Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Full hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel for a plastic molding die

To provide a steel for plastic molding die which possesses enough hardness, wear resistance and corrosion resistance, and is excellent in high-precision processability and mirror polishing properties. The steel for a plastic molding die contains not more than 0.80 wt% C, not less than 0.01 wt% and less than 1.40 wt% Si, not less than 0.05 wt% and not more than 2.0 wt% Mn, not less than 0.005 wt% and not more than 1.00 wt% Ni, not less than 13.0 wt% and not more than 20.0 wt% Cr, not less than 0.20 wt% and not more than 4.0 wt% Mo + 1 / 2 W, not less than 0.01 wt% and not more than 1.00 wt% V, not less than 0.36 wt% and not more than 0.80 wt% N, not more than 0.02 wt% O, not more than 0.80 wt% A1, and the remainder substantially including Fe and unavoidable impurities.

Owner:DAIDO STEEL CO LTD

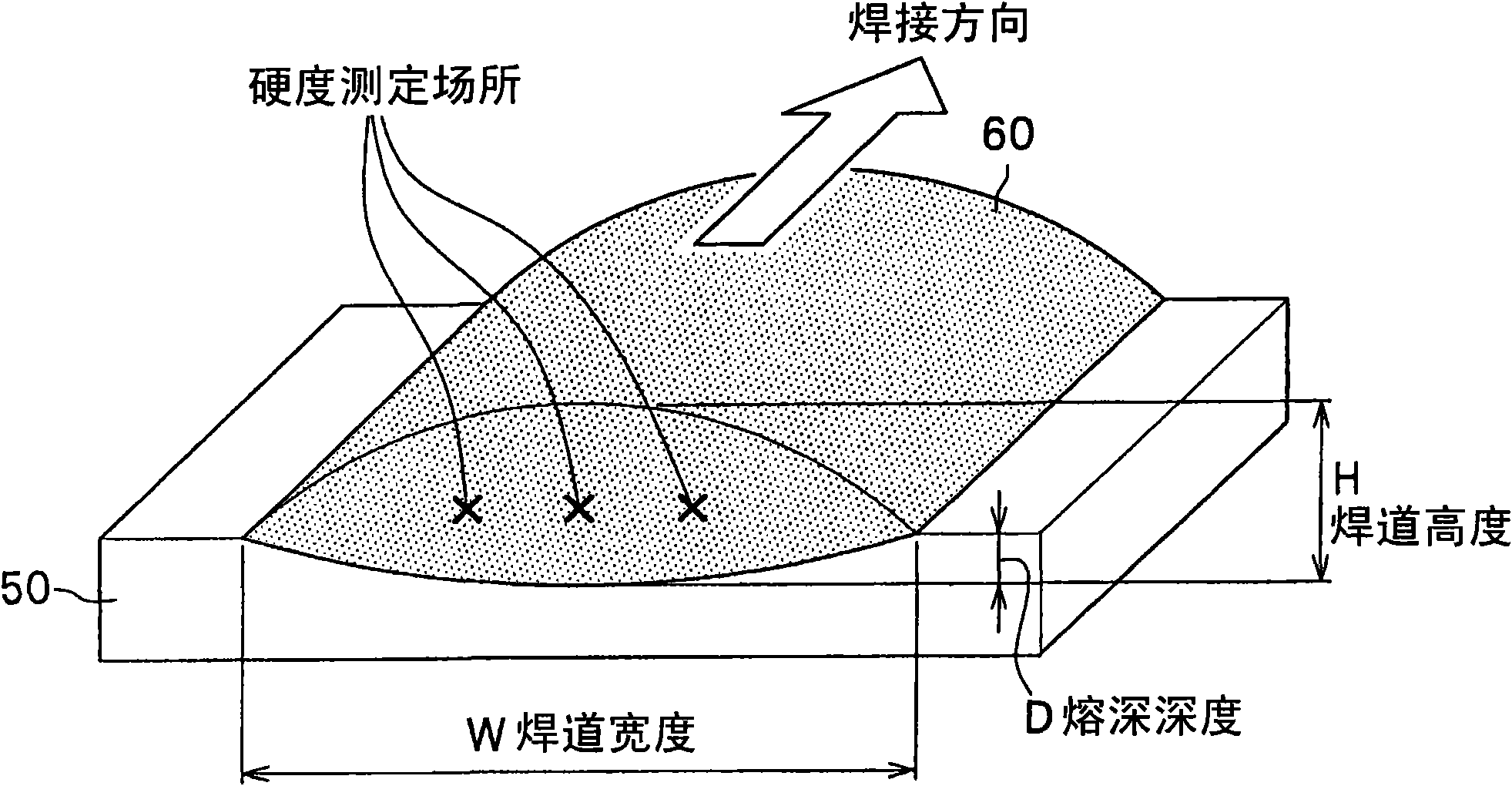

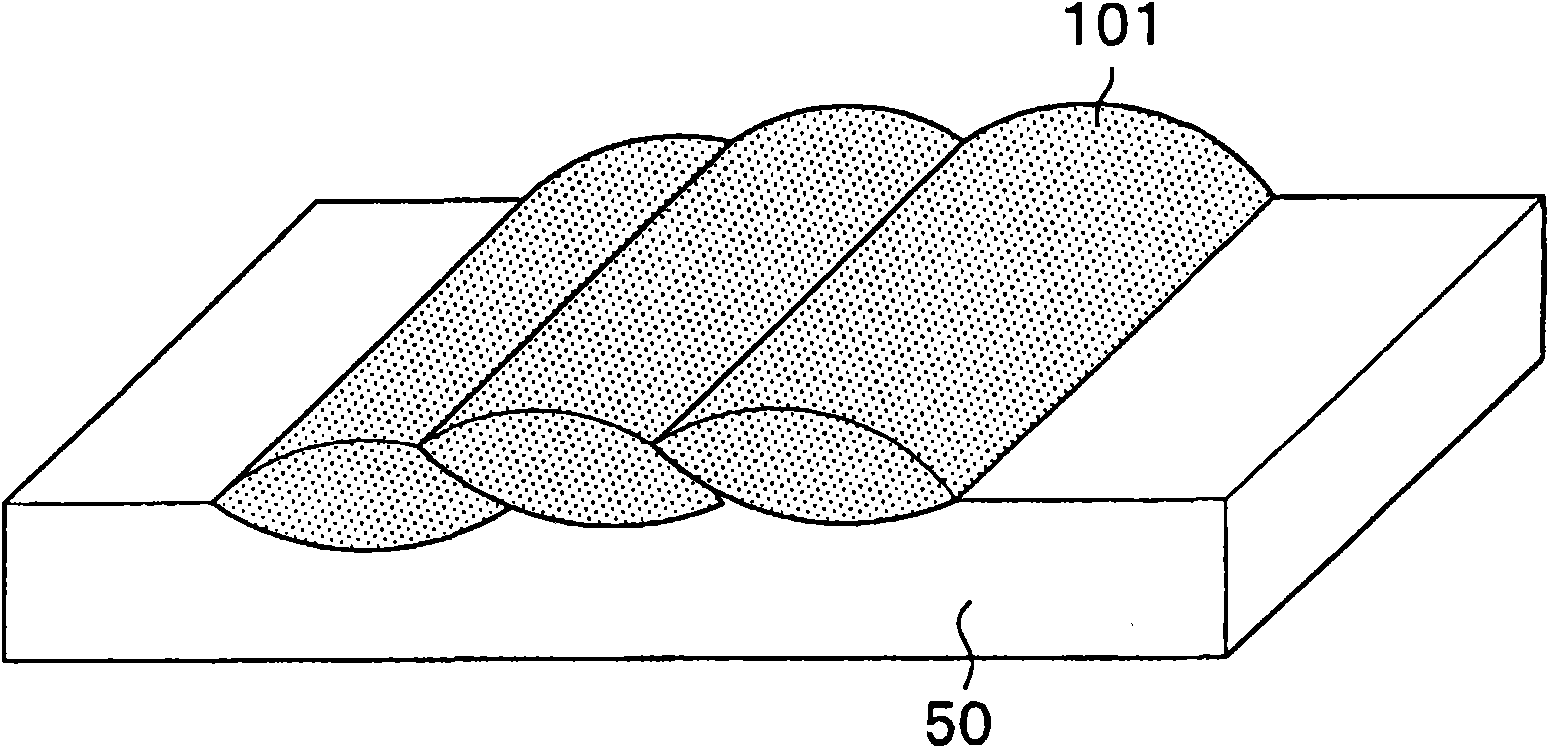

Hardfacing MIG-arc welding wire and hardfacing MIG-arc welding process

InactiveCN102059476AFlat shapeFull hardnessArc welding apparatusWelding/cutting media/materialsShielding gasCarbon Dioxide / Helium

A wire is adopted to hardfacing MIG-arc welding using a pure argon gas as a shielding gas. The wire is a flux-cored wire prepared through drawing a steel hoop or steel pipe as a sheath in which a flux is filled. The flux contains, based on the total mass of the wire, C: 0.12 to 5.00 percent by mass, Si: 0.50 to 3.00 percent by mass, Mn: 0.30 to 20.00 percent by mass, P: 0.050 percent by mass or less, S: 0.050 percent by mass or less, and at least one of TiO2, ZrO2, and Al2O3 (TiO2+ZrO2+Al2O3) in a total content of 0.10 to 1.20 percent by mass and has a total content of silicon and manganese (Si+Mn) of 1.20 percent by mass or more. The wire has a ratio of the total mass of the flux to the mass of the wire of 5 to 30 percent by mass.

