Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Excellent Environmental Durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

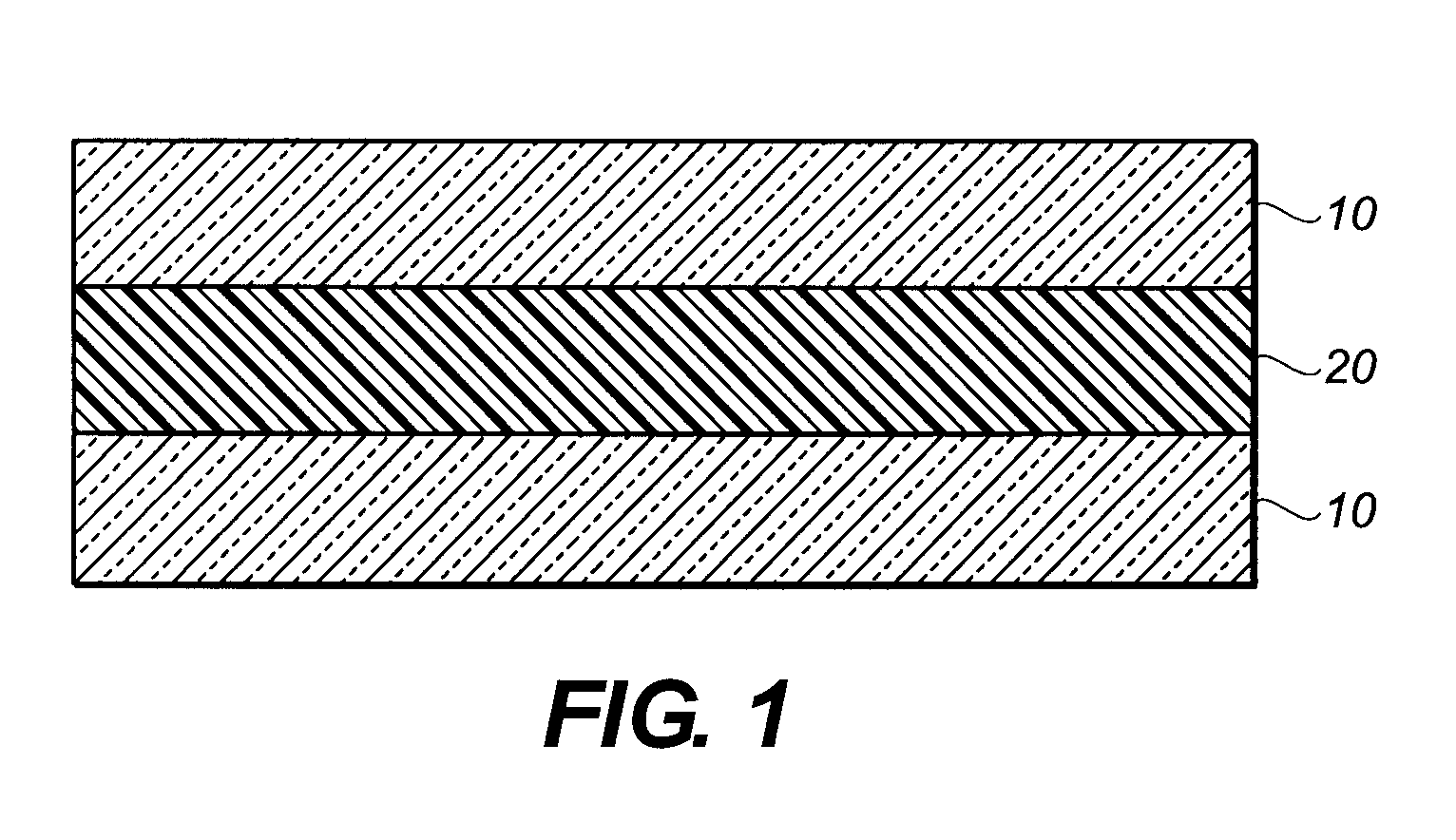

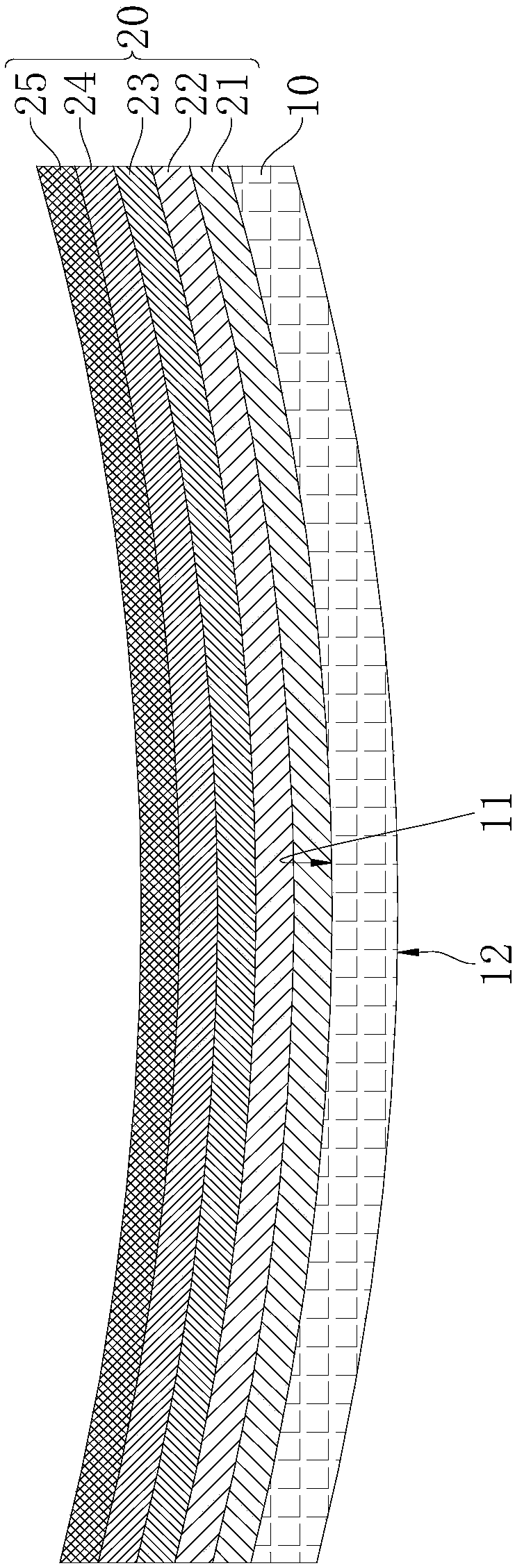

Heat ray reflective film and laminate thereof, and coating fluid for forming heat ray reflective layer

InactiveUS20110261443A1High heat ray reflectivityHigh environmental durabilityMaterial nanotechnologyMirrorsMetalLight reflection

Disclosed is a heat ray reflective film having a single layer structure, which has high heat ray reflectivity, can relatively control visible light absorption and visible light reflection and has excellent heat stability. Also disclosed is a heat ray reflective laminate which has high environmental durability and is suitable as a window material for buildings or automobiles.A heat ray reflective laminate which is a laminate comprising a transparent substrate and a heat ray reflective layer and which has a solar reflectance of at least 15% as measured from the side containing the heat ray reflective layer, wherein the heat ray reflective layer comprises a binder resin containing a hydrophilic group other than an N-pyrrolidonyl group, and a metal, and the heat ray reflective layer has a layer thickness of at most 100 nm.

Owner:MITSUBISHI CHEM CORP

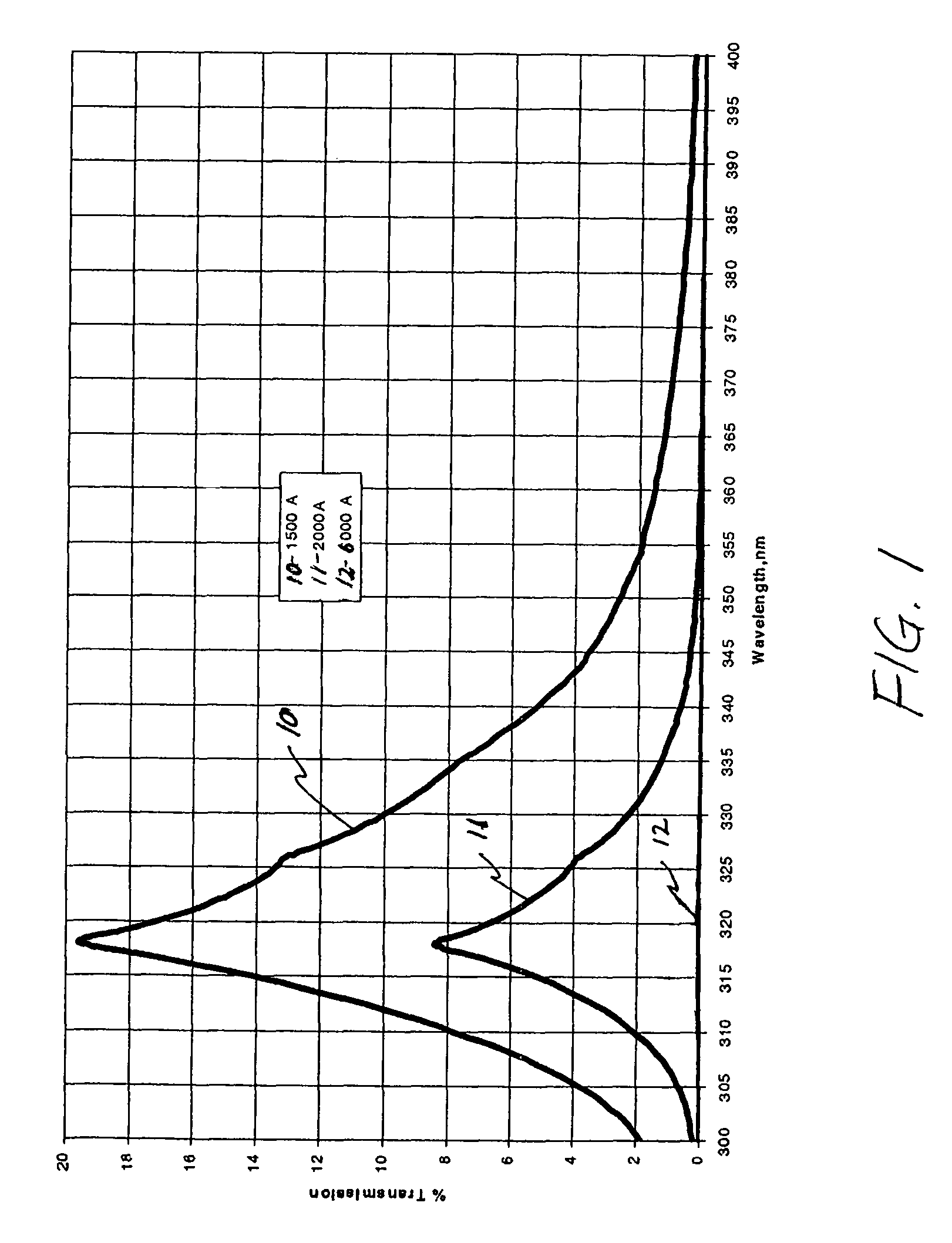

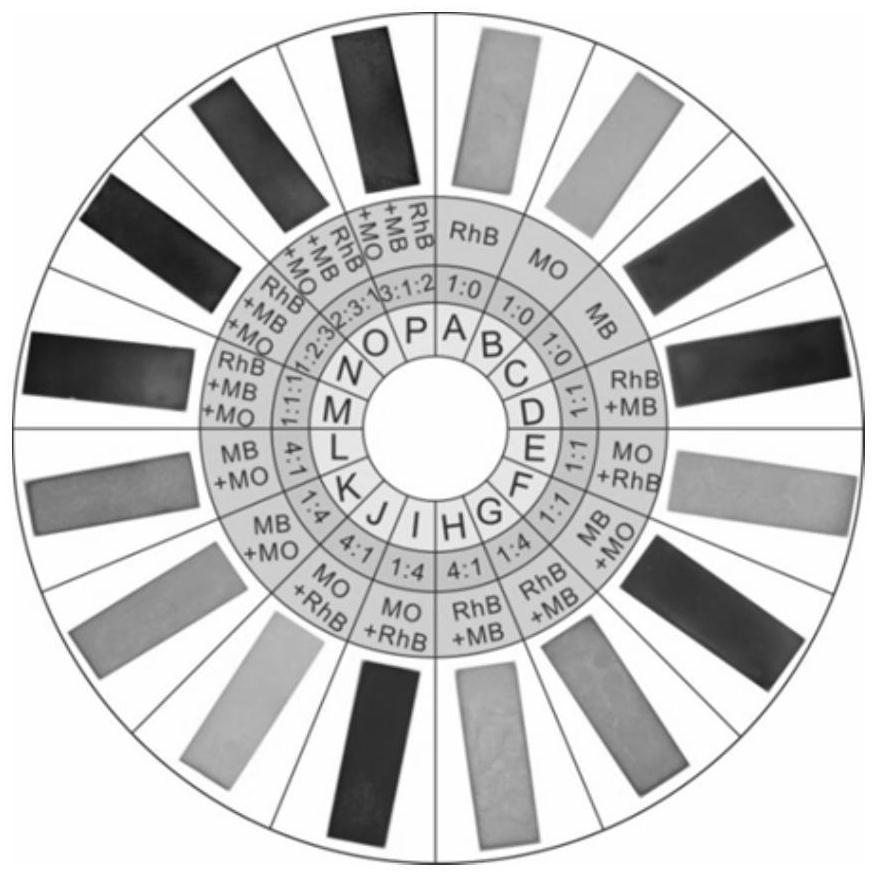

Solid fluorescence reference and method

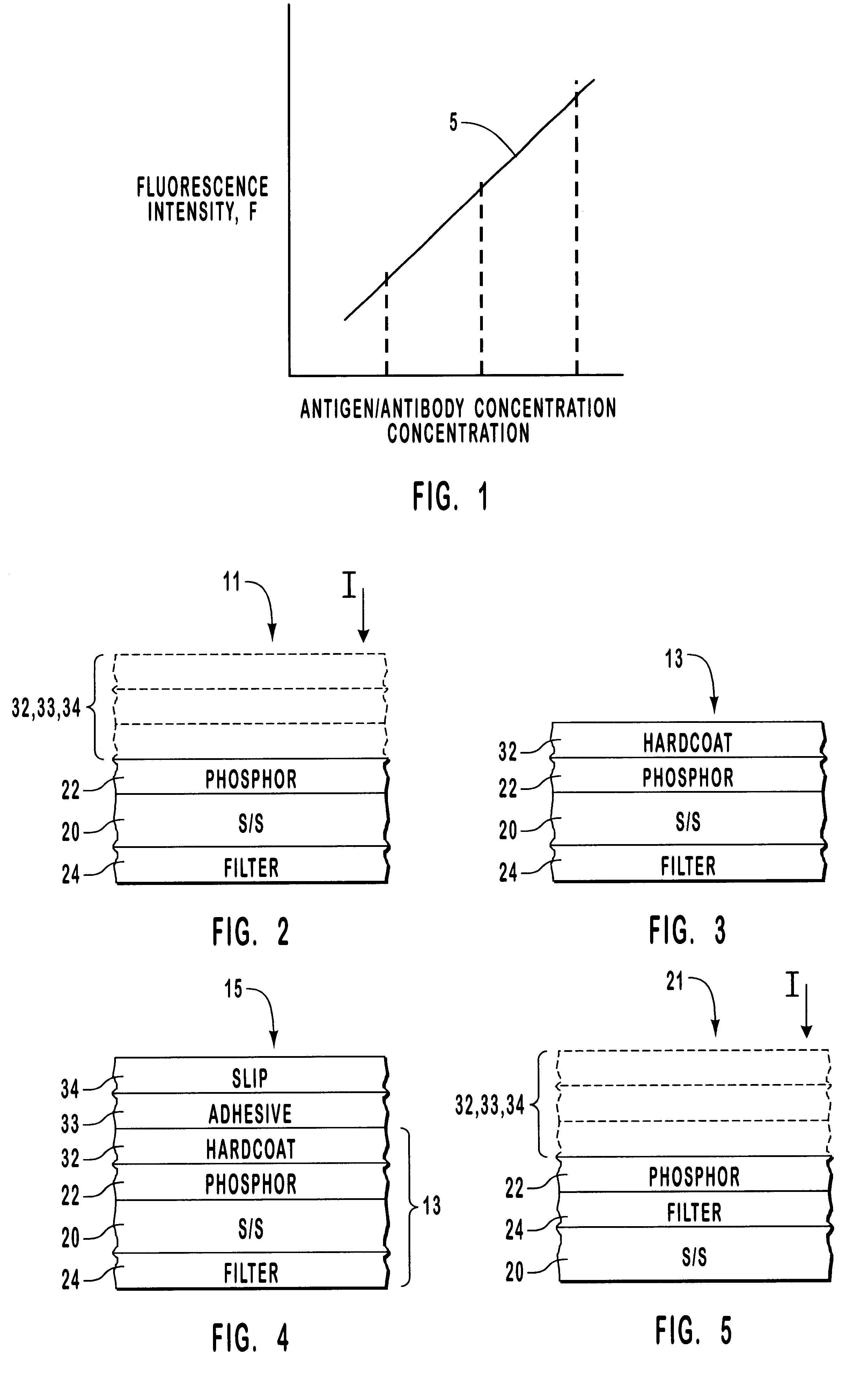

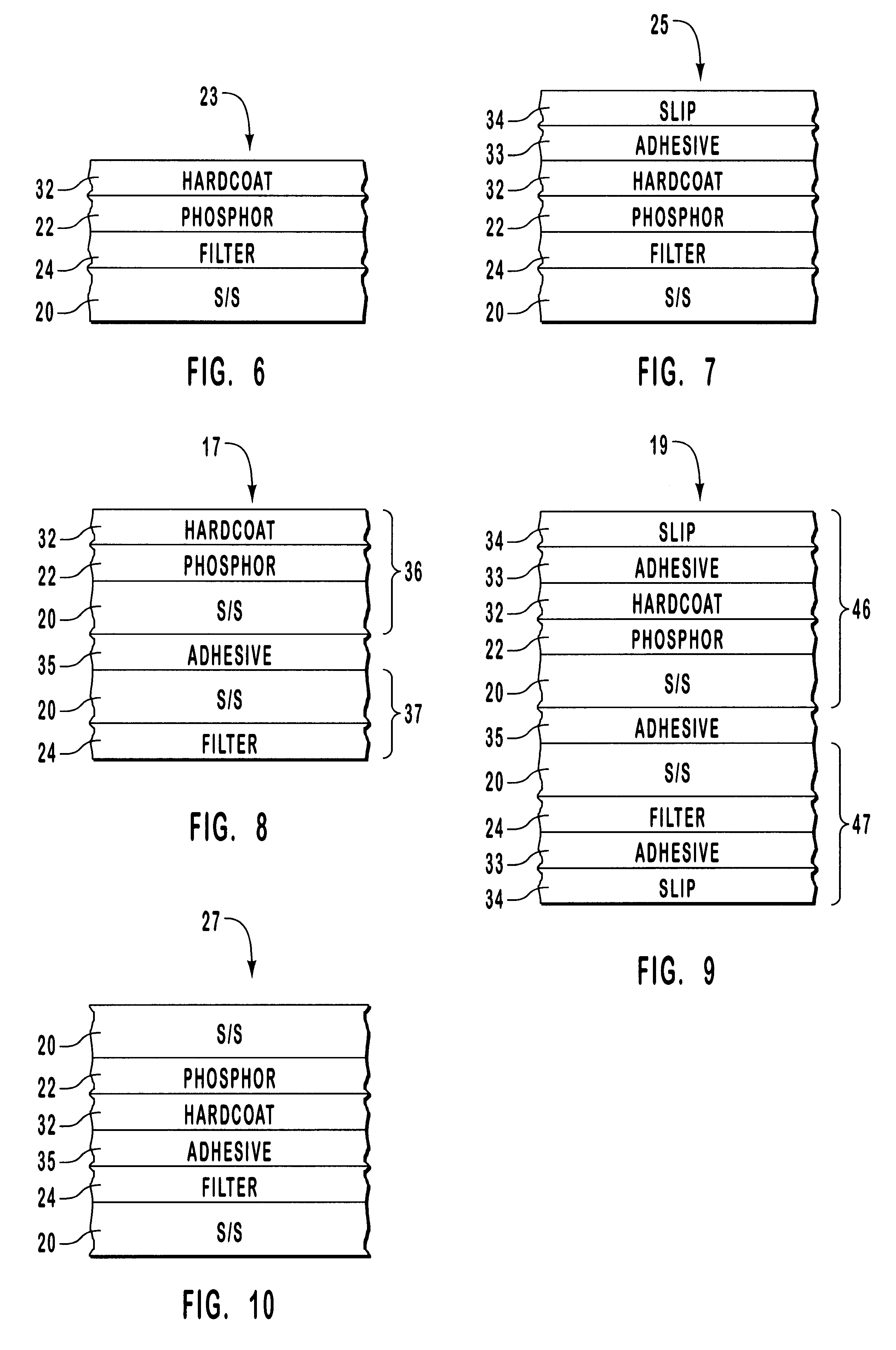

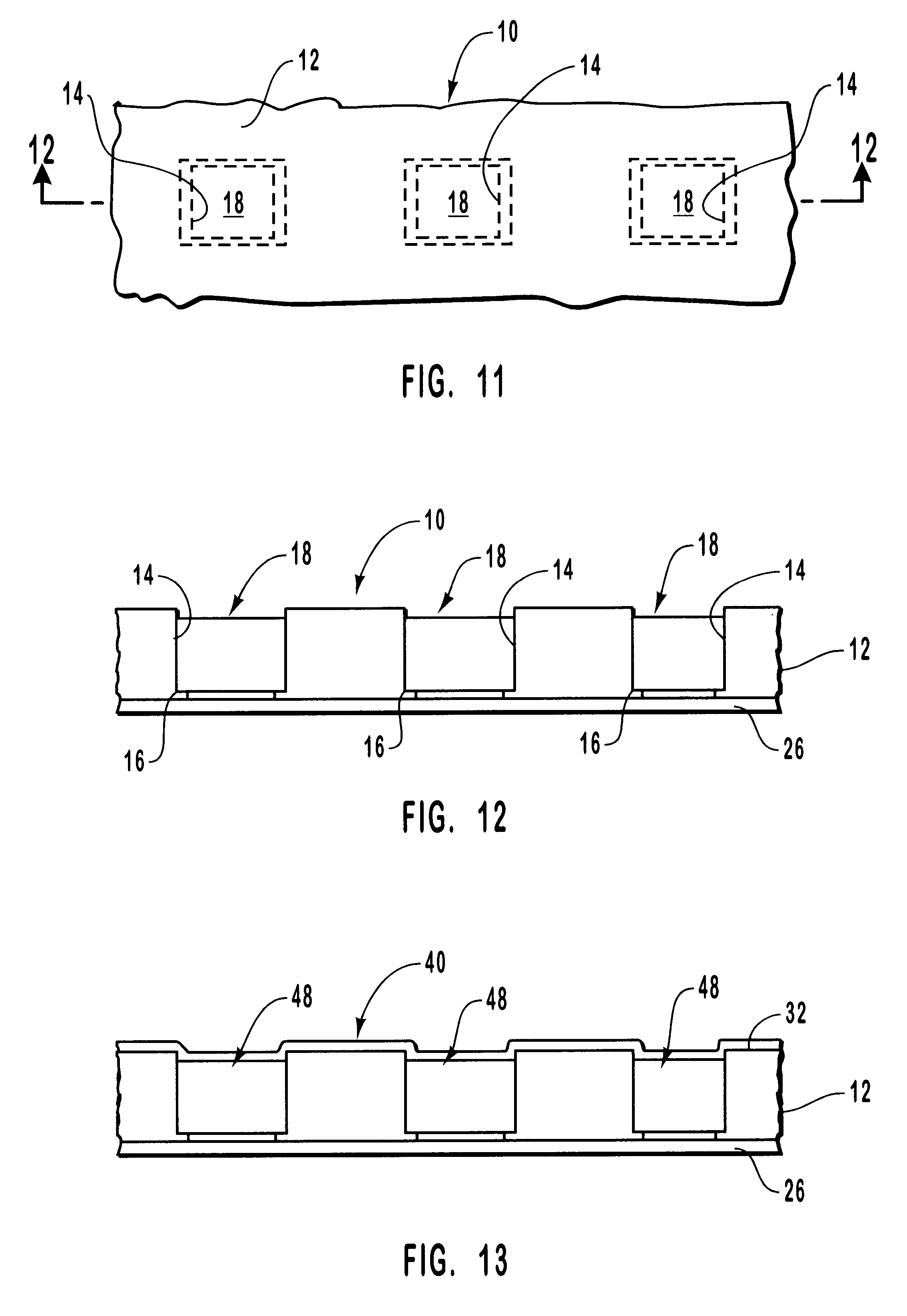

InactiveUS6242114B1Easily shapeExcellent Environmental DurabilityBleaching apparatusFluorescence/phosphorescenceSelective filterChemistry

An optical fluorescent composite which controls fluorescence intensity comprises a solid layer containing fluorescent material (such as a phosphor) formed on an optically transparent base or substrate and optically coupled to a spectrally selective filter, also formed on the base or substrate, that modifies the intensity of either or both the excitation or emission spectra of the phosphor. Devices constructed in this manner serve as stable references for fluorescent measurements. Sets of such device is made with filters having different transmittance amplitudes, can characterize fluorescent measurement response over several orders of magnitude. In one of numerous alternative structure, the fluorescent layer can be formed on one substrate, the filter formed on a second substrate and the two substrates joined together.

Owner:JDS UNIPHASE CORP

Polymer film, and phase difference film, polarizing plate and liquid crystal display device using the same

ActiveUS20090169775A1Easy to operateExcellent Environmental DurabilityLiquid crystal compositionsSynthetic resin layered productsLiquid-crystal displayPhase difference

There is provided a polymer film including a polymer; and a high molecular weight plasticizer that has a number average molecular weight of 700 to 10,000 and has a repeating unit derived from a dicarboxylic acid and a diol, wherein the dicarboxylic acid for forming the high molecular weight plasticizer includes at least one aliphatic dicarboxylic acid having 2 to 20 carbon atoms and at least one aromatic dicarboxylic acid having 8 to 20 carbon atoms, and the diol includes at least one diol selected from the group consisting of an aliphatic diol having 2 to 12 carbon atoms, an alkyl ether diol having 4 to 20 carbon atoms and an aromatic ring-containing diol having 6 to 20 carbon atoms.

