Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Excellent resistance to salt spray corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanometer solvent-free epoxy antirust paint and preparation method thereof

ActiveCN103709901AGood wear resistanceEasy to maintainAnti-corrosive paintsEpoxy resin coatingsSolventCardanol

The invention discloses nanometer solvent-free epoxy antirust paint and a preparation method thereof. The nanometer solvent-free epoxy antirust paint comprises the following raw material components in parts by weight: component A: 20-40 parts of E-44 epoxy resin, 5-15 parts of active diluent, 10-20 parts of zinc phosphate, 5-20 parts of mica powder, 10-20 parts of nanometer alumina, 10-20 parts of ferric oxide powder and 5-10 parts of aluminum triphosphate; component B: alicyclic amine or anacardol serving as a curing agent. The weight ratio of the component A to the component B is (6-8): 1. The nanometer solvent-free epoxy antirust paint disclosed by the invention is good in antirust property, environment-friendly, free of VOC emission, not harsh in construction conditions and low in requirements on base material, and the paint can be thickly coated once; the nanometer solvent-free epoxy antirust paint can be widely applied to a variety of fields, for example, bridge, guardrail steel structure, building material, machinery, etc.

Owner:FOSHAN GAOMING FULITE CHEM CO LTD

High-strength wear-resistant modified natural rubber and preparation method thereof

The invention discloses a high-strength wear-resistant modified natural rubber. The rubber comprises, by weight, 60-70 parts of natural rubber, 15-20 parts of ethylene propylene diene monomer, 6-9 parts of butadiene rubber, 8-10 parts of a reinforcing agent, 2.5-3.5 parts of epoxy resin, 2-3 parts of a silane coupling agent, 1-2 parts of an accelerant, 1-2 parts of an anti-aging agent, 0.3-0.5 part of an emulsifier and 4.5-5 parts of a plasticizer. The rubber shows good mechanical strength at a high temperature and a low temperature, and also has excellent wear resistance and good sunlight andultraviolet aging resistance and weather resistance. In addition, the rubber also has good salt spray corrosion resistance, excellent flame retardance, good comprehensive performances and long service life, and can meet the use requirements of various fields, such as aviation products, windscreen wipers for automobiles, sealing strips, sealing rings and the like.

Owner:贵州科润密封科技有限公司

Inductor encapsulation powder based on thermoplastic polymer material and production process thereof

PendingCN110835466AExcellent insulation levelExcellent resistance to salt spray corrosionPolymer chemistryCorrosion

Inductor encapsulation powder based on a thermoplastic polymer material and a production process thereof are disclosed. According to a technical scheme, the powder includes 0.5-25% by mass of a thermoplastic polymer and 25-99.5% by mass of magnetic metal powder. According to the inductor encapsulation powder, heat resistance of a cured inductor is at least 50 DEG C higher than that of an inductorencapsulated by utilizing conventional resin, and under the same addition amount, the encapsulated inductor has a better insulation level and better resistance to salt spray corrosion.

Owner:上海太朔材料技术有限公司

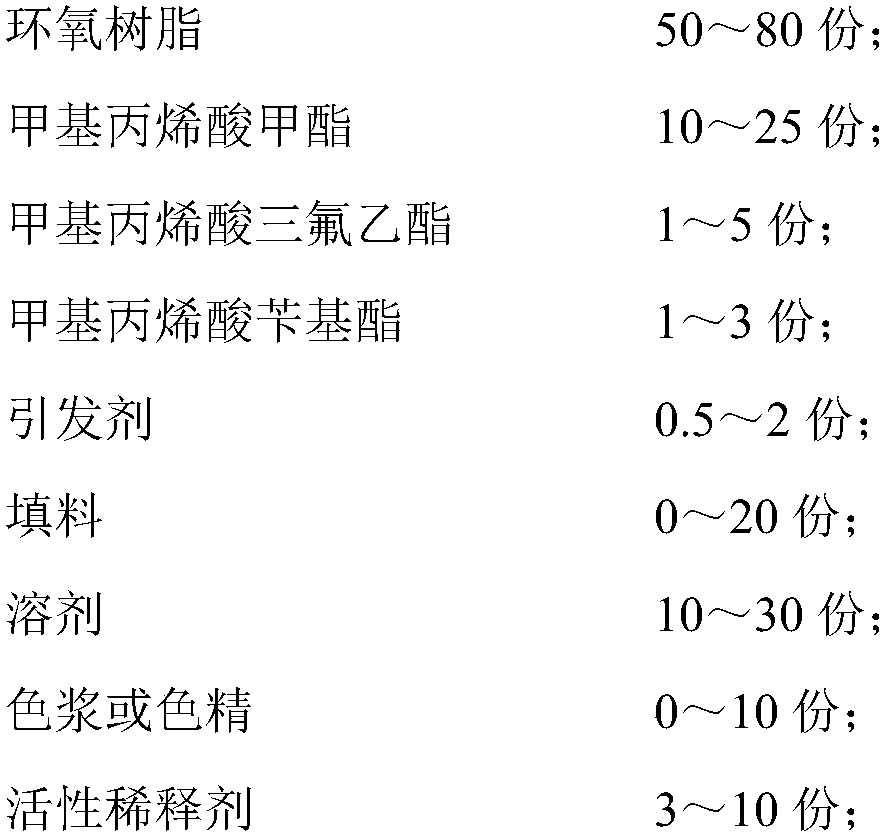

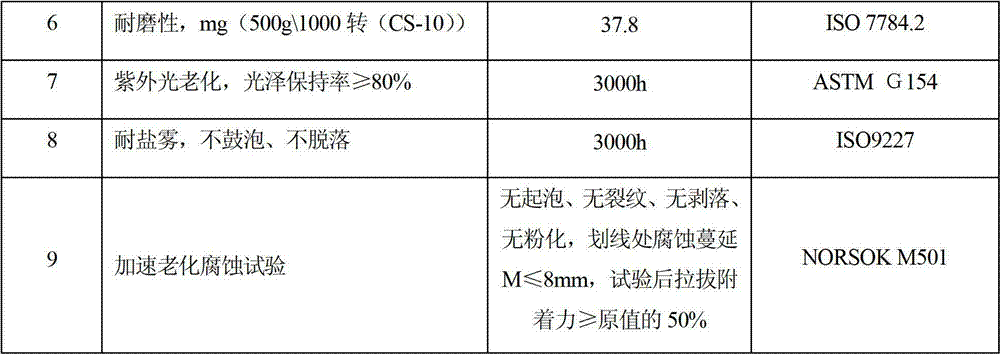

Durable polyurethane finish capable of resisting marine-atmosphere environment, and preparation method thereof

ActiveCN103589310ALow shrinkageReduce surface defectsAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyFatty acid

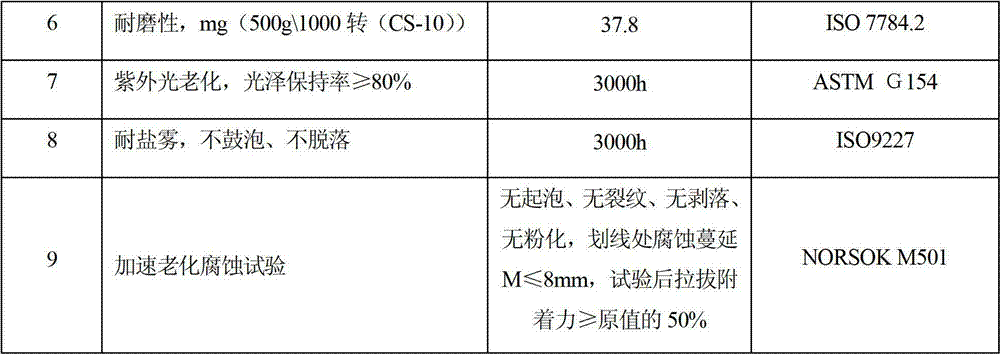

The invention relates to a durable polyurethane finish capable of resisting marine-atmosphere environment, and a preparation method thereof. An A solution is prepared by an HDI trimer, a corrosion inhibitor and polyurethane-grade butyl acetate; a B solution is prepared by a polyurethane resin hydroxyl component, xylene, a polymethacrylate solution, a fluorine-containing organosilicone solution, a silicone-free acrylic polymer, a polysiloxane-polyether copolymer, a mixture of alkaline and acidic fatty acid surface active substances, a ultraviolet absorber, a light stabilizer, a polyurethane curing accelerator, a polyethylene micronization wax and precipitated barium sulphate, quartz powder, sericite powder and rutile-structured titanium dioxide. When being in use, the A solution and the B solution are mixed and cured to form a coating. The coating has good adhesion with a micaceous iron epoxy coating and an epoxy paste coating and has excellent weather resistance and salt fog resistance. An artificial accelerated aging test shows that gloss retention of the finish can reach 80% at 3,000 h. The finish can be applied in ocean platform overhead pipelines and offshore wharf surface pipelines.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Salt spray test communication cable inner-layer coating material and production method thereof

ActiveCN102660070AVerification of salt spray corrosion resistanceQuality improvementCoaxial cables/analogue cablesLinear low-density polyethyleneAntioxidant

The invention relates to a salt spray test communication cable inner-layer coating material and a production method thereof. The invention aims at providing an improvement method of a coating material and a corresponding production method of the improved coating material. The production method provided by the invention can effectively improve salt spray corrosion resistance of a coaxial cable. A technical scheme of the production method comprises that the salt spray test communication cable inner-layer coating material comprises raw materials of linear low density polyethylene, ethylene-acrylic acid copolymer, a corrosion inhibitor for copper, calcium stearate, and an antioxidant for copper, wherein a weight ratio of the raw materials is (82-86): (11-15): 1: 1: 1; a buffer agent is benzotriazole or sodium mercaptobenzothiazole; the corrosion inhibitor for copper is methylbenzotriazole; and the antioxidant for copper is an antioxidant MD-1024 or an antioxidant 3114. The production method of the salt spray test communication cable inner-layer coating material comprises the following steps of 1, raw material reparation, 2, master batch preparation, 3, additive preparation and 4, extrusion and cutting.

Owner:ZHEJIANG WANMA TIANYI COMM WIRE & CABLE

Water-based, environment-friendly and high-temperature coating and preparation method thereof

ActiveCN105524548AImprove poor acid and alkali resistanceImproved resistance to chemical solventsCoatingsWater basedOil and grease

The invention provides a water-based, environment-friendly and high-temperature coating and relates to the technical field of chemical coatings. The coating comprises, in parts by mass, 20-40 parts of water-based polyether sulfone resin, 20-40 parts of water-based polyamide imide resin, 5-15 parts of water-based silicone resin, 1-5 parts of polytetrafluoroethylene resin, 5-15 parts of an ether solvent, 1-5 parts of a pigment, 5-20 parts of filler, 0.1-1 part of a wetting agent, 0.1-1 part of an antifoaming agent and 10-30 parts of deionized water. The coating has outstanding comprehensive performance, prominent hardness, rich gloss, excellent high temperature resistance, higher salt fog resistance, high resistance to water, steam, oil, solvents and chemicals, excellent adhesive force and toughness, and besides, the preparation method is simple and easy, medium in cost, particularly higher in cost performance and suitable for mass preparation.

Owner:开封夸克新材料有限公司

Environment-friendly epoxy floor paint and preparation method thereof

InactiveCN108342144AStrong adhesionCuring shrinkage is smallAnti-corrosive paintsCoatingRaw material

The invention particularly relates to the field of coatings, and particularly relates to environment-friendly epoxy floor paint and a preparation method thereof. The invention provides the environment-friendly epoxy floor paint. The environment-friendly epoxy floor paint is prepared from preparation raw materials which at least comprise a first component and a second component, wherein the weightratio of the first component to the second component is 20 to (1 to 5).

Owner:青岛舜捷通生物科技有限公司

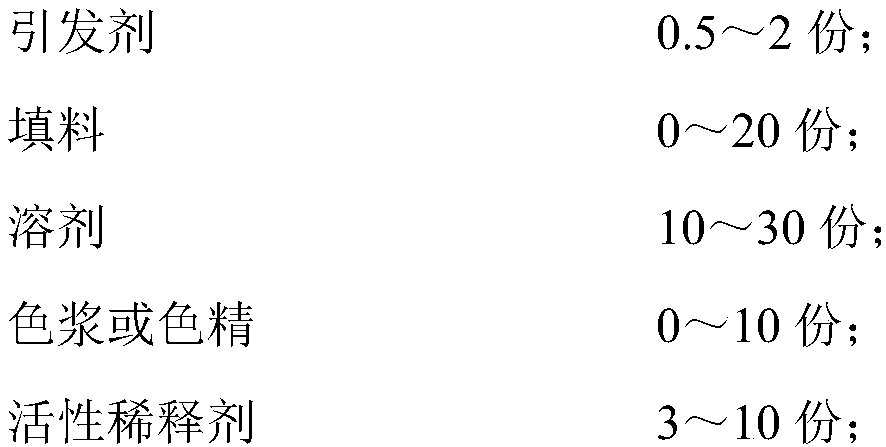

Novel painting reflective film

InactiveCN102854554AGood weather resistanceEasy to useSynthetic resin layered productsOptical elementsWeather resistanceGlass microsphere

The invention relates to a novel painting reflective film. The novel painting reflective film comprises a surface protection layer, a painting ink absorption layer, an acrylic surface layer, a glass microsphere layer, a reflective layer and release paper. The novel painting reflective film is good in light resistance, weather resistance and acid-base resistance, and can be widely applied to outdoor signboards or indicative marks. In addition, the novel painting reflective film has the characteristics of good flexibility, convenience for use and the like; temporary or long-term marks can be made by painting anytime and anywhere; and application range and area of the reflective film are expanded.