Owner:KOBE STEEL LTD

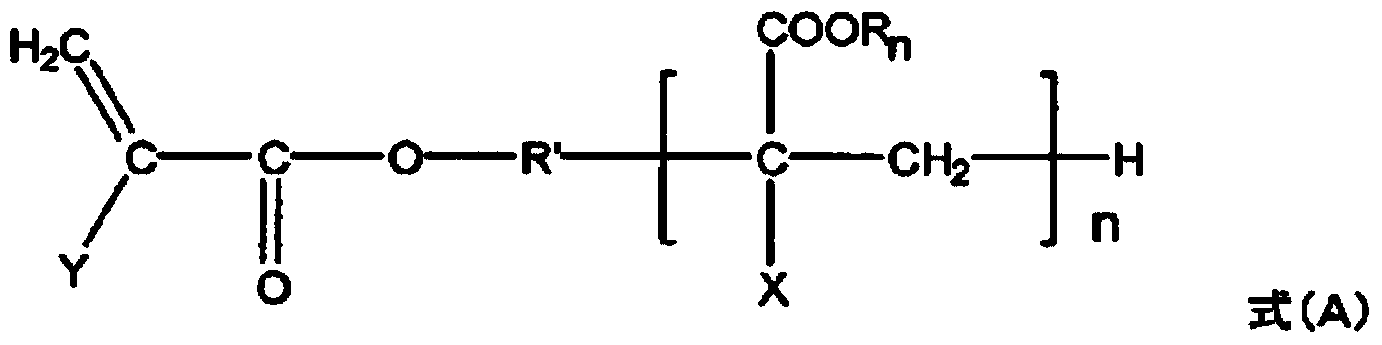

(meth)acrylate compound, resin composition containing the same, cured product of the resin composition, and energy ray-curable resin composition for optical lens sheet and cured product thereof

Disclosed is a photosensitive resin which is excellent in transparency, while having high refractive index and high adhesion by the resin itself. This photosensitive resin provides a cured product having a sufficient hardness. Also disclosed is a resin composition for optical lens sheet, which is excellent in mold releasability, mold reproducibility, adhesion to a base, while having high refractive index, high glass transition temperature and good light resistance. Specifically disclosed is a urethane compound (A) characterized by being obtained by reacting an epoxy resin (a), which is obtained by reacting a compound represented by the general formula (1) below with epihalohydrin, a monocarboxylic acid compound (b) having an ethylenically unsaturated group in a molecule, and an aromatic polyisocyanate compound (c). Also specifically disclosed is an energy ray-curable resin composition for optical lens sheet, which is characterized by containing the urethane compound (A) and a photopolymerization initiator (B).

Owner:NIPPON KAYAKU CO LTD

Transparent conductive film, electronic device, and touch panel

InactiveCN102473480AFull hardnessImprove scratch resistanceConductive layers on insulating-supportsSynthetic resin layered productsMethacrylateFilm base

Owner:NITTO DENKO CORP

On-vehicle camera lens glass material and on-vehicle camera lens

InactiveCN101271165AExcellent chemical durabilityImprove resistance to damageOptical viewingOptical elementsCamera lensRefractive index

This invention provides an on-vehicle camera lens glass material with excellent resistance to acid rain or medicine and full hardness, which comprises high reflection ratio through reducing the characteristic deterioration caused by ultraviolet ray, and is suitable for composing optical components such as on-vehicle camera lens on the on-vehicle camera which can be exposed under cruel environment, additionally, this invention provides an on-vehicle camera lens made of this on-vehicle camera lens glass material. The on-vehicle camera lens glass material satisfies at least one of conditions in which a measurement result in water resistance based on a powder method prescribed by Japanese Optical Glass Industrial Standard is the first class; a measurement result in Knoop hardness based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is sixth class or higher; a measurement result in solarization based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is 2% or less; and a measurement result in average linear expansion coefficient based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is less than 100*10(-7) DEG C (-1).

Owner:HOYA CORP

Rubber composition and pneumatic tire using the same

InactiveCN1922258AImprove liquidityGood dimensional stabilitySpecial tyresTyre beadsPolymer scienceSilicon dioxide

A rubber composition which comprises (i) a conjugated diene based rubber gel exhibiting a toluene swelling index of 16 to 70, (ii) a diene based rubber such as natural rubber, a polyisoprene rubber, an aromatic vinyl-conjugated diene copolymer rubber and / or a polybutadiene rubber, and optionally (iii) carbon black and / or silica; and (a) a pneumatic tire using the above composition in a high hardness reinforcing layer extending along a tire side wall from a bead section, which is improved in the fluidity and dimensional stability in extruding molding, with the retention of satisfactory hardness of a high hardness reinforcing rubber, (b) a pneumatic tire using the above composition in both end portions of an extruded tire tread, which is improved in its processability and dimensional stability in extruding molding, with the retention of flex fatigue characteristics in both end portions of a tread, and (c) a pneumatic tire using the above composition as an under tread having a thickness of 1.5 to 6 mm, which has a relatively thick under tread exhibiting a high elastic modulus and is excellent in processability and driving stability.

Owner:THE YOKOHAMA RUBBER CO LTD +1

Method for producing vinyl polymer and resin composition for water-based antifouling paint containing vinyl polymer

Provided is a method for producing a vinyl polymer comprising step (1) for polymerization of a monomer mixture (M1) comprising a carboxyl group-containing ethylenic unsaturated monomer (a1) and step (2) for polymerization of a monomer mixture (M2) comprising a divalent metal-containing ethylenic unsaturated monomer (a2), and in the method for producing a vinyl polymer, the monomer mixture (M1) and / or the monomer mixture (M2) comprise a macromonomer (a3) having radical polymerizable groups, and either the monomer mixture (M2) is added to the polymerization reaction solution after step (1) and then step (2) is performed, or the monomer mixture (M1) is added to the polymerization reaction solution after step (2) and then step (1) is performed.

Owner:MITSUBISHI CHEM CORP

Coating material, preparation of optical film, optical film, polarizing plate and image display device

InactiveCN1918252AHigh hardnessFull hardnessLiquid surface applicatorsSynthetic resin layered productsCyclohexanonePolymer science

The present invention provides a coating material for forming a coating layer that can achieve excellent adhesion to a transparent film. The coating material is prepared so that it contains a thermosetting resin, an inorganic filler, and a mixed solvent containing cyclohexanone. The content of the thermosetting resin is in the range from 5 to 20 wt % with respect to the total amount of the thermosetting resin and the inorganic filler, and the content of the cyclohexanone is in the range from 25 to 35 wt % with respect to the entire mixed solvent. By coating a surface of a transparent film with this coating material and then heat-treating the resultant coating, a coating layer with excellent adhesion can be formed on transparent film. The thus-obtained laminate of the transparent film and the coating layer can be used as an antireflection film.

Owner:NITTO DENKO CORP

Pneumatic tire

InactiveCN1876701AFull stiffnessFull hardnessSpecial tyresTyre tread bands/patternsCrack resistanceRolling resistance

A pneumatic tire which has a base tread having sufficient rigidity, hardness and crack resistance, and sufficiently satisfies the compatibility among steering stability, ride quality and lowering of rolling resistance is provided. The pneumatic tire has a base tread comprising a rubber composition containing 0.5 to 10 parts by weight of a thermosetting resin based on 100 parts by weight of a diene rubber, wherein complex elastic modulus E* of the rubber composition measured at a measurement temperature of 60 DEG C and dynamic strain of 1 % is 8 to 15 MPa, tan delta is at most 0.15, and elongation at break EB of the rubber composition in a tensile test is at least 300 %.

