Alignment device and alignment method for vertical looper track

A vertical looper and track technology, applied in metal processing, bending workpieces, metal processing equipment, etc., can solve the problems of large deviation of artificial readings, labor-intensive, hidden dangers of operation safety, etc., to improve work efficiency and simple operation. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

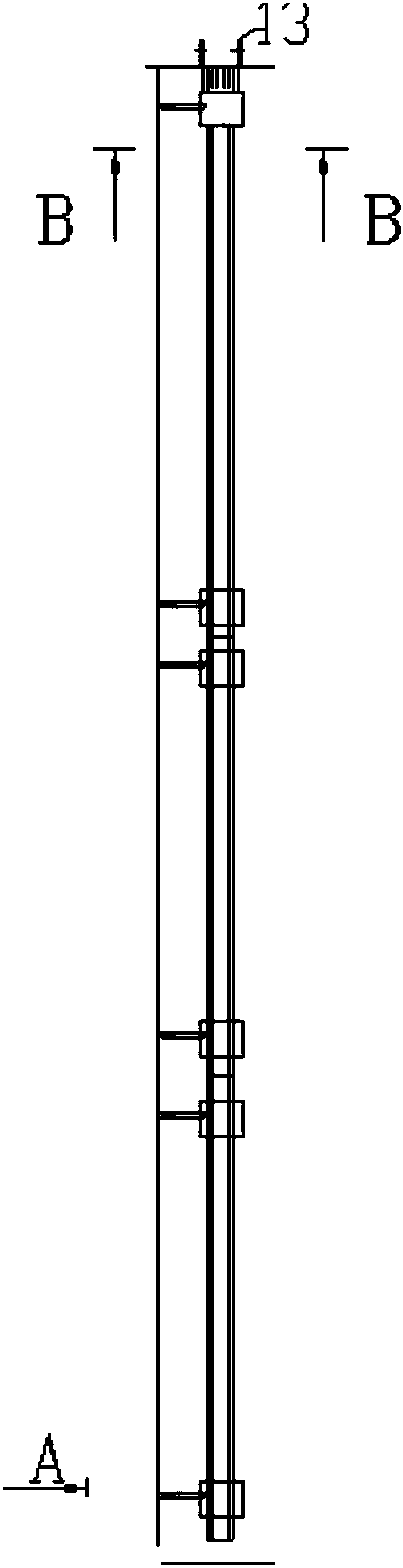

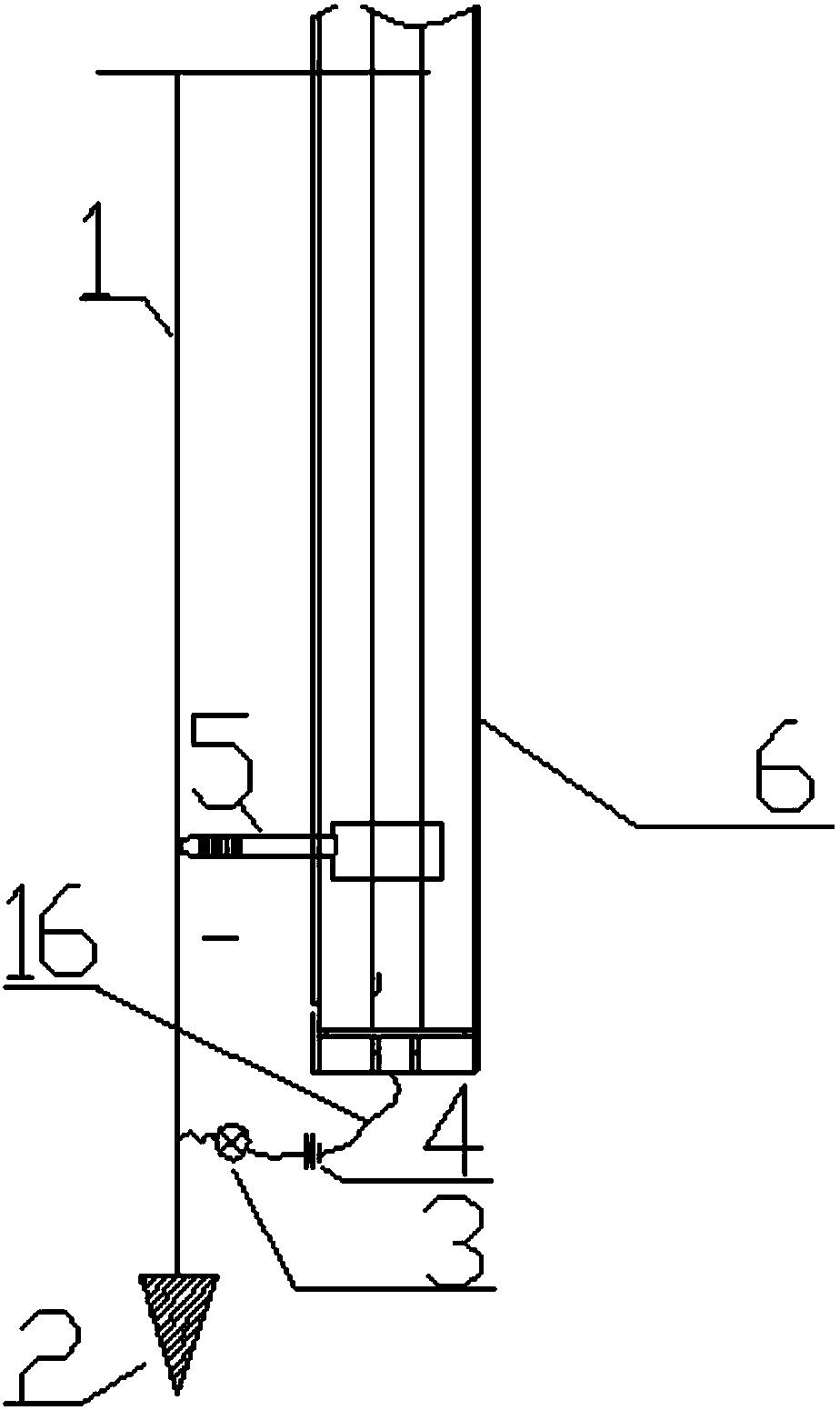

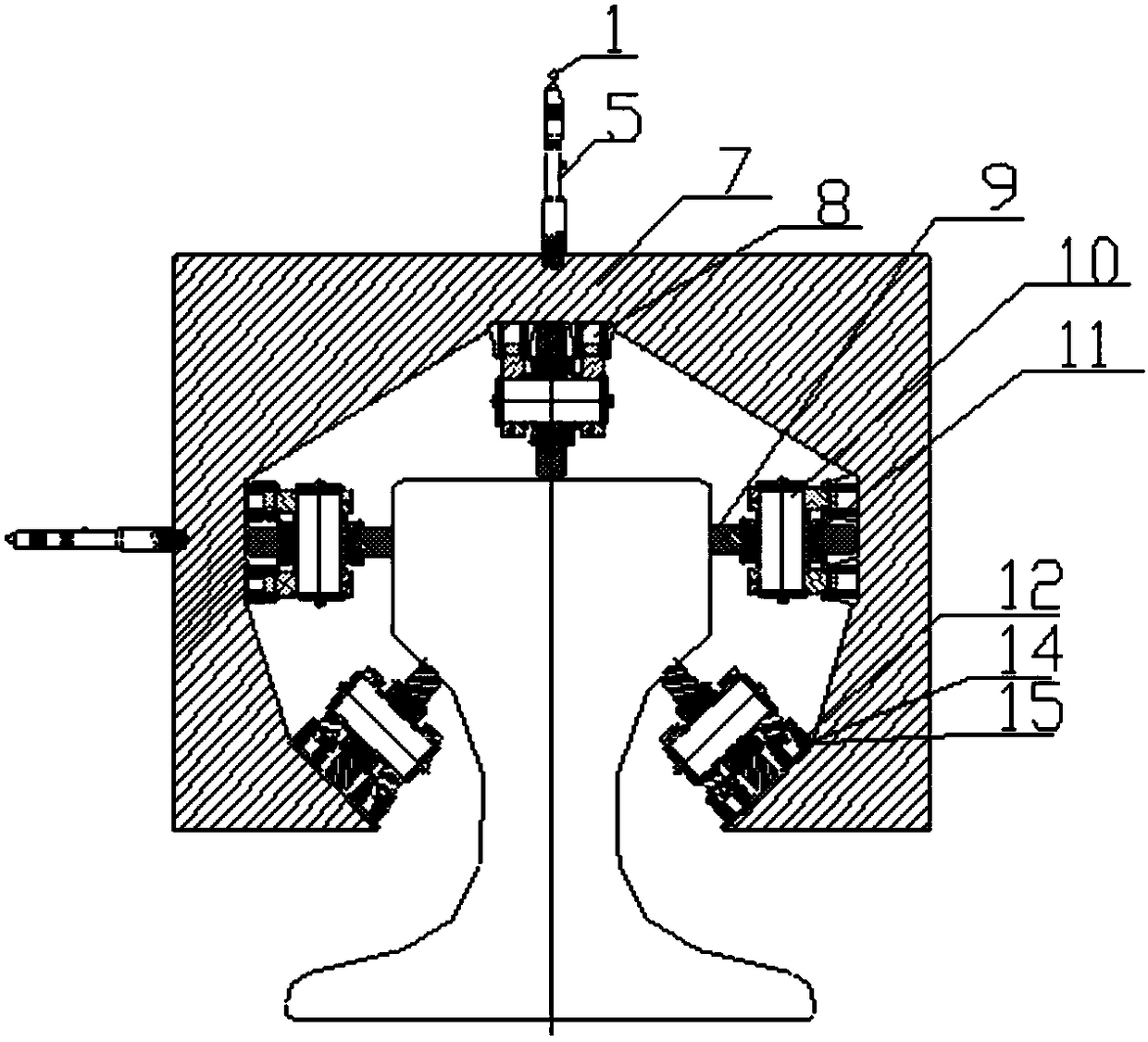

[0032] refer to Figure 1 ~ Figure 3 As shown, the alignment device for the vertical looper track in an embodiment provided by the present invention includes a dolly and a steel wire 1, the dolly is arranged on a vertical track 6, the dolly can move along the track 6, and the steel wire 1 Vertically arranged outside the track 6 along the length direction of the track 6, the steel wire 1 and the track 6 are connected by an electric wire 16, the electric wire 16 is provided with an indicator light 3 and a power supply 4 in turn, and the trolley is provided with a micrometer rod 5, if the track 6. If the deviation is within a reasonable range, the detection head of the micrometer rod 5 is in contact with the steel wire 1, otherwise the detection head of the micrometer rod 5 is not in contact with the steel wire 1; 16 and the indicator light 3 form a loo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com