Positioning and clamping device for cylindrical parts

A technology for positioning and clamping and parts, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of time-consuming, labor-intensive, low-efficiency, and poor clamping accuracy, and achieves increased flexibility and low production costs. , the effect of simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

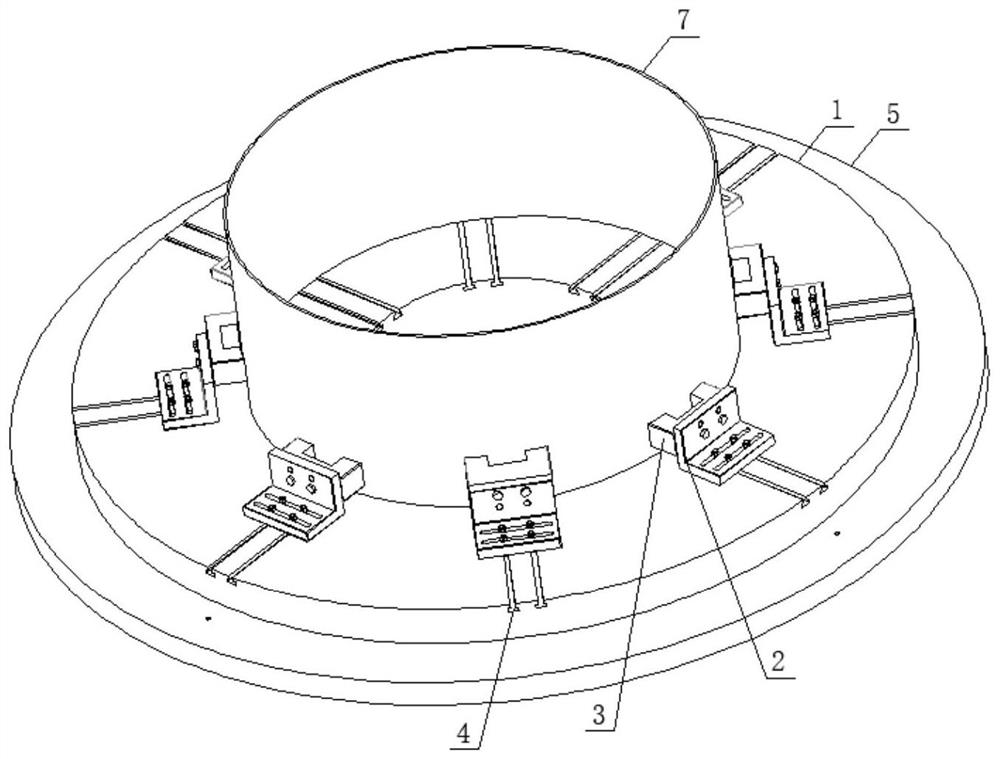

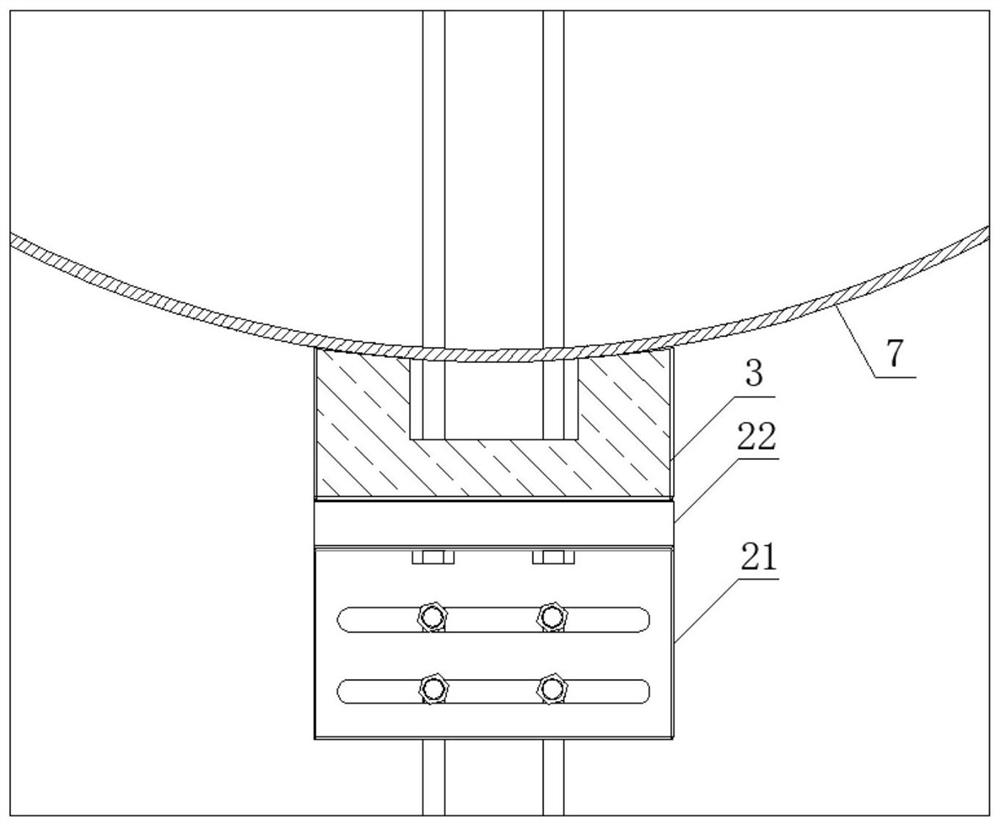

[0026] like Figures 1 to 3 As shown, this embodiment provides a positioning and clamping device for cylindrical parts 7, including a base 5, a tray 1, a positioning bent plate 2, and a top block 3; wherein, the tray 1 is an annular disk fixed on the upper part of the base 5; the tray 1. A number of slideways 4 are uniformly distributed in the circumferential direction. The cross section of the slideway 4 is inverted T-shaped and extends from the outer circle of the tray 1 to the inner circle of the tray 1. Two adjacent slideways 4 are arranged in parallel to form a slideway group. The slideway group is evenly distributed on the upper part of the tray 1 in the circumferential direction; the positioning bent plate 2 includes a positioning plate 21 and a mounting plate 22, and the positioning plate 21 is provided with waist-shaped mounting holes that are adapted to the positions of the two slideways 4 of a set of slideway groups. The length of the shaped mounting hole is adapted...

Embodiment 2

[0033] like Figure 4As shown, this embodiment is based on the positioning and clamping device of Embodiment 1, and a buffer pad 6 is provided at the end of the top block 3 away from the mounting plate 22. One end of the cushion pad 6 is detachably connected to the top block 3, and the other end is provided with the to-be-installed The arc surface of the outer wall of the clamping part 7 is adapted. After clamping, the top block 3 squeezes the buffer pad 6 to clamp the cylindrical part 7. During use, replace the suitable buffer pad 6 for pipes of different diameters , in this embodiment, a dovetail groove is provided at the end where the top block 3 is connected to the cushion pad 6, and a connecting block adapted to the dovetail groove is arranged on the cushion pad 6, and the cushion pad 6 is embedded in the dovetail groove through the connecting block. Various buffer pads 6 are mounted on the connection blocks. Cushion pad 6 is rubber material, when can avoid clamping forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com