Owner:SUMITOMO RUBBER IND LTD

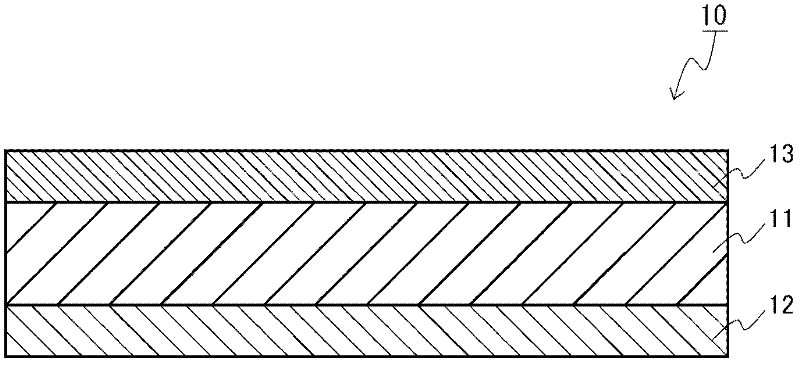

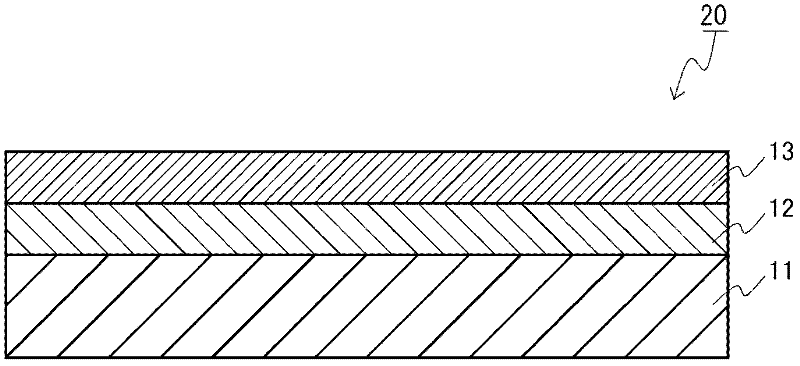

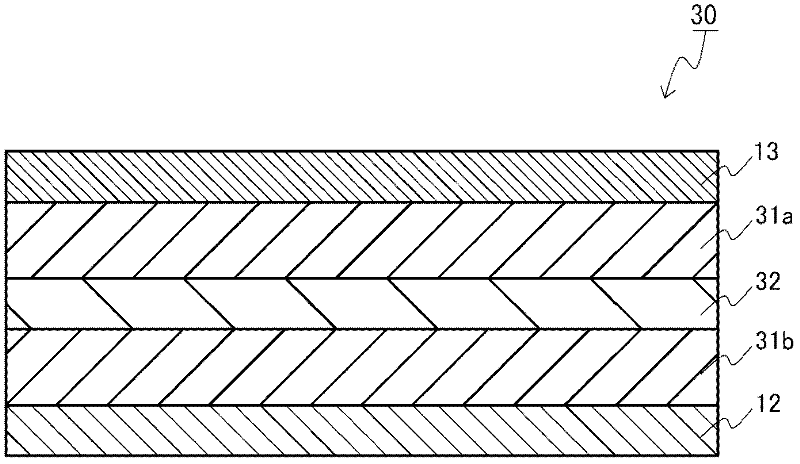

Optical laminate

ActiveCN105579871APrevent interference spotsFull hardnessSynthetic resin layered productsPolarising elementsRefractive indexHardness

Provided is an optical laminate which comprises a base layer and a hard coat layer, and has a sufficient hardness, while being prevented from interference irregularity. An optical laminate which comprises: a base layer that is formed of a thermoplastic resin film; and a hard coat layer that is formed by coating the thermoplastic resin film with a hard coat layer-forming composition containing a curable compound having a molecular weight of 600-2,500 and high-refractive-index fine particles having a refractive index of 1.50 or more. The hard coat layer has a permeation region that is formed by permeation of the hard coat layer-forming composition into the thermoplastic resin film. The high-refractive-index fine particles are segregated in the hard coat layer so that the concentration thereof is continuously decreased from the surface, on which the base layer is not arranged, in the thickness direction.

Owner:NITTO DENKO CORP

Method for coating metal materials and coated materials

InactiveCN1486795AFull hardnessImprove abrasion resistancePretreated surfacesSpecial surfacesCoating systemPlastic materials

Provided is a system capable of forming a coating film having sufficient coating film hardness, excellent abrasion resistance and excellent hue appearance on the surface of a metal material, which may have a surface flaw, such as a magnesium alloy material and a coating film uniform in hue appearance even to a coated article wherein a plastic material and a metal material are combined such as a housing or the like for a portable telephone, and a coated article using this system. A method of coating metal material is a coating system which forms a cured coating film with a film thickness of 20-40 [mu]m on the surface of a metal material using a powder paint and forms a colored coating film on the cured coating film using a solvent type thermoplastic acrylic resin paint and further forms a transparent coating film on the colored coating film using a UV curable clear paint. The powder paint to be used has the molten lowest viscosity of 1.0-2.0 Pas under a baking curing condition.

