Processing method for parallel threaded hole in inner cavity of large shaft

A hole processing method and parallel thread technology, which is applied in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve the problems of increasing transportation costs and processing costs, affecting the on-site manufacturing cycle, and being unable to process, etc., to achieve large savings Equipment manufacturing cycle, good application effect and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

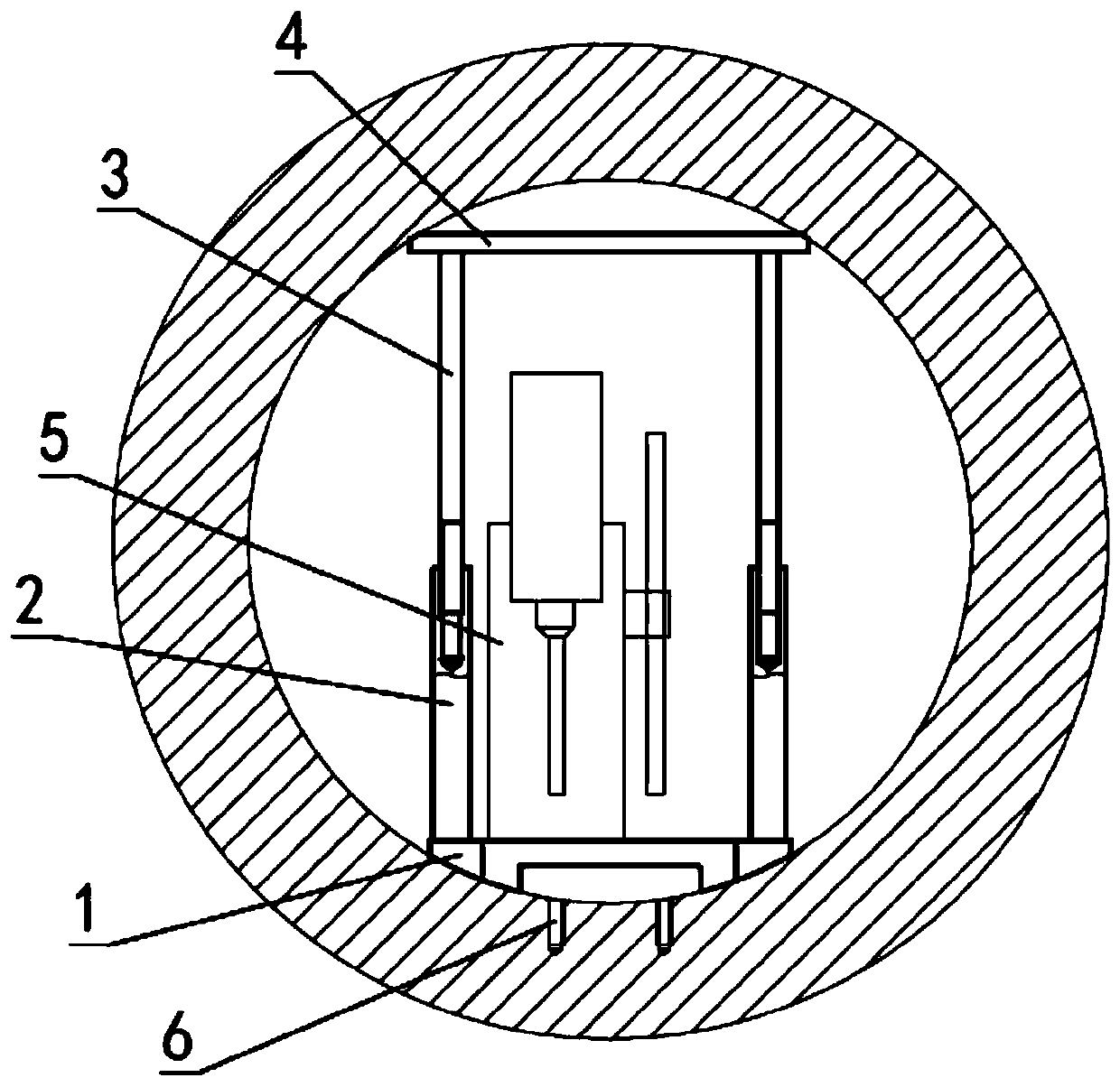

[0028] Such as figure 1 As shown, a large-scale shaft inner cavity parallel threaded hole processing method, the technical scheme is:

[0029] 1) Lay the large shaft flat, and use V-shaped support tools at both ends to fix it firmly to prevent the shaft from rotating;

[0030] 2) According to the requirements of the processing drawings, draw the position line of the parallel hole 6 in the inner cavity of the shaft, and the position line is clear and accurate;

[0031] 3) Place the mold 1 on the arc surface of the inner cavity of the shaft, adjust the position of the mold 1, so that the distance between the end surface of the mold 1 and the parallel threaded hole 6 meets the processing requirements of the magnetic drill 5;

[0032] 4) Adjust the tire mold 1 level within 0.02mm, and there is no gap between the tire mold 1 and the inner cavity of the shaft;

[0033] 5) Assemble the adjustment block 2 and the screw rod 3, and screw the screw rod 3 into the threaded hole of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com