Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Realize alignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

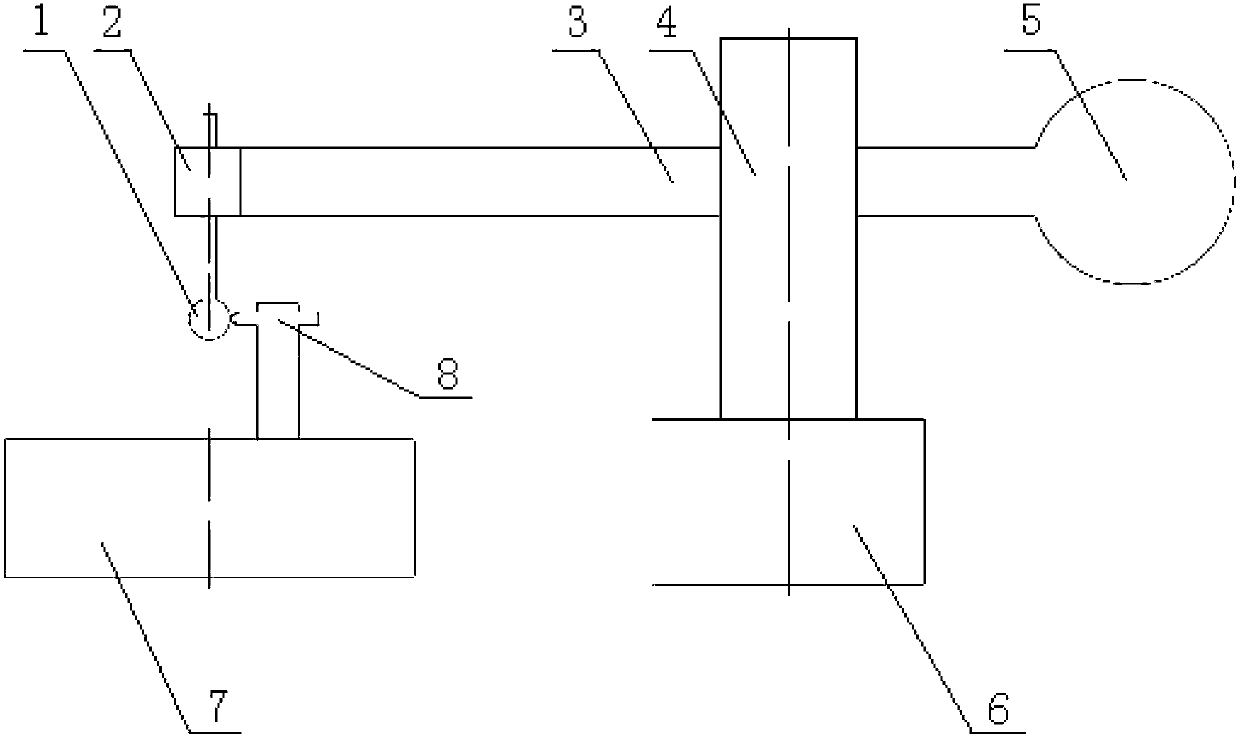

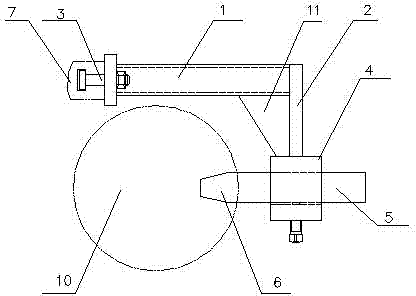

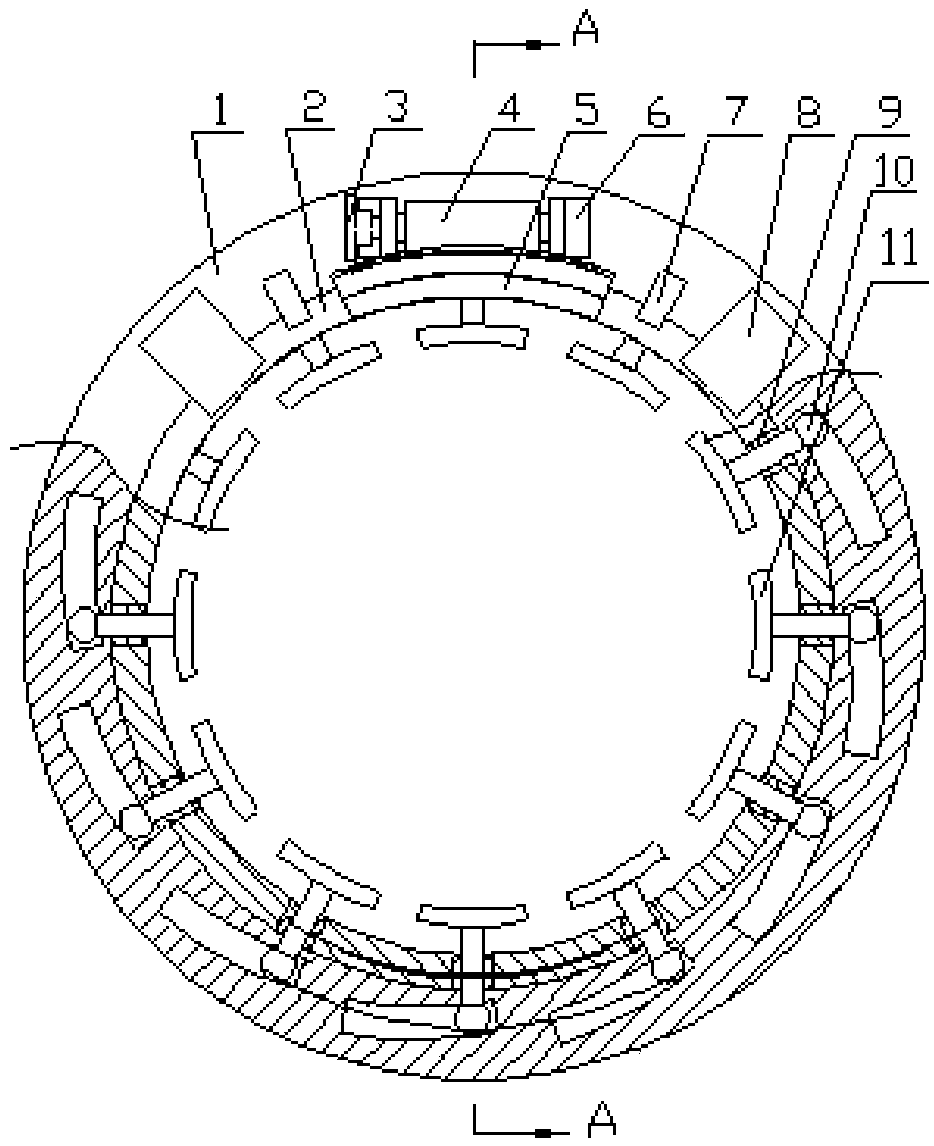

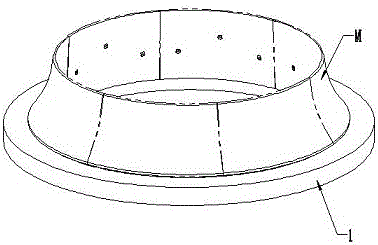

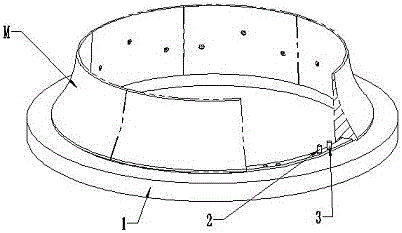

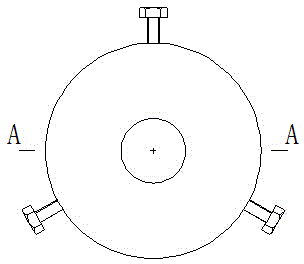

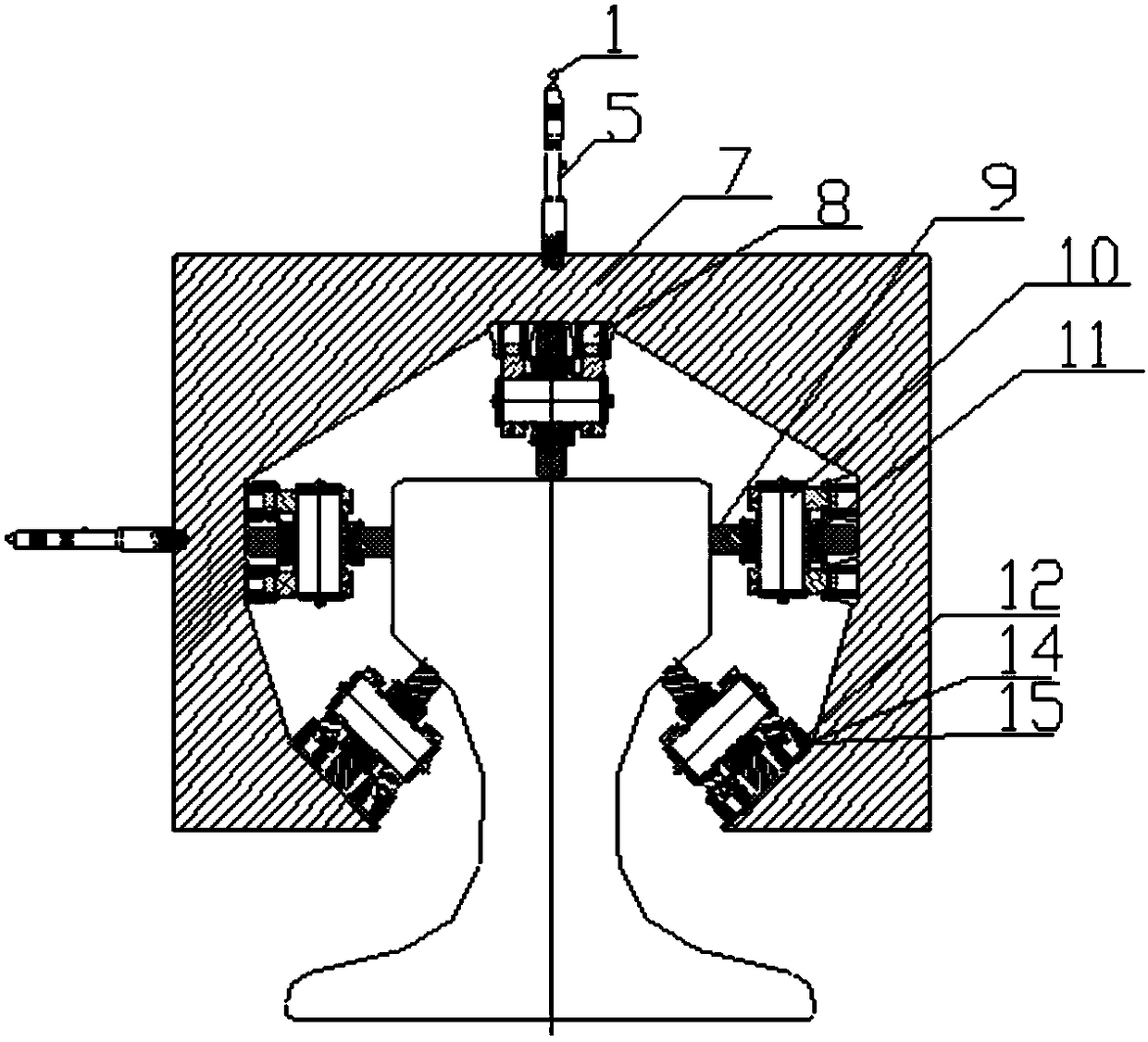

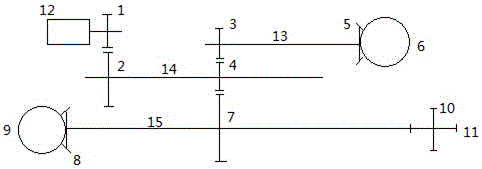

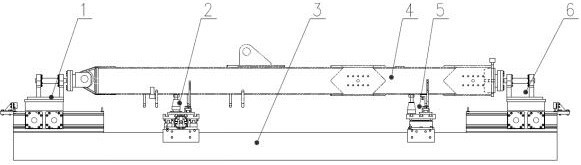

Aligning and leveling worktable for measuring cylindricity of slewing type workpiece

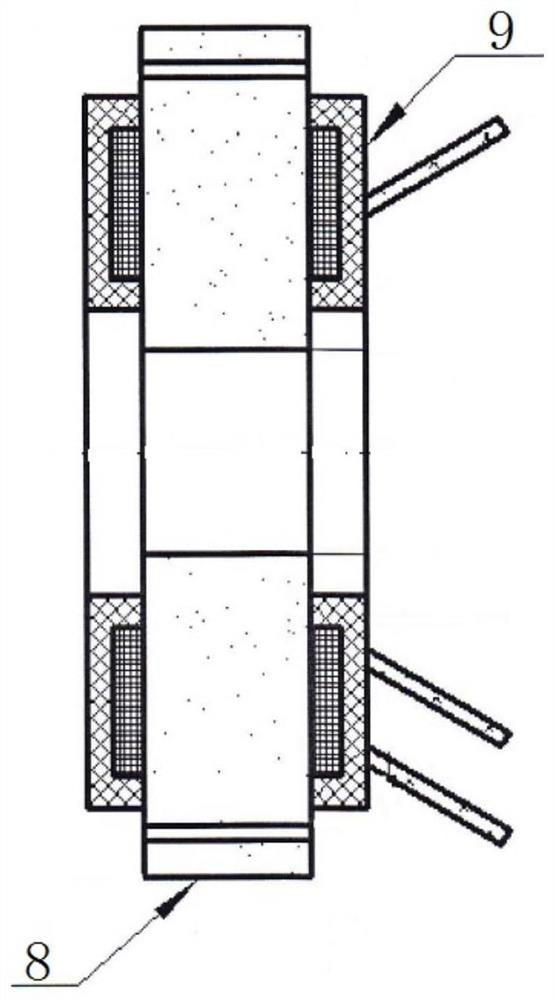

InactiveCN101788282ARealize alignmentRealize the leveling functionMeasurement devicesSteel ballEngineering

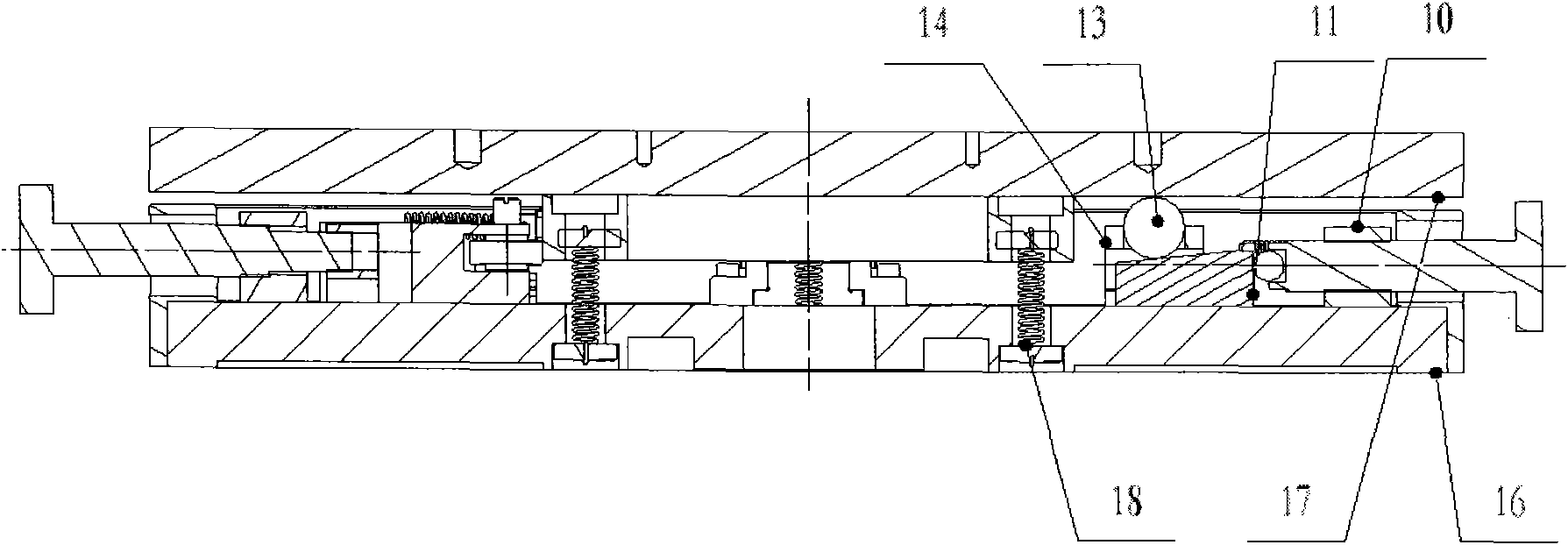

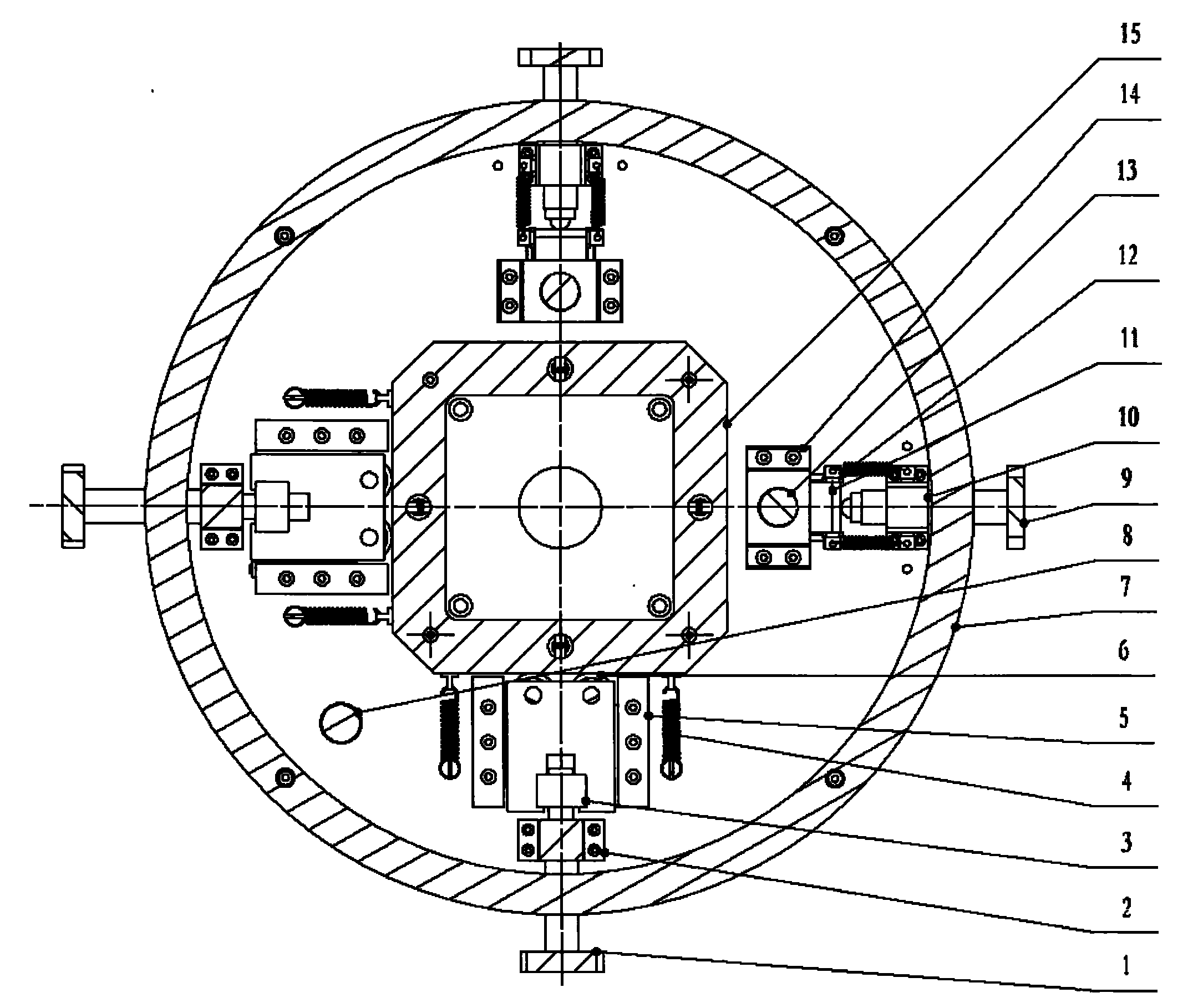

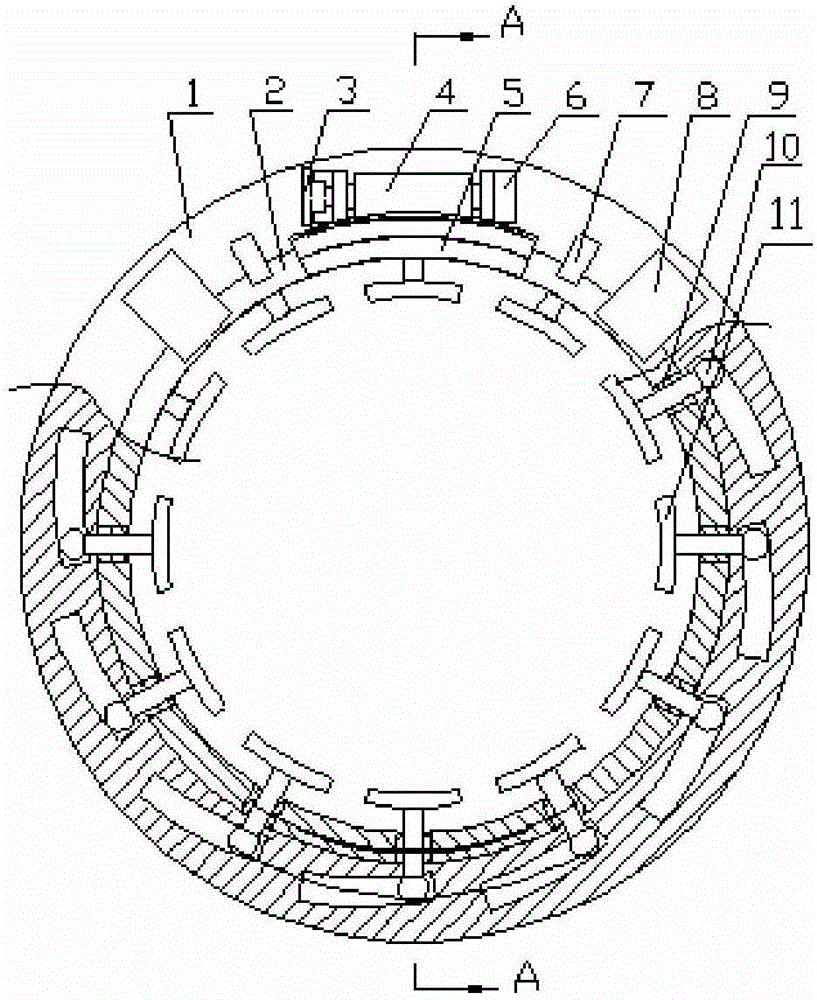

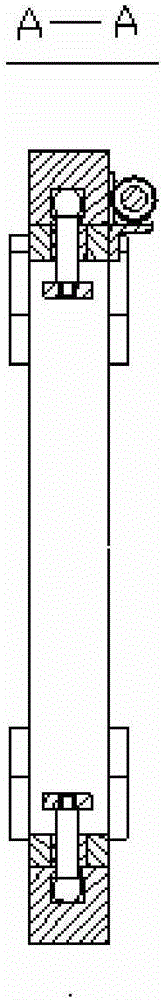

The invention provides an aligning and leveling worktable for measuring the cylindricity of a slewing type workpiece. The aligning and leveling worktable is composed of an aligning knob (1), an aligning supporting seat (2), an aligning sliding block (3), an aligning tension spring (4), an aligning fixed supporting seat (5), a bearing (6), an outer cover (7), a fixed steel ball (8), leveling knobs (9), a leveling knob supporting seat (10), an inclined block (11), a leveling tension spring (12), leveling steel balls (13), a leveling fixed supporting seat (14), a connecting ring (15), a base (16), a worktable (17) and a vertical tension spring (18). The leveling steel balls are movable supporting points, and the fixed steel ball is a fixed supporting point. The two leveling knobs are adjusted to lead the worktable to realize the leveling function under the support of the two leveling steel balls and the fixed steel ball. When the aligning knob is adjusted, the connecting ring drives the worktable to precisely move along two vertical directions under the action of the aligning tension spring so as to realize the aligning function of the worktable. The structure of the aligning and leveling worktable is simple and practical.