Owner:NIPPON PAINT CO LTD

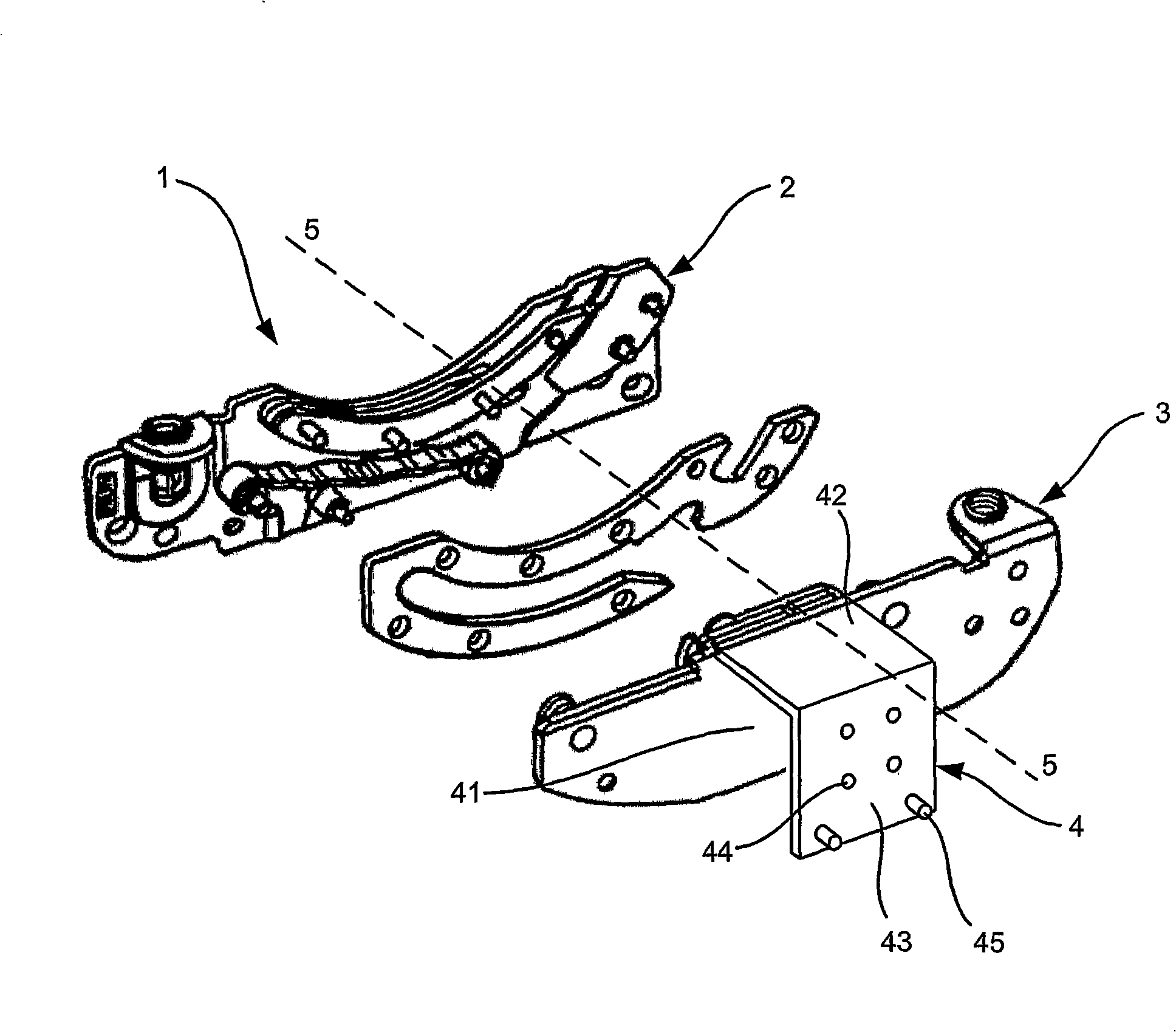

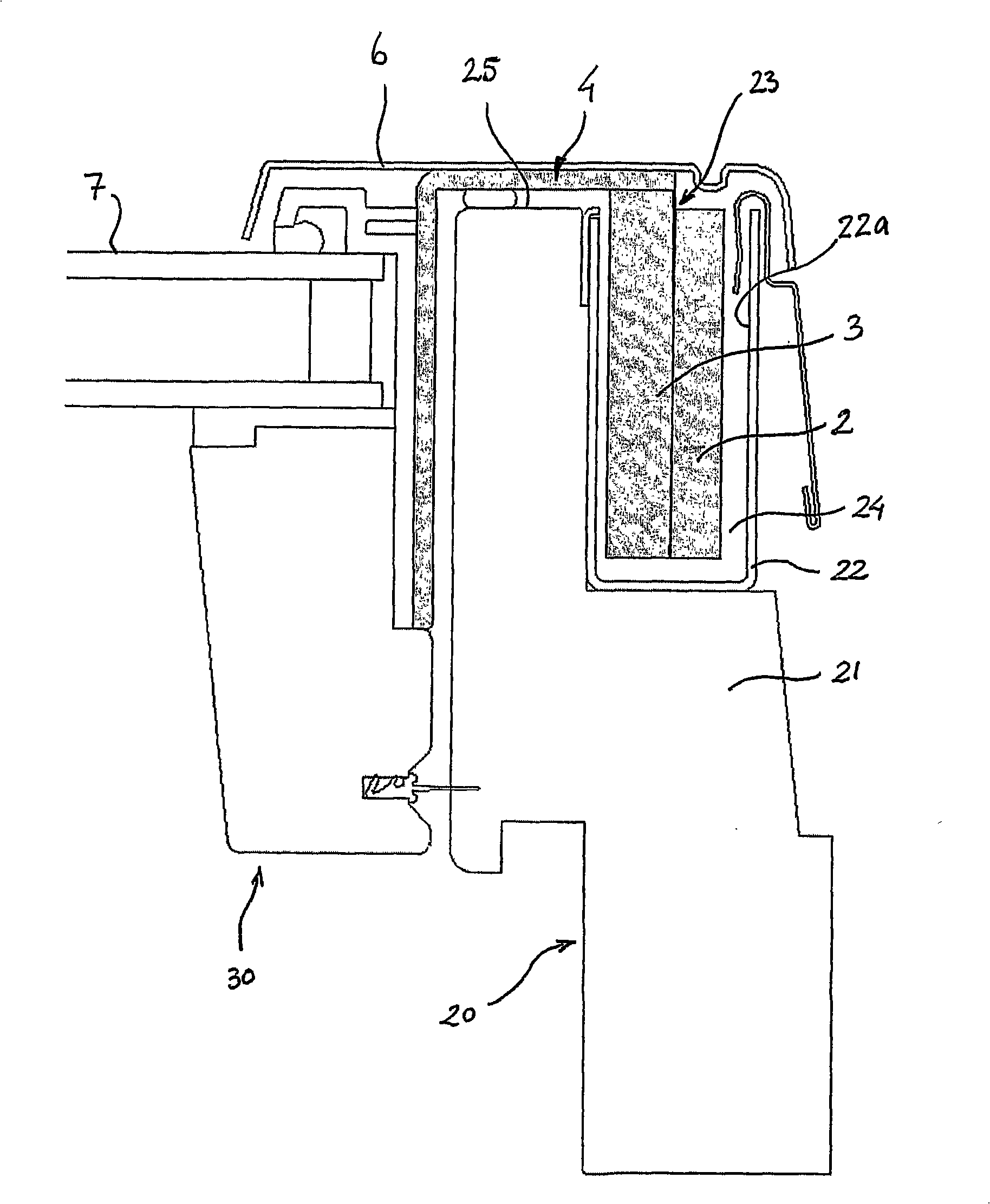

A pivot hinge and a pivot window

Owner:VKR HLDG AS

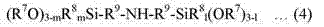

Room-temperature-curable polyorganosiloxane composition

Provided is a room-temperature-curable polyorganosiloxane composition which minimises the deterioration of hardness of a cured product in high-temperature and high-humidity conditions, and which has excellent adhesiveness to a variety of base materials. The composition is a two-component room-temperature-curable polyorganosiloxane composition comprising a main agent composition (A), and a curing agent composition (B). The main agent composition (A) contains, at a predetermined ratio, polyorganosiloxane that has a resin structure represented by (c) average unit formula: (R1 3SiO1 / 2)p[Si(OH)xO(4-x) / 2]q. The curing agent composition (B) contains: (e) a trifunctional or tetrafunctional silane compound, or a partial hydrolysis condensate thereof; and (f) an amino group-containing silicon compound.

Owner:MOMENTIVE PERFORMANCE MATERIALS JAPAN LLC

Steel for nitriding and nitrided steel components

InactiveCN102803542AHeat treatment strain is smallImprove fatigue strengthSolid state diffusion coatingMetallurgyImpurity

Provided is a steel for nitriding, which has a reduced strength before nitriding and therefore exhibits improved machinability. In the steel for nitriding, addionally, a nitrided layer with a large effective case depth can be formed for the purpose of improving the fatigue strength. A steel for nitriding, characterized by containing by mass 0.05 to 0.30% of C, 0.003 to 0.50% of Si, 0.4 to 3.0% of Mn, 0.2 to 0.9% of Cr, 0.19 to 0.70% of Al, 0.05 to 1.0% of V, and 0.05 to 0.50% of Mo, the contents of Al and Cr satisfying the relationship: 0.5% <= 1.9Al + Cr <= 1.8%, and the balance being Fe and unavoidable impurities.

Owner:NIPPON STEEL CORP

Plastic ampule

ActiveCN102014845AEasy to removeImprove draining effectBottlesPharmaceutical containersAmpouleEngineering

Provided is a plastic ampule being handled suitably at the time of unsealing wherein remaining content liquid can be removed easily by performing a removal operation for dropping the remaining content liquid into a body portion by shaking the plastic ampule before use even when the content liquid remains in the hollow portion of a head portion. The plastic ampule comprises a body portion, a head portion (6) provided continuously to the mouth portion (3) of the body portion through a cut-off portion (10), and a knob portion (9) provided continuously to the head portion (6), the ampule being unsealed by twisting the knob portion (9) with fingers to cut the head portion (6) off the mouth portion (3), wherein the hollow portion (8) in the head portion (6) is formed in the shape of a bowl. Since the hollow portion (8) is formed in the shape of a bowl, content liquid remaining in the hollow portion (8) can be discharged easily, the plastic ampule can be unsealed easily, and the content liquid remaining in the hollow portion (8) is not scattered easily at the time of unsealing.

Owner:NIPPON ZOKI PHARM CO LTD

Active energy ray-curable ink-jet ink

ActiveCN101305061AExcellent adhesionExcellent printing aestheticsDuplicating/marking methodsInksEngineeringTan delta

Owner:TOYO INK SC HOLD CO LTD

Rapidly dissolving oral tablet

InactiveCN103547265AExcellent oral disintegrationFull hardnessOrganic active ingredientsPill deliveryMentholWater insoluble

