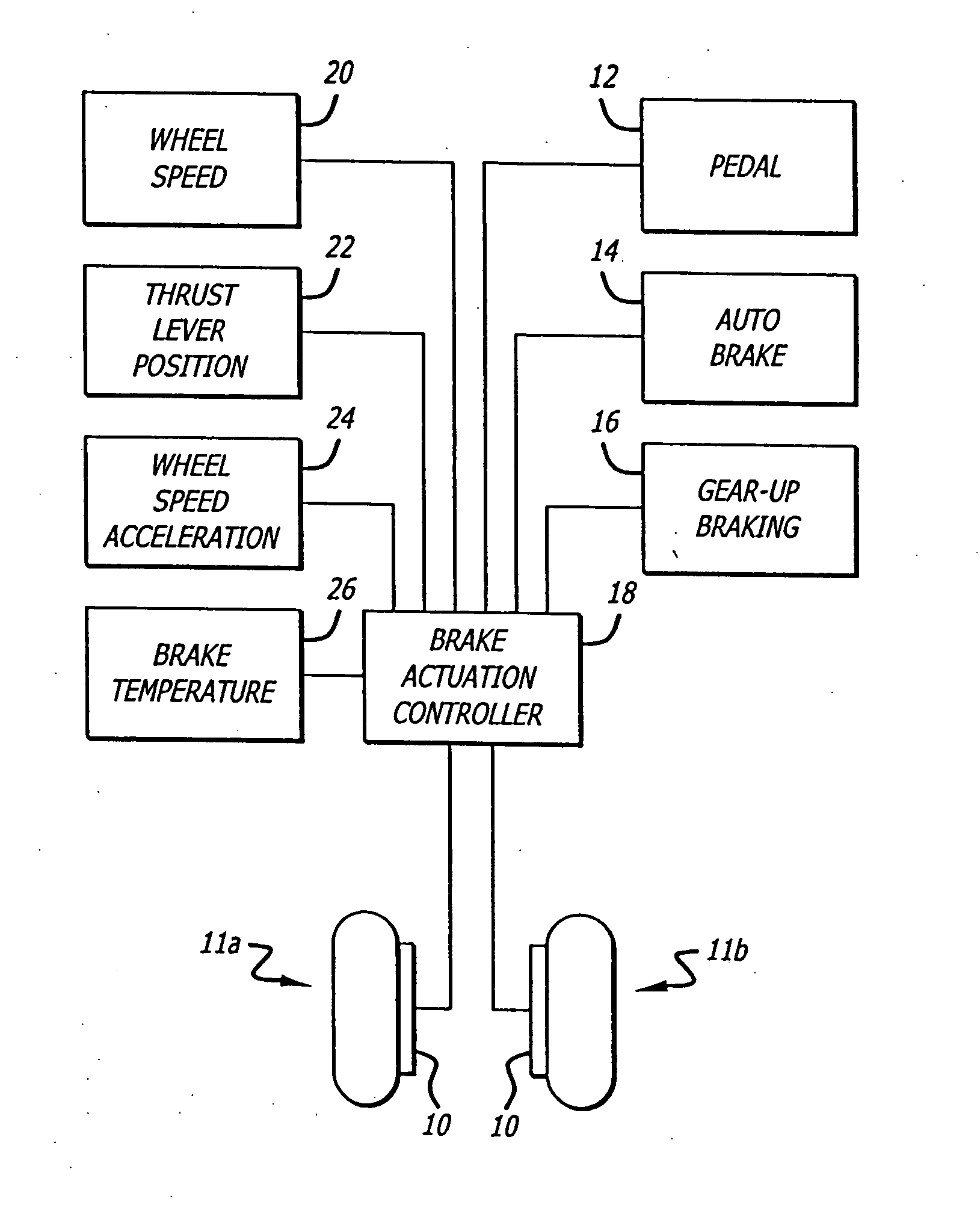

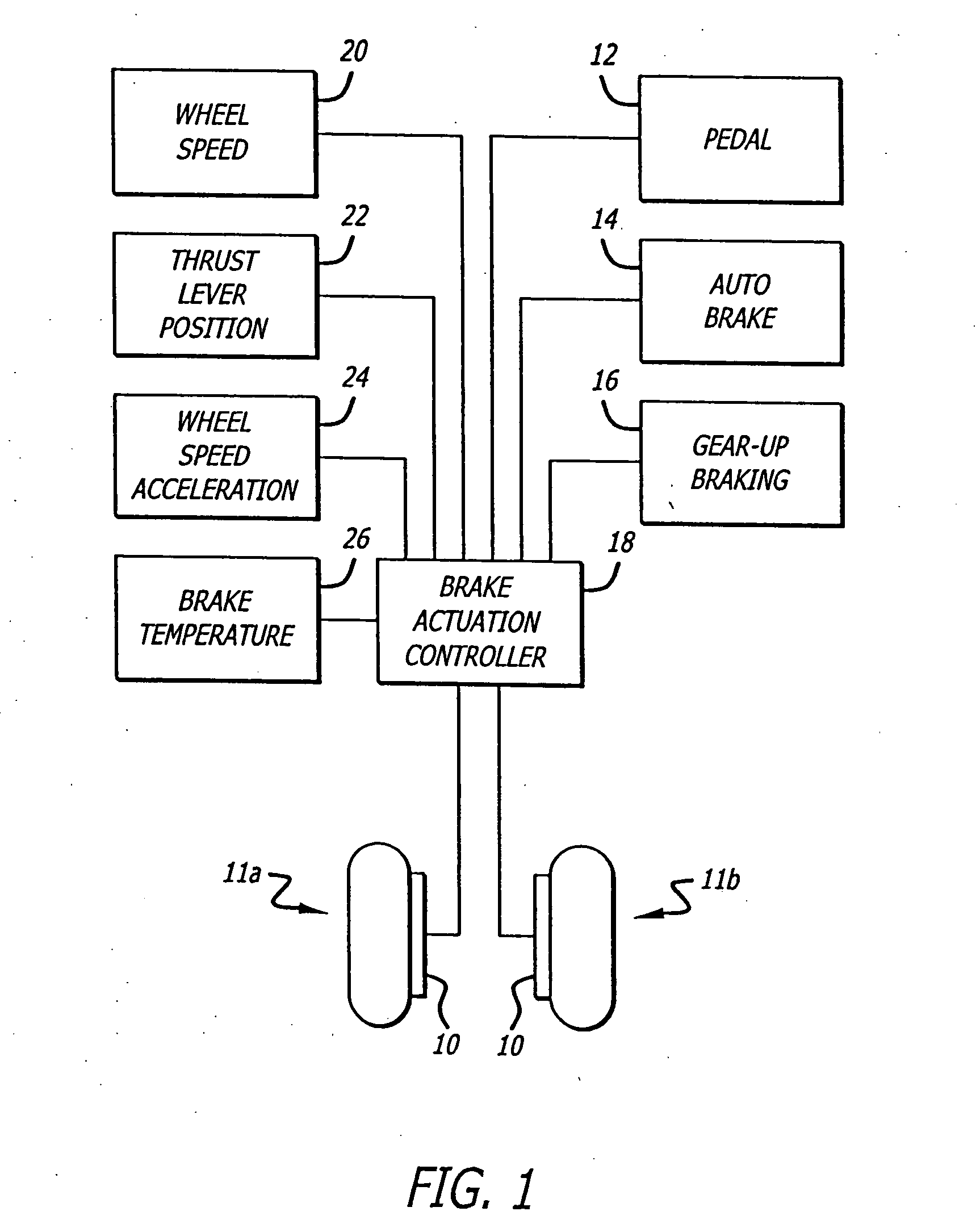

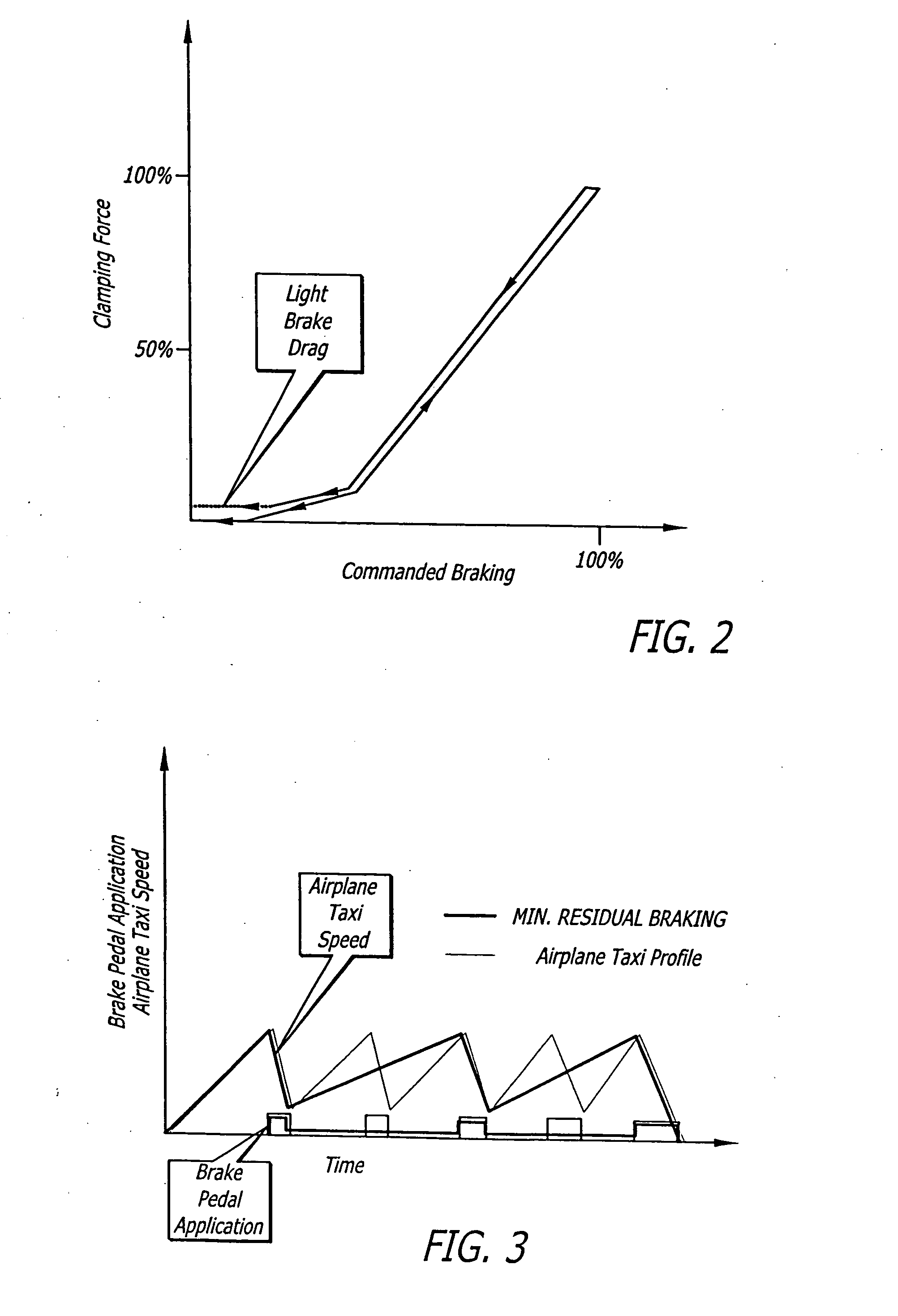

Method and system to increase electric brake clamping force accuracy

ActiveUS20070175713A1Improve accuracyGreat accuracy and sensitivity to brake commandBraking action transmissionElectrodynamic brake systemsElectric aircraftActuator

The method and system for increasing accuracy of clamping force of electric aircraft carbon brakes, once braking has been commenced, provides a first pair of electric brake actuators with a range of low brake clamping force responsive to low brake clamping force commands, and a second pair of electric brake actuators with a range of high brake clamping force responsive to high brake clamping force commands. The first pair of electric brake actuators is actuated to apply a minimum residual braking force once wheel braking is commenced, and the second pair of electric brake actuators is actuated only when the commanded braking force is in the high range of brake clamping force.

Owner:HYDRO AIRE AEROSPACE CORP

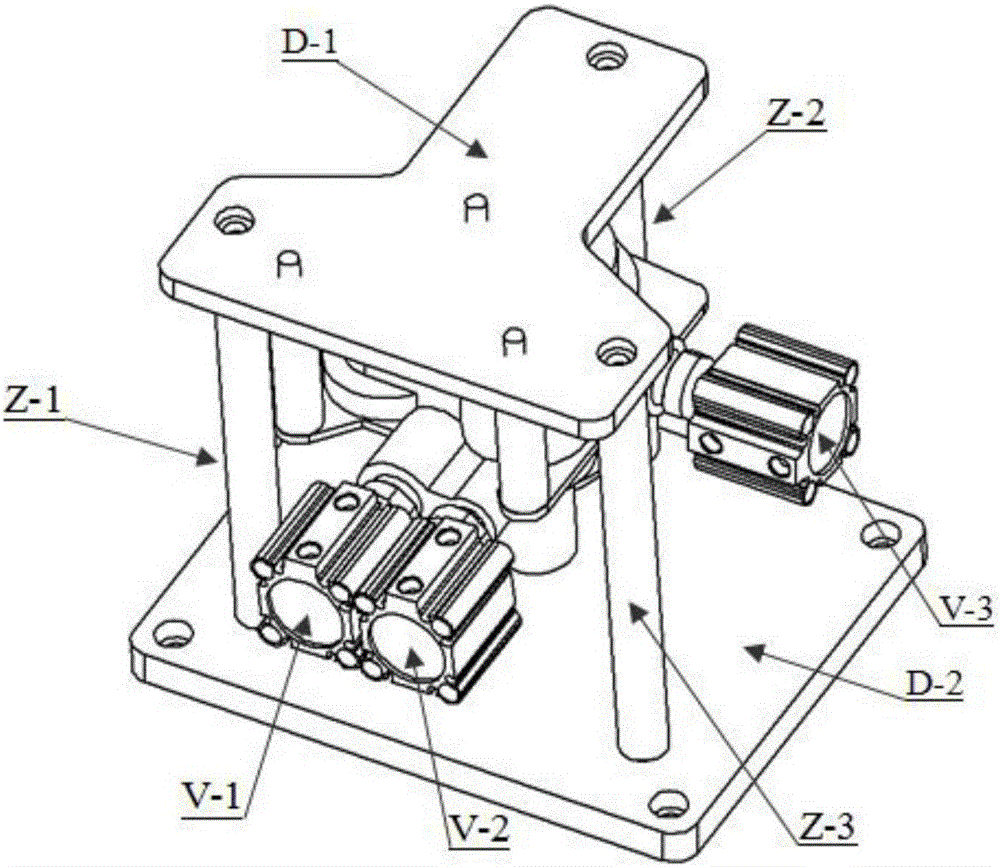

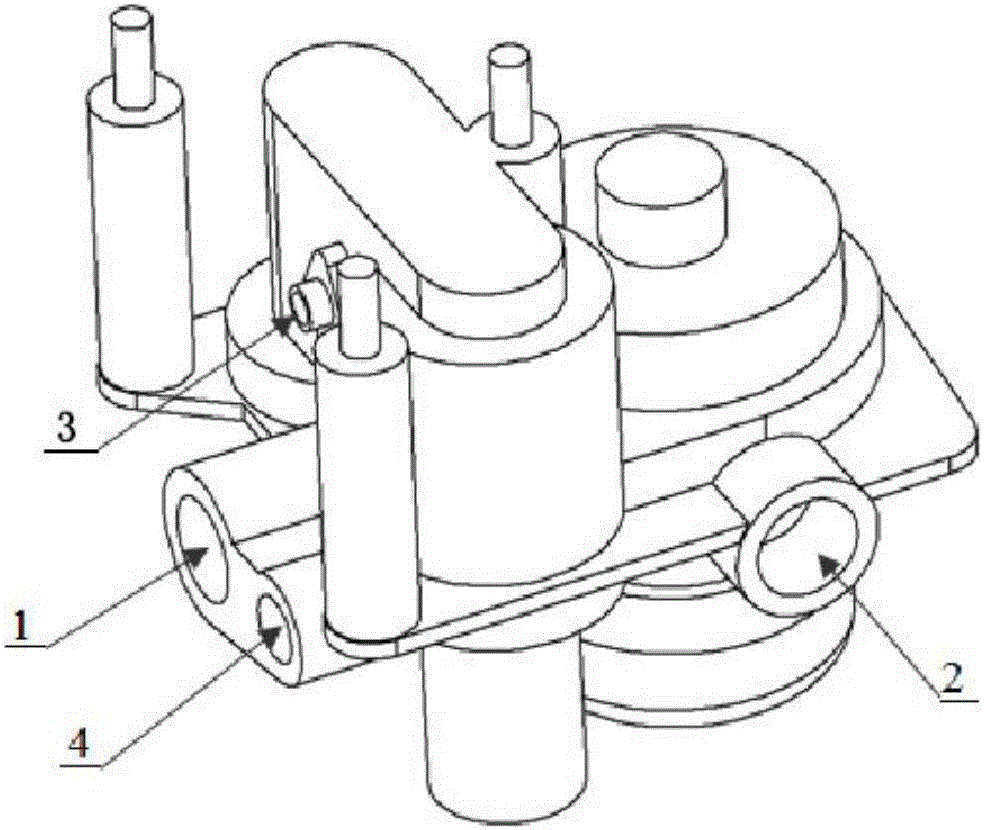

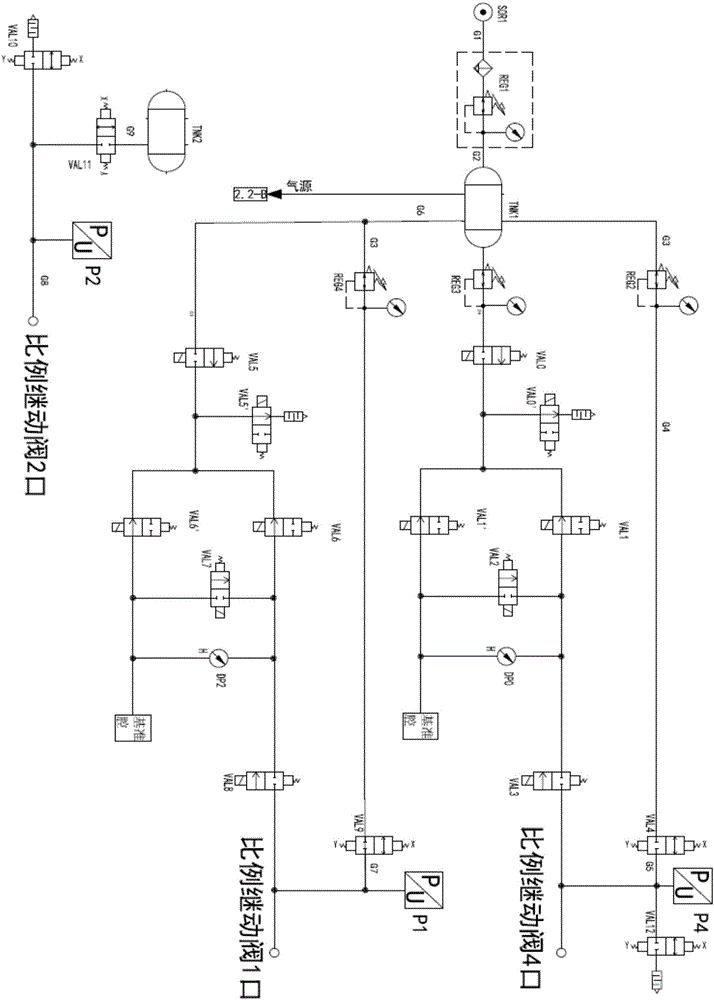

Vehicle proportion relay valve detection device and method

ActiveCN106706234AImprove test efficiencyImprove test accuracyMeasurement of fluid loss/gain rateInternal combustion piston enginesTest efficiencyPneumatic circuit

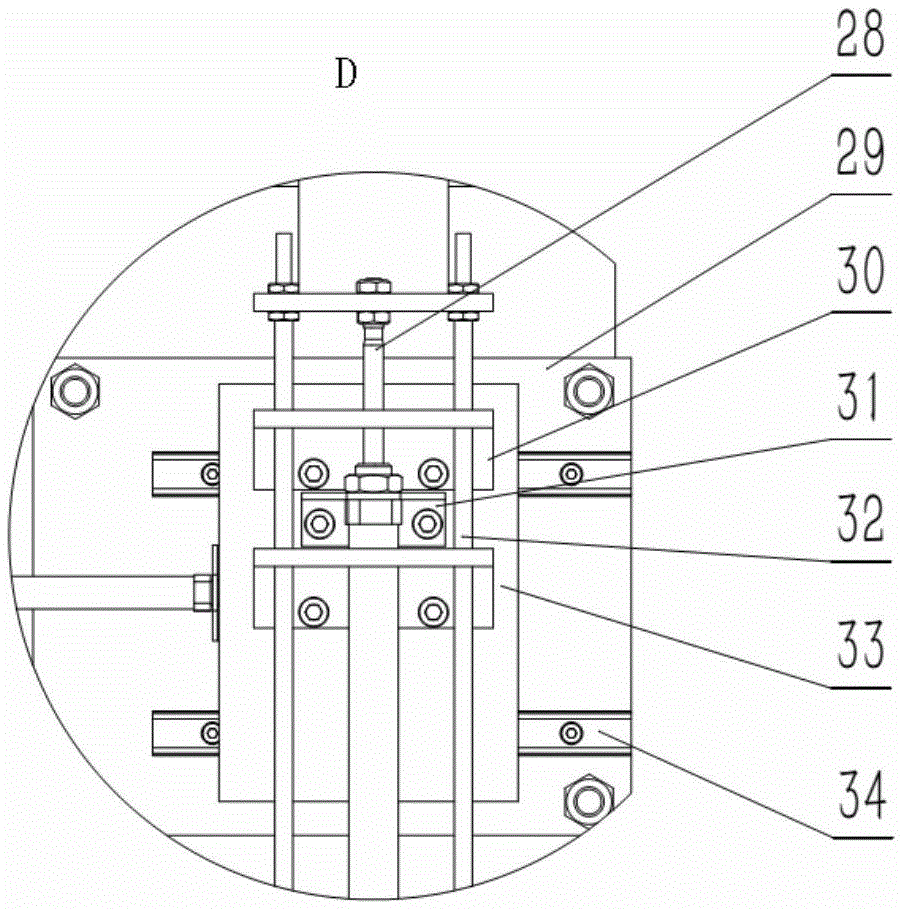

The present invention discloses a vehicle proportion relay valve detection device. The device is fixed at a test bed, and comprises a top cap D-1 fixing the proportion relay valve, a pedestal D-2, three bracing pieces Z-1, Z-2 and Z-3, a cylinder tool V-1 blocking the air inlet 1 of the proportion relay valve, a cylinder tool V-2 blocking the control port 4-1 of the proportion relay valve and a cylinder tool V-3 blocking the air outlet 2 of the proportion relay valve; each cylinder is provided with an end cap; and air is flown in from the air inlet of the cylinder to extend the end cap forwards connected with the cylinder to block the interface of the proportion relay valve. The present invention further provides a pneumatic circuit of the vehicle proportion relay valve detection device and a vehicle proportion relay valve detection method. The detection device is high in test efficiency and test precision. The fixed component structure is simple and practical and high in clamping precision.

Owner:CHINA JILIANG UNIV

Method for processing high accuracy high strength bolt

The process of producing high accuracy and high strength bolt includes preparing material, coarse turning, heat treatment, finish turning and other steps. The present invention machines two bolt simultaneously with one blank to facilitate fastening and save required fastening length. The present invention combines common lathe with numerically controlled lathe, and has the features of lowered machining cost, high bolt quality, less finish turning margin, high efficiency, high bolt precision, etc.

Owner:贵州凯星液力传动机械有限公司

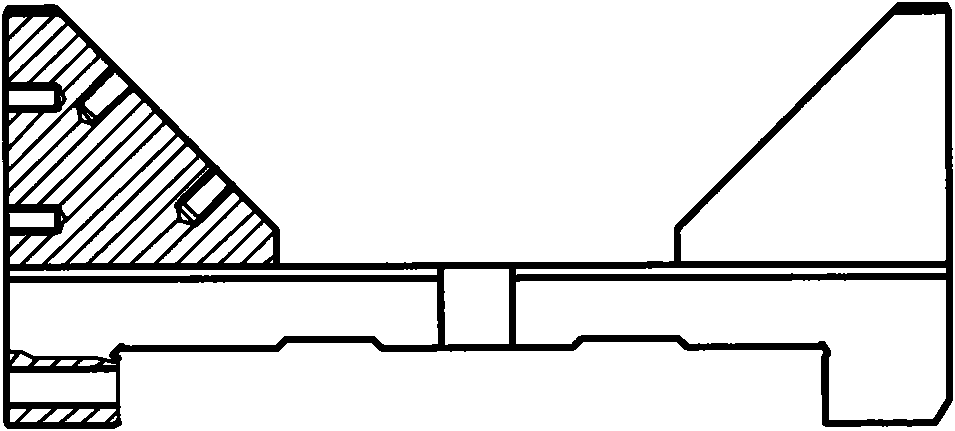

Clamping method for shaft parts and holding device

InactiveCN102107379AReduce vibrationHigh clamping precisionRevolution surface grinding machinesGrinding work supportsEngineeringScrew thread

A clamping method for shaft parts and a holding device belong to the technical field of grinding shafts. A conventional clamp has the disadvantages of smaller application range, complicated structure, higher cost, low positioning accuracy and low working efficiency. In the clamping method provided by the invention, radial positioning and centering of a workpiece can be achieved by adjusting the number and the heights of small cushion blocks, and the workpiece can be clamped and positioned in the axial direction and the radial direction by adjusting the length of screw threads of an adjusting bolt; the holding device of the invention also comprises a clamp seat, a big clamp block, a small clamp block, adjusting cushion blocks, center blocks and the like; the clamp seat is directly installed on a guide rail of a grinding machine; the two center blocks are arranged symmetrically and installed on two V-shaped surfaces of the big clamp block through the small cushion blocks; in addition, the big clamp block and the small clamp block are provided with V-shaped opening respectively, and are symmetrically arranged in the opposite directions. The clamping method and the holding device of the invention have the advantages of high positioning accuracy, simple operation, wide application range, low cost, high operating efficiency and the like, and the positioning accuracy can reach 0.001mm.

