Apparatus and method for machining gas turbine diffuser

A gas turbine, diffuser technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

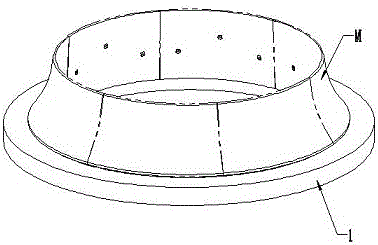

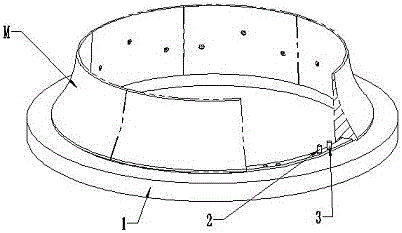

[0036] Examples such as Figure 1-4 As shown, the gas turbine diffuser processing device includes a first tooling and a second tooling. The first tooling is composed of a first chassis 1, a positioning pin 3 and a connecting bolt 2; the positioning pin 3 and the connecting bolt 2 are arranged on the first chassis 1 on the disk.

[0037] There are two positioning pins 3 and two connecting bolts 2 respectively.

[0038] Each part of the workpiece M is connected by two positioning pins 3 and two connecting bolts 2 to ensure reliable positioning and connection.

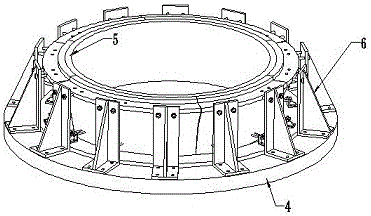

[0039] The second tooling is composed of a second chassis 4, an inner tank 5, a plurality of first fixing blocks 6, a plurality of second fixing blocks 7, and fixing bolts.

[0040] The second chassis 4 is disc-shaped, and the disk surface of the second chassis 4 is integrally connected with an annular seat 11, the annular seat 11 is coaxially arranged with the second chassis 4, and the inner bag 5 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com