Owner:MITSUBISHI TANABE PHARMA CORP

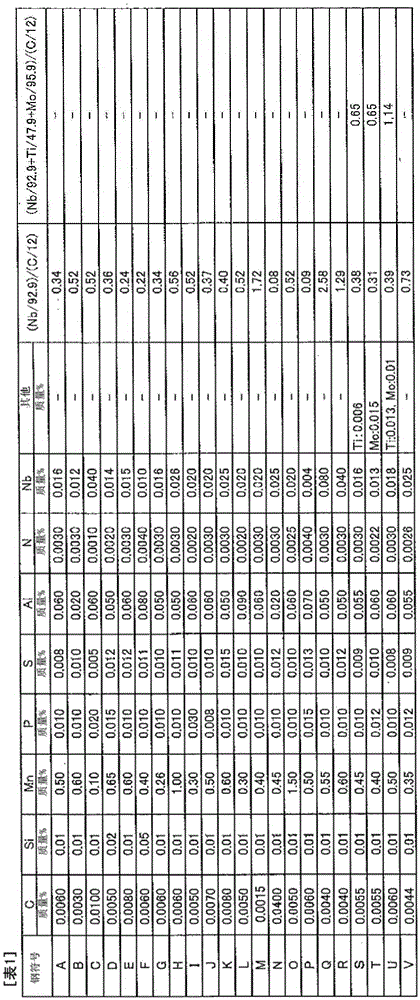

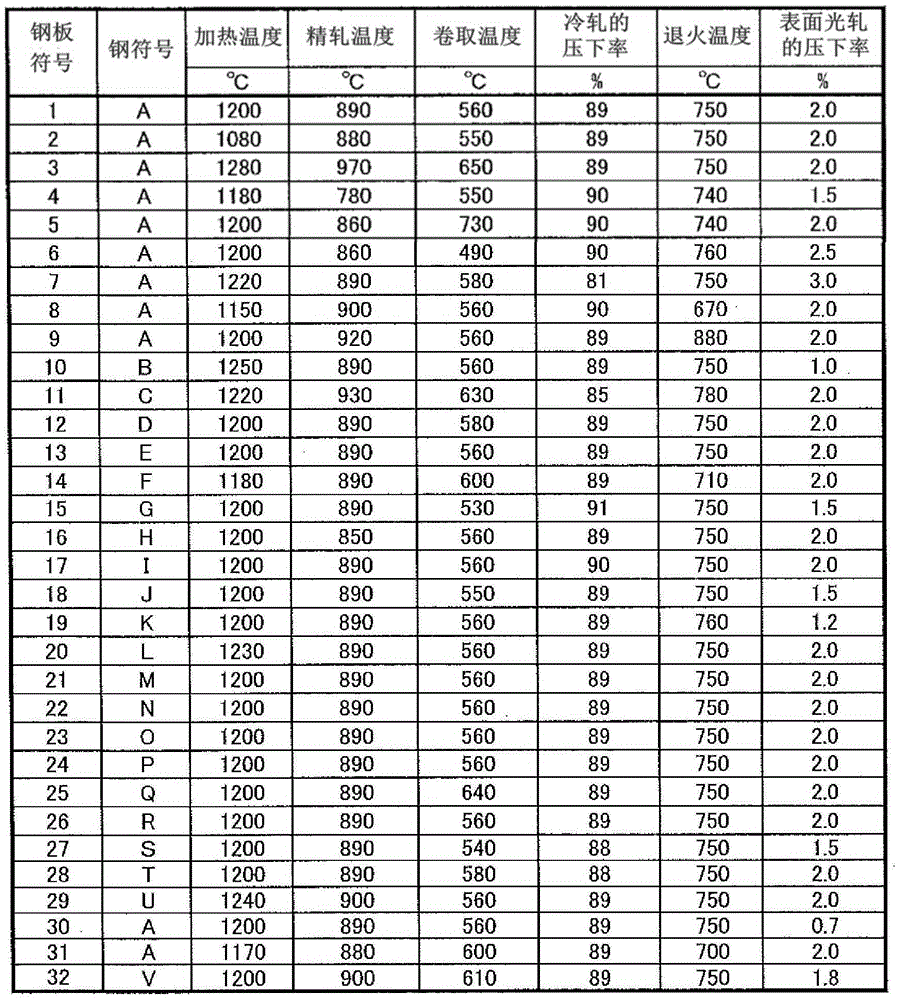

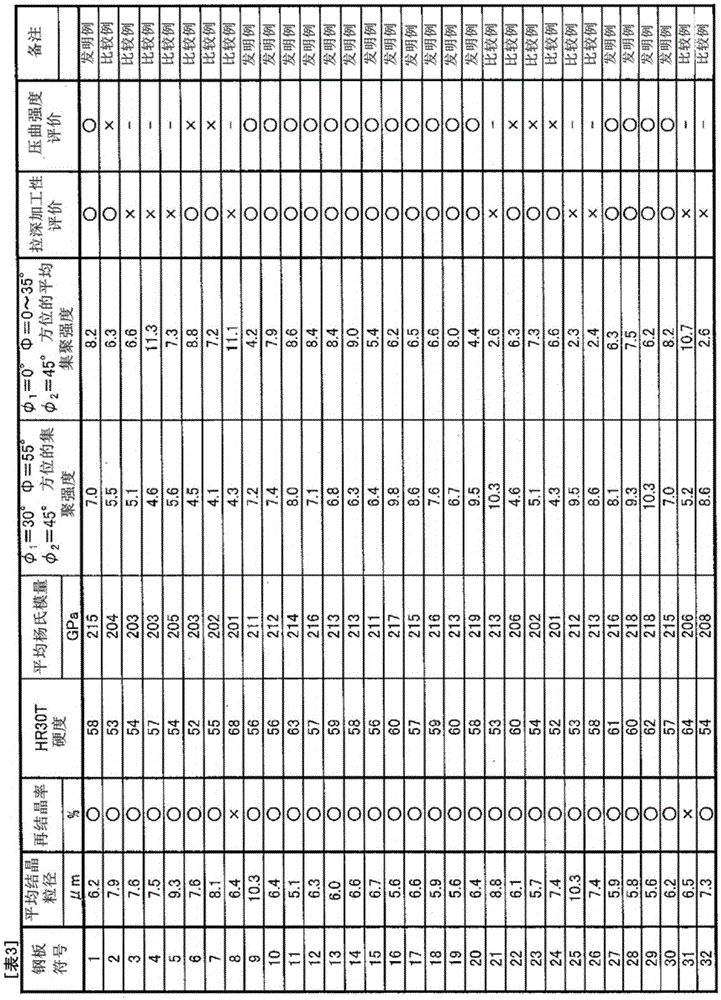

Steel sheet for can, and method for manufacturing same

ActiveCN105378134ARealize thin wallImprove rigidityFurnace typesHeat treatment furnacesYoung's modulusHardness

A purpose of the present invention is to provide a steel sheet for a can that has excellent spinning workability and exceptional strength against buckling at the base of the can resulting from external pressure, and a method for manufacturing the same. The steel sheet for a can is characterized in containing 0.0030% to 0.0100% C, 0.05% or less Si, 0.10% to 1.0% Mn, 0.030% or less P, 0.020% or less S, 0.010% to 0.100% Al, 0.0050% or less N, and 0.010% to 0.050% Nb, with the amount of C and Nb contained satisfying 0.10<=([Nb] / 92.9) / ([C] / 12)<0.60, the balance being Fe and unavoidable impurities, the HR30T hardness being 56 or greater, the average Young's modulus being 210 GPa or greater. A hot-rolled steel plate is cold-rolled with a rolling reduction of 85% or greater, and is annealed at a temperature equal to or greater than the recrystallization temperature, whereby the steel sheet for a can is obtained.

Owner:JFE STEEL CORP

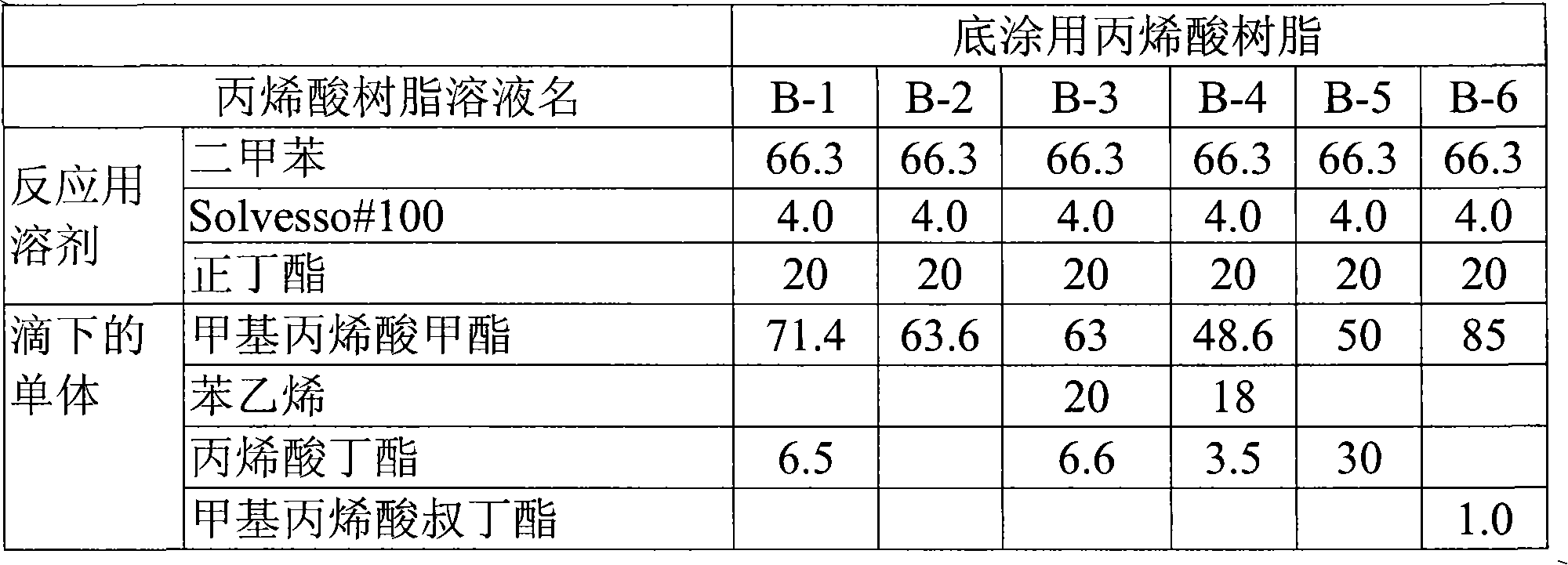

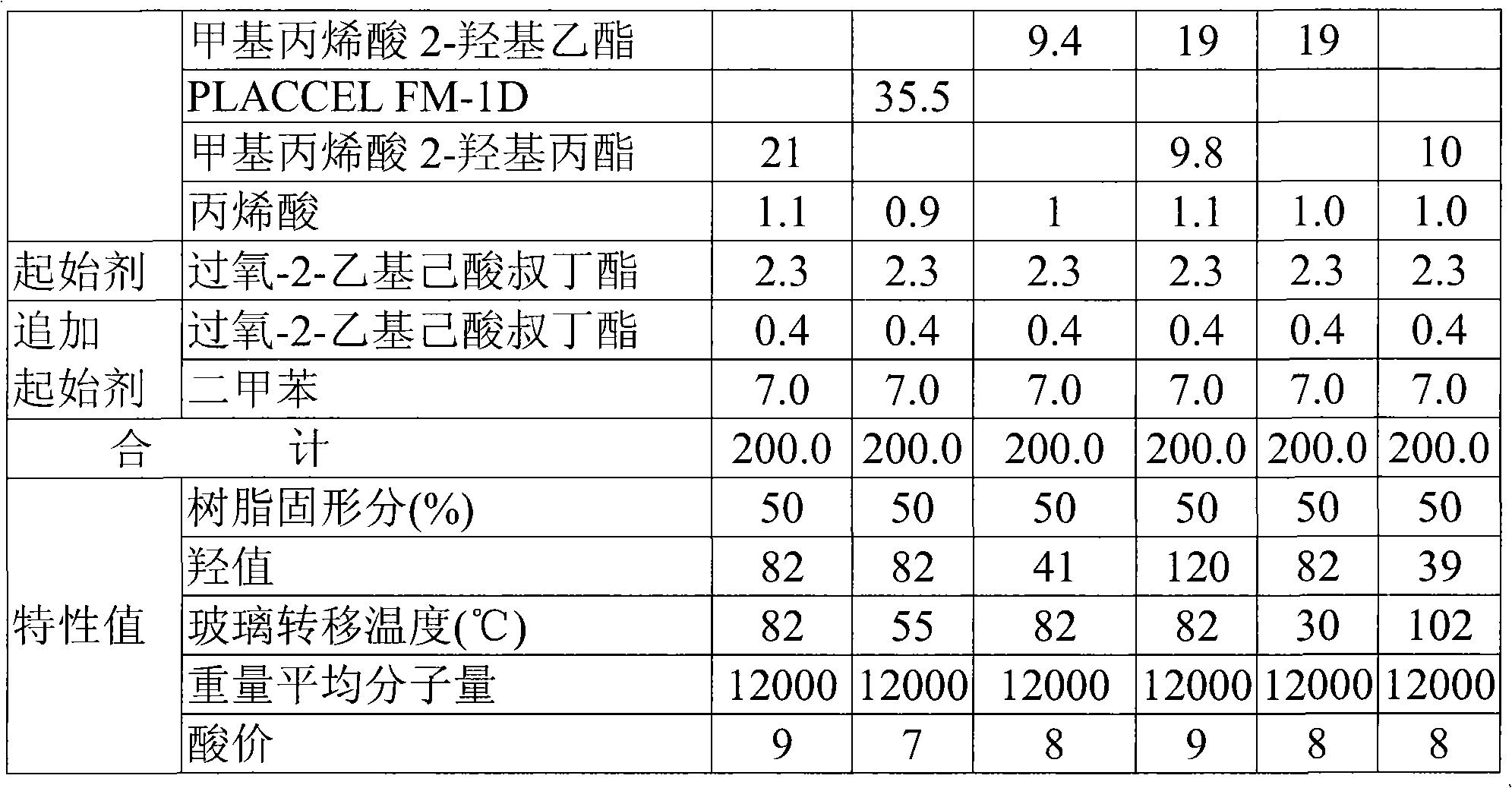

Method for formation of multi-layered coating film, and coated article

InactiveCN101678395AGood adhesionHigh hardnessSpecial surfacesPaints with free metalsCelluloseTotal solid content

Disclosed are: a method for forming a metallic multi-layered coating film having high luster, high hardness and high adhesion on a metallic material (MM); and a coated article having a coating film produced by the method. Specifically disclosed are: a method for forming a multi-layered coating film, which comprises the steps of: applying a base coat paint (BC) on the surface of an MM; applying a clear coat paint (CC) on the BC; and baking the BC and the CC simultaneously; wherein the BC comprises a melamine resin (MR), a hydroxyl-containing acrylic resin (AR) having a hydroxyl value of 50 to 100 mgKOH / g and a Tg of 50 to 100 DEG C, a cellulose resin (CR) and / or a microgel (MG), and a photoluminescent pigment, in which the ratio of the amount of the AR to the amount of the MR is 50:50 to 90:10 in terms of mass-based solid content and the ratio of the amount of the CR and / or the MG relative to the total solid content of the AR and the MR is 1.0 to 20 mass% in terms of solid content; andwherein the CC comprises an MR and an AR having a hydroxyl value of 50 to 100 mgKOH / g and a Tg of 70 to 100 DEG C, in which the ratio of the amount of the AR to the amount of the MR is 50:50 to 90:10in terms of mass-based solid content; and a coated article produced by the method.