Owner:LUOYANG BEARING RES INST CO LTD

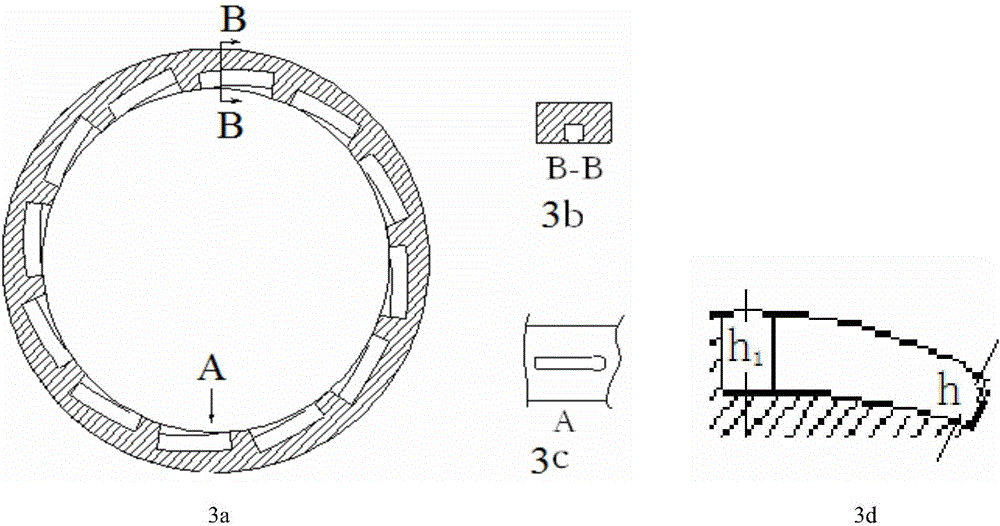

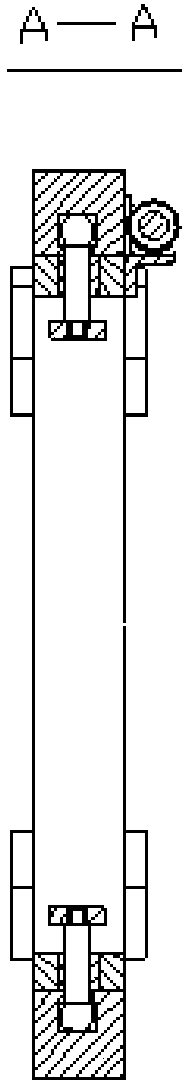

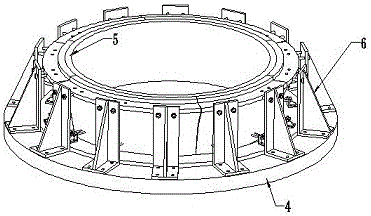

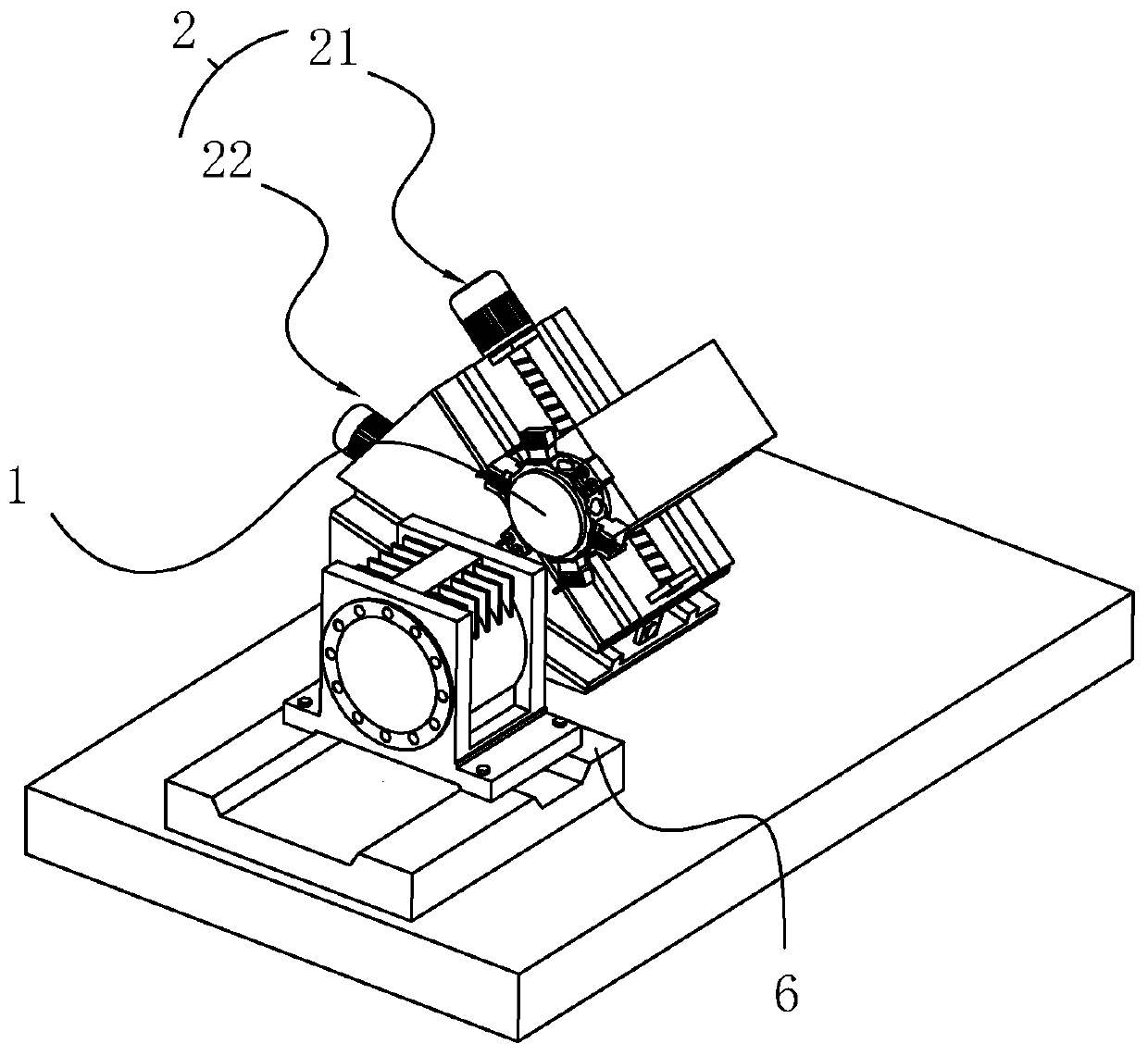

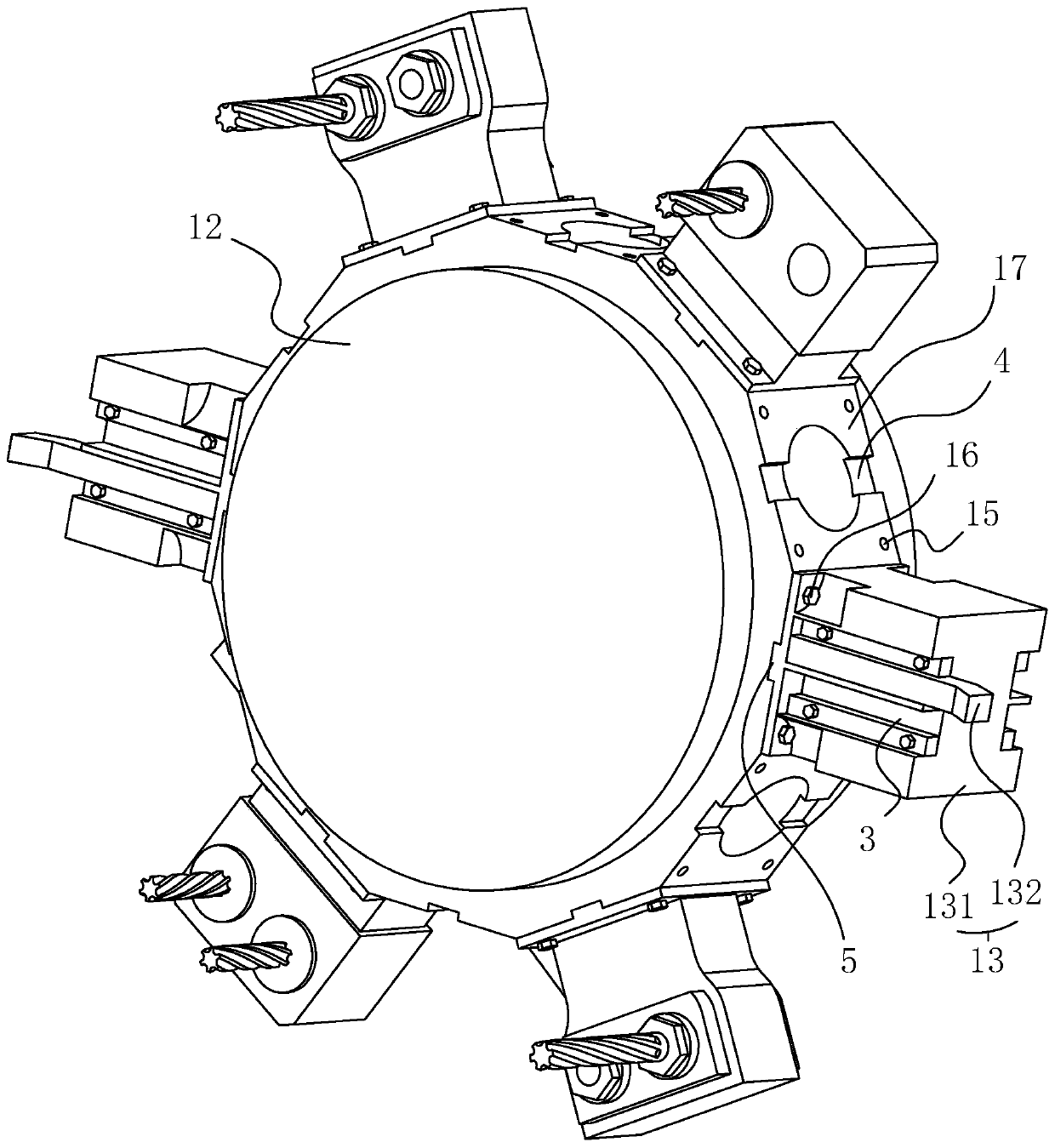

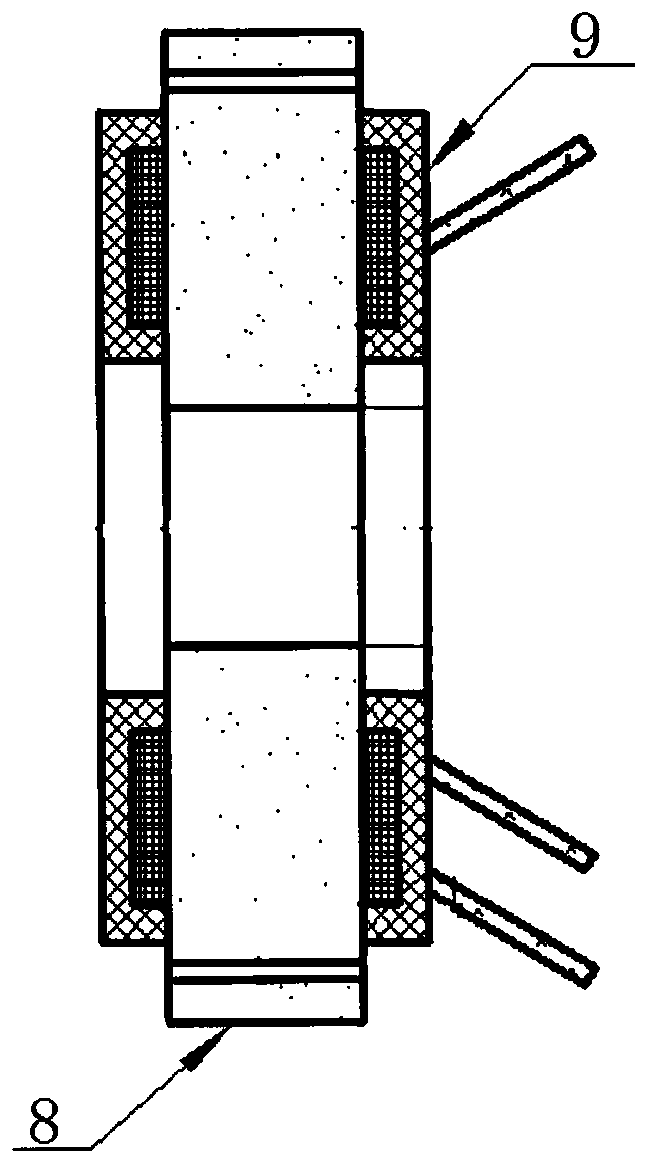

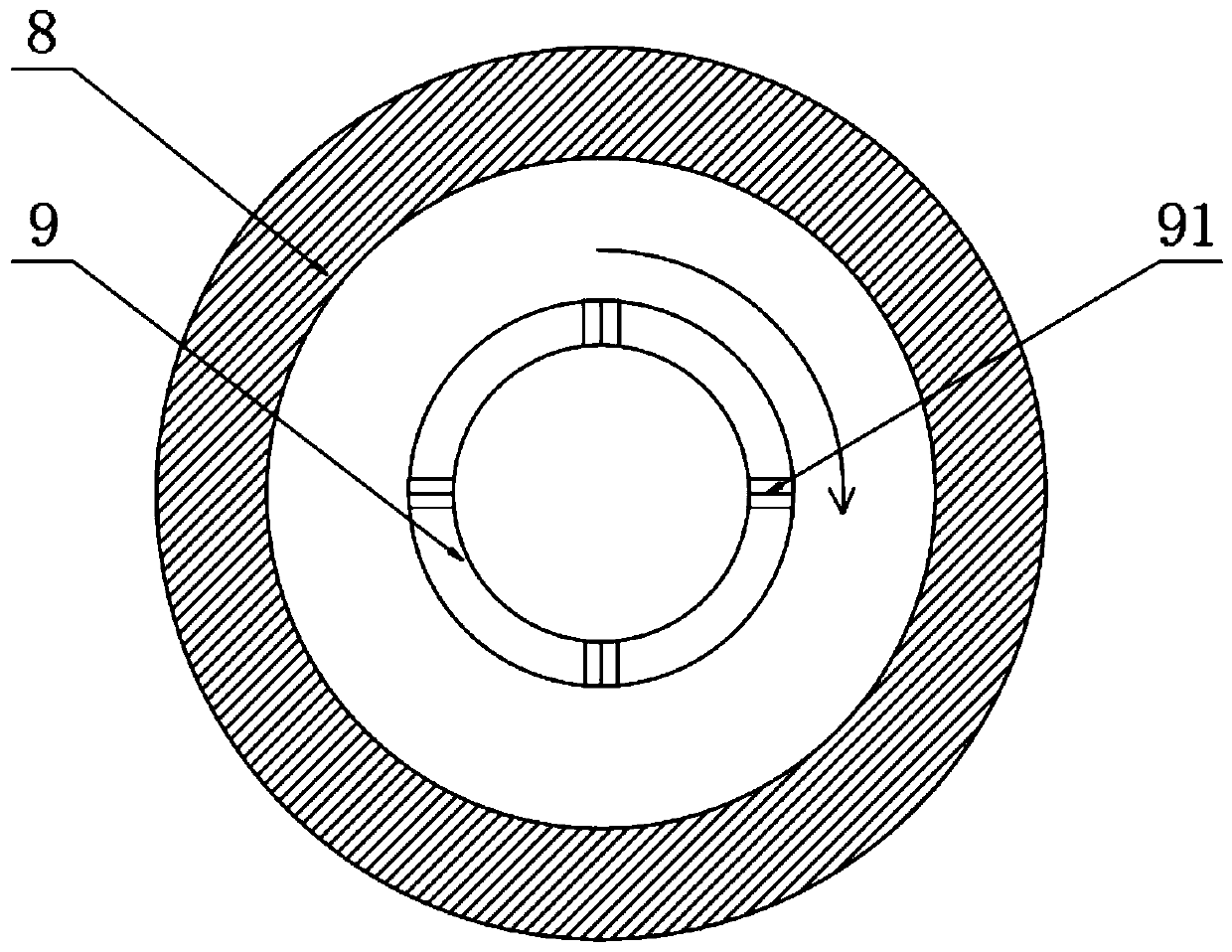

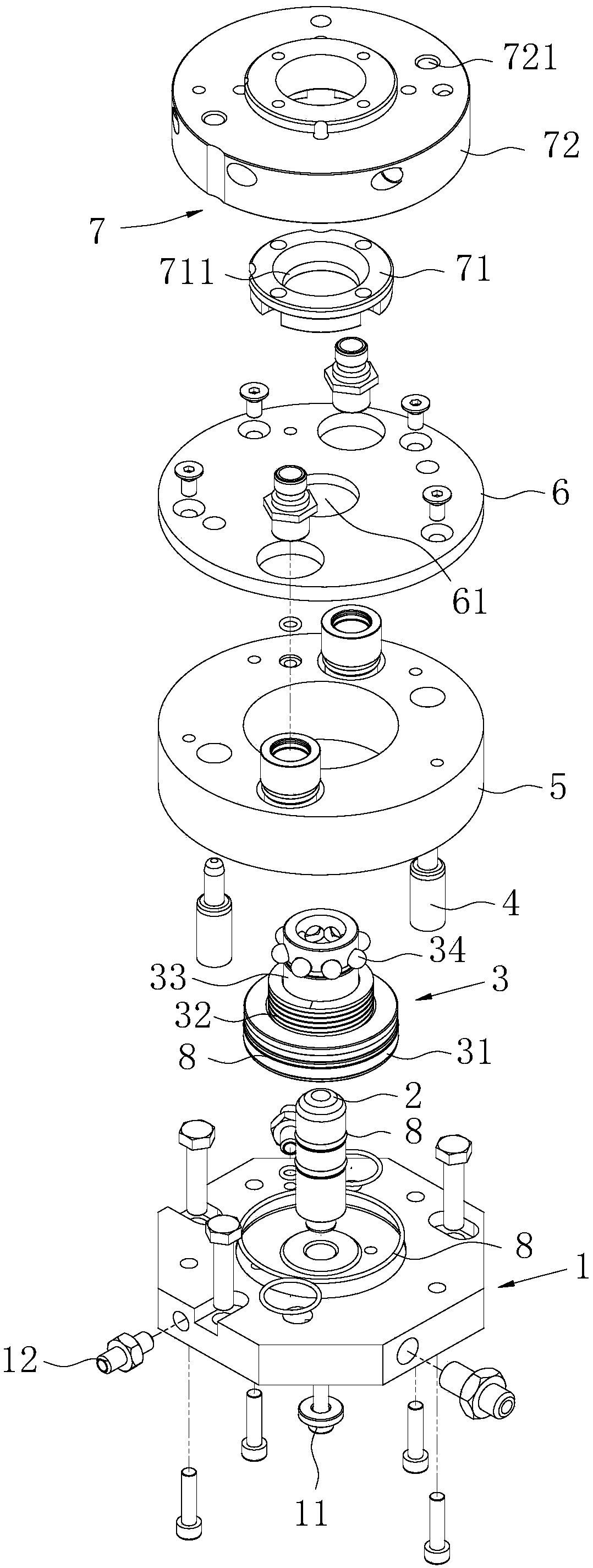

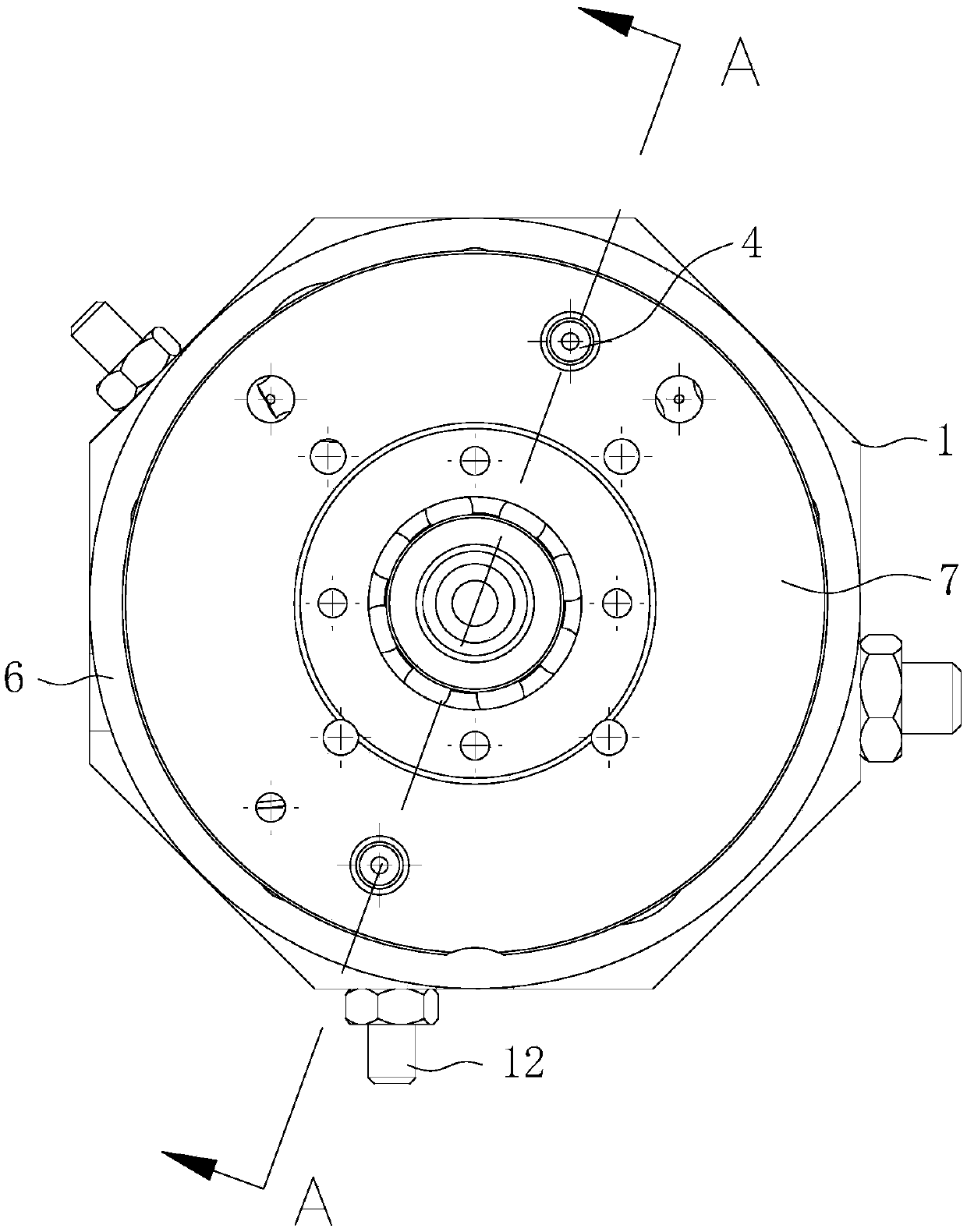

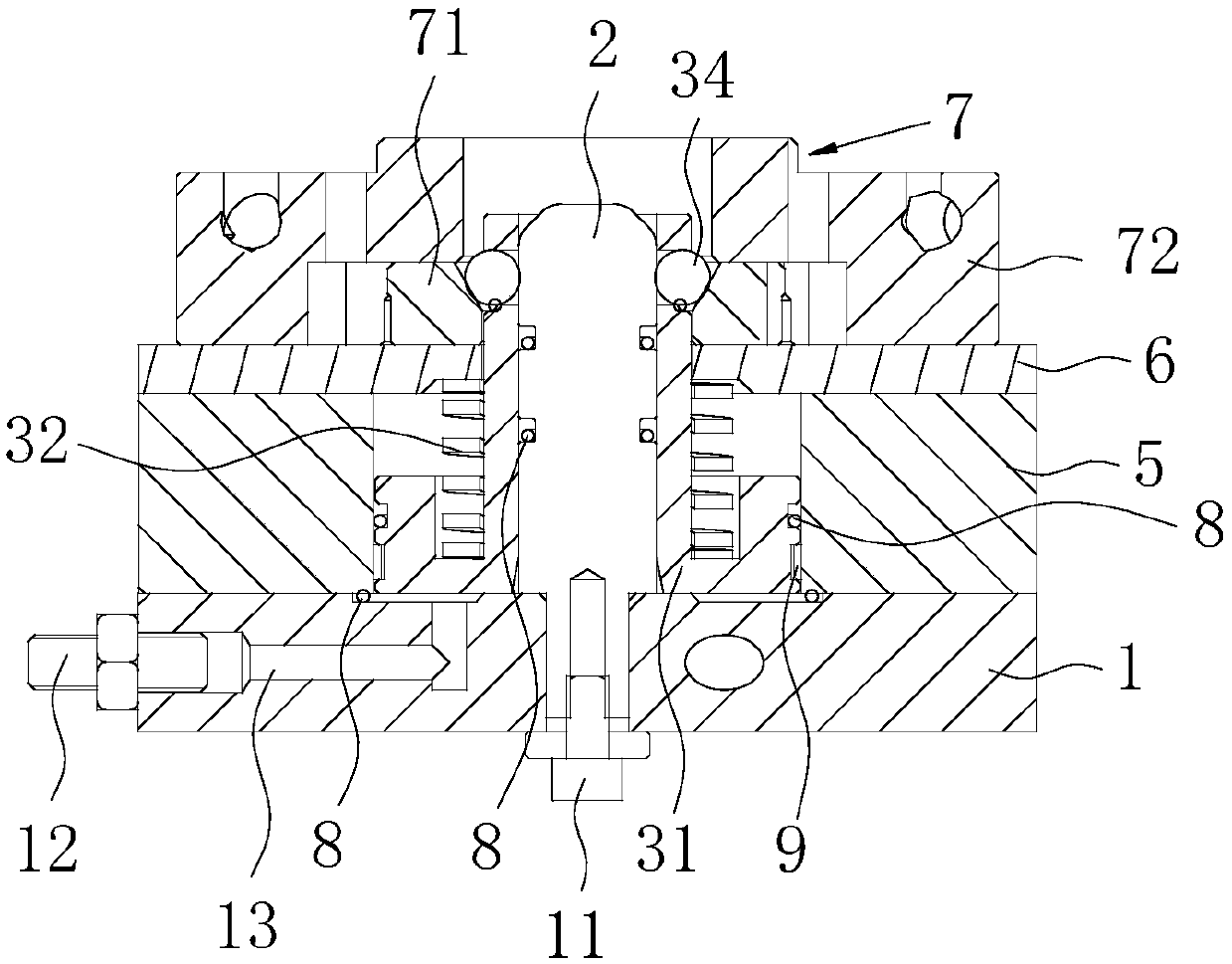

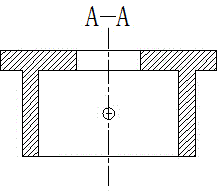

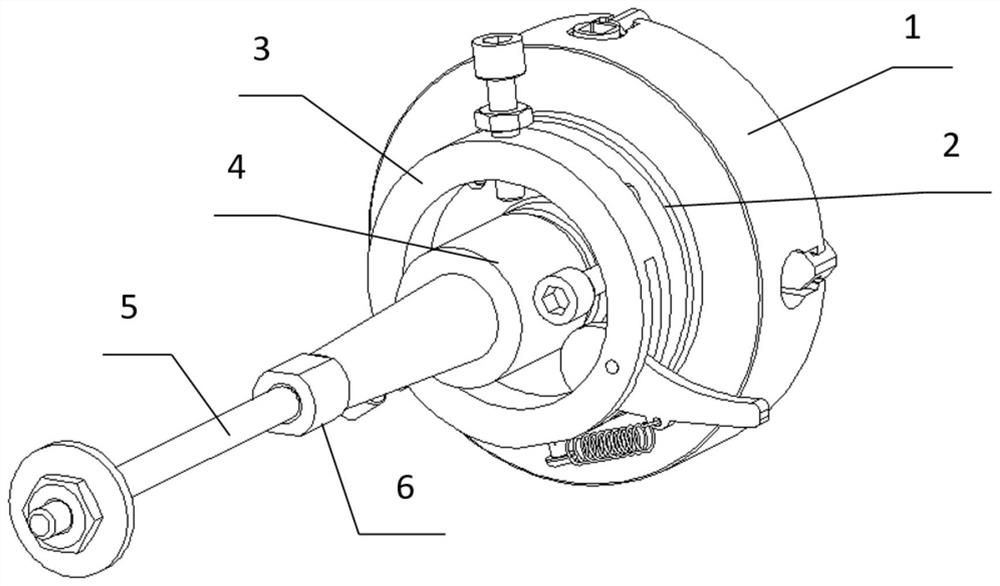

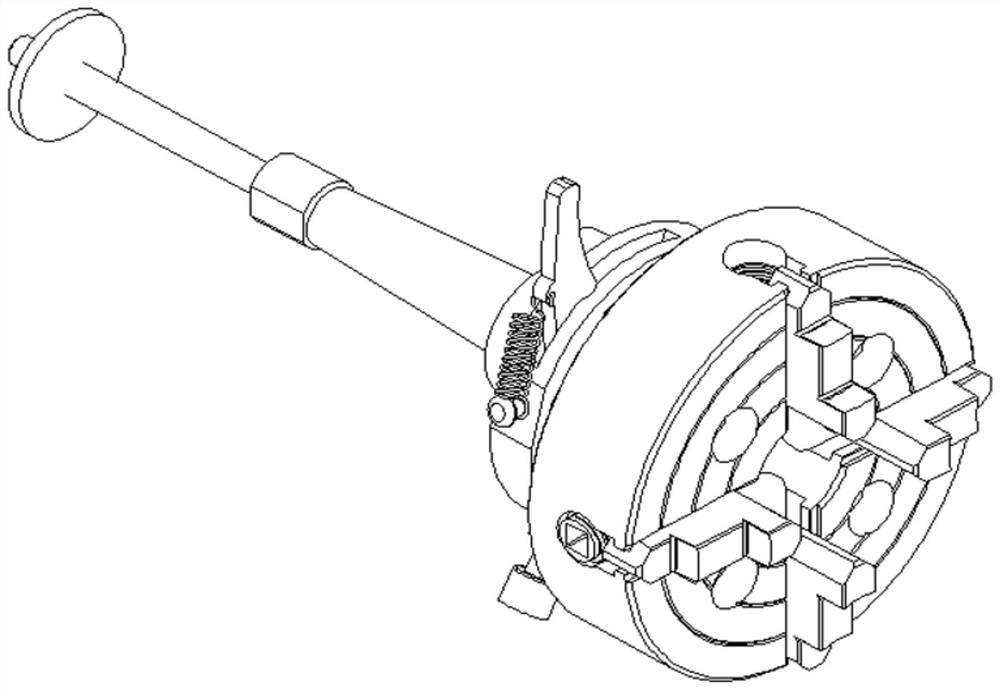

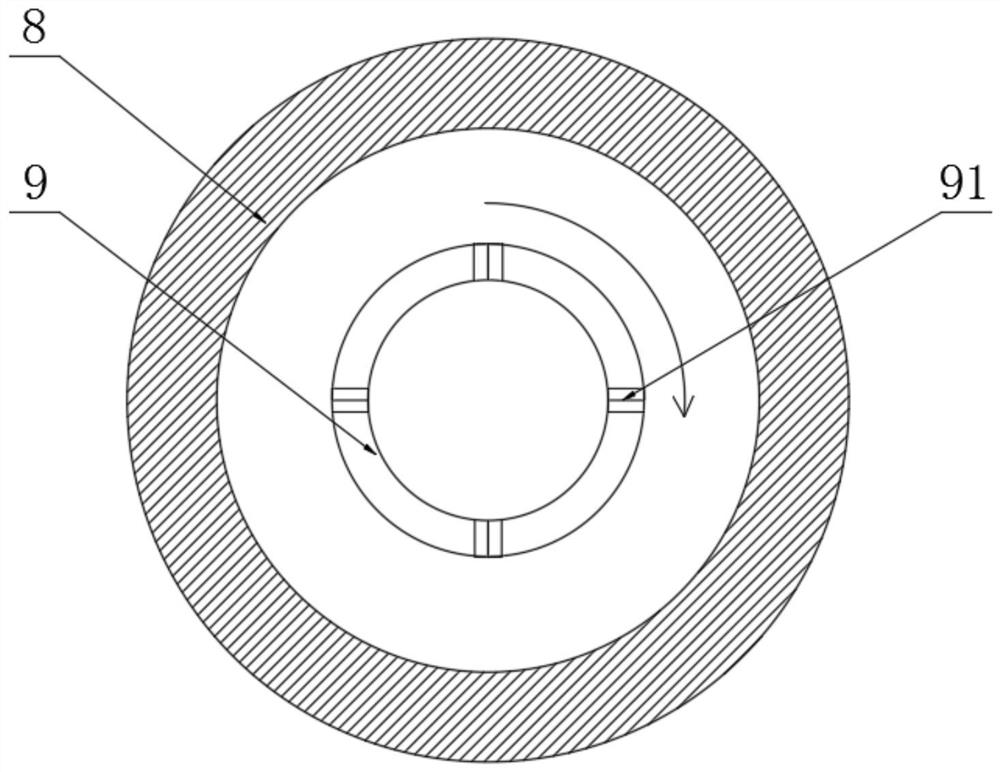

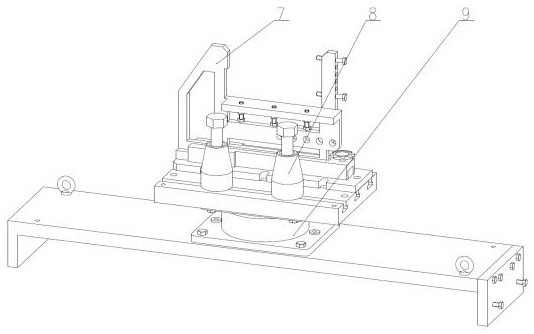

Automatic centring and clamping mechanism

ActiveCN106272160ARealize clampingRealize alignmentWelding/cutting auxillary devicesWork holdersEngineeringCentring

The invention discloses an automatic centring and clamping mechanism. An outer ring body is arranged on the surface of the outer circumference of an inner ring body in a sleeving manner, and the outer ring body and the inner ring body are in clearance fit. The ball head ends of telescopic shafts in a plurality of telescopic bodies penetrate guide holes in the circumference of the inner ring body and then are mounted in sliding grooves located in the inner circle surface of the outer ring body. A worm gear body is fixed to the end face of the inner ring body. A worm is fixed to the end face of the outer ring body through a bearing pedestal and engaged with the worm gear body, and therefore the outer ring body and the inner ring body generate relative rotation. The number of the guide holes in the surface of the outer circumference of the inner ring body, the number of the sliding grooves in the surface of the inner circumference of the outer ring body and the number of the telescopic shafts are the same. According to the automatic centring and clamping mechanism, in the clamping process, all clamping blocks stretch out and retract back at the same time through telescopic bolts, and the clamping blocks are rounded at the same time in the clamping process; and in the whole implementation process, no machine tool is needed, operation is easy and convenient, efficiency is high, and the high application and popularization value is achieved.