Owner:CHANGZHOU RIYUE REFLECTIVE MATERIAL

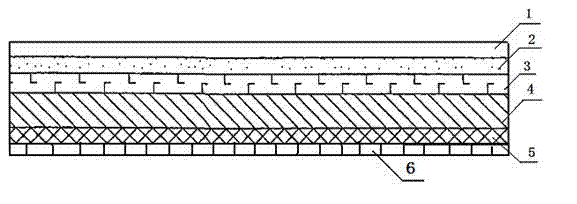

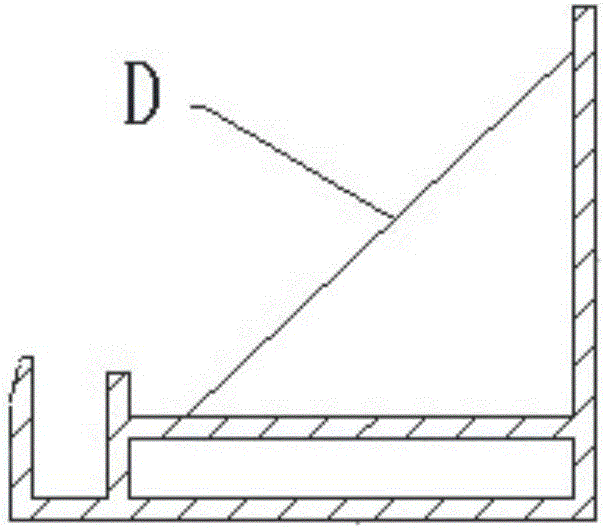

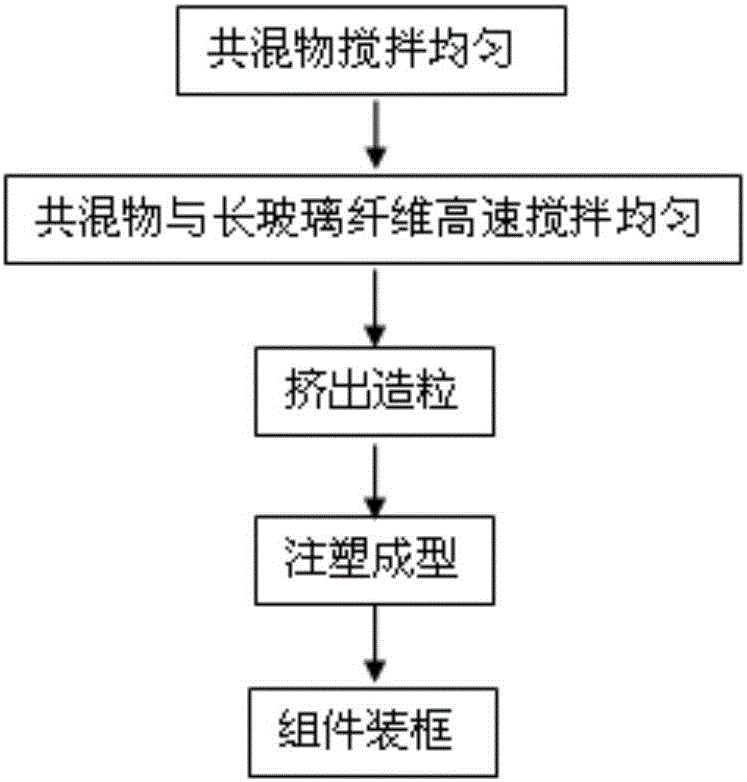

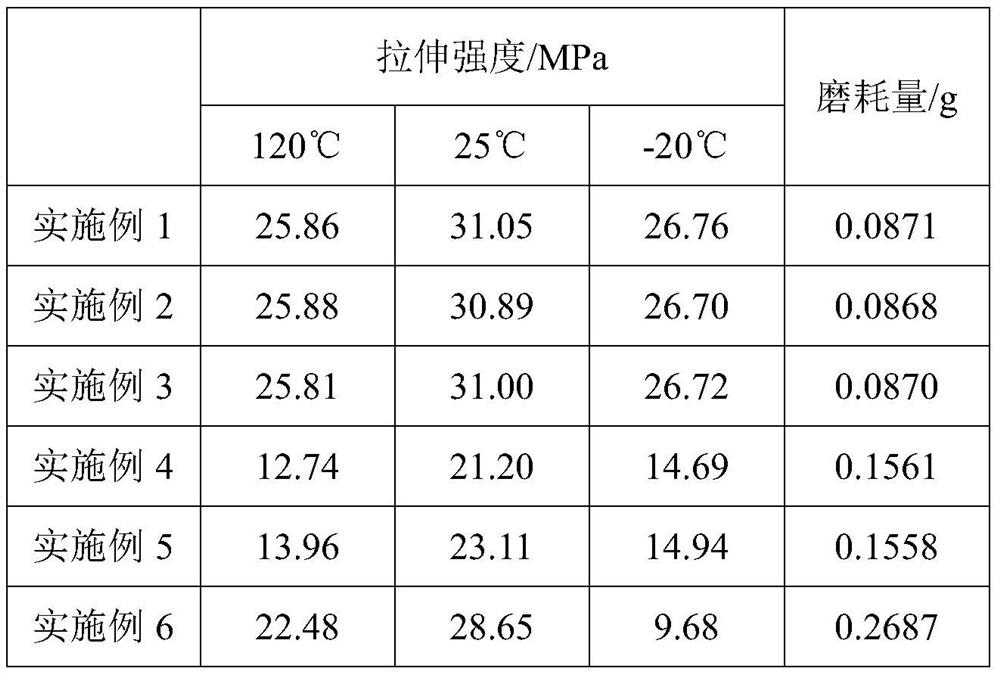

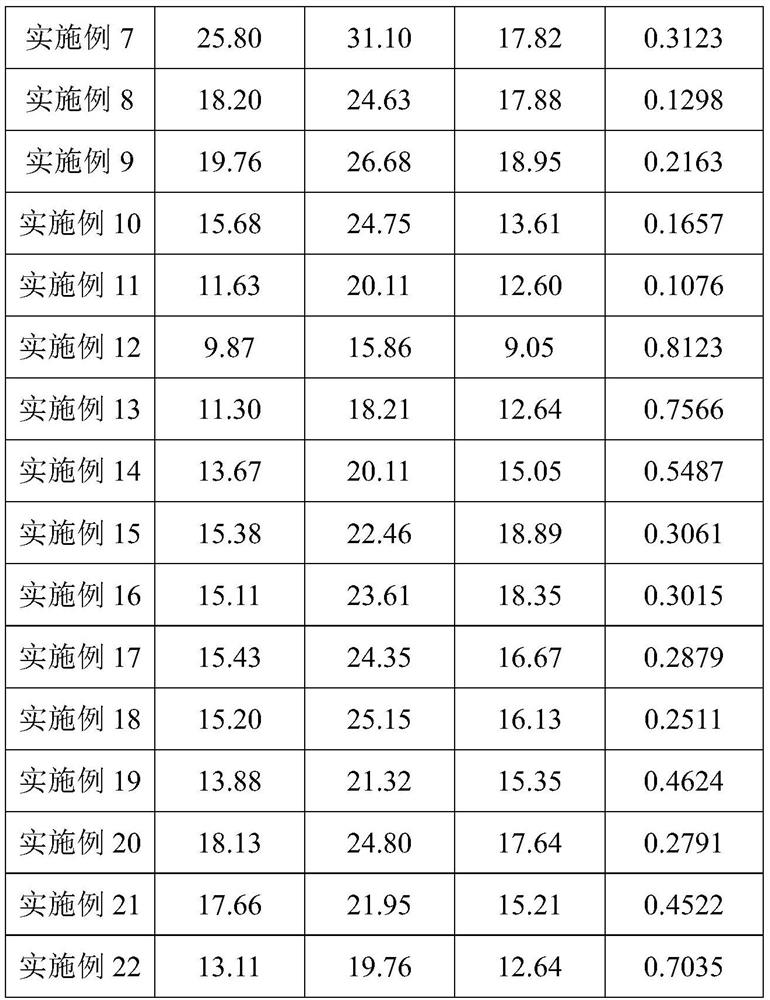

Resin frame, preparation method, and application thereof

The invention relates to a resin frame, a preparation method, and an application thereof and belongs to the field of photovoltaic materials. The resin frame is composed of, by weight, 80 parts of ABS resin, 10-50 parts of PA6, 20-50 parts of long-glass fibers, 3-20 parts of a compatilizer, 0.3-1.5 parts of an anti-oxidizing agent, 0.5-1.4 parts of an ultraviolet absorber, 0.3-1.3 parts of an impregnating agent, 0.01-0.6 parts of a photo-stabilizer, and 0.5-6 parts of a flame retarder. The ABS / PA6 resin material modified by the glass fibers and the additives is light in weight, has good insulation property and strong flame retarding performance, has strong anti-salt smoke corrosion capability, and can be used as a novel material in a frame of a solar component.