Owner:BASF COATINGS JAPAN

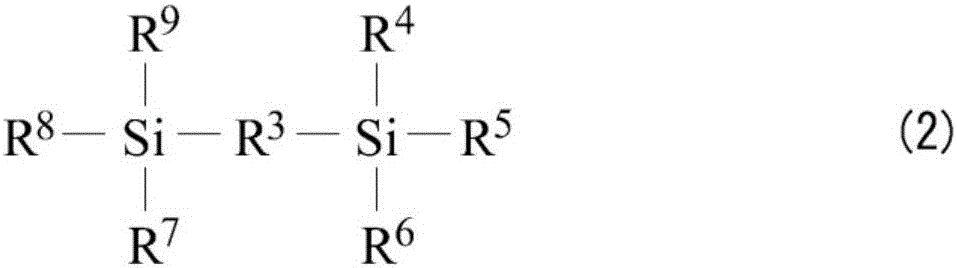

Glass substrate suitable for cover glass, etc., of mobile display device

ActiveCN108139506AImproves scratch resistanceImprove transmittanceSynthetic resin layered productsGlass/slag layered productsChemistryVisibility

Provided is a glass substrate suitable particularly as a cover glass or the like for a mobile display device, the glass substrate having high scratch resistance and smoothness, good visibility, and low reflectance. A glass substrate having, between a fluorine coating layer on a front surface side and a DLC layer on a substrate side, an intermediate layer containing a polysiloxane obtained by polycondensation of an alkoxy silane including an alkoxy silane represented by formula (1) and, as needed, an alkoxy silane represented by formula (2). (1): R1[Si(OR2)3]P (In formula (1), R1 represents a C1-12 hydrocarbon group substituted by a ureido group, R2 represents a C1-5 alkyl group, and p represents an integer of 1 or 2.) (2): (R3)nSi(OR4)4-n (In formula (2), R3 represents a hydrogen atom or aC1-8 hydrocarbon group which may be substituted by a hetero atom, a halogen atom, a vinyl group, an amino group, a glycidoxy group, a mercapto group, a methacryloxy group, an isocyanate group, or anacryloxy group, R4 represents a C1-5 alkyl group, and n represents an integer of 0-3.).

Owner:NISSAN CHEM IND LTD

Method for producing coating solution for metal oxide coating, coating solution for metal oxide coating, and metal oxide coating

ActiveCN104011260AStable and efficientFull hardnessInksLiquid/solution decomposition chemical coatingIn planeOrganic solvent

Provided are: a method for producing a coating solution for metal oxide coating whereby ample hardness is obtained even at low-temperature firing and without involving a solvent substitution step, and which possesses favorable printability and in-plane uniformity in flexographic printing; a coating solution for metal oxide coating thus produced; and a metal oxide coating. The method for producing a coating solution for metal oxide coating, the method being characterized in including: a first step for hydrolyzing a first metal alkoxide in the presence of a metal salt and organic solvent to obtain a first-step solution; a second step for adding to the first-step solution a second metal alkoxide of lower reactivity in comparison with the first metal alkoxide, and hydrolyzing / condensing to obtain a second-step solution; and a third step for adding a precipitation inhibitor to the second-step solution.

Owner:NISSAN CHEM IND LTD

Rasagiline orally disintegrating compositions

InactiveCN103494766ALow friabilityFull hardnessOrganic active ingredientsNervous disorderAlcohol sugarsRasagiline

This invention provides a solid pharmaceutical composition comprising rasagiline or a pharmaceutically acceptable salt of rasagiline, and particles having a non-filamentous microstructure of at least two sugar alcohols. This invention also provides a solid pharmaceutical composition comprising rasagiline or a pharmaceutically acceptable salt of rasagiline, a mixture of a disintegrant, a flow agent and particles having a non-filamentous microstructure of at least two sugar alcohols, a supplemental sugar alcohol, a supplemental flow agent, and a supplemental disintegrant. This invention further provides a method of treating a subject afflicted with Parkinson's disease comprising administering to the subject a therapeutically effective amount of the solid pharmaceutical composition, thereby treating the subject. Finally, this invention provides a process of making such solid pharmaceutical compositions.

Owner:TEVA PHARMA IND LTD

Functional composite film and wavelength conversion film

ActiveCN107360719AEasy to handleIncrease brightnessLayered product treatmentDiffusing elementsOligomerSide chain

A functional composite film having one or more combinations of an inorganic layer and a substrate organic layer on one surface thereof, and on the opposite surface thereof, having a light diffusion layer obtained by dispersing a light diffusion agent in a binder formed using a graft copolymer which: has an acrylic polymer as the main chain thereof; as a side chain thereof, has a urethane polymer with an acryloyl group on one end thereof, and / or a urethane oligomer with an acryloyl group on one end thereof; has a molecular weight of 10,000-3,000,000; and constitutes an acrylic equivalent of 500 g / mol or more. Also, a wavelength conversion film using the same. As a result, provided are a functional composite film and a wavelength conversion film which exhibit favorable light diffusion performance and light transmission properties.

Owner:FUJIFILM CORP

Orally disintegrating tablet comprising fat-soluble substance

InactiveCN101340899AShort disintegration timeFull strengthHydroxy compound active ingredientsPill deliveryCelluloseOrally disintegrating tablet

Disclosed is an orally disintegrating tablet which comprises a high dose of a fat-soluble substance, can be produced by a dry tableting process, and can be disintegrated in an oral cavity rapidly. Also disclosed is a process for production of the tablet. The tablet can be produced by preparing a granule comprising a porous substance and a fat-soluble substance adsorbed onto the porous substance, mixing the granule with a sugar alcohol, crystalline cellulose and a lubricant homogeneously, and shaping the mixture into a tablet.

Owner:EISIA R&D MANAGEMENT CO LTD

Photocurable support material composition for inkjet 3D printers, ink for inkjet 3D printers, cartridge for inkjet 3D printers, method for producing support material and method for producing optically shaped article

ActiveCN109641395AGood water solubilityFull hardnessAdditive manufacturing apparatus3D object support structuresPolymer scienceO-Phosphoric Acid

A photocurable support material composition for inkjet 3D printers according to the present invention contains a photopolymerization initiator and a water-soluble ethylenically unsaturated monomer that contains an ionic group and a counter ion. It is preferable that the ionic group is at least one group selected from the group consisting of a carboxylic acid group, a phosphoric acid group and a sulfonic acid group. It is also preferable that the counter ion is at least one ion selected from the group consisting of a sodium ion, a potassium ion and an ammonium ion.