Owner:FUJIFILM CORP

Low-temperature fabrication of glass optical components

InactiveUS7143609B2High refractive indexLow molding temperatureGlass transportation apparatusGlass pressing apparatusGratingMetallic Nickel

A method is provided for molding from glass certain complex optical components, such as lenses, microlens, arrays of microlenses, and gratings or surface-relief diffusers having fine or hyperfine microstructures suitable for optical or electro-optical applications. Thereby, mold masters or patterns, which define the profile of the optical components, made on metal alloys, particularly titanium or nickel alloys, or refractory compositions, with or without a non-reactive coating are used. Given that molding optical components from oxide glasses has numerous drawbacks, it has been discovered in accordance with the invention that non-oxide glasses substantially eliminates these drawbacks. The non-oxide glasses, such as chalcogenide, chalcohalide, and halide glasses, may be used in the mold either in bulk, planar, or power forms. In the mold, the glass is heated to about 10–110° C., preferably about 50° C., above its transition temperature (Tg), at which temperature the glass has a viscosity that permits it to flow and conform exactly to the pattern of the mold.

Owner:CORNING INC

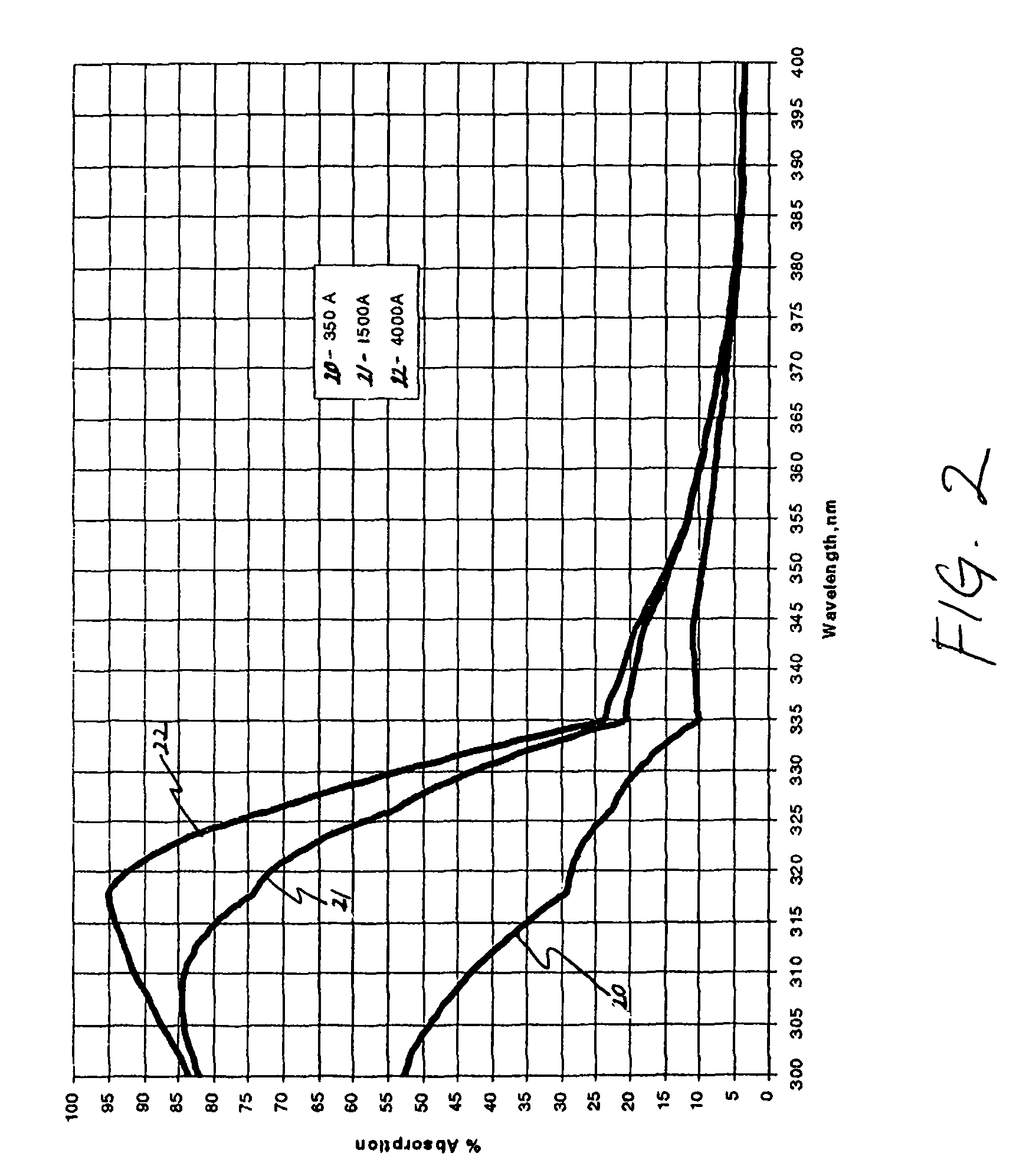

Durable silver mirror with ultra-violet thru far infra-red reflection

InactiveUS7838134B2Excellent Environmental DurabilityAvoid platingVacuum evaporation coatingSputtering coatingGalvanic cellUltraviolet

A durable highly reflective silver mirror characterized by high reflectance in a broad spectral range of about 300 nm in the UV to the far infrared (˜10000 nm), as well as exceptional environmental durability. A high absorptivity metal underlayer is used which prevents the formation of a galvanic cell with a silver layer while increasing the reflectance of the silver layer. Environmentally durable overcoat layers are provided to enhance mechanical and chemical durability and protect the silver layer from corrosion and tarnishing, for use in a wide variety of surroundings or climates, including harsh or extreme environments.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

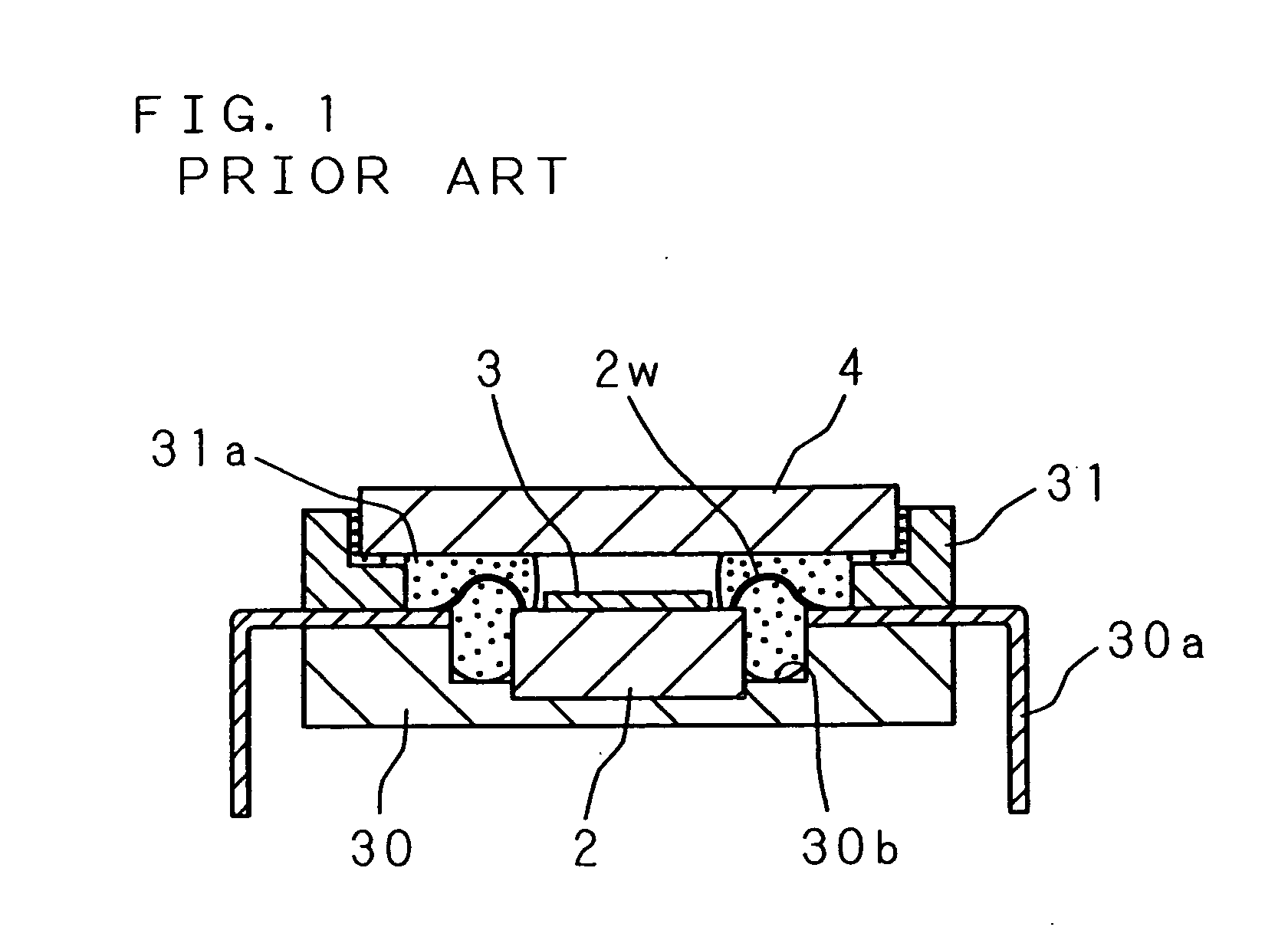

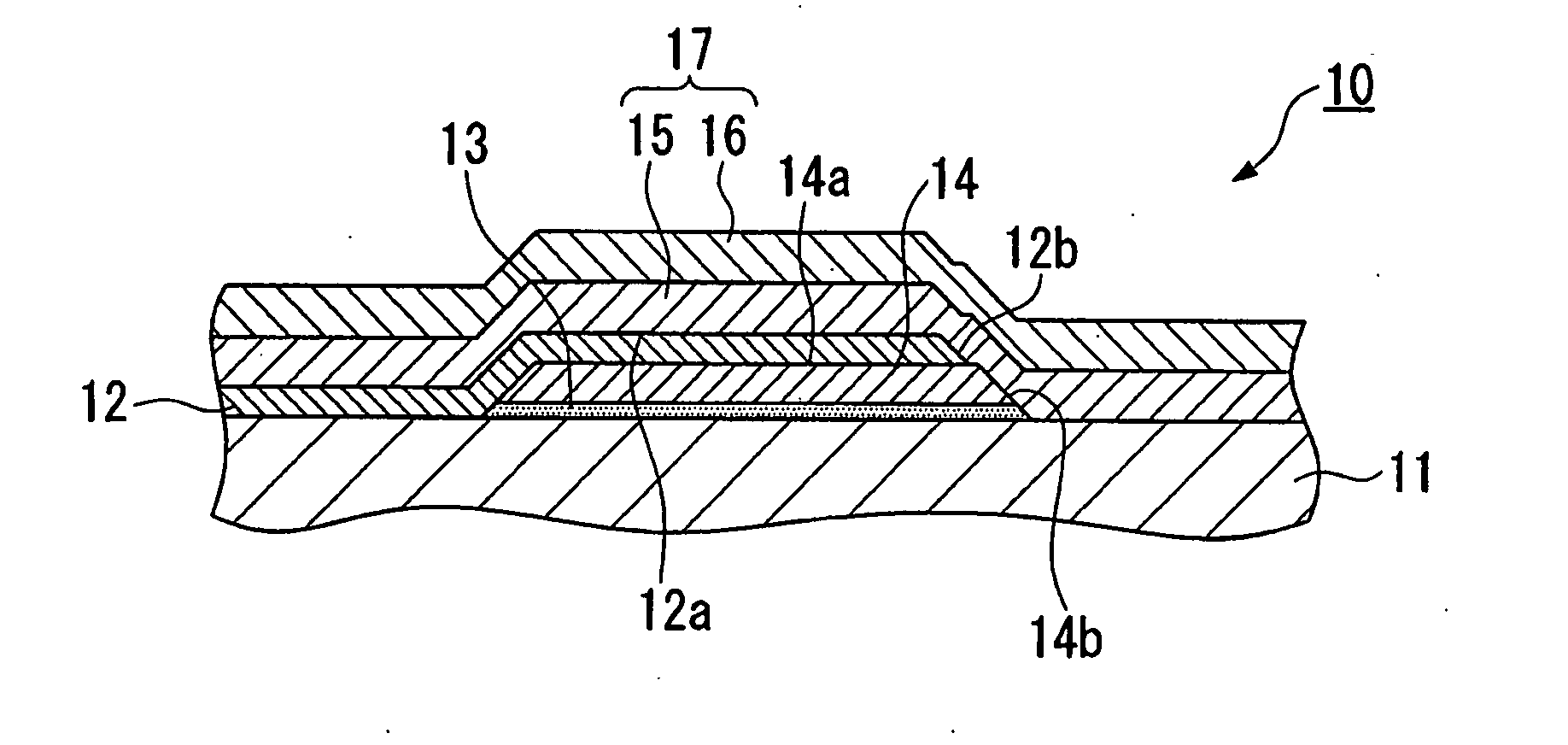

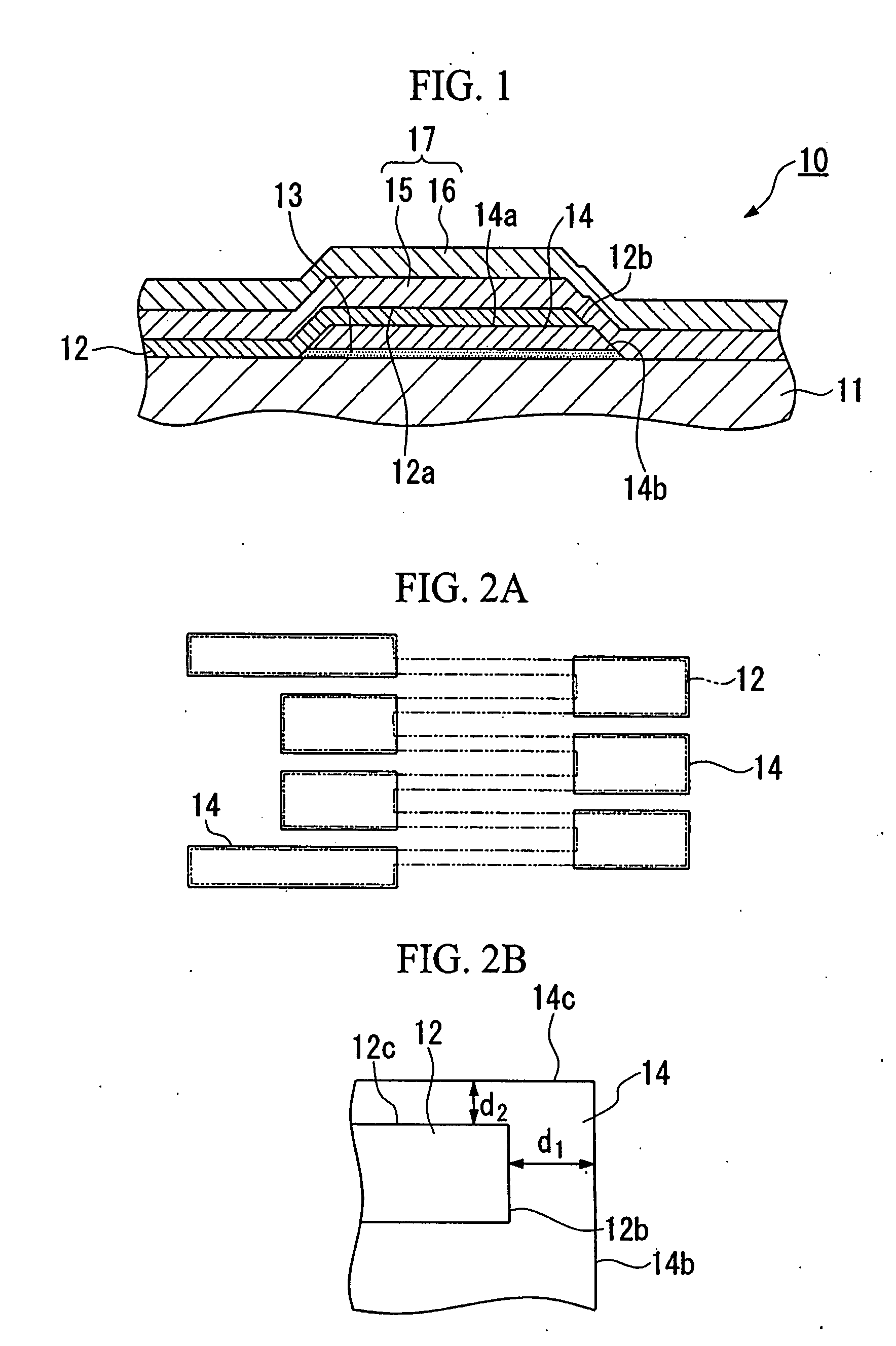

Magnetic sensor and manufacturing method therefor

InactiveUS20050054120A1Uniform layersImprove output stabilityNanomagnetismMagnetic-field-controlled resistorsTectorial membraneMagnetic reluctance

A magnetic sensor comprises a substrate, magnetoresistive element of a spin-valve type, a bias magnetic layer (or a permanent magnet film), and a protective film, wherein the bias magnetic layer is connected with both ends of the magnetoresistive element and the upper surface thereof is entirely covered with the lower surface of the magnetoresistive element at both ends. Herein, distances between the side surfaces of the both ends of the magnetoresistive element and the side surfaces of the bias magnetic layer viewed from the protective film do not exceed 3 μm. In addition, a part of the bias magnetic layer can be covered with both ends of the magnetoresistive element, and an intermediate layer is arranged in relation to the magnetoresistive element, bias magnetic layer, and protective film so as to entirely cover the upper surface of the bias magnetic layer.

Owner:YAMAHA CORP

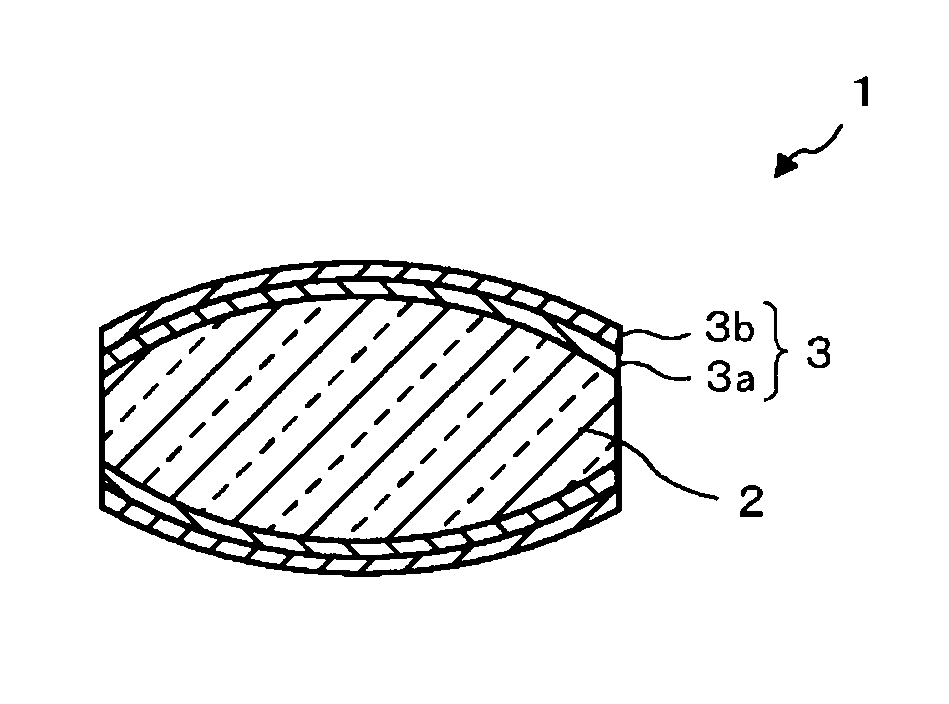

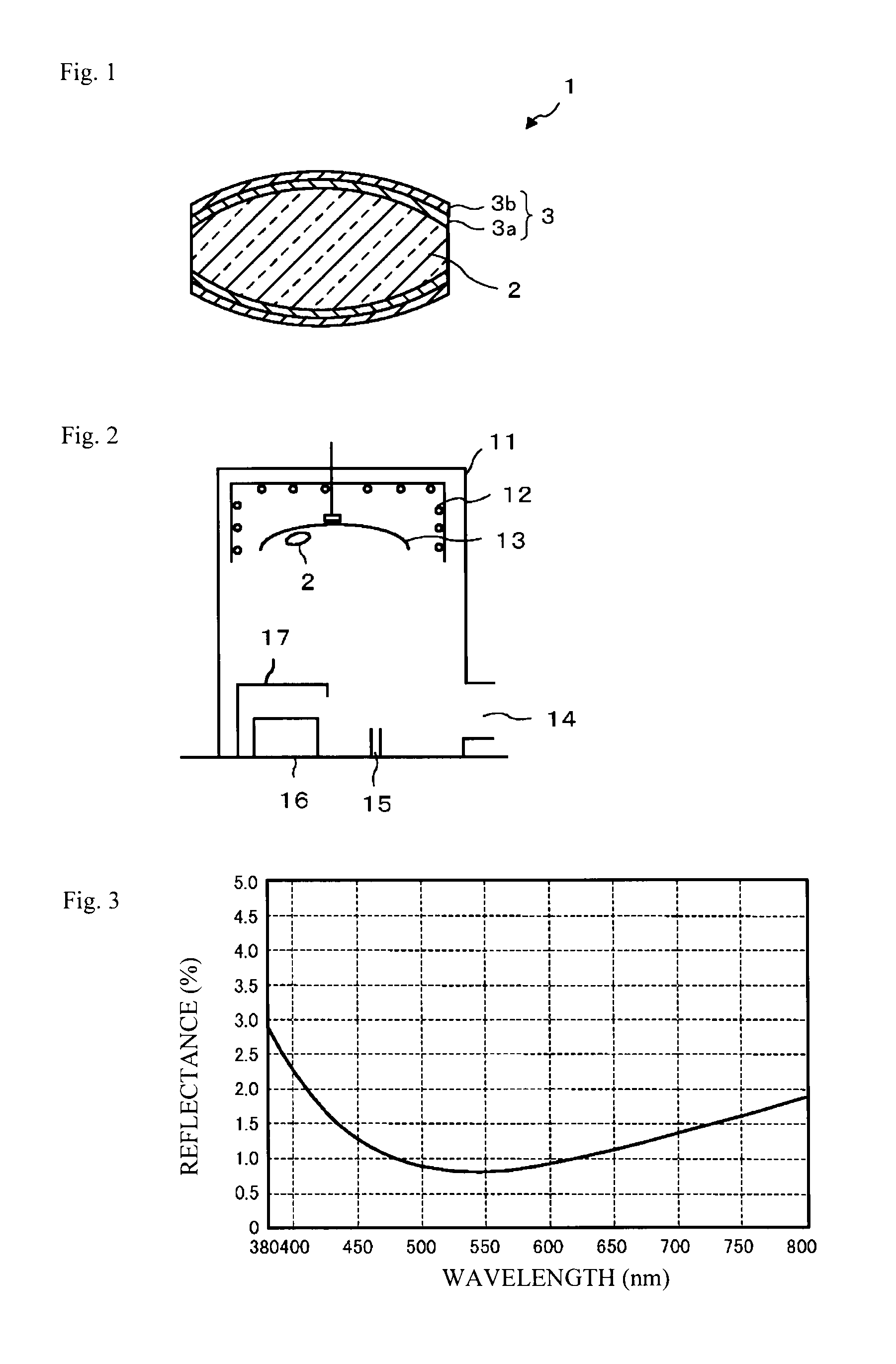

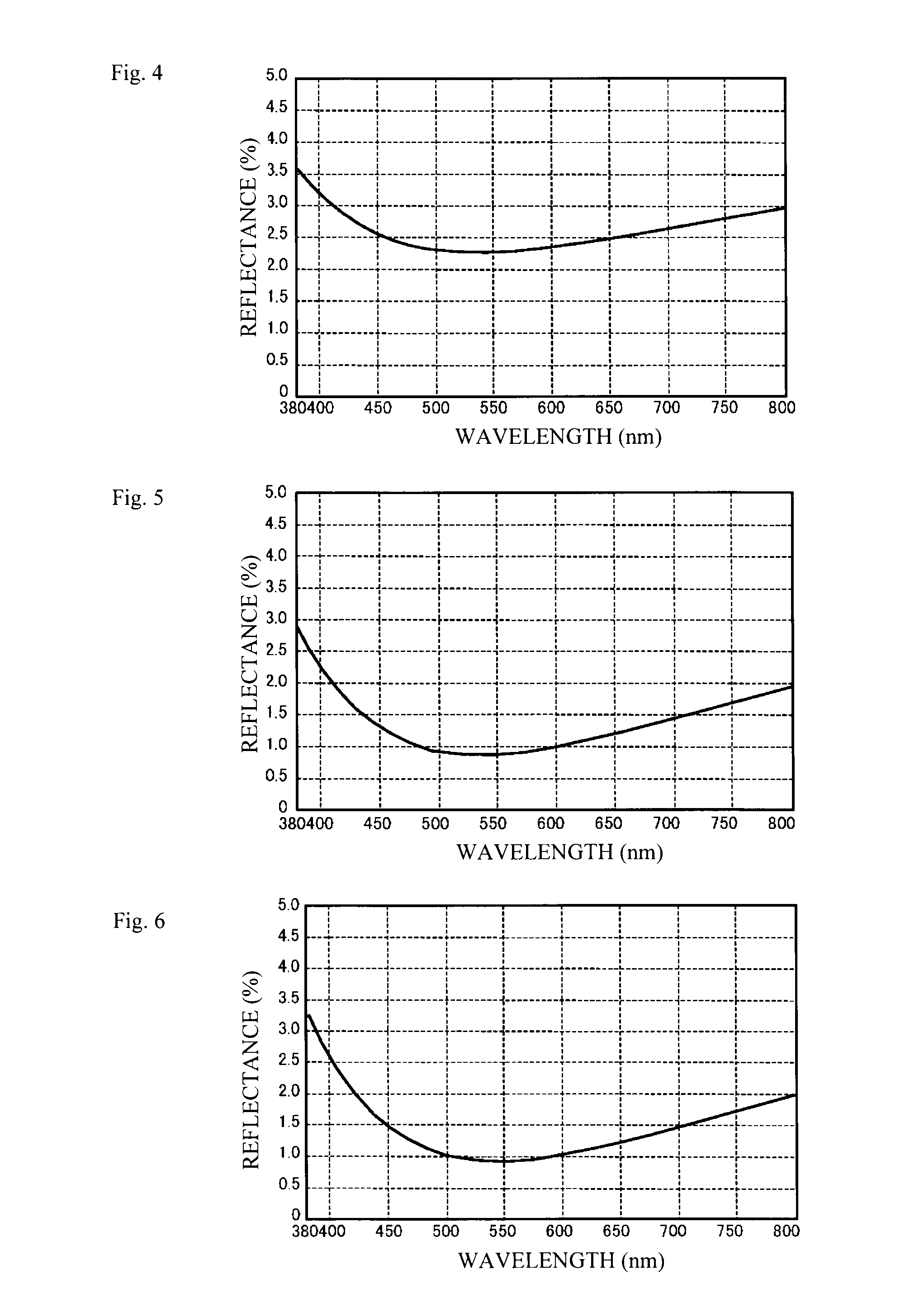

Optical element and method for producing the same

InactiveUS20100330378A1Suppress cloudinessImproved environmental durabilityGlass/slag layered productsSpecial surfacesFluorophosphate glassPhosphate glass

The present invention relates to an optical element comprising: a optical glass made of a phosphate glass or a fluorophosphate glass; and an optically functional film formed on a surface of the optical glass, wherein the optically functional film comprises two or more layers made of different materials, and the outermost surface layer thereof is made of a material(s) having low reactivity with phosphoric acid.