Owner:梁美旭

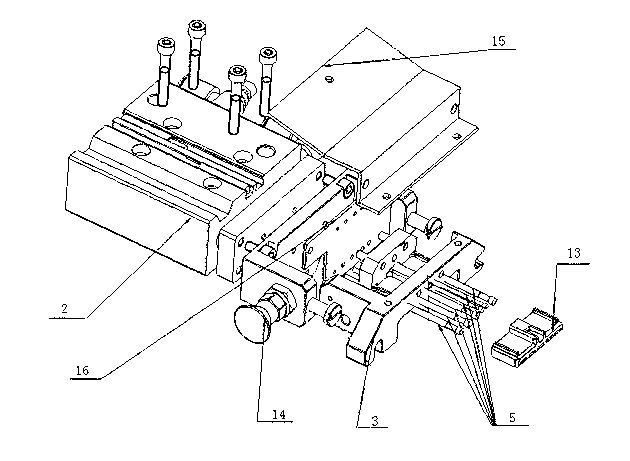

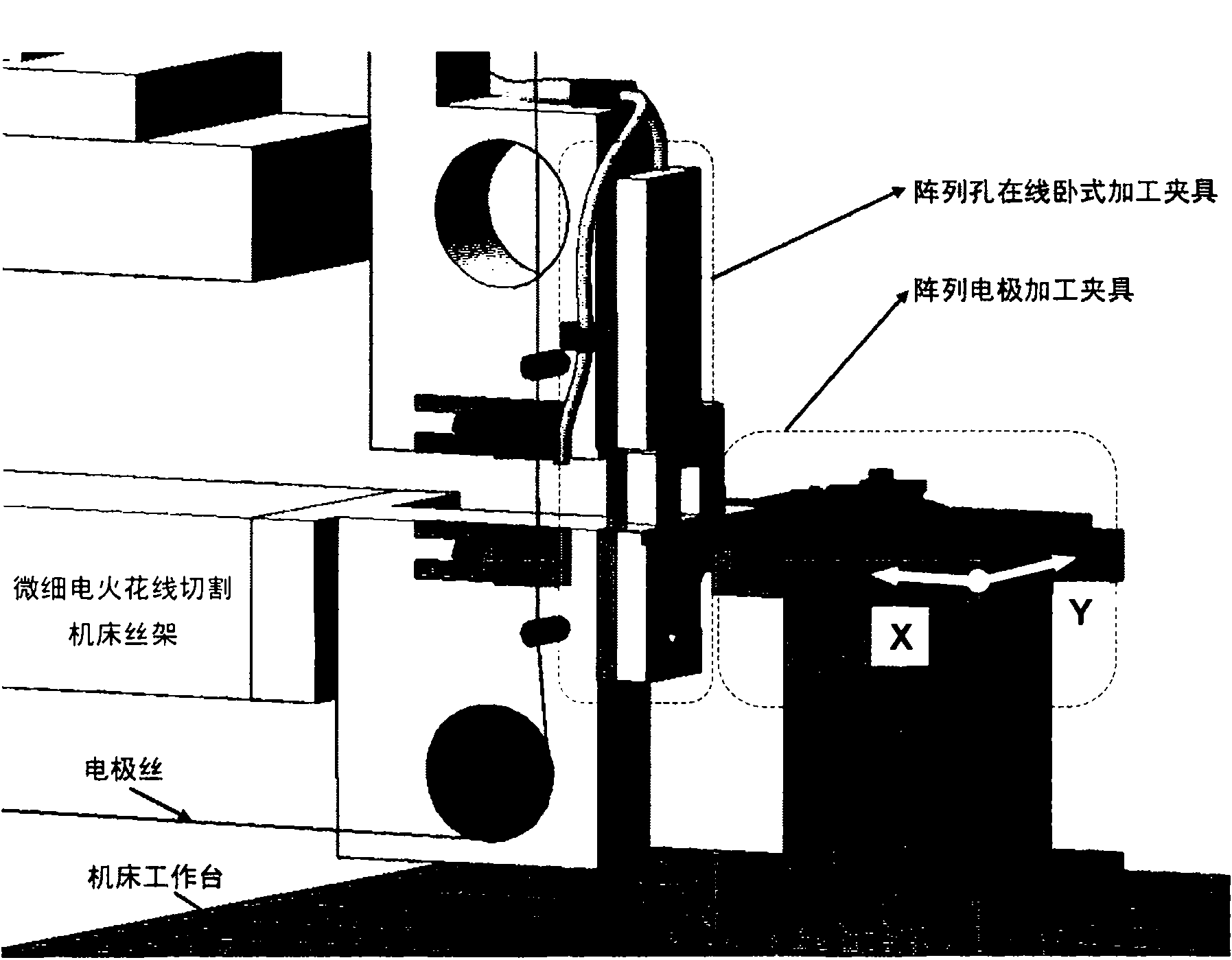

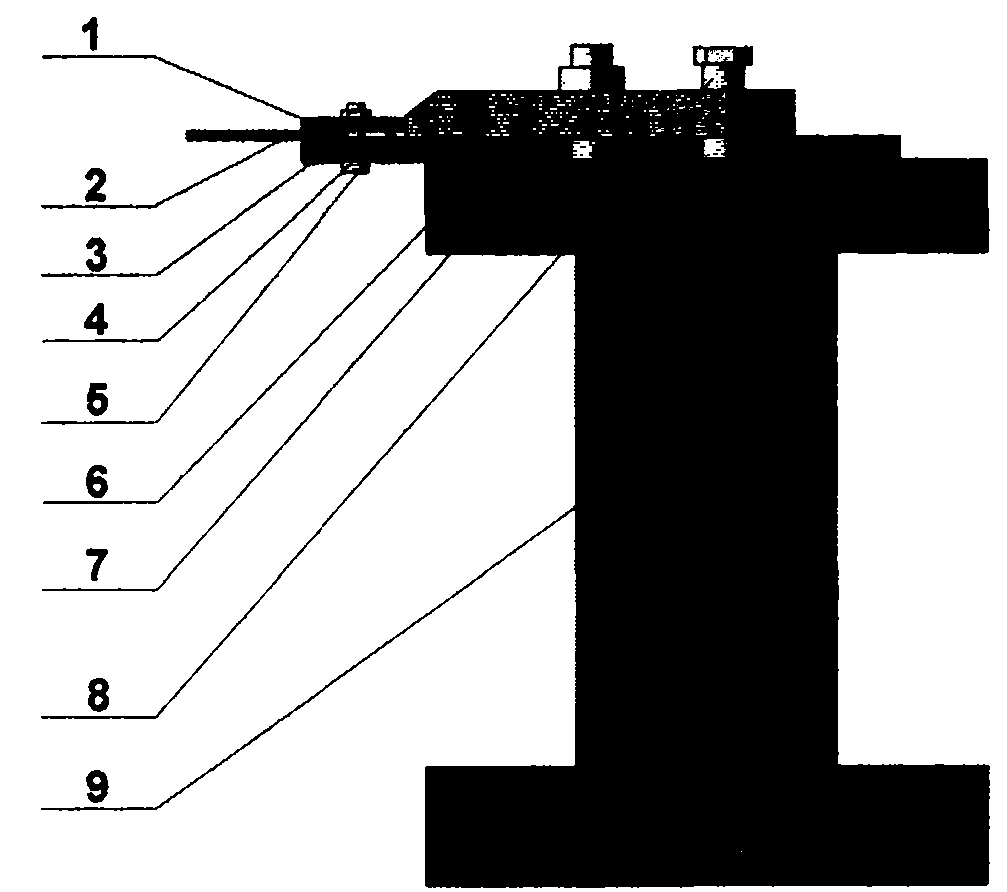

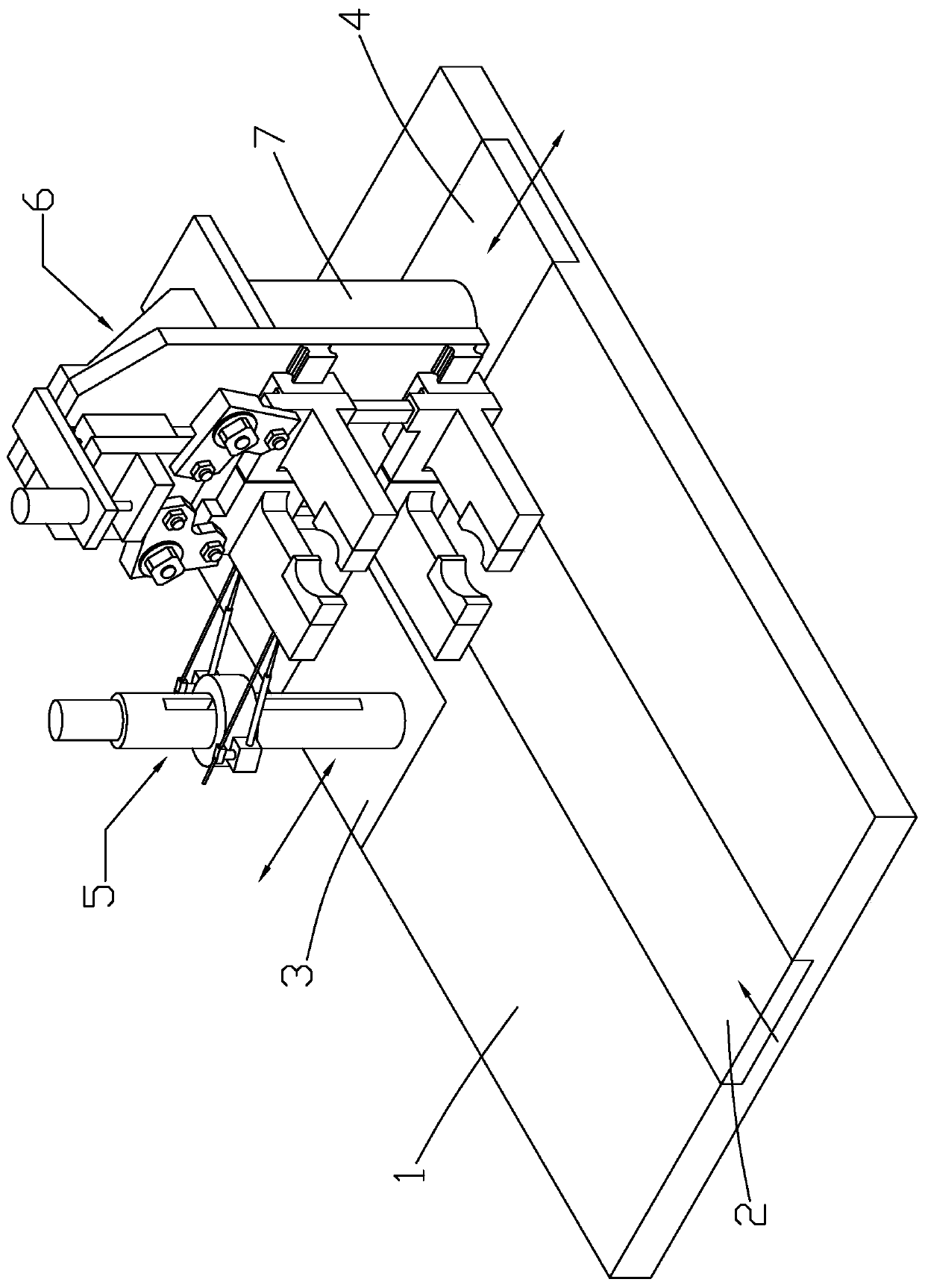

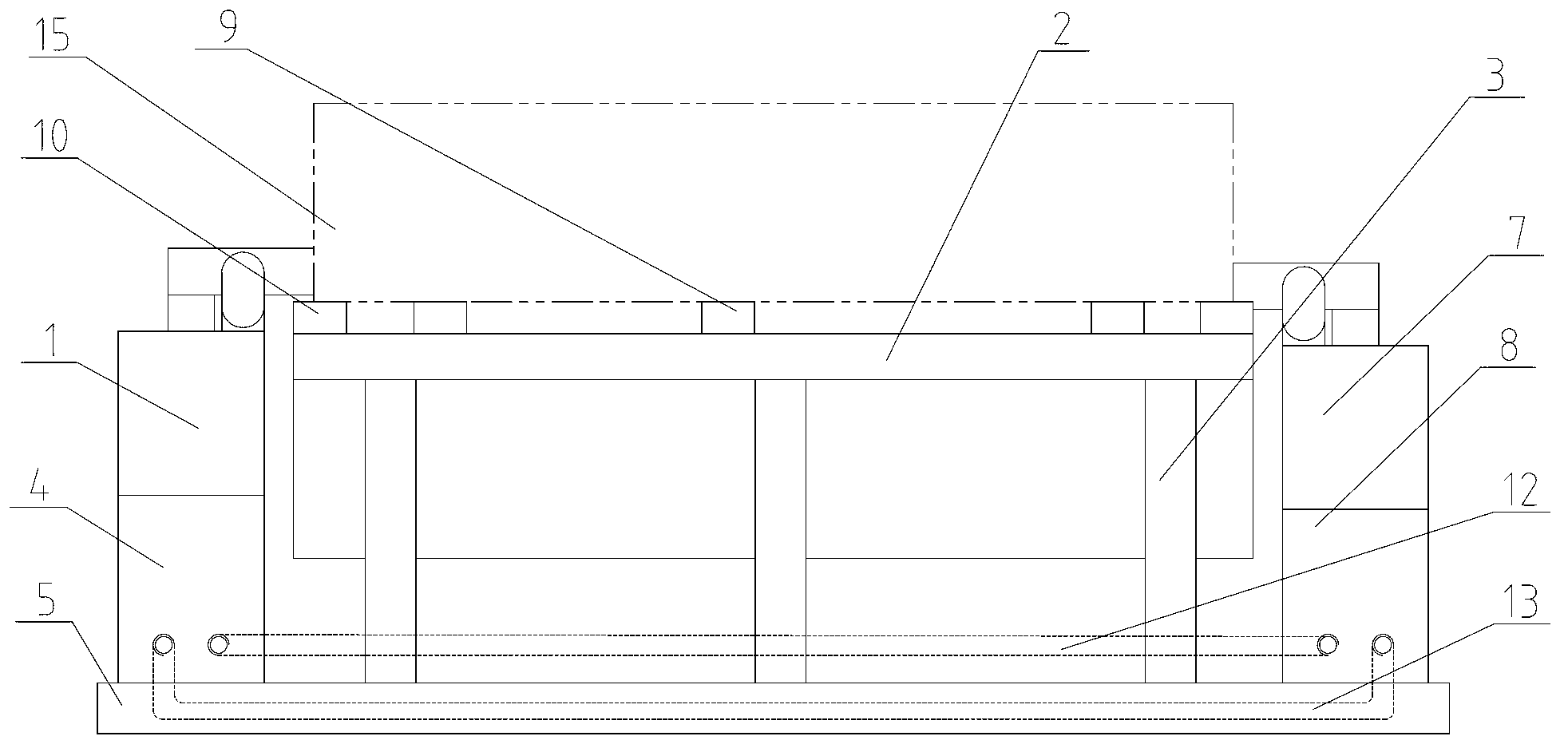

Special fixture for micro electrode array on-line horizontal electrospark machining

InactiveCN101890546AEasy to manufactureLow costPositioning apparatusElectrical-based auxillary apparatusElectrode arrayMachine tool

The invention relates to a special fixture for micro electrode array on-line horizontal electrospark machining, which comprises an electrode array square bar clamping mechanism, a fixture fixing mechanism and a support base. The special fixture is characterized in that a marble support (9) keeps the whole fixture in the working height position of a tool for electrode array machining; the electrode array square bar clamping mechanism comprises an upper fixing plate (1), an L-shaped lower fixing plate (3), fastening screws and nuts (4) and an adjusting block (5), an electrode array square bar (2) is clamped on the fixture by the upper fixing plate (1) and the L-shaped lower fixing plate (3) through the fastening screws and nuts (4), and the adjusting block (5) keeps the electrode array square bar (2) to stay at the same horizontal level with a workbench of the tool; and the fixture fixing mechanism comprises a fastening pressure plate (6), pressure plate bolts and nuts (7) and pretensioning bolts (8), the support base is the marble support (9), and the electrode array square bar clamping mechanism is fixed on the marble support (9) by the fastening pressure plate (6) through the pressure plate bolts and nuts (7) and the pretensioning bolts (8).

Owner:HARBIN INST OF TECH

Special mechanical gripper for automobile part positioning

InactiveCN110774042AHigh clamping precisionSimple structureGripping headsMetal working apparatusClassical mechanicsStructural engineering

Owner:HEFEI CHANGQING MACHINERY

Friction wedge type automatic clamp for cylindrical grinding and application method thereof

ActiveCN106965087AGuaranteed coaxialityRealize automatic clampingGrinding work supportsNeedle roller bearingGear wheel

The invention discloses a friction wedge type automatic clamp for cylindrical grinding and an application method thereof. The friction wedge type automatic clamp for cylindrical grinding comprises a connecting flange, a left end cover, a head rack tip, a positioning flange, an intermediate sleeve, a hexagonal nut, a spline inner sleeve, a supporting ring, a wedge ring, a shifting ring, wedges, a supporting ring positioning sleeve, a needle bearing and a right end cover, wherein the connecting flange is mounted onto a gear of a head rack through a screw; the connecting flange, the supporting ring and the shifting ring are sequentially fixed through the screws; the shifting ring is connected with three wedges through three uniformly-distributed shifting pins; the three wedges are correspondingly embedded into three bevel grooves of the wedge ring; the positioning flange is fixed to a machine body of the head rack and is fixedly connected with the intermediate sleeve; the spline inner sleeve is connected with the wedge ring; a pre-tensioned inner conical spring and a pre-tensioned outer conical spring are mounted between the intermediate sleeve and the spline inner sleeve. According to the friction wedge type automatic clamp for the cylindrical grinding, an automatic wedge clamping manner is used for replacing an existing general manual chuck and a hydraulic driving chuck, so that the structure is simplified, and meanwhile, the automatic clamping function is achieved; in addition, the grinding precision is ensured.

Owner:QUZHOU COLLEGE OF TECH

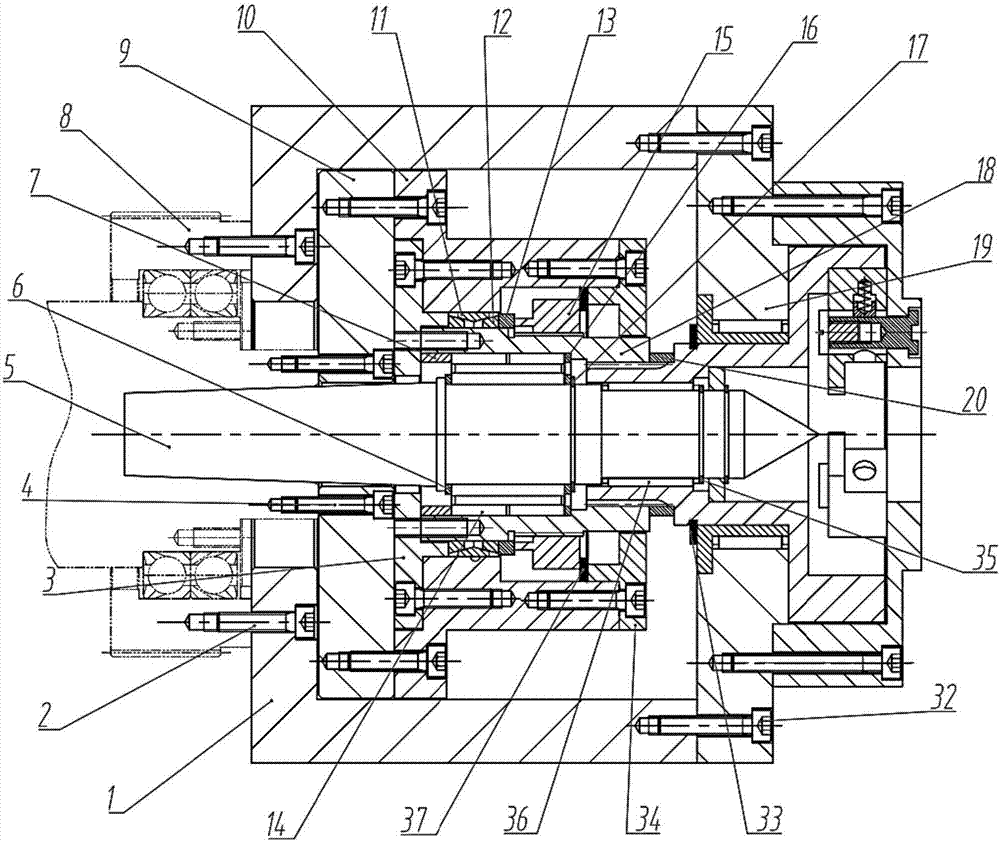

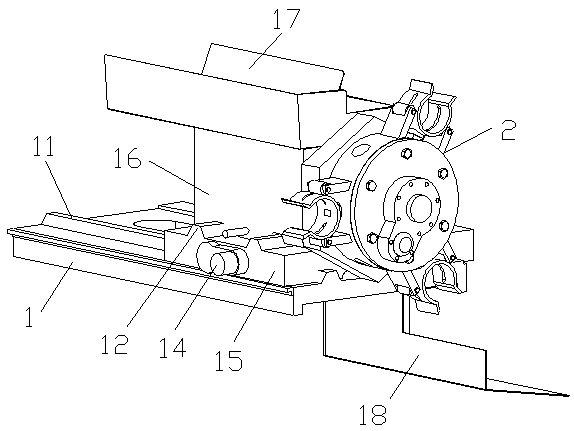

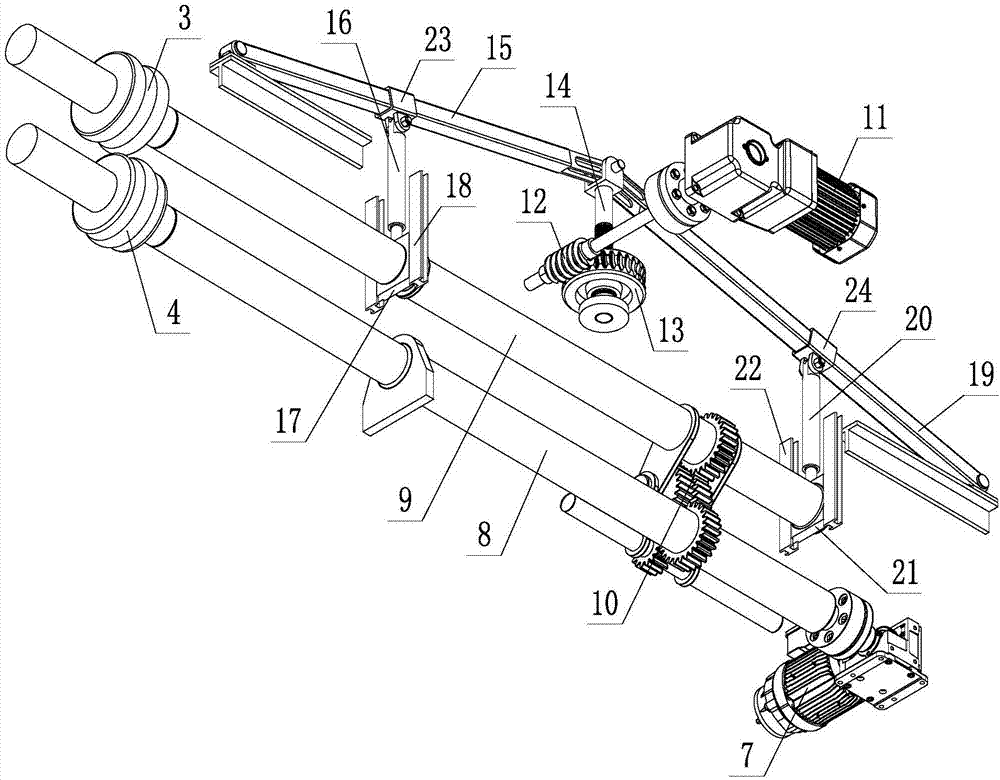

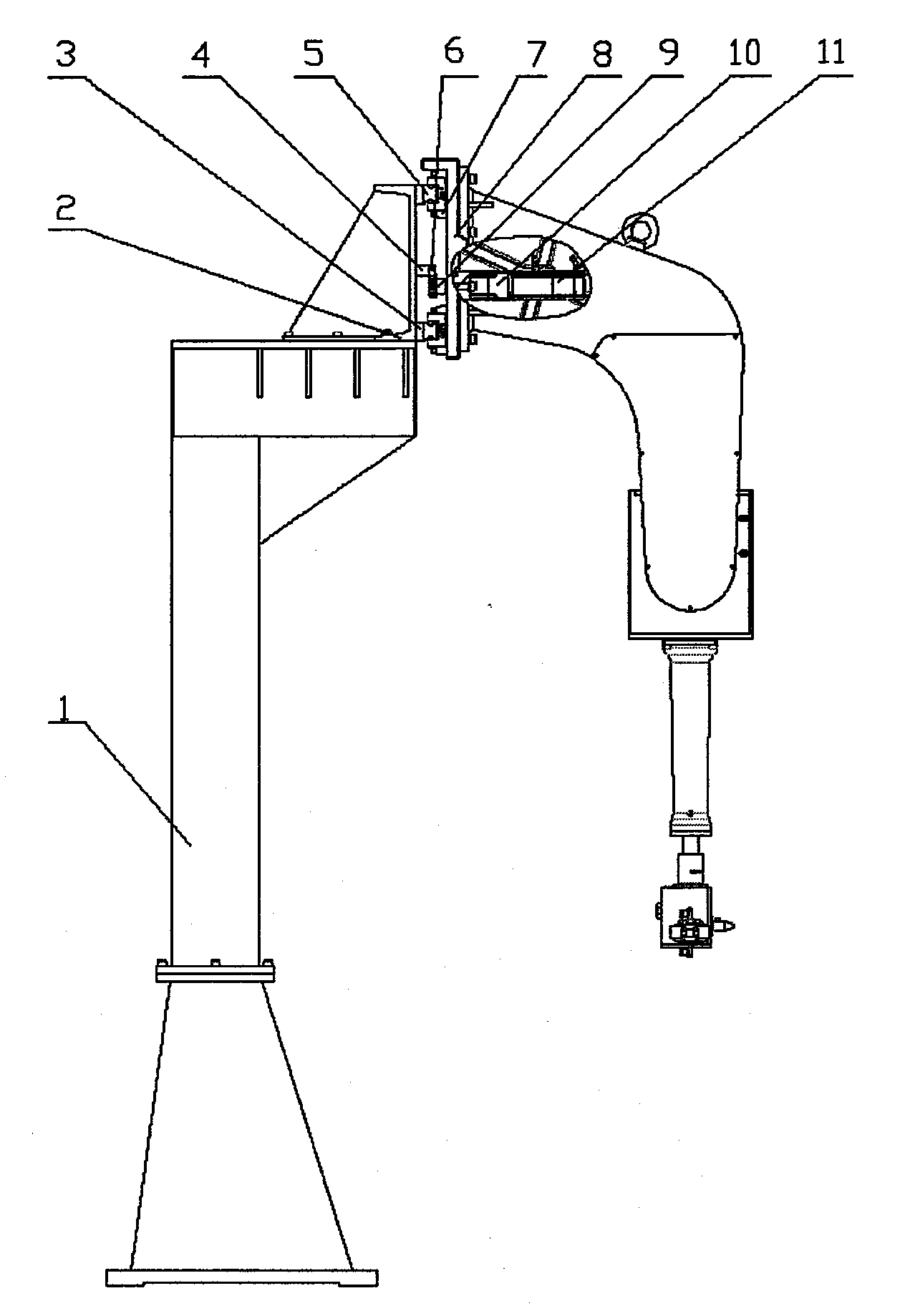

Loading manipulator of PMC threading machine

ActiveCN108296577AImprove reliabilityHigh clamping precisionThread cutting feeding devicesMotor driveDrive motor