Owner:NIPPON SHOKUBAI CO LTD

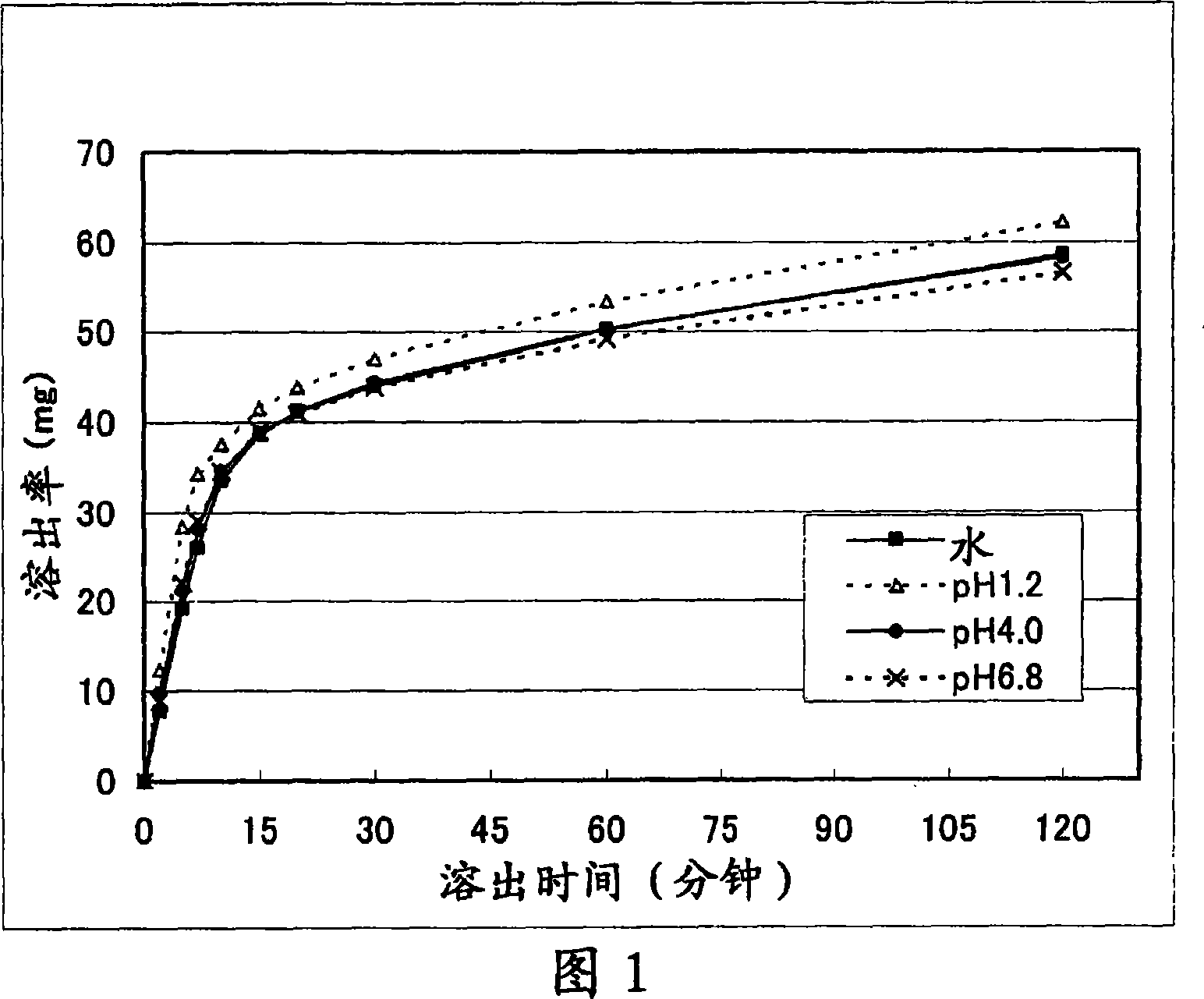

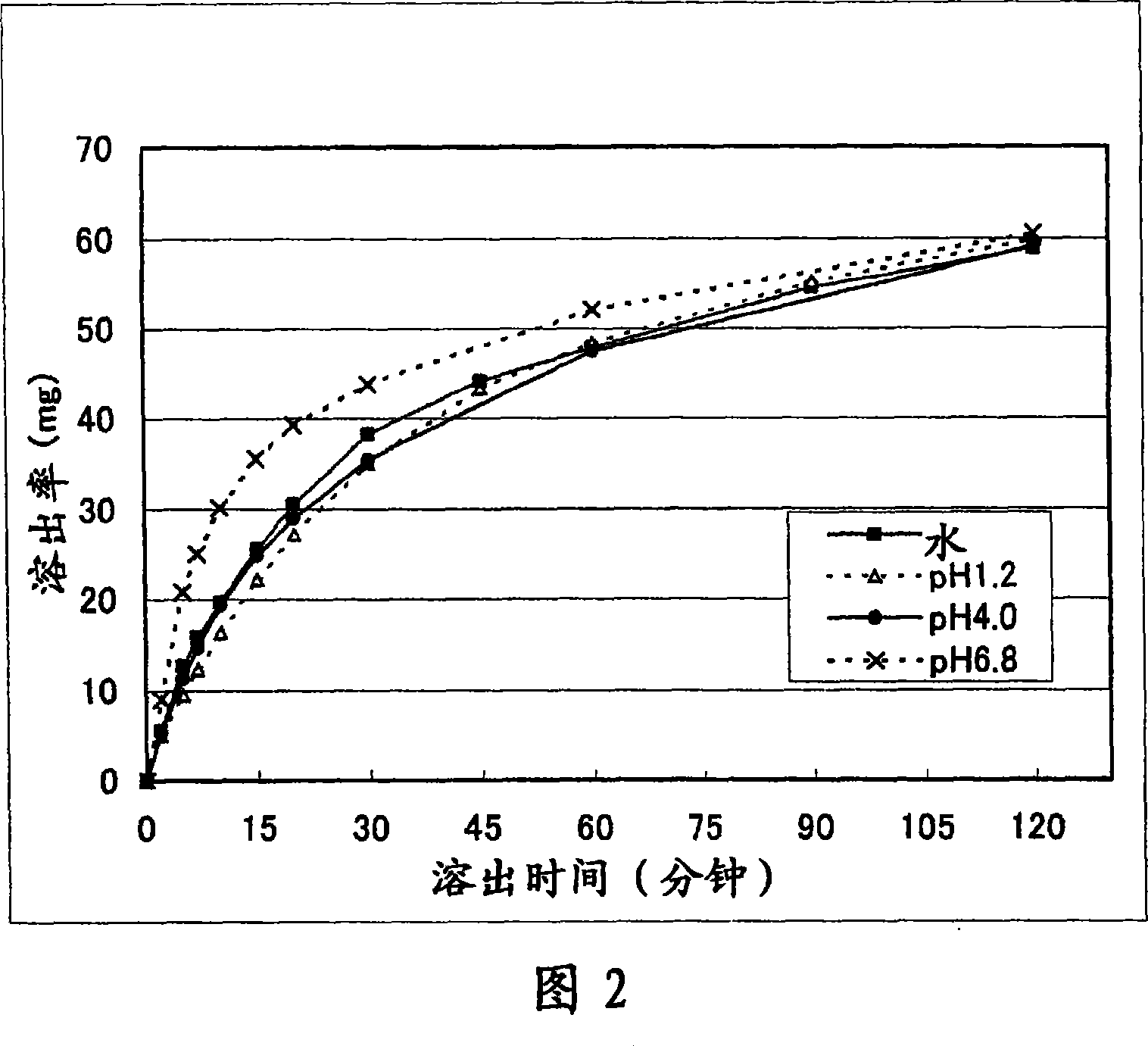

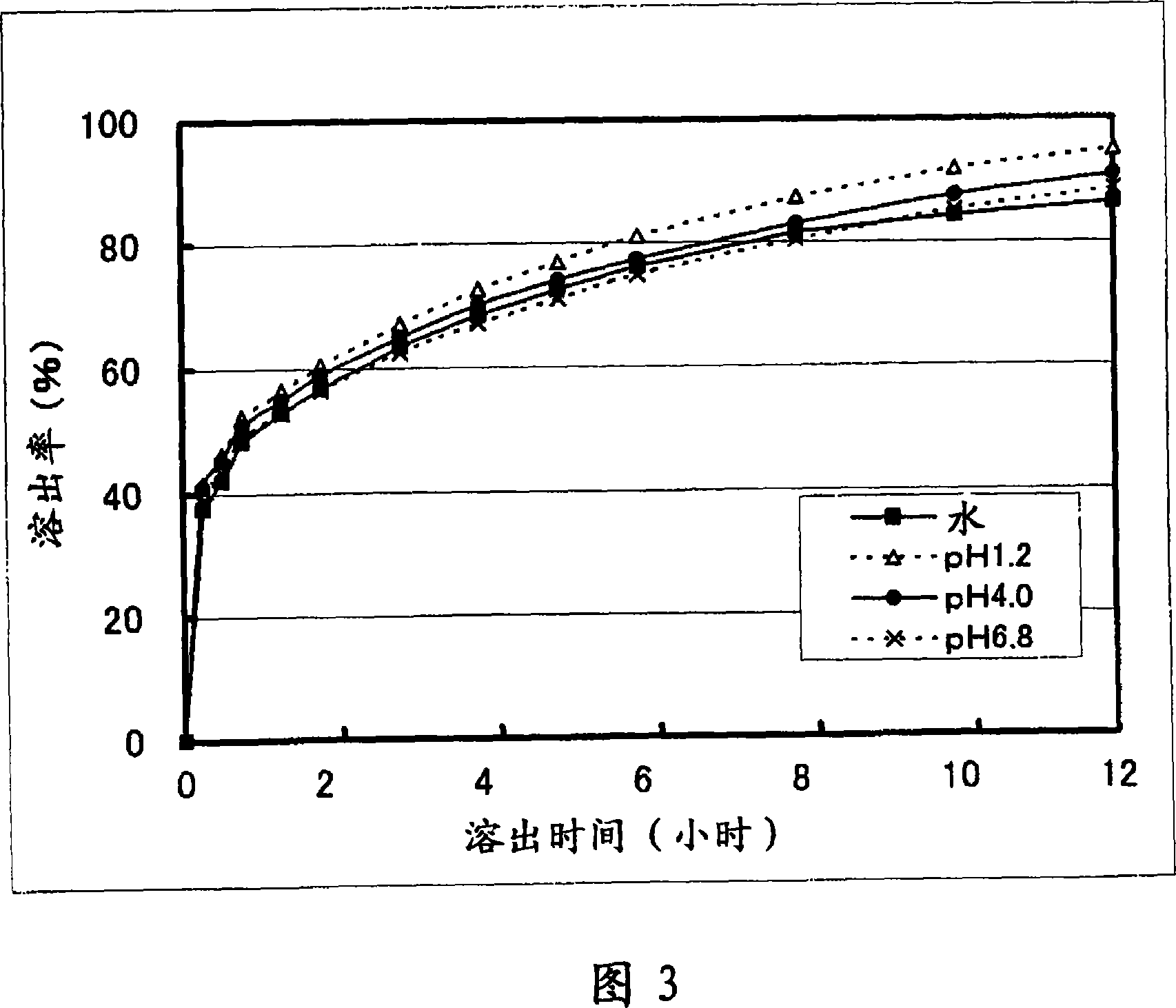

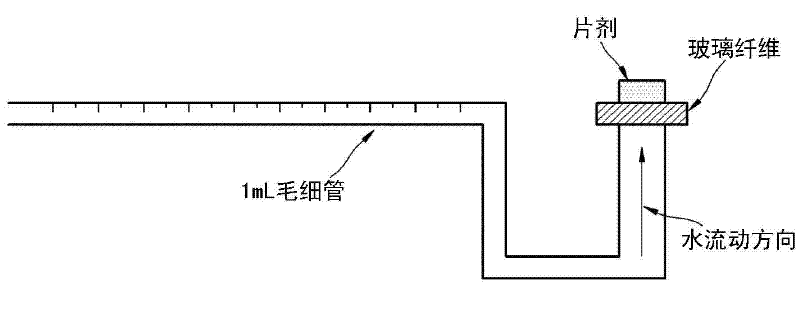

Solid pharmaceutical preparation

InactiveCN101031322AFull hardnessSwift independenceOrganic active ingredientsNervous disorderHas active ingredientAdditive ingredient