Owner:ASAHI GLASS CO LTD

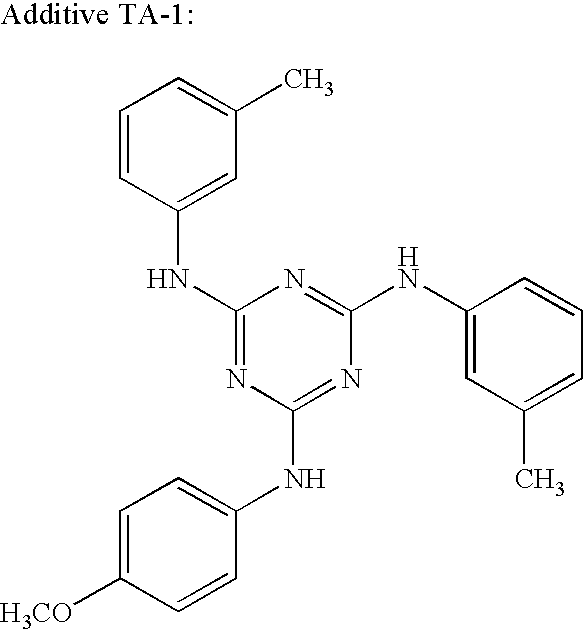

Protective films containing compatible plasticizer compounds useful in polarizing plates for displays and their method of manufacture

InactiveUS7252865B2Excellent Environmental DurabilityLiquid crystal compositionsSynthetic resin layered productsPolymer sciencePlasticizer

Polymer films comprising plasticizer compounds represented by Structure 1 as described in the specification are useful as protective films in polarizing plates for display applications. Methods of manufacturing such polymer films and polarizing plates are also disclosed.

Owner:EASTMAN KODAK CO

Protective films containing compatible plasticizer compounds useful in polarizing plates for displays and their method of manufacture

InactiveUS20060062933A1Excellent Environmental DurabilityLiquid crystal compositionsSynthetic resin layered productsPolymer sciencePlasticizer

Polymer films comprising plasticizer compounds represented by Structure 1 as described in the specification are useful as protective films in polarizing plates for display applications. Methods of manufacturing such polymer films and polarizing plates are also disclosed.

Owner:EASTMAN KODAK CO

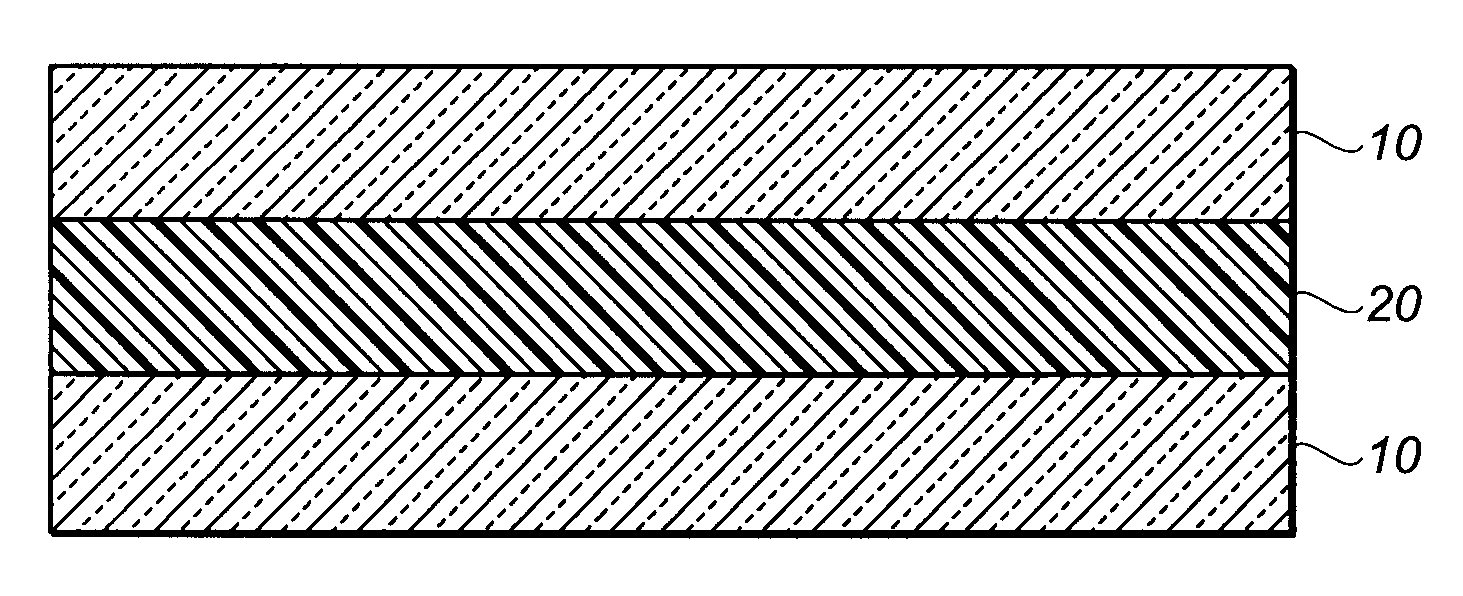

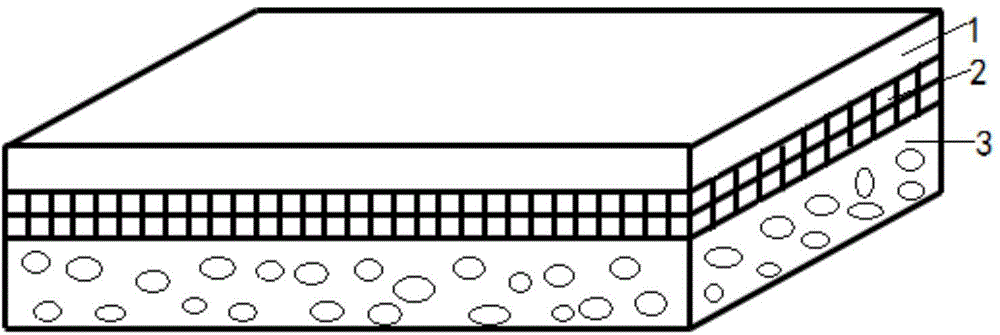

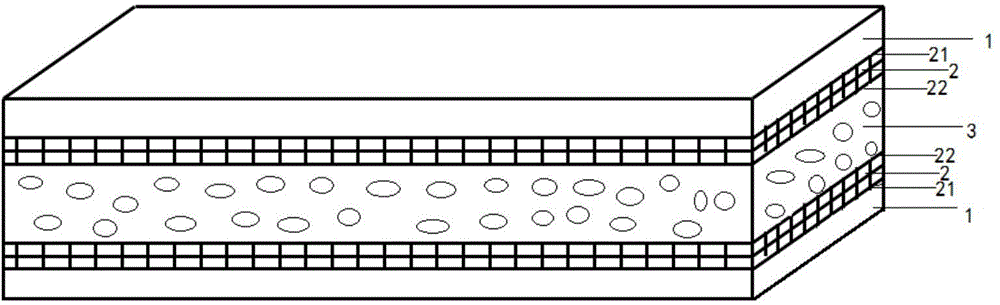

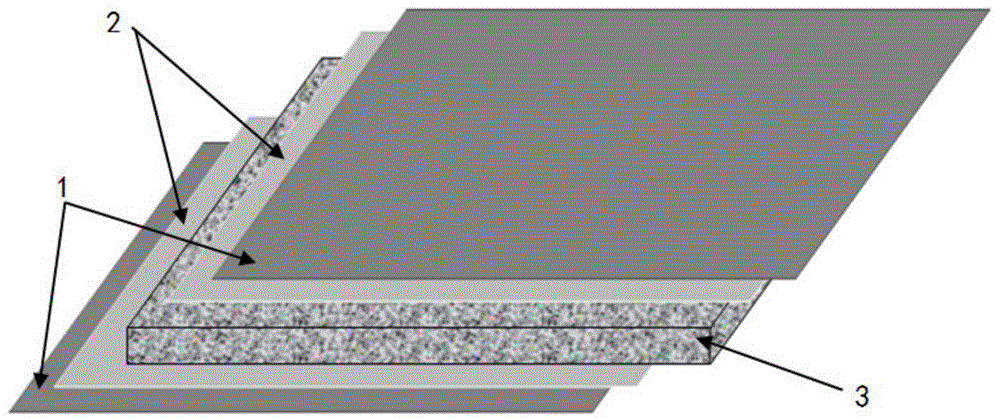

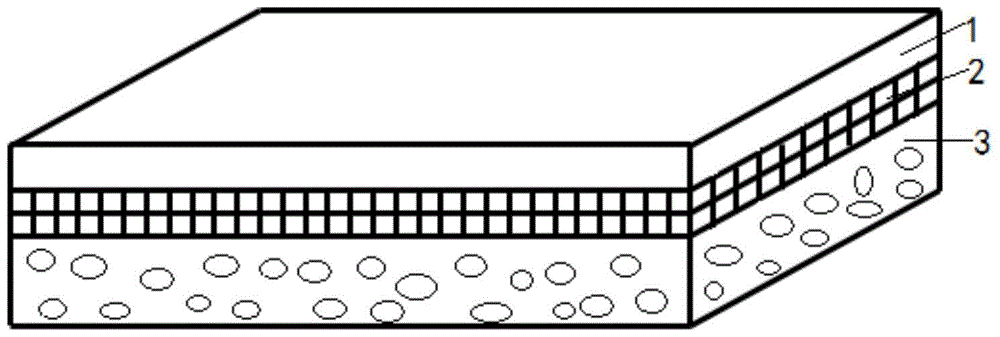

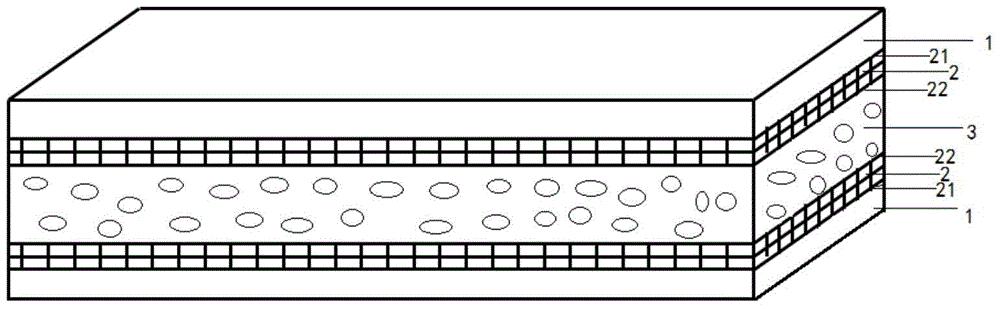

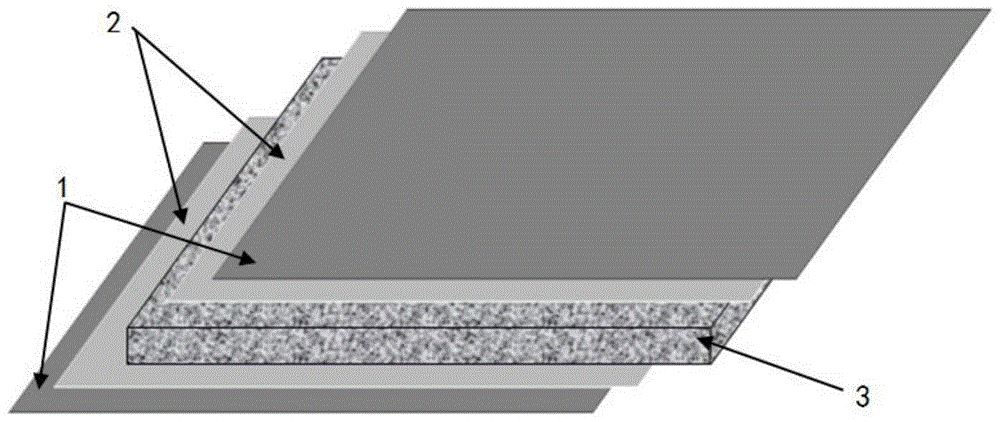

Metal-fiber foamed aluminum composite layer plate and preparation method thereof

ActiveCN104441809AImprove mechanical propertiesImprove energy absorptionLaminationLamination apparatusMetal fiberPolymer adhesive

The invention relates to a metal-fiber foamed aluminum composite layer plate. The composite layer plate comprises at least one metal plate layer, at least one fiber layer and at least one foamed aluminum layer, wherein the fiber layer and the foamed aluminum layer are alternately bonded through a high-temperature-resistant polymer adhesive compound; as the outermost layer, the metal plate layer is bonded with the fiber layer through a high-hardness polymer adhesive compound. The invention further relates to a preparation method of the metal-fiber foamed aluminum composite layer plate. The preparation method mainly comprises the following steps: surface decontaminating treatment is performed on the metal plate layer and the foamed aluminum layer, treated surfaces are coated with the high-temperature-resistant polymer adhesive compound and the high-hardness polymer adhesive compound, and pressure curing treatment is performed after all the layers are bonded together. Compared with a metal foamed aluminium sandwich structure, the metal-fiber foamed aluminum composite layer plate disclosed by the invention has a better mechanical property, a better characteristic of shock absorption and a better performance of sound insulation, and also has a good performance resistant to high-speed impact, a good capability resistant to bending deformation, an extremely high performance of fire resistance, and low cost.