The invention discloses a loading manipulator of a PMC threading machine. According to the manipulator, a middle support plate which is capable of reciprocating transversely is arranged on a rack; a longitudinal driving motor which is capable of reciprocating longitudinally is arranged on the middle support plate; a rotation shaft of the longitudinal driving motor is connected with a clamping mechanism; the clamping mechanism comprises a connection disk, a mounting sleeve, an end disk, a can, a cam driving motor and a plurality of clamping components; the connection disk, the mounting sleeve and the end disk are coaxially connected in sequence; a rotation shaft of an angle motor drives the connection disk; the cam is located at the inner ring of the mounting sleeve; the cam driving motor is arranged on the side surface of the end disk and drives the cam to rotate; the mounting sleeve is equidistantly provided with a plurality of through holes along the radial direction, one side of themounting sleeve is a guiding hole and the opposite side is a process hole; and the clamping component is arranged in the guiding hole and is driven by the cam and is used for clamping a workpiece bya clamping ring. The manipulator is capable of overcoming the workpiece clamping defects of traditional threading machines, effectively improving the workpiece clamping precision and efficiency, and preventing scrap iron from hurting people and scratching the workpiece surfaces, and is convenient to maintain and overhaul so as to improve the operation reliability of the threading machine.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

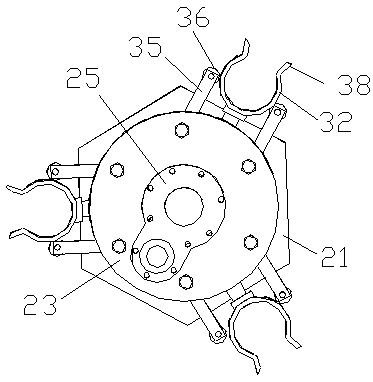

Positioning and clamping device for cylindrical parts

InactiveCN112440071AAchieve clampingAchieve relaxationWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringClip device

The invention provides a positioning and clamping device for cylindrical parts. The positioning and clamping device comprises a tray, a positioning bent plate and a top block, wherein a plurality of slideways are uniformly distributed on the tray in the circumferential direction, and the slideways have inverted T-shaped cross sections and extend from the edge of the tray to the middle of the tray.The positioning bent plate comprises a positioning plate and a mounting plate, wherein the positioning plate is fixed on the slideways of the tray through bolts, and the mounting plate is verticallyfixed on the upper portion of the positioning plate. The top block is arranged on the side, close to the middle of the tray, of the mounting plate. According to the positioning and clamping device forthe cylindrical parts, the positioning bent plate is installed on the slideways through the bolts, the positioning bent plate can slide along the slideways by unscrewing the bolts so that the parts can be clamped and loosened, and the positioning and clamping device is simple and reasonable in structure, low in manufacturing cost, suitable for clamping the cylindrical parts of different sizes within a certain range, high in universality, capable of realizing alignment and adjustment of the position of the parts by moving the positioning bent plate, easy to operate, and high in clamping precision.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Continuous drilling device for producing cylindrical hardware fittings

ActiveCN110394474AImprove stabilityImprove reliabilityPositioning apparatusMetal working apparatusEngineeringAssembly line

The invention discloses a continuous drilling device for producing cylindrical hardware fittings. The continuous drilling device comprises a base plate, a feeding mechanism and a discharging mechanism, and further comprises a continuous drilling component, wherein the bottom surface of the base plate is symmetrically provided with support feet; the feeding mechanism and the discharging mechanism are separately arranged on both sides of the continuous drilling component; the continuous drilling component includes a horizontal moving mechanism, a clamping mechanism, an I-shaped support plate anda drilling mechanism; the I-shaped support plate is fixedly connected to the upper portion of the base plate through a first column, and is parallel to the base plate; the horizontal moving mechanismis arranged between the I-shaped support plate and the base plate; the clamping mechanism is connected to the top surface of the horizontal moving mechanism; and the drilling mechanism is connected to the upper portion of the I-shaped support plate through a lifting mechanism. The continuous drilling device for producing the cylindrical hardware fittings has the advantages of simple structure andhigh practicability; and the continuous transportation and drilling of the cylindrical hardware fittings are achieved, the clamping accuracy of the cylindrical hardware fittings is improved at the same time, and then the accuracy and quality of drilling machining are improved so as to meet the needs of assembly line production.