Owner:NINGBO HUASHUN SOLAR ENERGY TECH

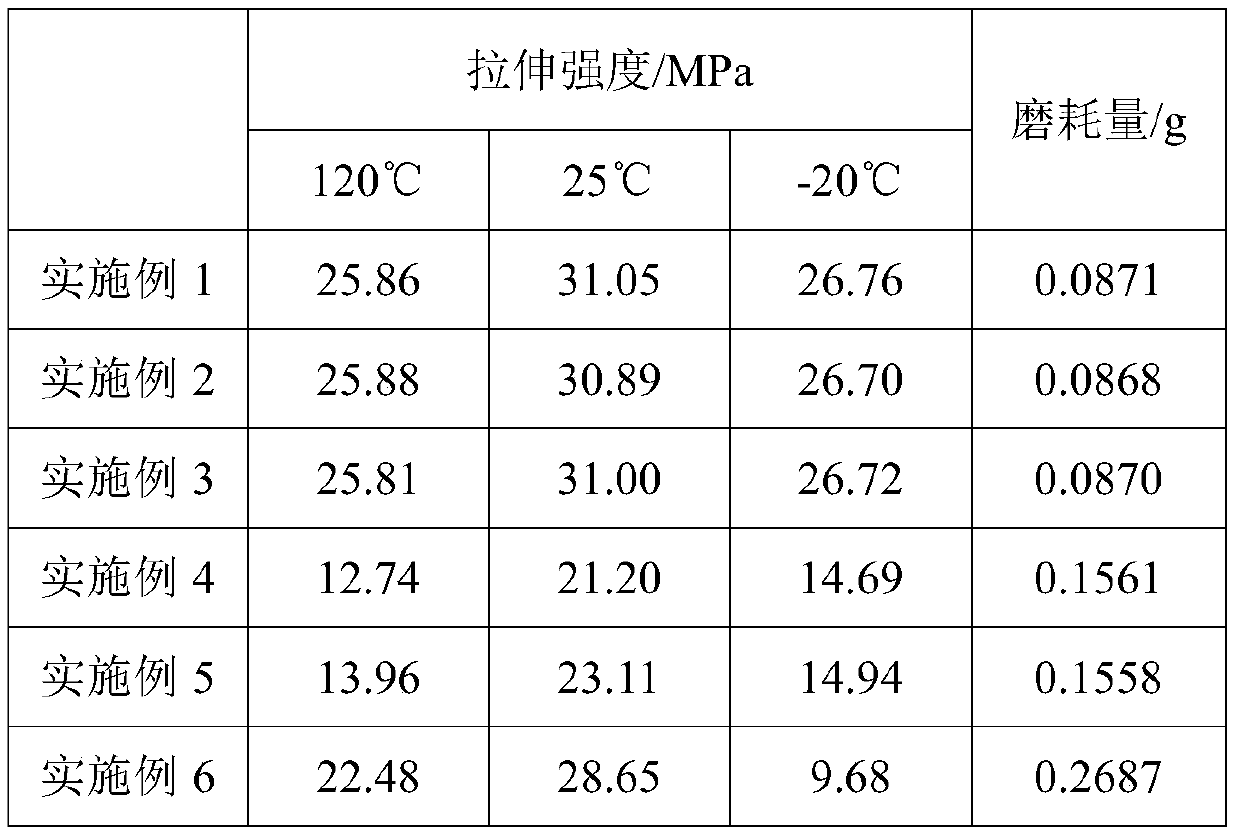

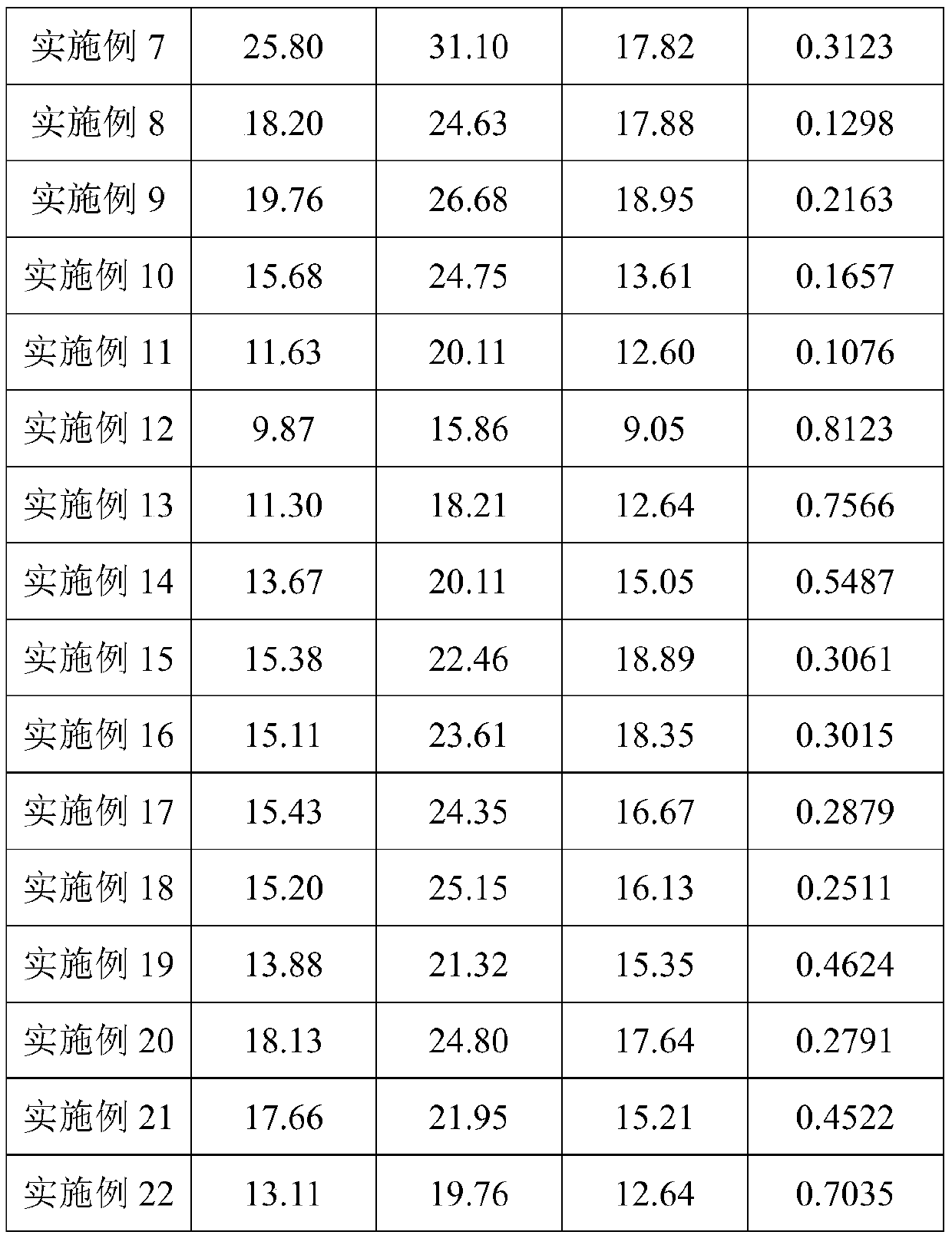

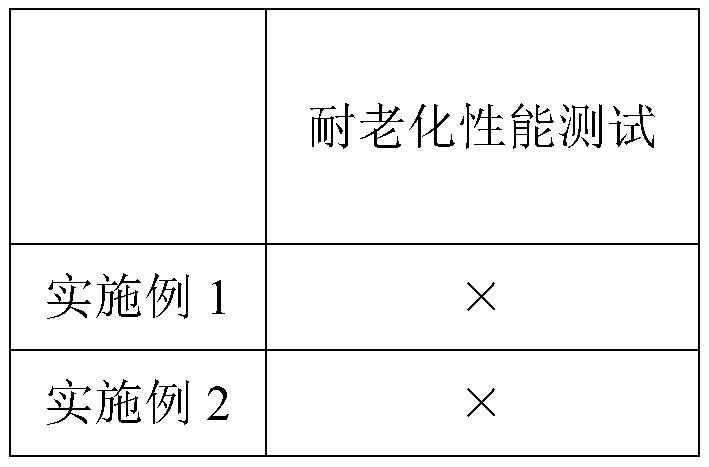

A kind of high-strength wear-resistant modified natural rubber and its preparation method

The invention discloses a high-strength wear-resistant modified natural rubber, which comprises the following raw materials in parts by weight: 60-70 parts of natural rubber, 15-20 parts of EPDM rubber, 6-9 parts of butadiene rubber, reinforcing agent 8-10 parts, 2.5-3.5 parts of epoxy resin, 2-3 parts of silane coupling agent, 1-2 parts of accelerator, 1-2 parts of anti-aging agent, 0.3-0.5 parts of emulsifier, 4.5-5 parts of plasticizer . The rubber obtained in the invention shows good mechanical strength at high temperature and low temperature, and also has excellent wear resistance, good sunlight resistance, ultraviolet aging resistance and weather resistance. In addition, the rubber obtained in the present invention also has good salt spray corrosion resistance, excellent flame retardancy, good comprehensive performance, long service life, and can meet various fields, such as aviation products and automotive wipers, sealing strips, sealing rings, etc. Requirements.

Owner:贵州科润密封科技有限公司

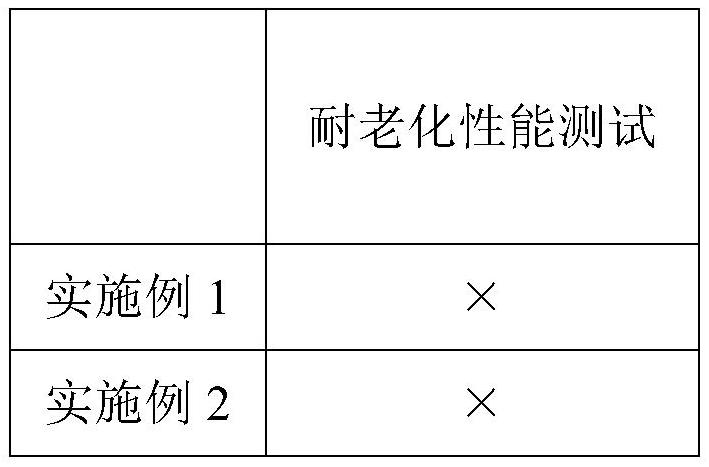

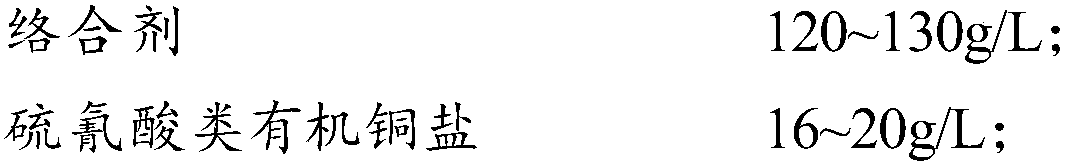

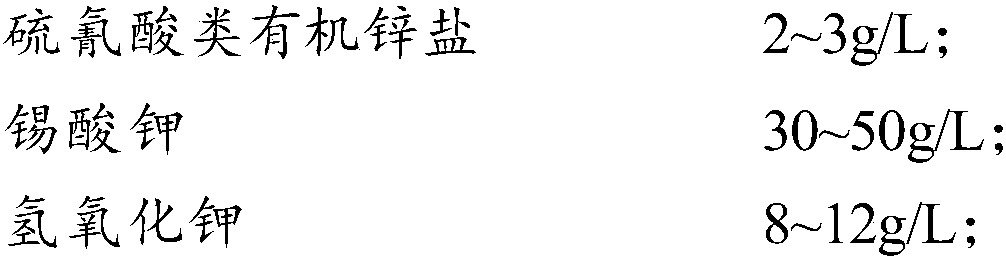

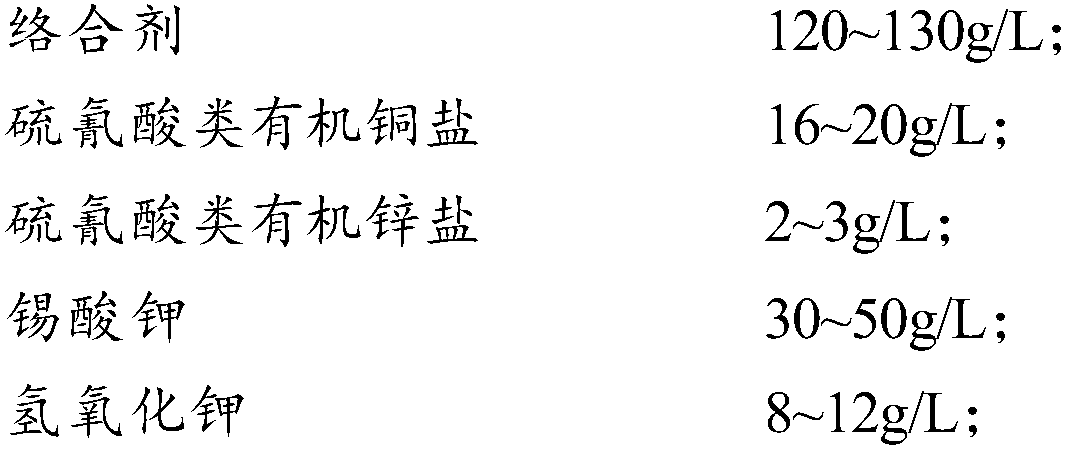

Cyanide-free white copper tin electroplating solution and preparation method thereof

InactiveCN108203837AImprove the plating effectImprove washing resistancePotassium thiocyanatePotassium

The invention provides a cyanide-free white copper tin electroplating solution and a preparation method thereof. The cyanide-free white copper tin electroplating solution provided by the invention isprepared from solvation water and the following components in content by volume: 120 to 130 g / L of complexing agent, 16 to 20 g / L of thiocyanate organic copper salt, 2 to 3 g / L of thiocyanate organiczinc salt, 30 to 50 g / L of potassium stannate and 8 to 12 g / L of potassium hydroxide, wherein the complexing agent is poly ammonium potassium thiocyanate and the general formula is (NH2K)mC2nN2n+1SOnHn+3, wherein n is greater than or equal to 1 and smaller than or equal to 50, and m is greater than or equal to 1 and smaller than or equal to 50. According to the preparation method of the cyanide-free white copper tin electroplating solution, the poly ammonium potassium thiocyanate is selected as the complexing agent and is matched with the thiocyanate organic copper salt, the thiocyanate organic zinc salt, the potassium stannate and the potassium hydroxide according to certain proportions to form water soluble liquid, and thereby a cyanide-free electroplating solution is obtained; in addition, the electroplating solution can produce excellent electroplating effects, so that an electroplating product has the advantages of excellent water resistance, salt fog resistance and pure white appearance.