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

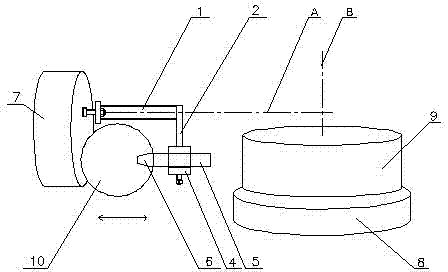

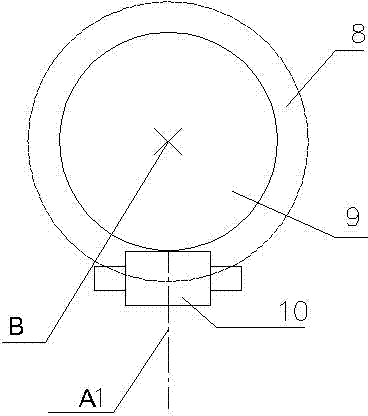

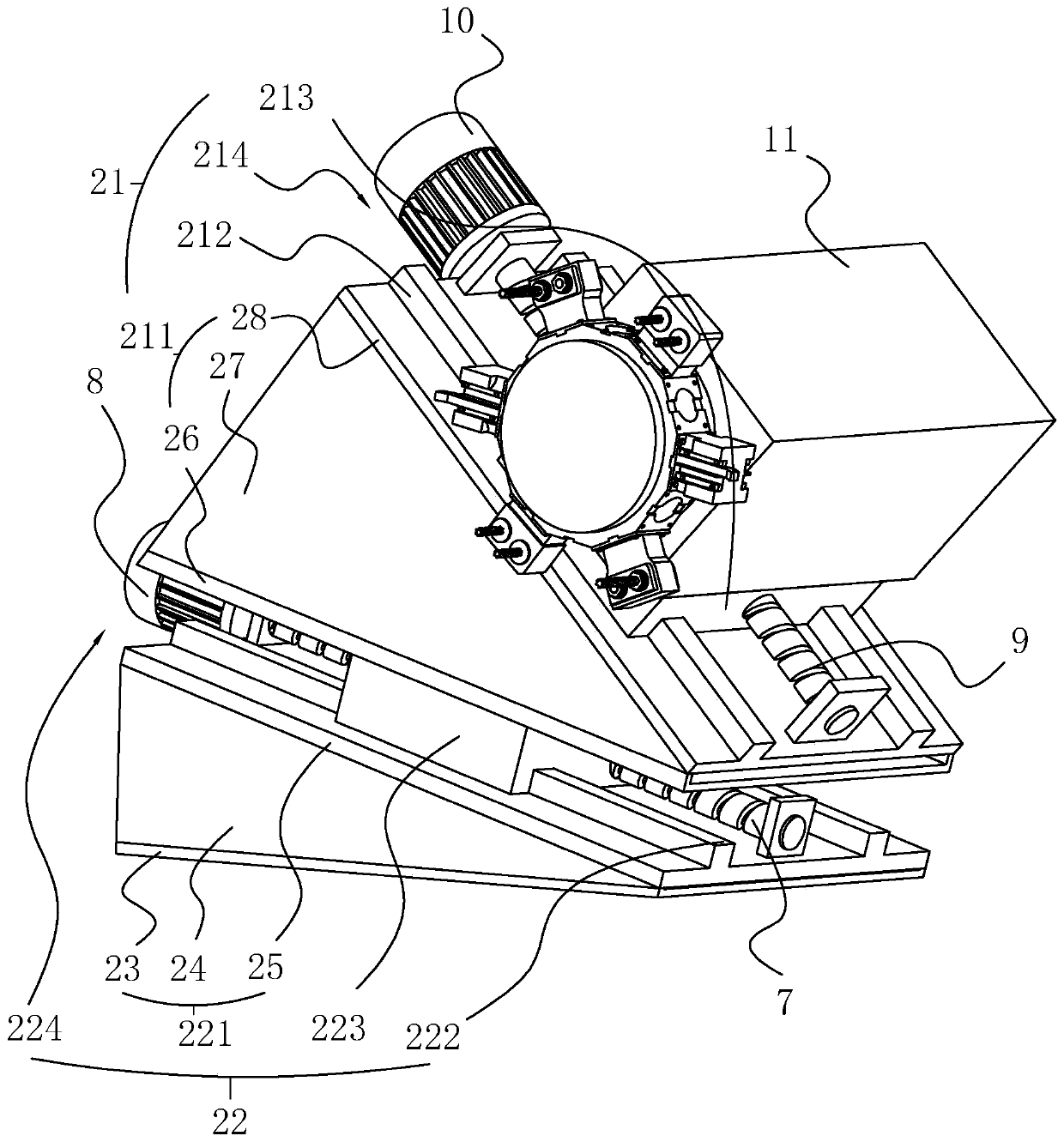

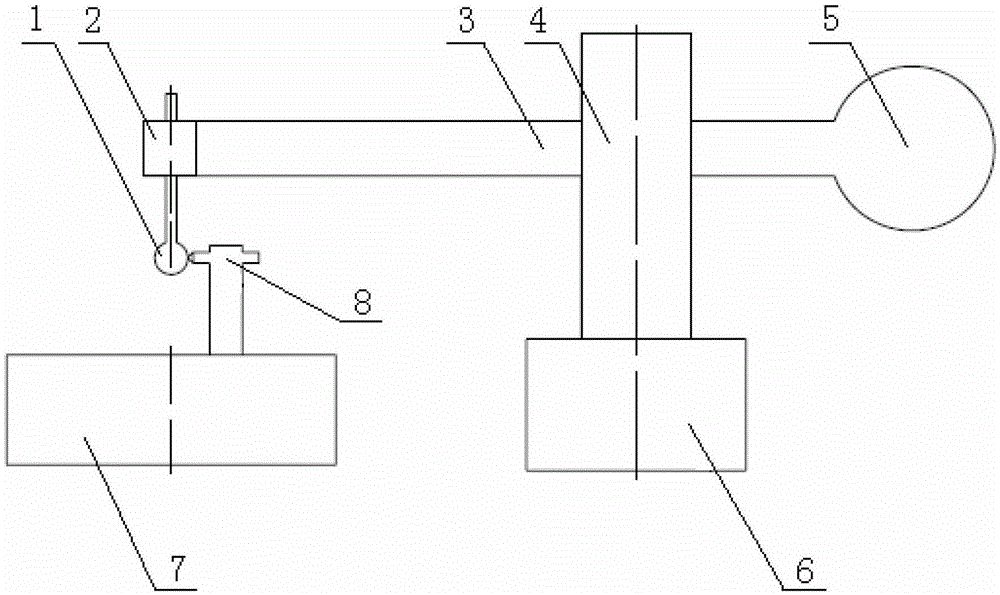

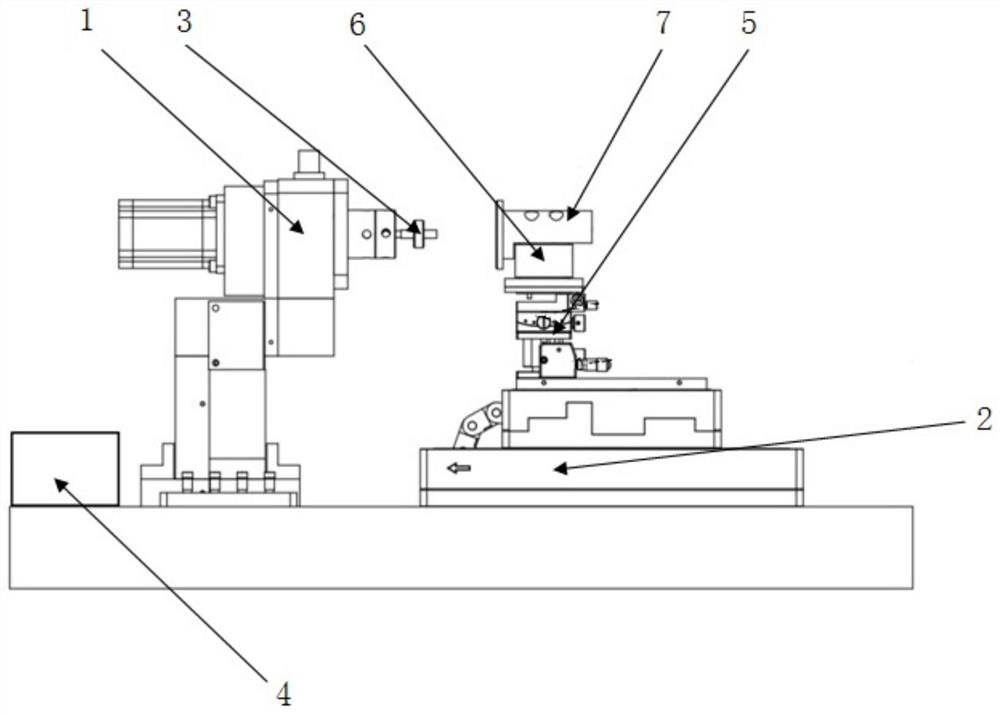

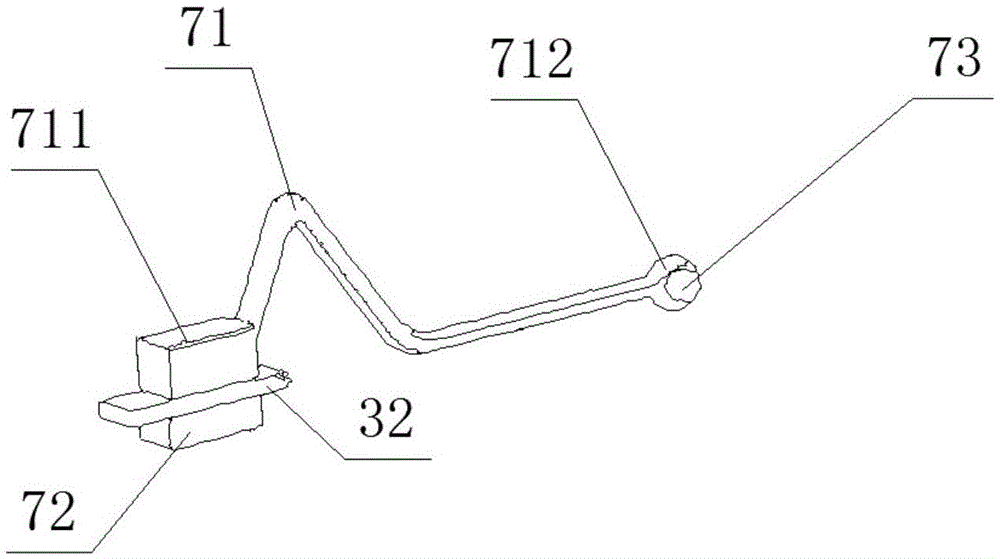

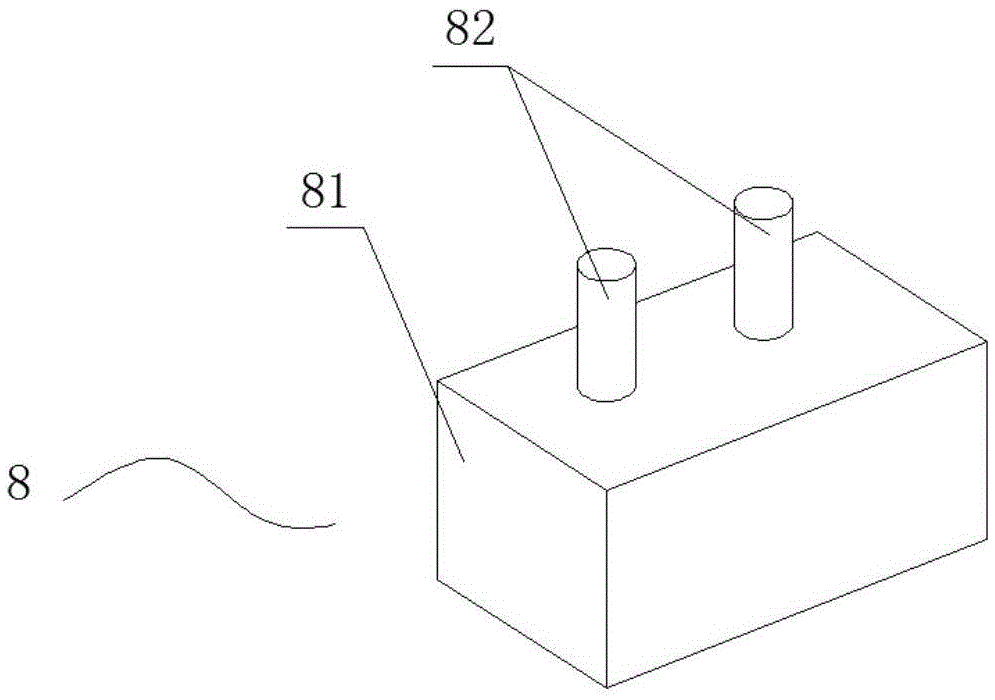

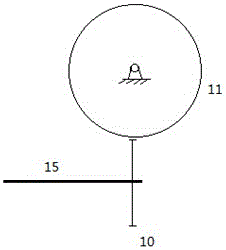

Swing arm type contourgraph measuring head alignment calibration device with rotating sensor

A swing arm type contourgraph measuring head alignment calibration device with a rotating sensor comprises a contourgraph measuring head, a contourgraph measuring head fine adjustment mechanism, a transverse arm, a stand column, a balance weight, a transverse arm rotary table, a workpiece rotary table and an optical measuring head, wherein the optical measuring head is fixed on the workpiece rotary table and carries out rotating motion around the contourgraph measuring head, outer contour data of the contourgraph measuring head are obtained, central position information of the contourgraph measuring head is calculated through a data processing algorithm, and alignment adjustment of the contourgraph measuring head and the workpiece rotary table is achieved through the adjustment of the contourgraph measuring head fine adjustment mechanism. According to the swing arm type contourgraph measuring head alignment calibration device, the alignment adjustment of the contourgraph measuring head and the workpiece rotary table is achieved, and a practical solution is provided for inplace measurement of a swing arm type contourgraph on an optical processing site.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