Owner:湖南兴天机械股份有限公司

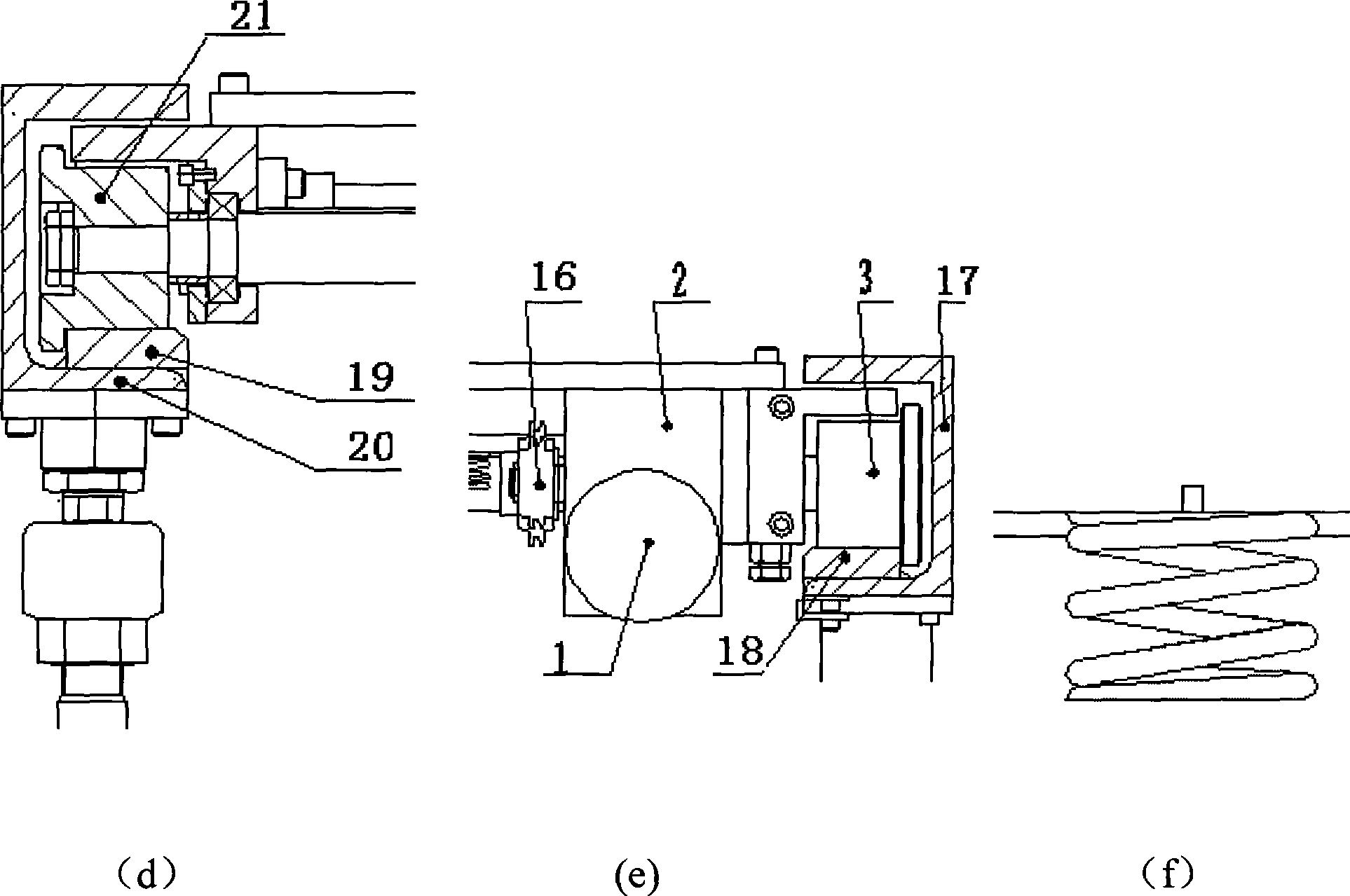

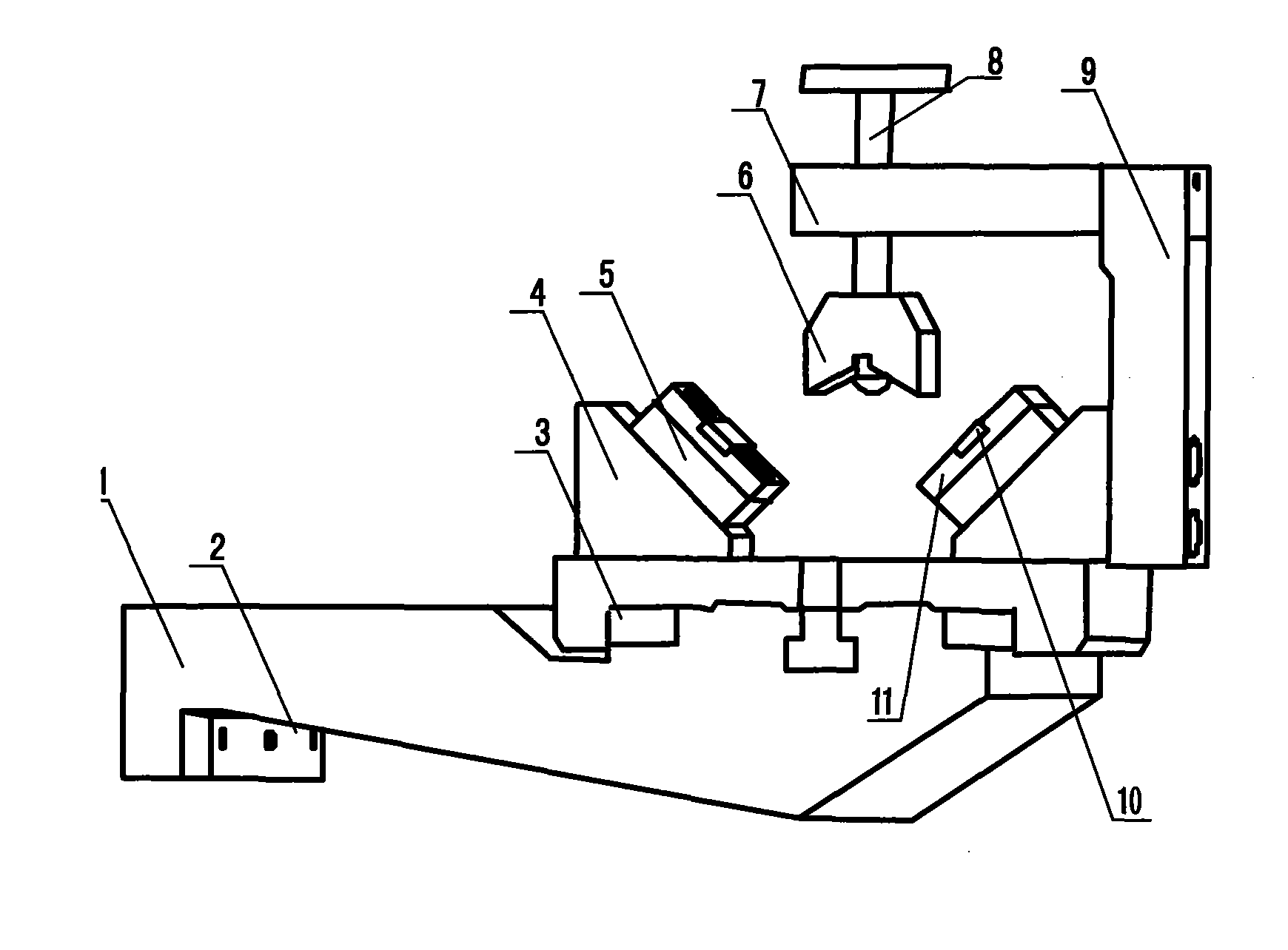

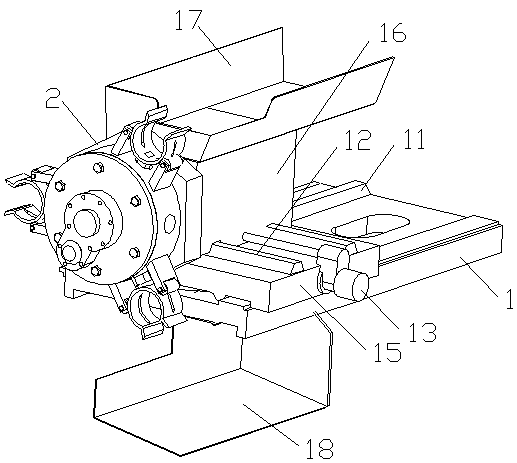

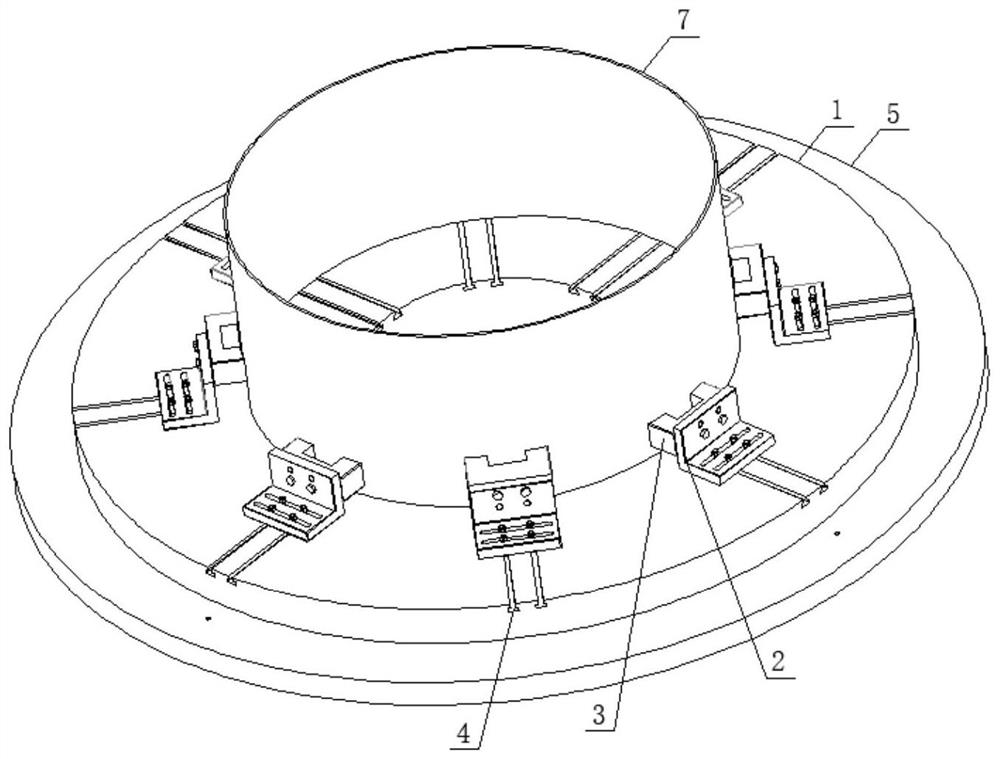

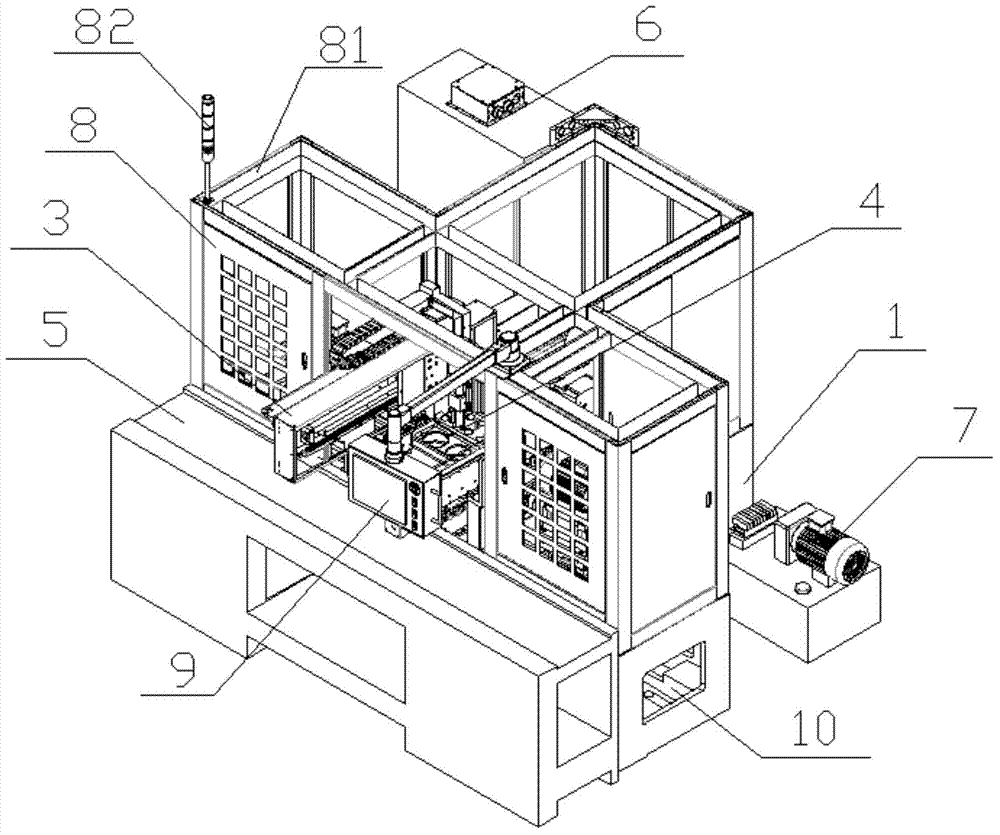

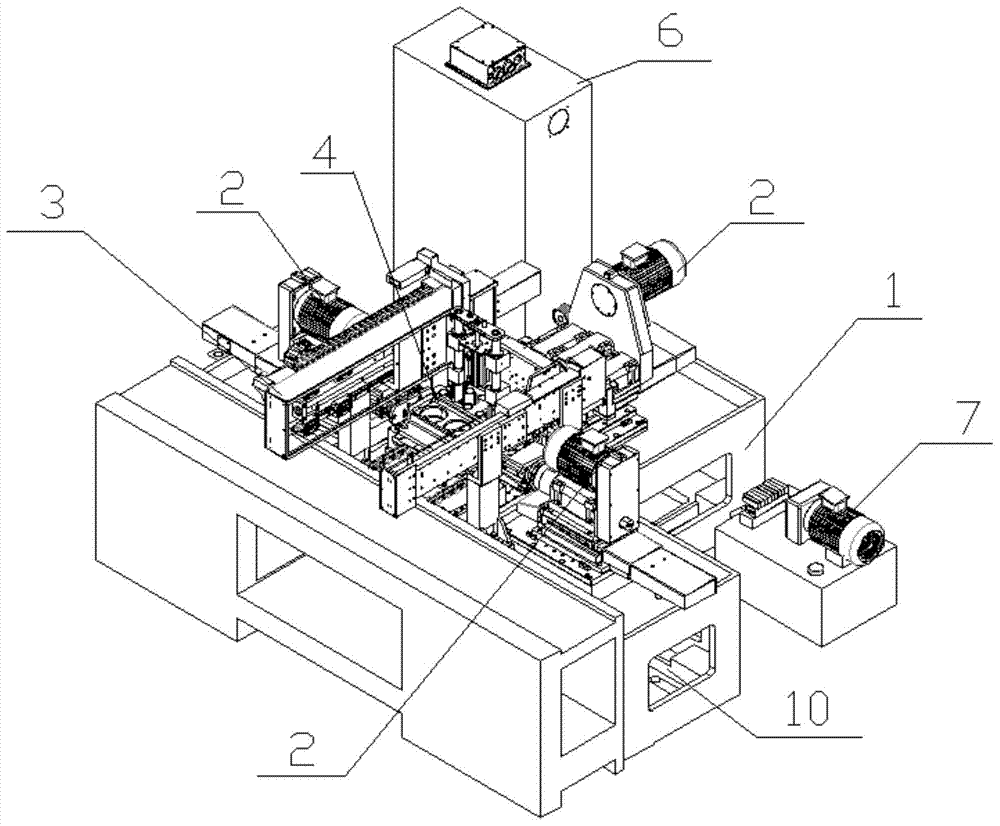

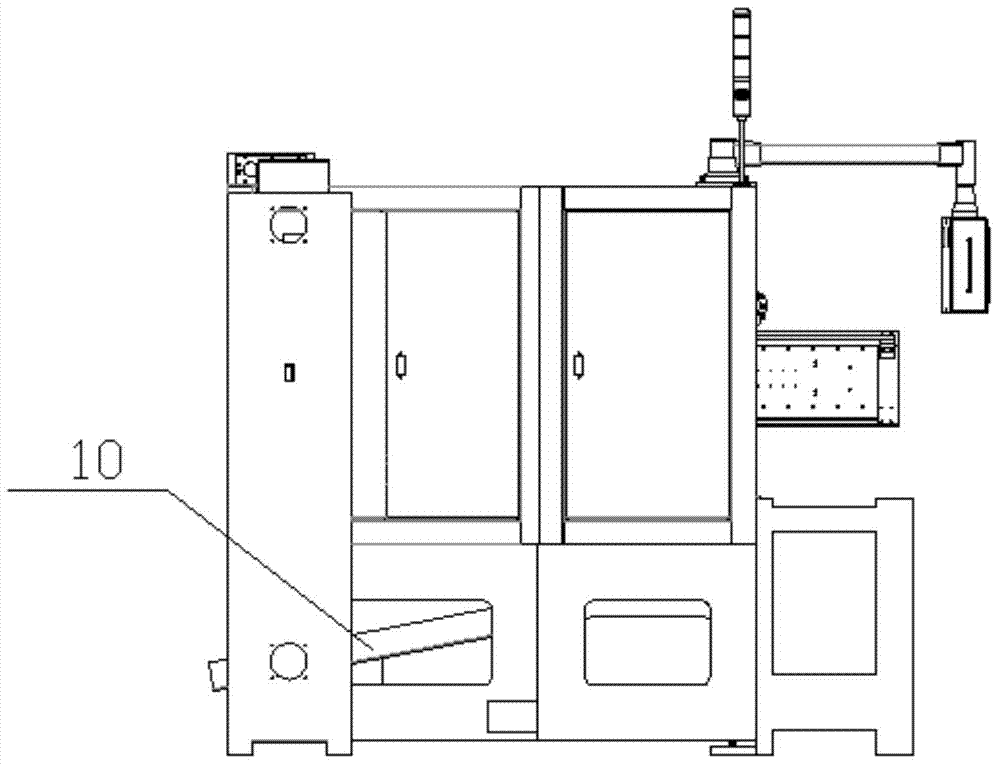

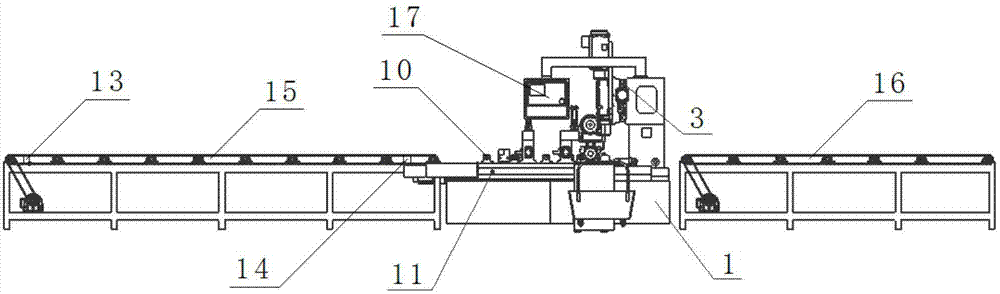

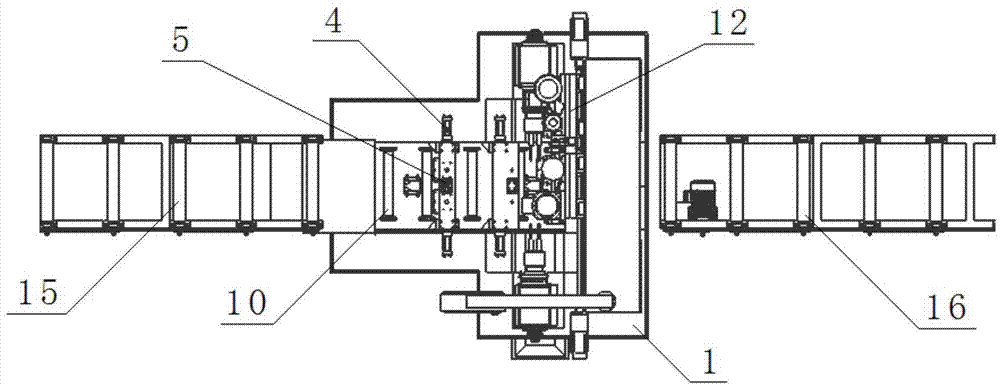

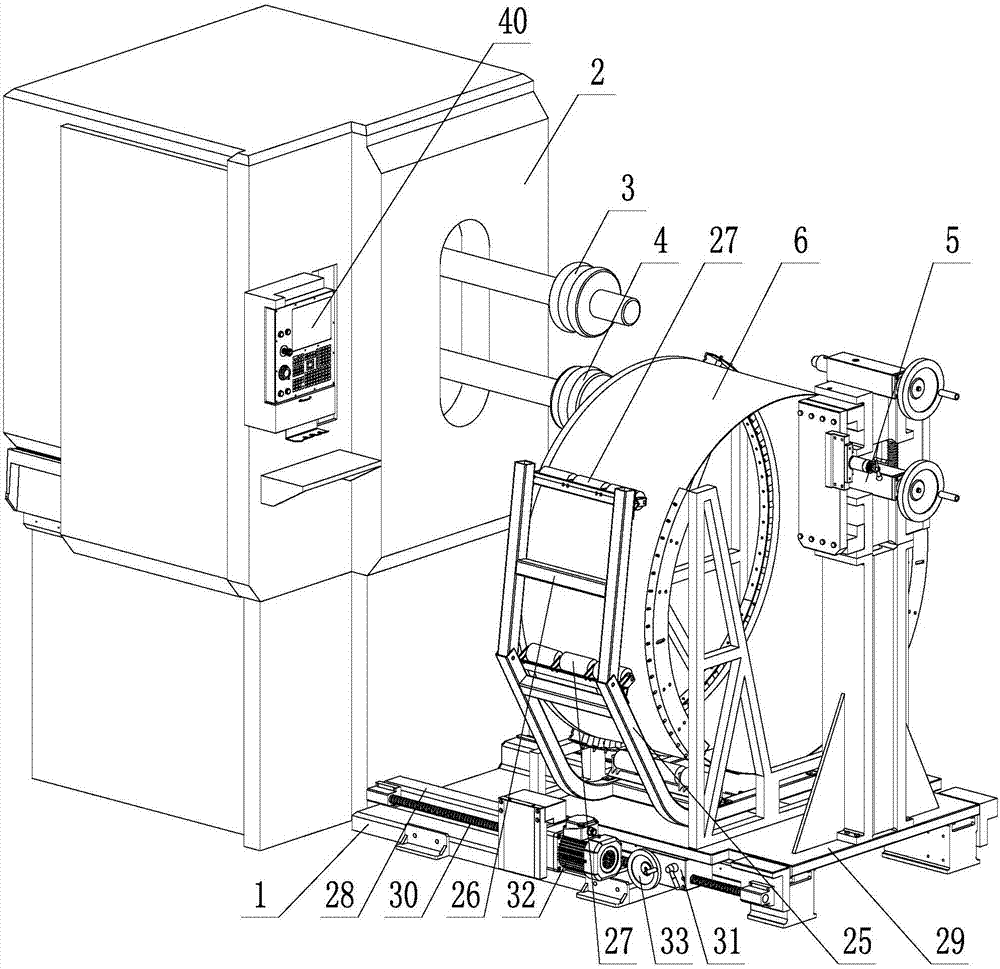

Yaw brake machine tool

ActiveCN104741932AReduce labor costsReduce manual labor intensityOther manufacturing equipments/toolsControl systemEngineering

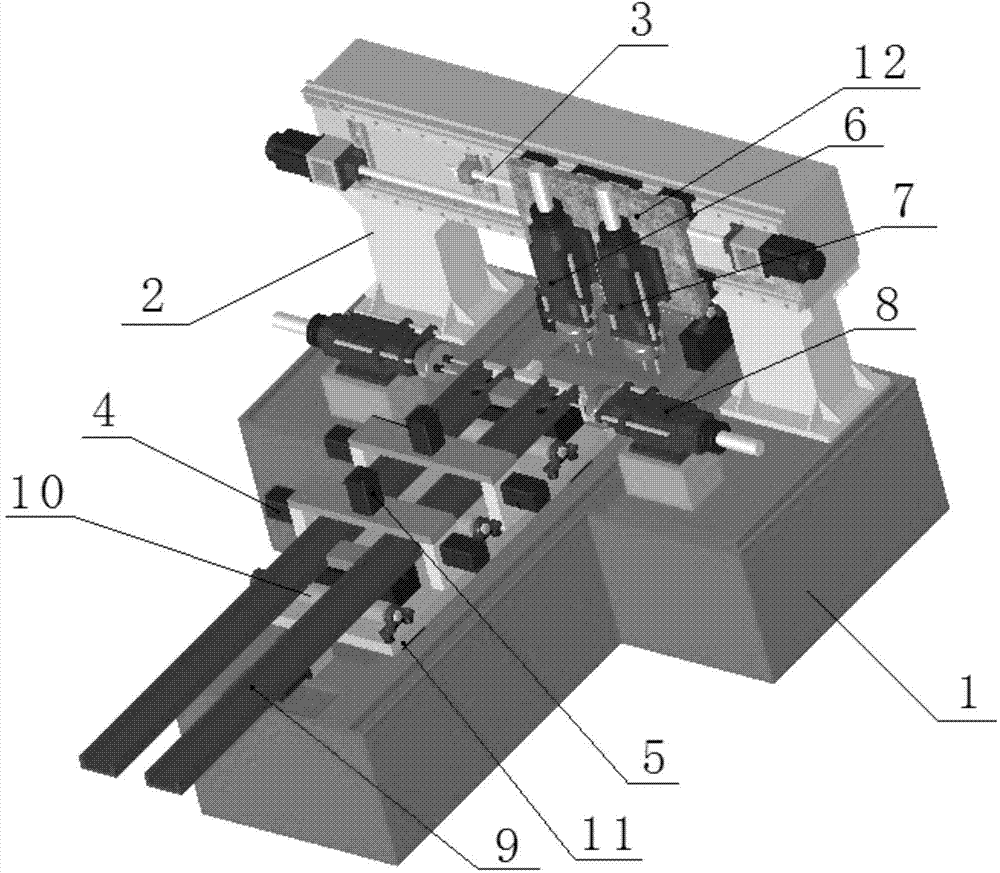

The invention relates to a yaw brake machine tool. The yaw brake machine tool comprises a base which is of an inverted T-shaped structure, a cutting tool system, a manipulator system, a workpiece clamping auxiliary system, an assembly line workbench, an electric appliance control system and a hydraulic system; the cutting tool system is formed by a left cutting tool unit, a right cutting tool unit and a rear cutting tool unit which are arranged at the left position, the right position and the rear position of the base respectively; the manipulator system is located between the left cutting tool unit and the right cutting tool unit; the workpiece clamping auxiliary system is fixed on the base and located below the manipulator system; the assembly line workbench is fixed at the front end of the base; a position of the assembly line workbench, which is corresponding to a manipulator, is provided with a sensor and a jack-up cylinder; the electric appliance control system and the hydraulic system are arranged at two ends behind the base respectively; the hydraulic system is connected with the workpiece clamping auxiliary system. According to the yaw brake machine tool, the simultaneous machining can be performed on a plurality of machining surfaces, a fixture, a cutting tool and a milling machine do not need to be replaced, the machining accuracy is high, and the intelligent automation control is implemented.