Owner:临海市伟星化学科技有限公司

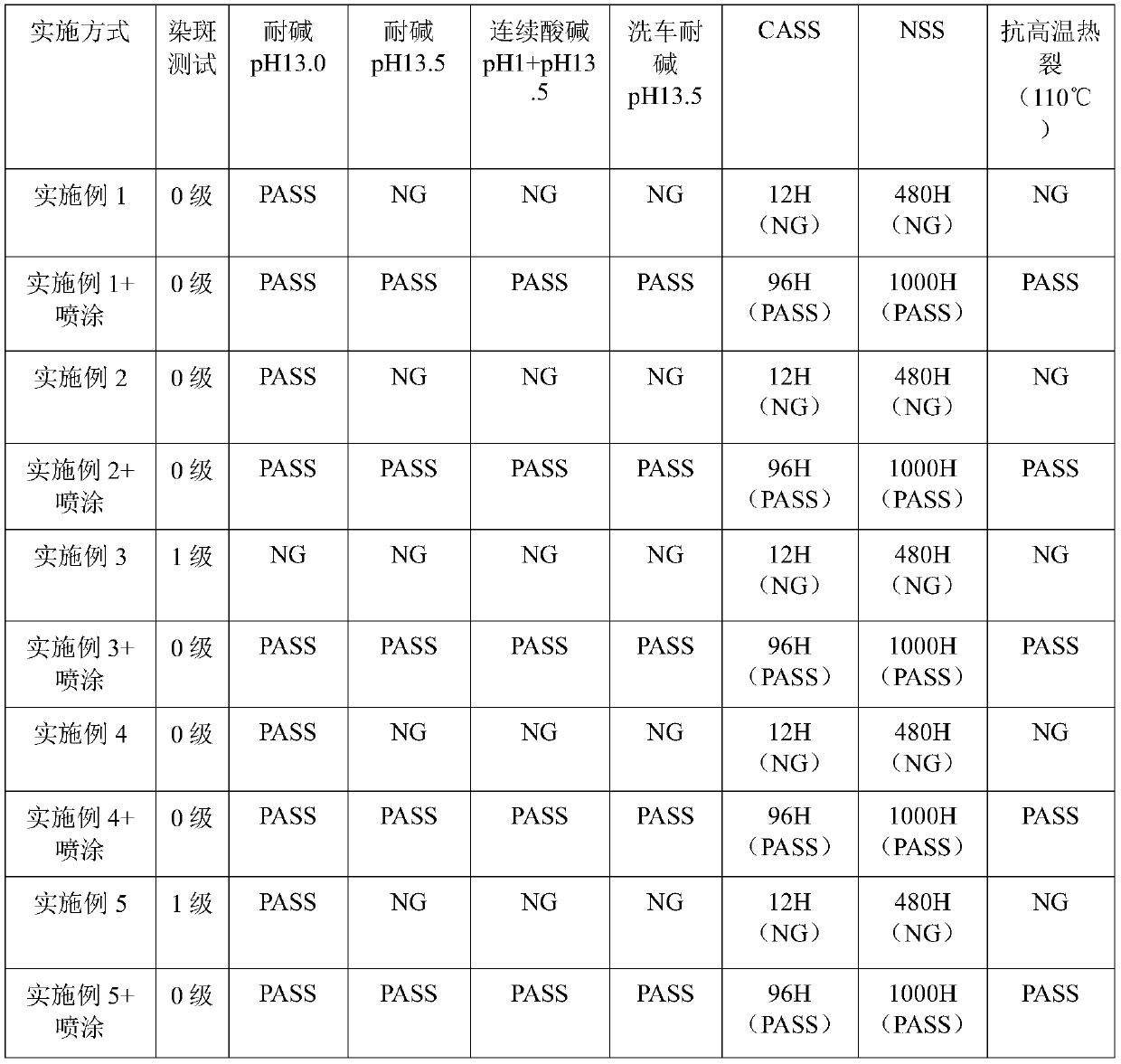

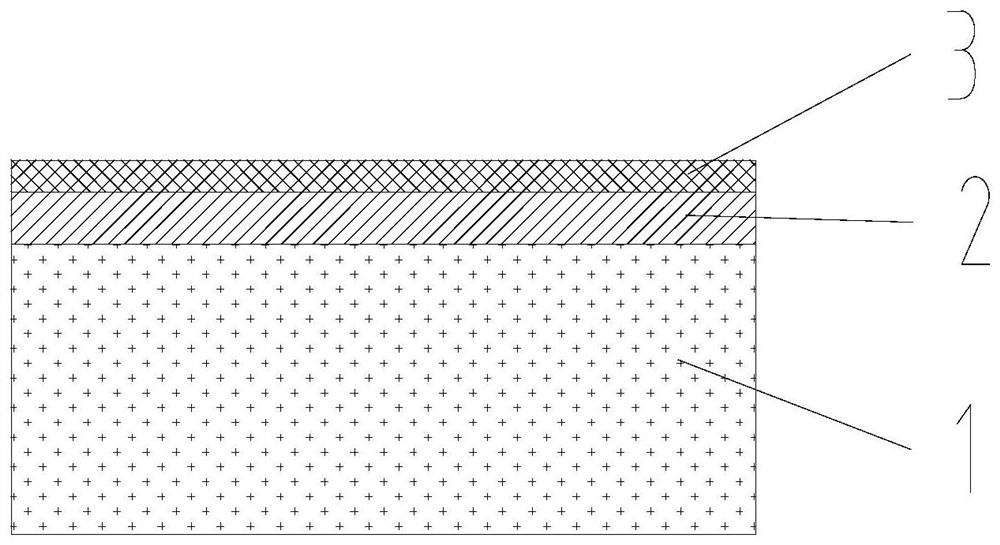

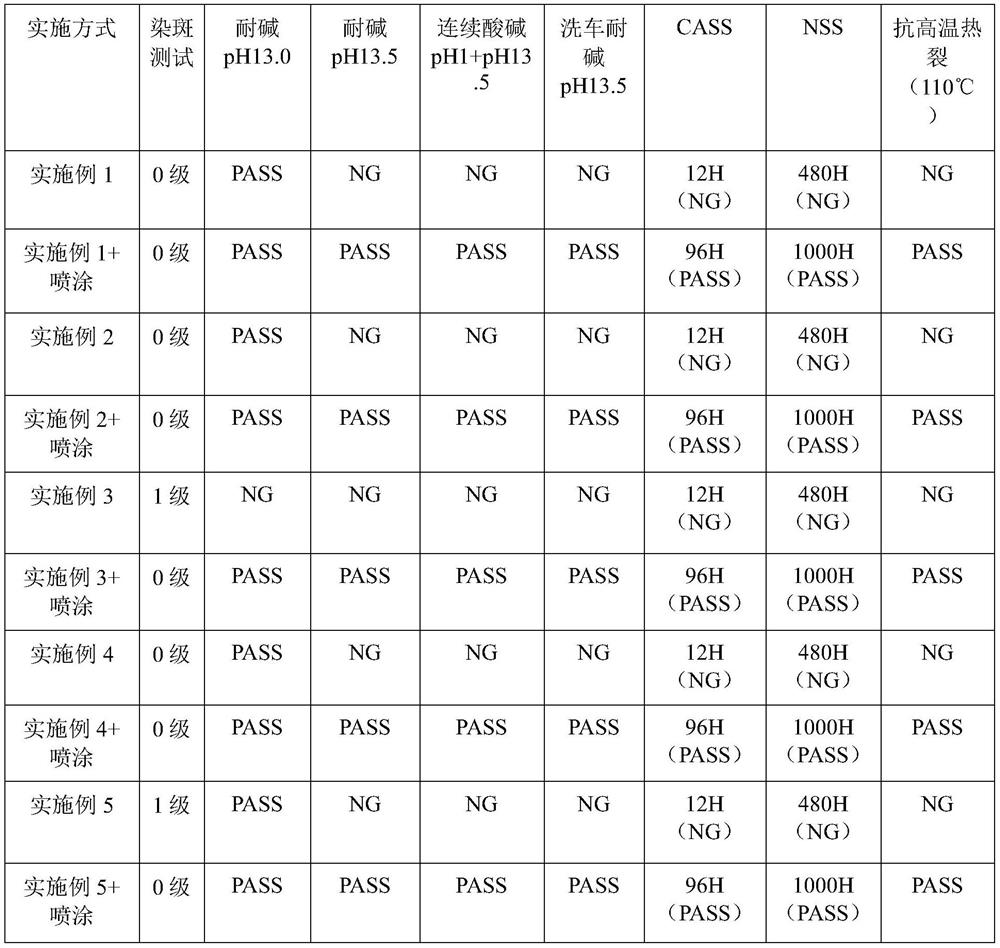

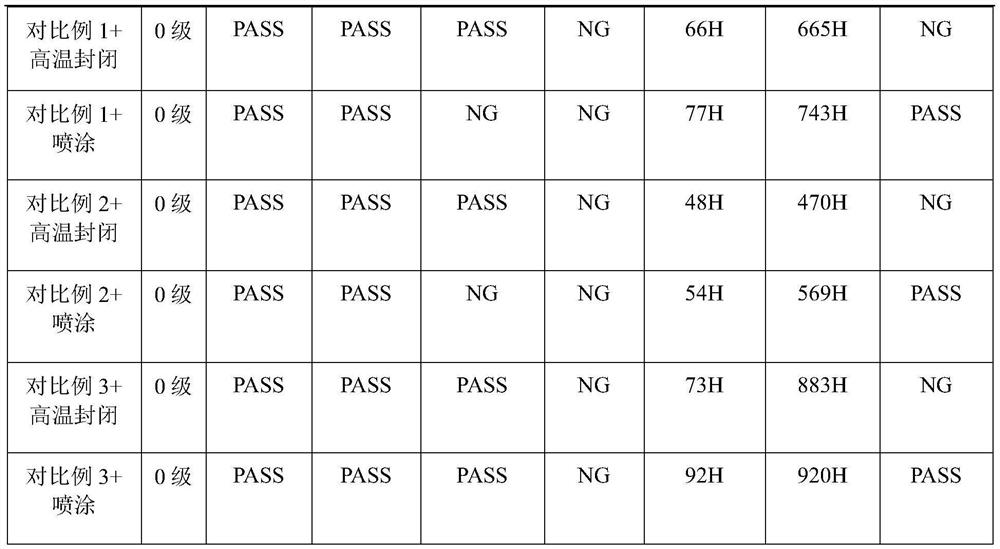

Anodic oxide film pre-hole-sealing method and hole sealing agent

ActiveCN111020667AImprove hydrophobicityImprove high temperature resistanceAnodisationNickel saltActive agent

The invention discloses an anodic oxide film pre-hole-sealing method and hole sealing agent. The method comprises pre-sealing and spraying protection. The invention simultaneously discloses a scheme of the hole sealing agent for pre-hole-sealing of an anodic oxide film of an aluminum alloy workpiece, and the main components of a protective agent, wherein the hole sealing agent comprises the following components of 2-10 g / l of nickel salt, 0.5-10 g / l of fluoride, 0.1-0.5 g / l of a complexing agent, 0.1-0.5 g / l of a dust inhibitor, 0.001-0.1 g / l of a pH conditioning agent, 0.01-0.1 g / l of graphene oxide, 0.05-2 g / l of a surfactant, and pure water is taken as a solvent. Compared with the prior art, the method is simple, the corrosion resistance, alkali resistance, continuous acid-alkali resistance and car washing alkali resistance of the processed anodic oxide film of the aluminum alloy workpiece can pass tests, the high-temperature thermal cracking resistance is stable, and the antifouling capability is strong.

Owner:广东双成金属表面科技有限公司

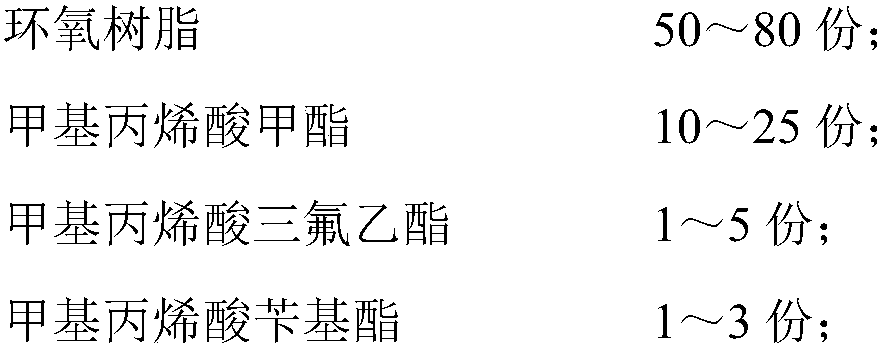

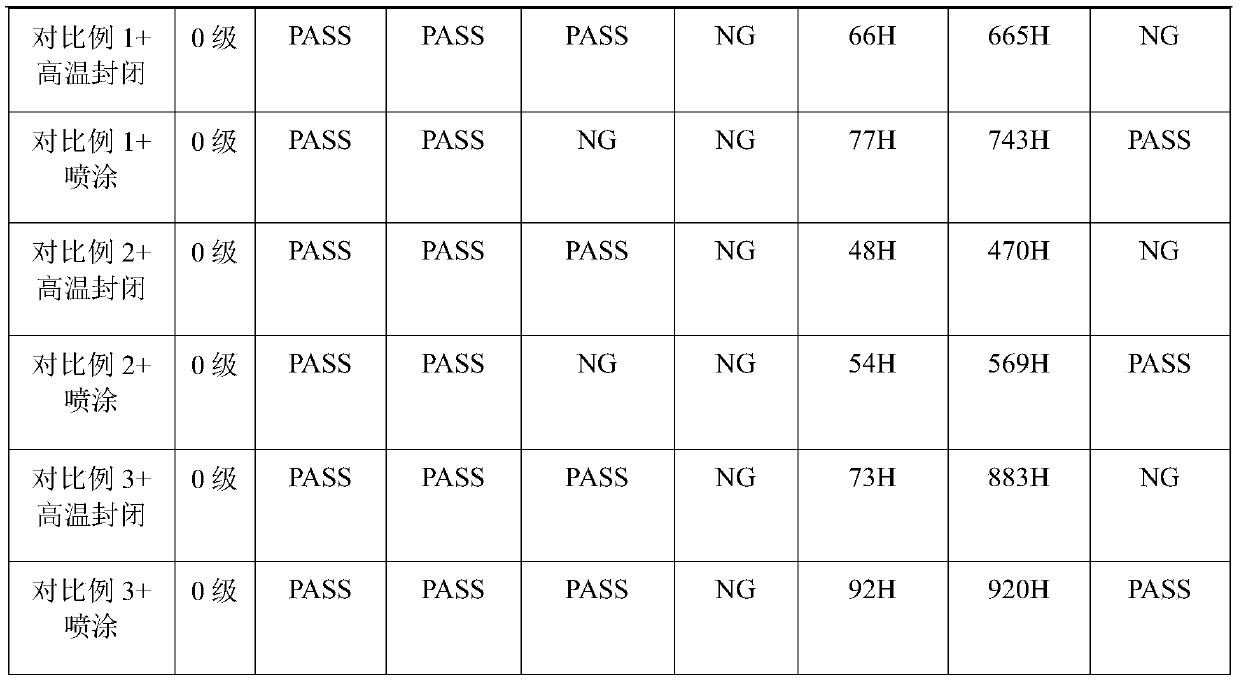

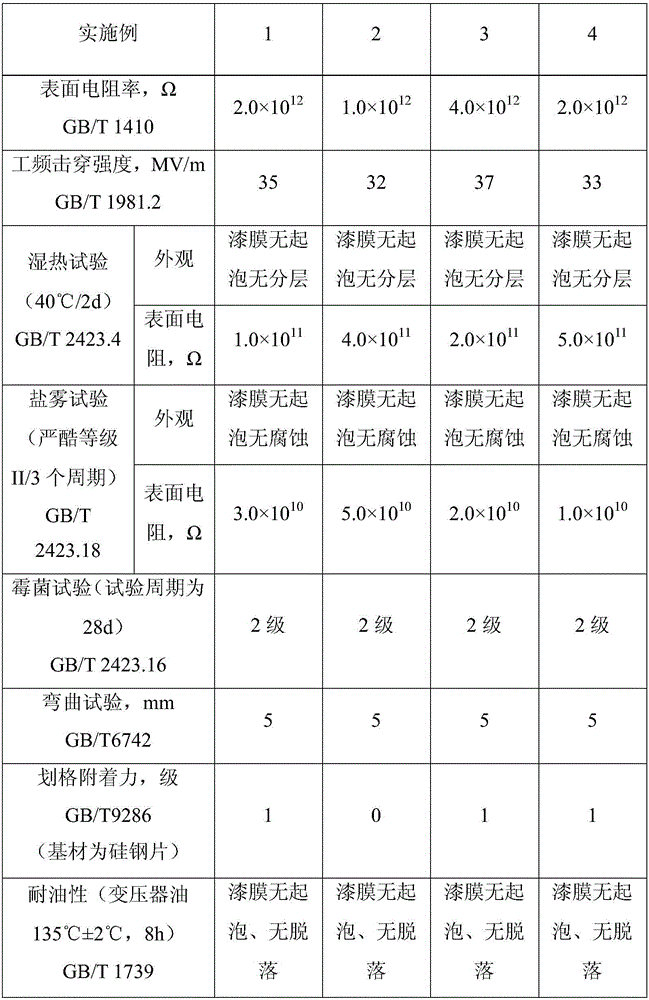

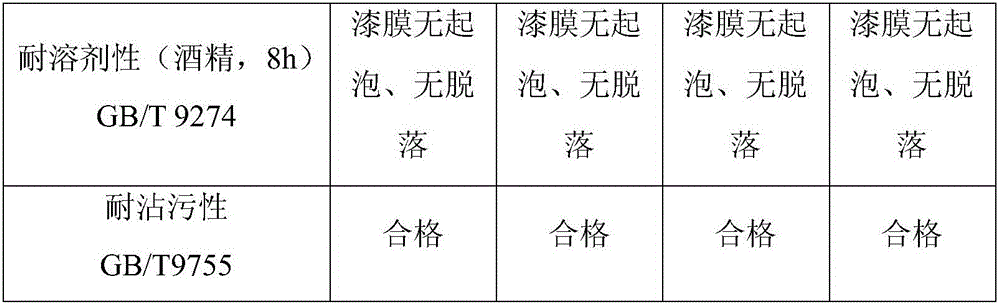

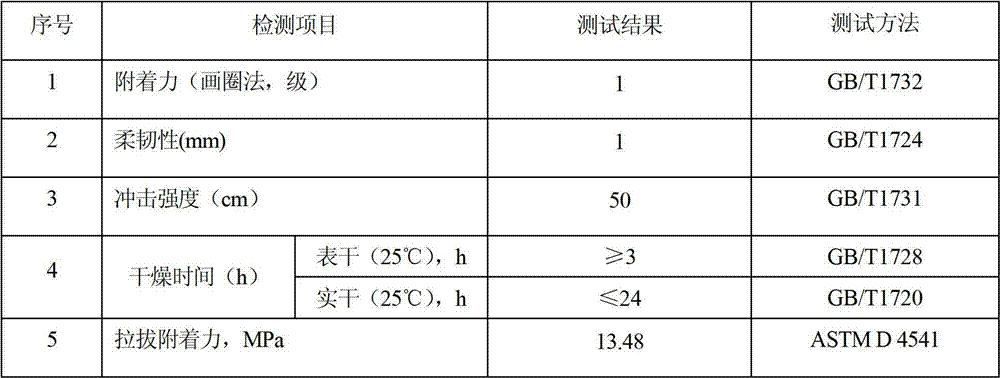

Corona-inhibiting and three-proofing insulating paint for large generators and preparation method of corona-inhibiting and three-proofing insulating paint