Owner:NINGBO HOPESUN NEW MATERIAL

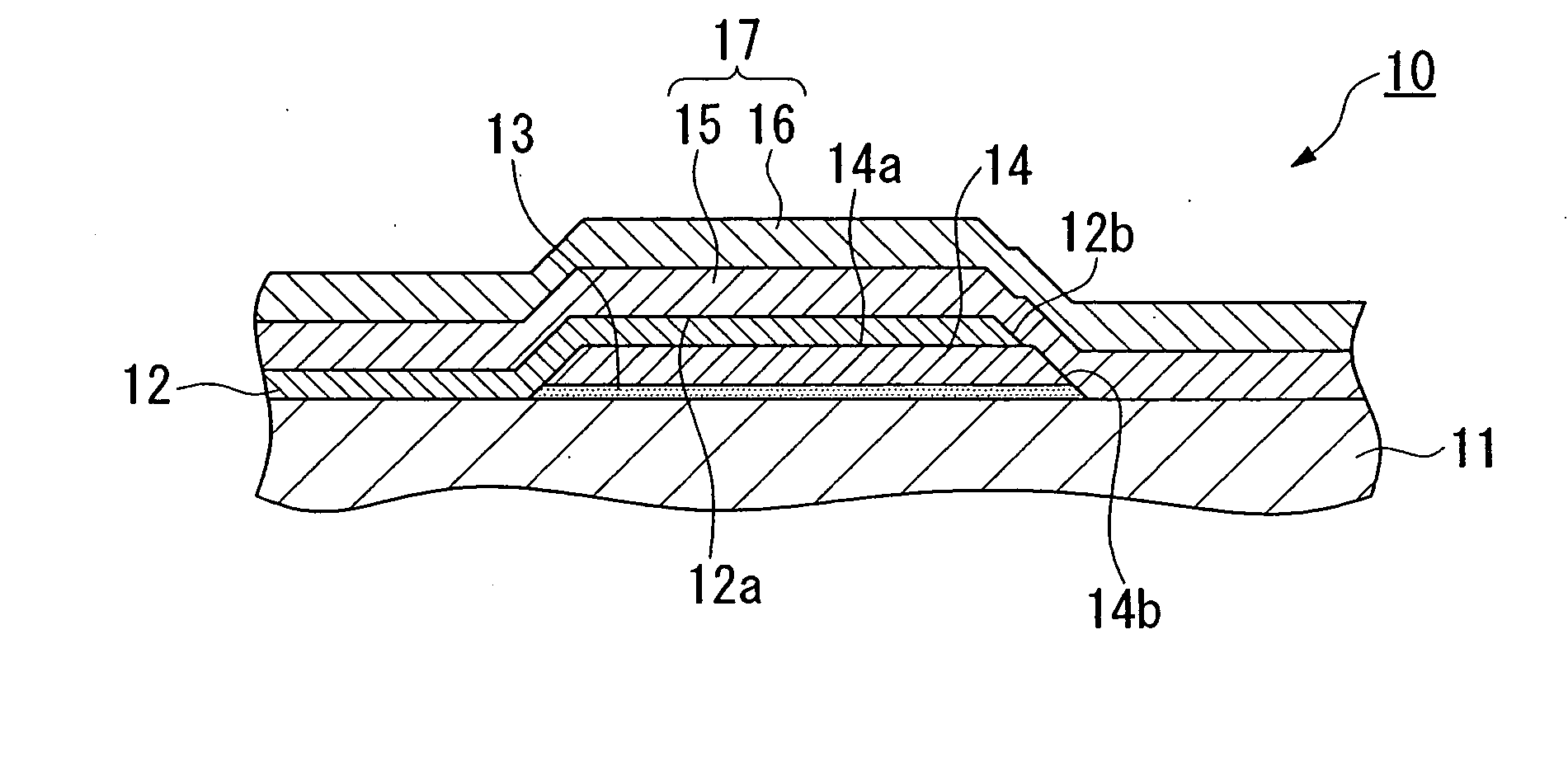

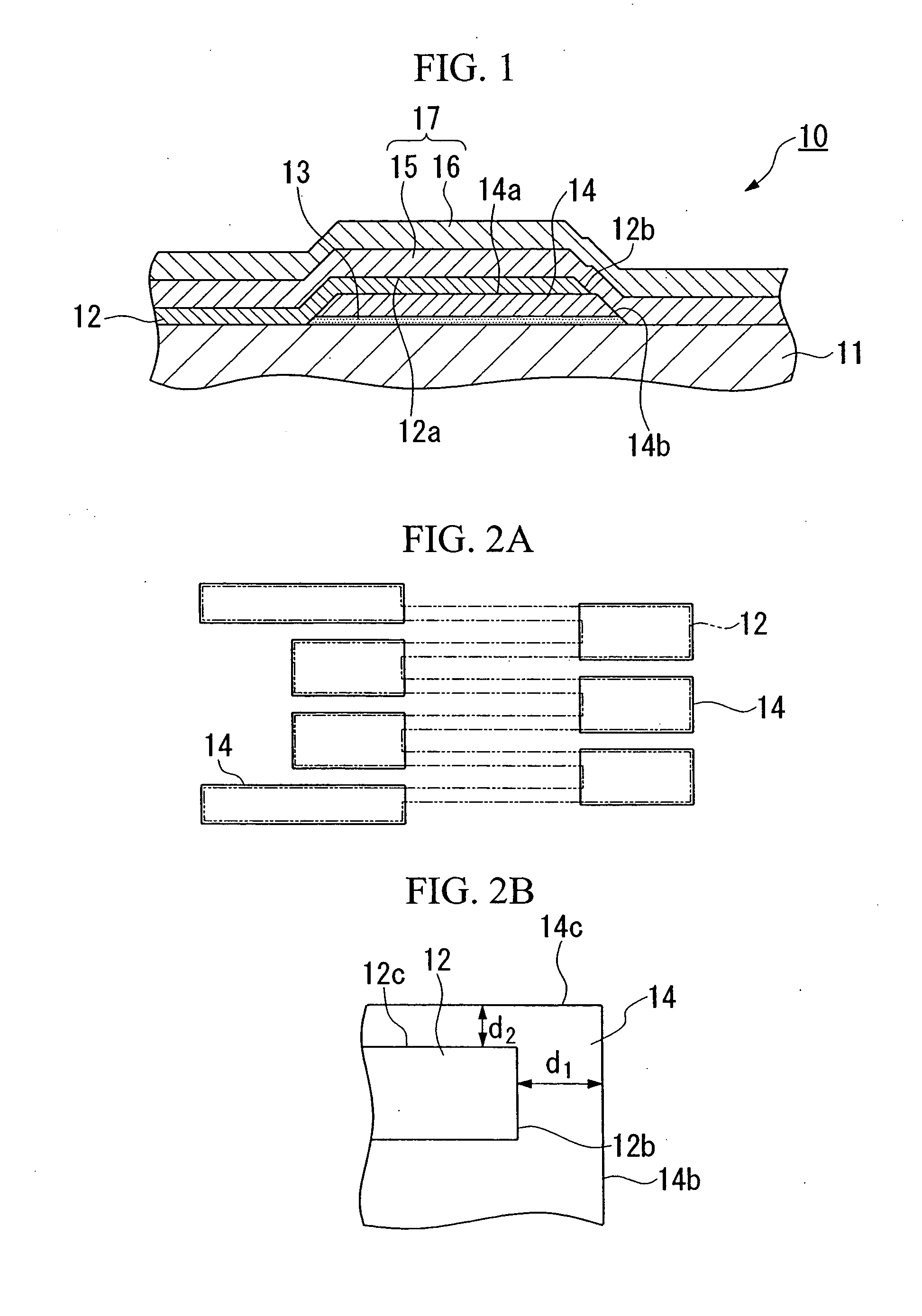

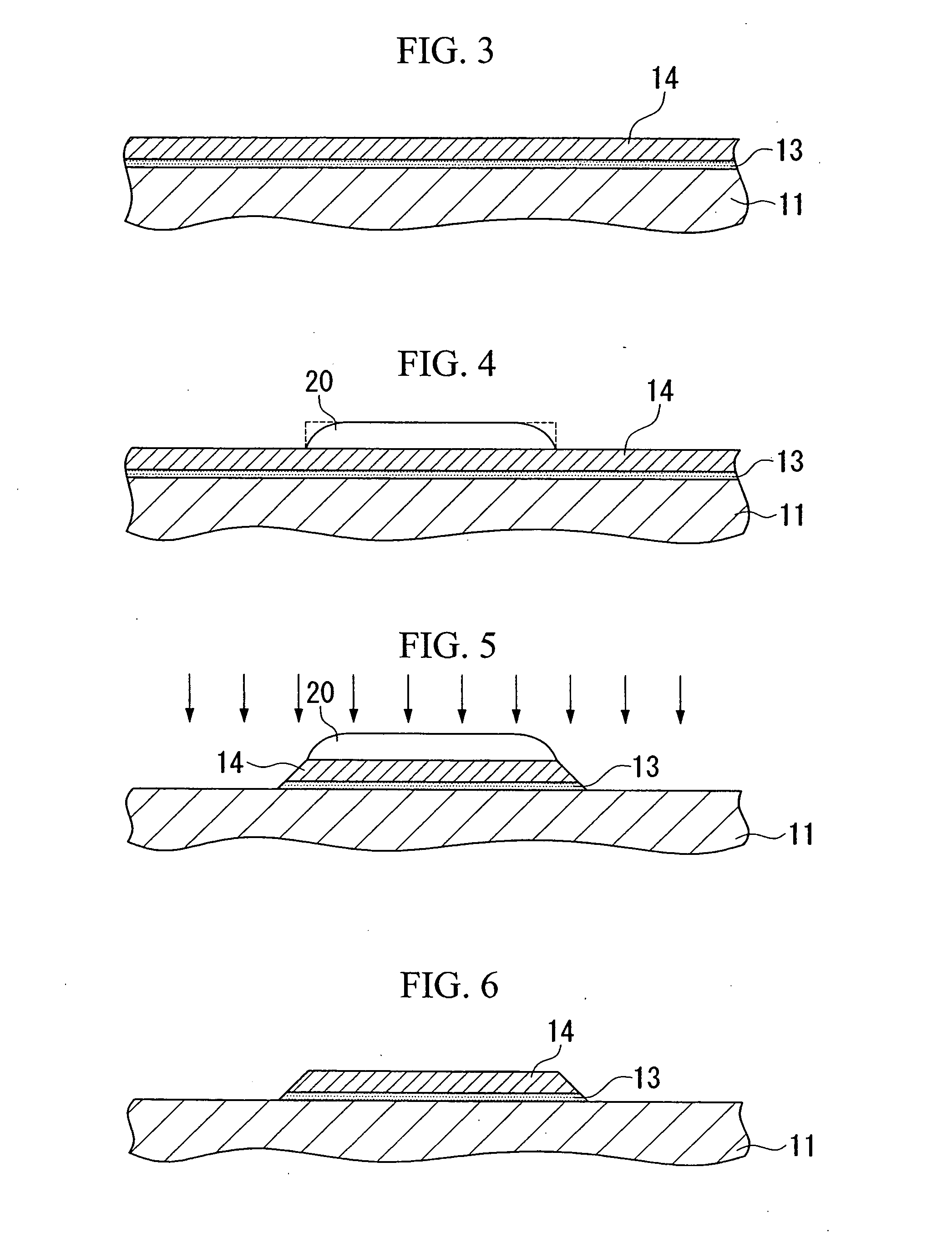

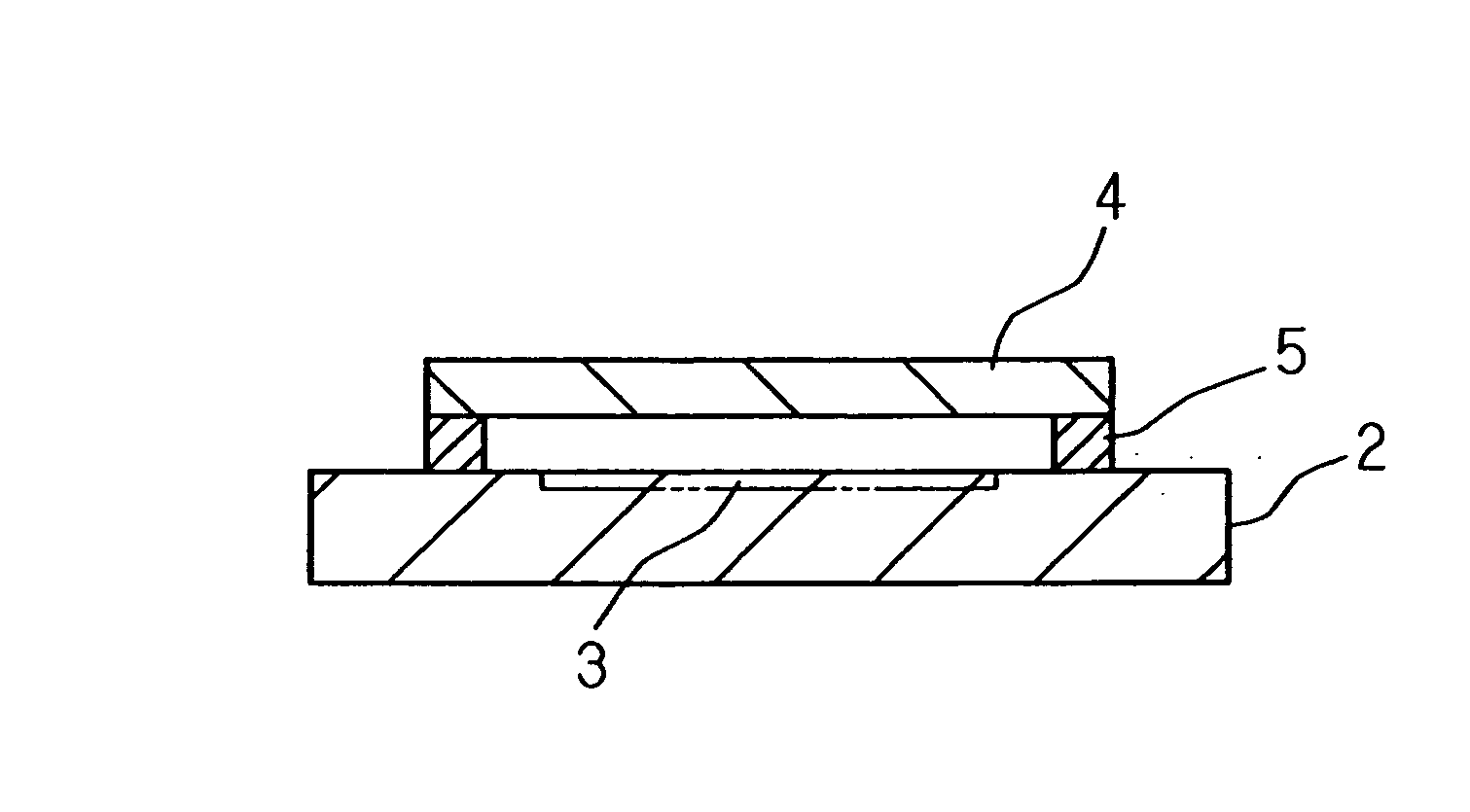

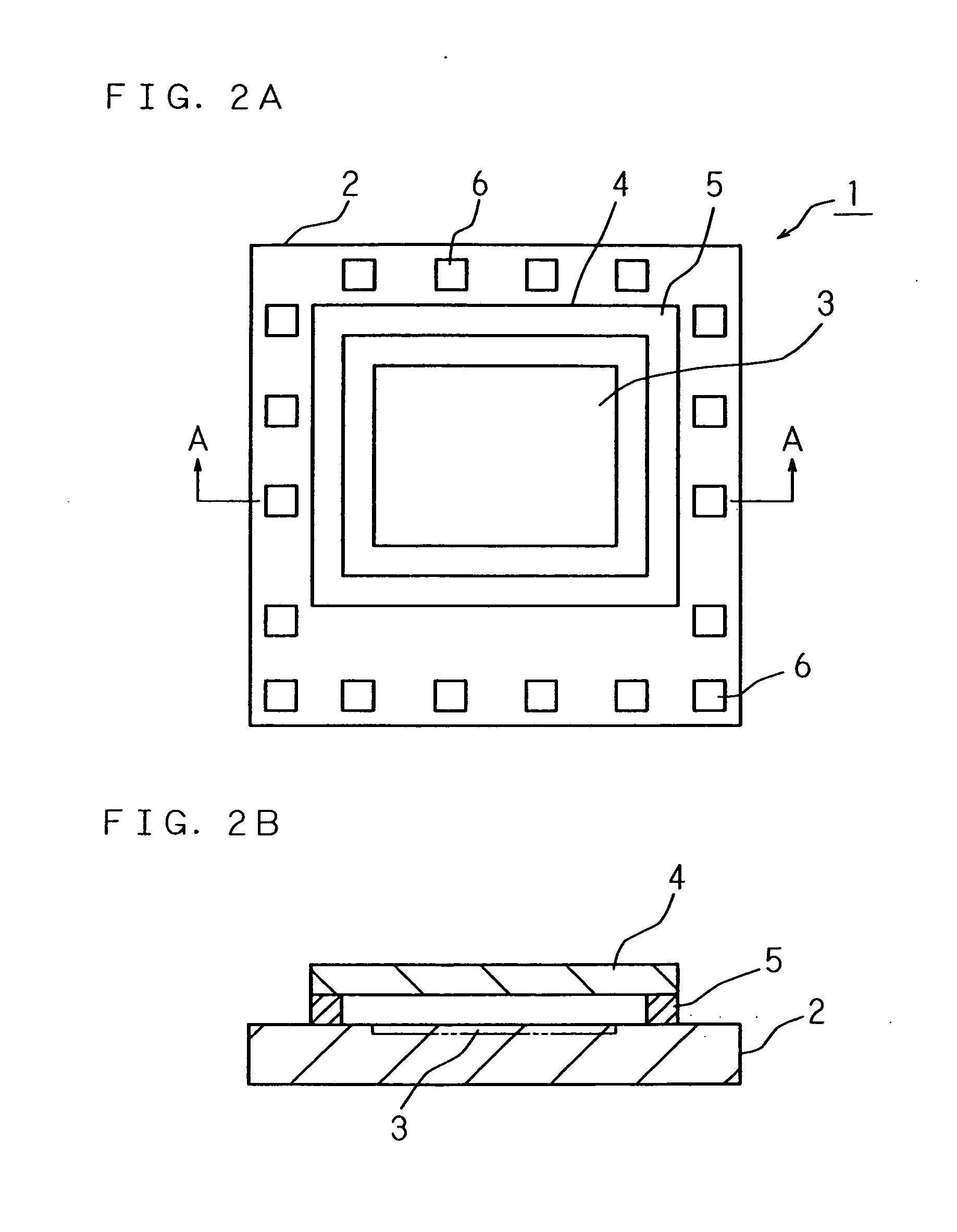

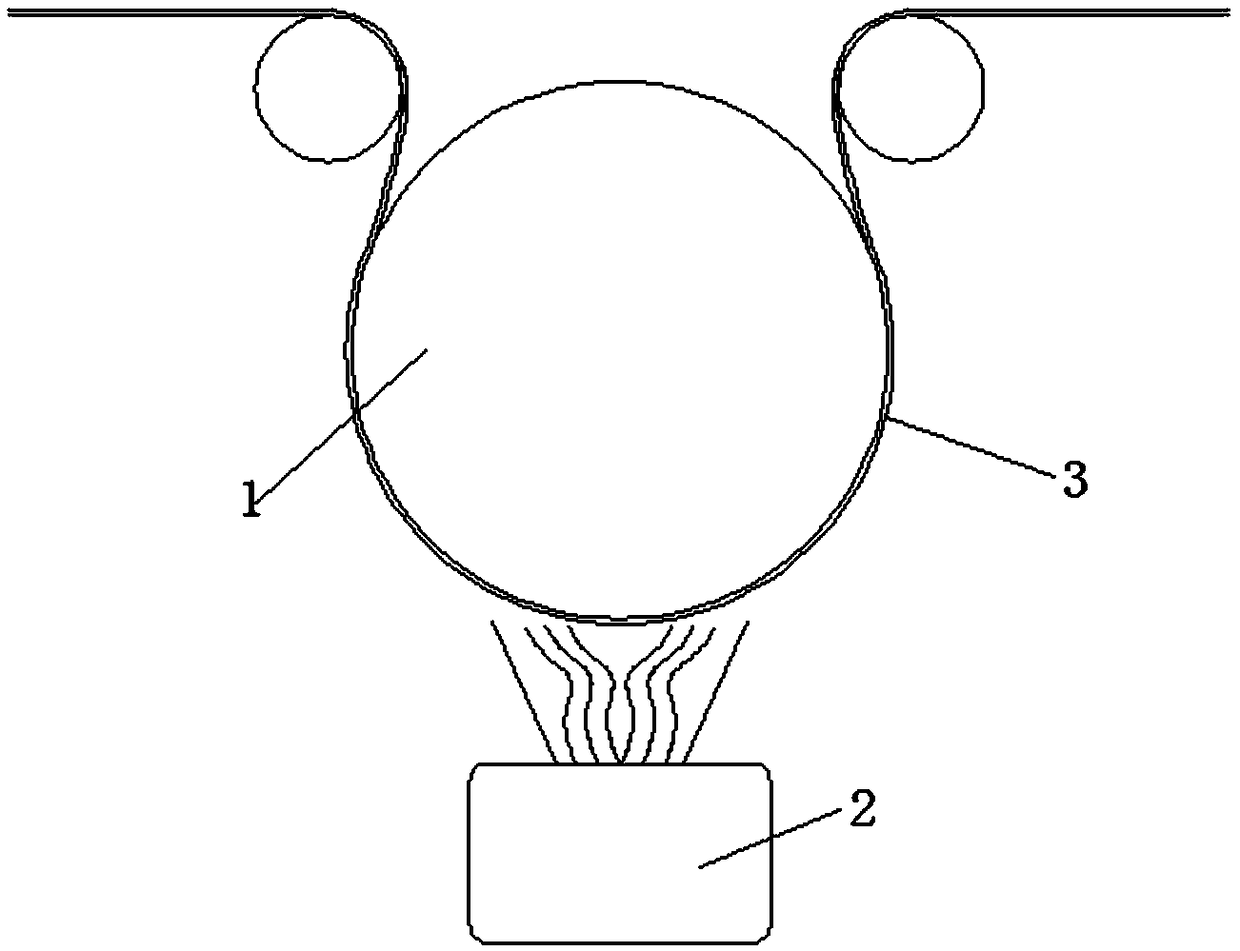

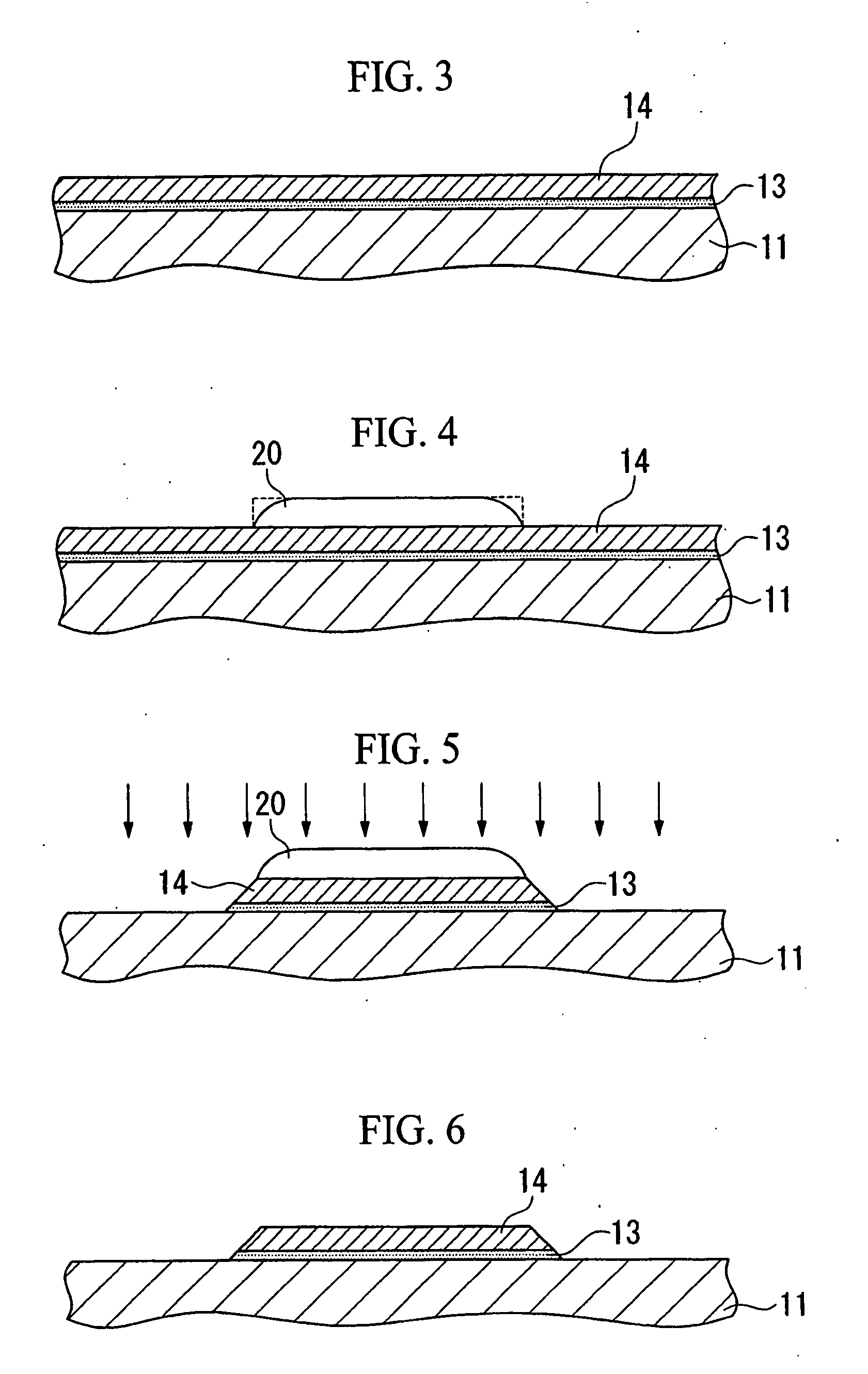

Solid state imaging device, semiconductor wafer, optical device module, method of solid state imaging device fabrication, and method of optical device module fabrication

InactiveUS20080277752A1Improve reliabilitySmall sizeTelevision system detailsSemiconductor/solid-state device detailsOptical ModuleDevice form

With the reduced size of a solid state imaging device, the invention provides: a solid state imaging device of a chip size and having good environmental durability; a semiconductor wafer used for fabricating a solid state imaging device; an optical device module incorporating a solid state imaging device; a method of solid state imaging device fabrication; and a method of optical device module fabrication. The solid state imaging device comprises: a solid state image pickup device formed on a semiconductor substrate; a light-transparent cover arranged opposite to an effective pixel region, so as to protect (the surface of) the effective pixel region formed in one surface of the solid state image pickup device against external environment; and an adhering section formed outside the effective pixel region in the one surface of the solid state image pickup device, so as to adhere the light-transparent cover and the solid state image pickup device.

Owner:SHARP KK

Method for preparing magic color reflective film through vacuum evaporation process

ActiveCN109468591AYi ShenghuaEasy strong reflection effectVacuum evaporation coatingSputtering coatingColor effectEngineering

The invention discloses a method for preparing a magic color reflective film through a vacuum evaporation process. A plated plant base film is placed in a vacuum evaporation chamber, then main drum conduct low temperature cooling, a molybdenum boat where evaporation target materials are arranged is placed in an evaporation tank, it is ensured that the distances between all evaporation target materials and the bottom end of the main drum in the center are different, the evaporation tank is covered with a cover plate to be sent into the evaporation chamber, and the evaporation chamber is vacuumized; the evaporation target materials are heated to a melting point to be vaporized, the cover plate of the evaporation tank is opened, the plated plant base film is controlled to move in the evaporation chamber at the constant speed, and evaporation operation is carried out step by step; and after evaporation is completed, the equipment is stopped. By means of the method, the magic color reflective film finally obtained by the method has the transparent surface and is suitable for deep processing at the later stage, meanwhile, the metal film is not prone to falling, and the color effect can be generated after the film meets light in a dim environment.

Owner:合肥市辉耀真空材料有限责任公司

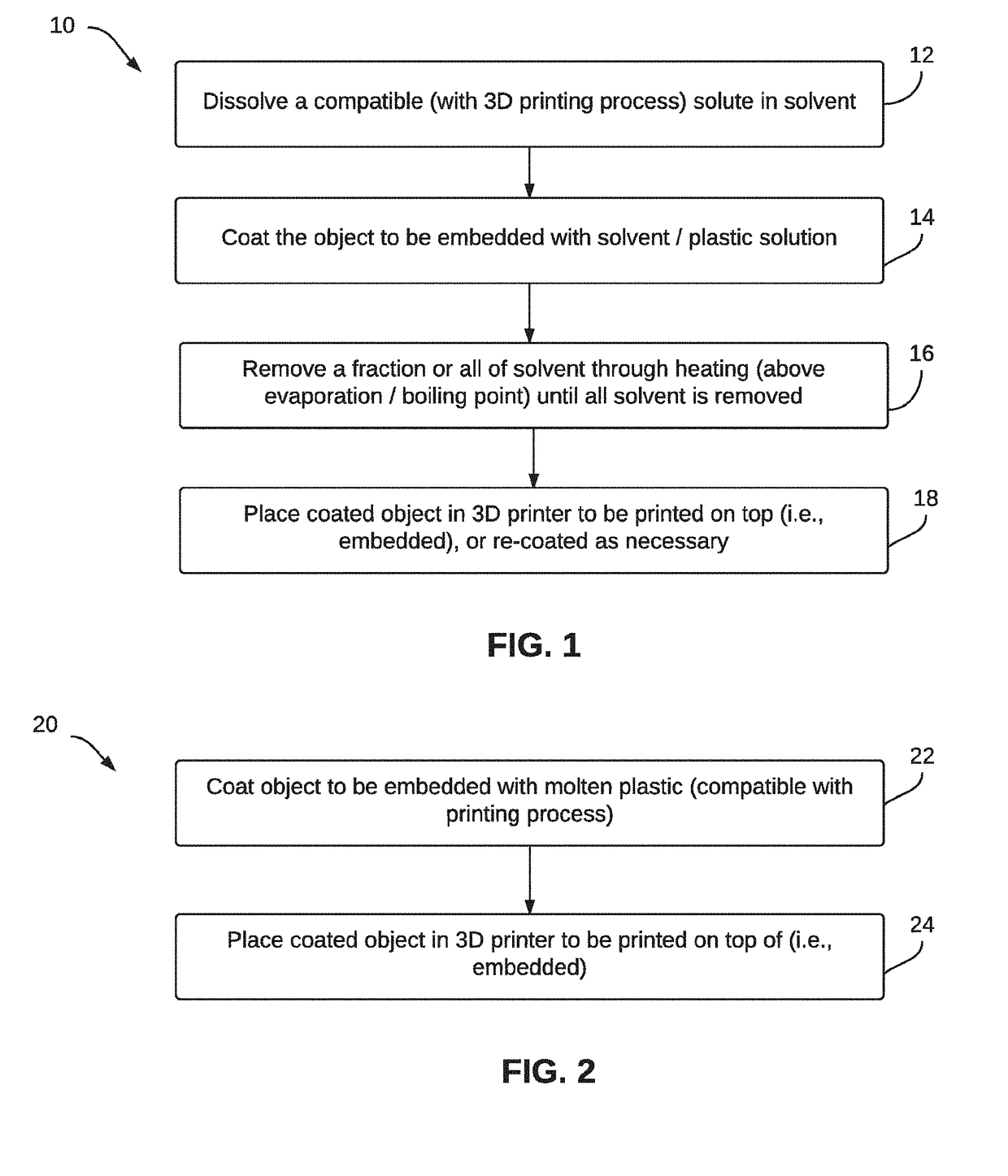

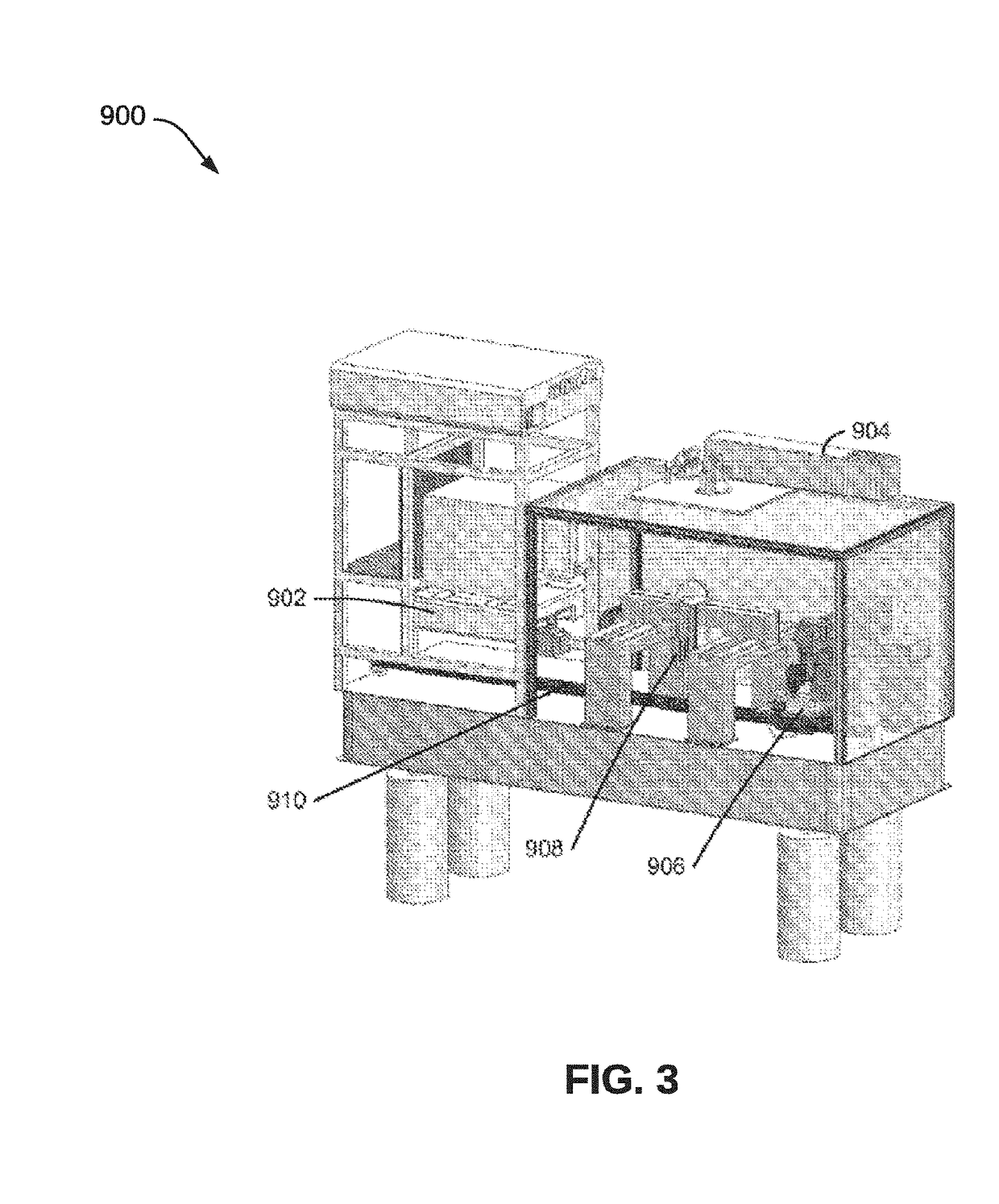

Embedding apparatus and method utilizing additive manufacturing

InactiveUS20180043618A1Excellent Environmental DurabilitySimple interfaceAdditive manufacturing apparatusPrinted circuit manufactureThermal energyAdhesive

An embedded material and an embedding apparatus and method. A compatible solute can be dissolved in a solvent. The object to be embedded can be coated with the solvent / plastic solution using, for example, addition and / or condensation polymerization. The solvent can be removed. The coated object can be inserted, snap fit, or submerged into a partially 3D printed substrate with or without the aid of ultrasonic embedding, thermal energy, joule heating, and / or the use of adhesives, and the 3D printing process resumes in order to fully embed the coated object within the 3D printed substrate. The coated object can be inserted, snap fit, or submerged into a partially 3D printed substrate with or without the addition of ultrasonic embedding, thermal energy, joule heating, and / or adhesives, and the 3D printing process resumes in order to fully embed the coated object within the 3D printed substrate.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

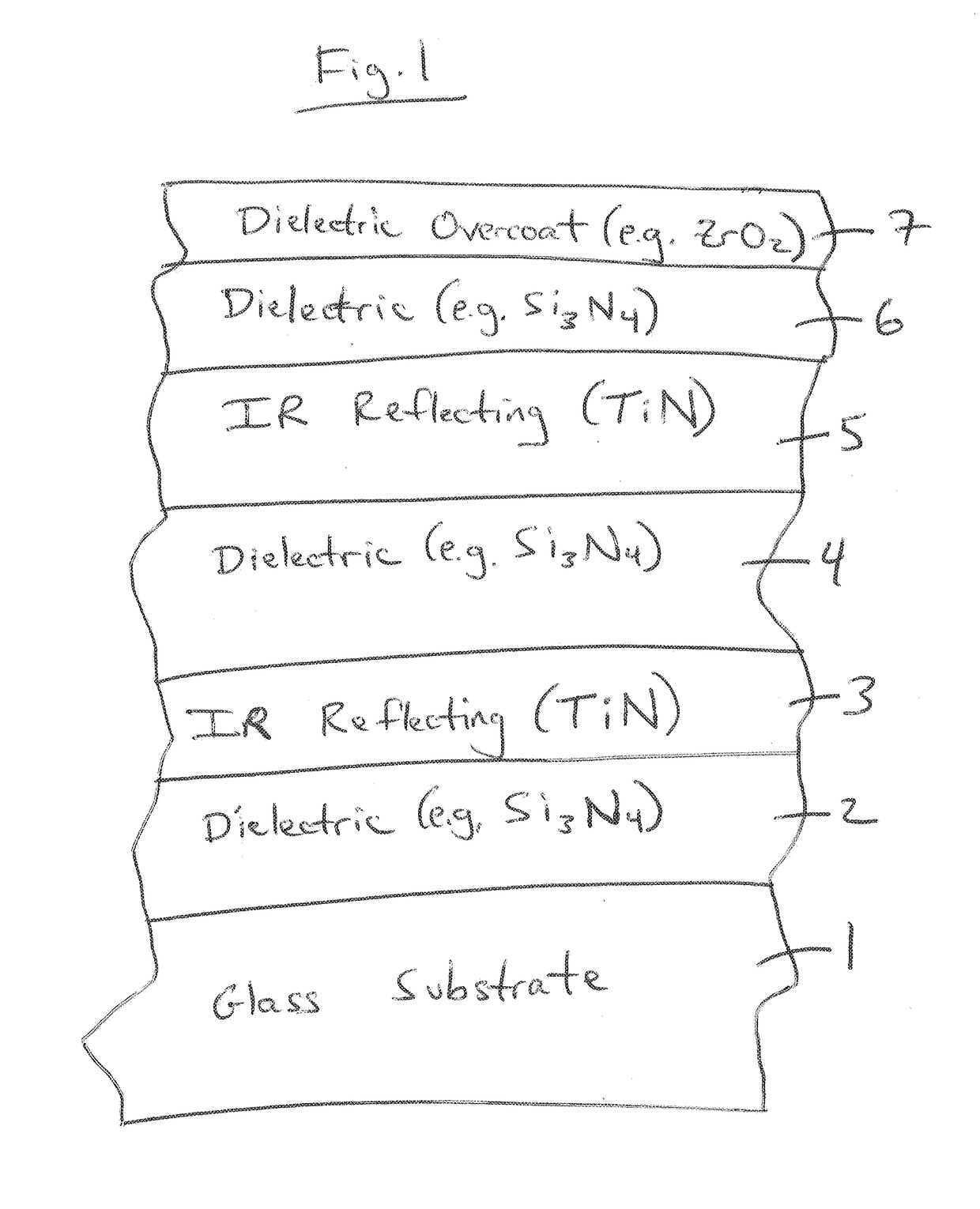

Heat treatable coated article having titanium nitride based ir reflecting layer(s)

ActiveUS20180186691A1Reduce red reflective colorImprove mechanical propertiesVacuum evaporation coatingSputtering coatingIr reflectionTitanium nitride

Owner:GUARDIAN GLASS LLC

Magnetic sensor and manufacturing method therefor

InactiveUS20070210792A1Good reproducibilitySimple manufacturing processNanomagnetismMagnetic-field-controlled resistorsTectorial membraneMagnetic reluctance

A magnetic sensor comprises a substrate, magnetoresistive element of a spin-valve type, a bias magnetic layer (or a permanent magnet film), and a protective film, wherein the bias magnetic layer is connected with both ends of the magnetoresistive element and the upper surface thereof is entirely covered with the lower surface of the magnetoresistive element at both ends. Herein, distances between the side surfaces of the both ends of the magnetoresistive element and the side surfaces of the bias magnetic layer viewed from the protective film do not exceed 3 μm. In addition, a part of the bias magnetic layer can be covered with both ends of the magnetoresistive element, and an intermediate layer is arranged in relation to the magnetoresistive element, bias magnetic layer, and protective film so as to entirely cover the upper surface of the bias magnetic layer.