Owner:嘉兴德威高传动系统股份有限公司

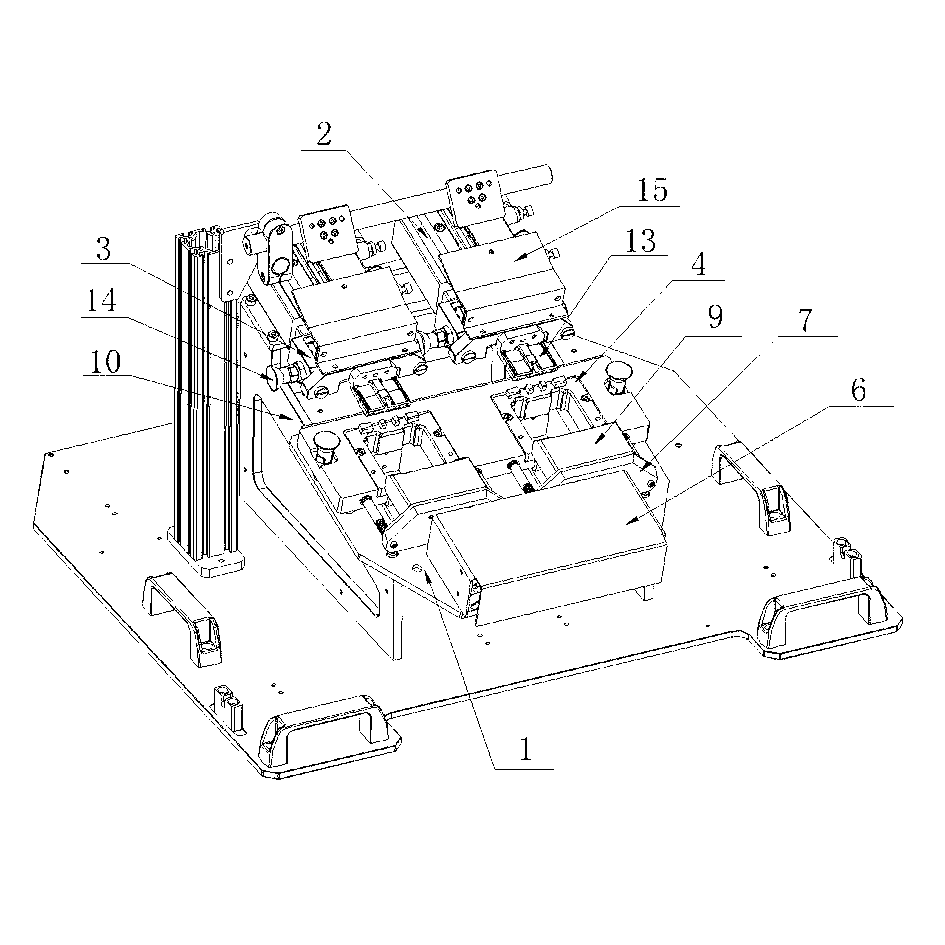

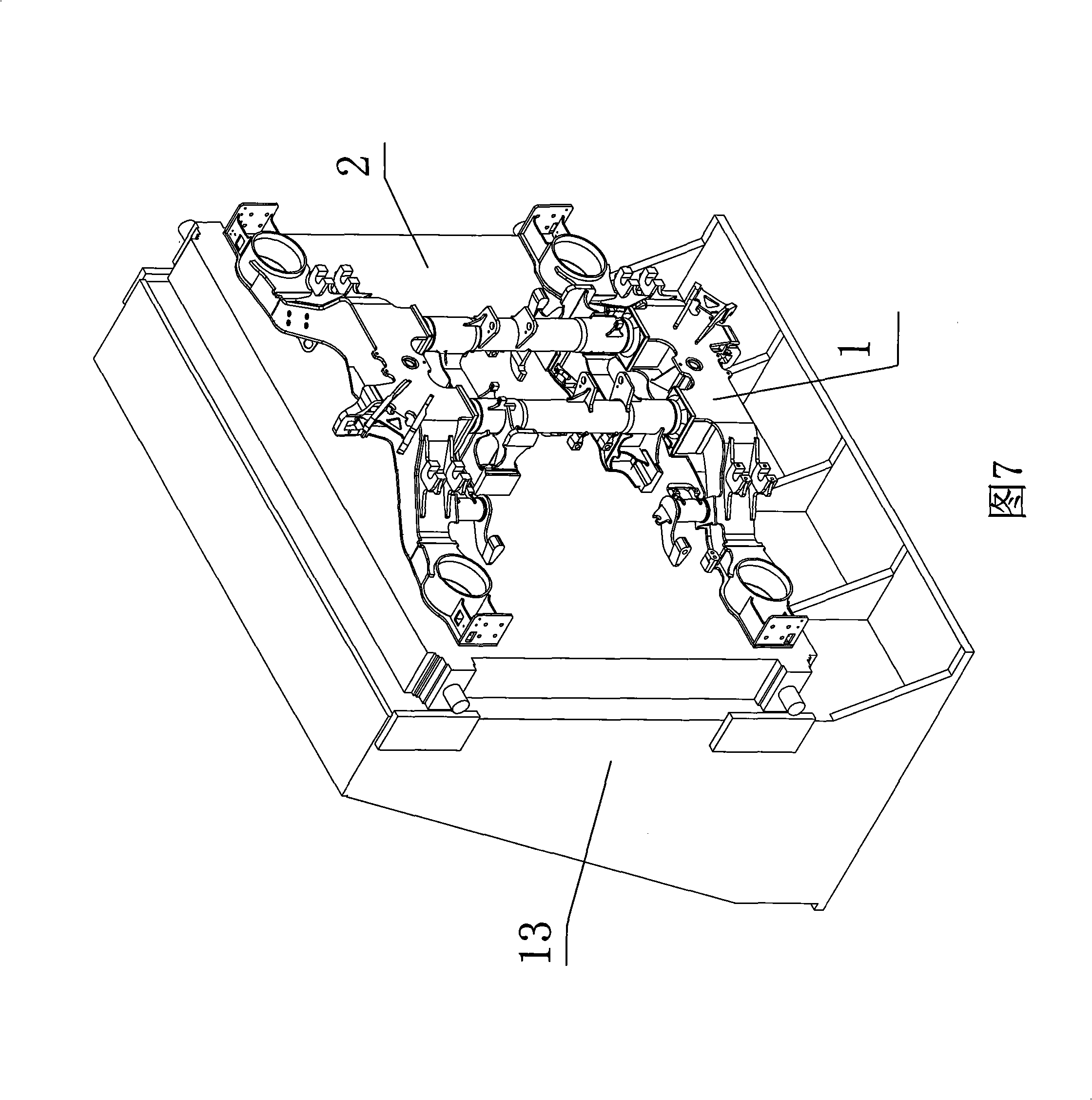

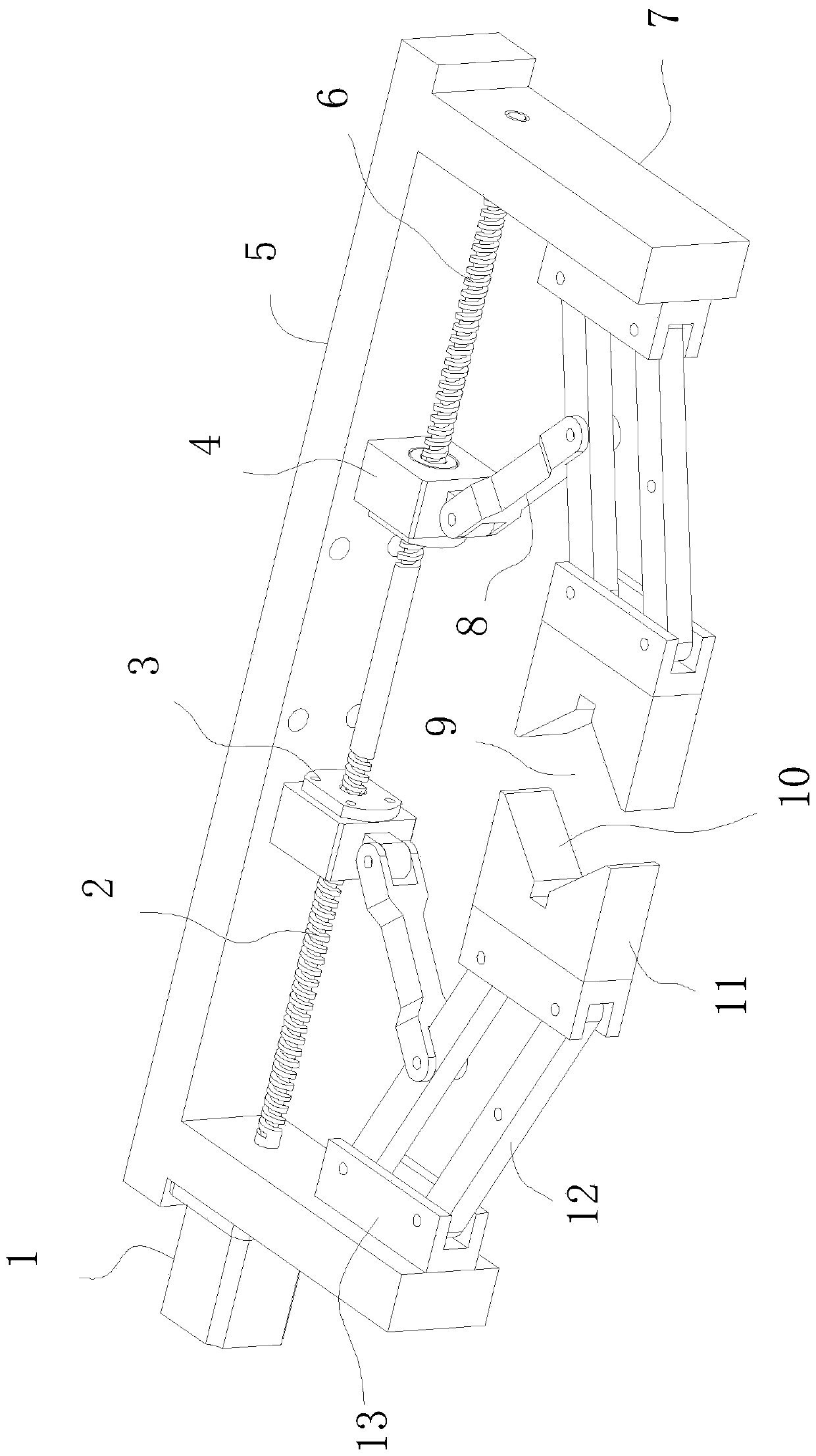

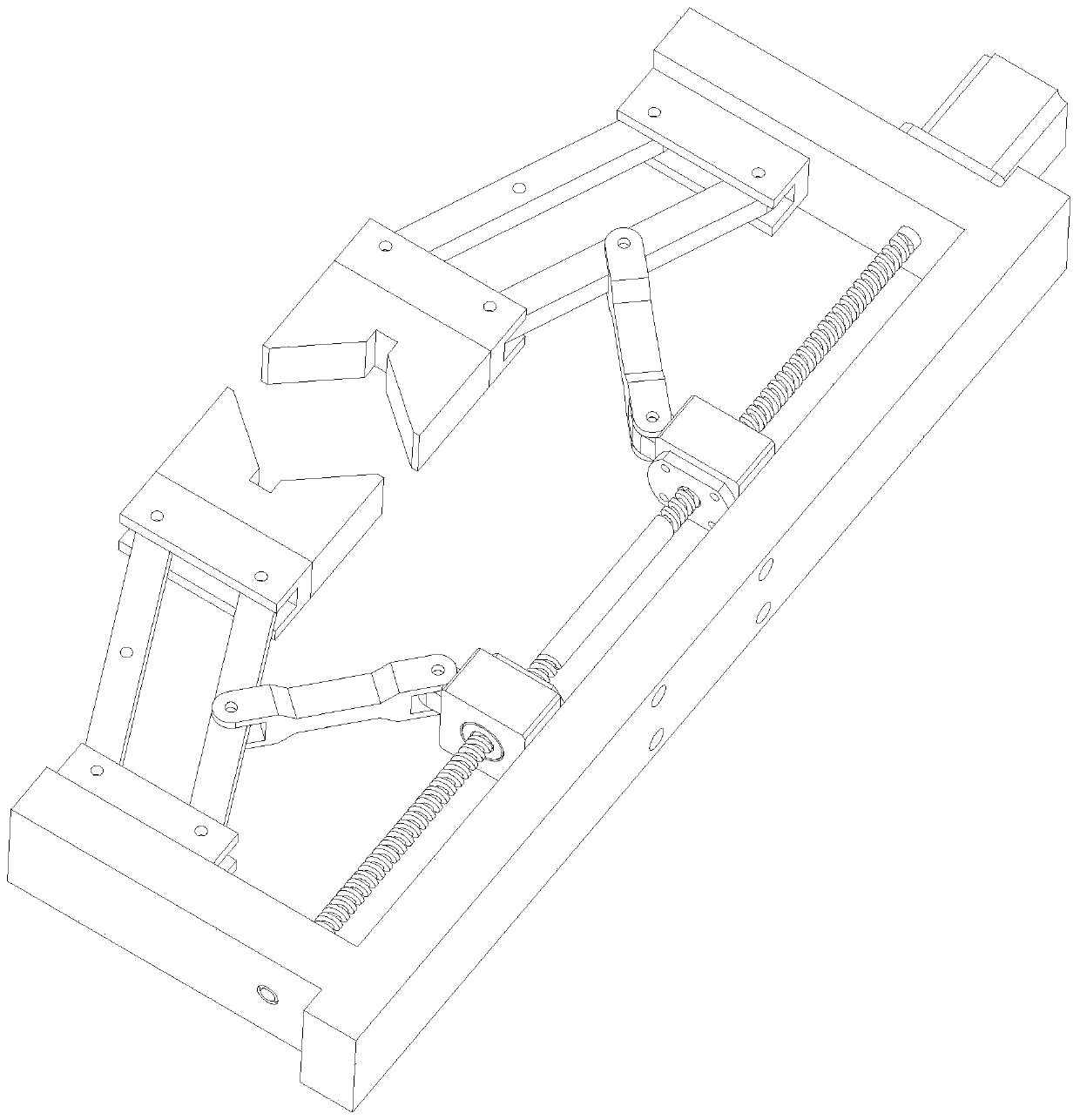

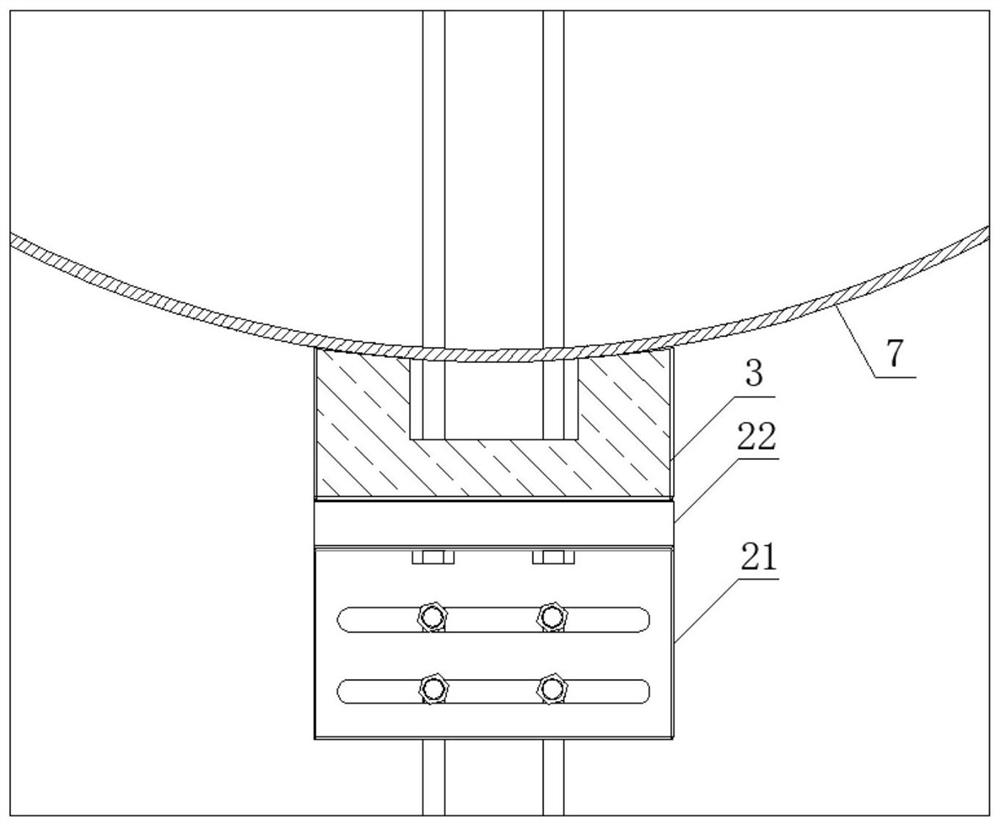

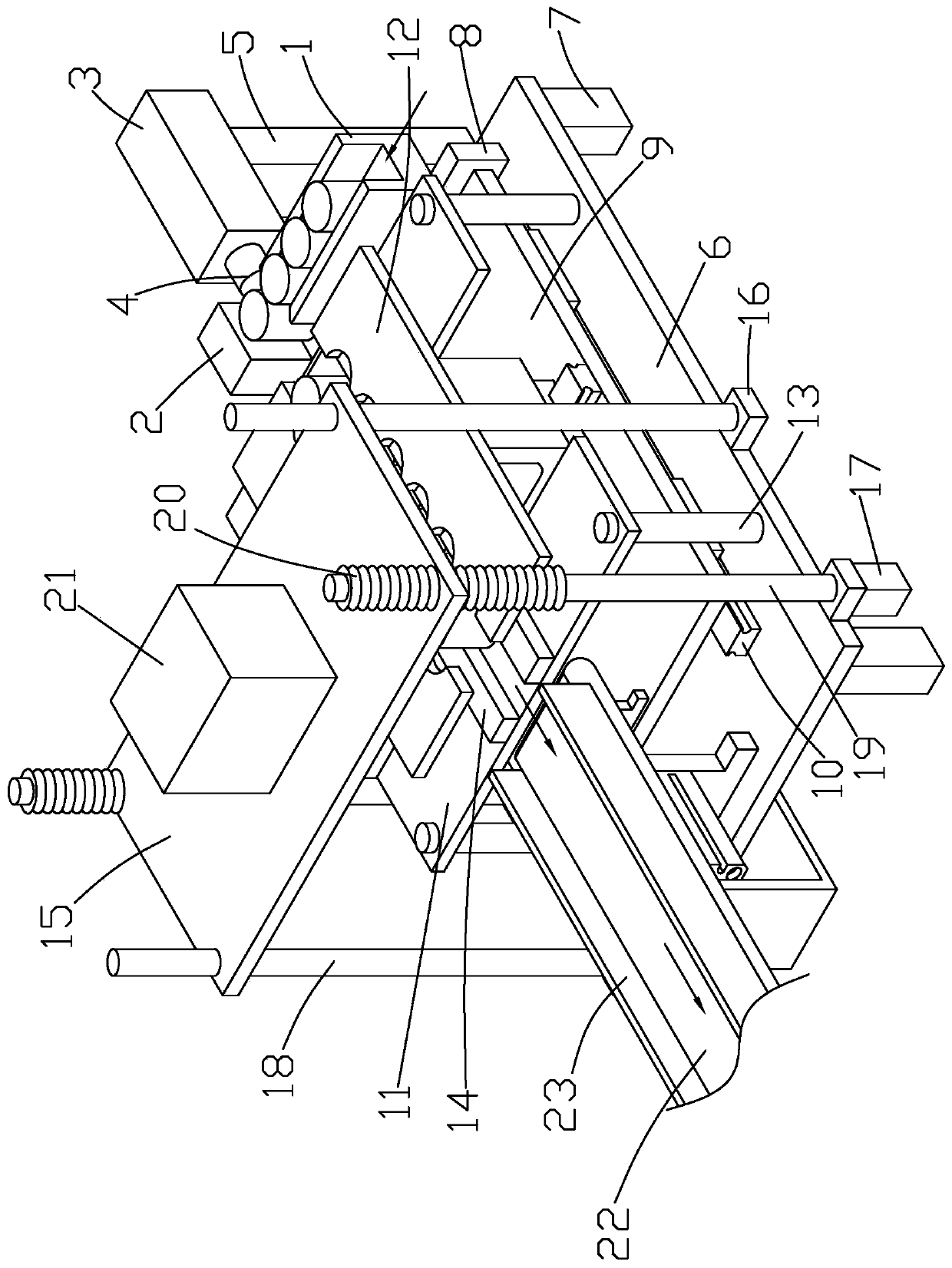

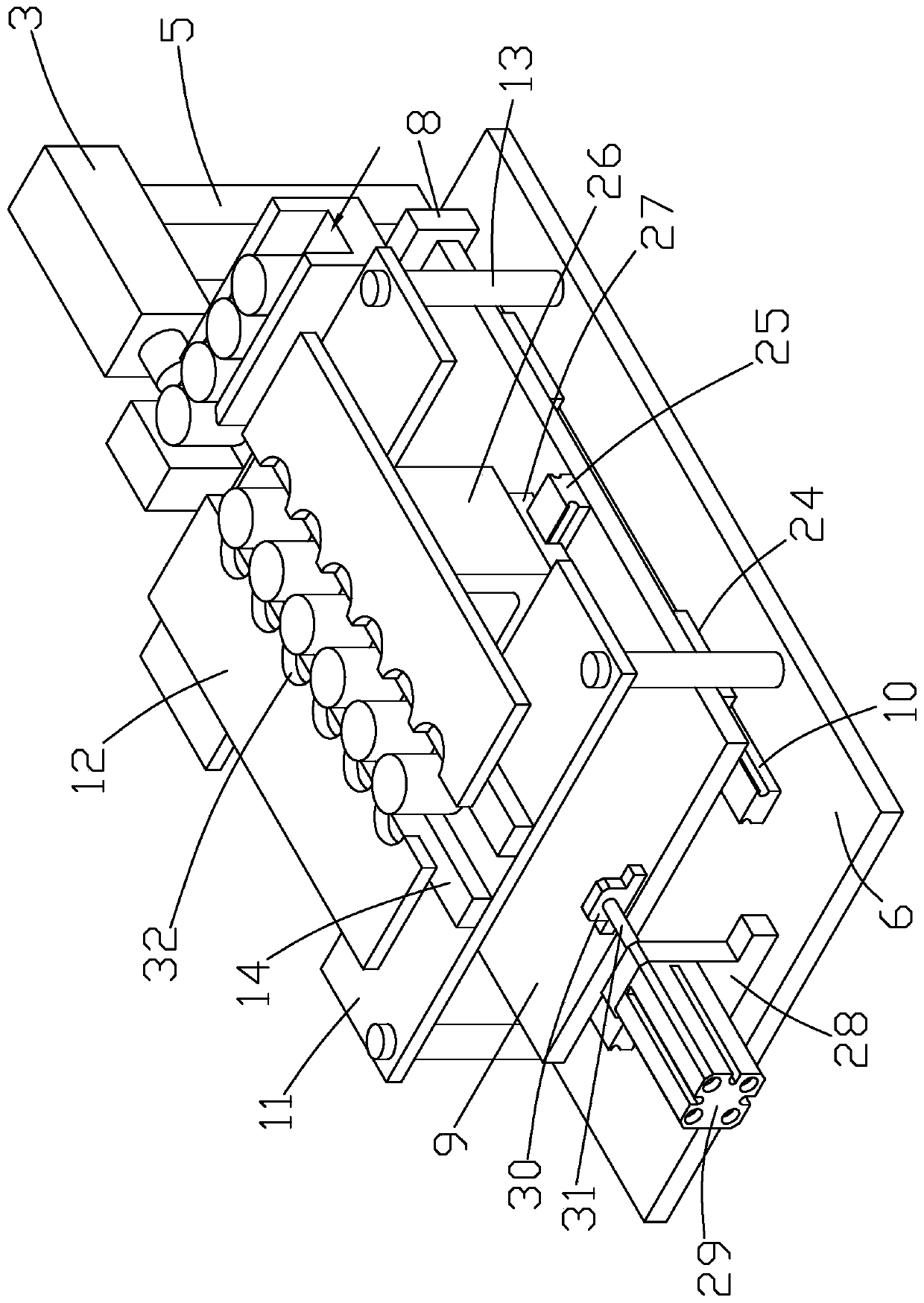

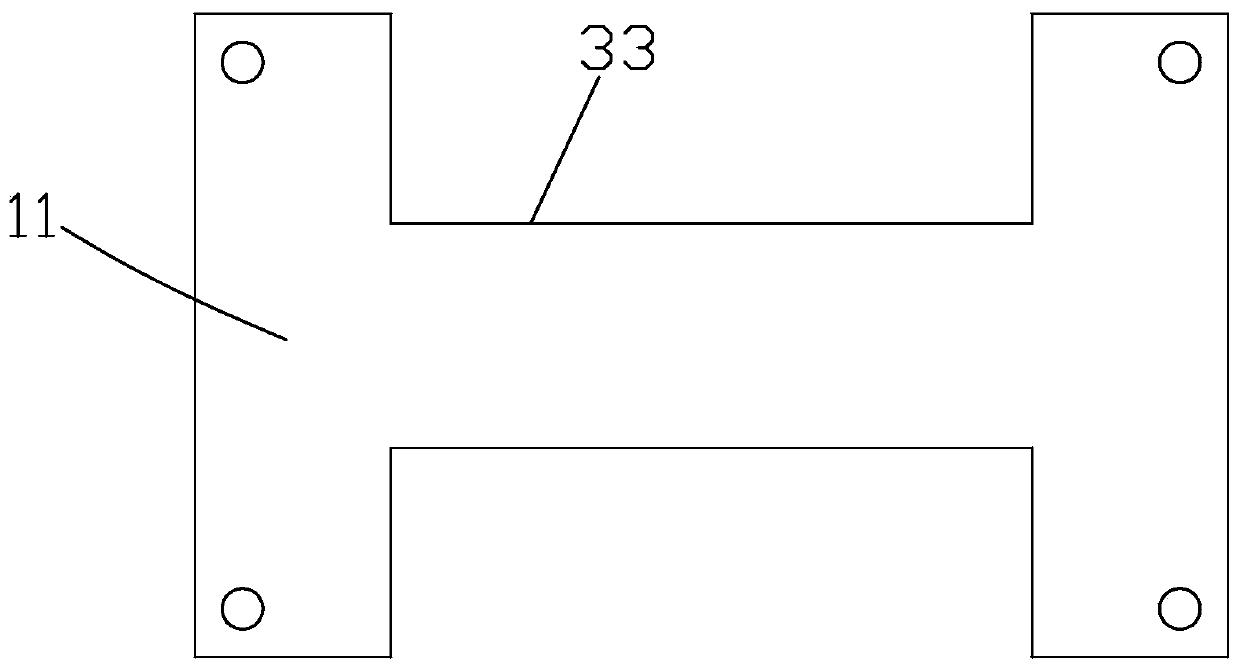

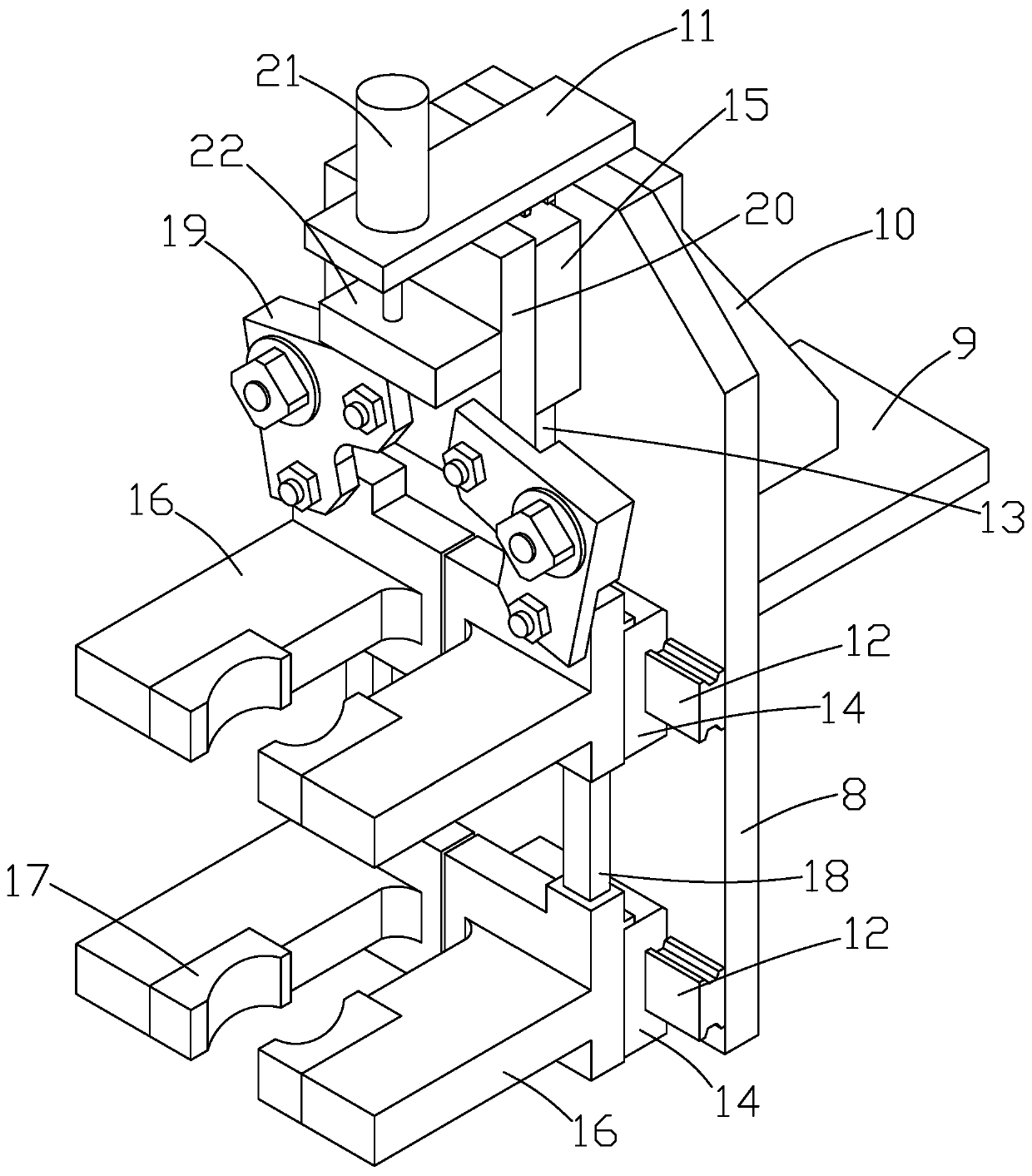

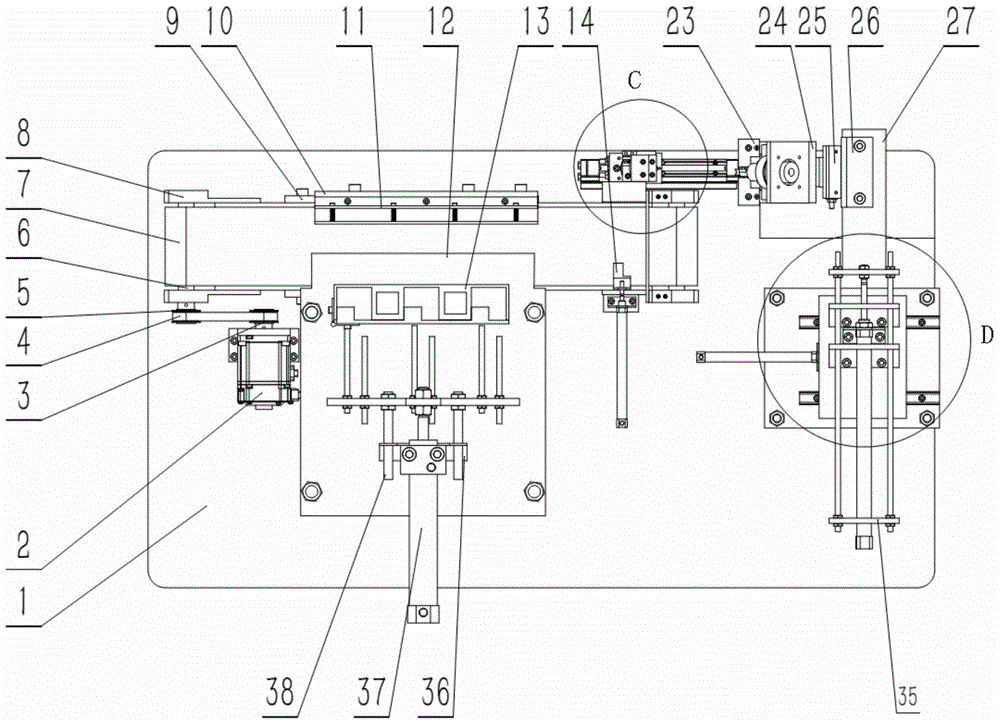

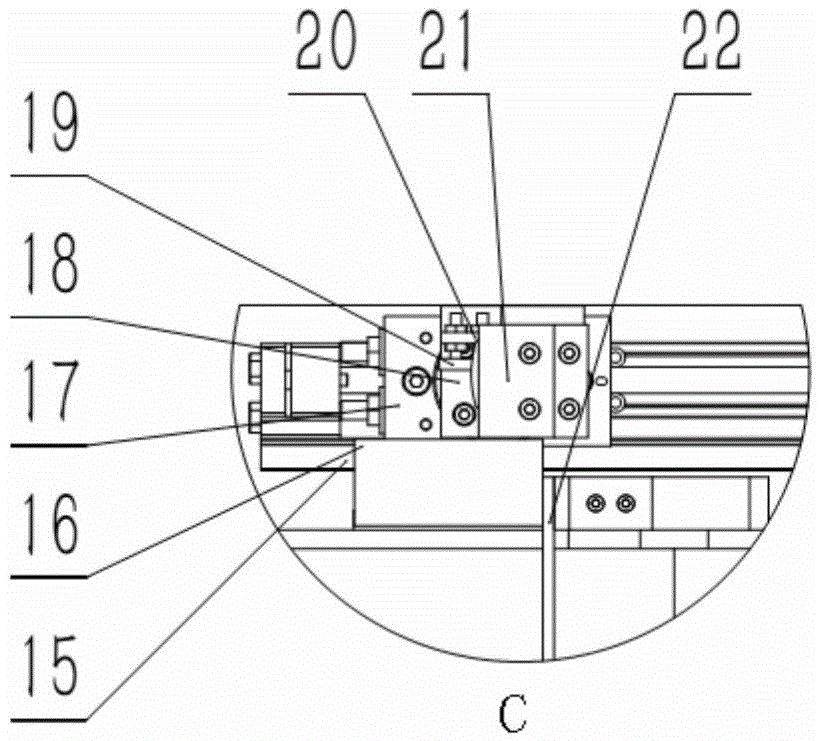

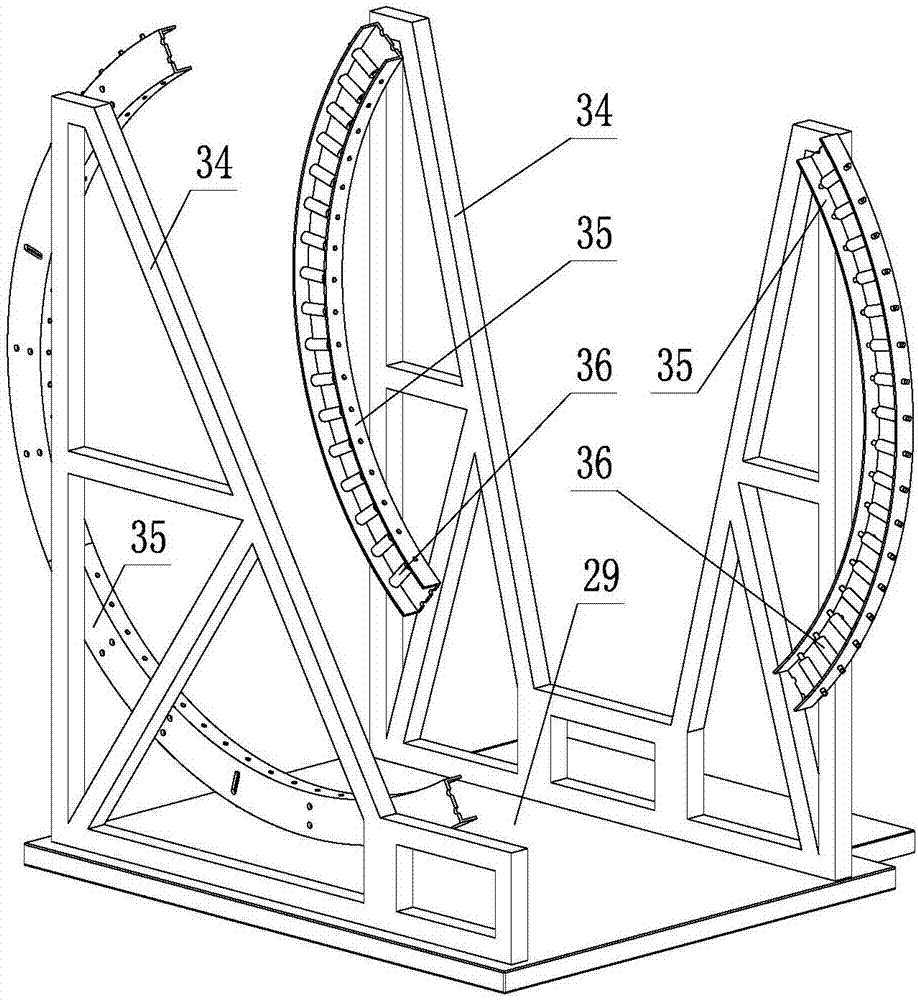

Drilling and tapping combined clamp for inner gantry steel channel and outer gantry steel channel of forklift and machining method thereof

ActiveCN103641041AHigh clamping precisionImprove production and processing efficiencyLifting devicesOther manufacturing equipments/toolsStructural engineeringMachining

The invention discloses a drilling and tapping combined clamp for an inner gantry steel channel and an outer gantry steel channel of a forklift and a machining method thereof. The drilling and tapping combined clamp comprises a T-shaped base and a conveying roller way, wherein the conveying roller way is used for conveying workpieces to be machined to a machining area automatically, an X-direction numerically controlled sliding table is mounted on the T-shaped base, and a pressing device used for positioning the workpieces is mounted on the X-direction numerically controlled sliding table. The drilling and tapping combined clamp further comprises a supported perpendicular to the T-shaped base, wherein a sliding rail is arranged on the support, a Y-direction numerically controlled sliding table is arranged on the sliding rail, a vertical drilling device and a vertical tapping device used for vertical tapping are arranged on the Y-direction numerically controlled sliding table, and the Y-direction numerically controlled sliding table moves on the sliding rail to achieve position adjustment. A pressing device comprises a lateral pressing oil cylinder used for pressing the workpieces horizontally and a vertical pressing oil cylinder used for pressing the workpieces vertically. According to the drilling and tapping combined clamp for the inner gantry steel channel and the outer gantry steel channel of the forklift and the machining method thereof, drilling and tapping of two workpieces to be machined can be achieved simultaneously, and then production efficiency is improved greatly.

Owner:芜湖金三氏数控科技有限公司

Auxiliary device for welding copper-aluminum pipe in refrigeration part and process of auxiliary device

ActiveCN110303260APlay a limiting roleAvoid shakingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCopper

The invention discloses an auxiliary device for welding a copper-aluminum pipe in a refrigeration part and a process of the auxiliary device. The auxiliary device comprises a welding table, a conveyorbelt, a first horizontal moving plate, a second horizontal moving plate, a welding mechanism and an auxiliary mechanism, wherein the welding mechanism is fixedly connected onto the top surface of thefirst horizontal moving plate; the first horizontal moving plate is connected onto the welding table through a first moving mechanism; the auxiliary mechanism is fixedly connected onto the second horizontal moving plate through a stand column; the second horizontal moving plate is welded on the welding table through a second moving mechanism; and the conveyor belt is rotationally connected onto the top surface of the welding table. The process comprises the following steps of processing the welding table, mounting the welding mechanism, mounting the first moving mechanism, mounting the auxiliary mechanism, mounting the second moving mechanism and welding the refrigeration part. Through the adoption of the auxiliary device and the process, the copper-aluminum pipe in the refrigeration pipecan be clamped and positioned, so that the condition that the refrigeration pipe shakes in the welding process to influence the welding quality and the welding precision of the copper-aluminum pipe in the refrigeration pipe is prevented.