ActiveCN106010106AExcellent resistance to salt spray corrosionImprove moisture resistancePlastic/resin/waxes insulatorsAntifouling/underwater paintsSilanesNano sio2

The invention belongs to the field of paint study and particularly relates to corona-inhibiting and three-proofing insulating paint for large generators and a preparation method of the corona-inhibiting and three-proofing insulating paint. The insulating paint comprises a component A and a component B, wherein the component A comprises a fluorosiloxane polymer, an amino-alkyl silane modified nano-SiO2 particle mixture, modified resin, pigment and filler and a compound broad-spectrum mildewproof algaecide; the component B is a curing system and comprises a curing agent and a cosolvent. The prepared paint has strong hydrophobicity, has larger wetting angle and low adhesiveness for dust and oil pollution, realizes low adhesiveness and impenetrability for pollutants such as water, gas, dust and the like and avoids bad effects of the substances on corona inhibition, insulation, corrosion and the like.

Owner:JINTAN HUARONG INSULATING MATERIAL CO LTD

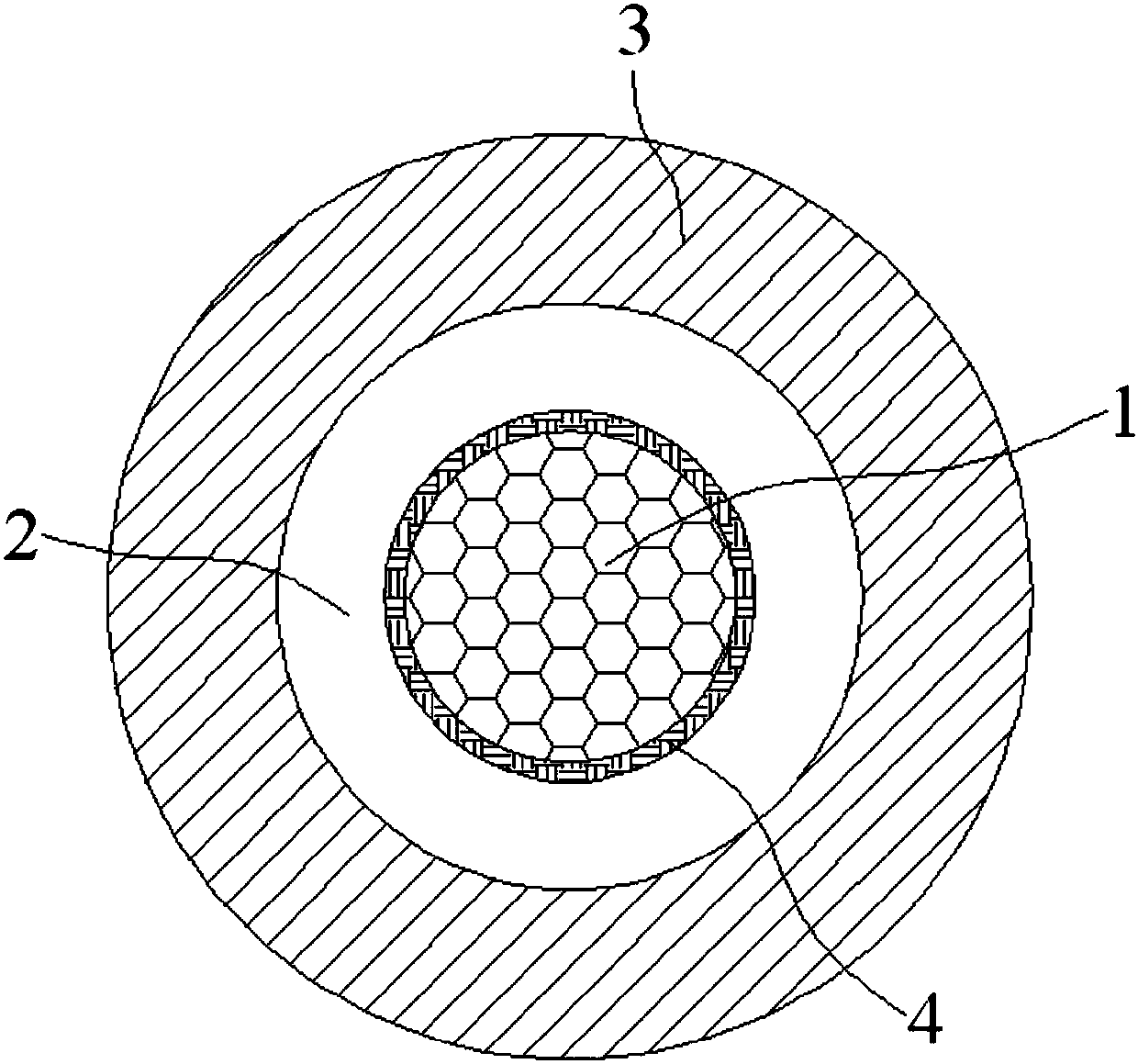

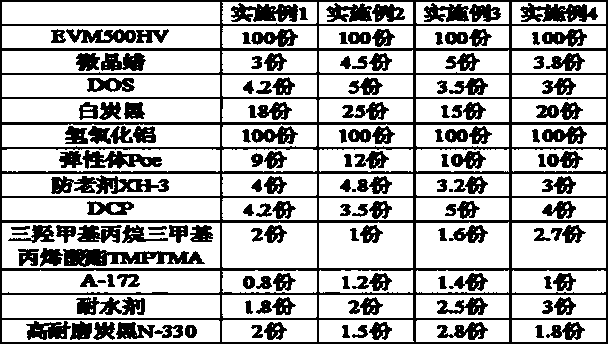

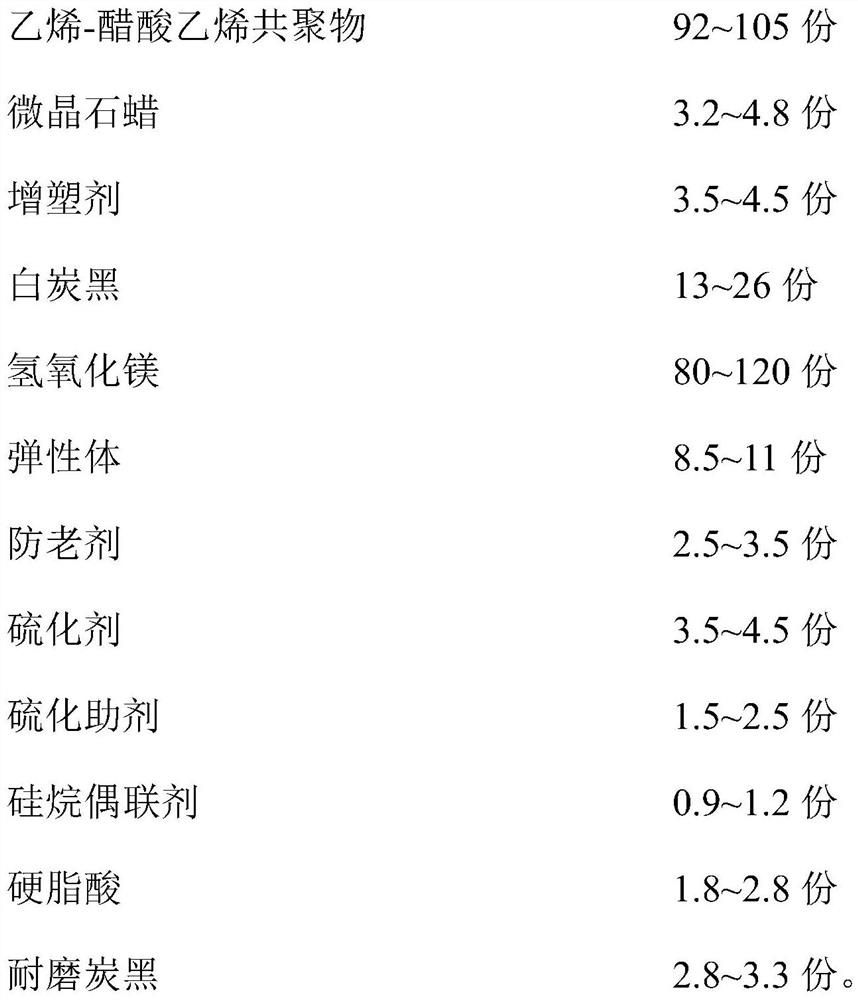

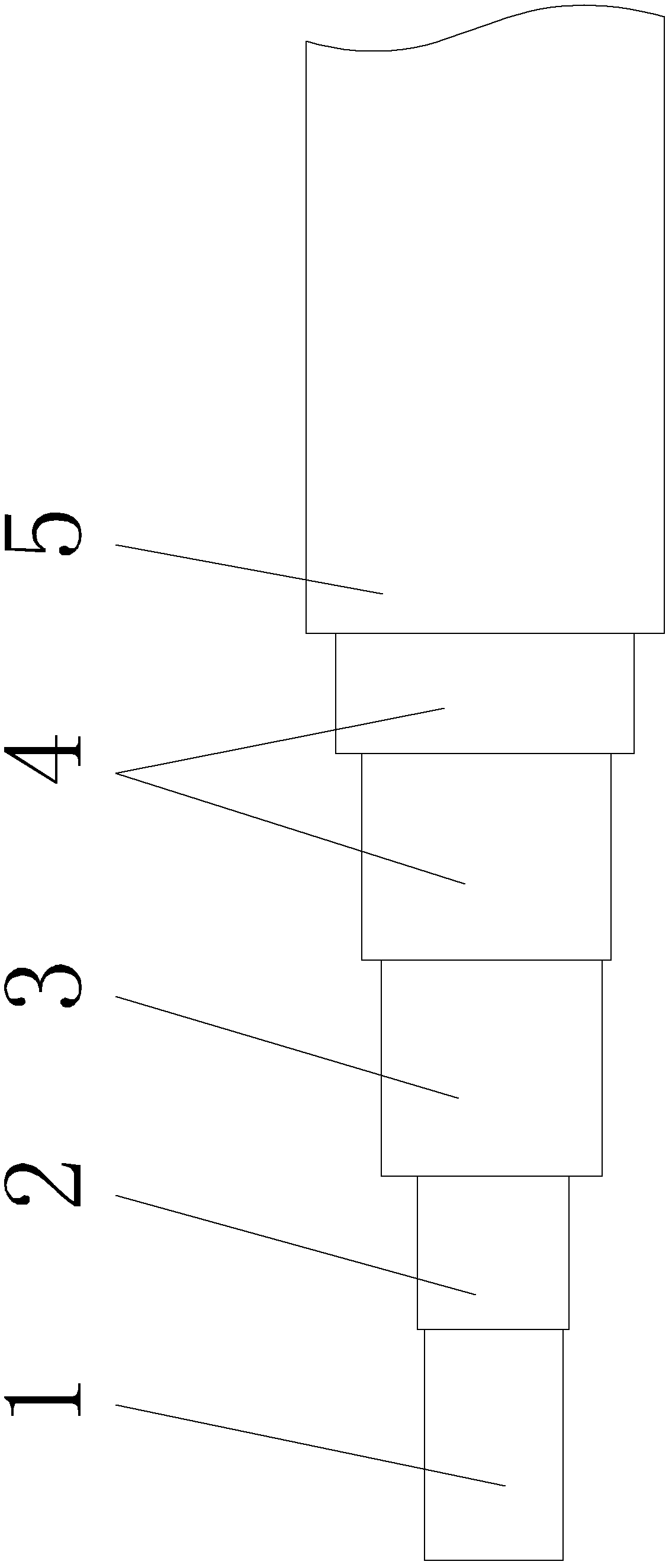

Halogen-free low-smoke rubber-sheathed flexible cable for marine wind power generation and preparation process thereof

InactiveCN109749321AEasy to operateImprove aging resistancePower cablesFlexible cablesElastomerCopper conductor

The invention discloses a halogen-free low-smoke rubber-sheathed flexible cable for marine wind power generation and a preparation process thereof. The flexible cable comprises a copper conductor positioned at the center, an isolation belt layer is wound on the outer surface of the copper conductor, an ethylene-propylene rubber insulating layer coats the outer surface of the isolation belt layer,and a 110DEG C halogen-free low-smoke polyolefin rubber sheath layer coats the outer surface of the ethylene-propylene rubber insulating layer and is composed of EVM500HV, microcrystalline wax, DOS,white carbon black, aluminum hydroxide, elastomer Poe, antiager XH-3, DCP, trimethylolpropane trimethylacrylate TMPTMA, A-172, waterproof agent and high-wear-resistance carbon black N-330. The problems of long-time high carrying capacity, aging, special oil resistance and large torsional angle of the flexible cable are solved, and the flexible cable reaches international leading level and has highpractical value and popularization value.