To provide a sustained-release solid pharmaceutical preparation having a quick-release part and a sustained-release part and stably having an excellent quick releasing characteristic with little pH dependency in an initial dissolution. The present invention relates to that, in a preparation containing a medical ingredient as an effective ingredient, particularly active analgesic ingredient, a sustained-release solid pharmaceutical preparation which is characterized in that it is a solid pharmaceutical form having a quick-release part and a sustained-release part and contains effective ingredient in both parts and the quick-release part contains a partly pregelatinized starch and a low substituted hydroxypropylcellulose as additives. In the preparation of the present invention, stable and quick initial dissolution behavior being independent upon pH is achieved even when some sustained-release part is contaminated in the quick-release part due to the difference in the tabletting method for multi-layered tablets. Furthermore, the preparation is practical as a preparation having a sufficient hardness in view of necessity that abrasion, breakage, crack, etc. are not generated when the tablet is coated.

Owner:NIPPON ZOKI PHARM CO LTD

Fast dissolving oral tablets and method for production thereof

InactiveCN102223881AFull hardnessNervous disorderInorganic non-active ingredientsBULK ACTIVE INGREDIENTActive ingredient

The present invention provides a fast dissolving oral tablet, and a method for the production thereof, comprising the steps of: compressing a mixture of active ingredients, pharmaceutically allowable additives, and supercritical fluid-soluble substances to produce the tablets; and allowing the tablets to contact a supercritical fluid to extract supercritical fluid-soluble substances and form fine pores in the tablets.

Owner:CJ CHEILJEDANG CORP

Antiglare film

PendingCN111602073AGood anti-glare effectNot easy to cause glareDiffusing elementsPolyolefinRefractive index

The present invention addresses the problem of providing an antiglare film which has an excellent antiglare property, in which glare is less likely to occur, and which is able to cope with higher definition. The abovementioned problem is solved by an antiglare film 1 which has an antiglare layer 11 on at least one surface of a substrate film 10, and is characterized in that the antiglare layer 11contains a base resin 12, particles A having a refractive index difference of 0.02 or more from the base resin 12 and a density exceeding 0.90 times the density of the base resin 12, and particles B having a density being 0.90 times or less the density of the base resin 12. By using low-density polyolefin particles or the like as the particles B, precipitation of the particles B can be prevented,thereby making it easier to solve the abovementioned problem.

Owner:KIMOTO & CO LTD 2 7 1 SHINJUKU SHINJUKU KU TOKYO JAPAN

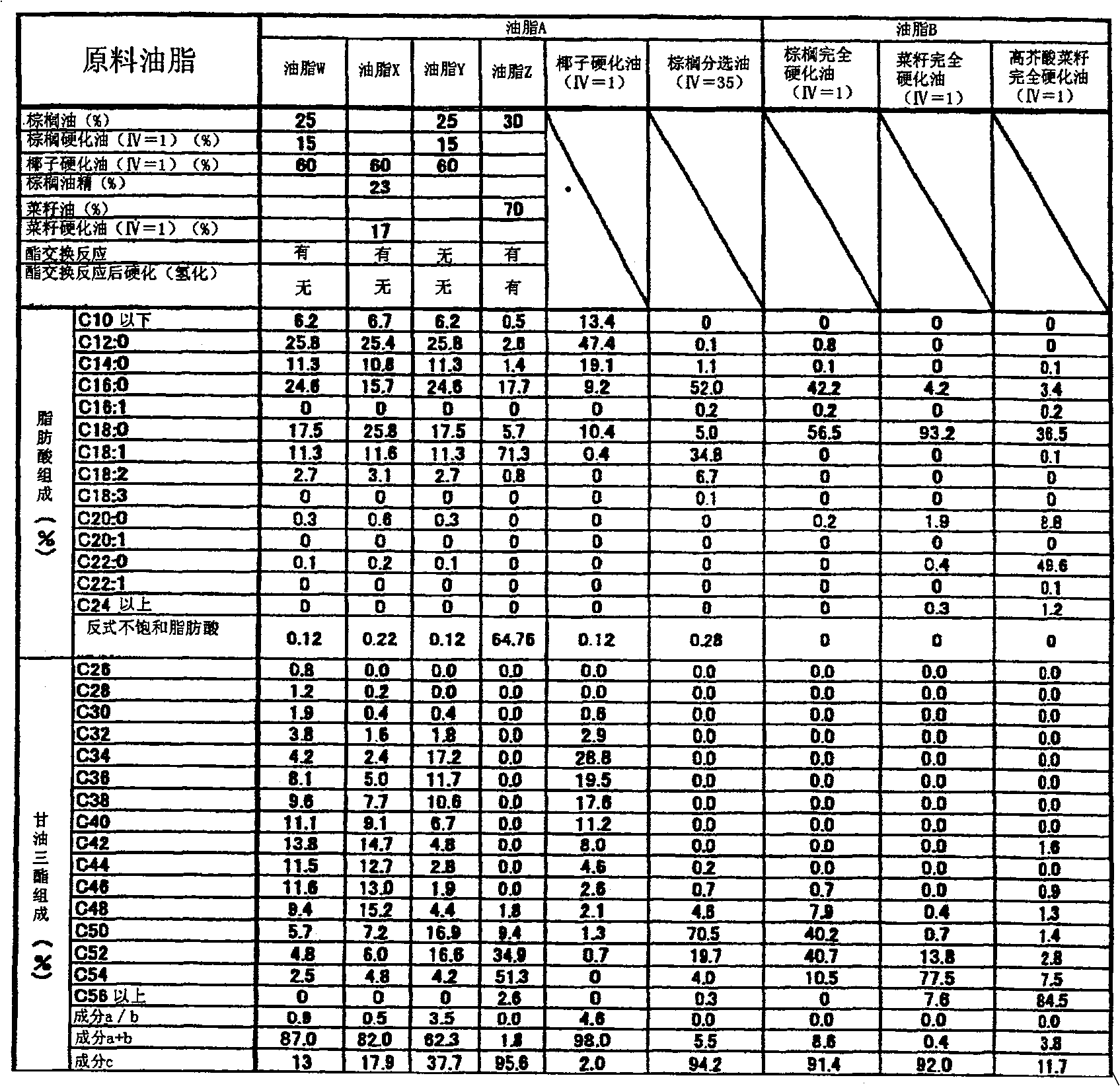

Hard fat and chocolate

ActiveCN101926391BFull hardnessStorage stabilityConfectionerySweetmeatsTriglycerideLipid composition

The invention provides hard fat comprising a lipid composition and chocolate comprising the hard fat. The lipid composition comprises lipid A and lipid B. Trans unsaturated fatty acids account for 5% in mass of all the fatty acids composed of lipid. Mass ratio of components a and b in lipid A to component c in lipid B is shown in following formula: c / a+b=0.001-0.3. Referring to lipid A: (1) in the composing fatty acids, saturated fatty acids with number of carbon atom less than 14 account for 25-60% in mass, and saturated fatty acids with carbon atom number more than 20 account for less than 1% in mass, (2) in triglyceride of the fatty lipid, mass ratio of triglyceride (component a) with number of carbon atoms composing the fatty acid being less than 40 to triglyceride (component b) with number of total carbon atoms composing the fatty acid being 42-48 is shown in the following formula: a / b=0.2-1; referring to lipid B: (3) in the composing fatty acids, saturated fatty acids account for 95% in mass, and fatty acids with carbon number more than 20 account for less than 5% in mass, (4) in triglyceride of lipid, triglyceride with number of carbon atom composing the fatty acids being 50-54 account for 80% in mass.

Owner:KAO CORP

Film-forming coating liquid manufacturing method of film-forming coating liquid and film-covered base material

The invention relates to a film-forming coating liquid manufacturing method of a film-forming coating liquid and a film-covered base material. According to the invention, the film-forming coating liquid is characterized in that: the film-forming coating liquid is formed by solving or diffusing at least any one (B component) of an organic compound (A component) which can form a chelate tegother with a metal alkoxide, 6-functional group silane and a hydrolyze condensate thereof and at least any one (C component) of the metal alkoxide and the hydrolyze condensate thereof. The mole ratio of the mole number of the A component and the mole number of the C component is more than 0.5 and less than 8. (as shown in the description) M (OR10)n (3).

Owner:JGC CATALYSTS & CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com