Owner:YAMAHA CORP

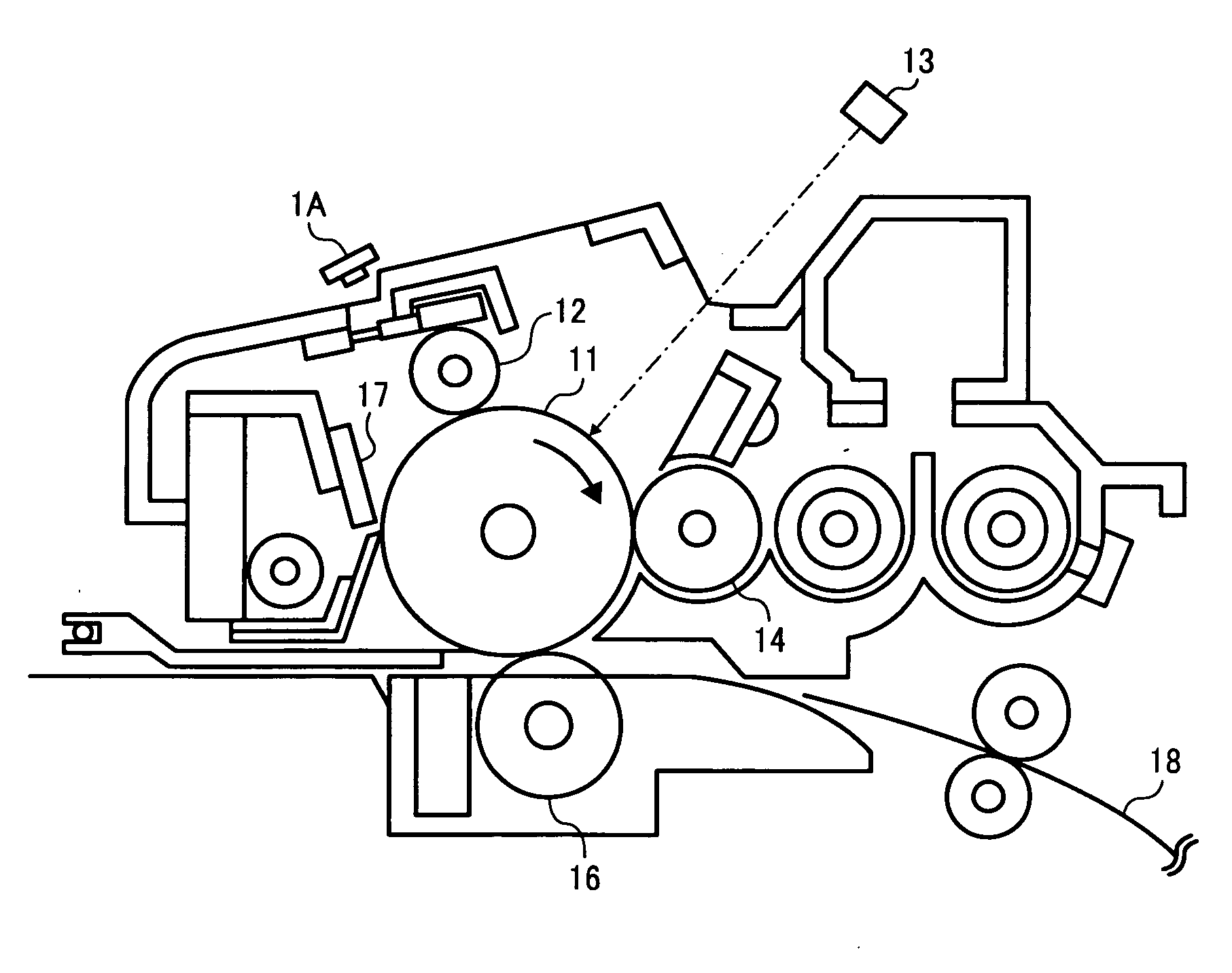

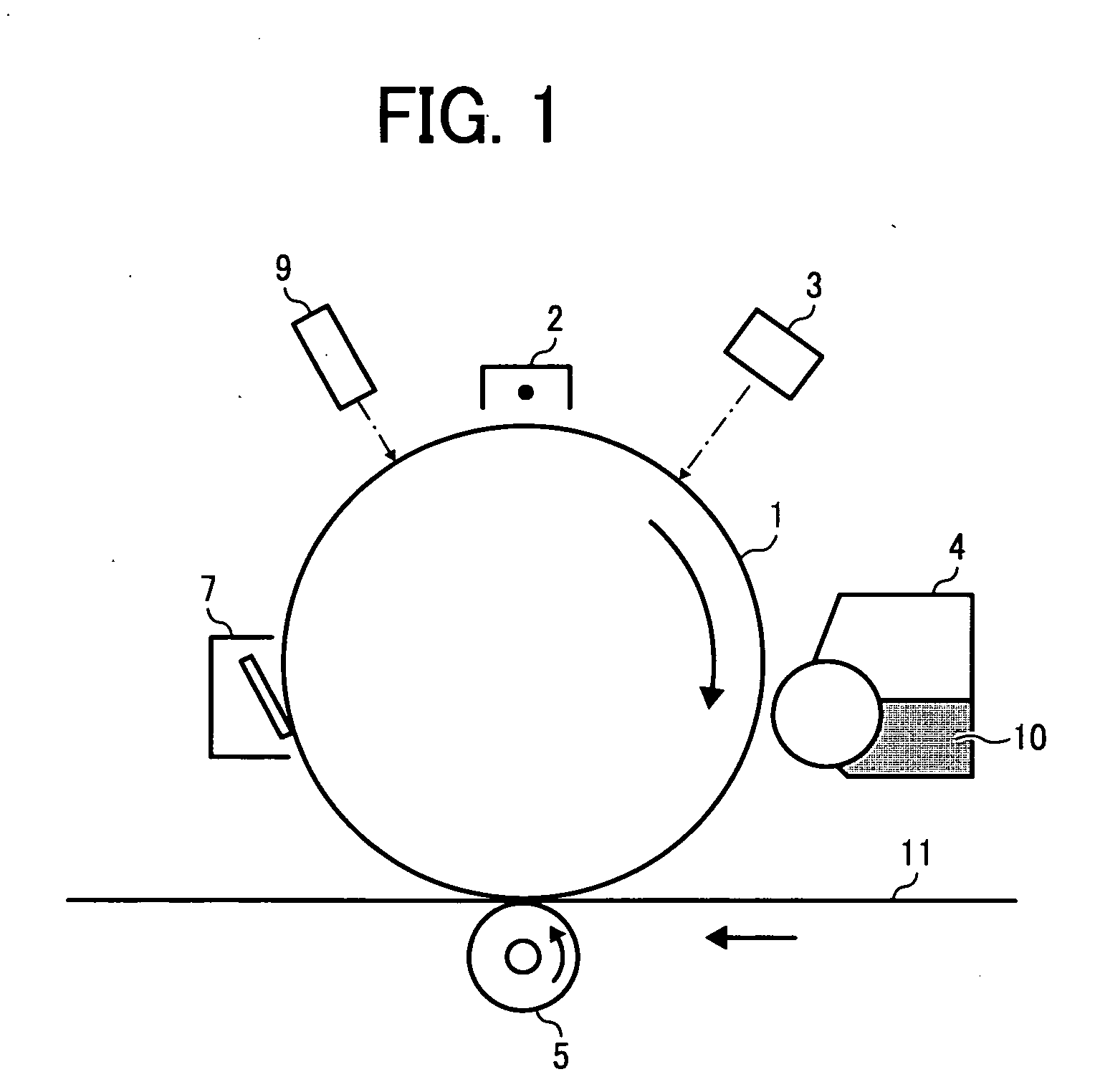

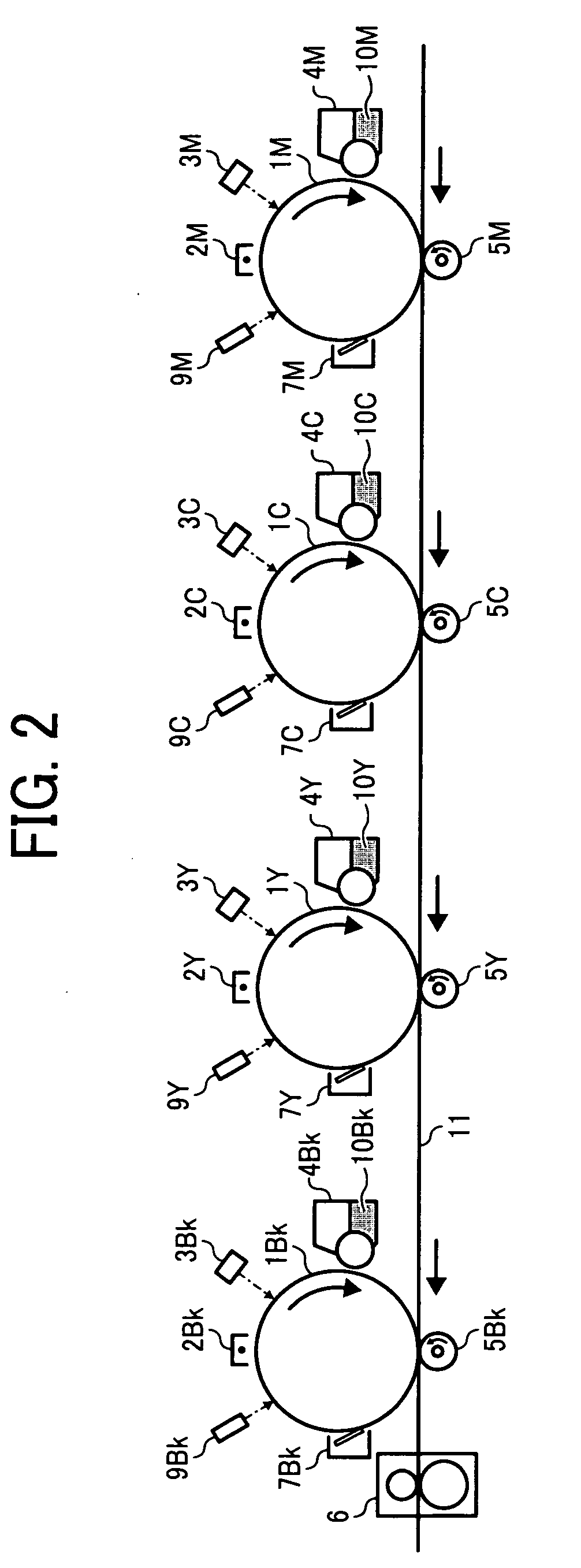

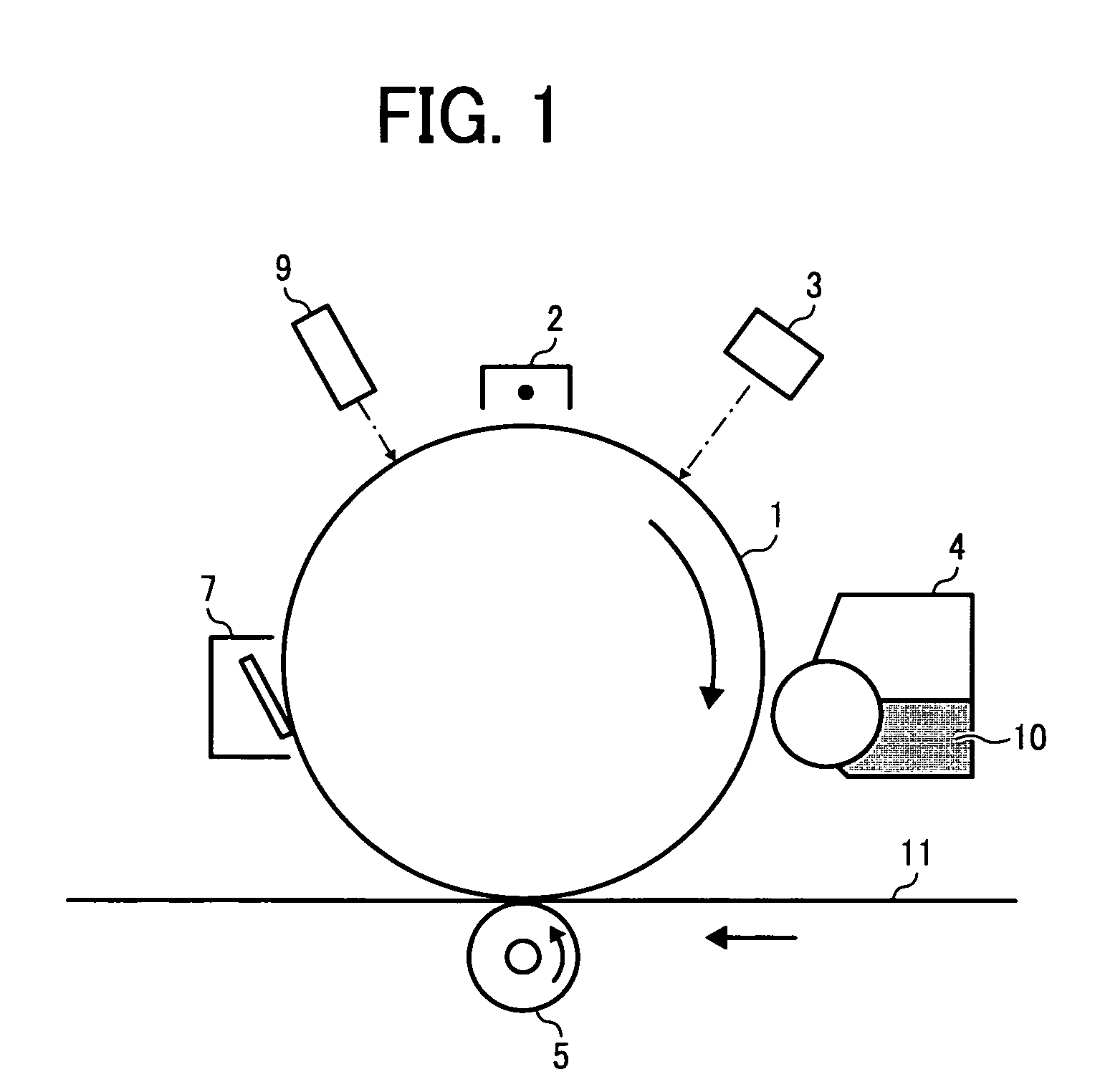

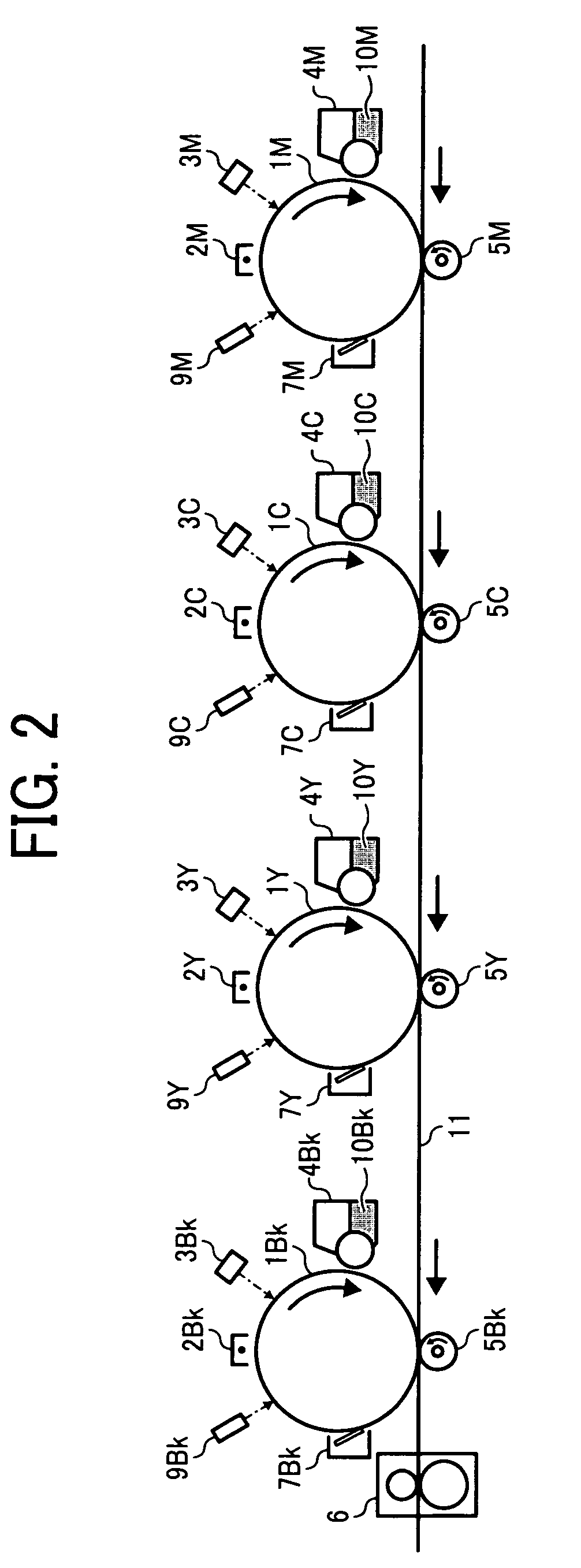

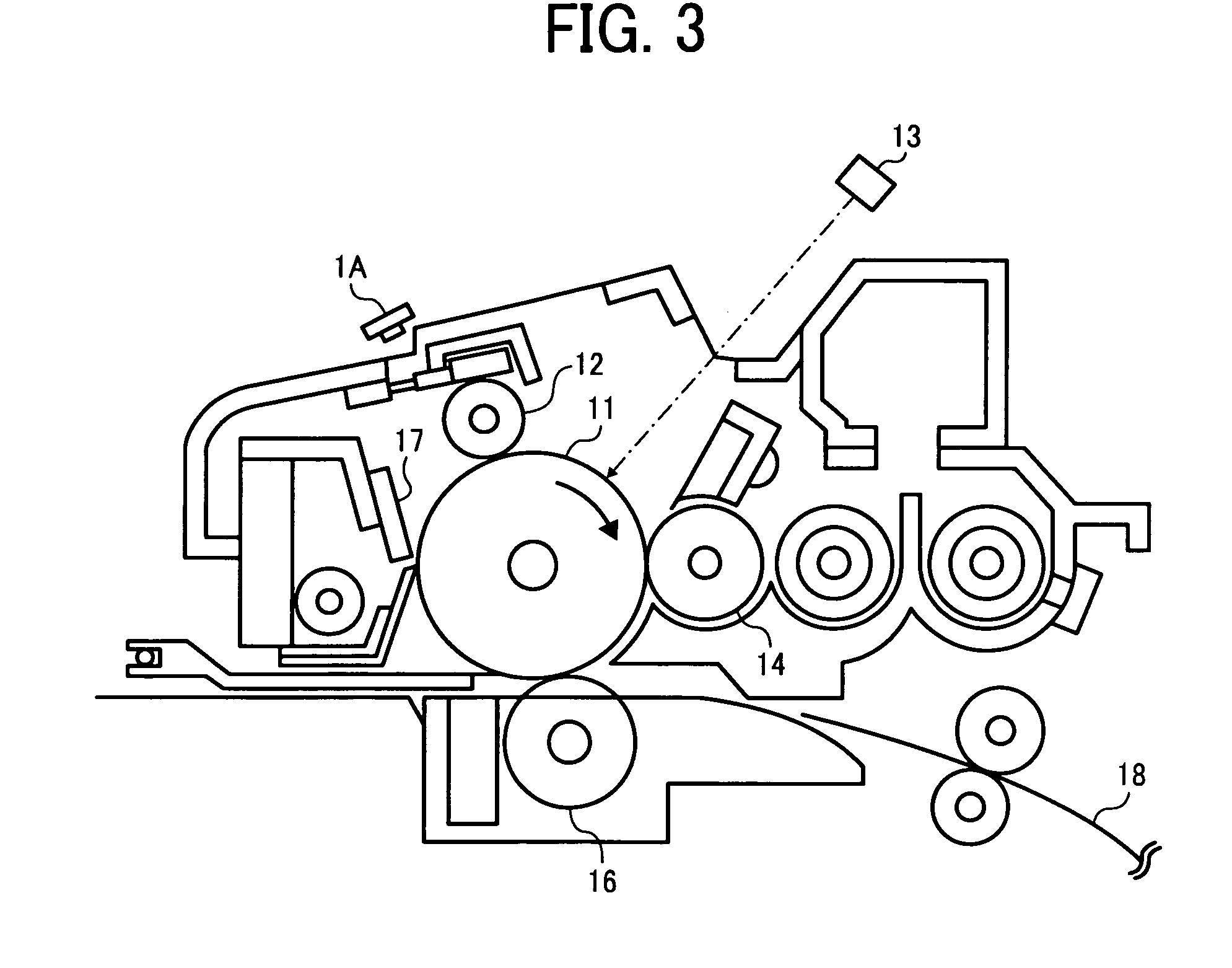

Image forming apparatus and process cartridge

InactiveUS20090180804A1Highly responsive optical attenuationExcellent Environmental DurabilityElectrographic process apparatusCorona dischargeChemical structureHydrogen atom

An image forming apparatus including at least an image bearing member having a substrate having a photosensitive layer thereon, the image bearing member to bear a latent electrostatic image on a surface thereof, a charging device to the surface of the image bearing member, an irradiation device to irradiate the surface of the image bearing member with light to form a latent electrostatic image thereon, a development device to develop the latent electrostatic with toner to obtain a developed image, a transfer device to transfer the developed image to a recording medium, and a cleaning device to clean the surface of the image bearing member, wherein the photosensitive layer includes naphthalene tetracarbonic acid diimide derivative as a charge transport material represented by the following Chemical Structure (1):In the Chemical Structure (1), Z represents a group represented by the following Chemical Formula (1):or the following Chemical Formula (2):—R9 Chemical Formula (2).In the Chemical Structure (1), and the Chemical Formulae (1) and (2), R1, R2, R3, R4 and R9 each, independently, represent a substituted or non-substituted alkyl group or a substituted or non-substituted aromatic hydrocarbon group, R5, R6, R7 and R8 each, independently, represent hydrogen atom, a substituted or non-substituted alkyl group, or a substituted or non-substituted aromatic hydrocarbon group, and R1 and R2 and R3 and R4 optionally share a bond connectivity to form a substituted or non-substituted heterocyclic group including a nitrogen atom.

Owner:RICOH KK

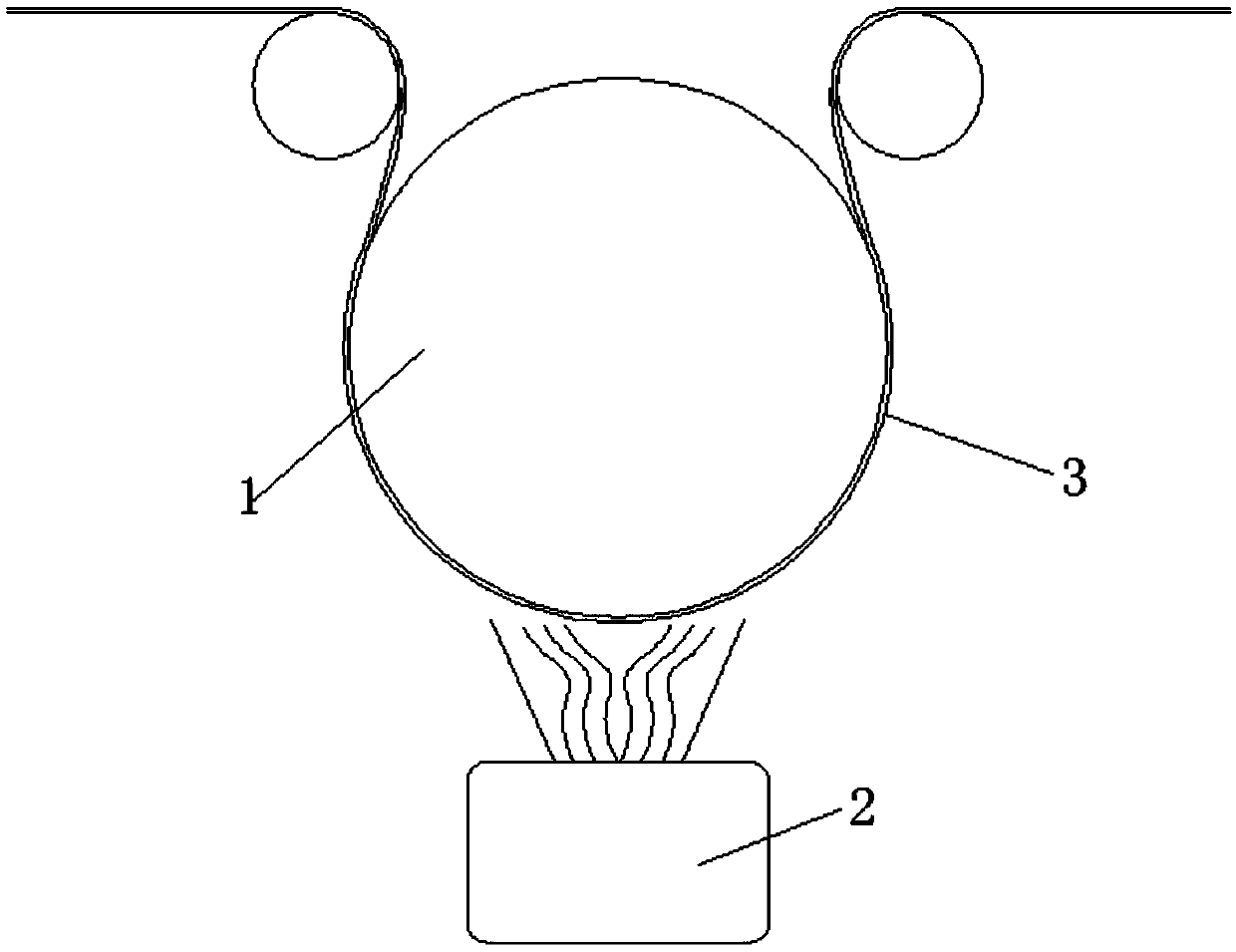

Blue mirror for automobile rearview mirror and preparation method thereof

ActiveCN107757495AReduce distractionsExcellent Environmental DurabilityVacuum evaporation coatingSputtering coatingDriver/operatorRefractive index

The invention belongs to the technical field of glass and particularly relates to a blue mirror for an automobile rearview mirror and a preparation method thereof. The blue mirror for the automobile rearview mirror comprises a hot bending glass substrate; the hot bending glass substrate comprises a concave surface and a convex surface which are arranged oppositely; the concave surface is sequentially provided with a first high refractive index film layer, a first low refractive index film layer, a second high refractive index film layer, a second low refractive index film layer and a metal film layer which are used for forming a composite film in a laminated mode; and the convex surface has a blue-green color. The blue mirror for the automobile rearview mirror has the advantages that the convex surface of the hot bending glass substrate is inward, and the film surface of the composite film is inward, so that the blue mirror is improved in the aspect of environmental durability; furthermore, the convex surface has the blue-green color, is soft to light and can effectively reduce the interference of glare to the sight line of a driver so as to achieve the effect of effectively preventing the driver from dazzling; and the hot bending glass substrate has double curvature, so that a wide view effect can be obtained. The blue mirror for the automobile rearview mirror has good functions and has more beautiful appearance.