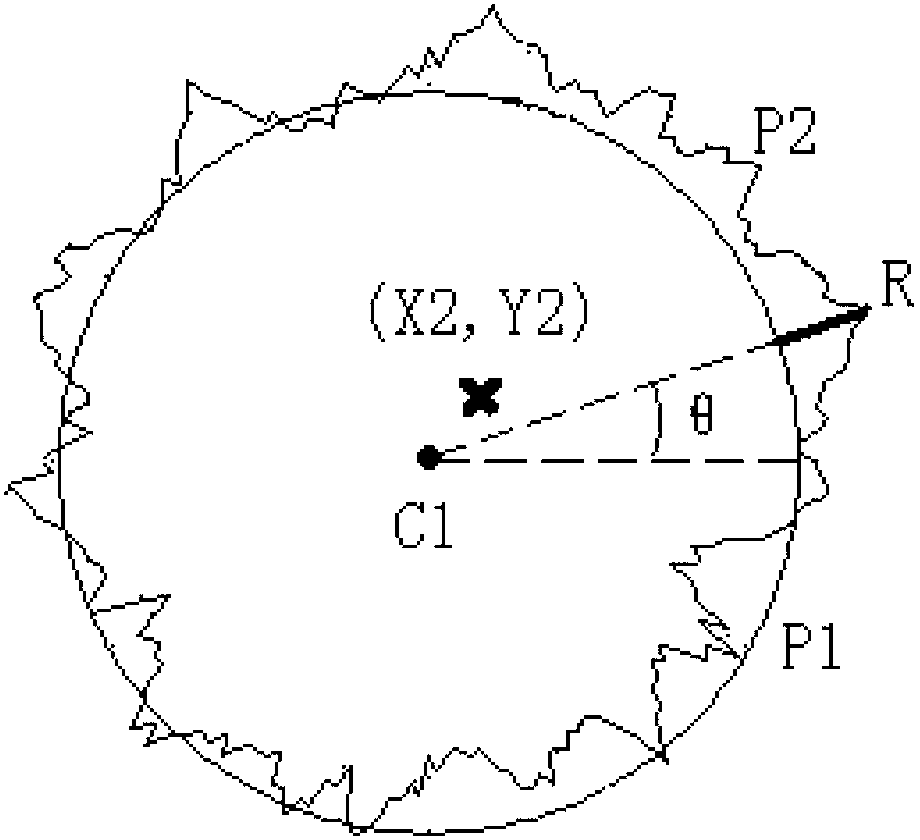

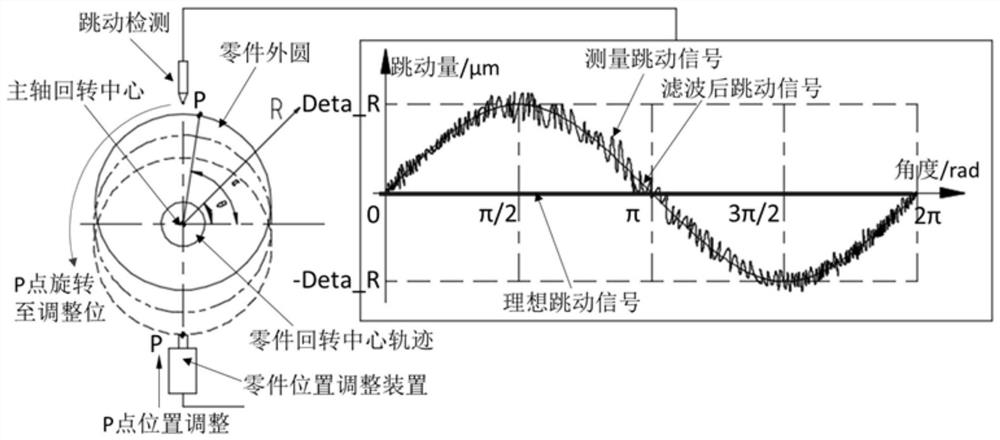

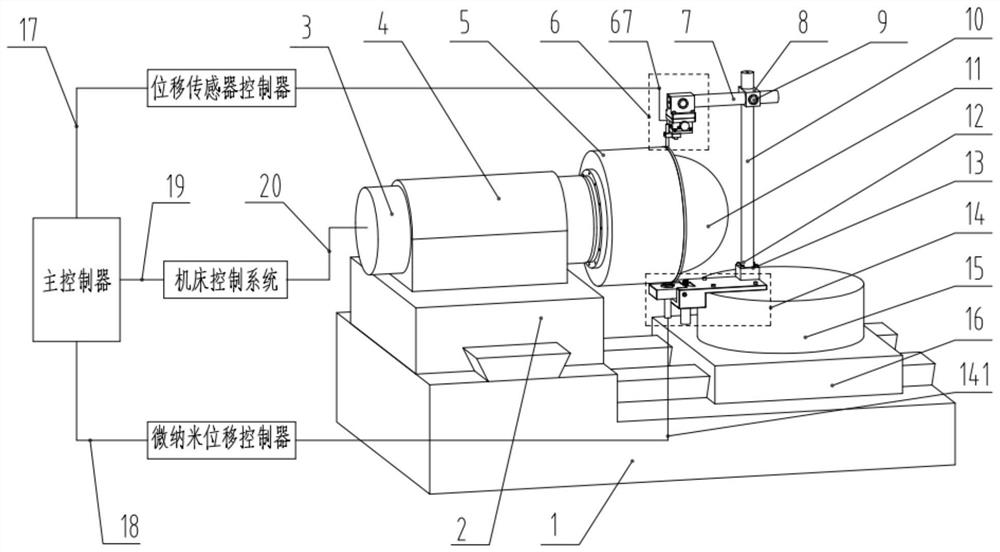

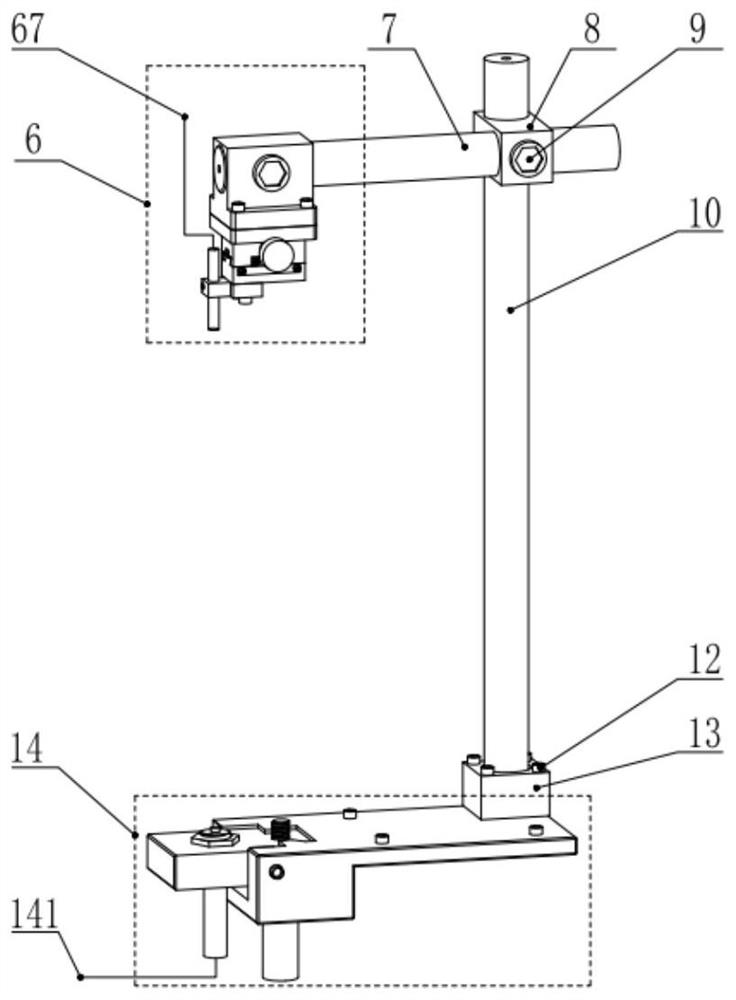

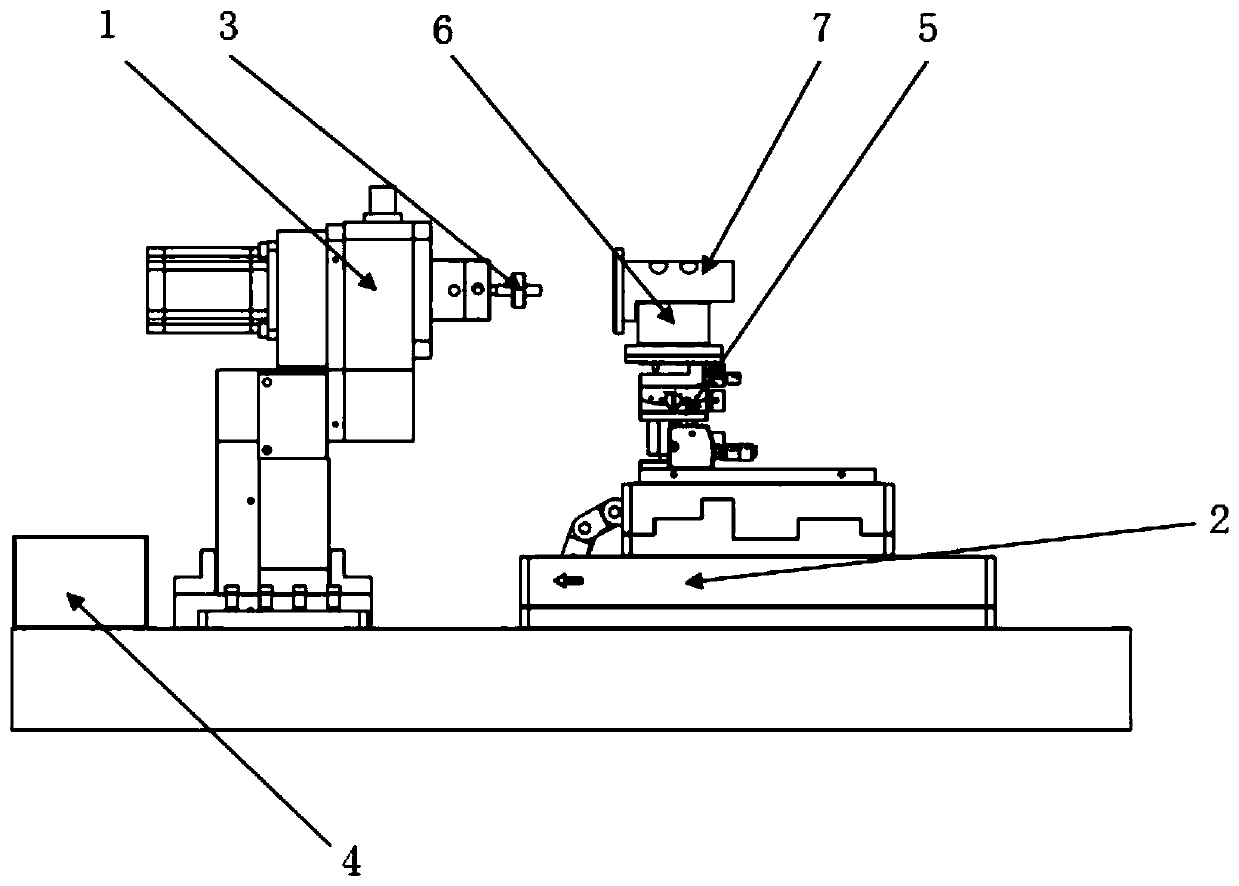

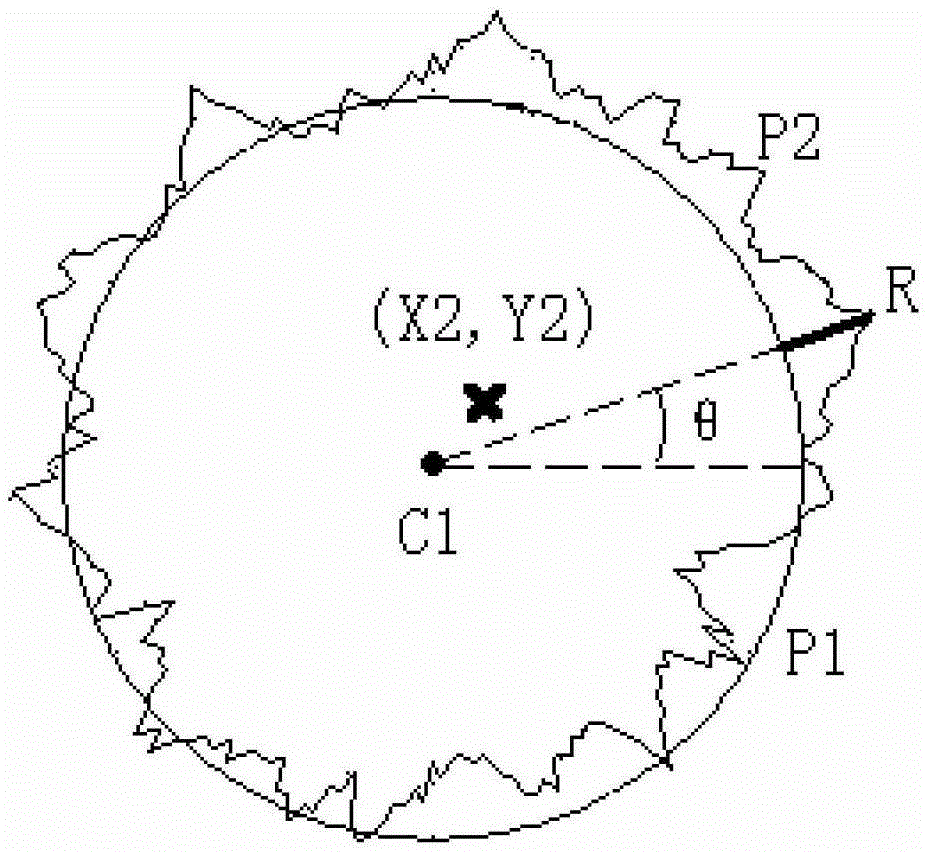

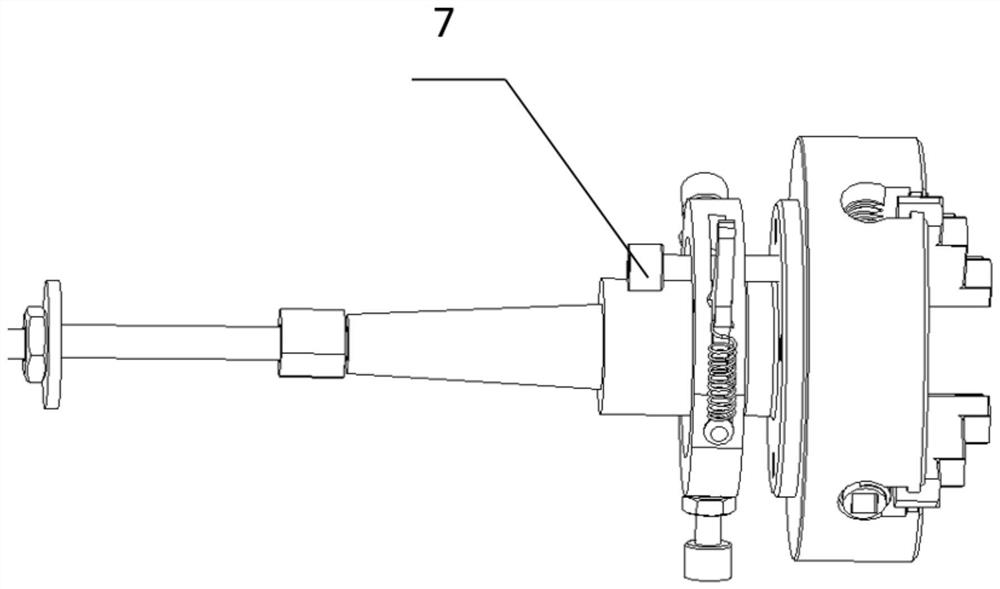

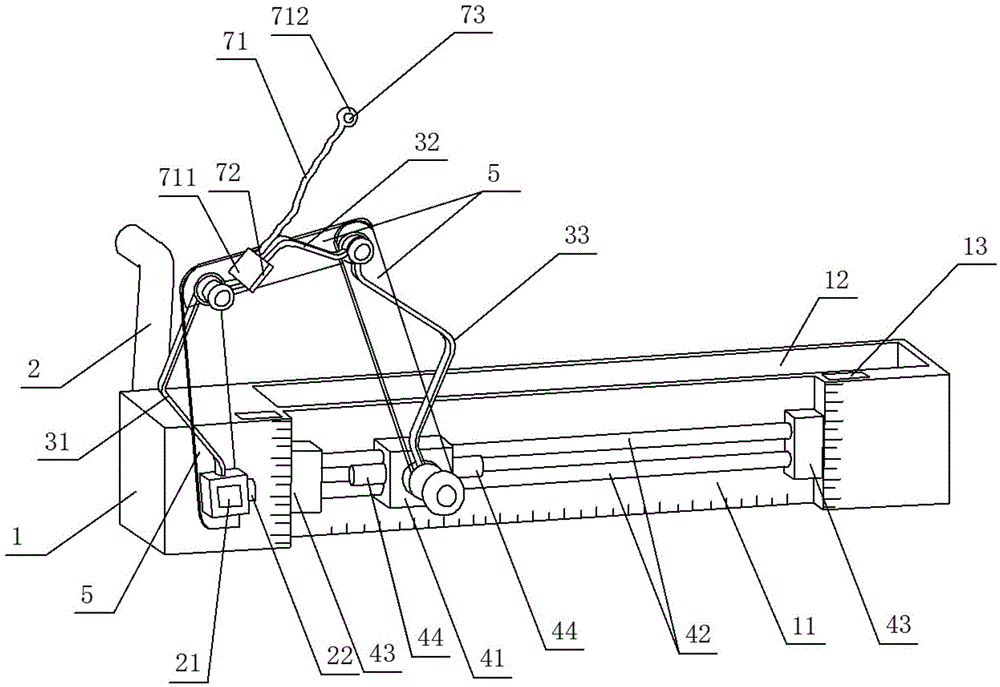

Rotary part on-machine precise and quick alignment device and method

ActiveCN111644878AFine adjustmentThe adjustment process is simple and convenientAutomatic control devicesMeasurement/indication equipmentsMicro nanoProcess engineering

The invention discloses a rotary part on-machine precise and quick alignment device and method, and belongs to the technical field of precision / ultra-precision machining. The rotary part on-machine precise and quick alignment device comprises a main controller, a high-precision displacement detection device and a micro-nano displacement adjusting device. The rotary part on-machine precise and quick alignment method comprises the steps that firstly, the high-precision displacement detection device is controlled by the main controller to conduct data acquisition on the excircle runout of a part,acquired data are subjected to low-pass filtering treatment and then least square fitting treatment is conducted; then the maximum deviation of the part and the corresponding deviation angle are calculated, a machine tool main shaft is controlled by the main controller to rotate to be located at the appointed angle, the micro-nano displacement adjusting device is adopted to adjust the displacement of the part within the nanometer-grade to micron-grade range, and then the excircle of the part is detected after adjustment is accomplished; and finally, the adjusting process is repeated until theexcircle runout of the rotary part meets the precision / ultra-precision machining requirement. The rotary part on-machine precise and quick alignment device and method have the advantages of being high in precision, being capable of achieving the submicron grade and even the nanometer grade, being convenient and fast to adjust, high in repeatability of the adjustment accuracy and low in dependenceof the technology of an operator, and easily achieving the automation.

Owner:DALIAN UNIV OF TECH

Tool setting device and tool setting method for gear machining on large-sized press

InactiveCN103692030ASimple structureEasy to installAutomatic control devicesFeeding apparatusHobbingControl theory

The invention relates to a tool setting device and a tool setting method in machining. In order to overcome the defects generated by traditional gear machining, the invention provides the tool setting device used for gear machining on a large-sized press. The tool setting device is characterized by comprising a horizontal shaft and a vertical connecting yoke, wherein the left end of the horizontal shaft is provided with a stud fixed to a T-shaped groove in a facing head disk of a gear hobbing machine; the right end of the horizontal shaft is vertically welded to the vertical connecting yoke; the lower part of the connecting yoke is provided with a mounting sleeve with a mounting hole; a tool setting shaft parallel with the horizontal shaft is arranged in the mounting hole in the mounting sleeve; the end part of the tool setting shaft is provided with a tool setting head. The tool setting method comprises the following steps: fixing the left end of the horizontal shaft of the tool setting device and the T-shaped groove in the facing head disk of the gear hobbing machine, and adjusting the axial position of the gear hobbing machine to enable center cutter teeth or tooth sockets of the gear hobbing machine to be aligned with the tool setting head. According to the device and the method, the technical problems that tooth profiles of the left tooth surface and the right tooth surface of a to-be-processed gear on the large-sized press are asymmetric, and the precision of the tooth surfaces are hard to guarantee are fundamentally solved.

Owner:RONGCHENG METAL FORMING MACHINE GROUP

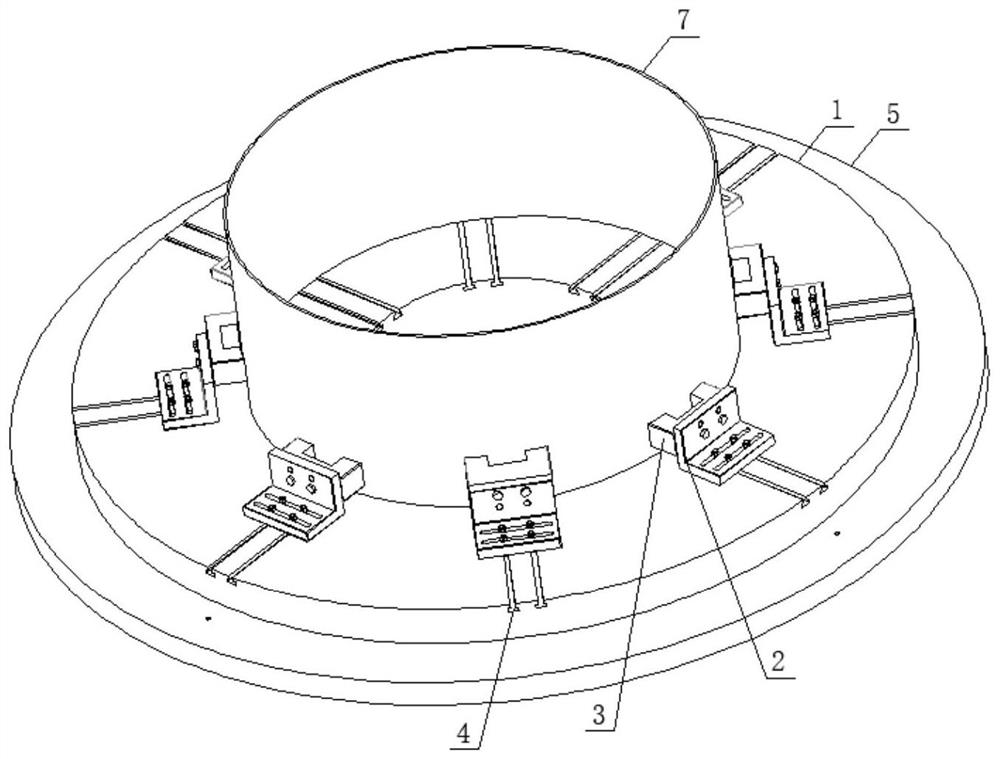

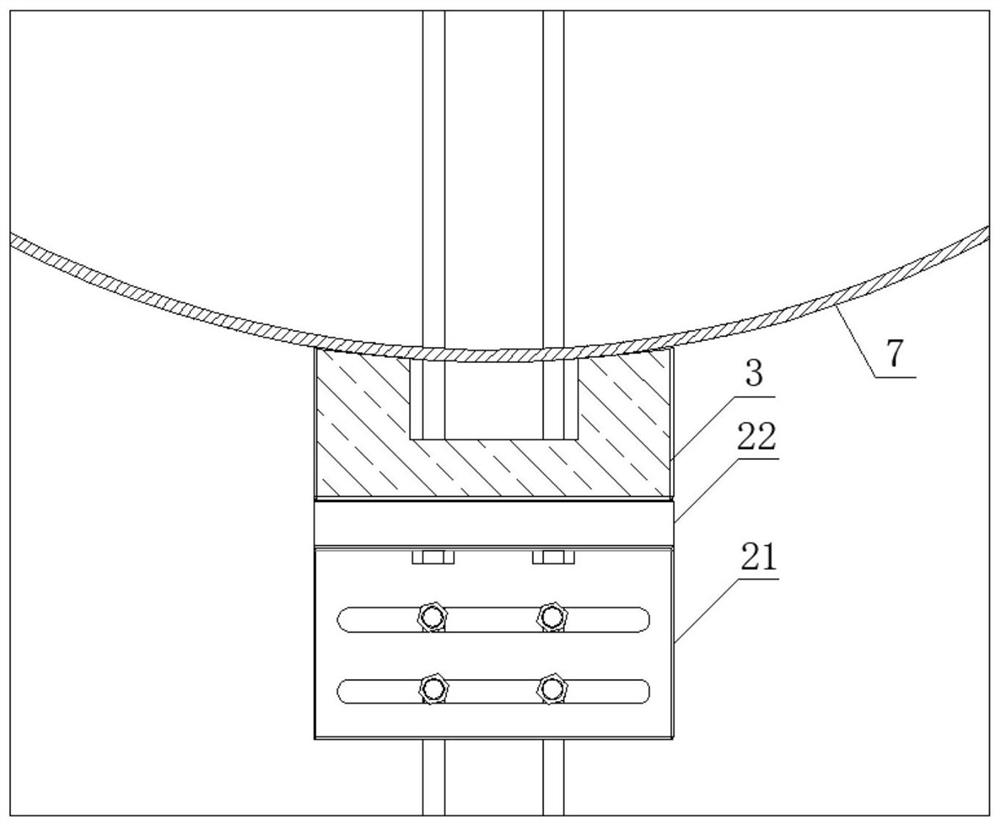

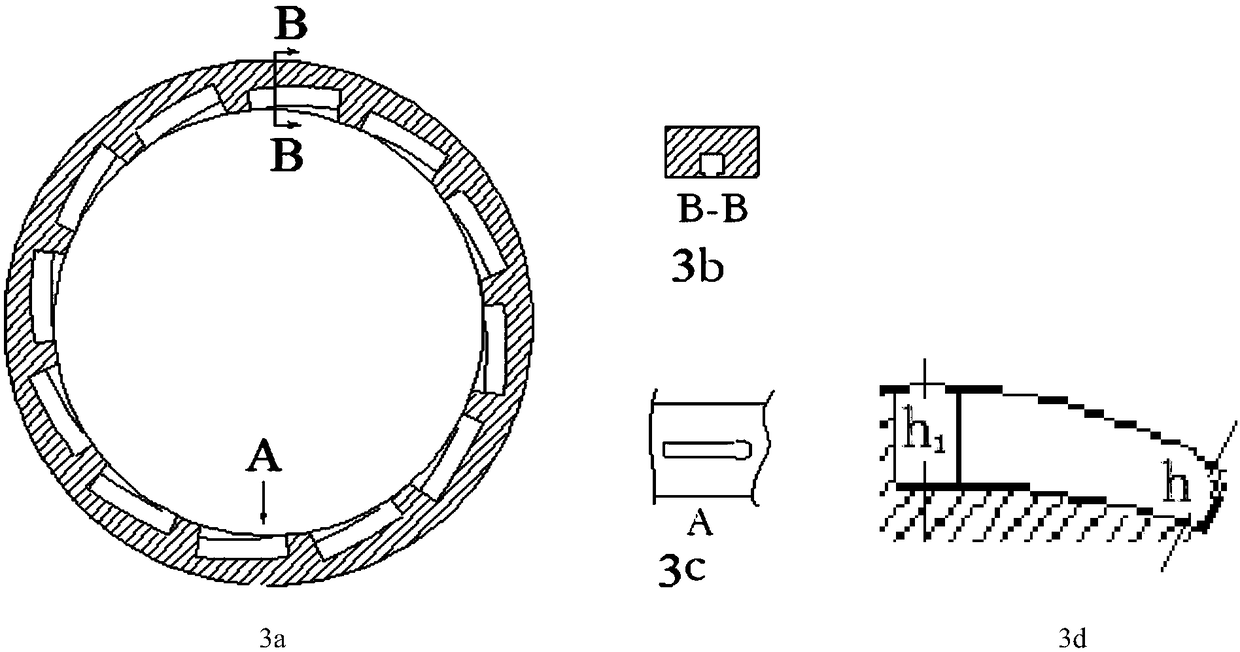

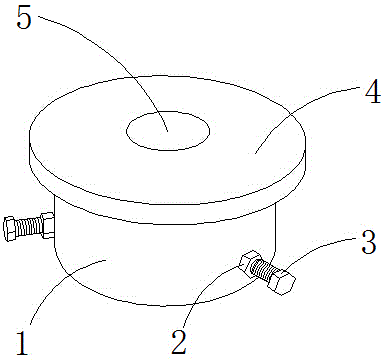

Positioning and clamping device for cylindrical parts

InactiveCN112440071AAchieve clampingAchieve relaxationWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringClip device