Owner:JIANGSU HENGTONG POWER CABLE

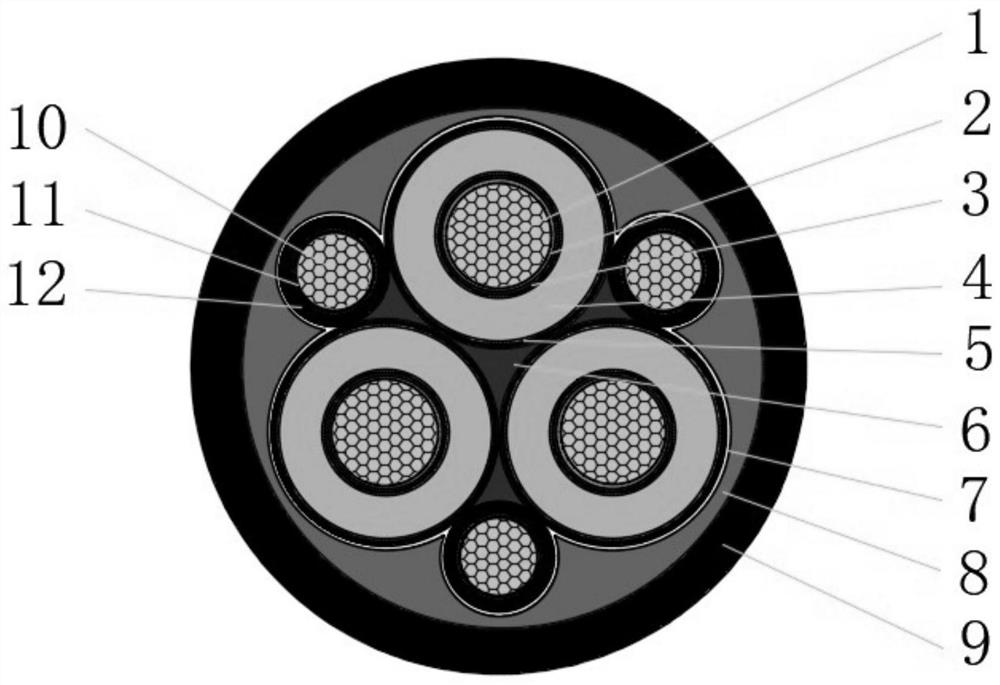

66 kV torsion-resistant cable for fan power transmission, and preparation method and application of 66 kV torsion-resistant cable

PendingCN112435787ASolve halogen-freeSolve low smokePower cables with screens/conductive layersInsulated cablesPolyolefinEngineering

The invention provides a 66kV torsion-resistant cable for fan power transmission, which solves the problems of no halogen, low smoke, aging resistance, special oil resistance and large torsion angle of a 66kV wind-energy torsion-resistant flexible cable for a high-power wind turbine generator by adopting a polyolefin rubber sheath material and reasonably designing a cable structure. Good practicalvalues and popularization values are realized; the invention further provides the preparation method of the 66kV torsion-resistant cable for fan power transmission, the preparation method adopts a double-layer co-extrusion technology, a first sheath layer and a second sheath layer are tightly bonded together, and the protection effect is good.

Owner:JIANGSU HENGTONG POWER CABLE

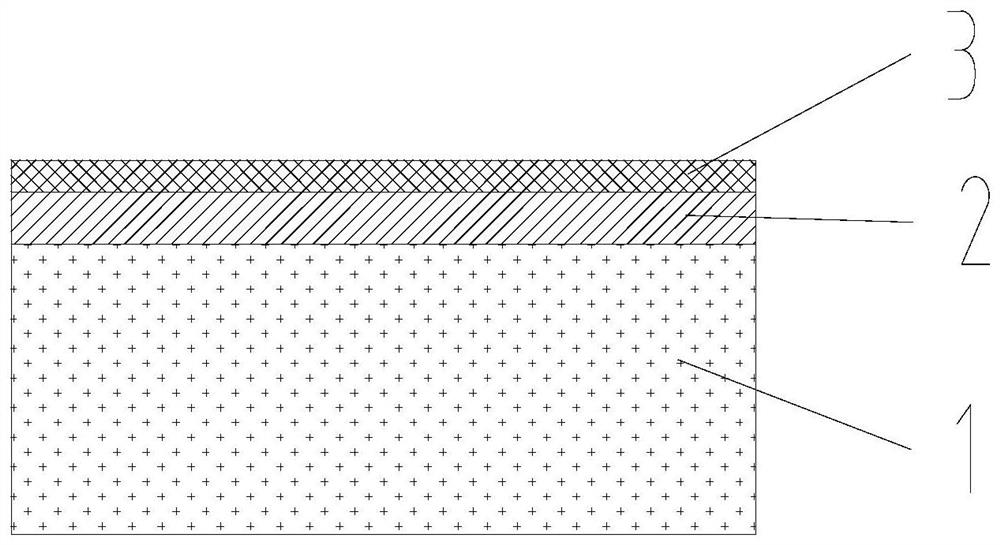

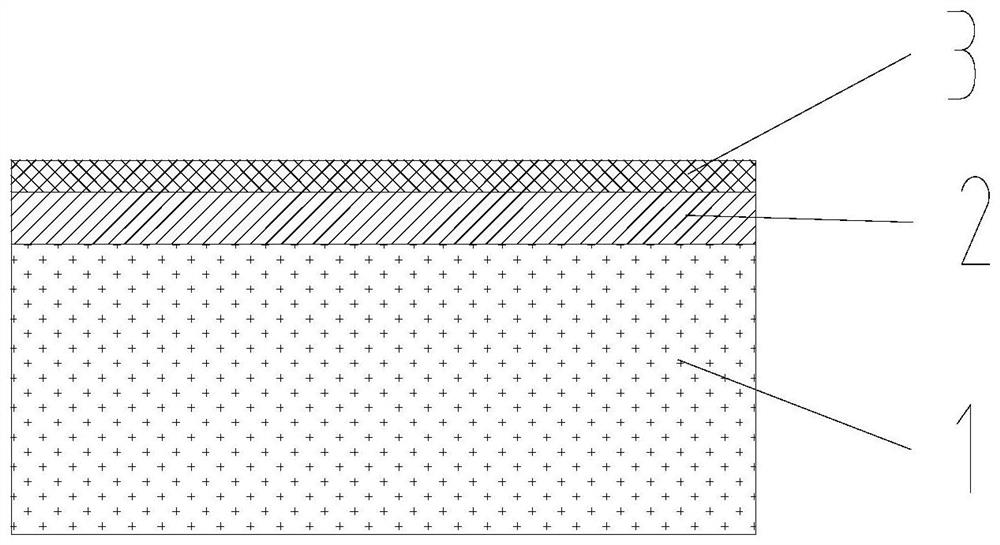

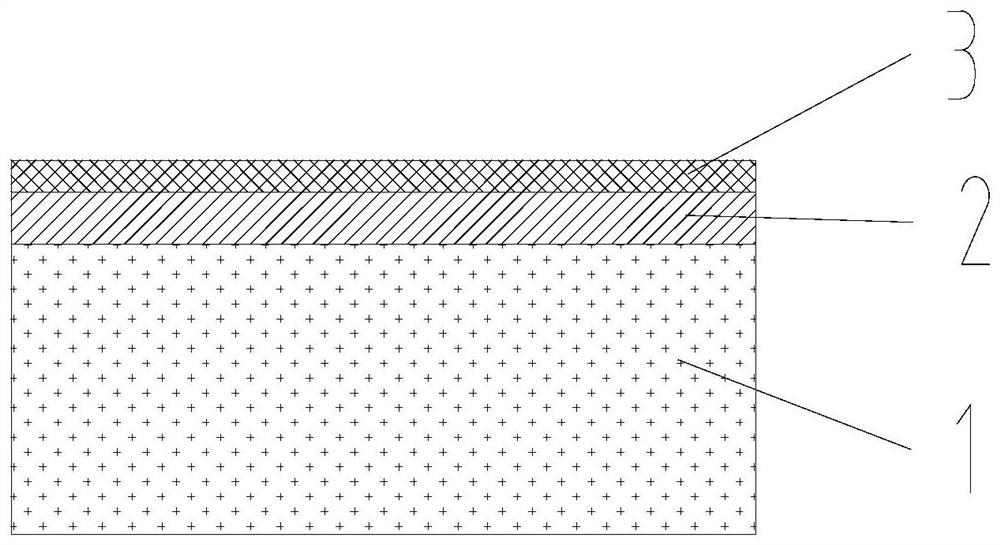

Anti-corrosion conductive hydrophobic coating for overhead line system assembly

ActiveCN113061361AAccelerated corrosionImprove conductivityAnti-corrosive paintsEpoxy resin coatingsPtru catalystAdhesive

The invention discloses an anti-corrosion, conductive and hydrophobic coating for an overhead line system component, which is characterized in that the anti-corrosion, conductive and hydrophobic coating is used for corrosion and hydrophobic protection of the overhead line system component in a tunnel, and the anti-corrosion, conductive and hydrophobic coating comprises the following components in parts by mass: 10-20 parts of film-forming resin, 55-65 parts of an organosilicon monomer, 0.5-2.5 parts of a cross-linking agent, 5-10 parts of an interface adhesive, 0.1-0.3 part of a catalyst, 30-60 parts of a conductive filler, 1-3 parts of a corrosion inhibition passivator, 0.2-0.4 part of a directional arrangement agent, 3-6 parts of a dust-proof agent, 10-20 parts of a solvent, 0.3-0.8 part of a defoaming agent and 5-20 parts of pigment and filler; The film-forming resin is organic silicon modified bisphenol A epoxy resin. After the pollution-repellent coating forms a film, the film is compact, high in hardness and low in surface energy, has excellent salt-spray corrosion resistance, damp-heat corrosion resistance, conductivity and pollution-repellent performance, and can meet the pollution-repellent, anti-corrosion and conductive requirements in a high-speed rail overhead line system assembly tunnel.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