Owner:XINYI PHOTOVOLTAIC IND (ANHUI) HLDG CO LTD

Vacuum evaporation process of high-brightness transparent light reflecting film

InactiveCN109609913AWith high temperature and corrosion resistanceHigh hardnessVacuum evaporation coatingSputtering coatingEngineeringEvaporation chamber

The invention discloses a vacuum evaporation process of a high-brightness transparent light reflecting film. A plated plant base film is mounted in an evaporation chamber, then a cooling roller carries out low-temperature cooling, molybdenum boats where evaporation targets are arranged are put into an evaporation tank, it is guaranteed that the distance between each evaporation target and the bottom end of a center main drum is the same, after a cover plate is closed, the evaporation tank is fed into the evaporation chamber, and the evaporation chamber is vacuumized; the evaporation targets are heated to the melting point and are vaporized, the cover plate of the evaporation tank is opened, the plated plant base film is controlled to move in the evaporation chamber at a constant speed, andstep-by-step evaporation operation is carried out; and equipment is shut down after evaporation is completed. According to the vacuum evaporation process of the high-brightness transparent light reflecting film, the light reflecting brightness of the finally-obtained light reflecting film is far higher than that of a common transparent light reflecting film, a good light reflecting effect is achieved, the surface is light, thin and transparent, the vacuum evaporation process is suitable for later deep processing treatment, and meanwhile a metal film is firm and not prone to falling off.

Owner:合肥市辉耀真空材料有限责任公司

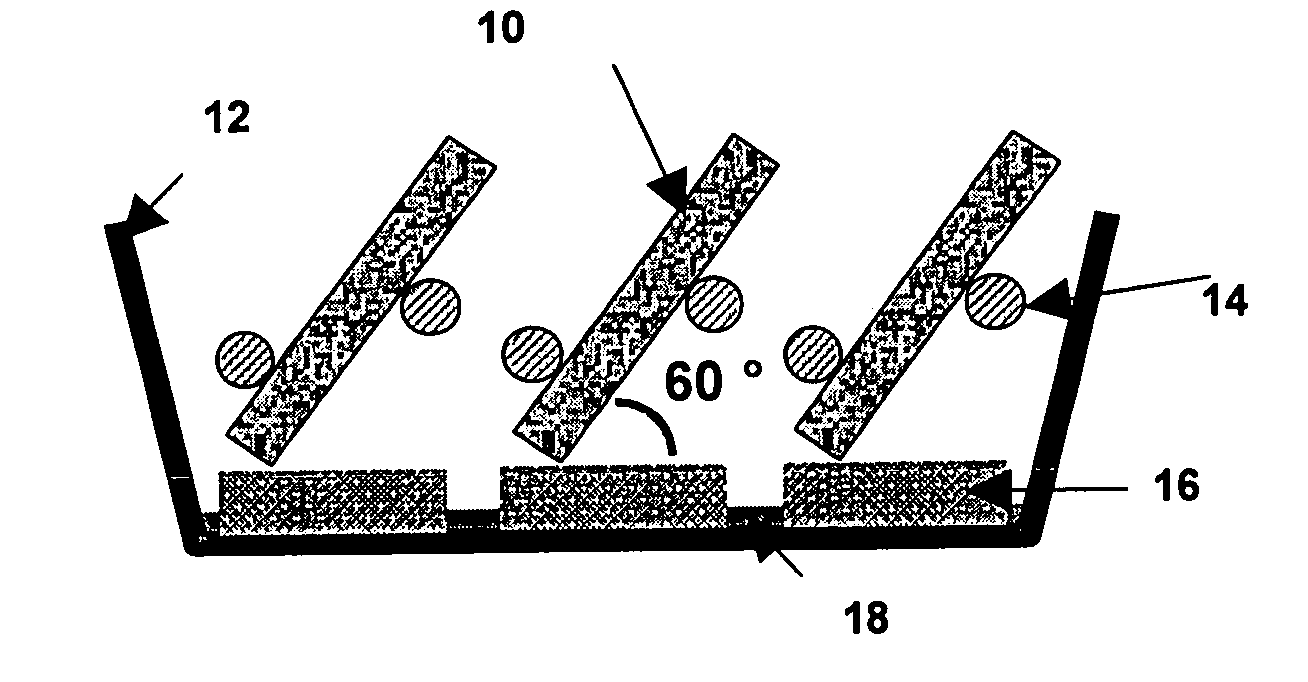

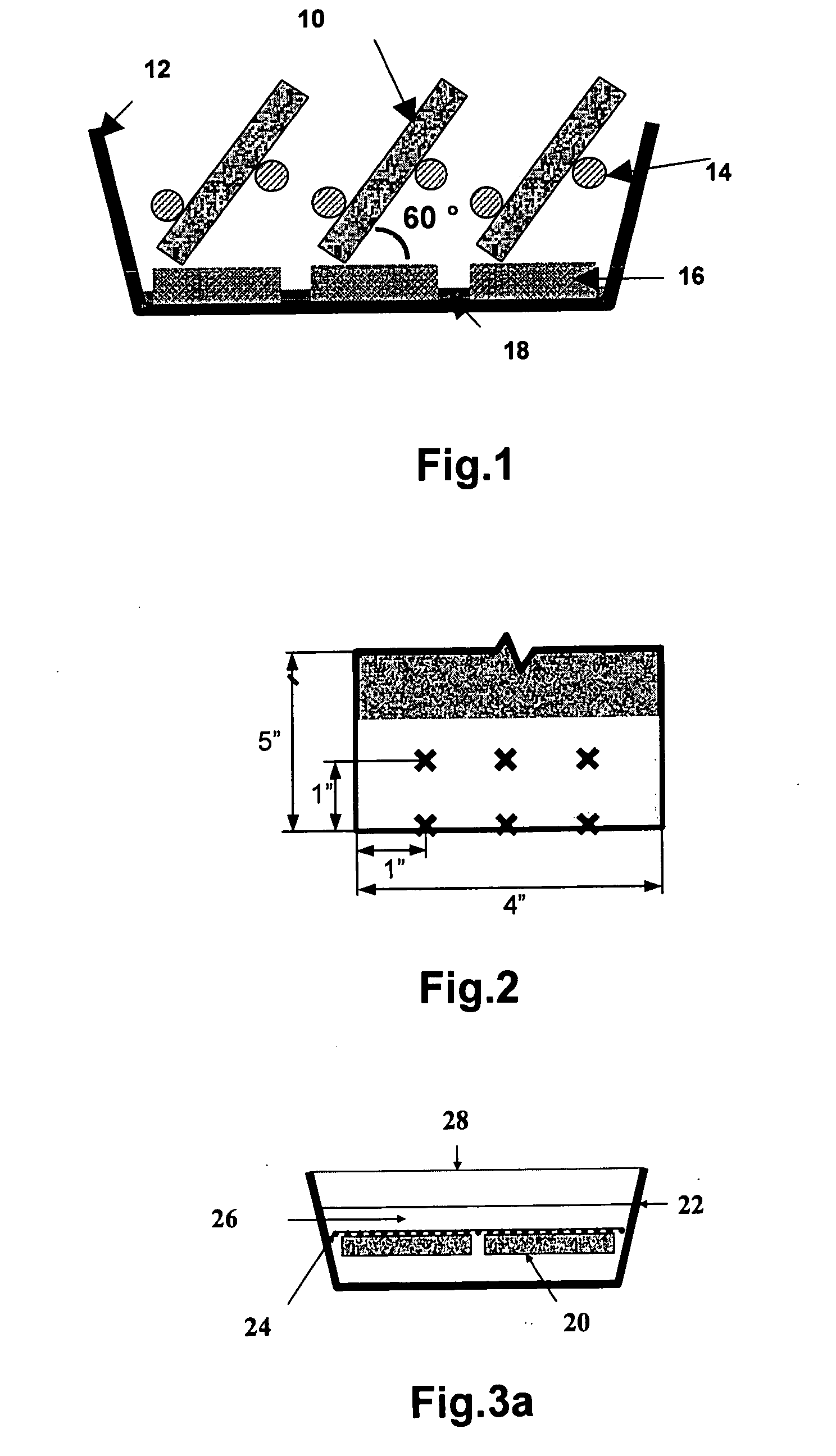

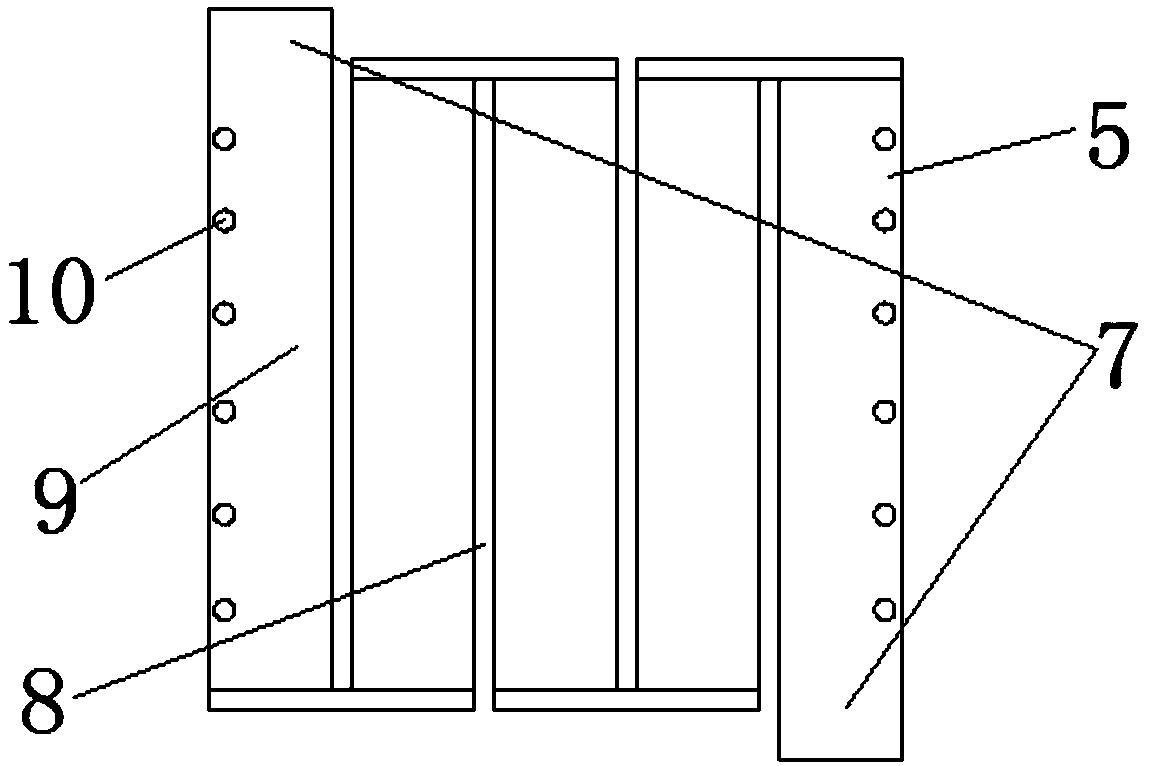

Multifunctional reinforcement system for wood composite panels

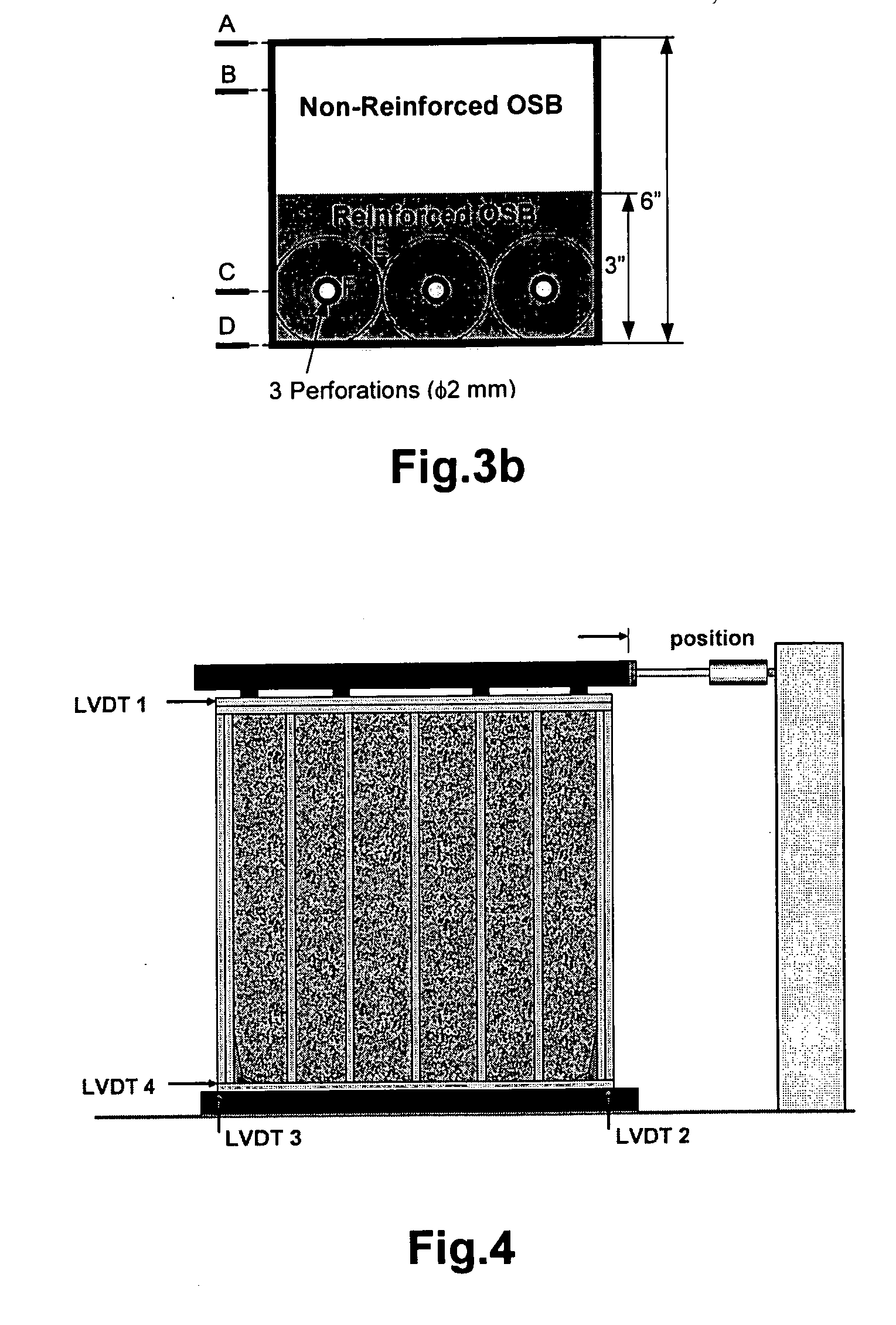

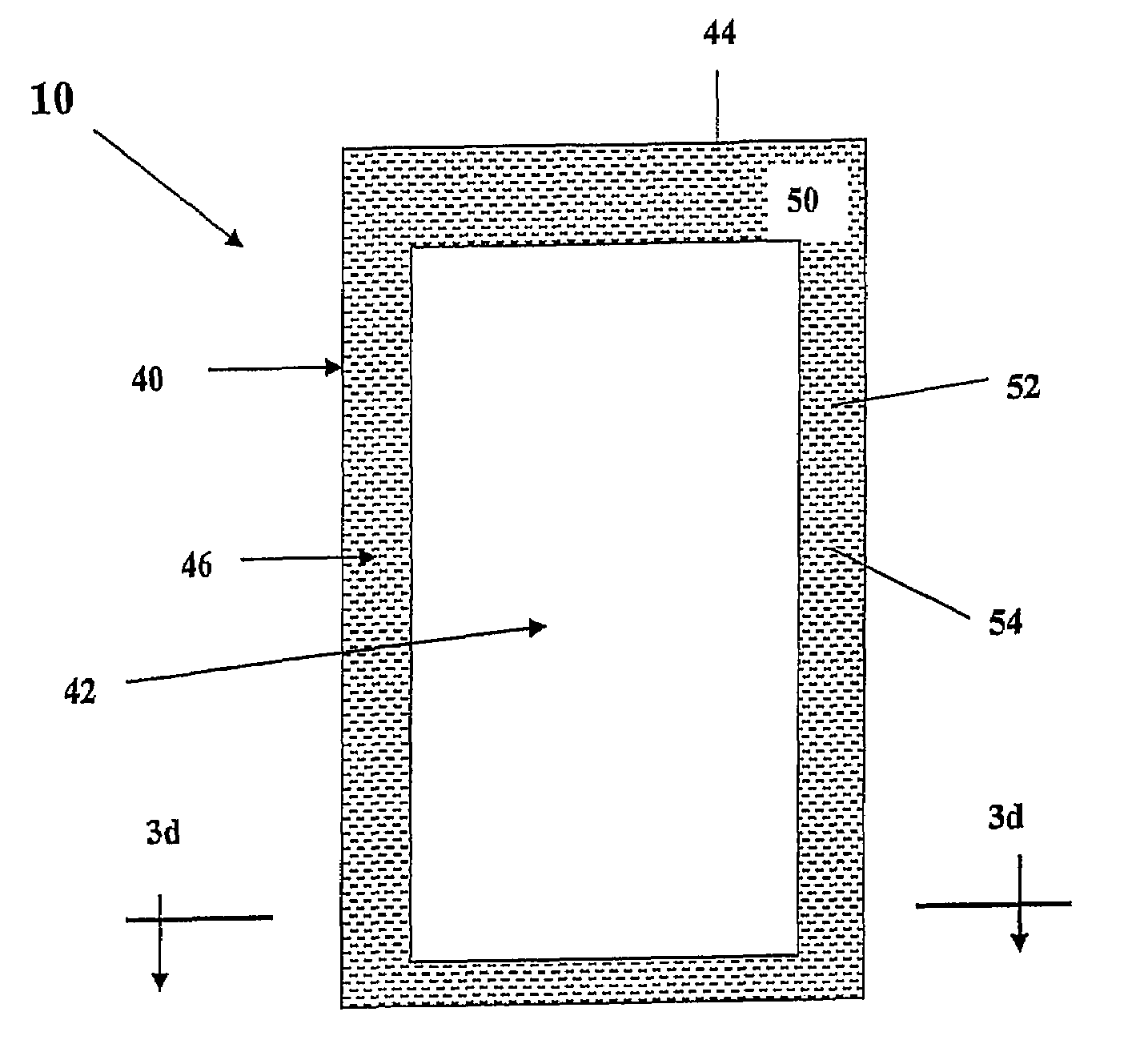

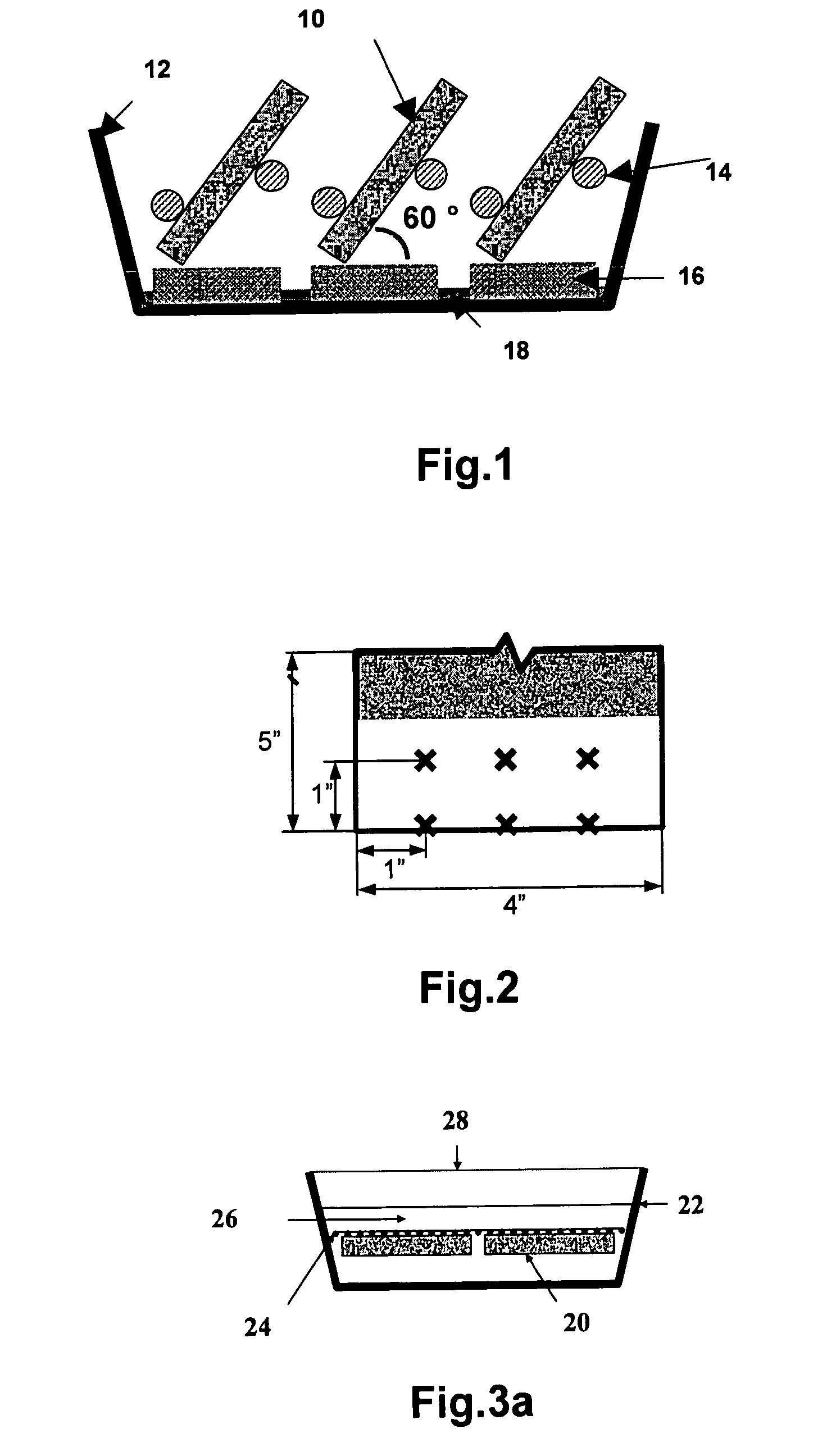

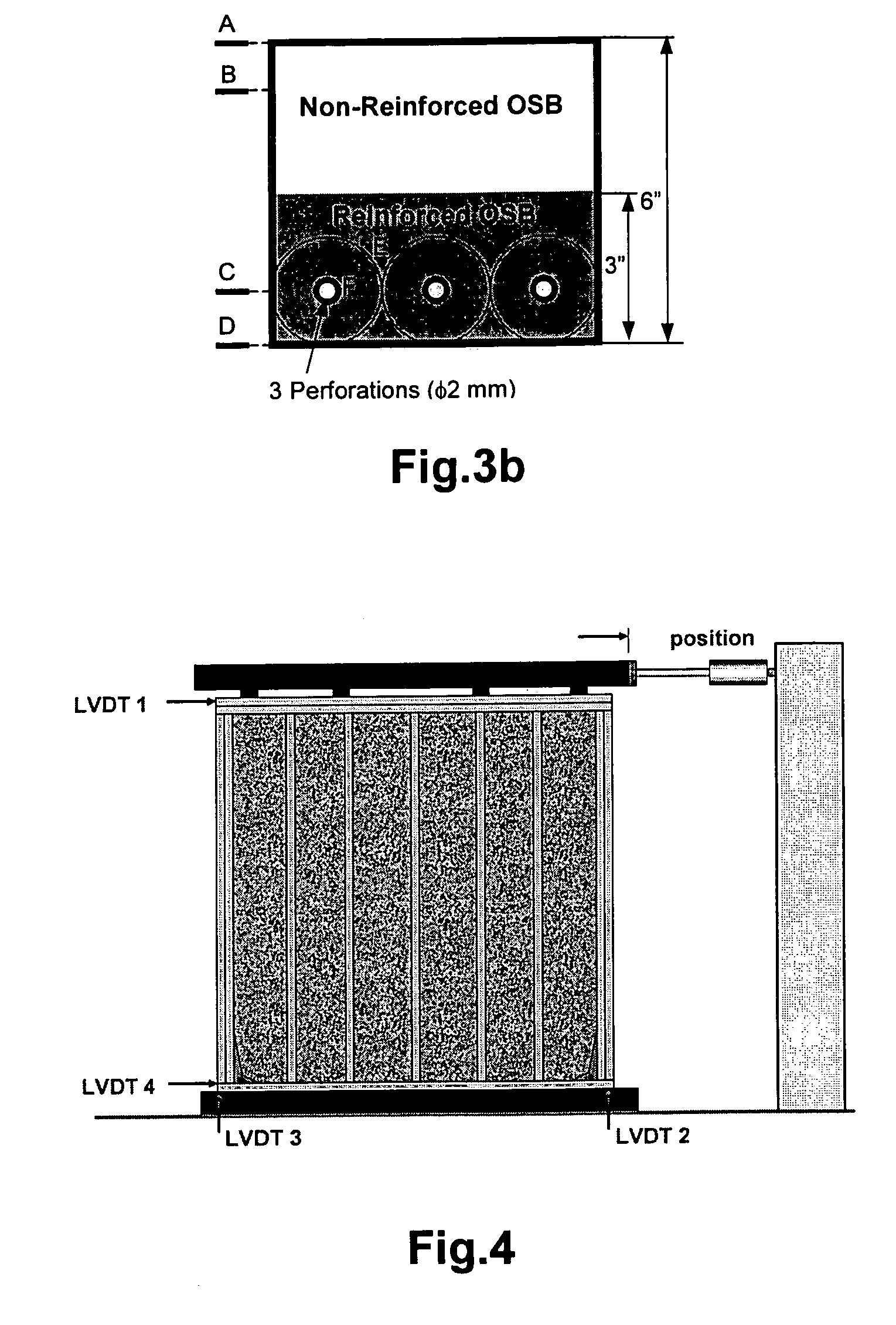

ActiveUS20060263618A1Enhanced strengthImproved connector performanceSynthetic resin layered productsCellulosic plastic layered productsStructural systemFastener

A moisture impermeable edge reinforced wood composite structural system includes a wood composite panel having opposing faces, at least one moisture impermeable reinforcement edge, and at least one moisture impermeable reinforcement perimeter zone. The perimeter zone is a coating of a moisture impermeable reinforcement / resin matrix material which provides the structural system with improved fastener performance and reduced panel edge swell as a result of moisture exposure.