The invention provides a positioning and clamping device for cylindrical parts. The positioning and clamping device comprises a tray, a positioning bent plate and a top block, wherein a plurality of slideways are uniformly distributed on the tray in the circumferential direction, and the slideways have inverted T-shaped cross sections and extend from the edge of the tray to the middle of the tray.The positioning bent plate comprises a positioning plate and a mounting plate, wherein the positioning plate is fixed on the slideways of the tray through bolts, and the mounting plate is verticallyfixed on the upper portion of the positioning plate. The top block is arranged on the side, close to the middle of the tray, of the mounting plate. According to the positioning and clamping device forthe cylindrical parts, the positioning bent plate is installed on the slideways through the bolts, the positioning bent plate can slide along the slideways by unscrewing the bolts so that the parts can be clamped and loosened, and the positioning and clamping device is simple and reasonable in structure, low in manufacturing cost, suitable for clamping the cylindrical parts of different sizes within a certain range, high in universality, capable of realizing alignment and adjustment of the position of the parts by moving the positioning bent plate, easy to operate, and high in clamping precision.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

An automatic centering clamping mechanism

ActiveCN106272160BRealize clampingRealize alignmentWelding/cutting auxillary devicesWork holdersEngineeringCentring

The invention discloses an automatic centring and clamping mechanism. An outer ring body is arranged on the surface of the outer circumference of an inner ring body in a sleeving manner, and the outer ring body and the inner ring body are in clearance fit. The ball head ends of telescopic shafts in a plurality of telescopic bodies penetrate guide holes in the circumference of the inner ring body and then are mounted in sliding grooves located in the inner circle surface of the outer ring body. A worm gear body is fixed to the end face of the inner ring body. A worm is fixed to the end face of the outer ring body through a bearing pedestal and engaged with the worm gear body, and therefore the outer ring body and the inner ring body generate relative rotation. The number of the guide holes in the surface of the outer circumference of the inner ring body, the number of the sliding grooves in the surface of the inner circumference of the outer ring body and the number of the telescopic shafts are the same. According to the automatic centring and clamping mechanism, in the clamping process, all clamping blocks stretch out and retract back at the same time through telescopic bolts, and the clamping blocks are rounded at the same time in the clamping process; and in the whole implementation process, no machine tool is needed, operation is easy and convenient, efficiency is high, and the high application and popularization value is achieved.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

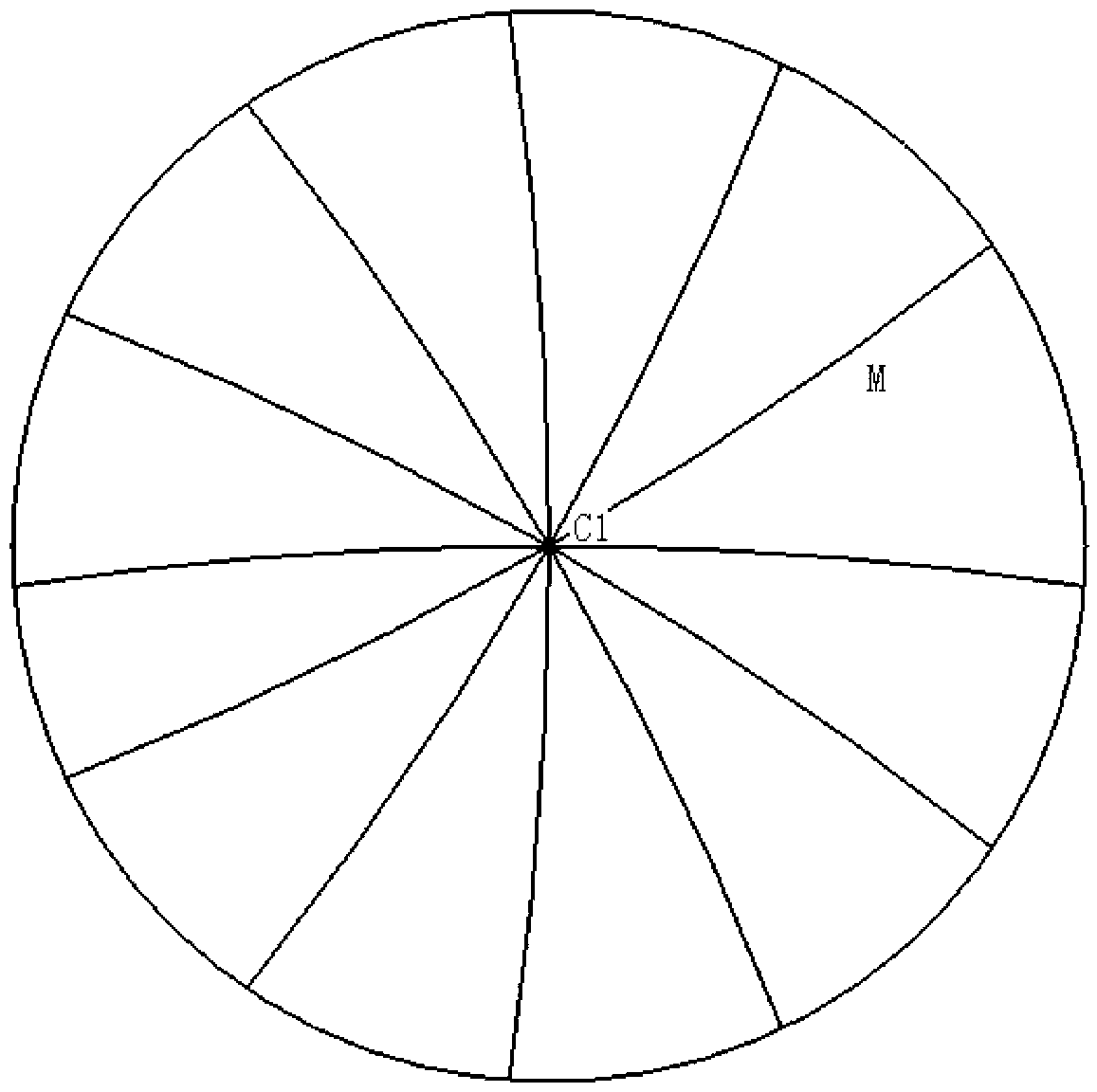

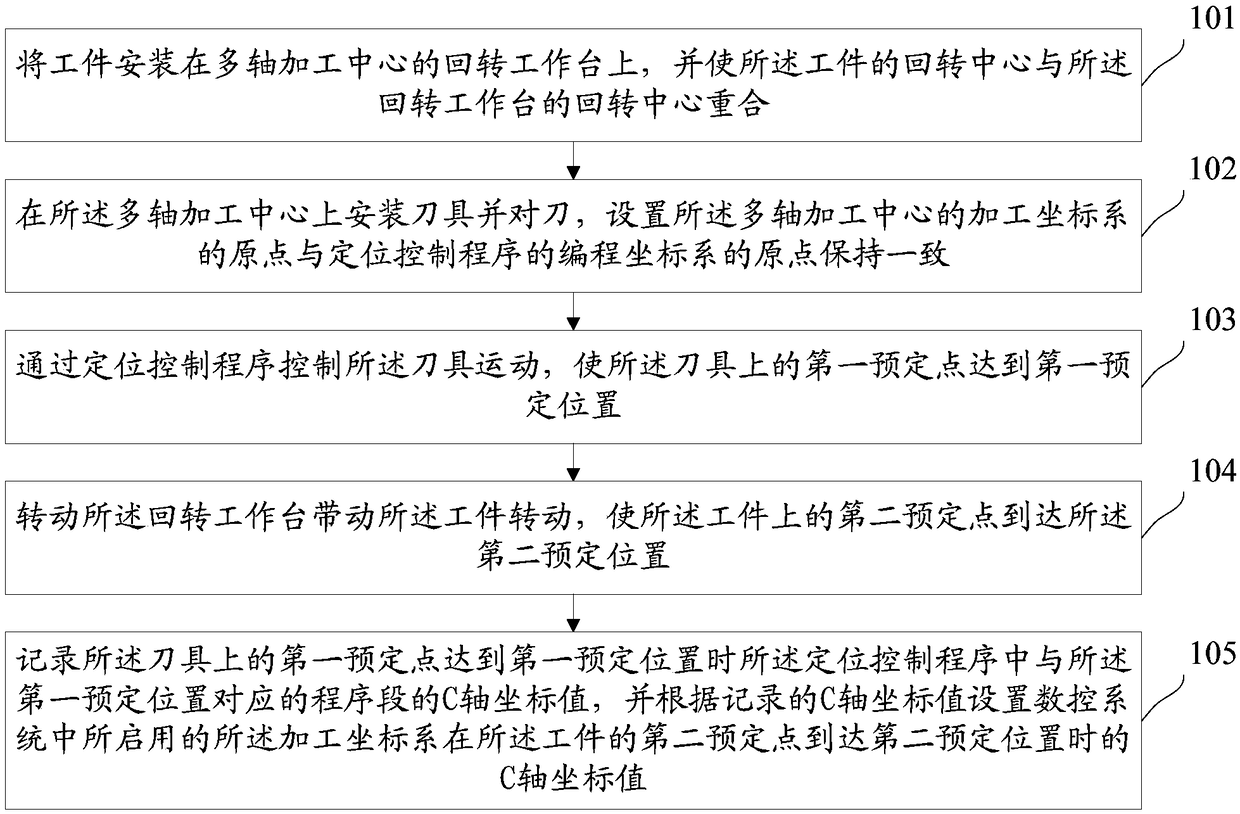

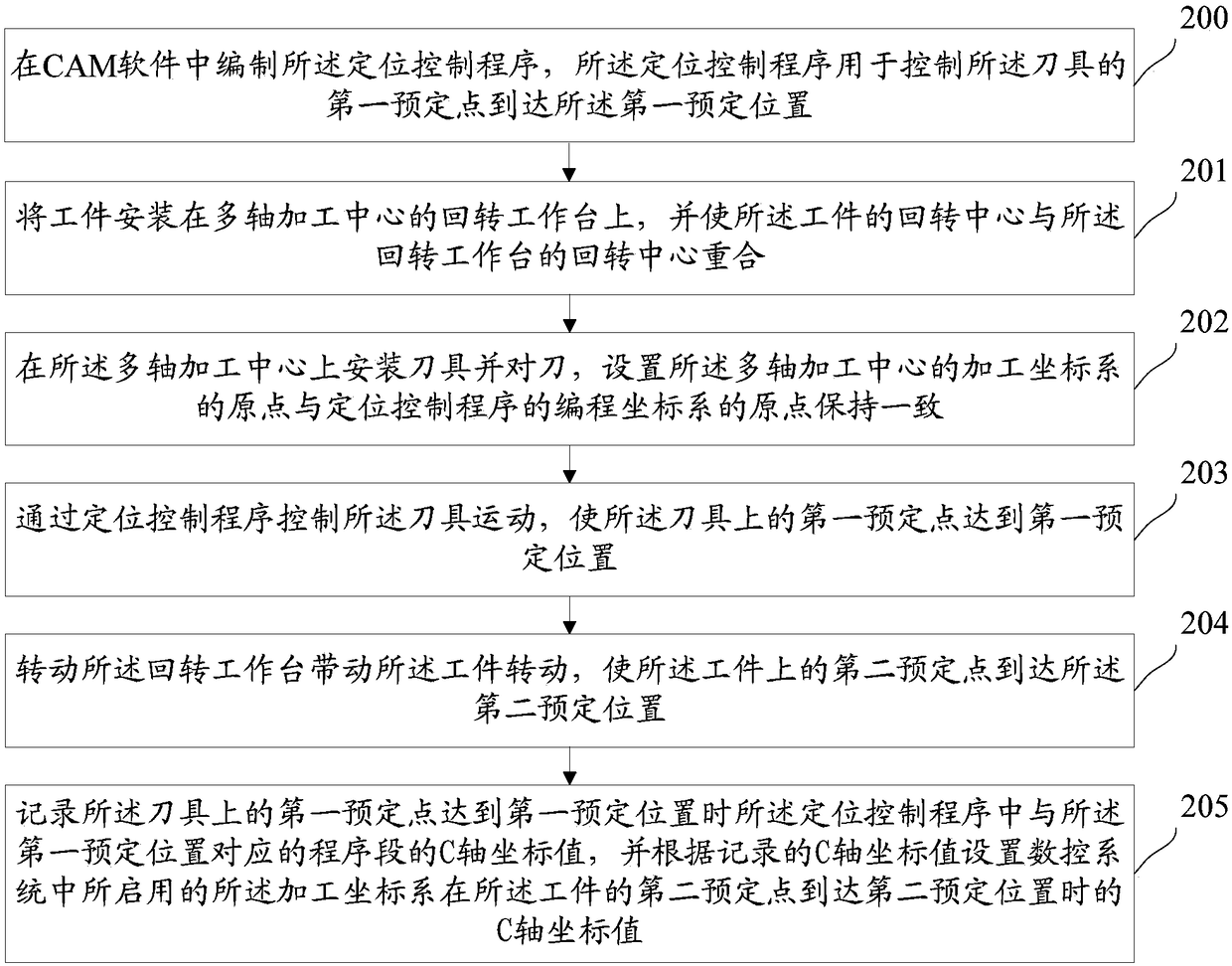

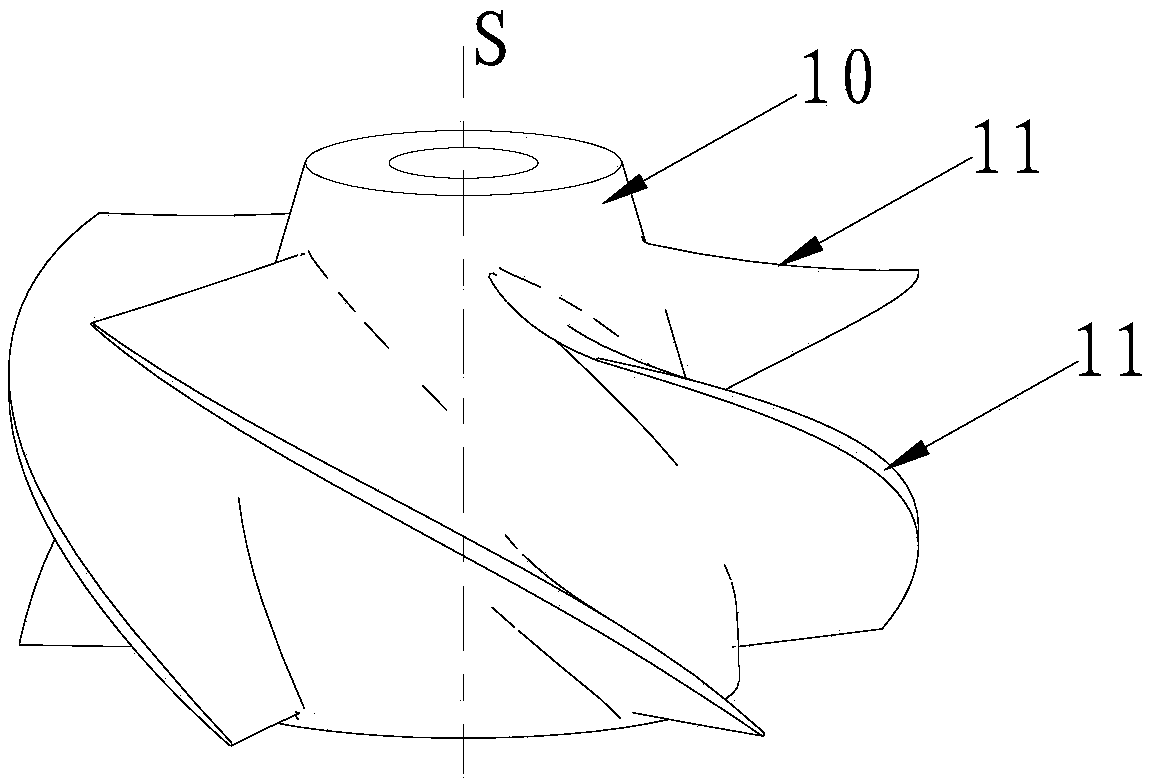

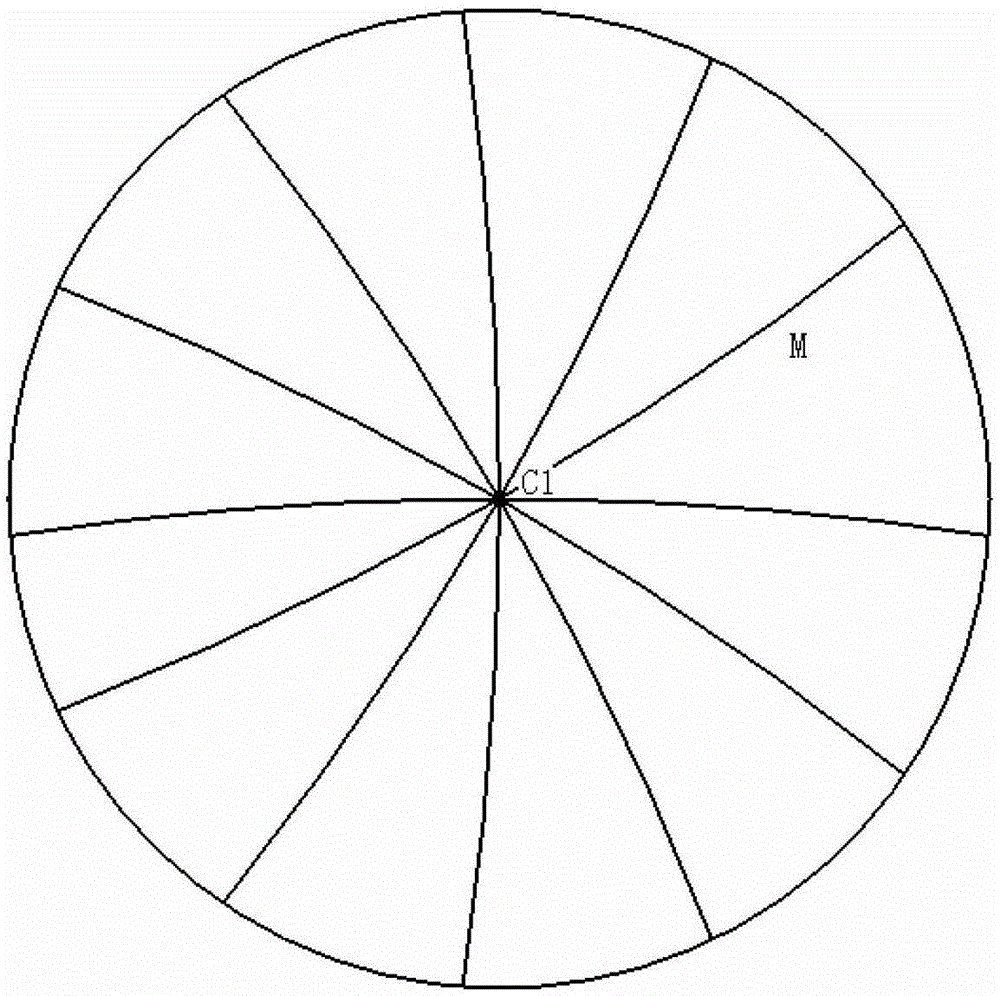

Workpiece alignment method

ActiveCN108098455ARealize alignmentEasy to operateAutomatic control devicesFeeding apparatusProgram segmentPosition control

The invention discloses a workpiece alignment method, and belongs to the technical field of machining. The method comprises the steps that a workpiece is installed on a rotary workbench of a multi-shaft machining center, and the rotation center of the workpiece is enabled to coincide with the rotation center of the rotary workbench; a cutter is installed on the multi-shaft machining center, cutteraligning is carried out, an original point of a processing coordinate system is set to be kept consistent with an original point of a programming coordinate system of a positioning control program, and the original point of the machining coordinate system is located on the rotation center of the workpiece; the positioning control program controls the cutter to move so as to make a first preset point on the cutter reach a first preset position; the rotary workbench is rotated to drive the workpiece to rotate so as to make a second preset point of the workpiece reach a second preset position, wherein the second preset position is a preset position corresponding to the first preset position; and C-axis coordinate values of the corresponding program segments in the positioning control programare recorded, and a C-axis coordinate value of a coordinate system started in a numerical control system is set according to the recorded C-axis coordinate values.

Owner:WUHAN MARINE MACHINERY PLANT

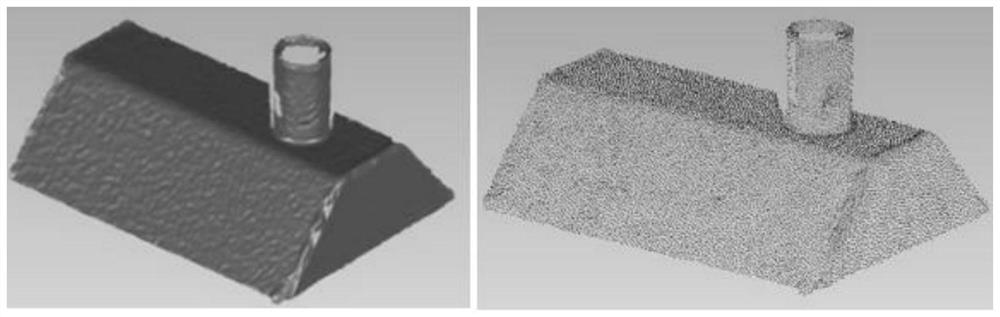

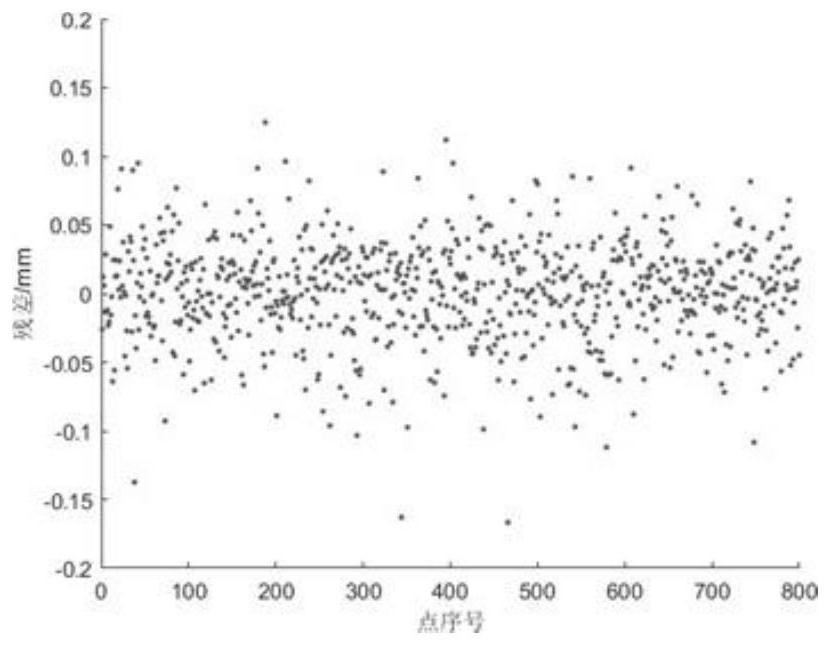

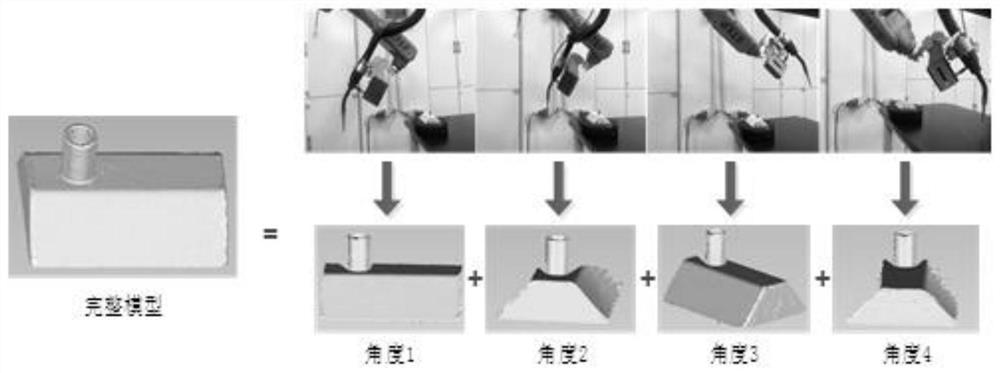

Workpiece position alignment method using point cloud registration technology and three-dimensional reconstruction technology

PendingCN113421291AKeep detailsRealize alignmentImage enhancementImage analysisReference modelingPoint cloud

A workpiece position alignment method using a point cloud registration technology and a three-dimensional reconstruction technology comprises the steps that firstly, a point cloud model is established through the point cloud technology, then multi-angle point cloud model coarse splicing is carried out according to the motion relation of a high-precision mechanical arm and the result of hand-eye calibration, then precise splicing is carried out through an ICP algorithm, a weldment reference model is obtained through point cloud fusion, then a workpiece model in an actual scene and the established reference model are aligned through the point cloud registration technology, the pose conversion relation between the workpiece model and the established reference model is obtained, the system can sense the pose of the workpiece in real time, and therefore positioning and alignment of the workpiece are achieved. The problem of workpiece positioning and alignment under the condition that a workpiece model is unknown is solved, and then an accurate robot motion path is obtained.