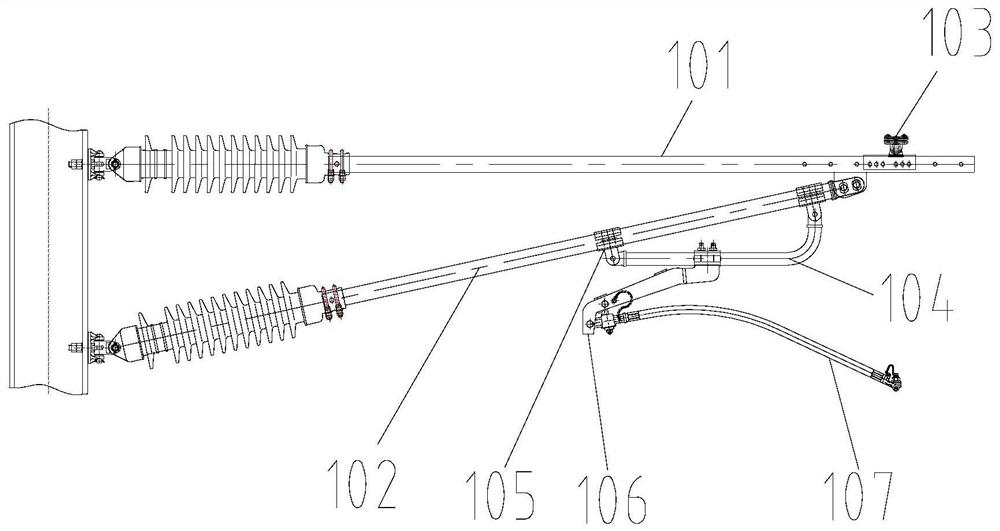

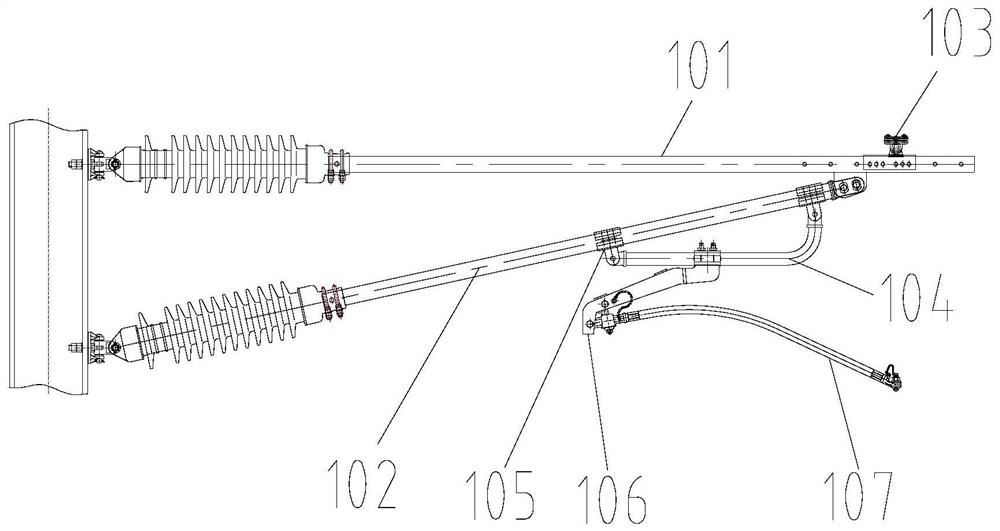

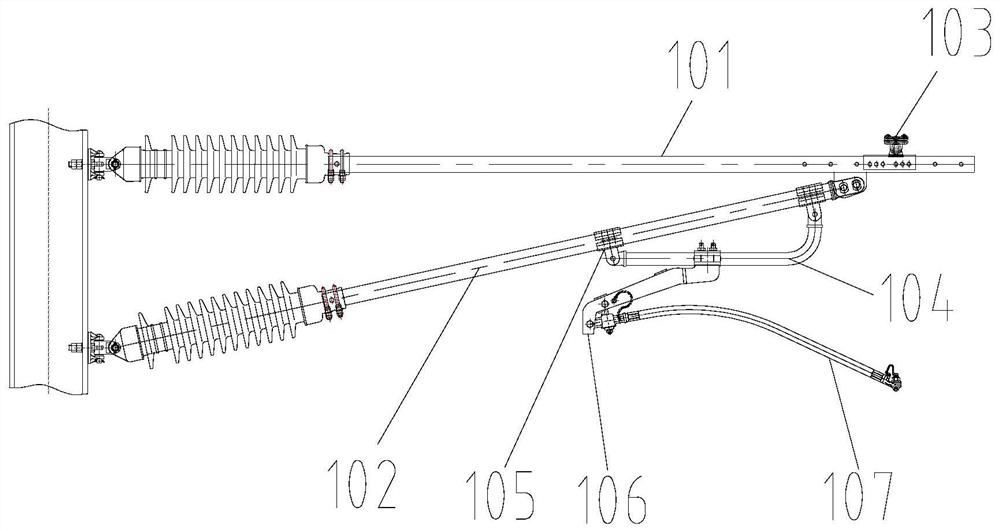

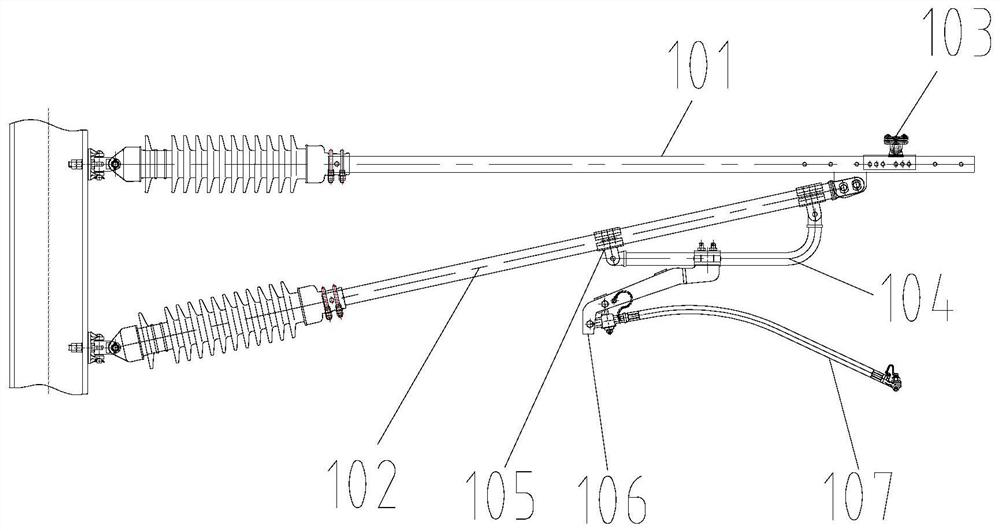

Positioning device and processing method for dirt-repellent anti-corrosion section steel cantilever of contact net

ActiveCN113201269AImprove corrosion resistanceExtended service lifeHot-dipping/immersion processesAnti-corrosive paintsSurface conductivityAlloy

The invention discloses a positioning device and a processing method for a dirt-repellent anti-corrosion section steel cantilever of a contact net. The pisitioning device is characterized in that the outer surfaces of part of or all parts are plated with hot-dip anti-corrosion plating layers, the outer surfaces of the hot-dip anti-corrosion plating layers are coated with dirt-repellent composite coatings, and the dirt-repellent composite coatings are anti-corrosion conductive dirt-repellent coatings. On the premise that the surface conductivity of a contact net assembly is not affected, the coating with the dirt repelling function is prepared on the hot-dip galvanized or GalFan alloy anti-corrosion coating, deposition of corrosive pollutants on the surface of the contact net assembly in a tunnel is reduced, and the overall anti-corrosion performance and the service life of the steel cantilever positioning device are improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Catenary steel wrist arm positioning device and processing method coated with dirt-repellent composite coating

ActiveCN113072876BImprove anti-corrosion performanceAvoid or reduce stickingAnti-corrosive paintsTrolley linesOperation safetyComposite coating

The invention discloses a catenary steel wrist arm positioning device coated with a dirt-repelling composite coating and a processing method, which is characterized in that: the outer surface of the bottom anti-corrosion coating of some or all parts is coated with a dirt-repelling composite coating, The dirt-repellent composite coating is an anti-corrosion conductive dirt-repellent paint. The catenary steel wrist arm positioning device of the present invention has low manufacturing cost, and the long-term anti-corrosion coating and the dirt-repellent composite coating have a good anti-corrosion effect, which can effectively avoid or reduce the adhesion of corrosive dirt such as dust, and greatly improve the anti-corrosion effect. The life and operation safety and reliability of the new steel wrist arm positioning device are guaranteed.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

A pollution-repellent and anti-corrosion steel wrist arm positioning device and processing method for catenary

ActiveCN113201269BImprove corrosion resistanceExtended service lifeHot-dipping/immersion processesAnti-corrosive paintsSurface conductivityAlloy

The invention discloses a dirt-repellent and anti-corrosion-type steel wrist arm positioning device and a processing method for contact nets. The surface is coated with a dirt-repelling composite coating, and the dirt-repelling composite coating is an anti-corrosion conductive dirt-repelling paint. On the premise of not affecting the surface conductivity of catenary components, a coating with fouling function is prepared on hot-dip galvanized or GalFan alloy anti-corrosion coating, which reduces the deposition of corrosive pollutants on the surface of catenary components in the tunnel and improves The overall anti-corrosion performance and service life of the steel wrist arm positioning device are guaranteed.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

A kind of aluminum alloy for the main frame structure of transmission tower and its preparation method

Owner:福建祥鑫股份有限公司

Salt spray test communication cable inner-layer coating material and production method thereof

ActiveCN102660070BVerification of salt spray corrosion resistanceQuality improvementCoaxial cables/analogue cablesLinear low-density polyethyleneAntioxidant

The invention relates to a salt spray test communication cable inner-layer coating material and a production method thereof. The invention aims at providing an improvement method of a coating material and a corresponding production method of the improved coating material. The production method provided by the invention can effectively improve salt spray corrosion resistance of a coaxial cable. A technical scheme of the production method comprises that the salt spray test communication cable inner-layer coating material comprises raw materials of linear low density polyethylene, ethylene-acrylic acid copolymer, a corrosion inhibitor for copper, calcium stearate, and an antioxidant for copper, wherein a weight ratio of the raw materials is (82-86): (11-15): 1: 1: 1; a buffer agent is benzotriazole or sodium mercaptobenzothiazole; the corrosion inhibitor for copper is methylbenzotriazole; and the antioxidant for copper is an antioxidant MD-1024 or an antioxidant 3114. The production method of the salt spray test communication cable inner-layer coating material comprises the following steps of 1, raw material reparation, 2, master batch preparation, 3, additive preparation and 4, extrusion and cutting.

Owner:ZHEJIANG WANMA TIANYI COMM WIRE & CABLE

A kind of long-acting polyurethane topcoat resistant to marine atmospheric environment and its manufacturing method

ActiveCN103589310BImprove constructabilityGood storage stabilityAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyFatty acid

The invention relates to a durable polyurethane finish capable of resisting marine-atmosphere environment, and a preparation method thereof. An A solution is prepared by an HDI trimer, a corrosion inhibitor and polyurethane-grade butyl acetate; a B solution is prepared by a polyurethane resin hydroxyl component, xylene, a polymethacrylate solution, a fluorine-containing organosilicone solution, a silicone-free acrylic polymer, a polysiloxane-polyether copolymer, a mixture of alkaline and acidic fatty acid surface active substances, a ultraviolet absorber, a light stabilizer, a polyurethane curing accelerator, a polyethylene micronization wax and precipitated barium sulphate, quartz powder, sericite powder and rutile-structured titanium dioxide. When being in use, the A solution and the B solution are mixed and cured to form a coating. The coating has good adhesion with a micaceous iron epoxy coating and an epoxy paste coating and has excellent weather resistance and salt fog resistance. An artificial accelerated aging test shows that gloss retention of the finish can reach 80% at 3,000 h. The finish can be applied in ocean platform overhead pipelines and offshore wharf surface pipelines.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Overhead line system steel cantilever positioning device coated with dirt-repellent composite coating and machining method

ActiveCN113072876AImprove anti-corrosion performanceAvoid or reduce stickingAnti-corrosive paintsTrolley linesCantileverOverhead line

The invention discloses an overhead line system steel cantilever positioning device coated with a dirt-repellent composite coating and a machining method. The device is characterized in that the outer surfaces of bottom anti-corrosive coatings of part or all of parts are coated with a dirt-repellent composite coating, and the dirt-repellent composite coating is an anti-corrosive conductive dirt-repellent coating. The overhead line system steel cantilever positioning device is low in production and manufacturing cost, the long-acting anti-corrosive coating and the dirt-repellent composite coating have a synergistic effect, the anti-corrosion effect is good, adhesion of dust and other corrosion dirt can be effectively avoided or reduced, the service life of the novel steel cantilever positioning device is greatly prolonged, and the operation safety and reliability of the novel steel cantilever positioning device are greatly improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

A kind of anti-corrosion conductive dirt-repellent paint for catenary components

ActiveCN113061361BAccelerated corrosionImprove conductivityAnti-corrosive paintsEpoxy resin coatingsContact networkPtru catalyst

The invention discloses an anti-corrosion conductive dirt-repellent paint for catenary components, which is characterized in that it is used for corrosion and dirt-repellent protection of catenary components in tunnels, and the anti-corrosion conductive dirt-repellent paint comprises the following components in mass parts Parts: 10-20 parts of film-forming resin, 55-65 parts of silicone monomer, 0.5-2.5 parts of crosslinking agent, 5-10 parts of interface adhesive, 0.1-0.3 parts of catalyst, 30-60 parts of conductive filler, slow 1-3 parts of corrosion passivator, 0.2-0.4 parts of orientation agent, 3-6 parts of anti-sedimentation agent, 10-20 parts of solvent, 0.3-0.8 parts of defoamer, 5-20 parts of pigment and filler; among them, The film-forming resin is silicone-modified bisphenol A epoxy resin. After the dirt-repellent coating is formed into a film, the coating film is dense, high in hardness, and low in surface energy. It has excellent salt spray corrosion resistance, moisture and heat corrosion resistance, electrical conductivity and dirt-repelling properties, which can meet the requirements of dirt-repelling and anti-corrosion in the tunnel of high-speed rail catenary components. and electrical needs.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

A peelable protective coating

ActiveCN103740226BImprove performanceExcellent peelabilityAnti-corrosive paintsRadiation-absorbing paintsAging resistanceUltraviolet

The invention relates to strippable protective coating, which is used for ocean transportation of mechanical products. The strippable protective coating comprises the following components in parts by mass: 30-50 parts of film former, 2.5-4.5 parts of ultraviolet absorber, 5-10 parts of corrosion inhibitor, 0.3-0.8 part of defoaming agent, 0.5-1 part of flatting agent, 2-5 parts of organic bentonite, 15-30 parts of pigment filler, 0.3-0.7 part of thermal stabilizer, and 60-80 parts of solvent, wherein the film former is a styrene-butadiene-styrene segmented copolymer. After forming films, the strippable protective coating has excellent salt spray corrosion resistance and ultraviolet aging resistance, has stable property in an ocean environment, and can solve the protection problem of mechanical products in ocean transportation.

Owner:CRRC YANGTZE CO LTD

A kind of method and sealing agent of anodized film pre-sealing

ActiveCN111020667BImprove hydrophobicityImprove high temperature resistanceAnodisationNickel saltActive agent

The invention discloses an anodic oxide film pre-hole-sealing method and hole sealing agent. The method comprises pre-sealing and spraying protection. The invention simultaneously discloses a scheme of the hole sealing agent for pre-hole-sealing of an anodic oxide film of an aluminum alloy workpiece, and the main components of a protective agent, wherein the hole sealing agent comprises the following components of 2-10 g / l of nickel salt, 0.5-10 g / l of fluoride, 0.1-0.5 g / l of a complexing agent, 0.1-0.5 g / l of a dust inhibitor, 0.001-0.1 g / l of a pH conditioning agent, 0.01-0.1 g / l of graphene oxide, 0.05-2 g / l of a surfactant, and pure water is taken as a solvent. Compared with the prior art, the method is simple, the corrosion resistance, alkali resistance, continuous acid-alkali resistance and car washing alkali resistance of the processed anodic oxide film of the aluminum alloy workpiece can pass tests, the high-temperature thermal cracking resistance is stable, and the antifouling capability is strong.

Owner:广东双成金属表面科技有限公司

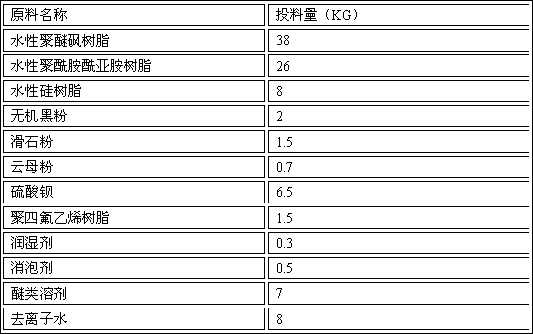

A kind of water-based environment-friendly high-temperature paint and preparation method thereof

The invention provides a water-based, environment-friendly and high-temperature coating and relates to the technical field of chemical coatings. The coating comprises, in parts by mass, 20-40 parts of water-based polyether sulfone resin, 20-40 parts of water-based polyamide imide resin, 5-15 parts of water-based silicone resin, 1-5 parts of polytetrafluoroethylene resin, 5-15 parts of an ether solvent, 1-5 parts of a pigment, 5-20 parts of filler, 0.1-1 part of a wetting agent, 0.1-1 part of an antifoaming agent and 10-30 parts of deionized water. The coating has outstanding comprehensive performance, prominent hardness, rich gloss, excellent high temperature resistance, higher salt fog resistance, high resistance to water, steam, oil, solvents and chemicals, excellent adhesive force and toughness, and besides, the preparation method is simple and easy, medium in cost, particularly higher in cost performance and suitable for mass preparation.