Owner:新昌县三元机械有限公司

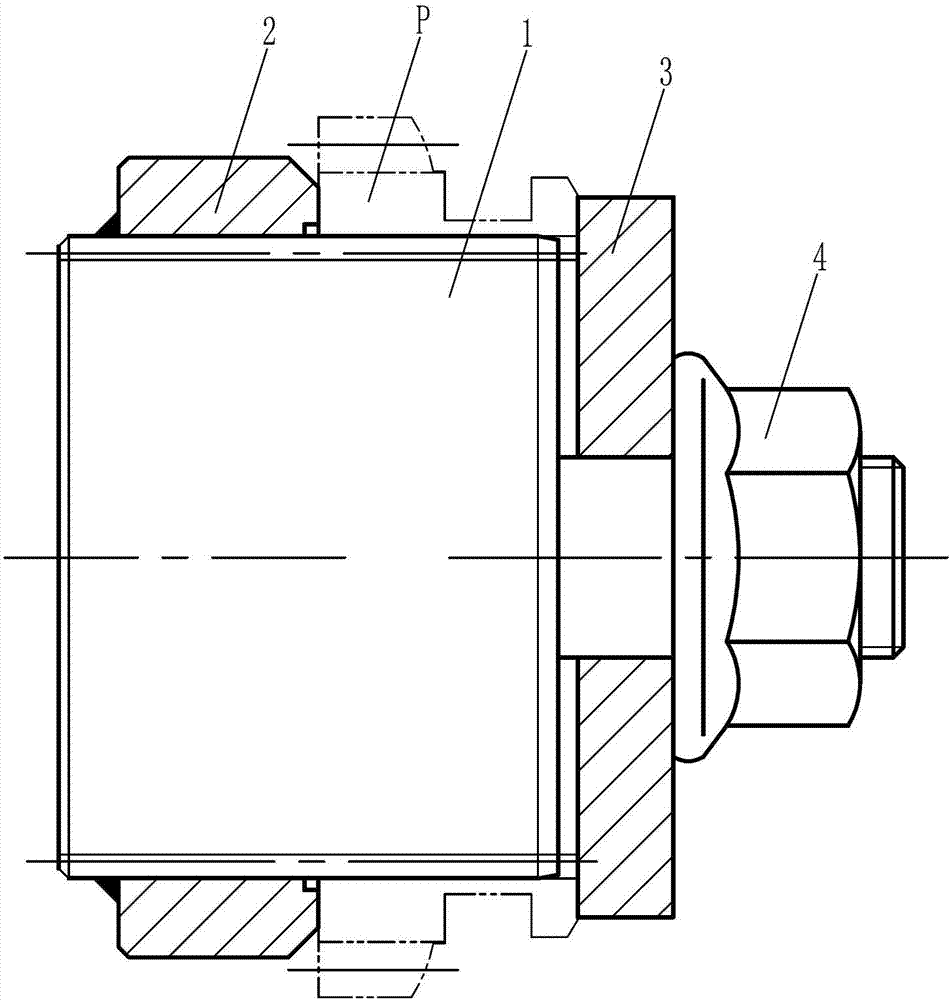

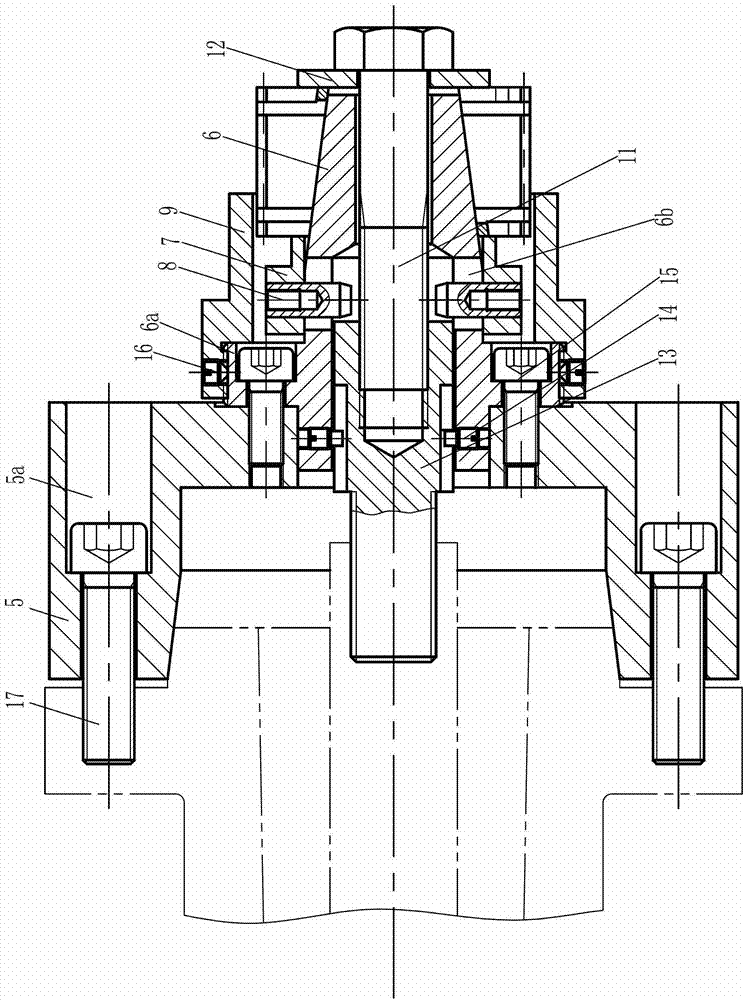

Grooving jig used for clamping synchronizer duplicate gear

The invention discloses a grooving jig used for clamping a synchronizer duplicate gear. The left end of a mandrel is inserted into a small diameter section of an inner hole of a connecting plate, and an annular installing boss on the left end portion of the mandrel is fixed with the connecting plate; a sliding sleeve is coaxially sleeved on the middle portion of the mandrel, a cylindrical pin is connected in a radial hole formed in the sliding sleeve, and the inner end of the cylindrical pin stretches into a center hole of the mandrel after penetrating through a strip-shaped sliding hole formed in the mandrel; a positioning sleeve is sleeved outside the sliding sleeve, and the left portion of the positioning sleeve is fixed with the annular installing boss; the right portion of the mandrel is a conical part with the left big and the right small, an expansion sleeve is sleeved on the right portion of the mandrel, a conical inner hole of the expansion sleeve is matched with the conical part of the mandrel, axial grooves are formed in the left portion of the expansion sleeve along the circumferential direction, and external splines are arranged on the positions, between every two adjacent axial grooves, of the expansion sleeve; after a washer is sleeved on the rod portion of a bolt, the rod portion of the bolt is inserted into the center hole of the mandrel and connected with an inner thread hole formed in the right end portion of a draw bar; and the draw bar is located on the left side of the cylindrical pin, and an outer thread section of the left portion of the draw bar stretches into a large hole diameter section of the inner hole of the connecting plate. Inner spline holes of gear blanks are positioned through the expansion sleeve, the expansion sleeve is even in deformation in the peripheral direction, the clamping precision can be thus improved, the jig can be used for installing and detaching gears very conveniently, and therefore shortcomings of a traditional grooving jig are effectively overcome.

Owner:CHONGQING WINSTAR PRECISE MACHINERY

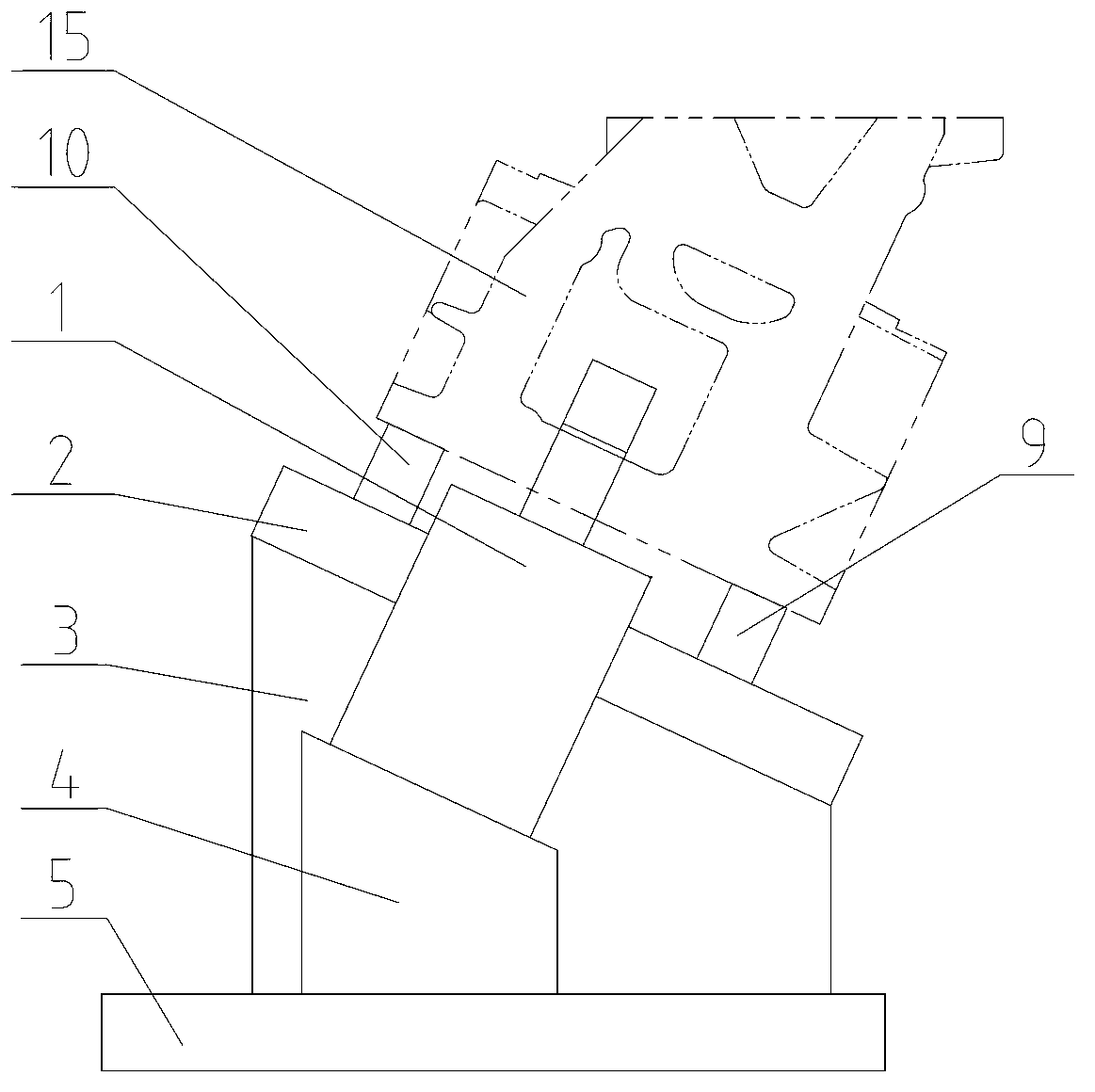

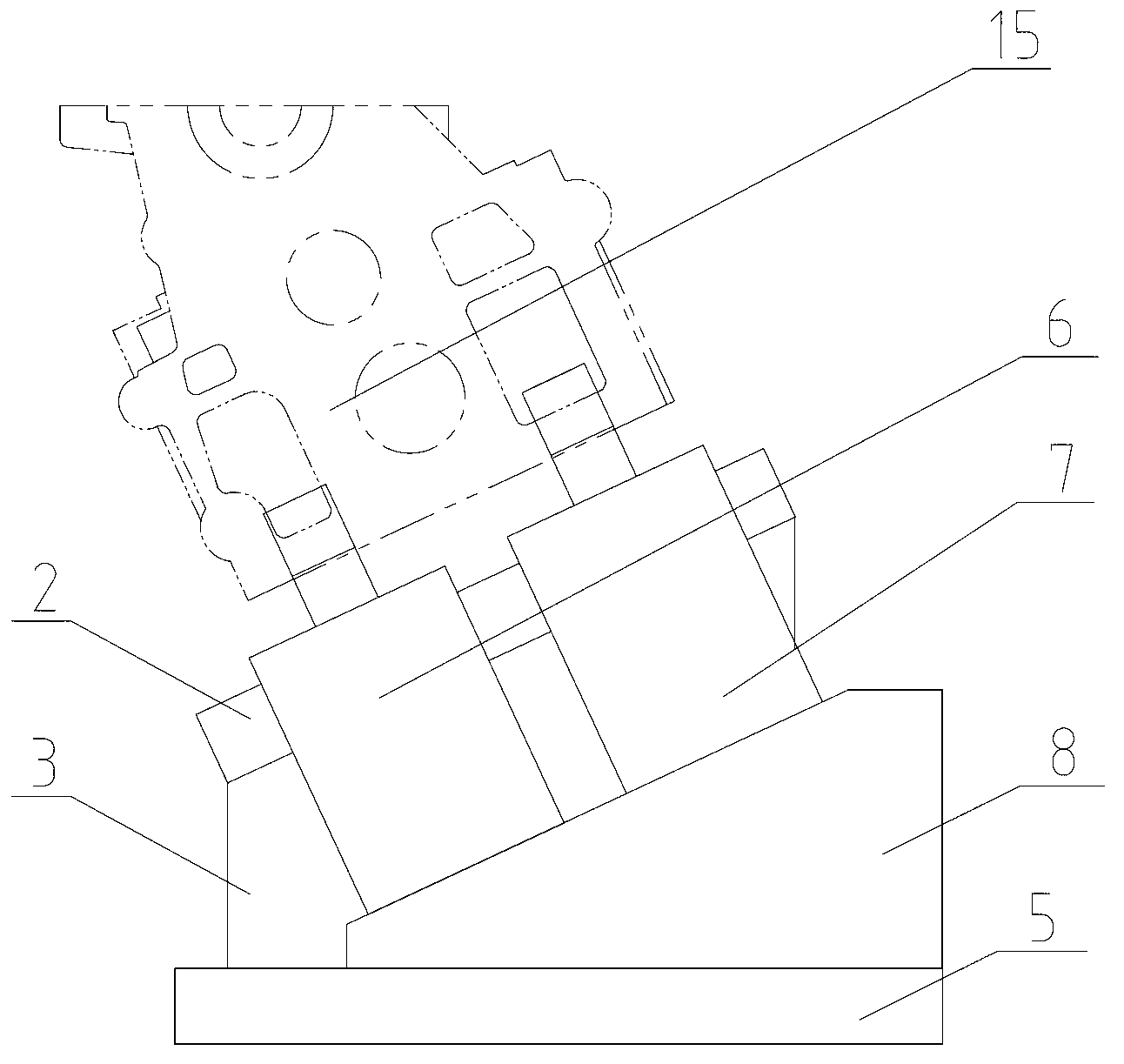

Finish-milling clamp suitable for top surface of inclined cylinder head

ActiveCN103223608AImprove clamping efficiencyHigh clamping precisionPositioning apparatusMetal-working holdersCylinder headEngineering

The invention discloses a finish-milling clamp suitable for the top surface of an inclined cylinder head. The finish-milling clamp comprises a base arranged on a cylinder head and a hold-down mechanism arranged on the base and used for fixing the cylinder head, wherein the base comprises an obliquely arranged positioning plate; the cylinder head is positioned by a positioning mechanism of which the bottom surface is placed on the positioning plate; and an inclined plane with the same inclined angle as the top surface of the cylinder head is formed on the positioning mechanism. Compared with the prior art, as the mounting and placing position of the cylinder head are consistent with the angle of the top surface of the cylinder head, after the cylinder head is clamped, processing of a machine tool cutter in the horizontal direction can be kept, accordingly, the problem of complicated angular adjustment in a traditional tool is greatly solved, conveniences are brought to a worker to operate and clamp, and the clamping efficiency of the cylinder head is remarkably improved; and the finish-milling clamp has the advantages of high clamping precision, simple structure and convenience in operation, and staff for processing the product can start to work without training.

Owner:WUHU YONGYU AUTOCAR INDAL

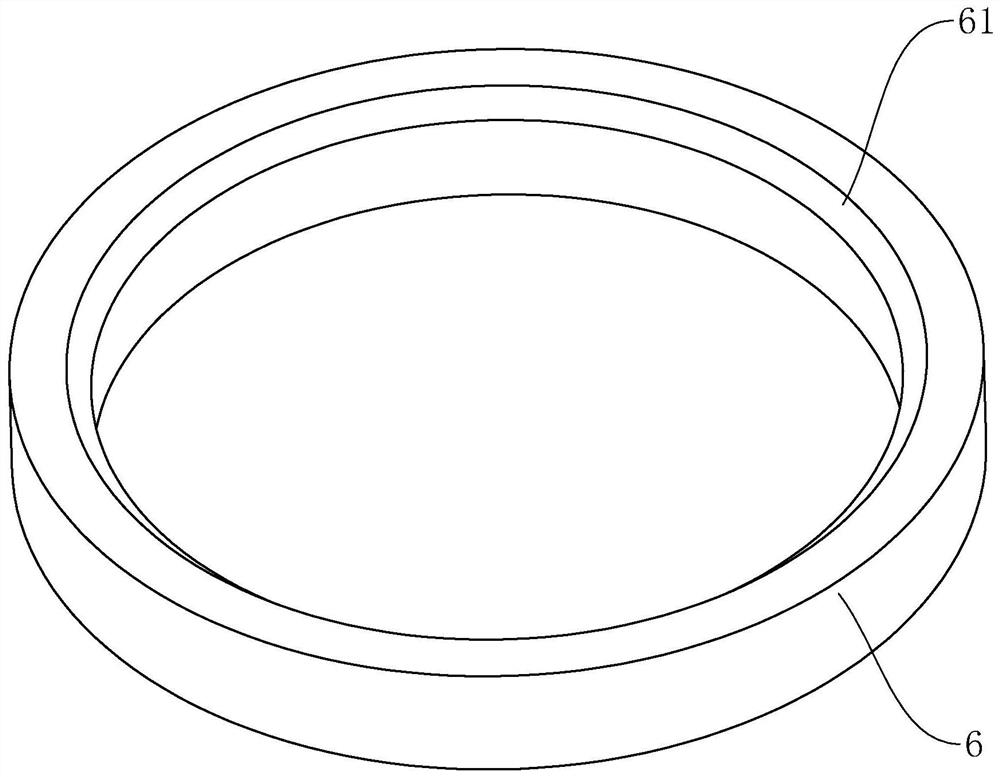

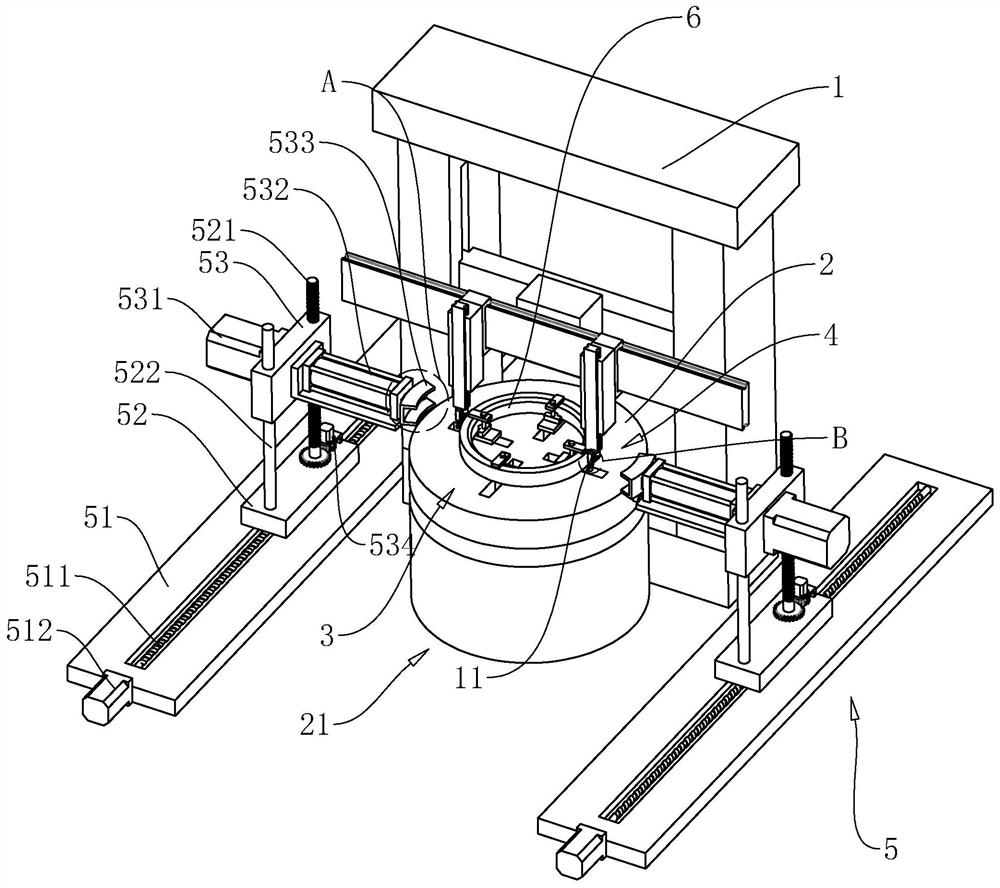

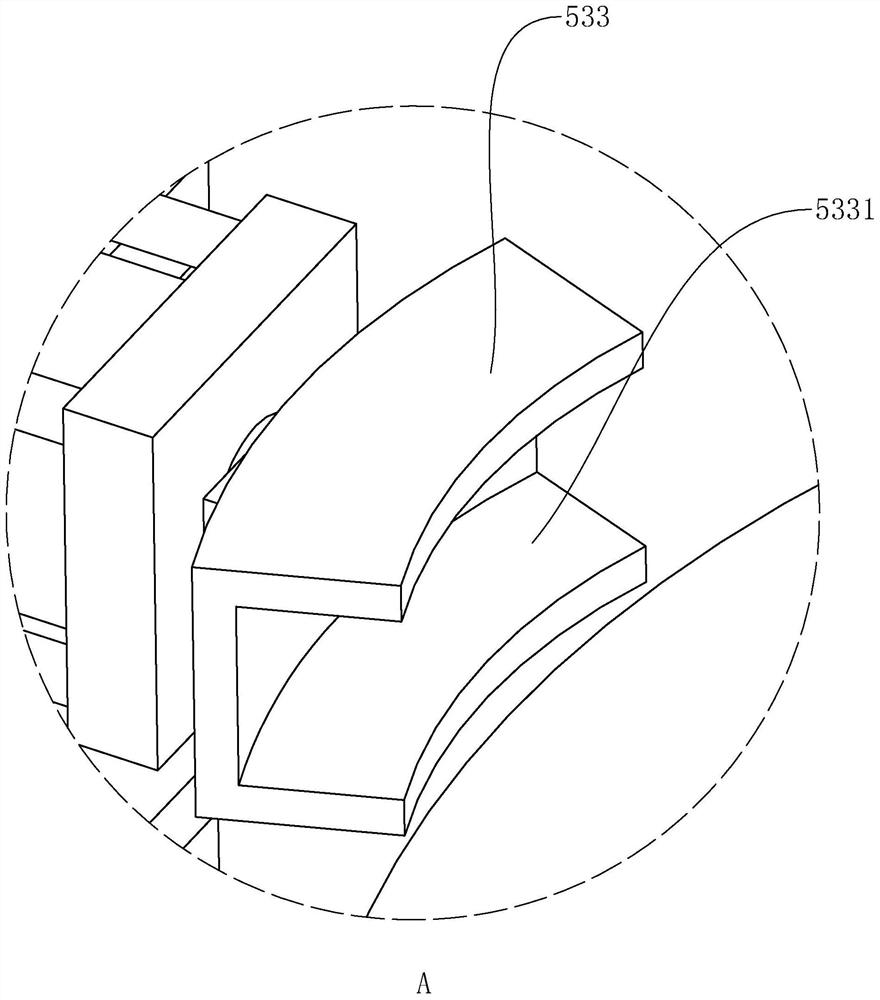

Vertical lathe for distance ring machining and machining process of distance ring

ActiveCN112139515AImprove processing qualityHigh clamping precisionAuxillary equipmentPositioning apparatusClassical mechanicsMachining process

The invention relates to the field of distance ring machining, in particular to a vertical lathe for distance ring machining and a machining process of a distance ring. The vertical lathe comprises alathe body and a vertical chuck, and an automatic clamping device is further arranged in the vertical chuck. The automatic clamping device comprises first screw rods and a second screw rod which are perpendicular to each other, the first screw rods are oppositely arranged on the two sides of the second screw rod in the axial direction of the first screw rods, a first bevel gear is arranged at theend, facing the axis of the vertical chuck, of one first screw rod, a second bevel gear engaged with the first bevel gear is arranged on the second screw rod, a third bevel gear is arranged at the end, facing the axis of the vertical chuck, of the other first screw rod, and a fourth bevel gear engaged with the third bevel gear is further arranged on the second screw rod. Threaded sections are oppositely arranged on the second screw rod in the axial direction of the second screw rod, the two threaded sections are located on the two sides of the first screw rods, clamping blocks are in threadedconnection to the first screw rods and the threaded sections, and sliding grooves allowing the clamping blocks to slide are formed in the vertical chuck. The vertical lathe has the effects that the clamping precision is improved, and then the machining quality of the distance ring is improved.