Owner:UNIVERSITY OF MAINE

Multifunctional reinforcement system for wood composite panels

ActiveUS7547470B2Improve connector resistanceExcellent Environmental DurabilitySynthetic resin layered productsCellulosic plastic layered productsComposite constructionResin matrix

A moisture impermeable edge reinforced wood composite structural system includes a wood composite panel having opposing faces, at least one moisture impermeable reinforcement edge, and at least one moisture impermeable reinforcement perimeter zone. The perimeter zone is a coating of a moisture impermeable reinforcement / resin matrix material which provides the structural system with improved fastener performance and reduced panel edge swell as a result of moisture exposure.

Owner:UNIVERSITY OF MAINE

Image forming apparatus and process cartridge

InactiveUS8380109B2Highly responsive optical attenuation propertyExcellent Environmental DurabilityElectrographic process apparatusCorona dischargeChemical structureHydrogen atom

An image forming apparatus including at least an image bearing member having a substrate having a photosensitive layer thereon, the image bearing member to bear a latent electrostatic image on a surface thereof, a charging device to the surface of the image bearing member, an irradiation device to irradiate the surface of the image bearing member with light to form a latent electrostatic image thereon, a development device to develop the latent electrostatic with toner to obtain a developed image, a transfer device to transfer the developed image to a recording medium, and a cleaning device to clean the surface of the image bearing member, wherein the photosensitive layer includes naphthalene tetracarbonic acid diimide derivative as a charge transport material represented by the following Chemical Structure (1):In the Chemical Structure (1), Z represents a group represented by the following Chemical Formula (1):or the following Chemical Formula (2):—R9 Chemical Formula (2).In the Chemical Structure (1), and the Chemical Formulae (1) and (2), R1, R2, R3, R4 and R9 each, independently, represent a substituted or non-substituted alkyl group or a substituted or non-substituted aromatic hydrocarbon group, R5, R6, R7 and R8 each, independently, represent hydrogen atom, a substituted or non-substituted alkyl group, or a substituted or non-substituted aromatic hydrocarbon group, and R1 and R2 and R3 and R4 optionally share a bond connectivity to form a substituted or non-substituted heterocyclic group including a nitrogen atom.

Owner:RICOH KK

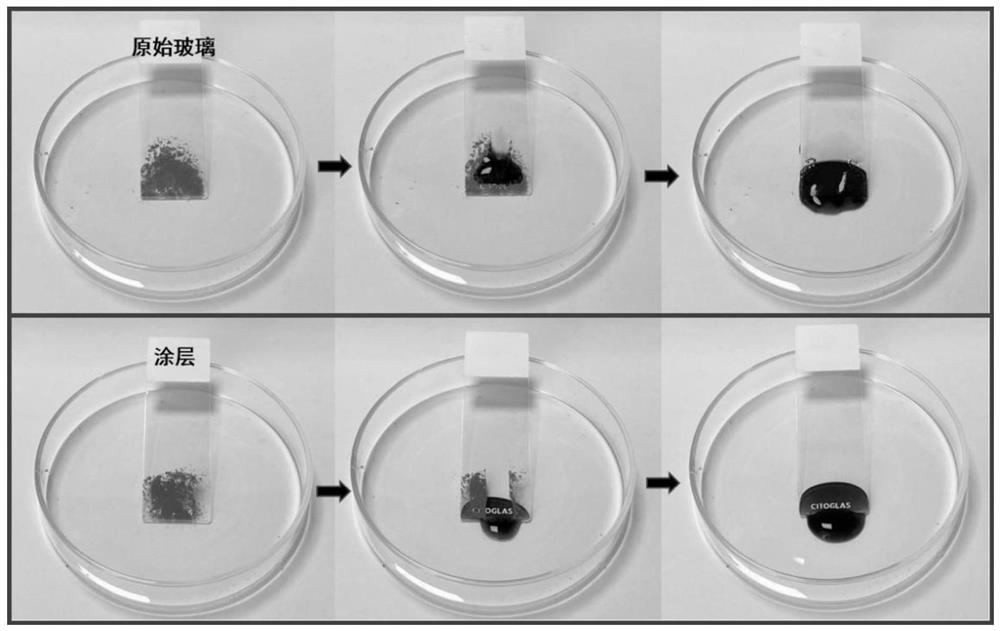

Antifouling paint, antifouling coating and preparation method thereof

ActiveCN113444430ADoes not affect appearanceDoes not change glossAnti-corrosive paintsPolyurea/polyurethane coatingsMelamine formaldehyde resinP-Toluenesulfonic acid

The invention provides an antifouling paint, an antifouling coating and a preparation method thereof, and relates to the technical field of functional materials. The antifouling paint is prepared from the following raw materials: a hexamethylene diisocyanate tripolymer, amino-terminated polydimethylsiloxane, N, N-dimethylformamide, methylated melamine formaldehyde resin and a p-toluenesulfonic acid aqueous solution. The antifouling paint provided by the invention has the advantages of easily available raw materials, simple preparation method, low cost, no fluoride harmful to the environment, and environmental friendliness; The antifouling paint is wide in application range and can be applied to various types of base materials, and the obtained coating is high in transparency and does not affect the appearance of the base materials. The antifouling coating provided by the invention has wide liquid repellency and good self-cleaning performance, pollutants such as dust on the surface of the coating can be easily washed away by water and some oily liquid drops, and the antifouling coating has the advantages of high transparency, high smoothness, high hardness, flexibility, wear resistance, acid, alkali and salt resistance, corrosion resistance, ultraviolet radiation resistance and good environmental durability.

Owner:LANZHOU UNIVERSITY

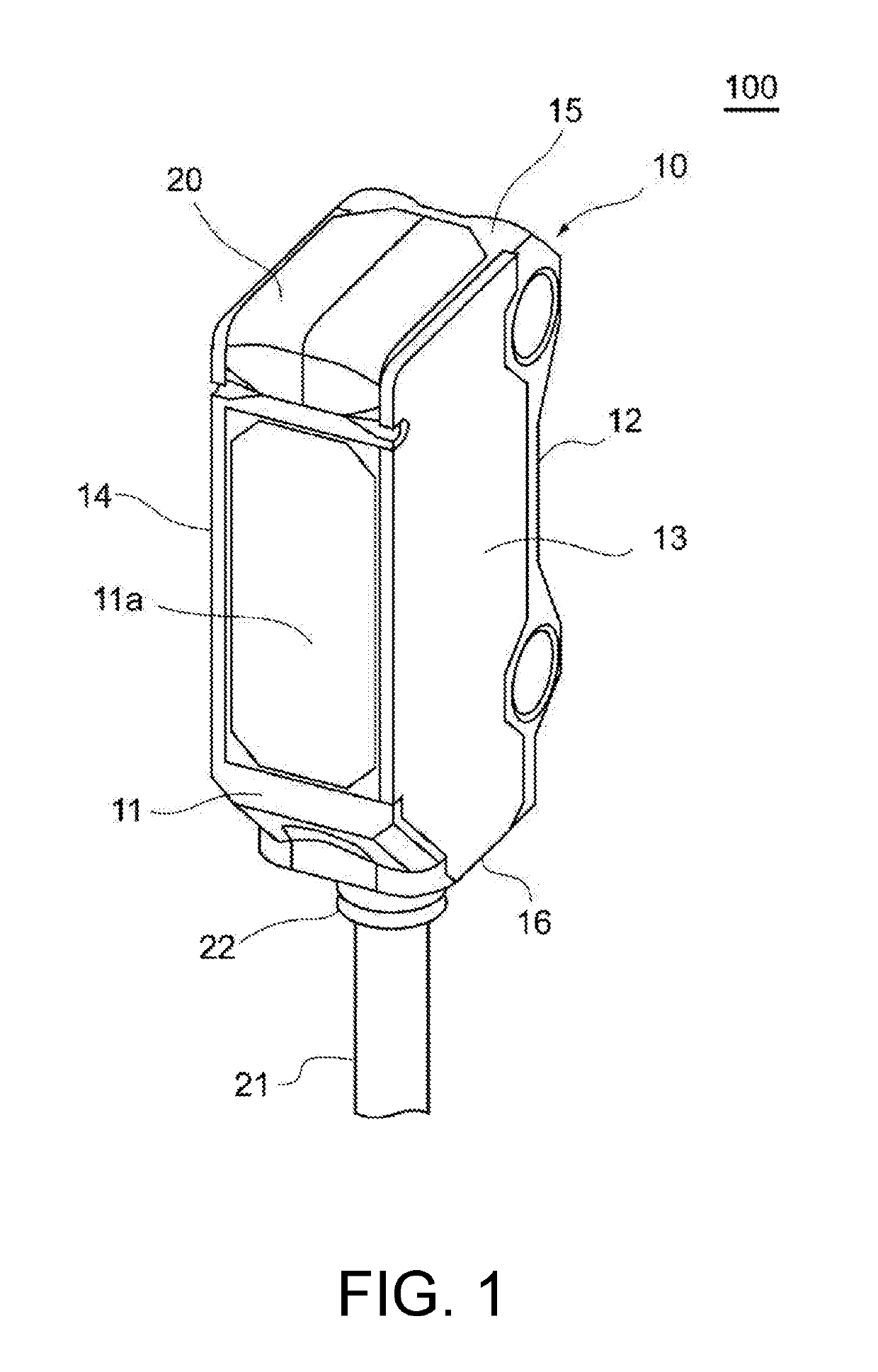

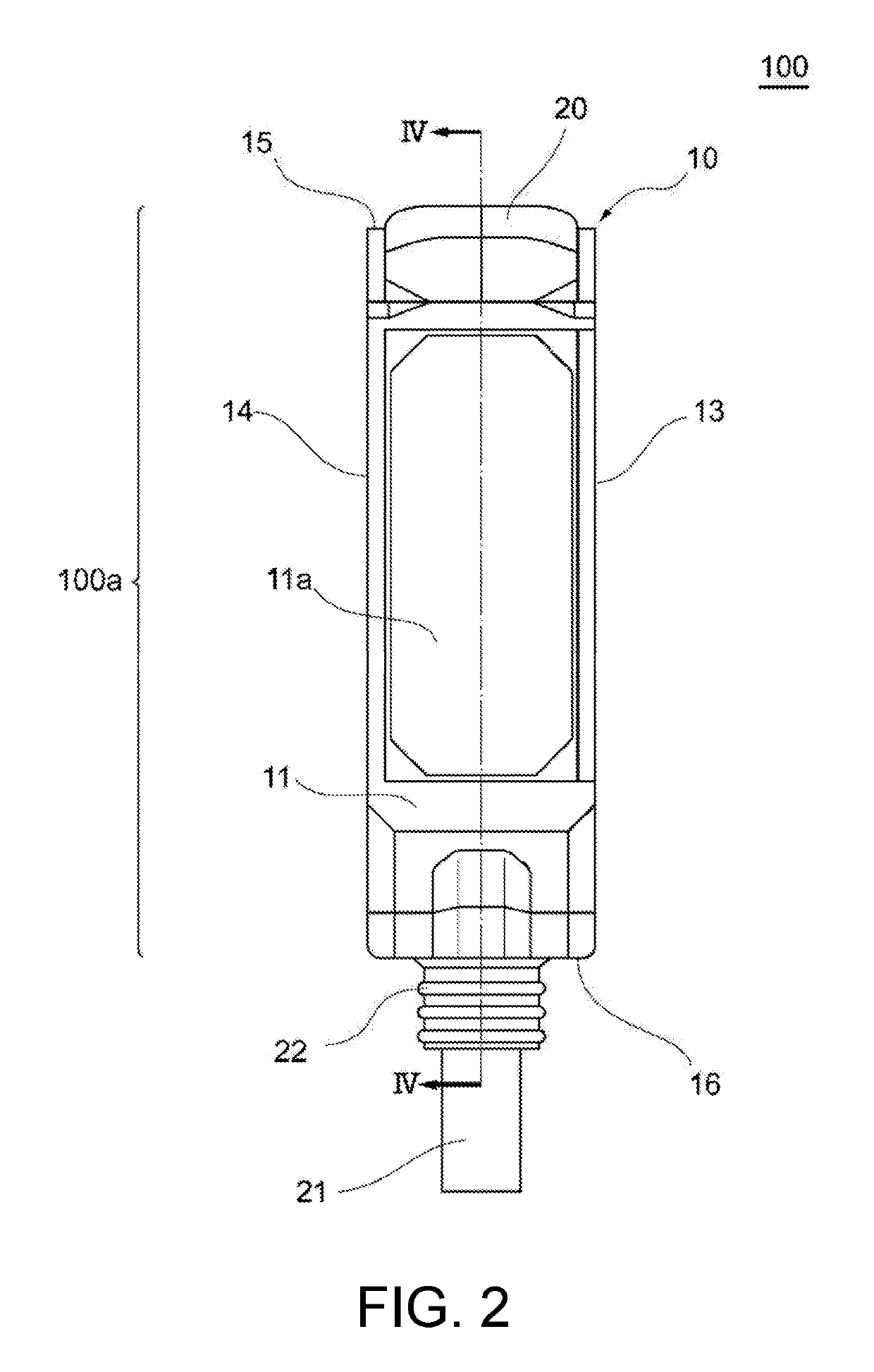

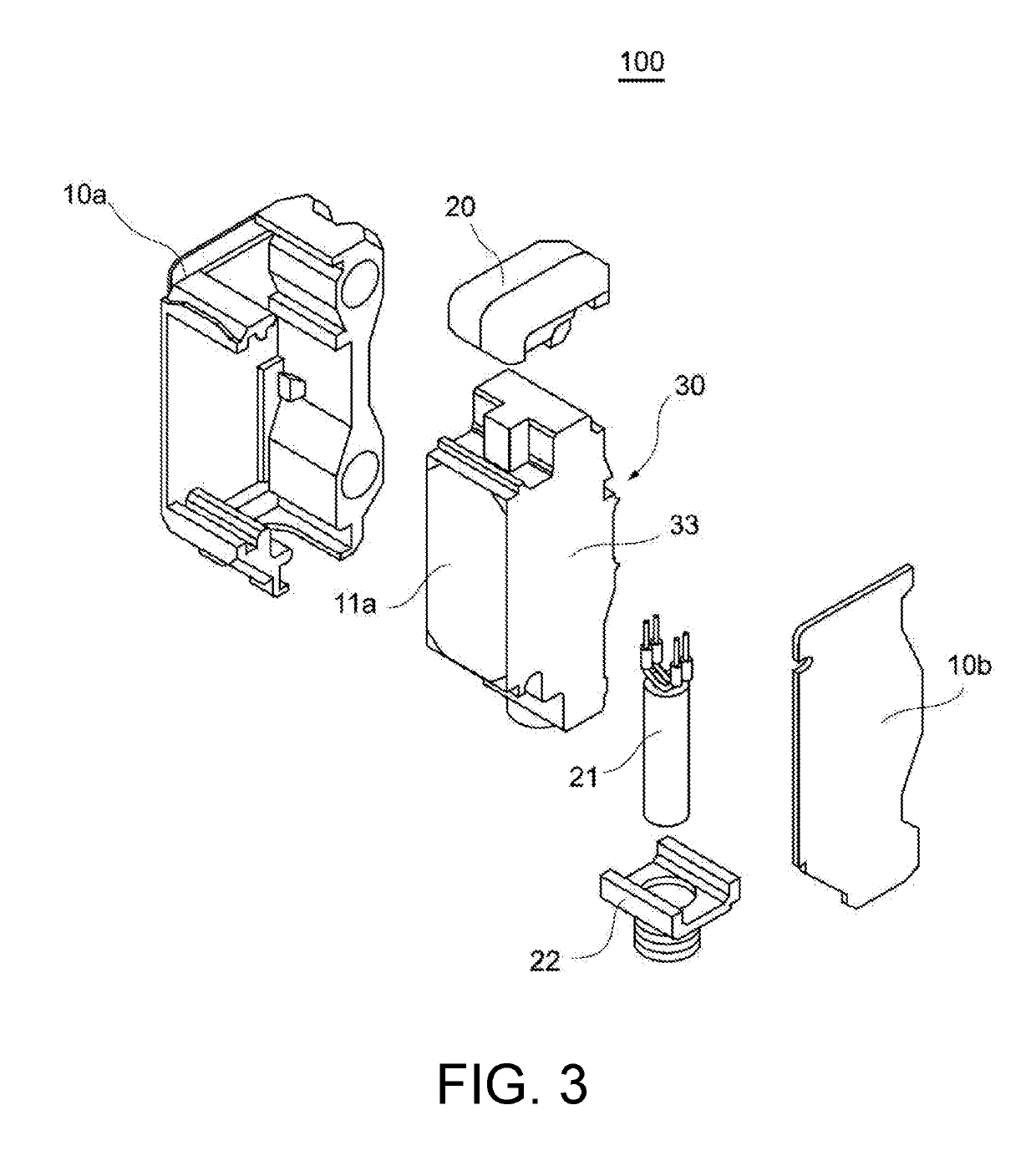

Photoelectric sensor and manufacturing method thereof

ActiveUS20190285465A1Excellent Environmental DurabilityLow costMeasurement apparatus componentsSolid-state devicesEngineeringPhotoelectric sensor

Owner:ORMON CORP

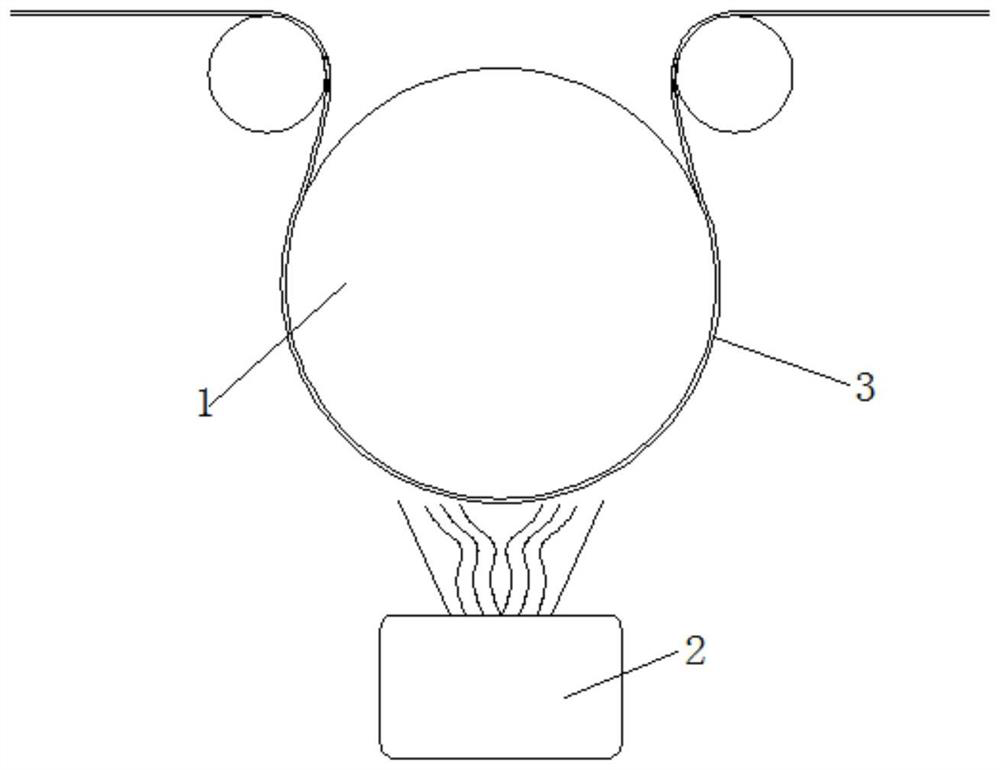

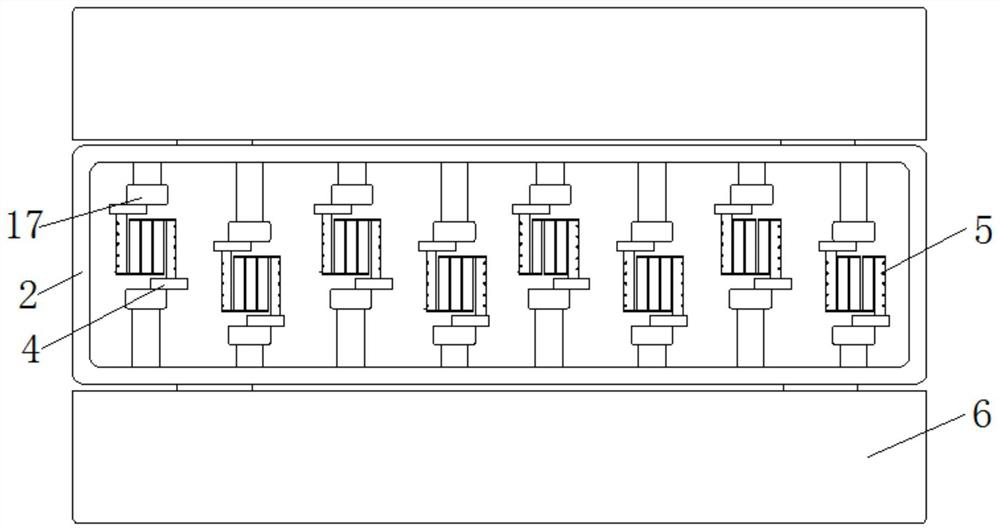

Improved type evaporation groove of rainbow film electroplating technology

ActiveCN109518137AWith high temperature and corrosion resistanceIncrease the resistance valueVacuum evaporation coatingSputtering coatingRainbowAgricultural engineering

The invention discloses an improved type evaporation groove of a rainbow film electroplating technology. The improved type evaporation groove of the rainbow film electroplating technology comprises anevaporation groove and a cover plate covering the top end of the evaporation groove. Two rows of first copper column electrodes and second copper column electrodes are fixedly installed uniformly ina spaced manner on the two side walls inside the evaporation groove. A molybdenum boat is placed between each set of first copper column electrode and second copper column electrode, and each molybdenum boat is distributed between the corresponding first copper column electrode and the corresponding second copper column electrode in a spaced manner. Electrode connecting heads are formed respectively on the two sides of each molybdenum boat. Conductive connection is conducted through placement of copper pieces between each first copper column electrode, each second copper column electrode and the corresponding electrode connecting heads. Multiple target materials are tightly arranged on each molybdenum boat correspondingly. The lower end of each molybdenum boat is also cushioned with an upper supporting cushion block and a lower supporting cushion block, and both the upper supporting cushion blocks and the lower supporting cushion blocks are insulated cushion blocks. The evaporation groove assembly provided is matched with a vacuum evaporation plating technology, and the processing technological process of the transparent reflective rainbow film can be achieved.