Owner:开封夸克新材料有限公司

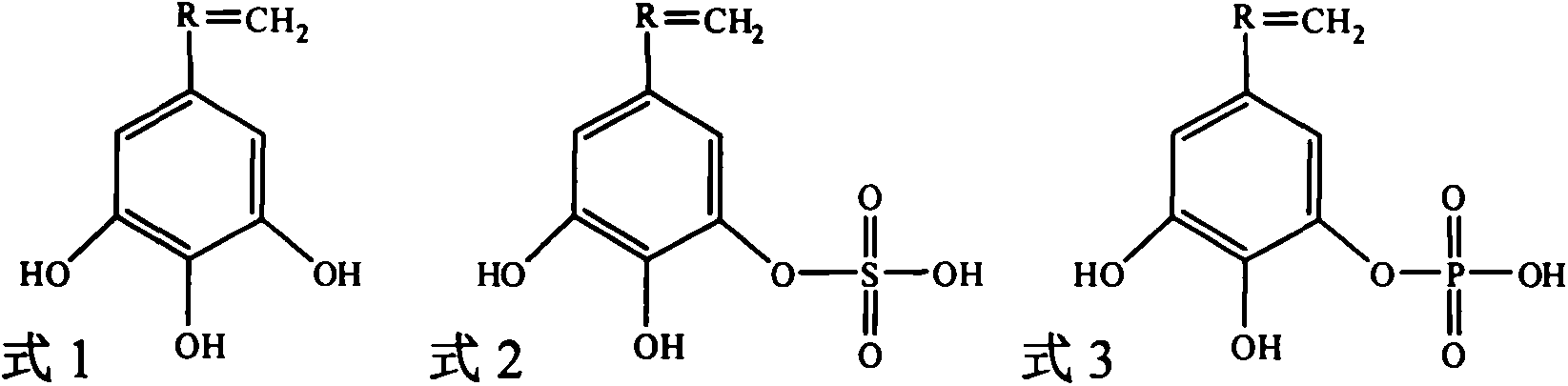

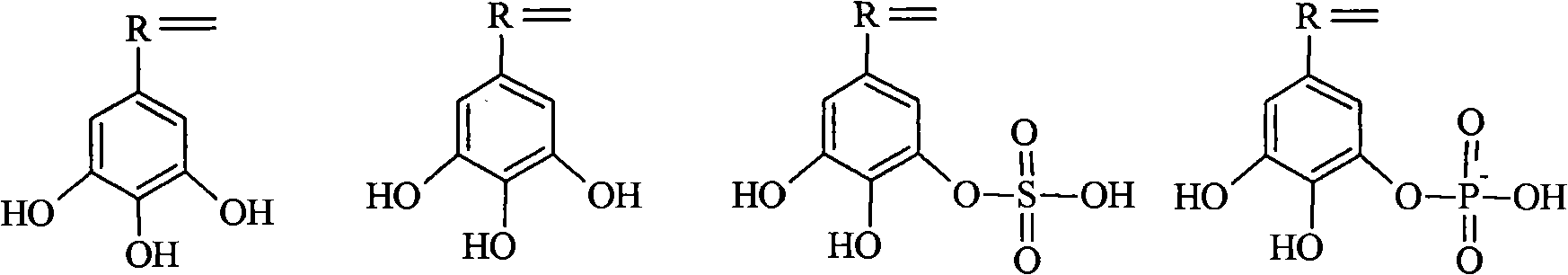

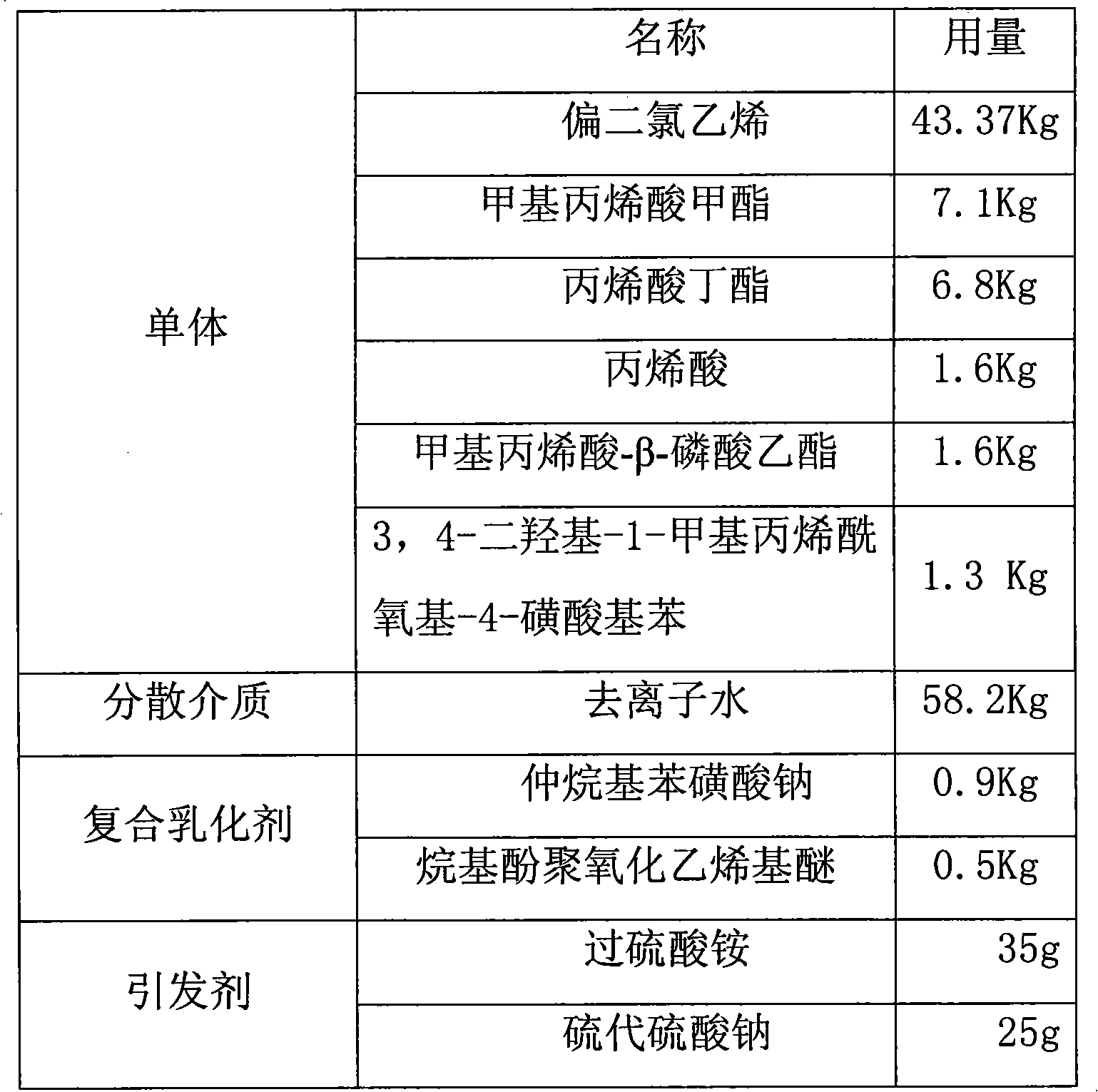

Waterborne rust conversion polymer emulsion, coating thereof and method for preparing same

InactiveCN101704914BAvoid Flash RustImprove adhesionAnti-corrosive paintsPhosphoric Acid EstersPolymer science

Owner:深圳海润德添加剂有限公司

Aluminum alloy for transmission tower auxiliary frame structure and preparation method thereof

The invention discloses an aluminum alloy for an auxiliary frame structure of a transmission tower and a preparation method thereof and relates to the field of aluminum alloy casting, in particular to an aluminum alloy for an auxiliary frame structure of a transmission tower and a preparation method thereof. The invention aims to solve the problem that an existing aluminum alloy is not suitable for manufacturing the auxiliary frame structure of the transmission tower. The aluminum alloy is prepared from the following components in percent by mass: 5-6.1% of Zn, 1.2-1.9% of Mg, 0.1-0.3% of Mn, 0.05-0.25% of Cu, 0.05-0.25% of Zr, 0.02-0.1% of Ti, less than or equal to 0.25% of Fe, less than or equal to 0.15% of Si and the balance of Al and other inevitable impurity elements. The preparation method comprises the following steps: I, material preparation; II, smelting; III, two-stage refining; IV, coordinated deterioration; and V, casting. The preparation method provided by the invention is used for casting a high strength aluminum alloy for the auxiliary frame structure of the transmission tower.

Owner:福建祥鑫股份有限公司

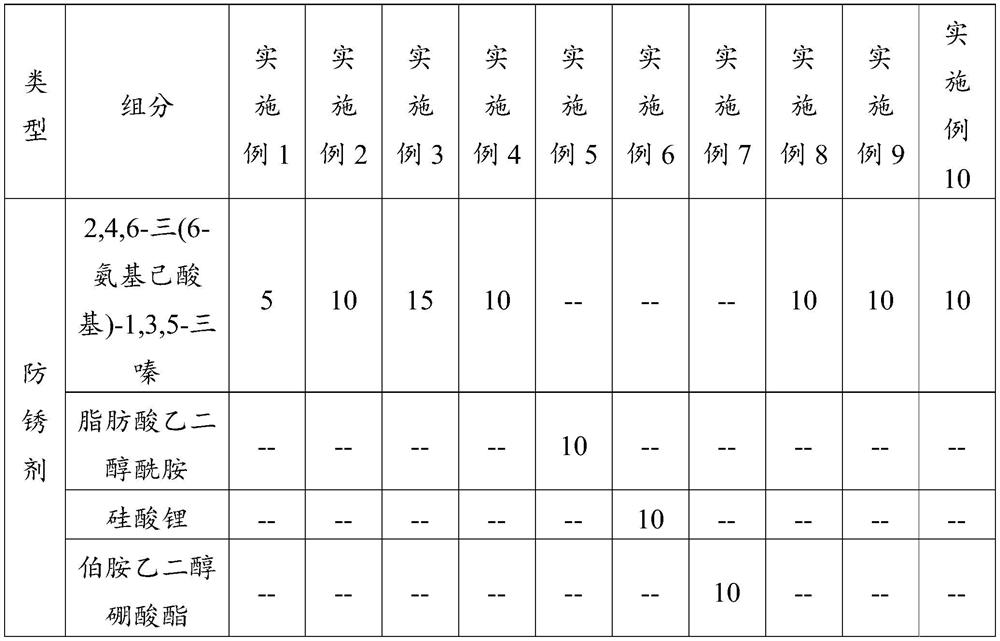

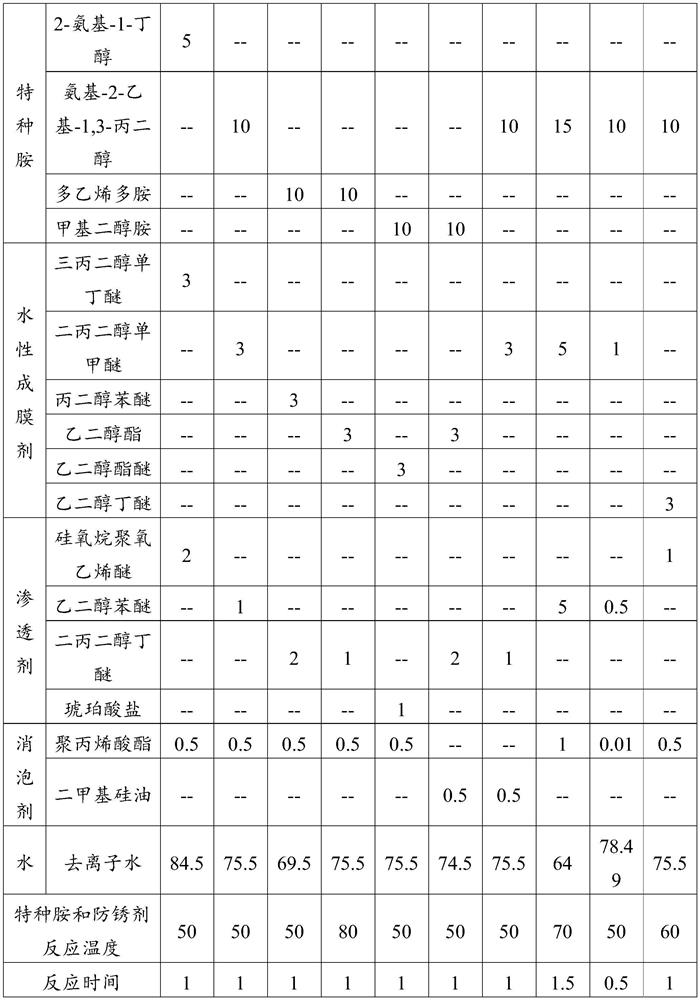

Environment-friendly water-based antirust liquid as well as preparation method and application thereof

ActiveCN114410370AExcellent resistance to salt spray corrosionExcellent heat and humidity resistanceLubricant compositionMetallic materialsEnvironmental engineering

The invention discloses environment-friendly water-based antirust liquid as well as a preparation method and application thereof, and belongs to the field of water-based antirust liquid. The environment-friendly water-based antirust liquid comprises the following preparation raw materials in percentage by mass: 5-15% of an antirust agent, 5-15% of special amine, 1-5% of a water-based film-forming agent, 0.5-5% of a penetrant, 0.01-1% of a defoaming agent and the balance of water. The environment-friendly water-based antirust liquid has the characteristics of excellent salt spray corrosion resistance, humidity and heat resistance and low foam, is free of environmental pollution substances such as heavy metal residues and the like, and meets the requirements of environmental protection laws and regulations. The antirust liquid can be directly applied to protection of materials such as metal materials, instrument and equipment parts and the like. The preparation method provided by the invention is simple and convenient to operate, does not need a special process and can realize industrial production.

Owner:广州国机润滑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com