Owner:南京永庆机械制造有限公司

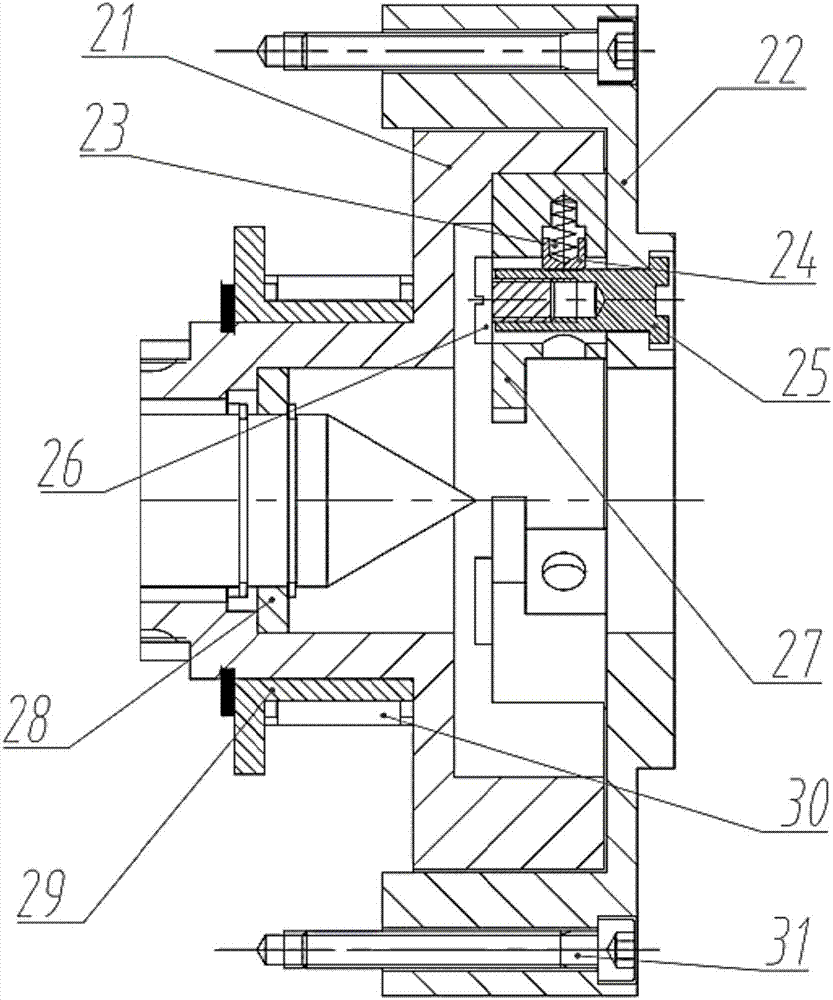

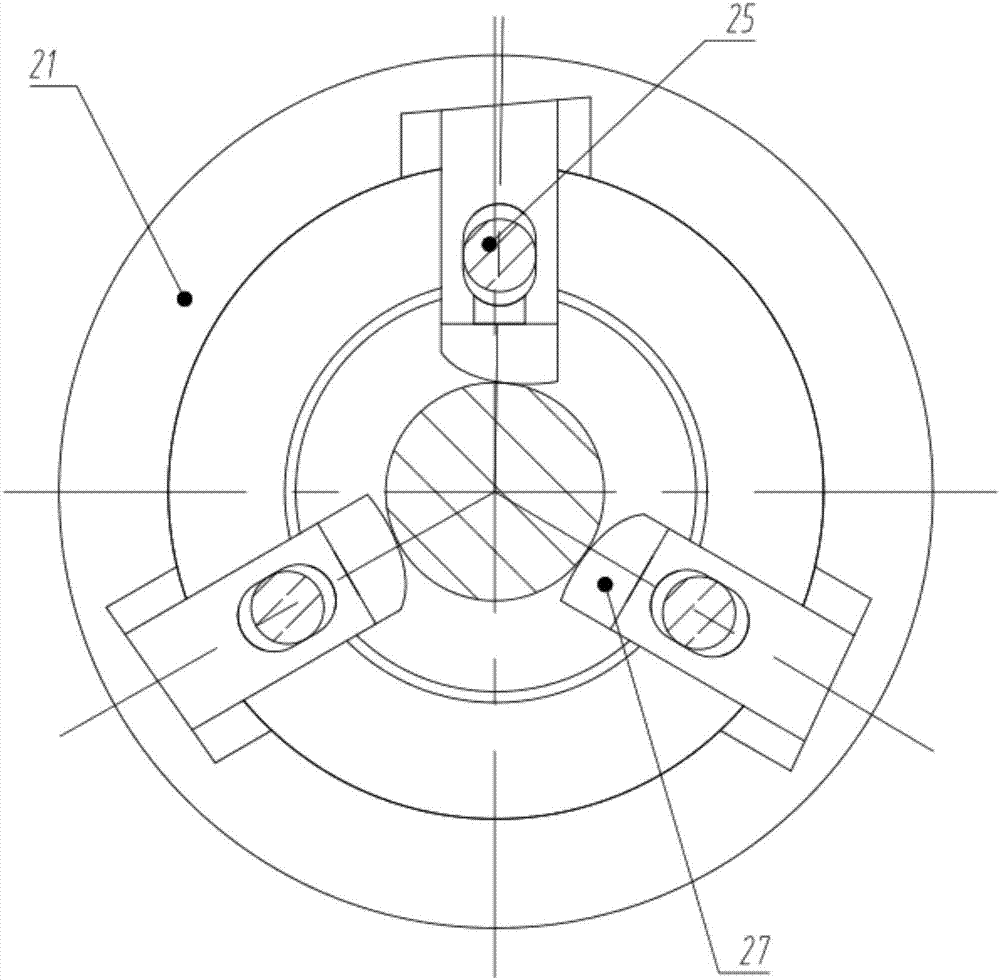

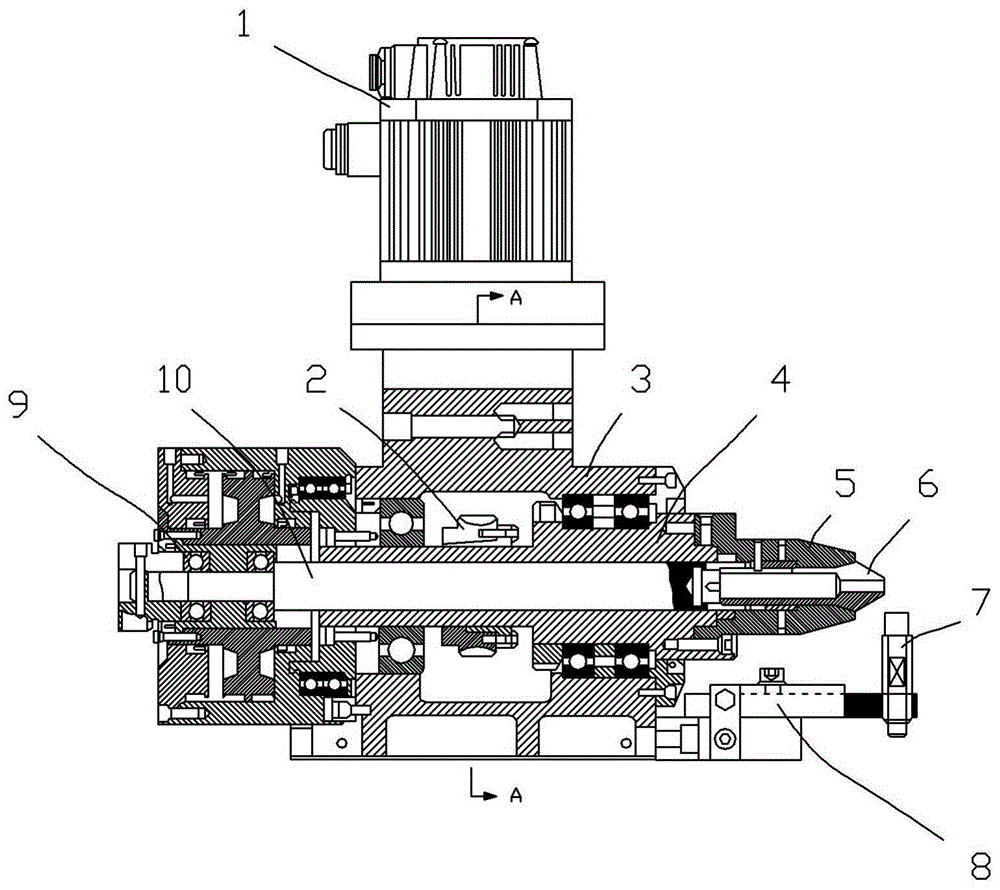

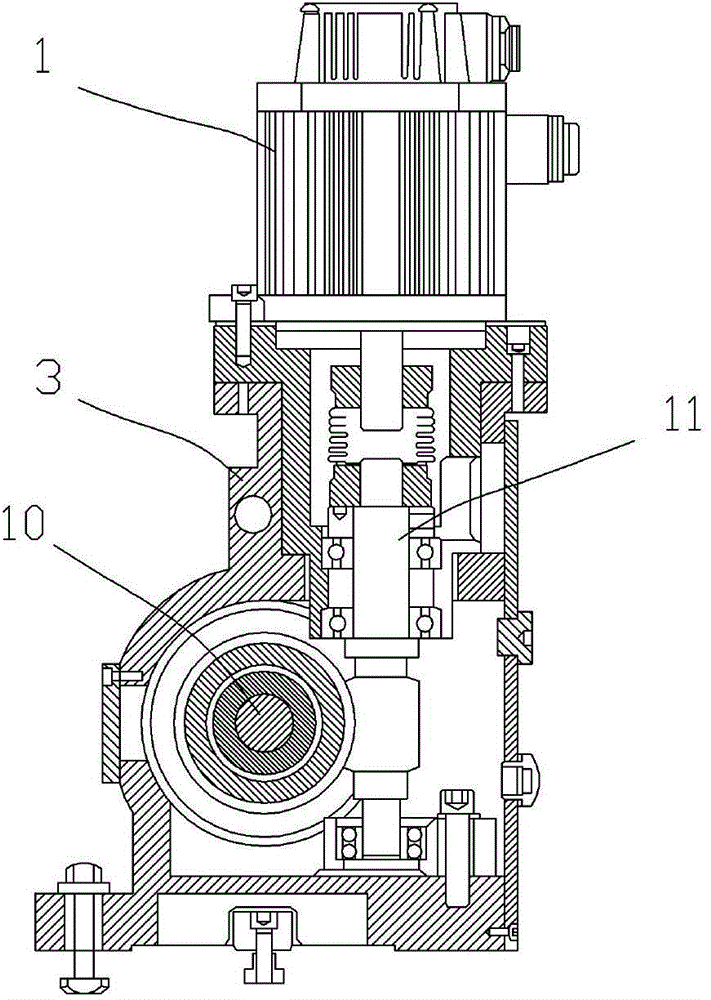

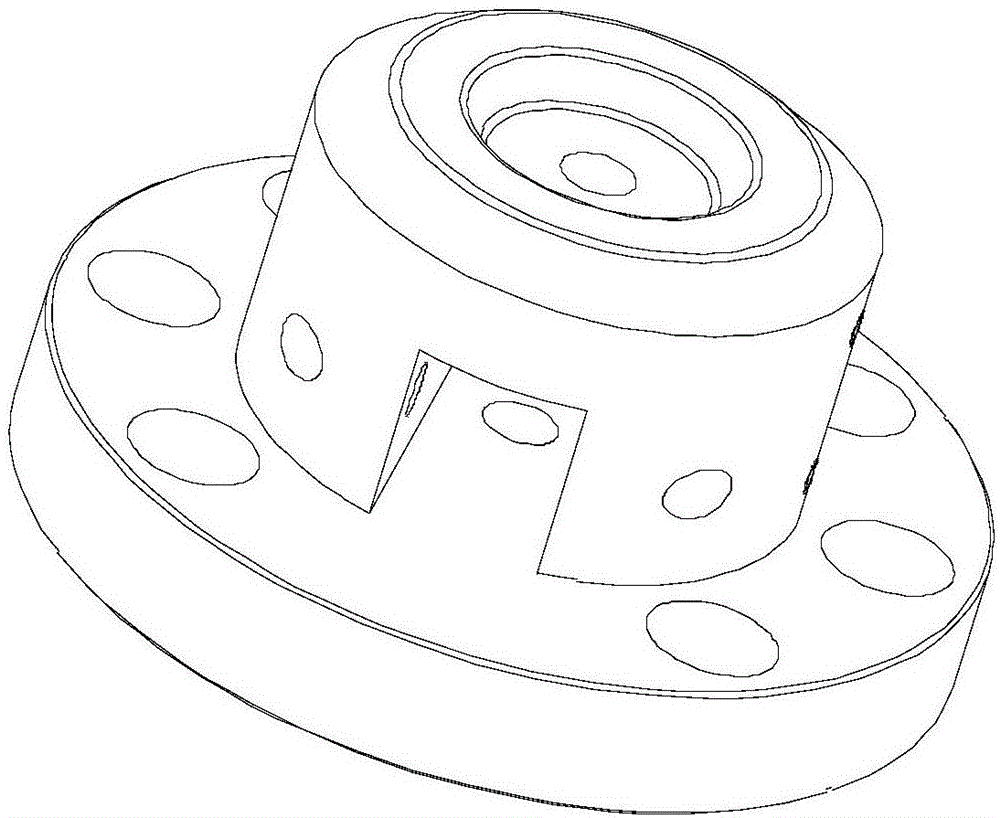

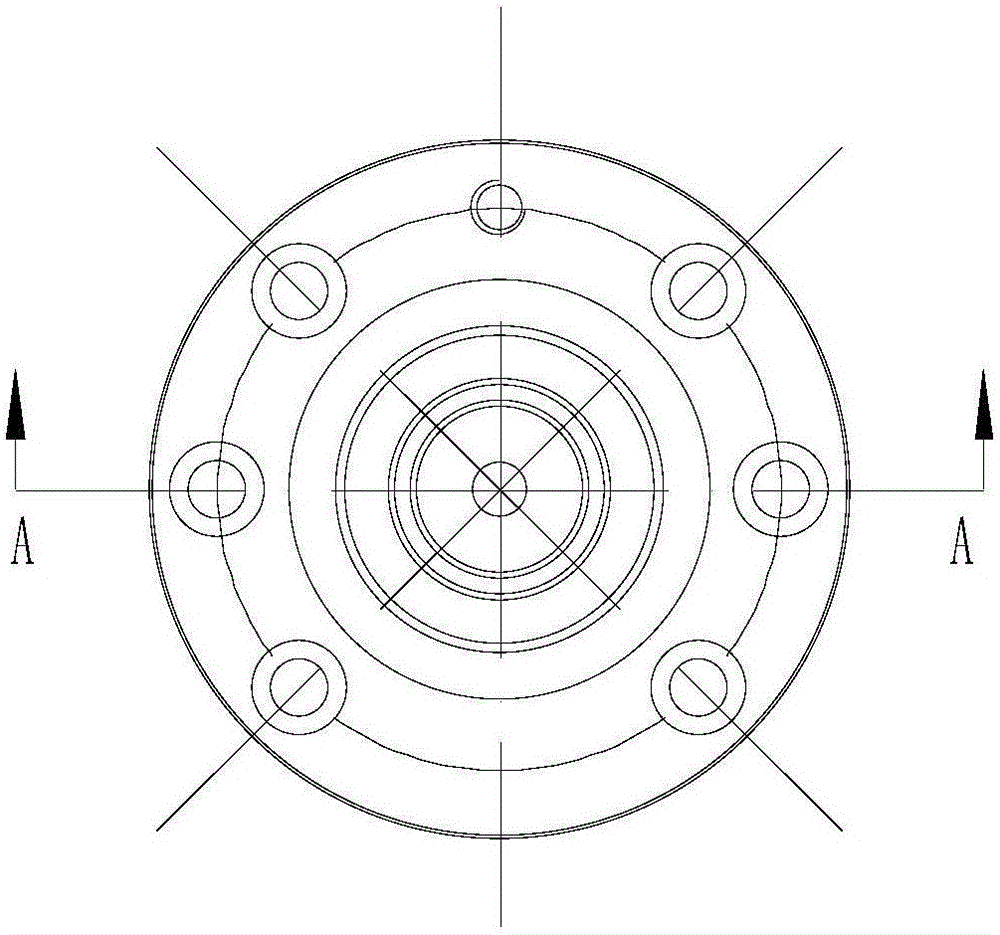

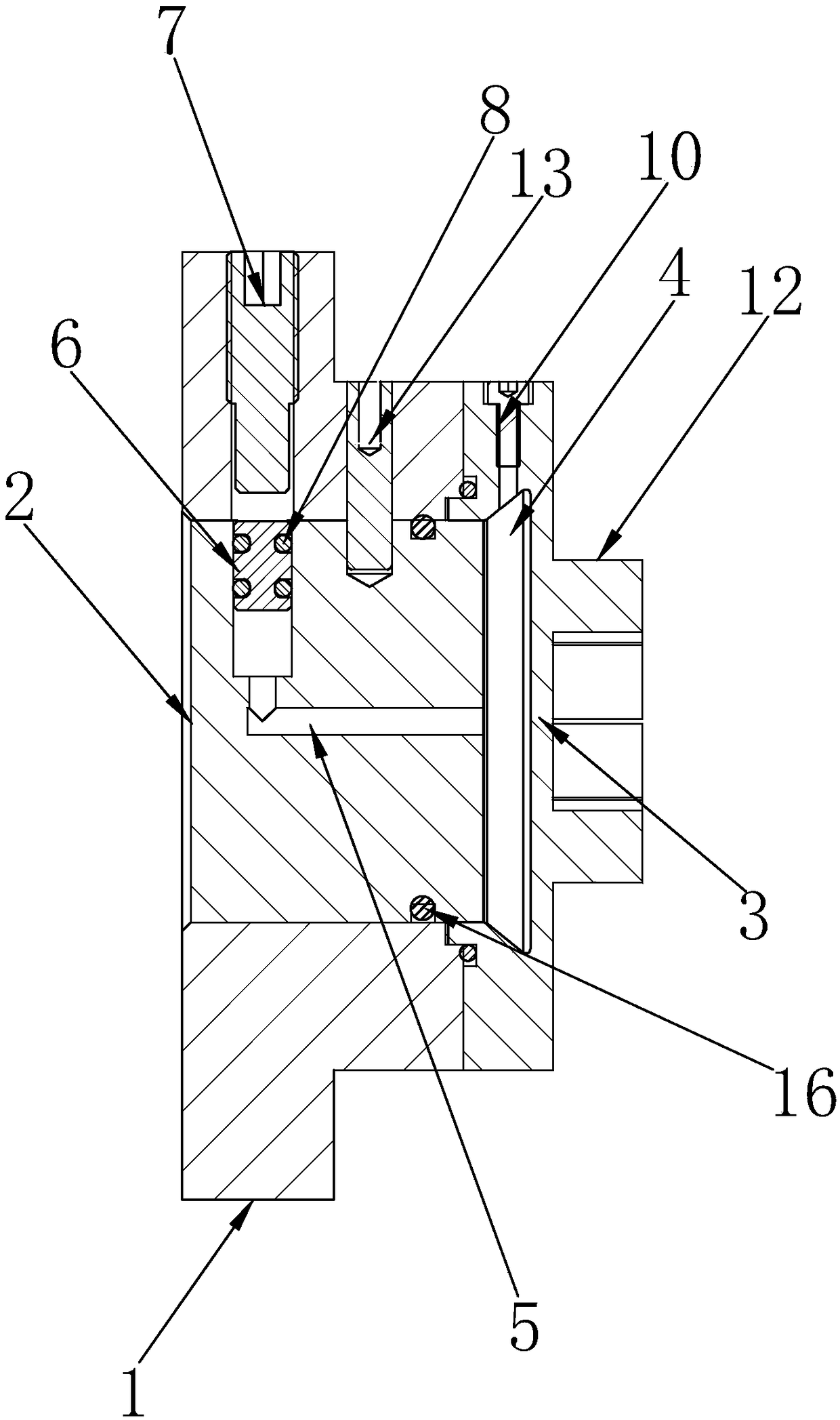

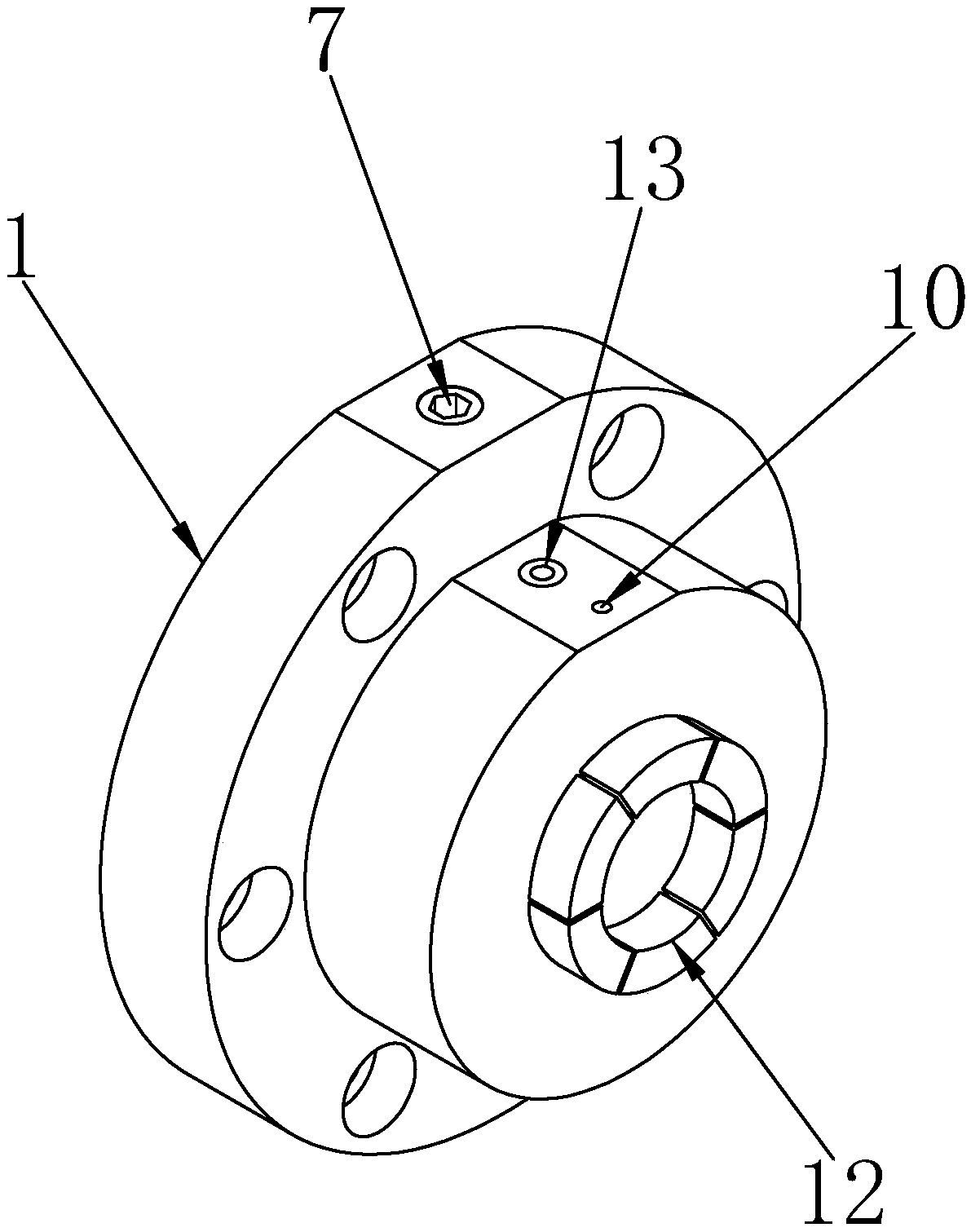

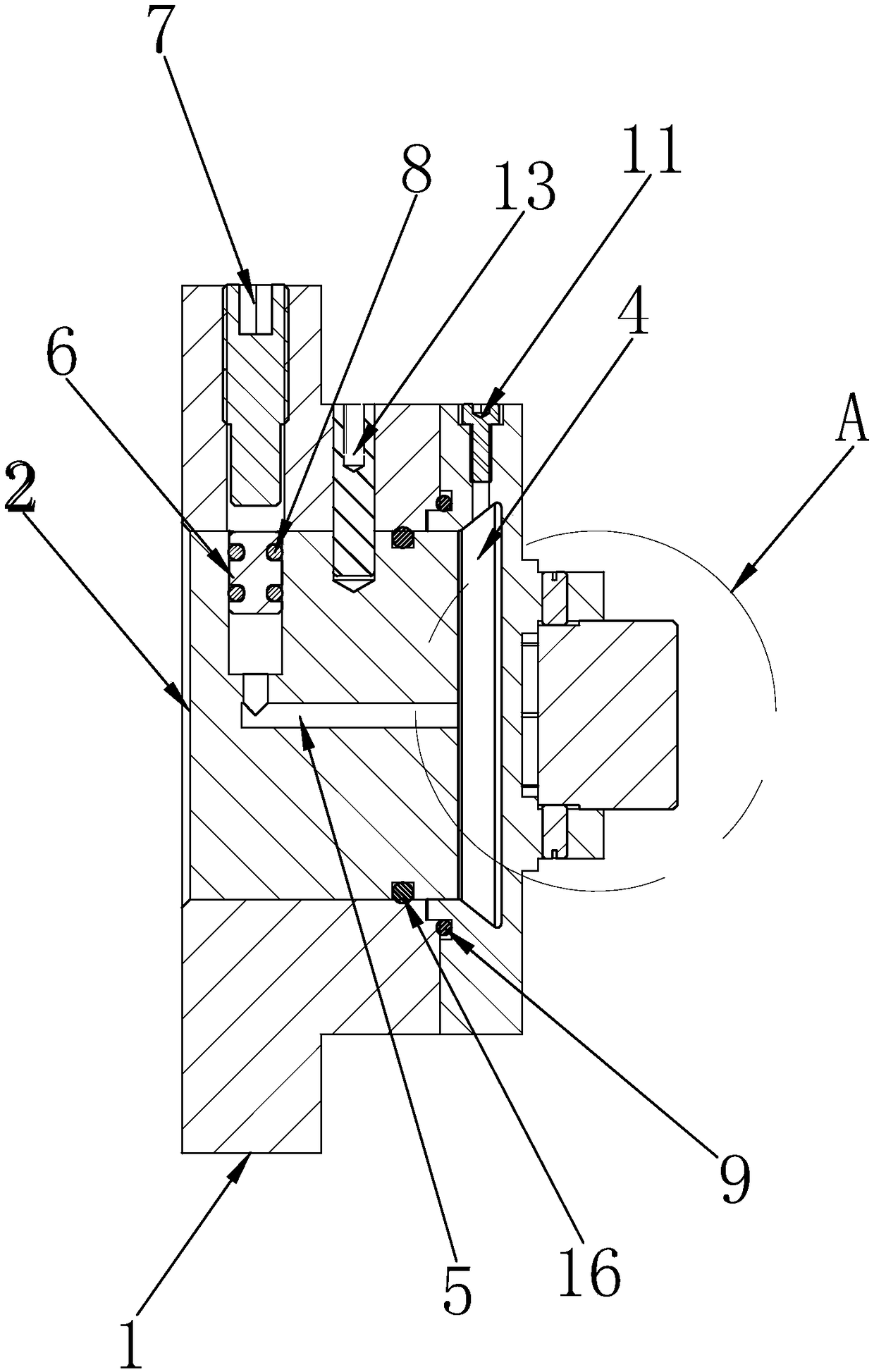

Rotatable workpiece clamping mechanism for automatic cutter grinding machine

InactiveCN104786113AHigh precisionHigh clamping precisionOther manufacturing equipments/toolsGrinding work supportsEngineeringMechanical engineering

The invention discloses a rotatable workpiece clamping mechanism for an automatic cutter grinding machine. The mechanism comprises a base body and a motor, wherein the motor is mounted on the base body; the base body has a mounting through hole; a rotating shaft is pivoted and mounted in a mounting through hole; a mounting disc is fixed at the front end of the rotating shaft; the rotating shaft and the mounting disc have communicated inner holes; a center pull rod is movably mounted in the inner hole of the rotating shaft; the front end of the center pull rod is connected with a clamping head part; the back end of the center pull rod is connected with a piston of the cylinder; the clamping head part is movably mounted in the inner hole of the mounting disc; the inner wall of the rotating shaft has an inclined surface; the outer wall of the clamping head part has an inclined taper surface fitting an inclined surface; a center hole for placing a workpiece is formed in the clamping head part; and the rotating shaft is driven by the motor. The mechanism can improve the claming precision of a cutter required to be sharpened, and further can the cutter sharpening precision.