Owner:北京华睿盛德科技有限公司

Apparatus and method for machining gas turbine diffuser

InactiveCN106141741ASolve unprocessable problemsRealize clampingTurning machinesPositioning apparatusEngineeringMachining process

The invention discloses an apparatus and method for machining a gas turbine diffuser. The apparatus comprises a first fixture, wherein the first fixture comprises a first chassis, a positioning pin and a connecting bolt. By adopting the technical scheme, the apparatus and the method have the beneficial effects: the difficulty in machining workpiece is solved; by adopting the apparatus, the clamping and centering of the workpiece are realized, and the dimension precision at various positions of the workpiece can be controlled within 0.01mm; and moreover, the machining process is simple and easy to operate.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

Tool turret device applied to machine tool with Y axis

ActiveCN109794808AExpand the scope of processingPrecise positioningFeeding apparatusMetal working apparatusAcute angleEngineering

The invention discloses a tool turret device applied to a machine tool with a Y axis. The tool turret device applied to the machine tool with the Y axis comprises a tool turret and a driving mechanism. The driving mechanism comprises an X axis driving assembly and a Y axis driving assembly. The Y axis driving assembly drives the X axis driving assembly to move and the moving direction and a spindle installation datum panel form a first acute angle, and the X axis driving assembly drives the tool turret to move and the moving direction and the moving direction of the X axis driving assembly form a second acute angle. The tool turret device applied to the machine tool with the Y axis can realize the machining of a workpiece milling plane.

Owner:津上精密机床(浙江)有限公司

Alignment method for radial magnetic suspension stator element of gyroaccelerometer

ActiveCN110645884ARealize alignmentElectric/magnetic position measurementsUsing electrical meansStator inductanceTester device

An alignment method for a radial magnetic suspension stator element of a gyroaccelerometer includes a turntable and a cross slide table. A stator tool is arranged on the turntable and connected with an inductance tester. An adjustment mechanism is arranged on the cross slide table. The adjustment mechanism is provided with a torque sensor. After adjusting a pitch angle, a yaw angle and a center height of a rotor tool, by passing a stator element through a rotor element, variation on inductance values of the stator element is measured through the inductance tester and an axial coincidence position is obtained according to the variation on inductance values of the stator element. By contacting a rotor element with coils of the stator element, a contact force is measured by the torque sensorand sent to an industrial personal computer for calculating a coaxial position. By the method, coincidence of the stator element to the rotor element in the axial position and coaxial alignment of theradial position of the stator element are achieved.

Owner:SHAANXI AEROSPACE TIMES NAVIGATION EQUIP CO LTD +1

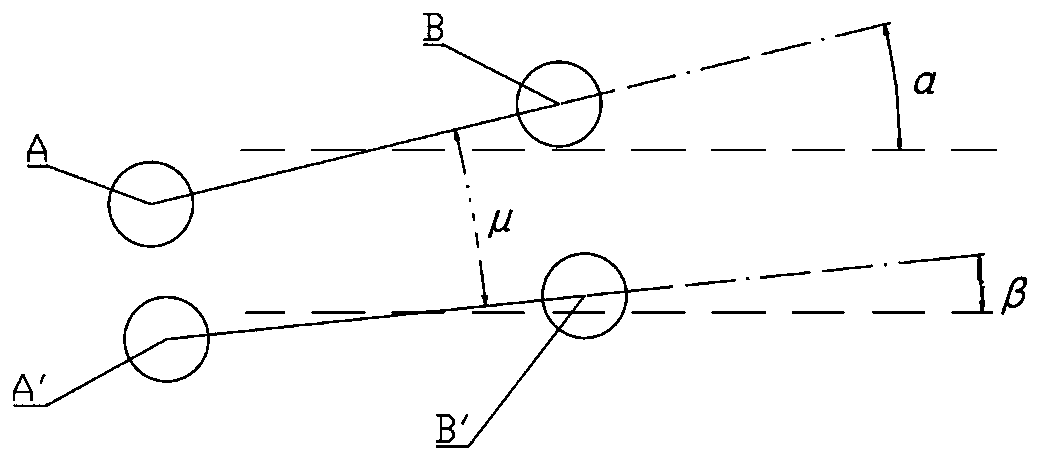

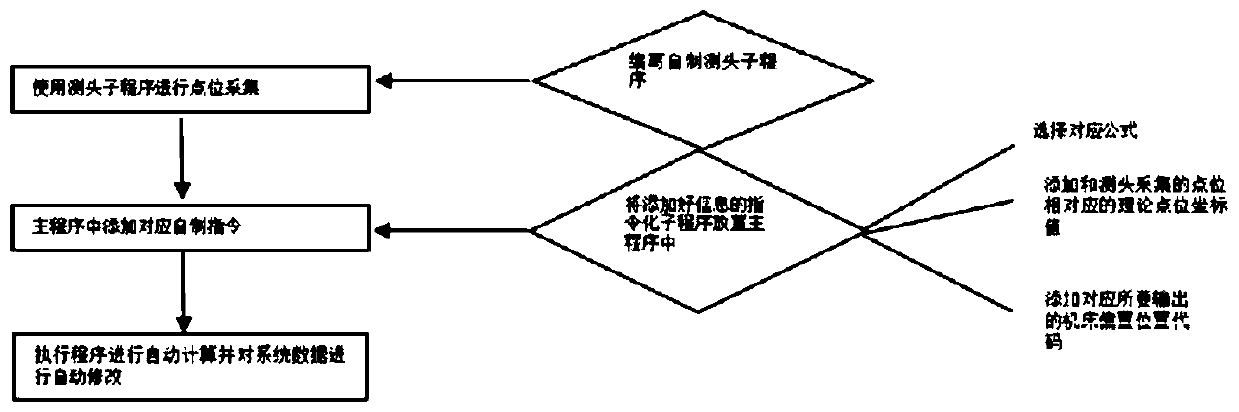

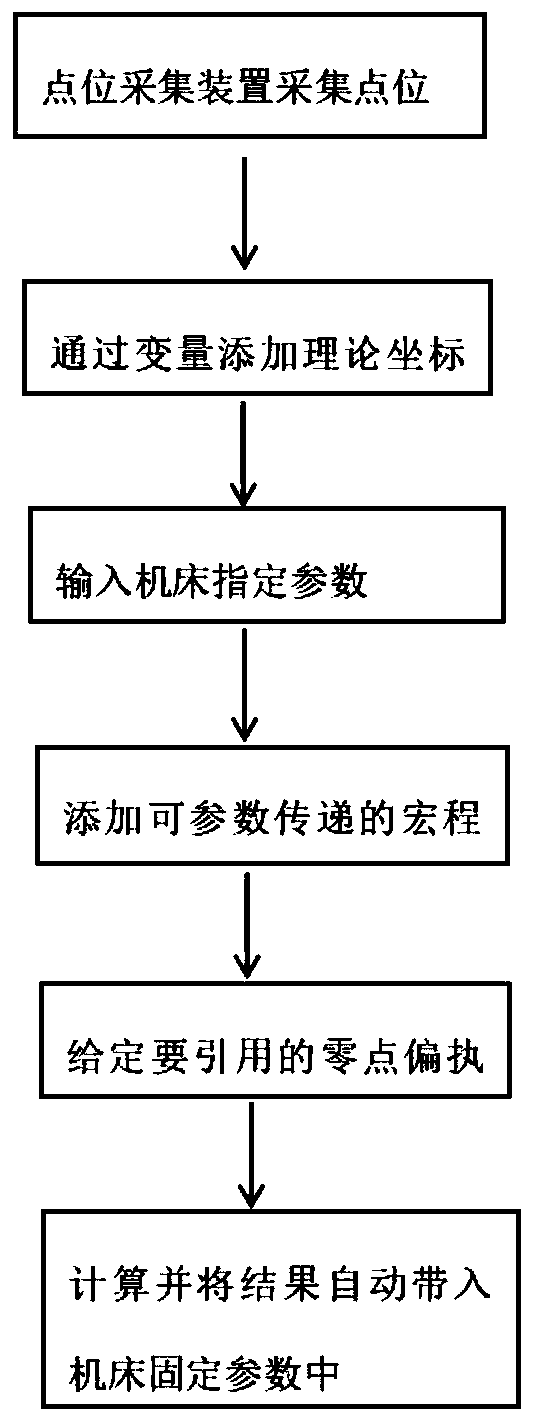

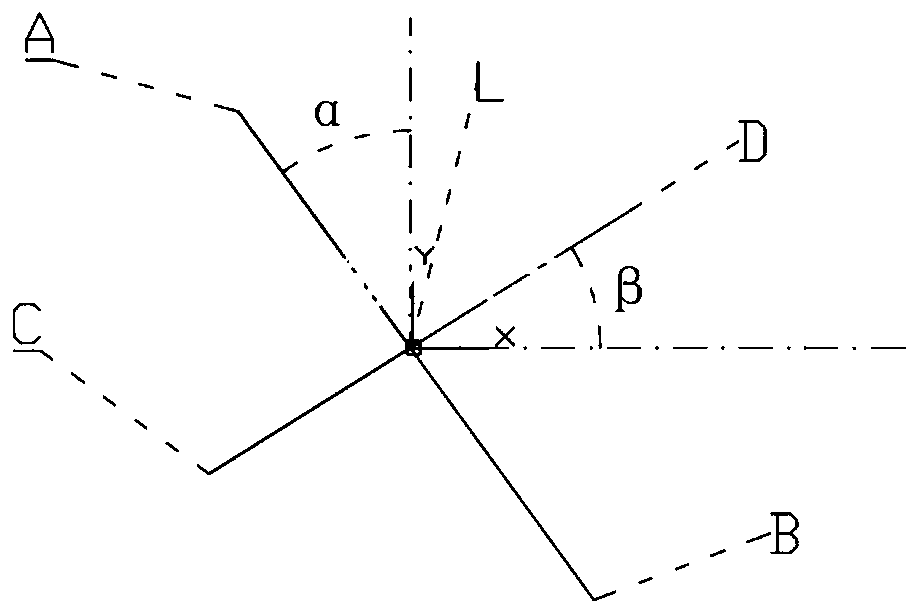

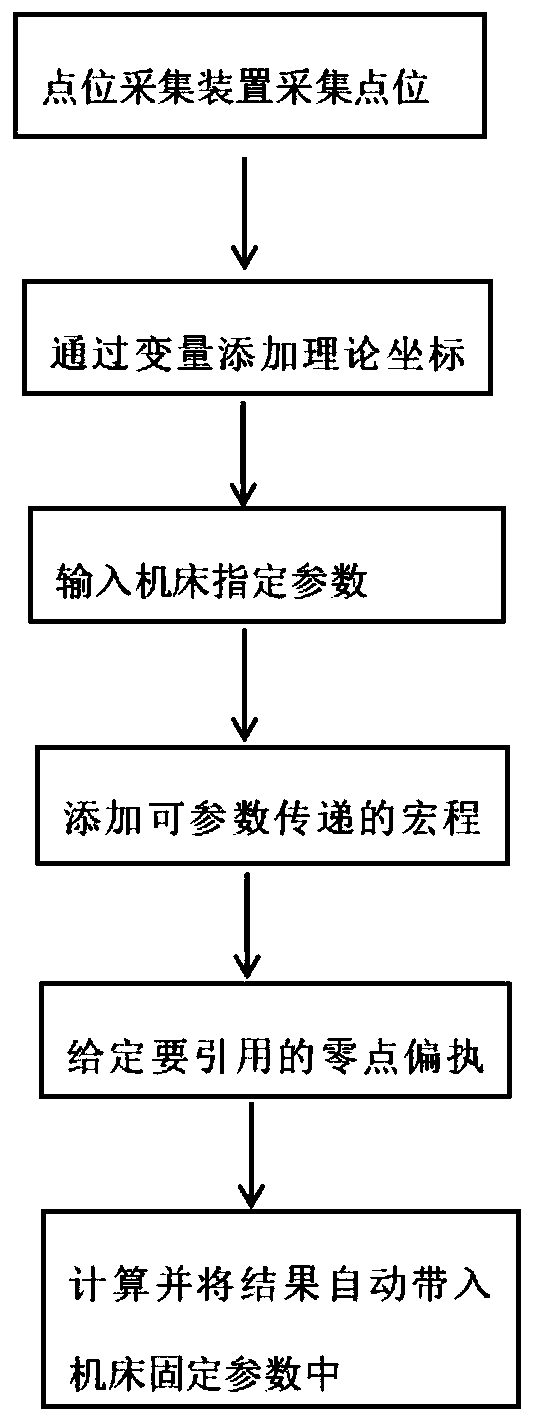

Single-machine calculation-point-free automatic alignment machining method

PendingCN111552232ARealize alignmentRealize automatic generationProgramme controlComputer controlNumerical controlProcess engineering

The invention belongs to the technical field of numerical control machining, and particularly relates to a single-machine calculation-point-free automatic alignment machining method. A self-made measuring head point collecting program is used, and a calculation formula is designed according to different machining requirements. Point position acquisition and automatic calculation of coordinate system offset angle point positions are realized. The technical problems that in the current production preparation process, errors are prone to occurring and efficiency is low due to the fact that offsetis calculated through manual point location alignment are solved. The numerical control machining center uses the measuring head for alignment and then directly inputs the measuring head into a specific area of an equipment operation system, needed parameters are automatically generated, programs are automatically read, human intervention is not needed, the error rate is reduced, time is saved, and production efficiency is improved.

Owner:HARBIN DONGAN ENGINE GRP

Bottom mold locking device and using method thereof

ActiveCN109664481AEnables automatic alignmentRealize alignmentHollow articlesGlass productionEngineeringMechanical engineering

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

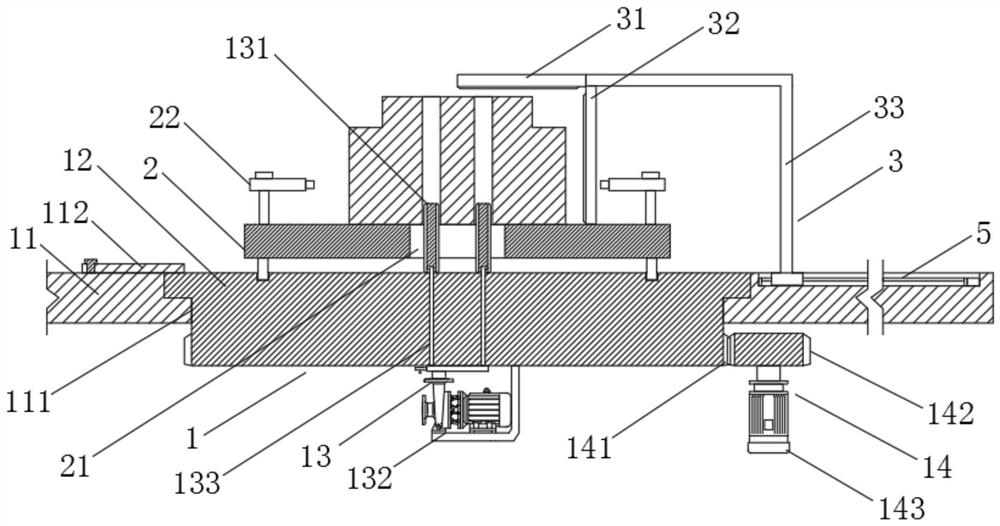

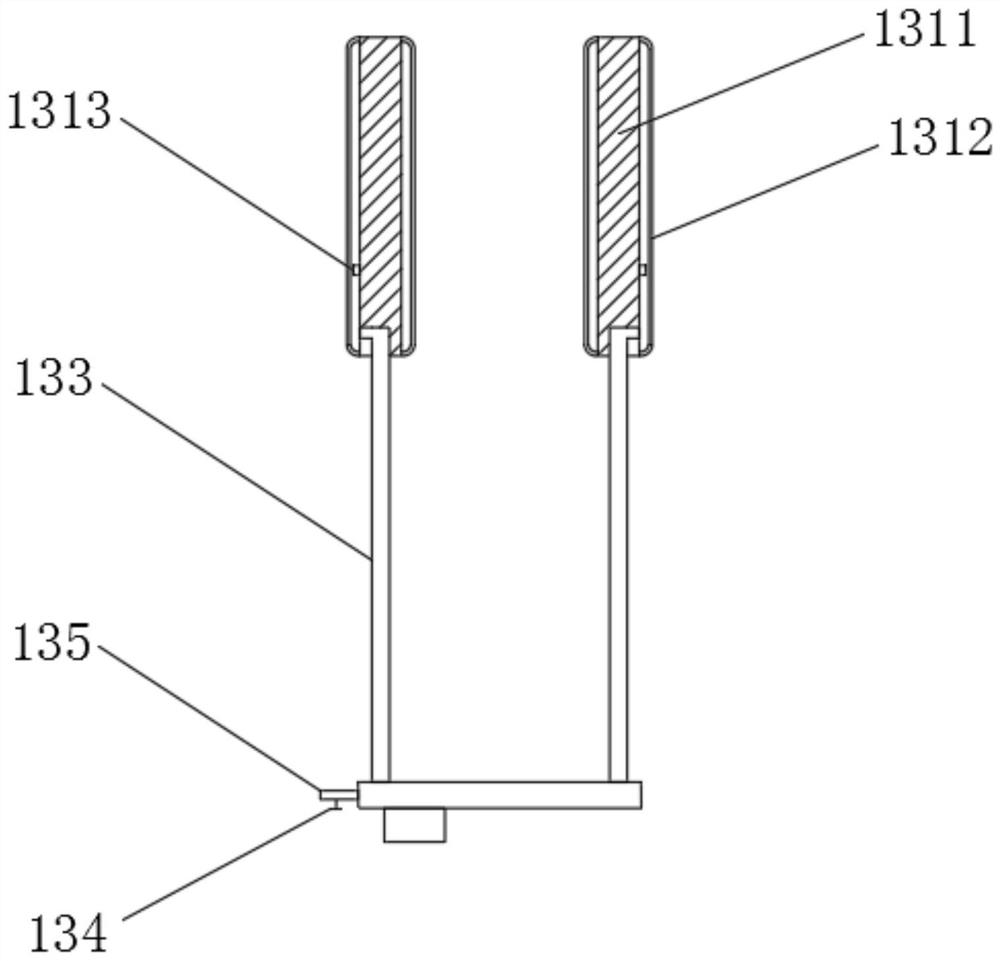

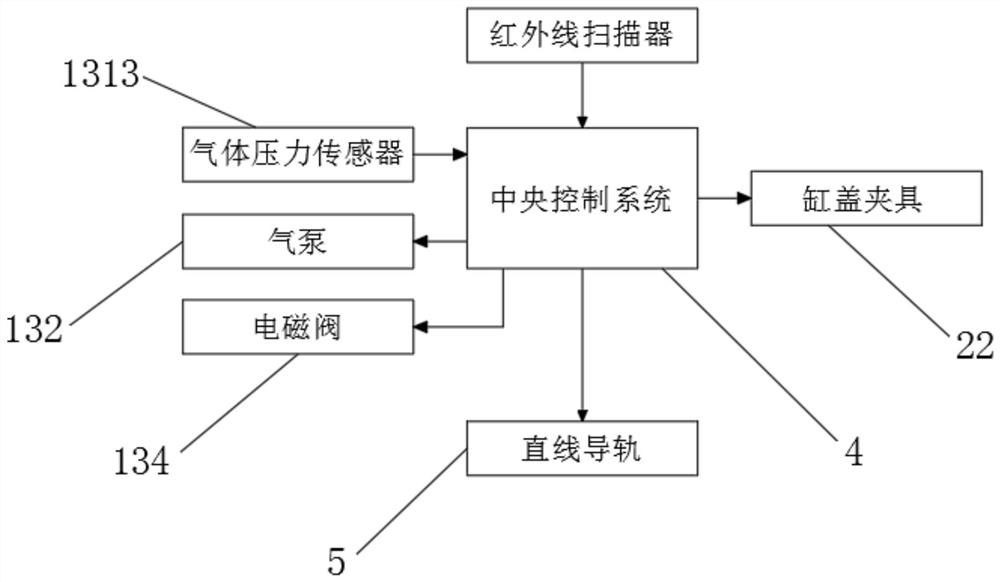

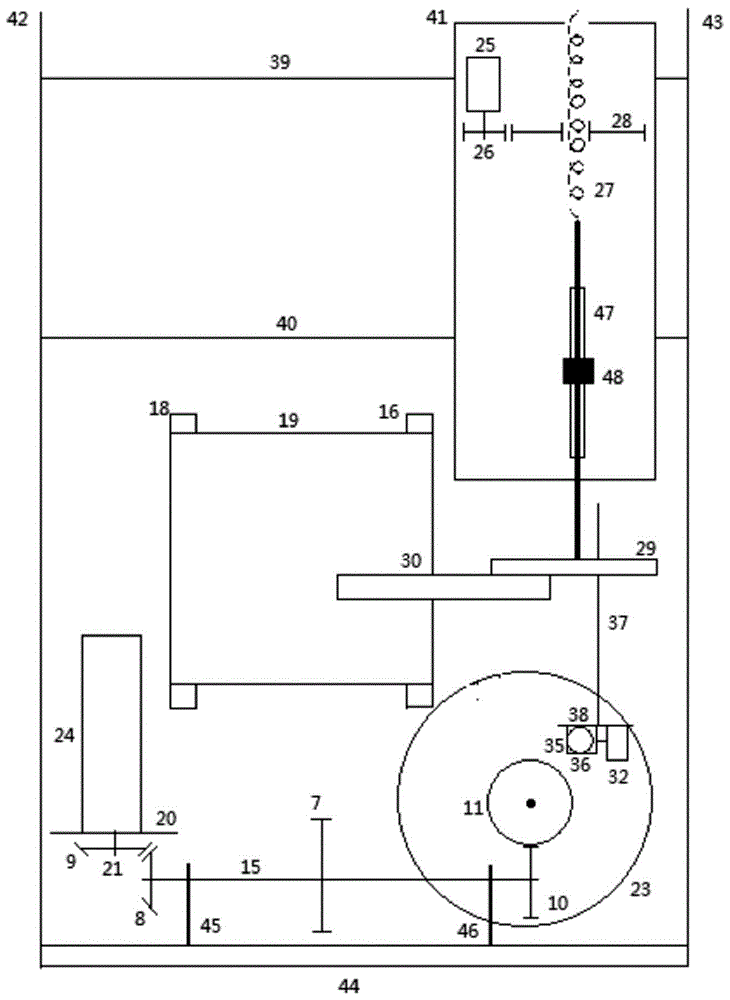

Automatic alignment and detection system based on diesel engine cylinder cover machining machine tool

ActiveCN113664616ARealize alignmentDoes not hinder processingAutomatic control devicesMeasurement/indication equipmentsRotary stageMachined surface

The invention relates to an automatic alignment and detection system based on a diesel engine cylinder cover machining machine tool. The system comprises a machine tool workbench, a tool clamp, a cylinder cover surface scanning device and a central control system. The machine tool workbench comprises a fixed table, a rotating table clamped in the middle of the fixed table, a cylinder cover limiting assembly fixed on the rotating table, and a driving device for driving the rotating table to rotate. The tool clamp is arranged on the rotating table and drives a cylinder cover to rotate along with the rotating table, a through hole is formed in the middle of the tool clamp, and the cylinder cover limiting assembly penetrates through the through hole and extends into a hole system in the lower surface of the cylinder cover so as to fix the cylinder cover. The cylinder cover surface scanning device is arranged on the fixed table and is used for scanning feature point data of a to-be-machined surface of the rotating cylinder cover. The central control system is used for receiving and processing the feature point data of the to-be-processed surface of the cylinder cover and controlling the tool clamp to adjust the position of the cylinder cover. Automatic alignment and detection of the cylinder cover can be achieved, the whole system is ingeniously combined with the machine tool, the space of the machine tool is not occupied, and work of the machine tool is not hindered.