Owner:合肥市辉耀真空材料有限责任公司

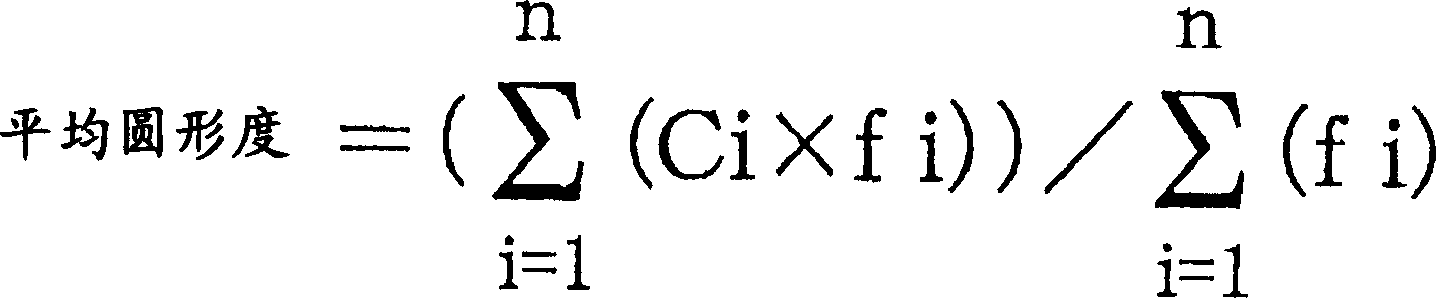

Toner for electrostatic charge image development

InactiveCN1922552AGood heat and dirt resistanceExcellent Environmental DurabilityDevelopersShear rateCharge control

Owner:ZEON CORP

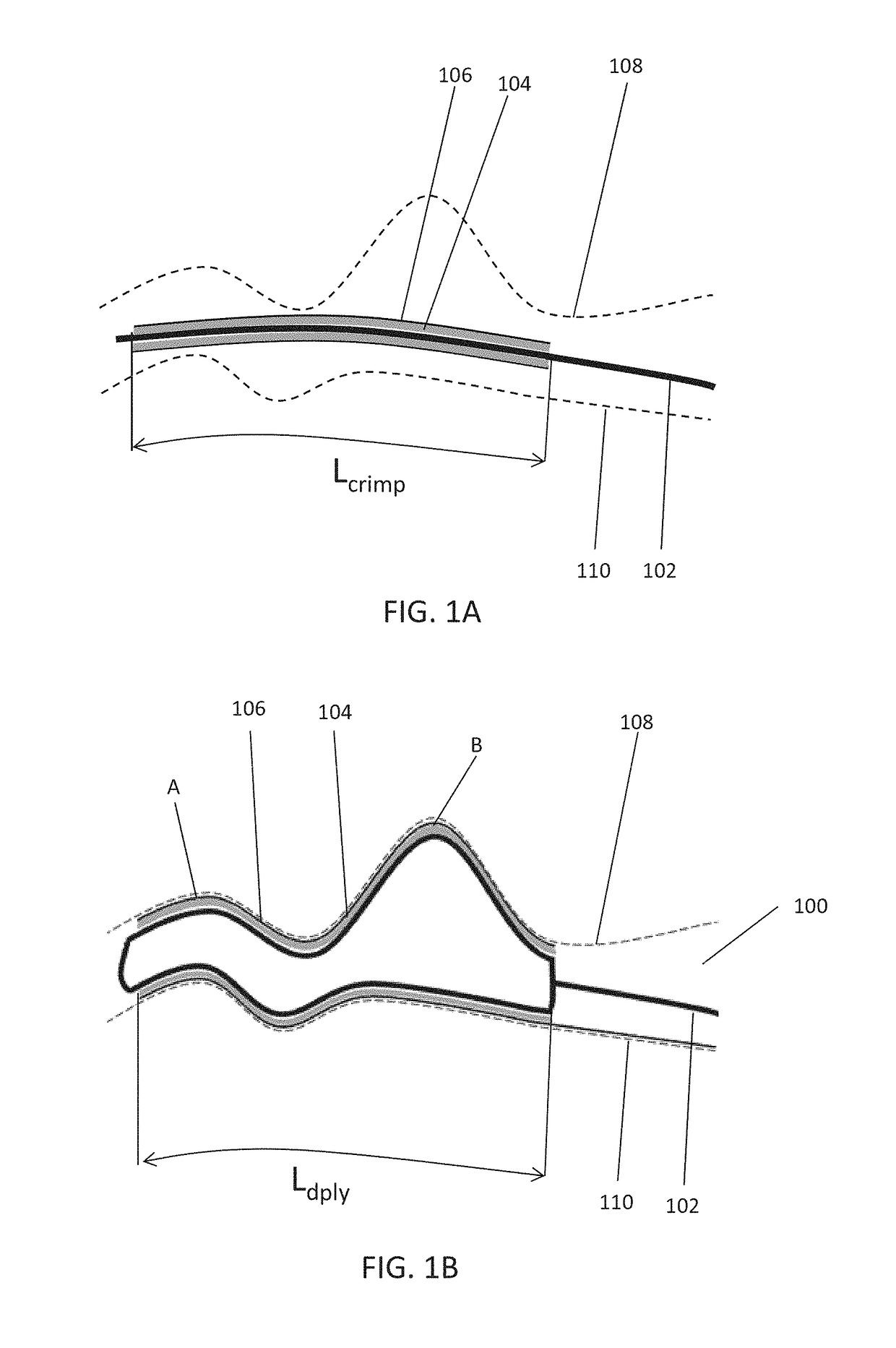

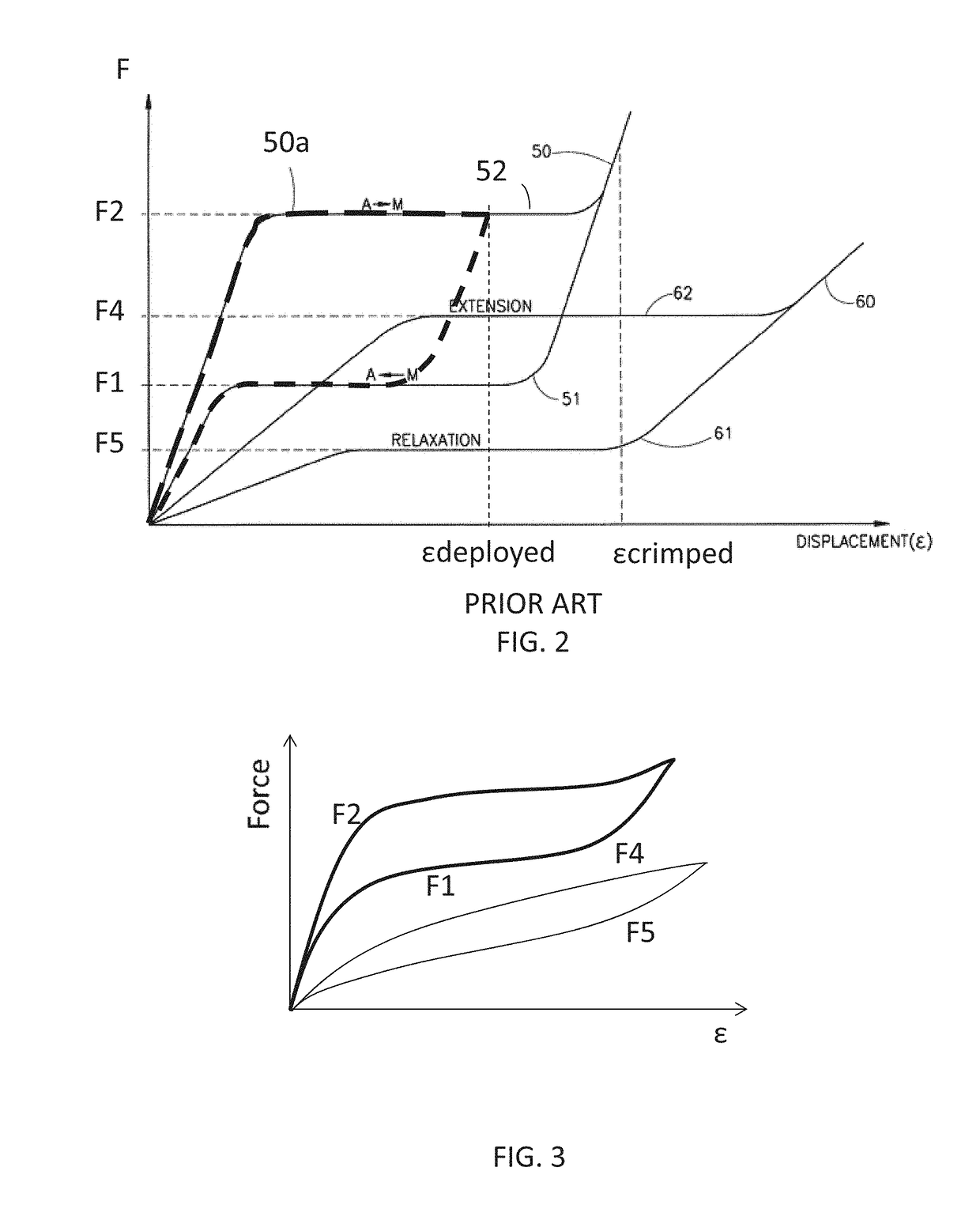

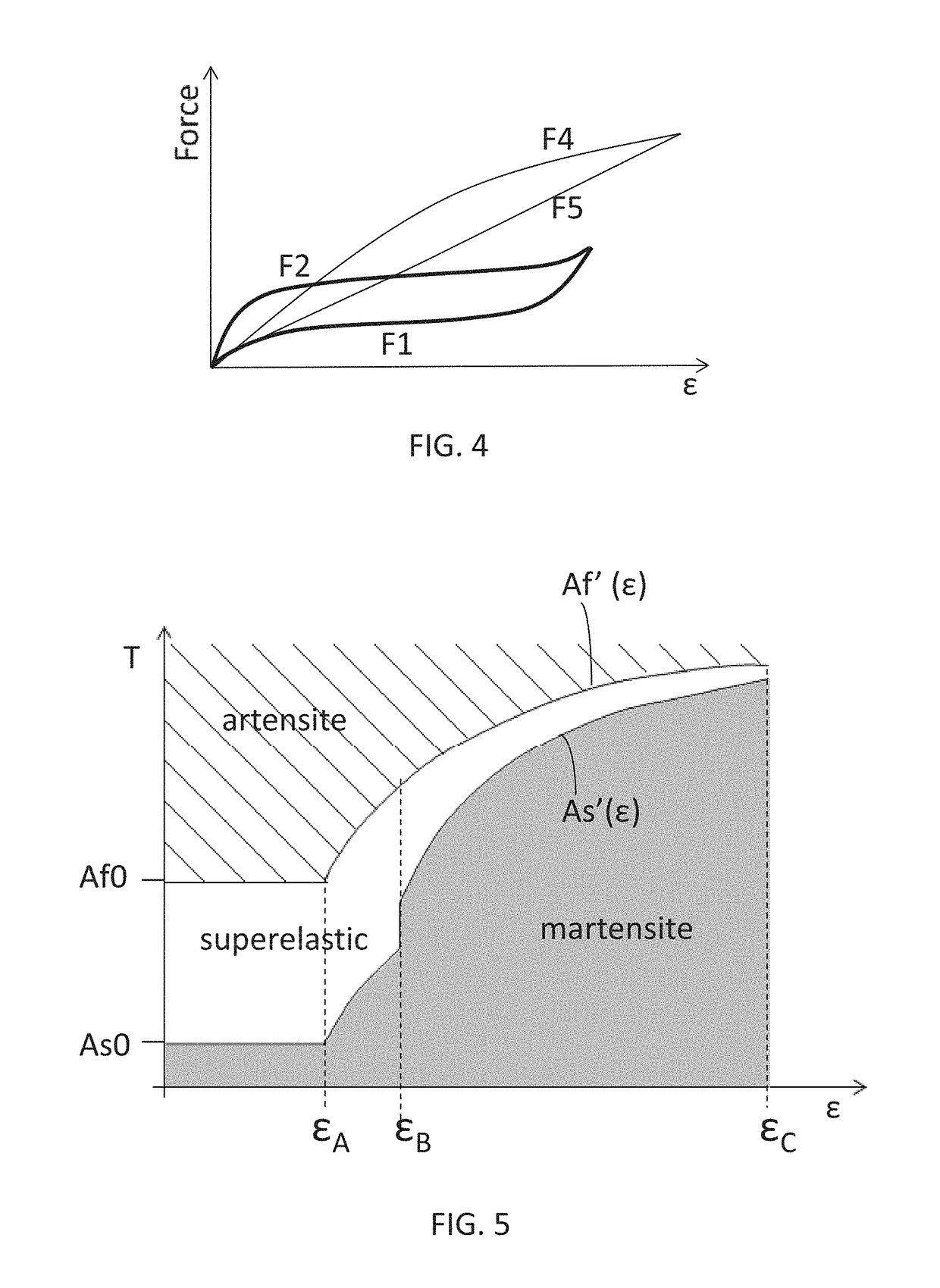

Shape change structure for treatment of nasal conditions including sinusitis

ActiveUS20180360626A1Excellent Environmental DurabilityImprove creep resistanceStentsNose implantsEnvironmental resistanceNasal cavity

A method of treatment of nasal conditions comprising: delivering an expandable structure in a crimped configuration to a nasal lumen; expanding the expandable structure within the nasal lumen to a stable expanded configuration; removing the structure from the nasal lumen, after a time period, where removing comprises causing the structure to self-crimp. The expandable structure optionally comprises: a first shape memory (SM) portion which is in a strain-induced state; and a second portion which resists expansion of said structure due to said first portion, over a plurality of different expansion states of said first portion. Optionally, the properties of the second portion vary over its cross section. For example an outer surface and / or peripheral layer may have desirable environmental resistance properties and / or a frame may have desirable mechanical properties, for example a high creep resistance.

Owner:S T S MEDICAL

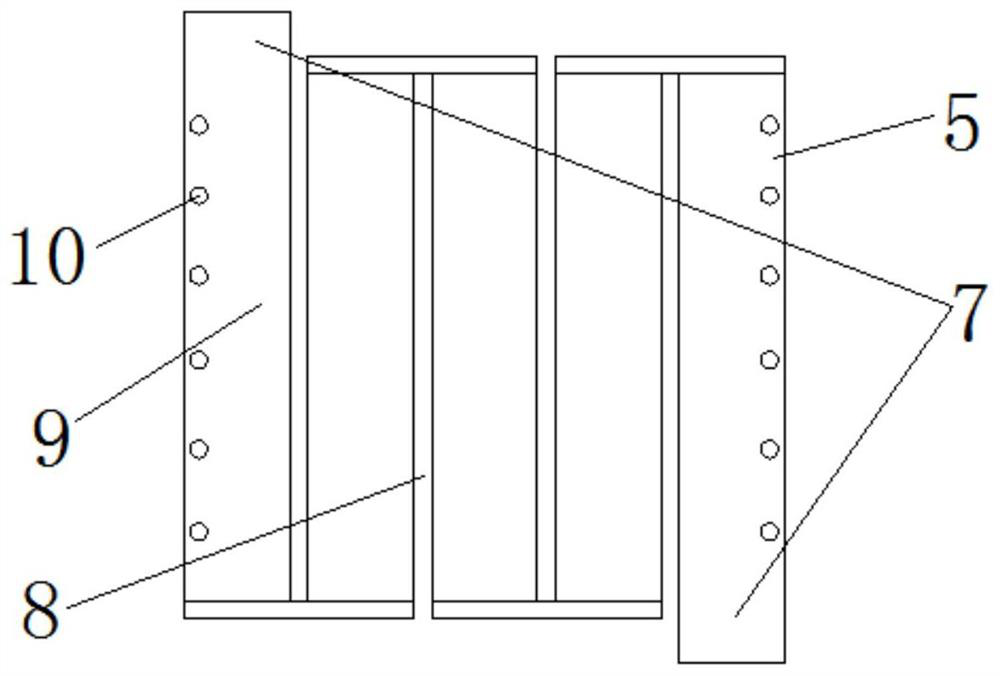

A kind of metal fiber foam aluminum composite laminate and preparation method thereof

ActiveCN104441809BImprove mechanical propertiesImprove energy absorptionLaminationLamination apparatusMetal fiberPolymer adhesive

The invention relates to a metal-fiber foamed aluminum composite layer plate. The composite layer plate comprises at least one metal plate layer, at least one fiber layer and at least one foamed aluminum layer, wherein the fiber layer and the foamed aluminum layer are alternately bonded through a high-temperature-resistant polymer adhesive compound; as the outermost layer, the metal plate layer is bonded with the fiber layer through a high-hardness polymer adhesive compound. The invention further relates to a preparation method of the metal-fiber foamed aluminum composite layer plate. The preparation method mainly comprises the following steps: surface decontaminating treatment is performed on the metal plate layer and the foamed aluminum layer, treated surfaces are coated with the high-temperature-resistant polymer adhesive compound and the high-hardness polymer adhesive compound, and pressure curing treatment is performed after all the layers are bonded together. Compared with a metal foamed aluminium sandwich structure, the metal-fiber foamed aluminum composite layer plate disclosed by the invention has a better mechanical property, a better characteristic of shock absorption and a better performance of sound insulation, and also has a good performance resistant to high-speed impact, a good capability resistant to bending deformation, an extremely high performance of fire resistance, and low cost.

Owner:NINGBO HOPESUN NEW MATERIAL

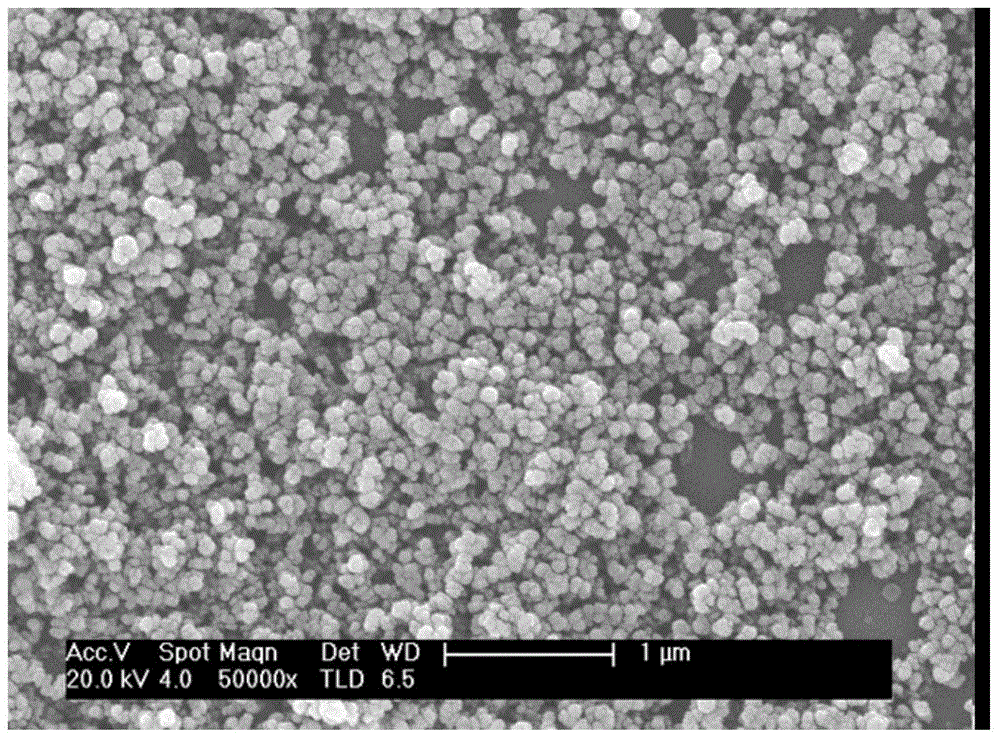

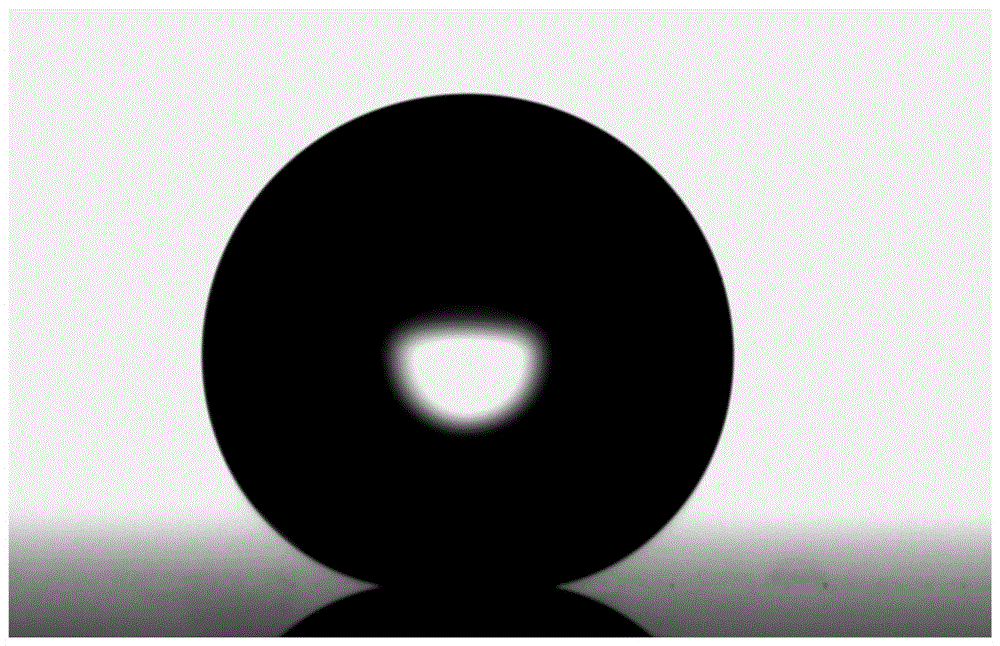

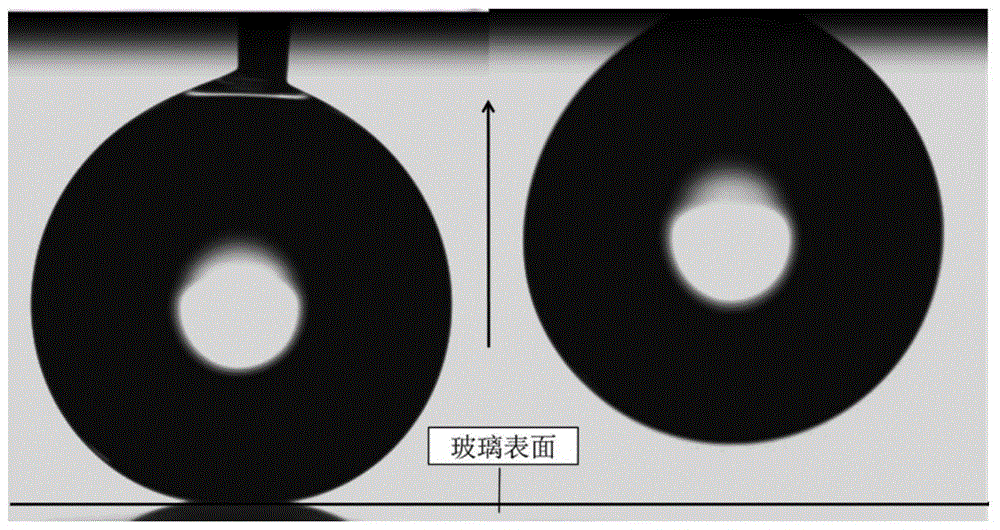

A kind of transparent superhydrophobic nano-coating and its spraying preparation method

ActiveCN104231916BHydrophobicAvoid compromising transparencyPretreated surfacesCoatingsGas phaseSolvent

The invention relates to a transparent super-hydrophobic nano-coating and a spraying and preparation method thereof. In the method, firstly, acetone is taken as solvent to respectively prepare a hydrophilic or hydrophobic gas phase silicon dioxide nano-particle solution with the concentration of 5 to 20 mg / mL, and a silicone rubber prepolymer solution with the concentration of 2 to 10 mg / mL; after ultrasonic dispersion, the two solutions are intensively mixed in an isopyknic manner, then ultrasonic dispersion is performed to obtain an organic and inorganic hybridization emulsion; afterwards, deionized water is added, and the volume ratio of the added deionized water to the emulsion is 1:(1-9), and then ultrasonic dispersion is performed again to obtain spraying suspending liquid; a spray rod or a spray pen is adopted for spraying according to the size of a spraying area; the spraying pressure is 10-80 psi; a transparent super-hydrophobic surface can be obtained after criss-cross spraying and curing. The invention has the advantages that the preparation technology of the coating is simple, the spraying method is simple and convenient, no damage is caused to a base material, the transparency is high, the water pressure resistance, the impact resistance, the chemical stability and the environment durability are relatively good, and the method is suitable for mass production.

Owner:CUBESPACE FURNITURE

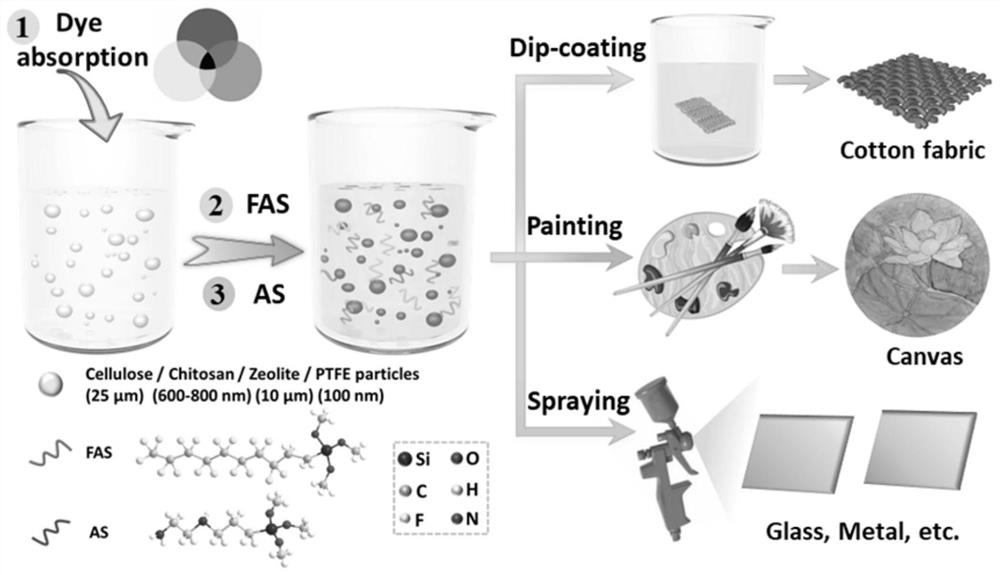

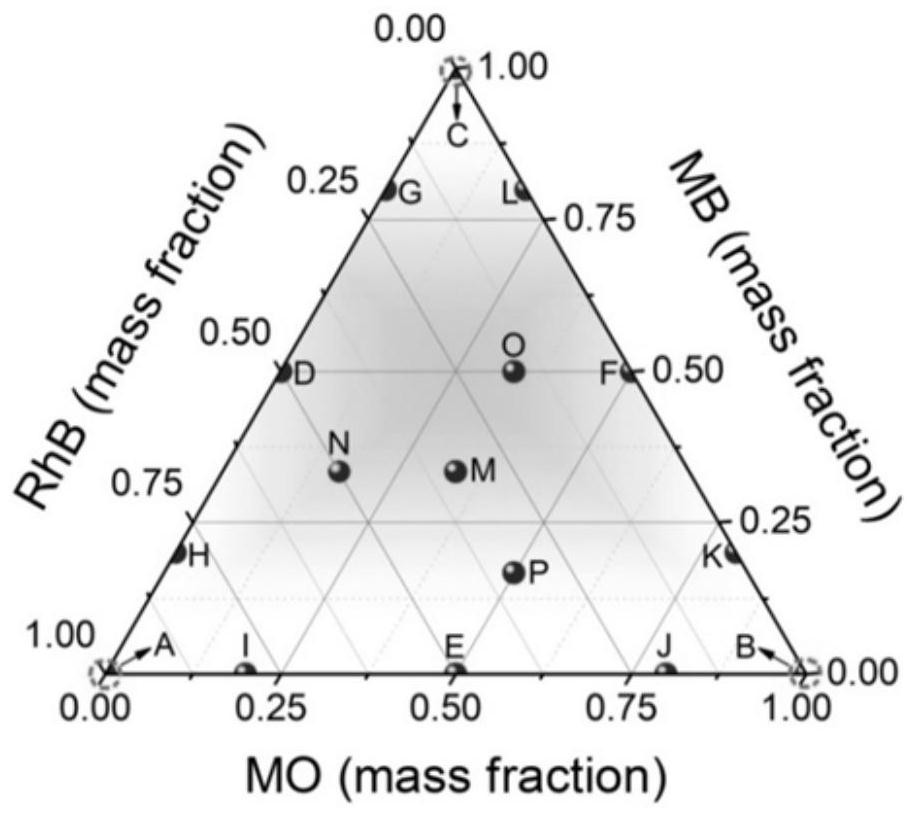

Preparation method and use of biomass-based superhydrophobic coating with durability and color diversity

ActiveCN113322006BImprove mechanical propertiesWater repellentMulticolor effect coatingsCelluloseMicro nano

The invention belongs to the field of coatings. It relates to the preparation method and application of a biomass-based super-hydrophobic coating, especially to a preparation method and application of a biomass-based super-hydrophobic coating with color diversity and excellent durability. In a mixed solution of water ethanol and acetic acid; the micro-nano particles are three or four kinds of cellulose, chitosan, zeolite and PTFE; dyes are added to the above solution, and stirred at 40-80°C for 5 ‑8h to obtain a colored suspension; FAS was added dropwise to the above solution and stirred for 1‑3 hours; AS was added dropwise and continuously stirred for 2‑4h to finally obtain a colored coating solution. The present invention utilizes the biomass material to obtain multi-colored and mechanically good colored super-hydrophobic coatings through a simple method, and endows the super-hydrophobic coating with a variety of colors. It can also be dipped, sprayed or used as Paints to paint and more.

Owner:QILU UNIV OF TECH

A kind of method for preparing magic color reflective film by vacuum evaporation process

ActiveCN109468591BYi ShenghuaEasy strong reflection effectVacuum evaporation coatingSputtering coatingMetal membraneEvaporation chamber

Owner:合肥市辉耀真空材料有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com