Owner:DJTOL GRINDING MACHINE GRP

Pneumatic and electric matched automatic loading and unloading device

ActiveCN105619155AAchieve teleportationRealize commutationMetal working apparatusTransmitted powerControl system

The invention discloses a pneumatic and electric matched automatic loading and unloading device. The device consists of a control system, a worktable, a feeding mechanism and a loading and unloading mechanism; a motor transmits power to a conveying belt; and the taking of workpieces to be machined is realized through combined action of the motor and a feeding cylinder. The workpieces are pushed to a pneumatic slide table through a workpiece pushing cylinder; and the pneumatic slide table and a swing cylinder are matched to realize conveying and reversing of the workpieces. A finger-shaped air jaw realizes loading and unloading movement under effects of a transverse moving cylinder and a longitudinal telescopic cylinder. The finger-shaped air jaw and a needle-shaped cylinder are matched to realize clamping, placement and positioning of the workpieces; and the longitudinal telescopic cylinder and the transverse moving cylinder are matched to realize transverse and longitudinal movement of the loading and unloading mechanism. The control system adopts a PLC and an industrial controller to control the feeding mechanism and the loading and unloading mechanism, and realizes independent work of different mechanisms according to demands; and the pneumatic and electric matched automatic loading and unloading device realizes quick loading and unloading of a machine tool, and improves the production efficiency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Coating film jig and bearing tool

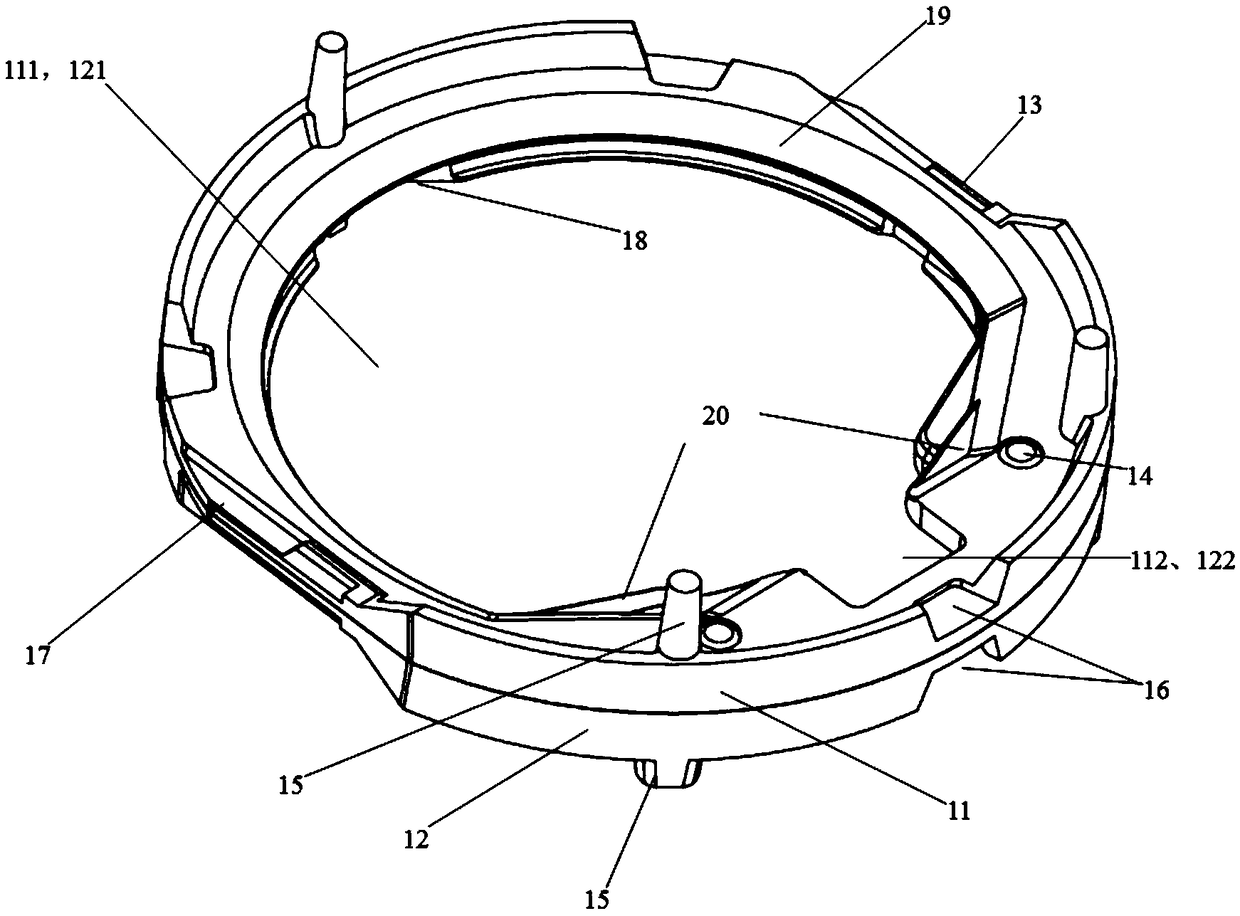

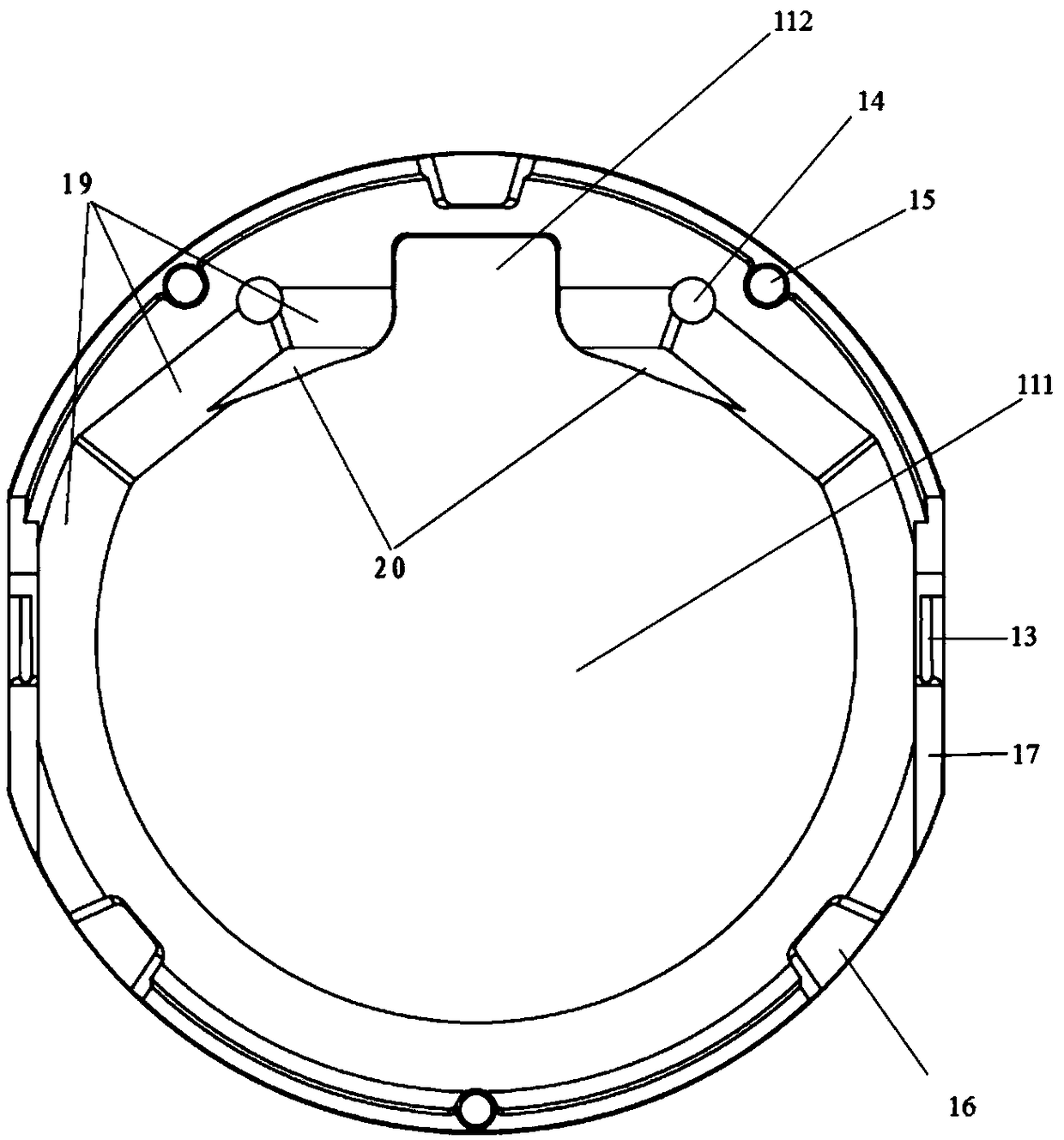

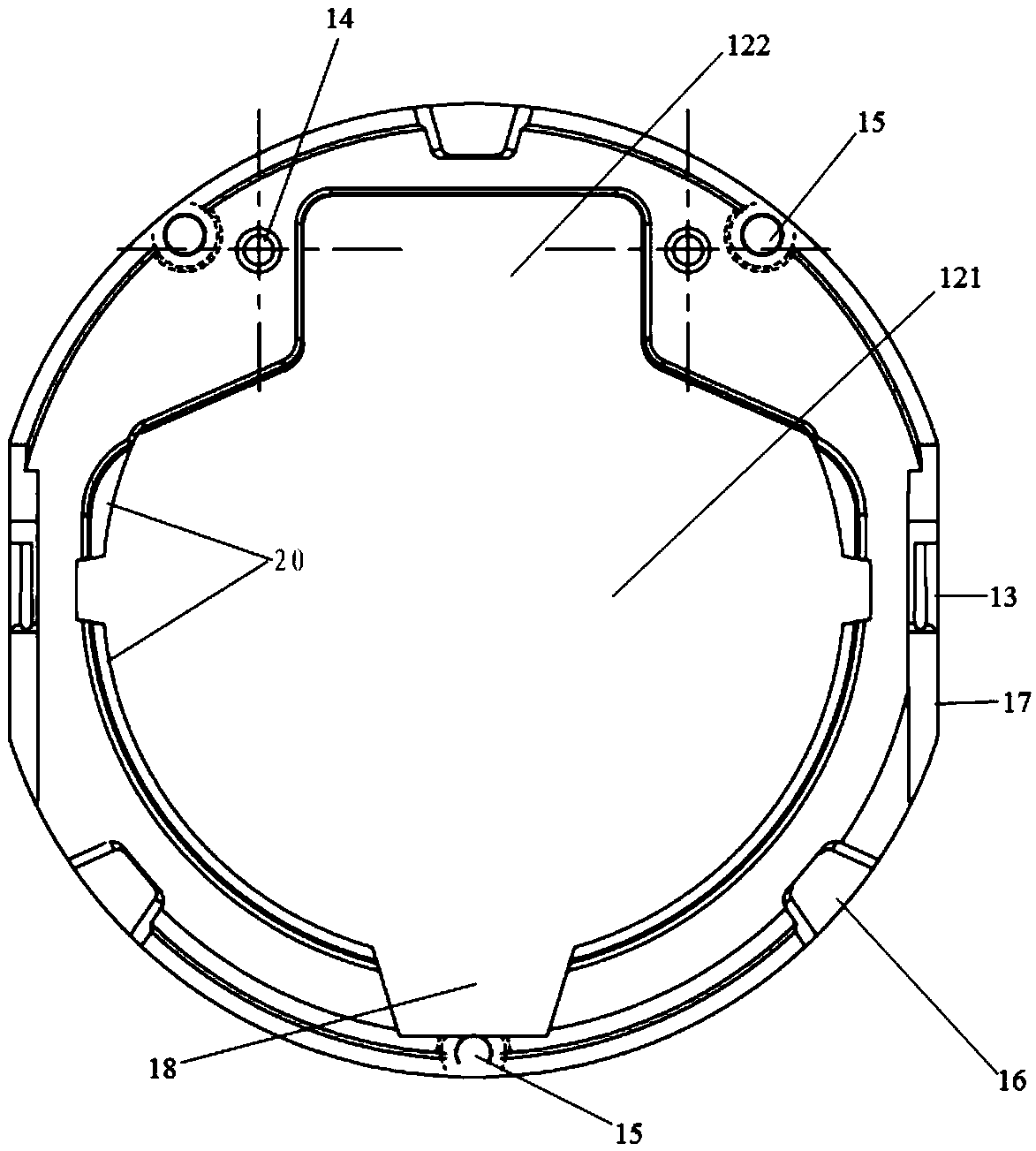

PendingCN109402594AQuick clampingGuaranteed clamping stabilityVacuum evaporation coatingSputtering coatingBiochemical engineeringCoating

The invention relates to a coating film jig. The jig comprises a first clamping piece (11) and a second clamping piece (12) for clamping materials, and a connecting piece (13) for connecting the firstclamping piece (11) with the second clamping piece (12); the first clamping piece (11) is provided with a first through hole (111) and a first gap (112) communicated with the first through hole (111), and the second clamping piece (12) is provided with a second through hole (112) and a second gap (122) communicated with the second through hole (121); the first through hole (111) is communicated with the second through hole (112), and the first gap (112) is communicated with the second gap (122). According to the scheme, by adopting the combination mode of the first clamping piece and the second clamping piece, due to the clamping effect of the connecting piece, the materials can be rapidly clamped, production efficiency is improved, and the clamping precision is high.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Clamp structure used for center hole positioning and clamping

The invention discloses a clamp structure used for center hole positioning and clamping. A base is in a form of a flange plate structure, the bottom of a positioning pin is installed in a center hole in the base, a spring is installed in the center hole in the base, and the top face of the spring is pressed against the bottom face of the positioning pin. A press rod is installed in a square groove in the base through a rotary shaft, a screw is sleeved with a lower circular gasket, and the bottom face of the lower circular gasket is pressed against the top face of the press rod. An upper circular gasket is installed in an arc-shaped groove in the lower circular gasket, the screw is sleeved with the upper circular gasket, the tail portion of the screw is installed in a threaded hole in the base, and the screw passes through a through hole in the press rod. A part is installed on the top face of the base, the positioning pin is sleeved with the part and a pressure head, the bottom face of the pressure head is pressed against the top face of the part, and a galvanized iron sheet is fixedly installed on the outer cylindrical surface of the base through a bolt. The clamp structure can be suitable for any machining devices, and no machining region space can be occupied; the clamp structure has the advantages of being low in manufacturing cost, convenient in clamping, high in positioning and clamping precision, long in service life and the like.

Owner:江苏瑞尔隆盛叶轮科技有限公司

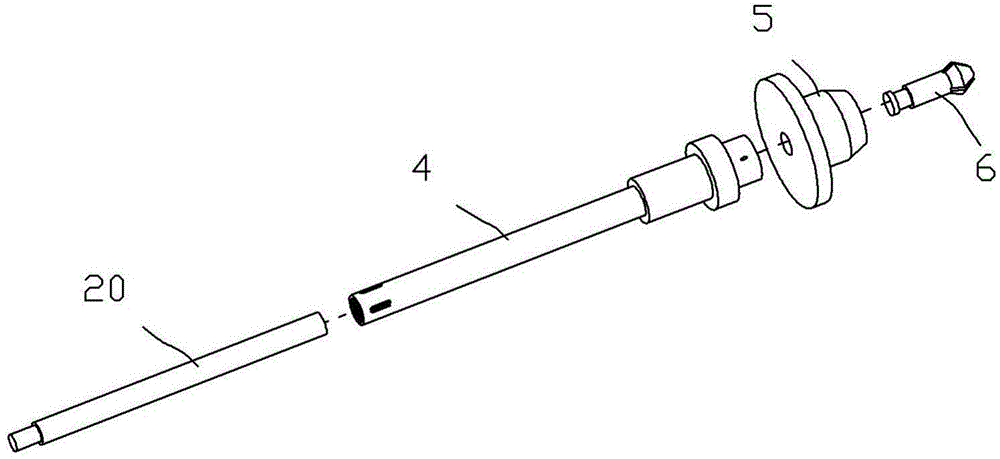

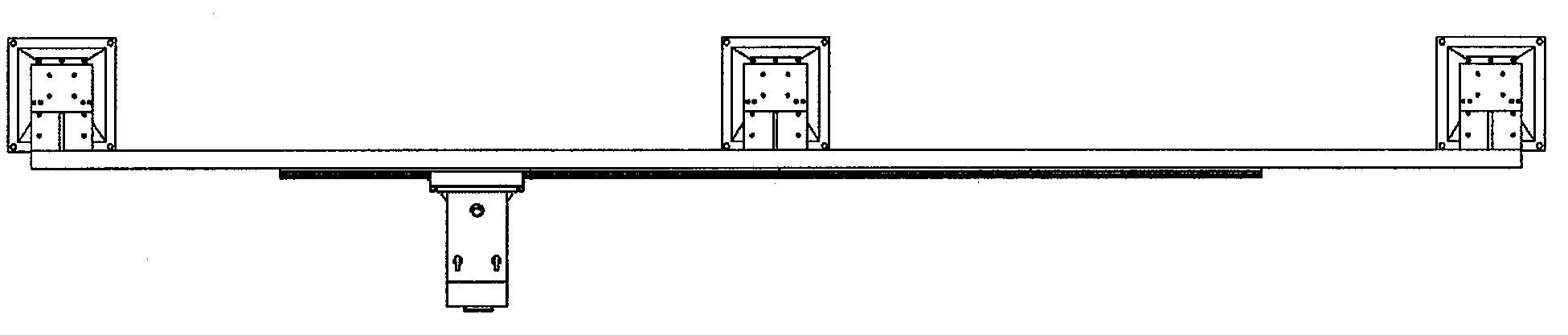

Cantilever type rolling device suitable for rolling processing of thin-walled cylindrical workpieces

ActiveCN107127280AHigh clamping precisionImprove processing qualityMetal rollingWork rollDrive shaft

A cantilever type rolling device suitable for rolling processing of thin-walled cylindrical workpieces comprises a base, a machine body, an upper working roll, a lower working roll, a working roll driving assembly, a downward pressing driving assembly, a workpiece clamping assembly and a working roll tightening tailstock, wherein the working roll driving assembly and the downward pressing driving assembly are positioned in the machine body; the downward pressing driving assembly is used for driving the upper working roll to carry out downward pressing action; the workpiece clamping assembly and the working roll tightening tailstock are mounted on the base; the workpiece clamping assembly is positioned between the machine body and the working roll tightening tailstock; a workpiece is positioned in the workpiece clamping assembly; the working roll driving assembly comprises a working roll driving motor, a driving shaft and a driven shaft; the working roll driving motor is connected with the driving shaft; the driving shaft is connected with the driven shaft through an idle gear system; the driving shaft and the driven shaft synchronously and reversely rotate; the lower working roll is mounted on the driving shaft; the upper working roll is mounted on the driven shaft; a sliding table plate is arranged on the base; and the workpiece clamping assembly and the working roll tightening tailstock are positioned on the sliding table plate.

Owner:LIAONING TECHNICAL UNIVERSITY

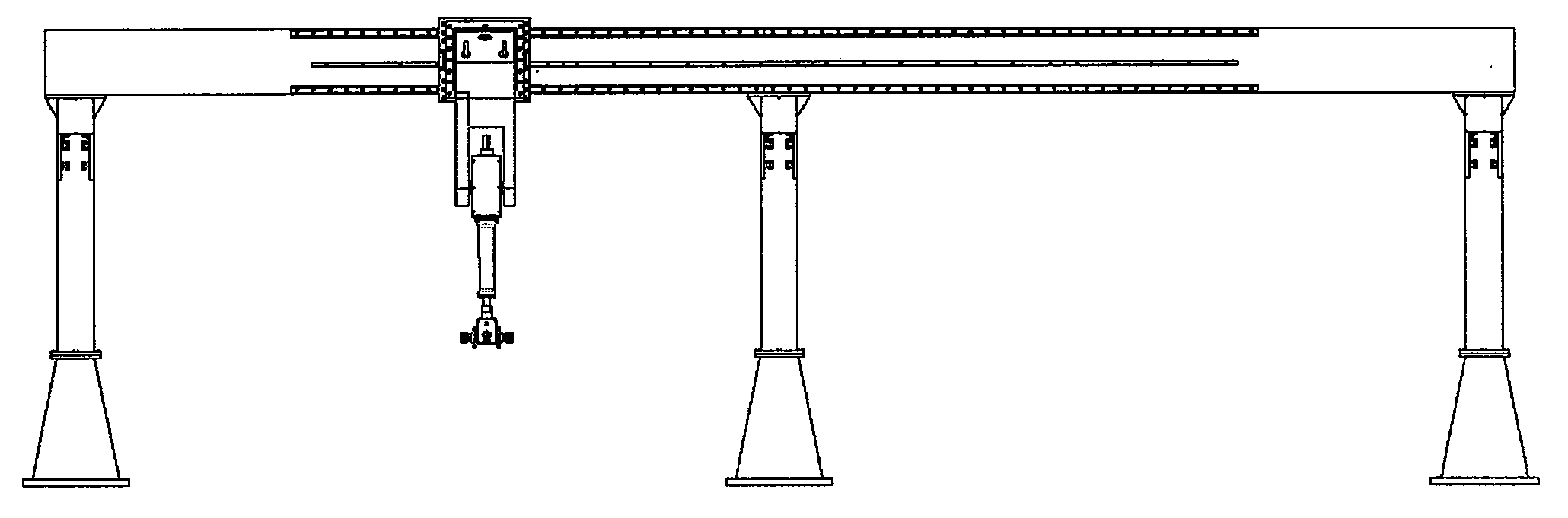

Four-coordinate automatic loading-unloading robot

InactiveCN103978399ASo as not to damageHigh clamping precisionMetal working apparatusManipulatorBall screwReducer

The invention relates to a four-coordinate automatic loading-unloading robot, comprising an upright column and cross beam unit, a robot body unit and a swing unit, wherein the upright column and cross beam unit comprises three upright columns and a cross beam; the cross beam is fixedly arranged on the upright columns through screws; a linear guide rail is arranged on the cross beam; the robot body unit comprises a sliding pillow, an X-way motor, a crank arm, a crank arm leg and a crank arm motor; the sliding pillow is arranged on the linear guide rail; the swing unit comprises a nut side motor, a nut side speed reducer, a nut, a spline nut side motor, a spline nut side speed reducer, a spline nut, a ball screw spline shaft and a small arm; under the combined action of the nut side motor and the spline nut side motor, power is transmitted to the nut and the spline nut through a nut side synchronous belt and a spline nut side synchronous belt, so that the ball screw spline shaft moves. By applying the four-coordinate robot, the rapid loading and unloading of a machine tool can be realized; therefore the clamping precision is improved, the production period is shortened, the efficiency is improved, and the production cost is lowered.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Hydraulic elastic chuck and clamping method thereof

The invention relates to the technical field of machining and particularly relates to a hydraulic elastic chuck and a clamping method thereof. By pushing a sealing plunger to pressurize hydraulic fluid, a thin wall deforms and expands outwards, claws at the front end of the thin wall are driven to stretch outwards, and the claws loosen workpieces or clamp the workpieces. The structure is simple, the production cost is low, and the operation is flexible. The clamping of the workpieces is convenient, the machining precision of the workpieces is improved, and the production efficiency is increased. According to the machining method of the hydraulic elastic chuck, after the hydraulic elastic chuck is fixedly arranged on a machine tool spindle, machining is carried out on the outer sides and / orinner sides of the claws, and a ring formed by a plurality of claws which get together is highly concentric with the machine tool spindle, so that the machining precision can be improved; and then, through locating structures on the claws, the to-be-machined workpieces are precisely located in axial, radial and rotating directions, so that when the same batch of workpieces are massively produced,the initial machining position points of all workpieces are ensured to be the same, and the machining precision during the mass production of the products is improved.

Owner:梅木精密工业(珠海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com