Owner:ANQING CSSC MATING POWER

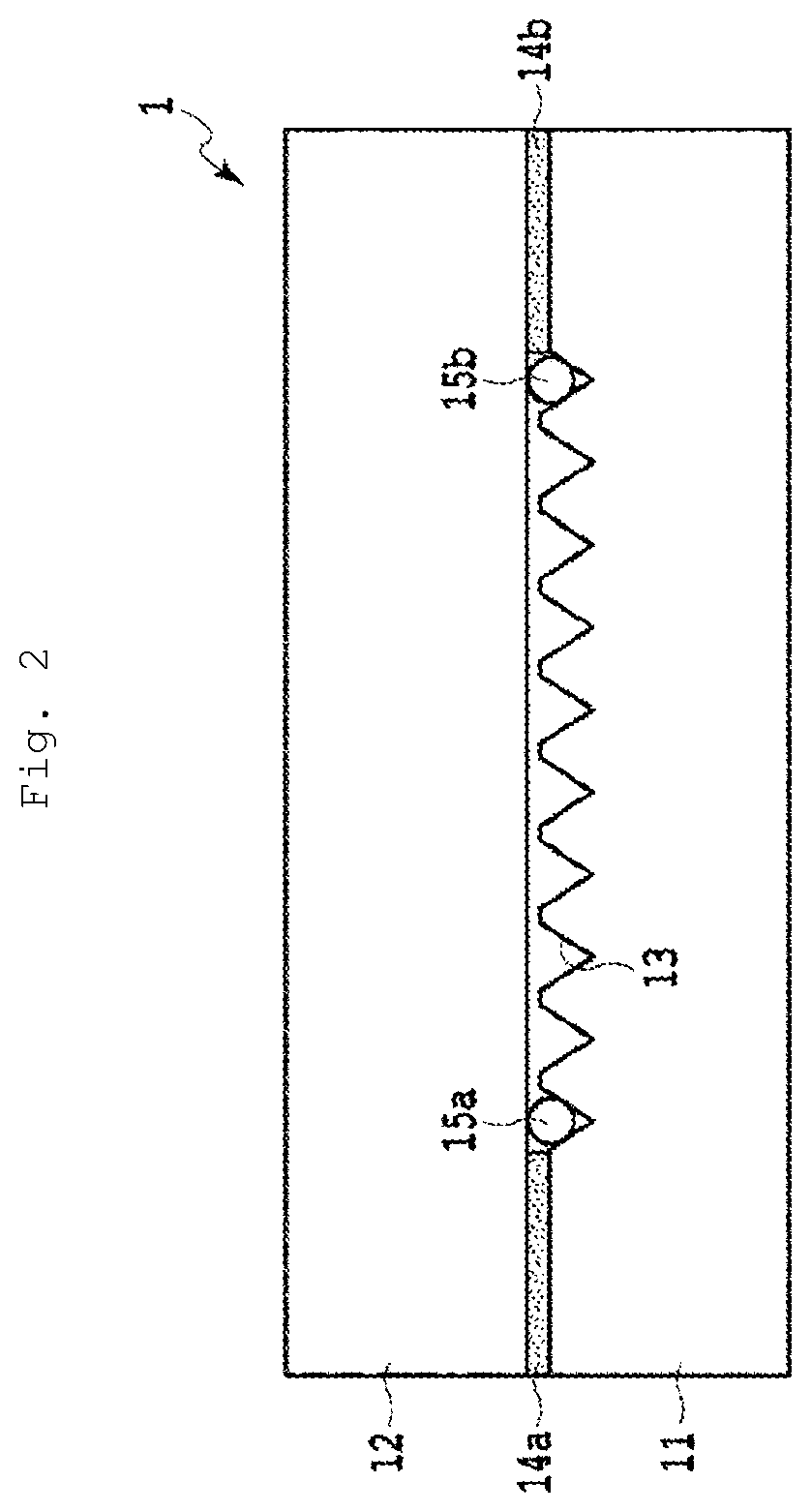

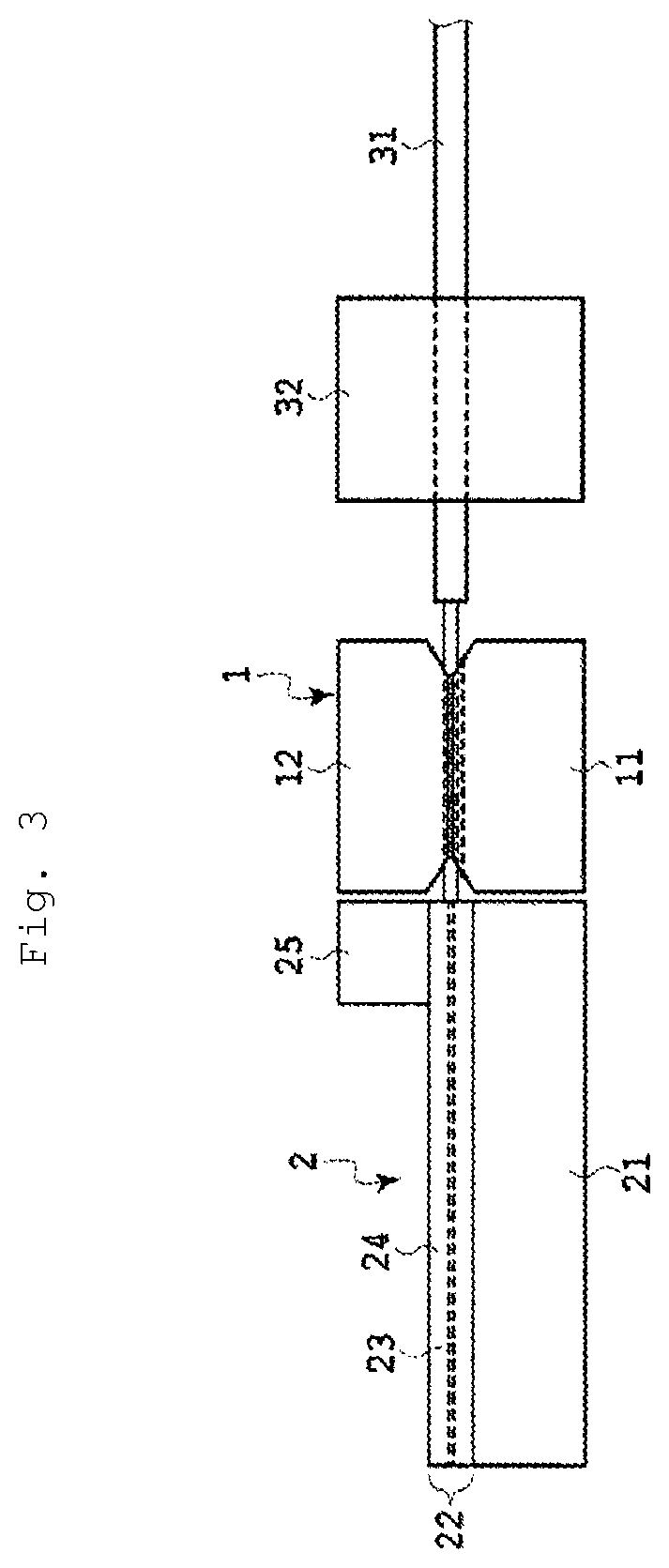

Optical Circuit and Optical Connection Structure

Optical alignment between an optical waveguide device and an optical connection part is realized easily and at low cost. An optical circuit in which optical waveguides to be connected to optical fibers are formed includes: an alignment optical waveguide configured to be opposed to, on an optical waveguide edge face to which an optical connection part having guide holes for insertion of core wires of the optical fibers is to be fixed, a guide hole into which an alignment optical fiber is to be inserted; and a light path changing member configured to change a path of light to a vertical direction with respect to the optical axis direction of the core of the alignment optical waveguide.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

Single-machine automatic alignment calculation-point-free machining method

PendingCN111552230ARealize alignmentEfficiently detects underlining errorsNumerical controlProcess engineeringPoint location

The invention belongs to the technical field of numerical control machining, and particularly relates to a single-machine automatic alignment calculation-point-free machining method. A self-made measuring head point collecting program is used, and a calculation formula is designed according to different machining requirements. Point position acquisition and automatic calculation of coordinate system offset angle point positions are realized. The technical problems that in the current production preparation process, errors are prone to occurring and efficiency is low due to the fact that offsetis calculated through manual point location alignment are solved. By using the method to process the blank benchmark, the time for manually straightening the product is reduced. At the same time, theadded cross curve intersection angle verification and theoretical point position calibration can effectively discover alignment errors or workpiece lineation errors. The program performs automatic reading without human intervention, so that the error rate is reduced, the time is saved, and the production efficiency is improved.

Owner:HARBIN DONGAN ENGINE GRP

A centering calibration device for a sensor-rotating swing-arm profiler measuring head

A swing arm type contourgraph measuring head alignment calibration device with a rotating sensor comprises a contourgraph measuring head, a contourgraph measuring head fine adjustment mechanism, a transverse arm, a stand column, a balance weight, a transverse arm rotary table, a workpiece rotary table and an optical measuring head, wherein the optical measuring head is fixed on the workpiece rotary table and carries out rotating motion around the contourgraph measuring head, outer contour data of the contourgraph measuring head are obtained, central position information of the contourgraph measuring head is calculated through a data processing algorithm, and alignment adjustment of the contourgraph measuring head and the workpiece rotary table is achieved through the adjustment of the contourgraph measuring head fine adjustment mechanism. According to the swing arm type contourgraph measuring head alignment calibration device, the alignment adjustment of the contourgraph measuring head and the workpiece rotary table is achieved, and a practical solution is provided for inplace measurement of a swing arm type contourgraph on an optical processing site.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Simple three-claw centering clamp for steel pipe machining

InactiveCN106312602ASimple structureWorking principle is clearPositioning apparatusMetal-working holdersSteel tubeEngineering

The invention discloses a simple three-claw centering clamp for steel pipe machining, and belongs to the technical field of machine manufacturing. The simple three-claw centering clamp comprises a cylindrical steel pipe. Three fixing nuts are evenly distributed on the same circumference of the outer circle surface of the cylindrical steel pipe. Adjusting bolts are arranged in the fixing nuts correspondingly. A cylindrical clamping disc is arranged at one end of the cylindrical steel pipe. A center hole communicating with the interior of the cylindrical steel pipe is formed in the center of the cylindrical clamping disc. The simple three-claw centering clamp is simple in structure, the work principle is clear, and the basic function of steel pipe clamping is achieved. Through the interaction of the adjusting bolts and the fixing nuts, steel pipe clamping center alignment and fine adjustment are achieved, and the steel pipe machining precision is improved. The clamp manufacturing cost is extremely low, operation is easier, and later maintaining on the clamp is not needed.

Owner:扬州巨业耐磨复合材料有限责任公司

Alignment device and alignment method for vertical looper track

ActiveCN106078189BEasy to detectRealize alignmentFlexible work arrangmentsMetal working apparatusEngineeringElectric wire

The invention discloses an alignment device and alignment method for a vertical type loop rail. The alignment device comprises a trolley and a steel wire. The trolley is arranged on the vertical rail and can move along the rail. The steel wire is vertically arranged outside the rail in the length direction of the rail. The steel wire is connected with the rail through an electric wire. An indicator light and a power source are sequentially arranged on the electric wire. A dial rod is arranged on the trolley. If the deviation of the rail is within a reasonable range, a detection head of the dial rod makes contact with the steel wire, and otherwise, the detection head of the dial rod does not make contact with the steel wire. High-altitude detection is not needed; and the alignment device and alignment method are simple, visual, safe and reliable, operation is easy, convenient and fast, and the working efficiency is improved.

Owner:CHINA FIRST METALLURGICAL GROUP

Clamping device capable of being used for improving grinding precision of shaft parts

PendingCN112589674AImprove grinding accuracyRealize clampingGrinding work supportsAviationMechanical engineering

The invention belongs to the technical field of aviation equipment manufacturing, and particularly relates to a clamping device capable of being used for improving the grinding precision of shaft parts. The clamping device comprises a four-jaw chuck, a flange plate, a locking device, a live center, a tensioning pull rod, an adapter and a locking screw. According to the clamping device capable of being used for improving the grinding precision of the shaft parts, an operator can very easily clamp, align and repair the shaft parts, the grinding precision of the shaft parts is greatly improved, and the rejection rate of the parts is obviously reduced.

Owner:大连长丰实业总公司

Alignment method for radial magnetic levitation stator element of gyro accelerometer

ActiveCN110645884BRealize alignmentElectric/magnetic position measurementsUsing electrical meansGyroscopeAccelerometer

An alignment method for a radial magnetic suspension stator element of a gyroaccelerometer includes a turntable and a cross slide table. A stator tool is arranged on the turntable and connected with an inductance tester. An adjustment mechanism is arranged on the cross slide table. The adjustment mechanism is provided with a torque sensor. After adjusting a pitch angle, a yaw angle and a center height of a rotor tool, by passing a stator element through a rotor element, variation on inductance values of the stator element is measured through the inductance tester and an axial coincidence position is obtained according to the variation on inductance values of the stator element. By contacting a rotor element with coils of the stator element, a contact force is measured by the torque sensorand sent to an industrial personal computer for calculating a coaxial position. By the method, coincidence of the stator element to the rotor element in the axial position and coaxial alignment of theradial position of the stator element are achieved.

Owner:SHAANXI AEROSPACE TIMES NAVIGATION EQUIP CO LTD +1

A Teaching Model of Rod Mechanism

ActiveCN104240581BRealize alignmentReduce manufacturing costEducational modelsEngineeringLaboratory facility

Owner:SHAOGUAN COLLEGE

A Cam Mechanism Research Instrument

InactiveCN104070895BRealize alignmentAdjust the size of the radiusNon-circular curve drawing instrumentsEngineeringCam

Owner:陈志昂

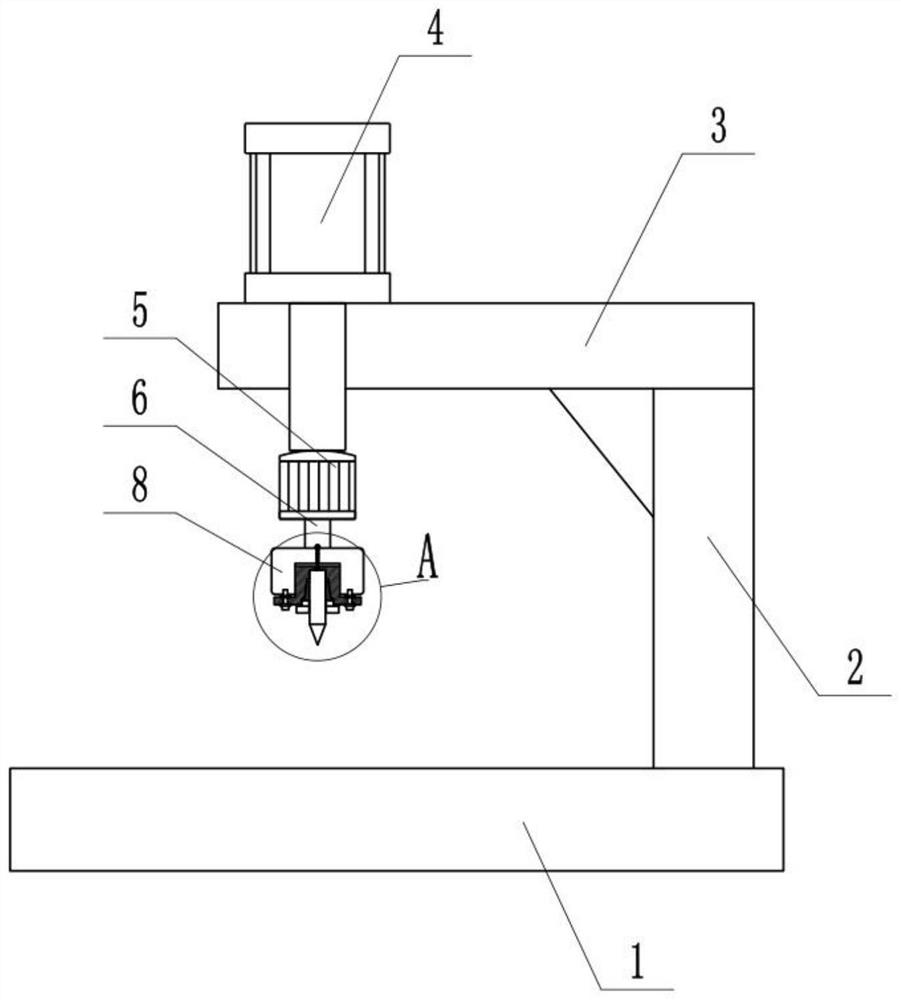

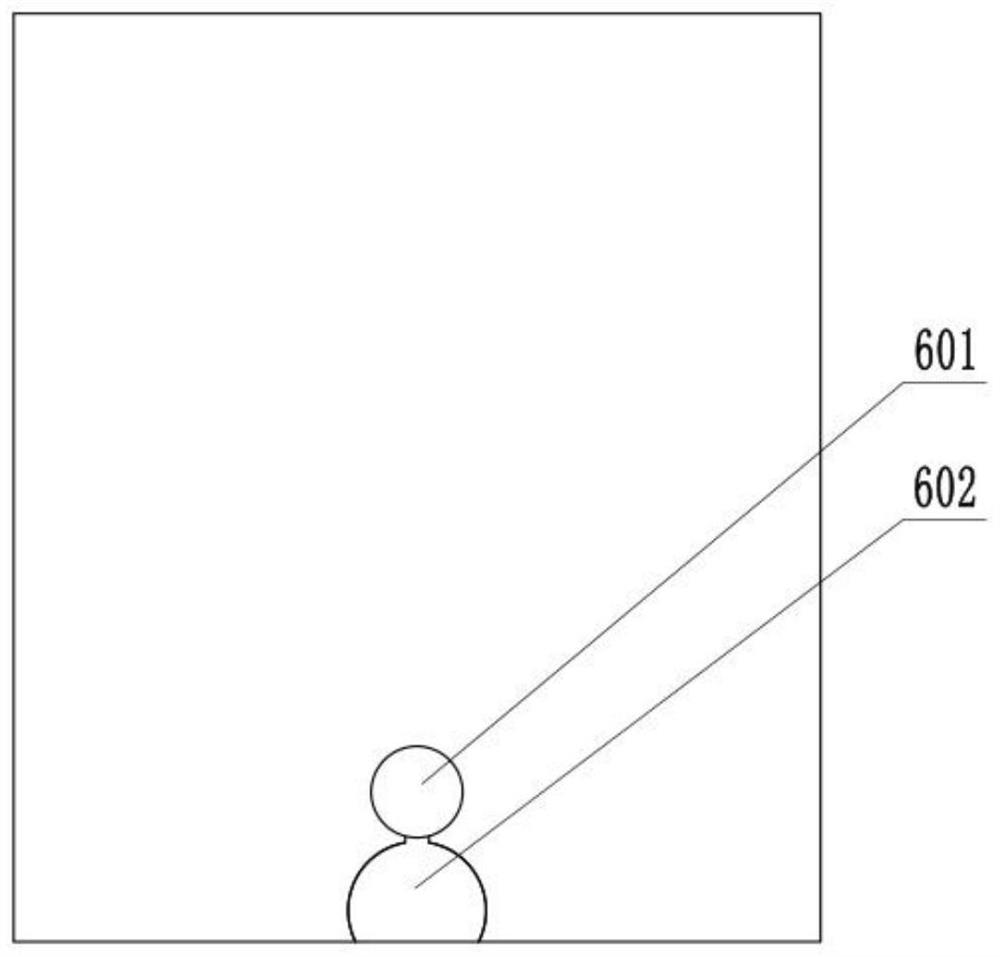

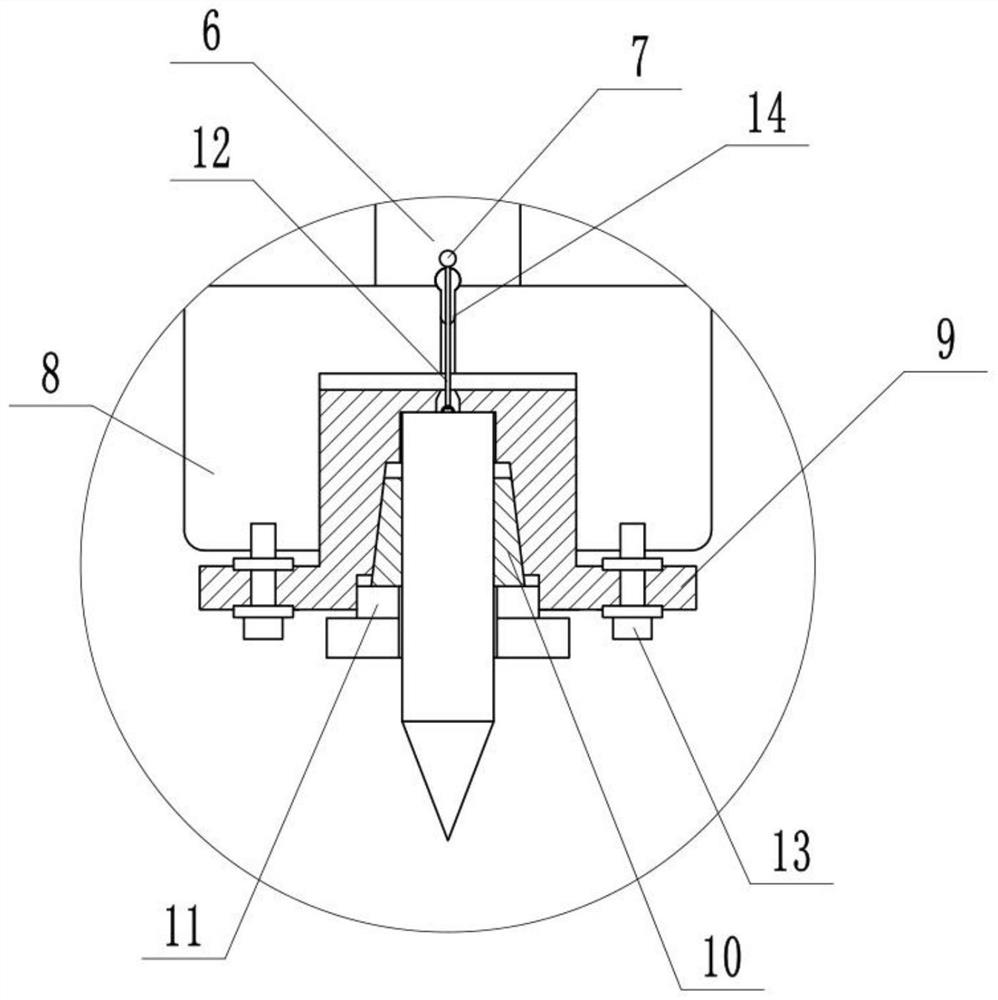

A kind of drilling machine which is convenient to install the drill bit

ActiveCN113145886BRealize alignmentRealize regulationPositioning apparatusMetal-working holdersMining engineeringMachine design

The invention discloses a drilling machine which is convenient for installing a drill bit, and relates to the technical field of drilling machine design. The drill bit is suspended by a positioning rope so that the drill bit is vertically downward. After positioning in the vertical direction, clamping blocks, inclined blocks and locking fixed on the block, so as to ensure that the drill bit is installed in the vertical direction, and realize the centering of the drill bit; the design of the positioning rope, locking screw and adjusting screw can realize the adjustment and fixing of the drill bit height; the whole design saves time and effort, and reduces the need for labor. The installation technical requirements of the operator.

Owner:HUBEI POLYTECHNIC UNIV

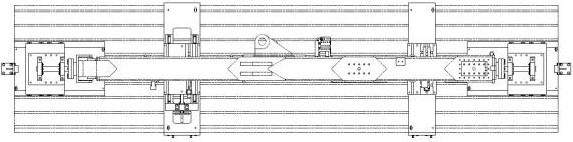

Alignment and flipping device for boom

ActiveCN111922773BRealize alignmentReduce time spentLarge fixed membersMetal working apparatusHeadframeMachining process

The invention discloses an aligning and turnover device of a cantilever crane. The aligning and turnover device comprises a head frame, a tail frame, a translation support and a rotary support. The head frame comprises a head frame body and a head frame chuck for being detachably and fixedly connected with one end of the cantilever crane, and the head frame chuck and the head frame body are rotationally connected in the longitudinal direction. The tail frame comprises a tail frame body and a tail frame chuck for detachably and fixedly connected with the other end of the cantilever crane, and the tail frame chuck and the head frame body are rotationally connected in the longitudinal direction. The translation support comprises a support body capable of sliding relative to a workbench in thetransverse direction and a first lifting mechanism fixed to the support body and used for supporting the cantilever crane. The rotary support comprises a base and a supporting frame rotationally connected with the base in the vertical direction. A coarse positioning block is detachably arranged on the supporting frame, and at least two second lifting mechanisms arranged in the transverse direction at an interval are fixedly connected with the supporting frame. By means of the aligning and turnover device, the machine tool occupying time of alignment and turnover in the machining process of cantilever crane type workpieces is shortened, the production efficiency is improved, and the production cost is reduced.

