Processing device for drilling and milling internal cavity by refitting ordinary horizontal lathe

A horizontal lathe and processing equipment technology, applied in metal processing equipment, metal processing mechanical parts, other manufacturing equipment/tools, etc., can solve the problems of modifying the design plan, unable to process, etc., to achieve reliable fixation, to achieve product design requirements, Achieving the effect of implementability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

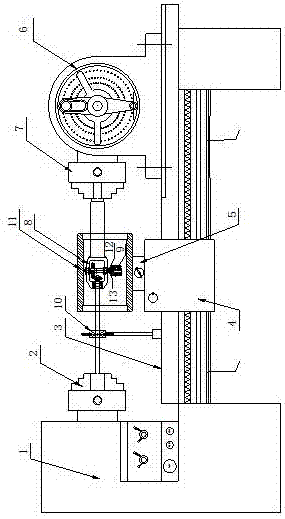

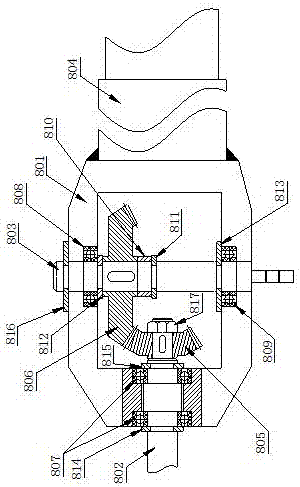

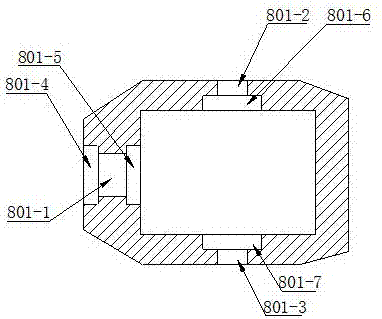

[0020] refer to Figure 1-8 , the specific embodiment adopts the following technical solutions: a processing equipment for drilling and milling the inner cavity by refitting a common horizontal lathe, which consists of five parts, the first part includes a common horizontal lathe 1, a first three-jaw chuck 2, The lathe guide rail 3, the large pallet 4 for controlling the Z direction and the middle pallet 5 for controlling the X direction, the second part includes a 360° rotatable index plate 6, the second three-jaw chuck 7, and the third part is a gear box 8. The fourth part is the drilling and milling tool chuck 9, the fifth part is the center support 10, the first three-jaw chuck 2 and the lathe guide rail 3 are installed on the ordinary horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com