Loading manipulator of PMC threading machine

A technology of thread turning machine and manipulator, which is applied in metal processing equipment, tangential feeding devices, manufacturing tools, etc., can solve the problems of complex structure, complicated maintenance and repair, and it is difficult to ensure the clamping force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

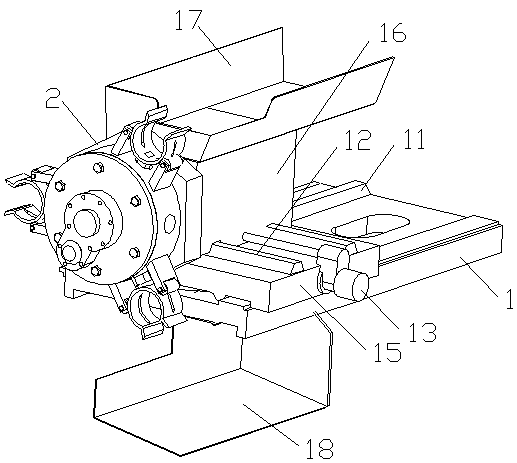

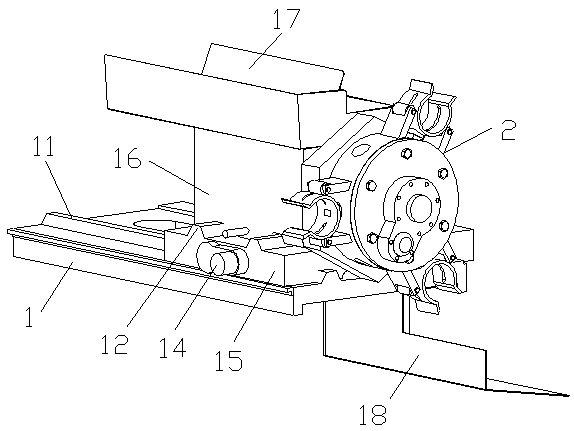

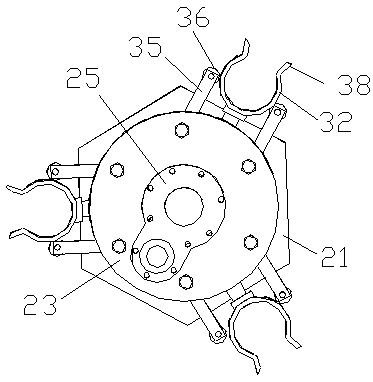

[0024] Example Figure 1 to Figure 7 As shown, the PMC threading machine feeding manipulator of the present invention comprises frame 1, transverse guide rail 11, longitudinal guide rail 12, transverse drive motor 13, longitudinal drive motor 14, middle pallet 15, corner motor 16, feeding tray 17, blanking Disk 18 and clamping mechanism 2, described transverse guide rail 11 is arranged on the top surface of described frame 1, and described transverse drive motor 13 and longitudinal drive motor 14 are respectively arranged on the both sides of described middle support plate 15, and described middle support Plate 15 is arranged on described transverse guide rail 11 and moves back and forth along described transverse guide rail 11 under the drive of transverse driving motor 13, and described longitudinal guide rail 12 is arranged on the top surface of described middle support plate 15, and described corner motor 16 is arranged on The longitudinal guide rail 12 also moves back and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com