Owner:CHINA RAILWAY CONSTR HEAVY IND

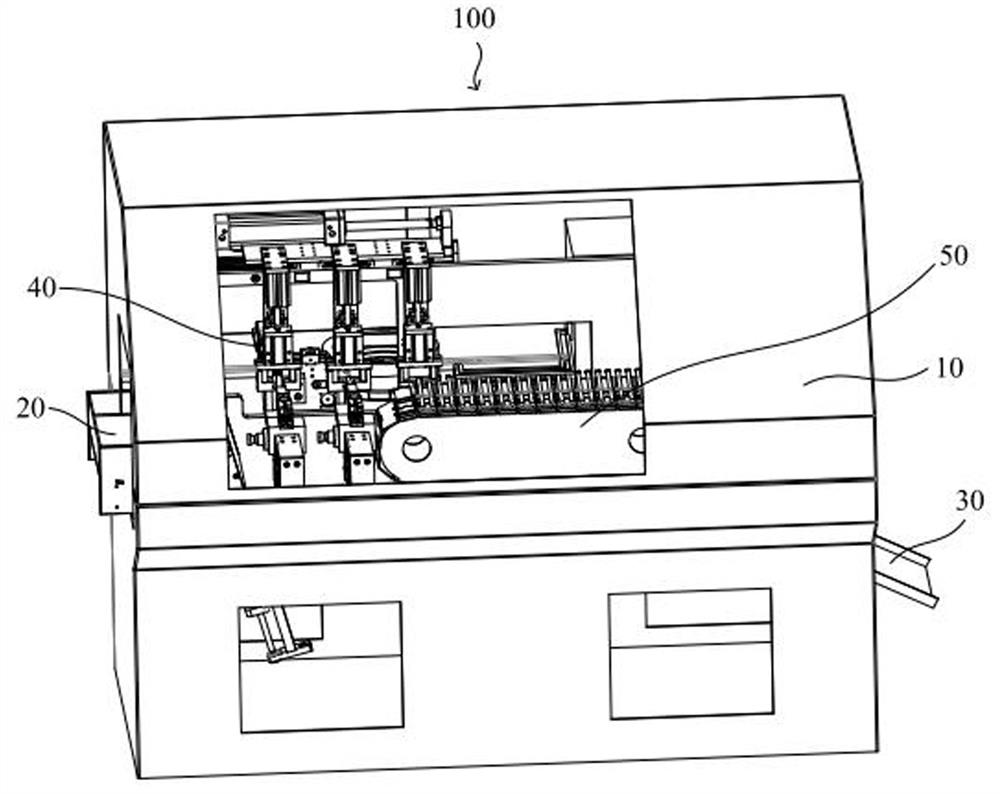

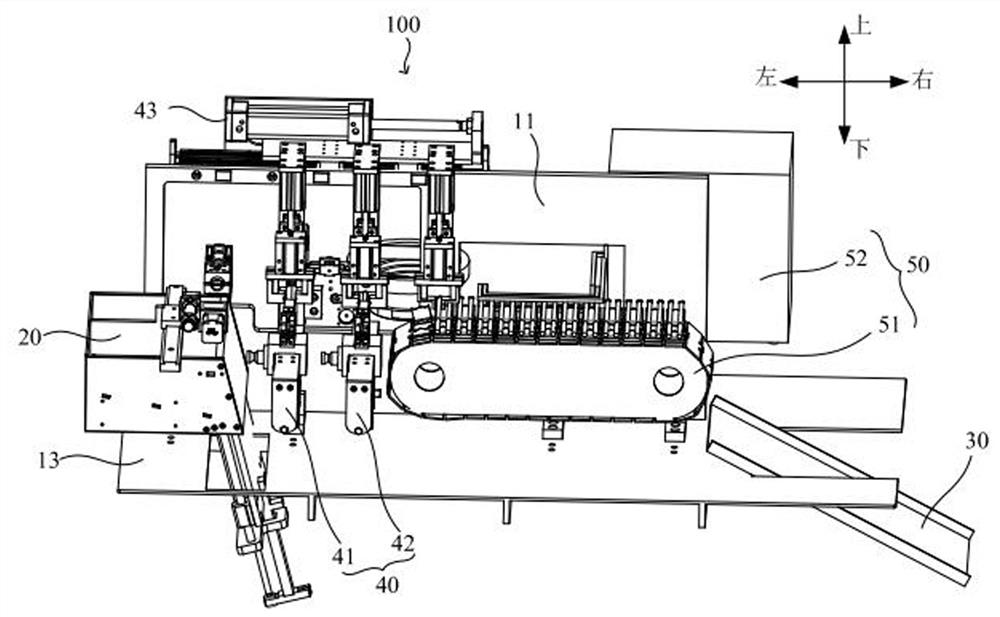

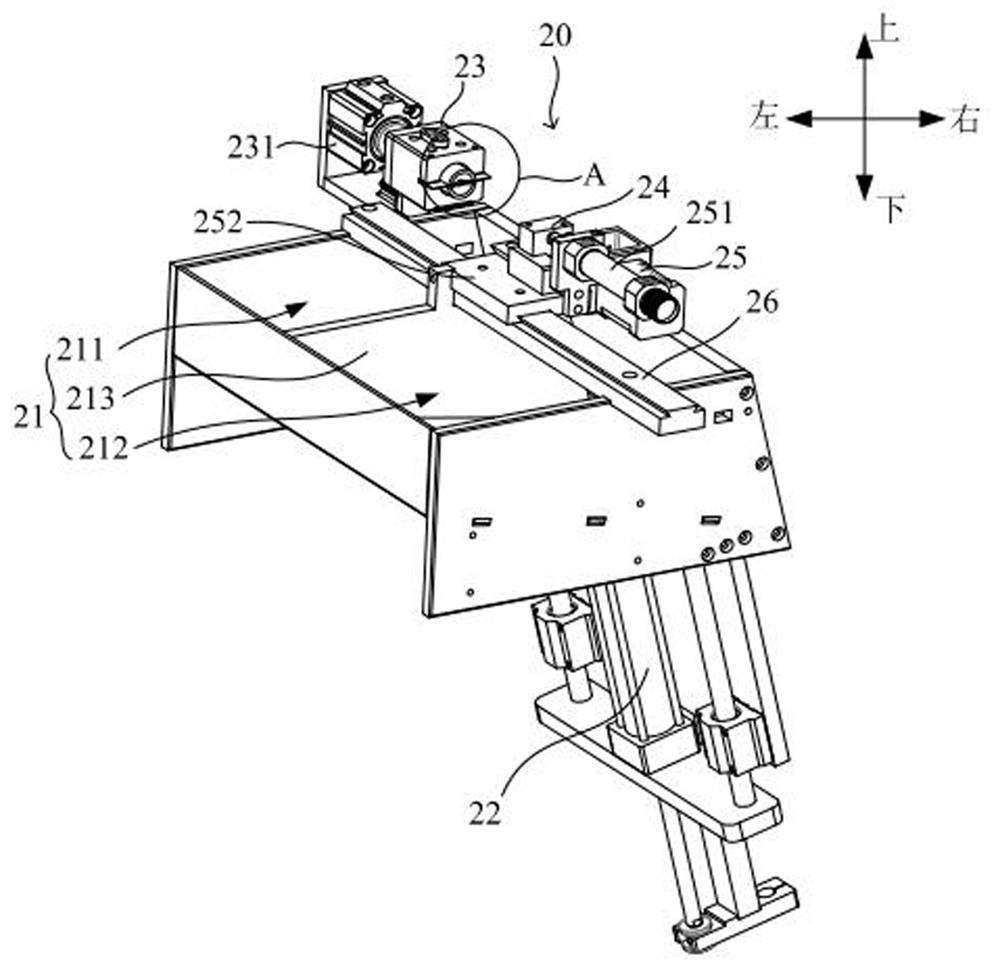

A kind of automatic welding machine and welding process

ActiveCN113996965BImprove welding efficiencyRealize continuous weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAlloy

The invention provides an automatic welding machine and a welding process. The automatic welding machine includes: an assembly mechanism and a welding mechanism; the assembly mechanism can assemble the drill bit and the alloy sheet to form a drill body, and the welding mechanism includes: a welding part, and the welding part is arranged on the assembly mechanism One side of the drill bit body is used for welding the drill bit body; the conveying member is arranged at a position close to the welding part, and the conveying member can install a plurality of the drill bit bodies, and the conveying member is used for The drill body is transported to the welding part; wherein, when the transport member transports the drill body, the drill body can pass through the welding part in sequence to realize welding. The invention can solve the technical problems that the automatic welding machine cannot weld multiple drill bits at the same time and the welding efficiency of the welding machine is low.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD

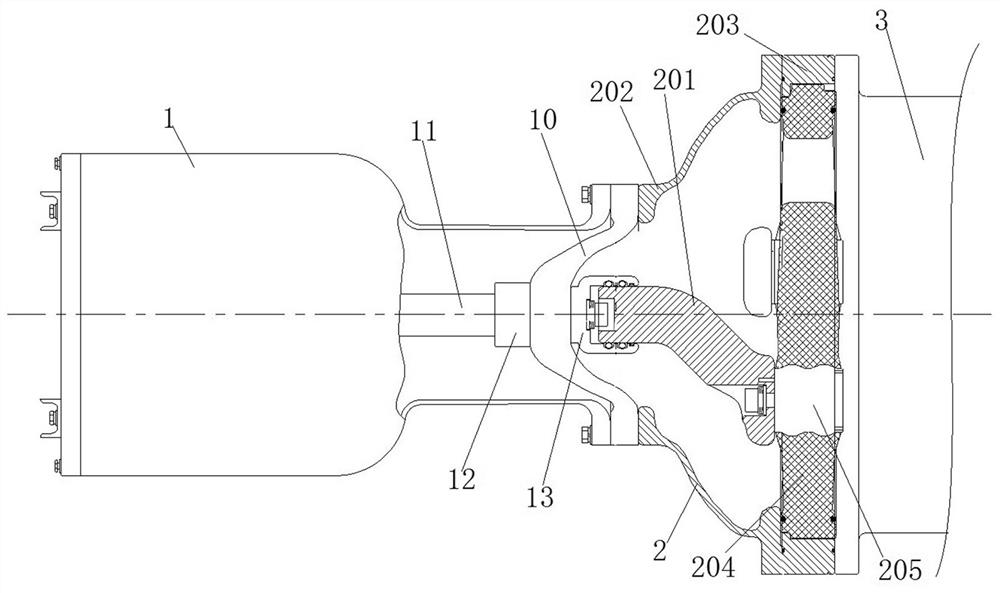

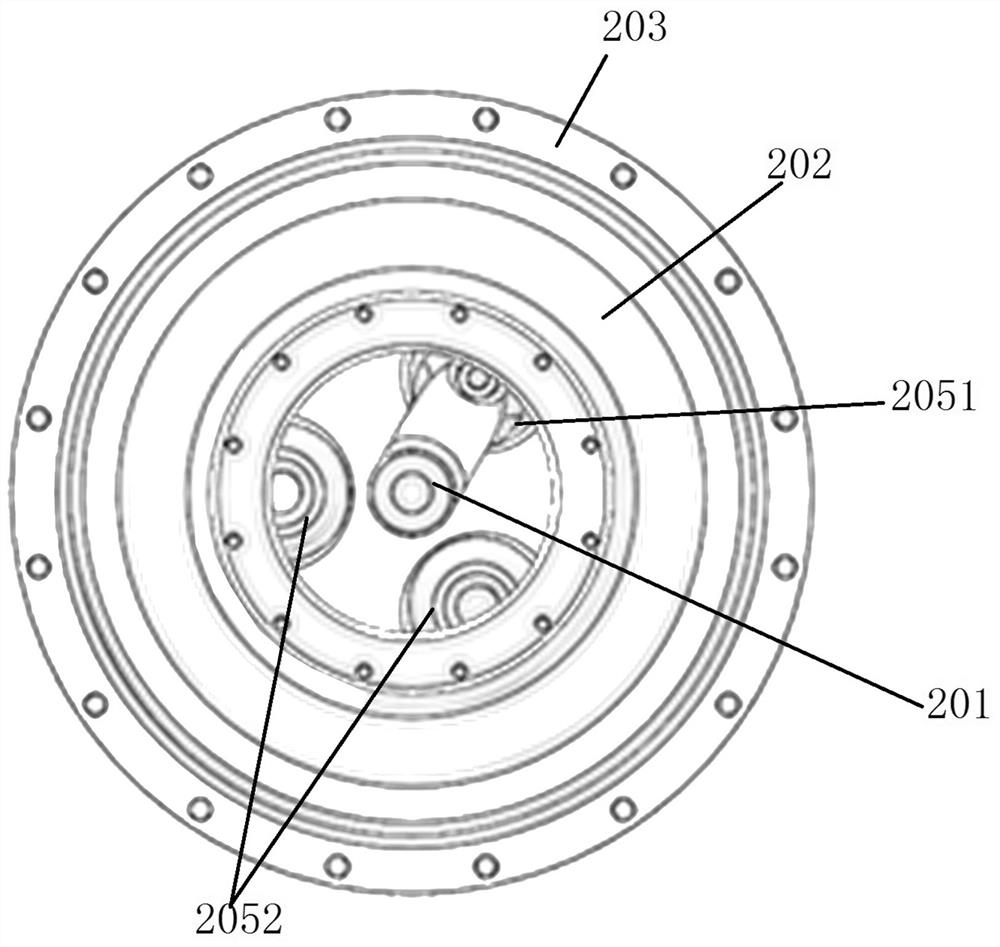

GIS transition bus and GIS

ActiveCN112636230AEasy to realize fixed assemblyRealize fixed assemblyBus-bar/wiring layoutsSwitchgear arrangementsInsulator (electricity)Electrical conductor

The invention relates to a GIS transition bus and a GIS, the transition bus comprises a transition connection shell, a support insulator and a connection conductor, the transition connection shell is used to conveniently realize fixed assembly of a three-phase common box cylinder and a single-phase voltage transformer, the transition connection shell has a smooth reducing section, the radial size of the front end of the transition connection shell is smaller than that of the rear end; and the connection conductor is provided with an inclined extension section, so that a conductive plugging terminal is arranged corresponding to the center of the transition connection shell. According to the transition bus for the GIS, fixed assembly of the three-phase common-box cylinder and the single-phase voltage transformer is conveniently achieved through the transition connection shell, the single-phase voltage transformer and any phase of conductor can be conductively connected through the connecting conductor matched with the conductive insert, electricity taking operation is achieved, and through the inclined extension section on the connection conductor, centering arrangement of the single-phase voltage transformer is convenient to achieve, centering outgoing is convenient, and the overall arrangement coordination of GIS parts is improved.

Owner:HENAN PINGGAO ELECTRIC +2

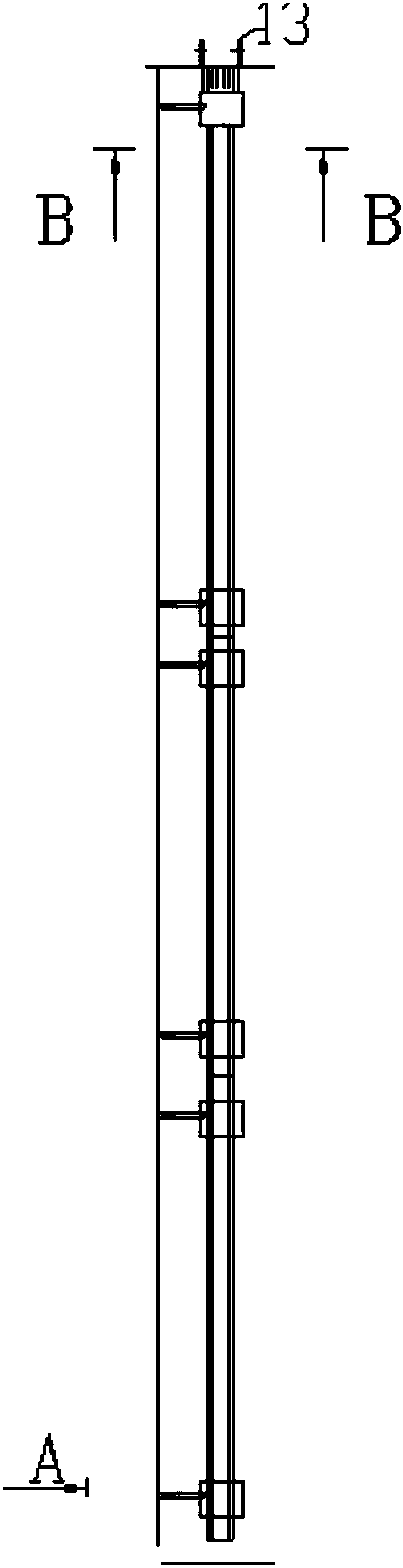

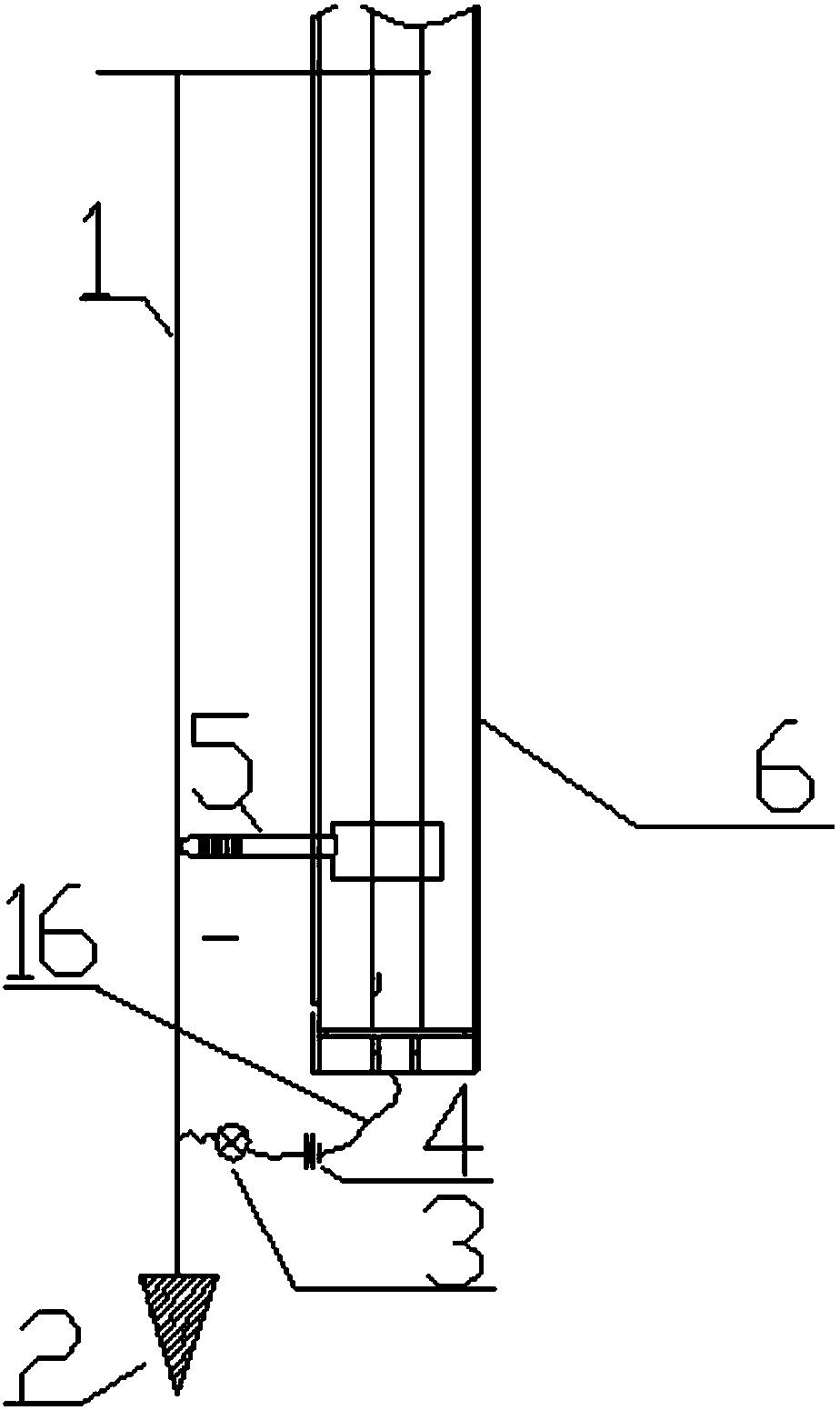

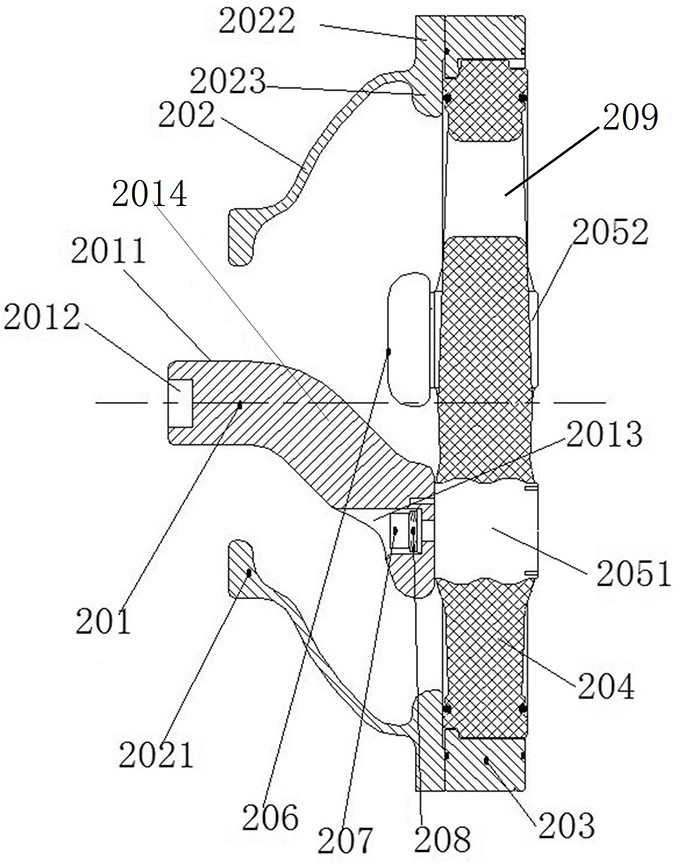

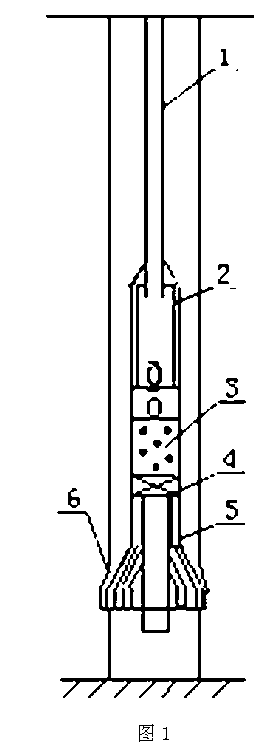

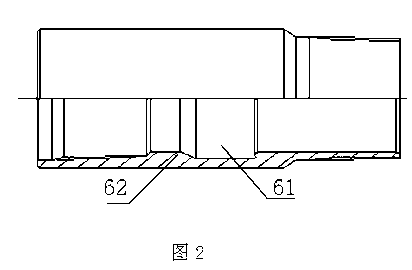

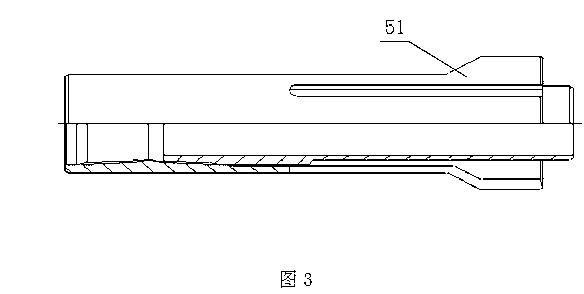

Small hole well completion lifting technology tubular column and use method thereof

InactiveCN103161431AEasy to operateReduce control structureDrilling rodsFluid removalSmall holeIndustrial engineering

The invention provides a small hole well completion lifting technology tubular column and a use method of the small hole well completion lifting technology tubular column, and solves the problems that an existing lifting tubular column in an oil field is inconvenient to lift and locate in the using process, and the like. The small hole well completion lifting technology tubular column comprises a hollow oil rod, a rod pump, an anchor and a lifting operating barrel, wherein the lifting operating barrel is provided with a mechanism which is matched with an anchoring mechanism of the anchor. At the time of well completion, firstly, the lifting operating barrel is placed downwardly to the position, corresponding to the depth where the rod pump is to be hung, of a casing pipe, then a connected combination of the hollow oil rod, the rod pump and the anchor is placed downwardly, and the anchoring mechanism of the anchor and the corresponding and matching mechanism on the lifting operating barrel are used for accurate location. At the time of an overhaul, the hollow oil rod is lifted upwardly to enable the anchoring mechanism to break away from the lifting operating barrel, and then the rod pump can be taken out. The small hole well completion lifting technology tubular column has the advantages of being simple in structure, easy to control, convenient to overhaul and operate and the like, and is mainly used for an oil well with a small hole.

Owner:CHINA PETROLEUM & CHEM CORP +1

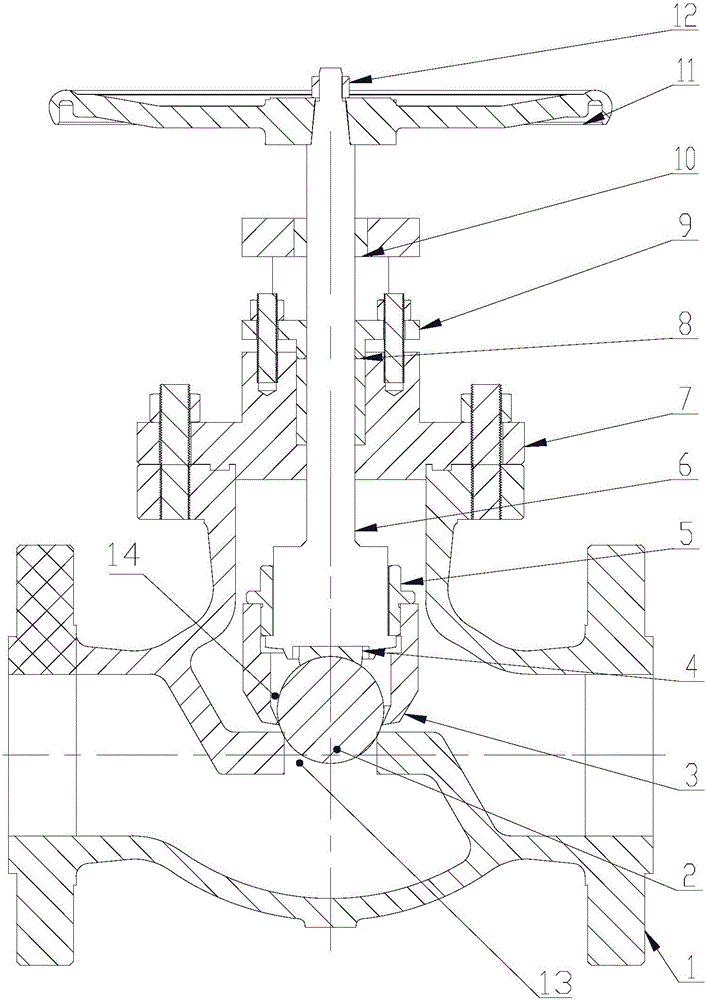

Stop valve with double automatic aligning and sealing assemblies

ActiveCN105927745AImprove the sealing levelAchieve the technical effect of zero leakageLift valveEngineeringSpherical joint

The invention discloses a stop valve with double automatic aligning and sealing assemblies. The stop valve with the double automatic aligning and sealing assemblies comprises a valve body, the double automatic aligning and sealing assemblies, a valve rod, a valve deck, filler, a gland, a valve rod nut, a hand wheel and a nut. Each automatic aligning and sealing assembly is provided with a fixing nut, a concave spherical joint, a sphere retainer sleeve and a sphere sequentially from top to bottom. A groove in the bottom of the valve rod is in horizontally sliding connection with the top of each concave spherical joint. The bottom of each concave spherical joint is of a concave spherical surface shape. The concave spherical surface of the bottom of each concave spherical joint is matched with the spherical surface of the sphere in shape, and is an isometric spherical surface. The spherical surface of the sphere and the arc surface of the upper surface of a spherical opening in the isolation inner wall of the valve body are matched in shape and are isometric spherical surfaces. The stop valve with the double automatic aligning and sealing assemblies is provided with the two automatic aligning structures and has the multiple technological advantages of being long in service life, good in sealing effect, high in structure practicability and the like.

Owner:湖南西爱斯流体控制设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com