Fast dissolving oral tablets and method for production thereof

An oral tablet, rapid technology, applied in the direction of pill delivery, pharmaceutical formula, medical preparations of non-active ingredients, etc., can solve the problems of inapplicability, abnormal size of tablets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

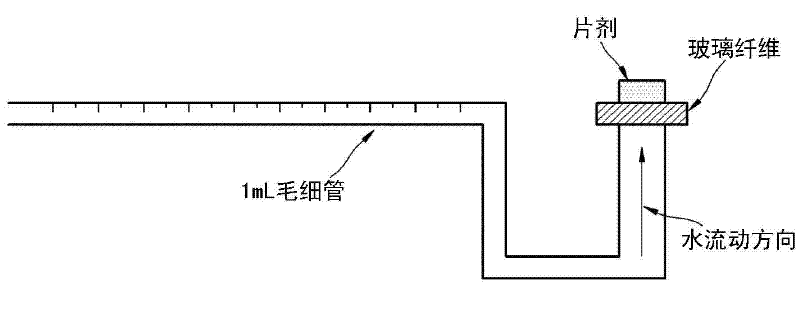

Method used

Image

Examples

Embodiment 1

[0039] A general tablet with a total tablet weight of 100 mg and a hardness of 7 kp was obtained by using 90 mg D-mannitol as a sugar alcohol, 2.5 mg PVR k-30 as a binder, 5 mg cetyl alcohol as a supercritical fluid-soluble substance, and 2.5 mg SiO 2 Made as a lubricant. And then, cetyl alcohol as a supercritical fluid-soluble substance was purified and extracted by contacting the tablet with supercritical fluid at a temperature of 40° C. and a pressure of 80 bar for 30 minutes to produce a fast-dissolving tablet with micropores.

Embodiment 2

[0041] A general tablet with a total tablet weight of 100 mg and a hardness of 7 kp was obtained by using 90 mg D-mannitol as a sugar alcohol, 2.5 mg PVR k-30 as a binder, 5 mg cetyl alcohol as a supercritical fluid-soluble substance, and 2.5 mg SiO 2 Made as a lubricant. And then, cetyl alcohol as a supercritical fluid-soluble substance was purified and extracted by contacting the tablet with supercritical fluid at a temperature of 40° C. and a pressure of 80 bar for 30 minutes to produce a fast-dissolving tablet with micropores. The extraction rate of the supercritical fluid-soluble matter is 50.4%.

Embodiment 3

[0043] The same method as in Example 2 was used to produce fast dissolving tablets, except that the generic tablet in Example 2 above was contacted with supercritical fluid at a temperature of 40° C. and a pressure of 80 bar for 90 minutes. The extraction rate of the supercritical fluid-soluble matter is 101.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com